Integrated technique and special equipment for raw gas waste heat recovery and steam replacement with heat transfer soil

A technology of waste heat recovery and process method, which is applied in the direction of lighting and heating equipment, indirect heat exchangers, climate sustainability, etc., can solve the problem of low recovery efficiency of riser vaporization cooling devices, waste of cooling water for high-quality sensible heat, and frequent Stop production and other problems, achieve the effect of improving the operating conditions of the furnace top, high ash accumulation and ash blocking capacity, and small space for energy-saving renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] Embodiment: the following further elaboration of the present invention:

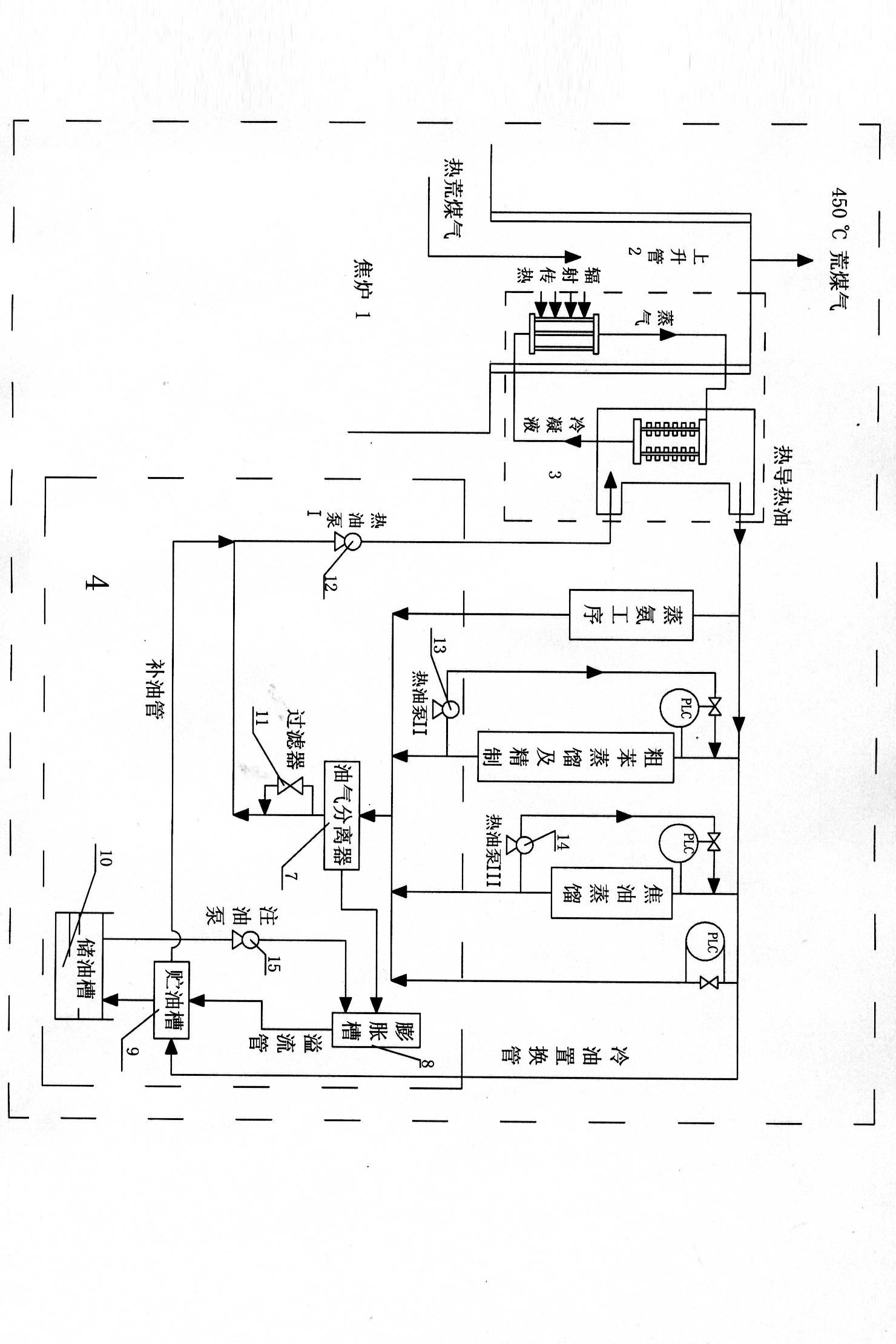

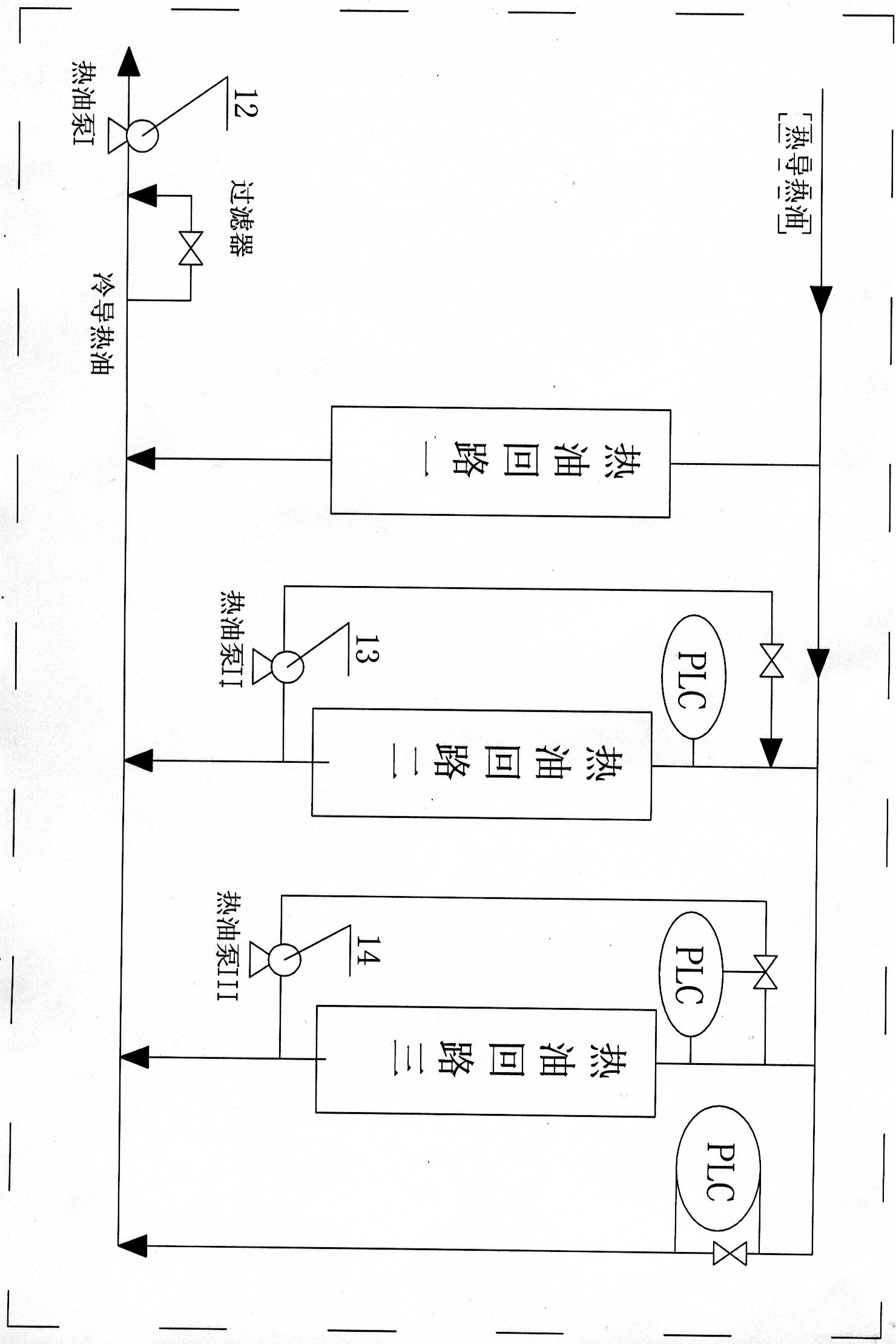

[0041] like figure 1 As shown, the present invention provides a process method for the integration of waste heat recovery of raw coal gas and replacement of heat transfer oil. The specific steps of the method are as follows:

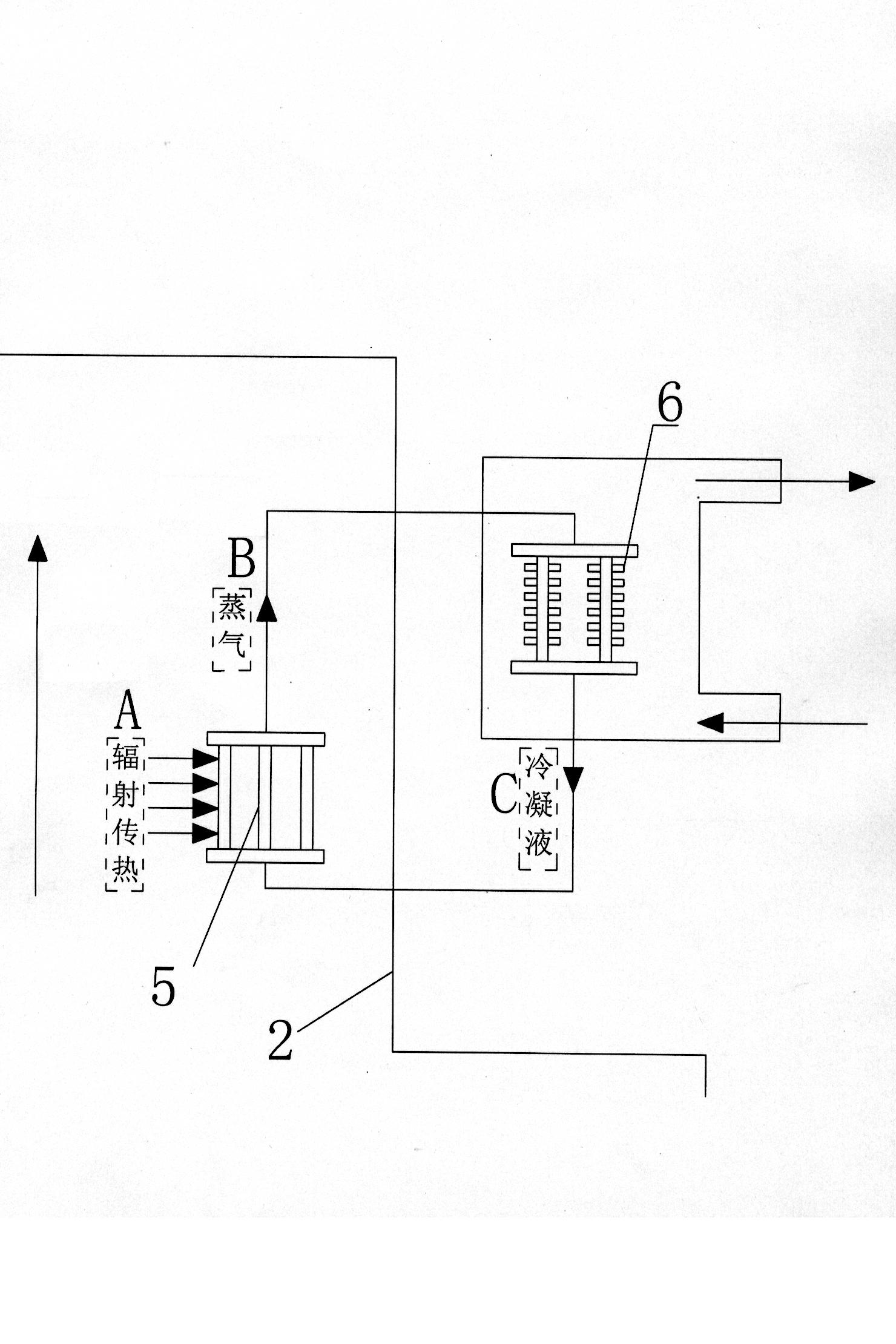

[0042] The raw coal gas at 750-850°C coming out of the coke oven carbonization chamber is introduced from the lower part of the riser, and the raw gas transfers heat to the heating end of the high-temperature separated gravity sodium heat pipe 5 arranged on the inner wall of the riser shell through radiation heat exchange. Tube bundle, so that the raw gas leaves the riser when the temperature drops to 450°C; then use the original ammonia water spraying system to cool the raw gas leaving the riser to 80-85°C before entering the gas collection pipe;

[0043] After the tube bundle at the heating end in the ascending tube absorbs radiant heat, the sodium in the tube evaporates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com