Low-nitrogen combustion technique based on circulating fluidized bed boiler

A circulating fluidized bed, low-nitrogen combustion technology, applied in the field of boiler combustion, can solve the problems of affecting the full combustion of fuel in the boiler, the reduction of boiler combustion efficiency, and the full combustion of unfavorable fuels, etc. Long time, the effect of reducing the generation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

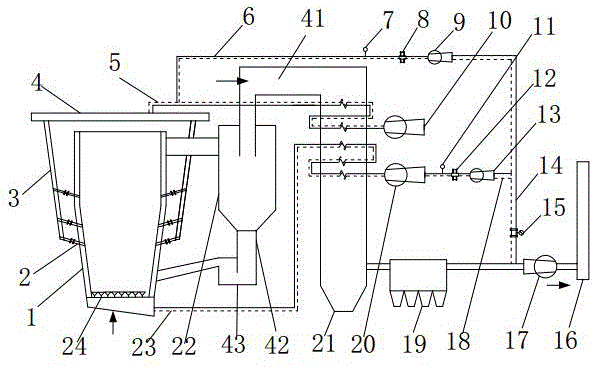

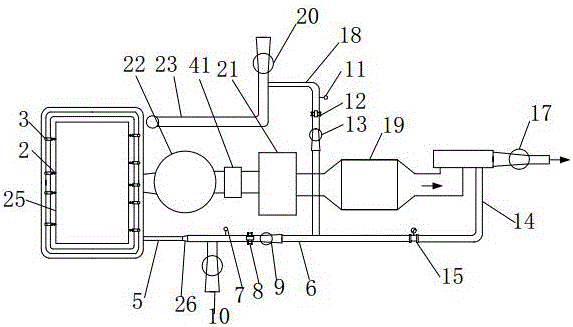

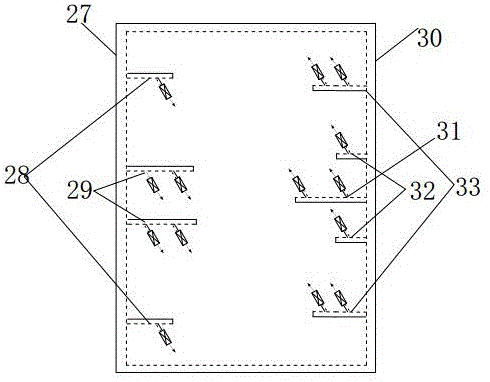

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] As shown in the figure, a low-nitrogen combustion process based on a circulating fluidized bed boiler, the circulating fluidized bed boiler includes a boiler 1, a cyclone separator 22, a dust collector 19, an induced draft fan 17 and a chimney 16 connected in sequence, The four walls of the inner wall of the boiler 1 are provided with a water-cooled wall 25 with diversion pipes. The diversion pipes include single-hole diversion pipes and double-hole diversion pipes. The upper part of the boiler 1 is a dilute-phase oxidation zone, and the lower part is a dense-phase reduction zone. The bottom is equipped with a water-cooled air distribution plate 24 for primary air distribution, the outlet of the boiler 1 is connected to the inlet of the cyclone separator 22, and the cyclone separator 22 is connected to the dense-phase reduction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com