Charcoal-containing flying ash recycling system based on electric bag dust remover

A precipitator and electrostatic precipitator technology, which is applied in the direction of burning fuel, lighting and heating equipment, fluidized bed combustion equipment, etc. Enthalpy increase and other problems, to solve the effect of high carbon content in fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

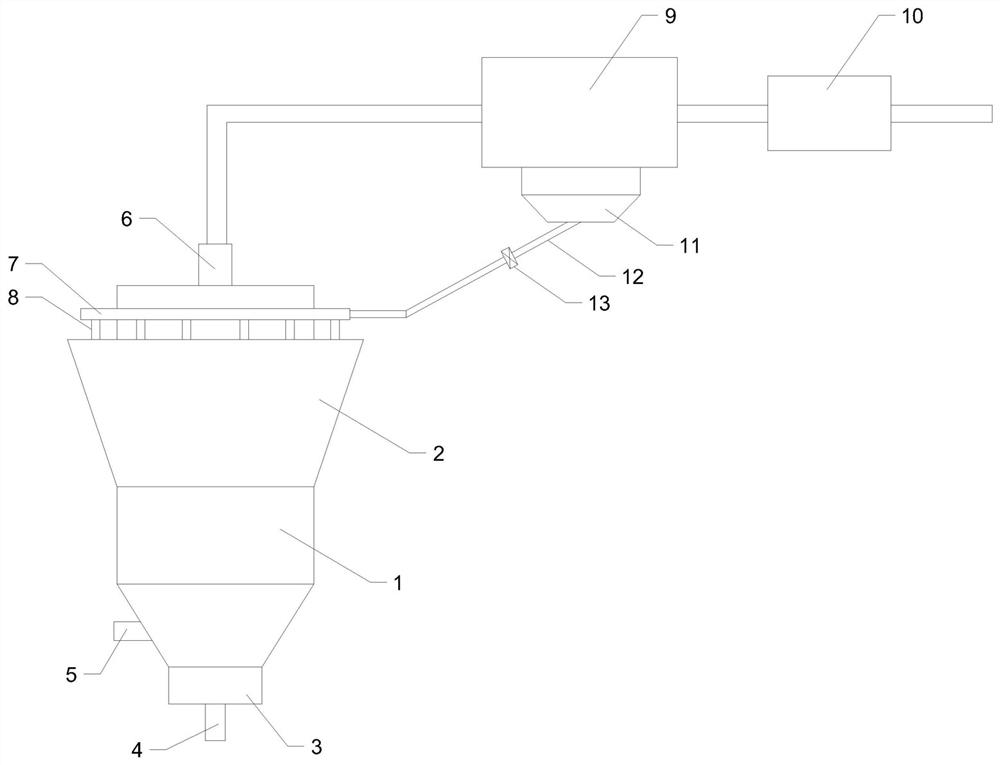

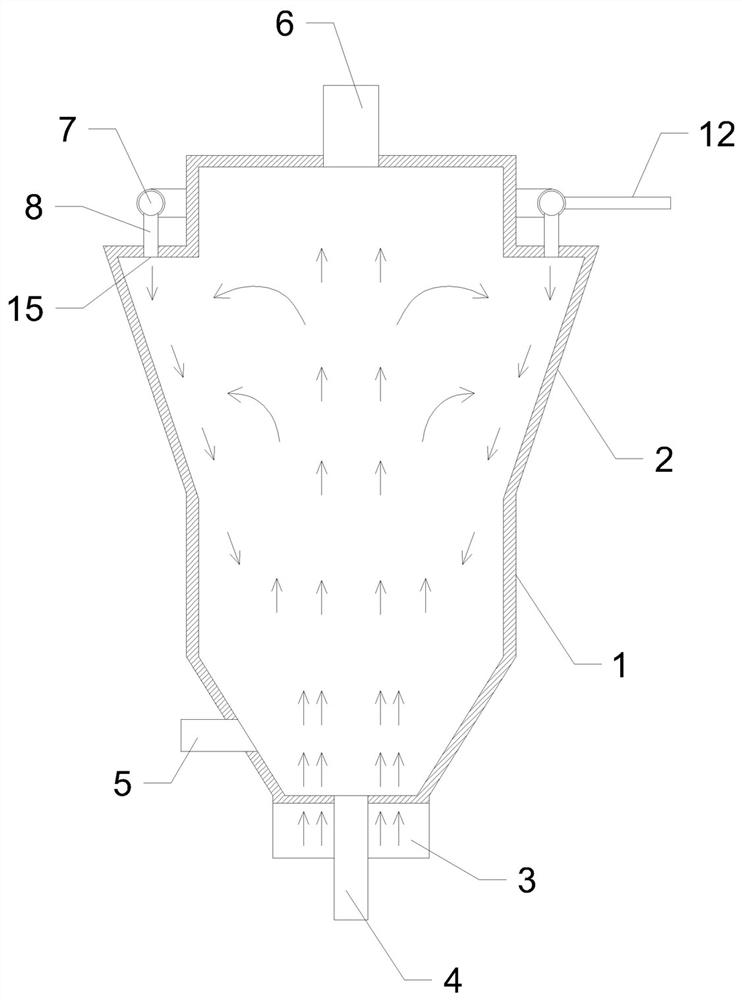

[0020] According to the idea of the present application, an embodiment of a carbon-containing fly ash recycling system based on an electric bag filter is provided here with reference to the accompanying drawings. see Figure 1 to Figure 4 , the carbon-containing fly ash recycling system includes a combustion furnace 1, an electrostatic precipitator 9 and a bag filter 10, wherein the electric filter 9 is used to enrich the carbon-containing ash in the fly ash, and the bag filter 10 is used to collect Mineral components in the fly ash are enriched, and the combustion furnace 1 is used to fully burn the carbon-containing ash enriched by the electrostatic precipitator 9 in the circulation area.

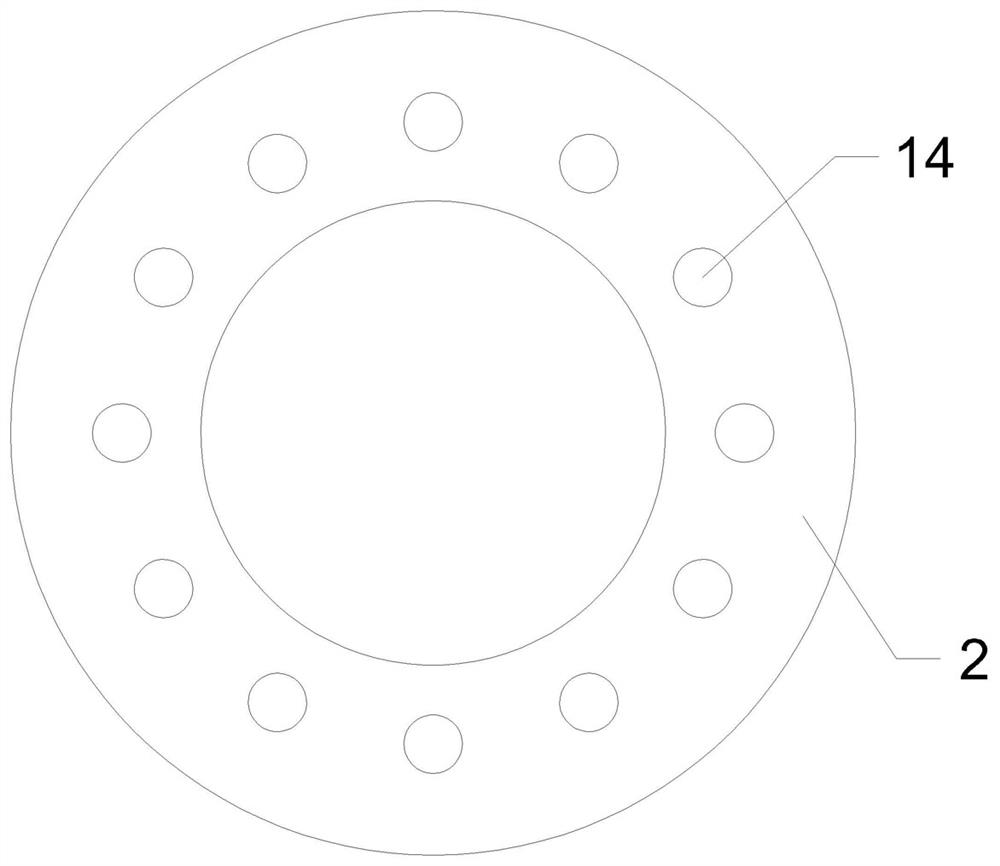

[0021] Specifically, the upper part of the combustion furnace 1 protrudes outward along the circumferential direction to form a stagnation part 2. The stagnation part 2 has a trapezoidal structure along the cross section. The diameter of the lower end of the retention part 2 is smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com