Organic solid waste epitaxial annular cavity gas guide fixed bed gasifier and gasification method

A fixed-bed gasifier and annular cavity technology, which is applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of high tar content, gas leakage at the feed port, and high carbon content in solid ash and slag, and achieves low carbon content. Effect of carbon content, quality improvement, and reduction of components in high temperature areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

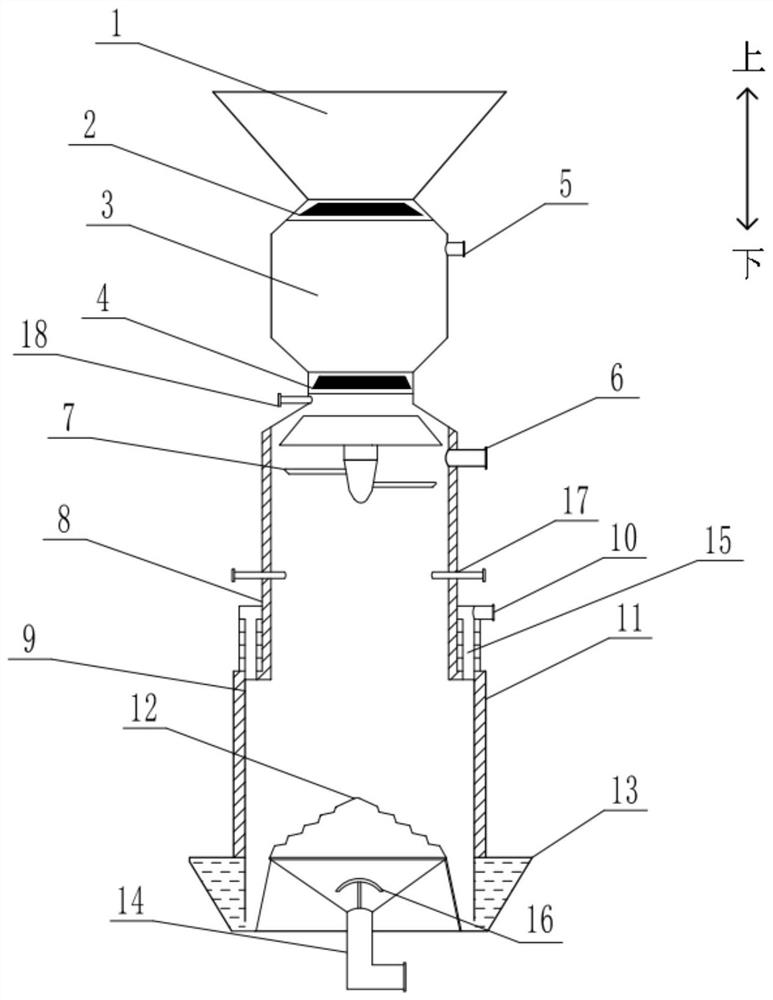

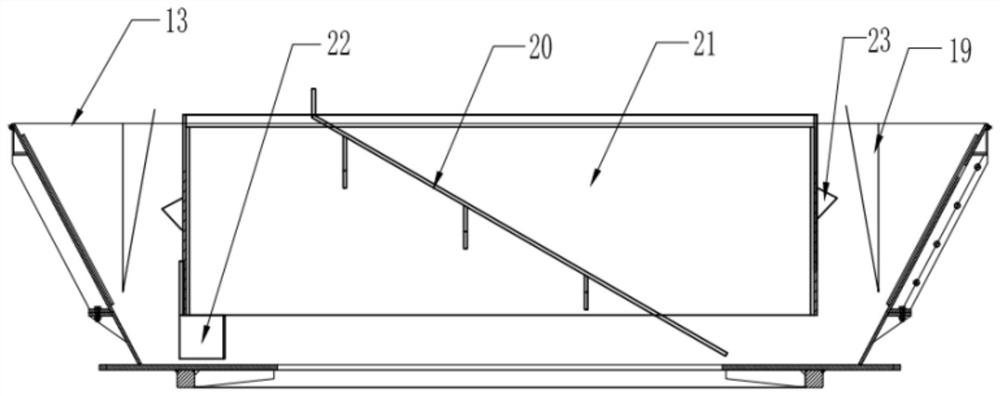

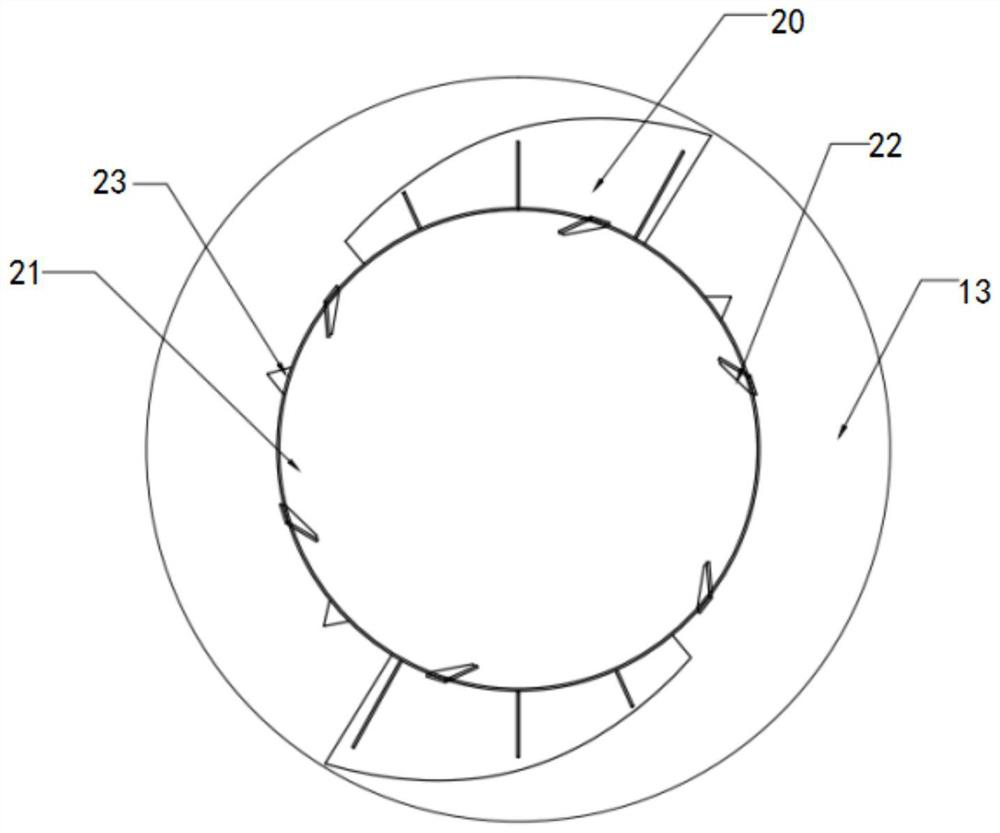

[0090] The structure of organic solid waste epitaxial annular cavity gas-conducting fixed-bed gasifier is as follows: Figure 1-3 as shown, Figure 1-3 Middle: 1-feed inlet, 2-upper valve of feed buffer bin, 3-feed buffer bin, 4-lower valve of feed buffer bin, 5-filling and releasing port of feed buffer bin, 6-top gasification Agent inlet, 7-distributing device, 8-upper furnace body, 9-lower furnace body, 10-gas outlet, 11-membrane water wall, 12-furnace grate, 13-ash tray, 14-bottom gasification Agent inlet, 15-extended annular cavity, 16-gasification agent distribution regulator, 17-middle gasification agent inlet, 18-inert gas purge inlet, 19-slag ring, 20-th One ash knife, 21-fire grate support, 22-the second ash knife, 23-broken slag block.

[0091] (1) Feed

[0092] The organic solid waste gasification furnace of the present invention is composed of three parts: a feeding device, a gasification device and a slagging device. The feeding device is composed of feed port...

Embodiment example

[0102] The inner diameter of the bottom of the gasifier is 3.6m, and the material to be treated is domestic waste, with a treatment capacity of 4100kg / h. The main operating conditions and gasification results are as follows:

[0103] (1) Material industry analysis is shown in the following table:

[0104]

[0105] (2) Operating conditions:

[0106] Gasification pressure: 7kPa;

[0107] Gasification agent: air + water vapor;

[0108] Air volume: 4600Nm 3 / h;

[0109] Water vapor volume: 500kg / h.

[0110] (3) Gasification result:

[0111] Gas production: 7200Nm 3 / h;

[0112] Composition of gas: H 2 : 16.17%, CO: 24.80%, CH 4 : 1.50%, CO 2 : 6.89%, N 2 : 50.44%, O 2 : 0.10%, C n h m : 0.10%;

[0113] Gasification efficiency: 69%;

[0114] Ash carbon content: 2.8%;

[0115] Gas tar content: 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com