Patents

Literature

62results about How to "Reduce the probability of error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

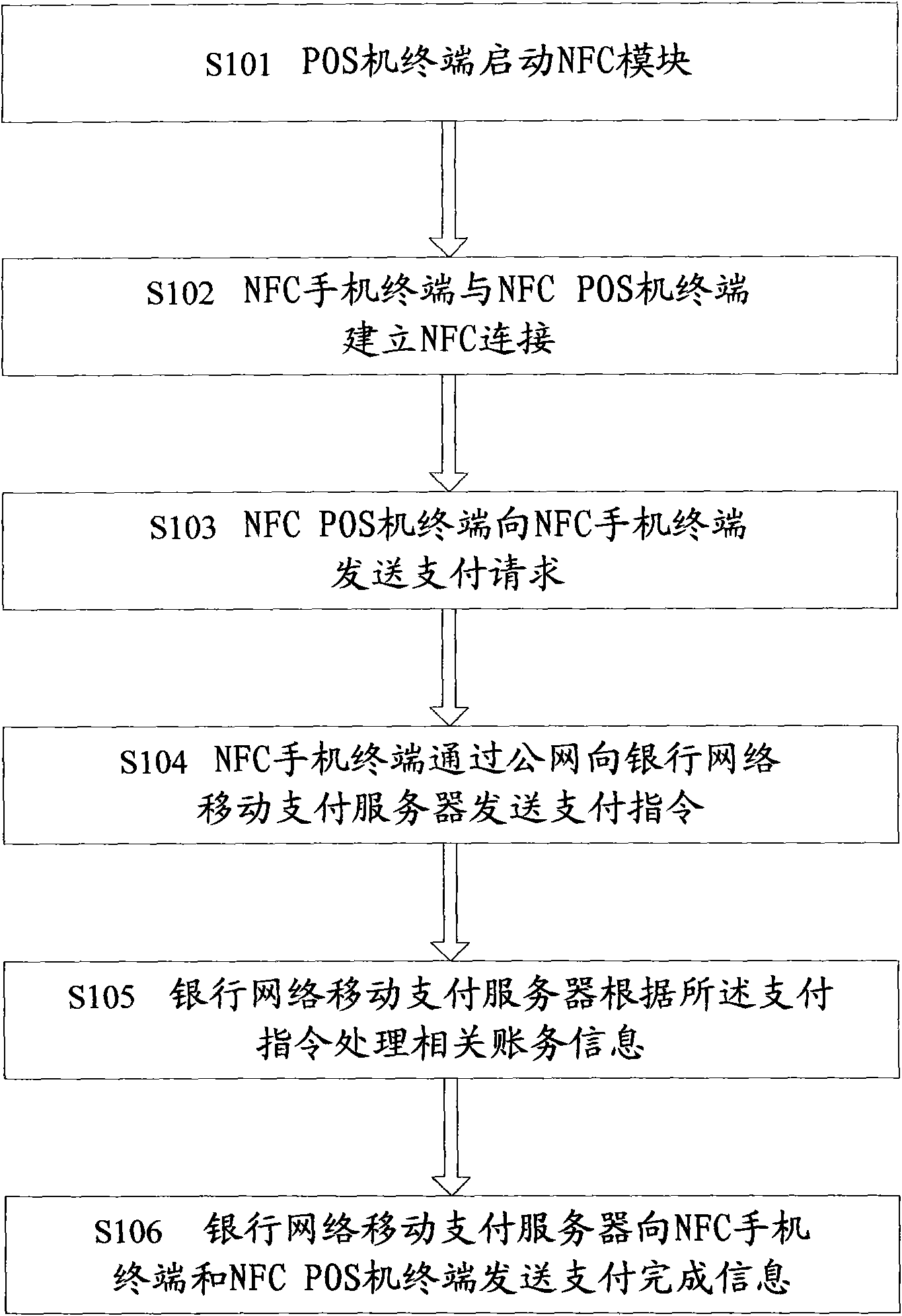

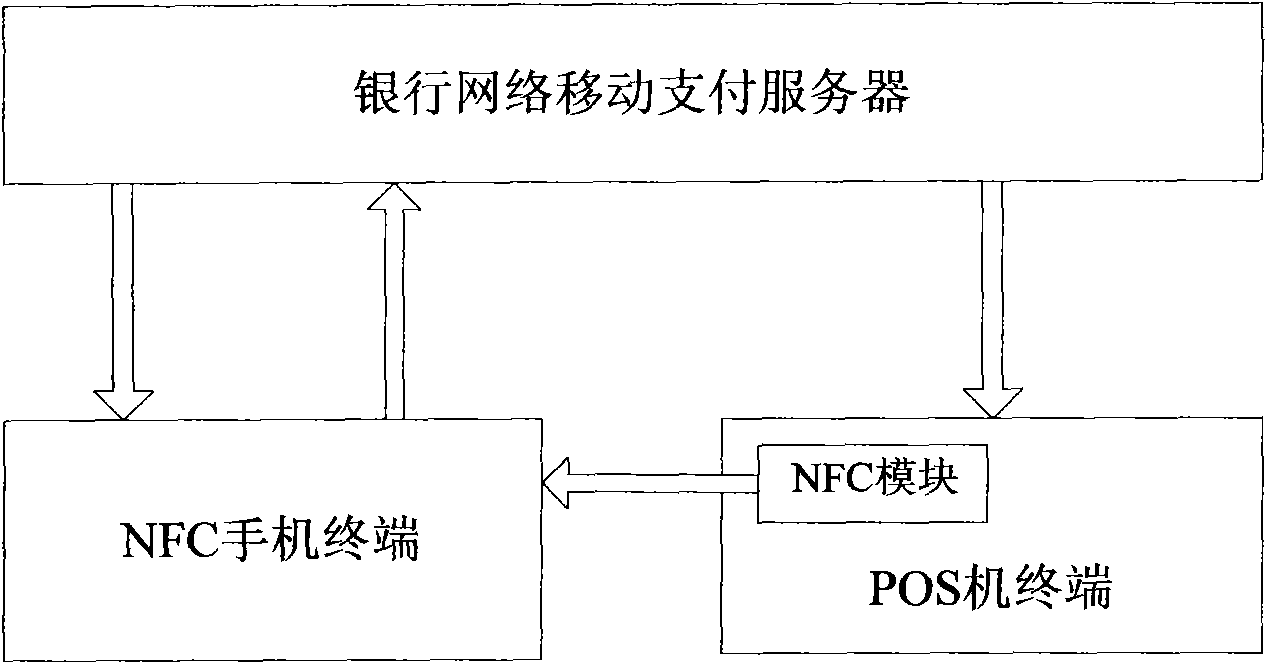

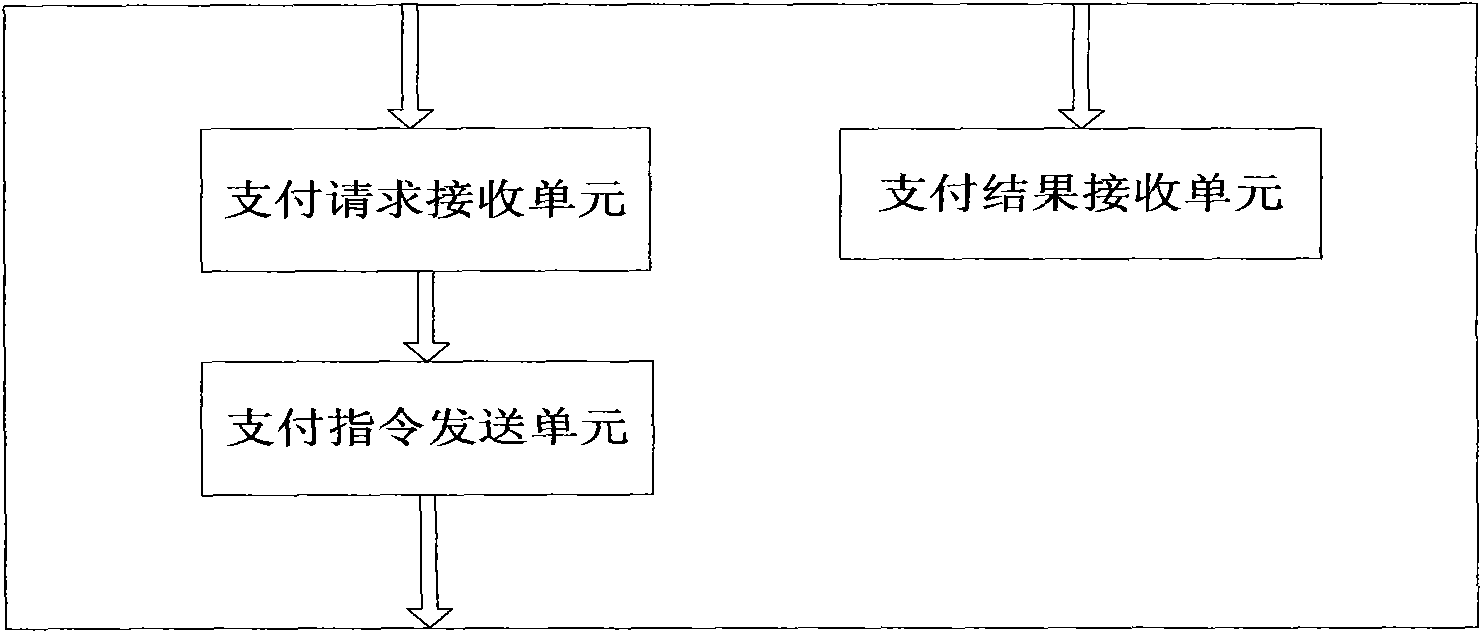

Method and system for payment of NFC mobile phone-POS machine

InactiveCN101567108AInput less informationReduce the probability of errorComplete banking machinesAccounting/billing servicesMobile paymentMobile phone

The invention discloses a method and a system for payment of an NFC mobile phone-POS machine, which are designed to solve the problems of complicated operation and easy mistakes in the prior mobile phone payment mode. The system comprises an NFC mobile phone terminal, an NFC POS machine terminal and a bank network mobile payment server; the NFC POS machine terminal is used for sending a payment request to the NFC mobile phone terminal through NFC signals; the NFC mobile phone terminal is used for receiving the payment request and sending a payment instruction to the bank network mobile payment server according to the payment request; and the bank network mobile payment server receives the payment instruction, processes related financial information and sends an operation result to the NFC POS machine terminal and the NFC mobile phone terminal. The method and the system are suitable for consumption settlement between consumers and trade companies.

Owner:BEIJING AIO TIME INFORMATION TECH

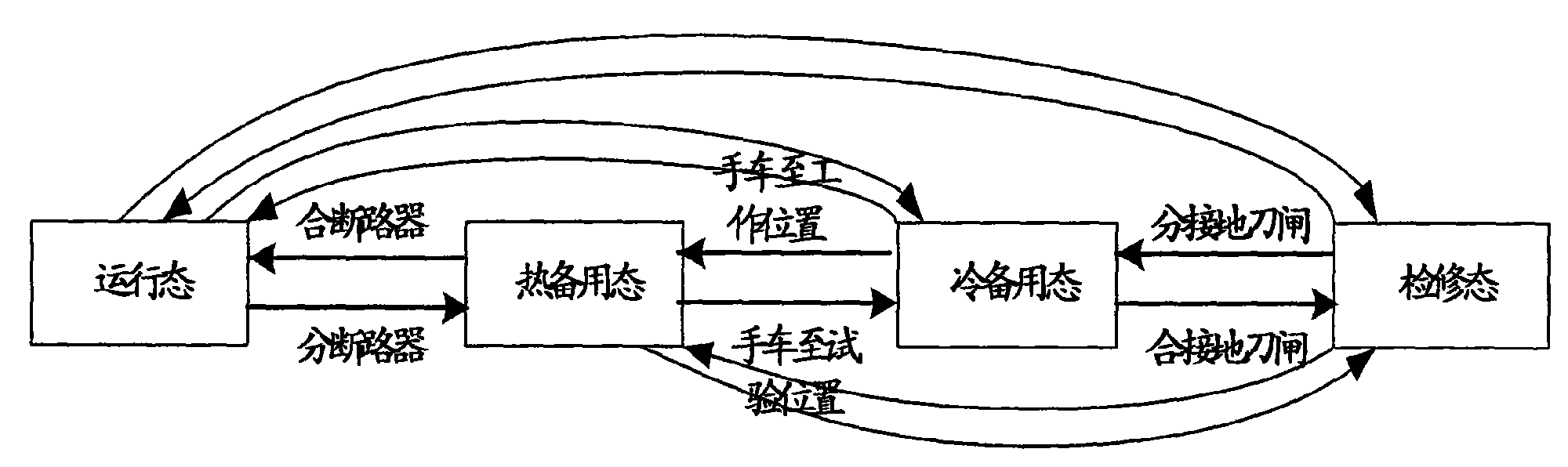

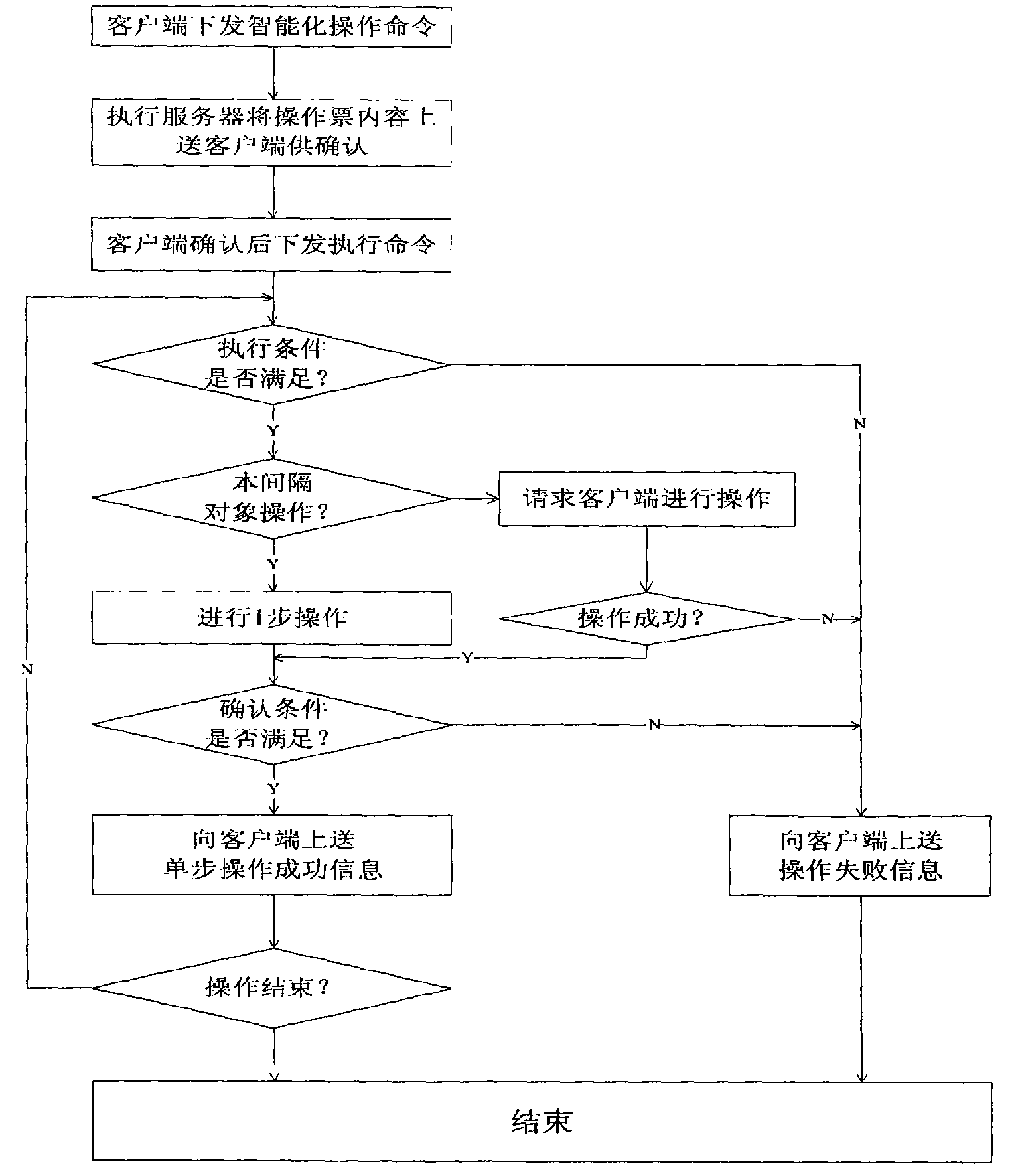

Intelligent control method for automatic system of transformer station

InactiveCN101594004AReduce human workReduce the probability of errorCircuit arrangementsEmbedded systemSmart control

The invention relates to an intelligent control method for an automatic system of a transformer station, which realizes ticket operation by computer intelligentization instead of manual operation, and controls and operates equipment through intelligentization. Various operations of the transformer station are pre-edited into intelligent ticket operation and are downloaded into an execution server, wherein the operations in pure interval are downloaded into an intelligent device of an interval layer, and the cross-interval operations are downloaded into a special intelligent operation server (which can be implemented by a background monitoring or remote controlling device or an autonomous device). When the transformer station is operated, if the operations are needed, executive commands are sent to the execution server through a background monitoring interface or a scheduling terminal in a remote control mode, and the execution server automatically finishes a series of switching operations, wherein error protections related to various operations are also processed by the execution server according to pre-edited rule contents. The whole switching operations achieve 'one-key operation'.

Owner:JIANGSU WISCOM TECHNOLOGY CO LTD

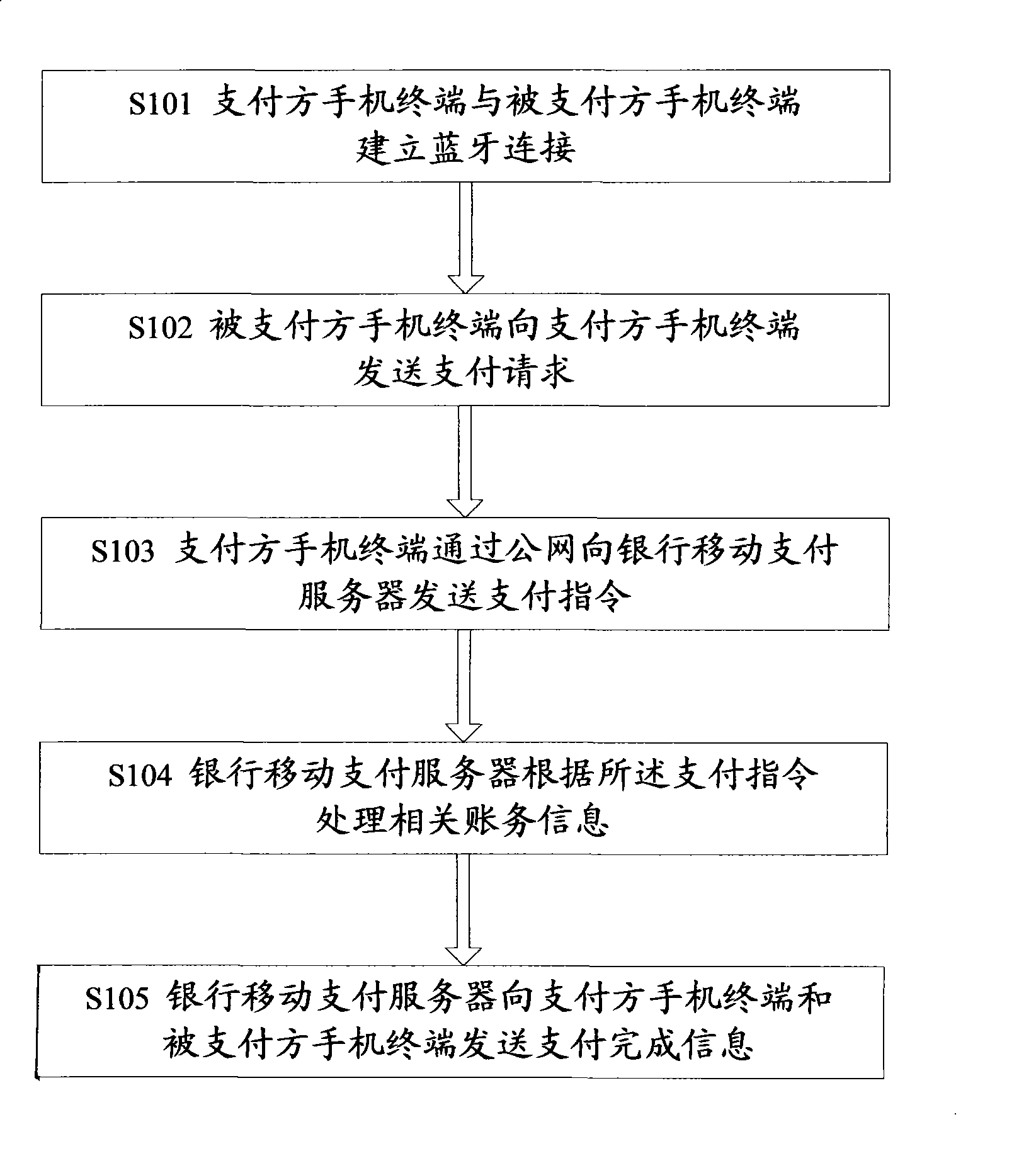

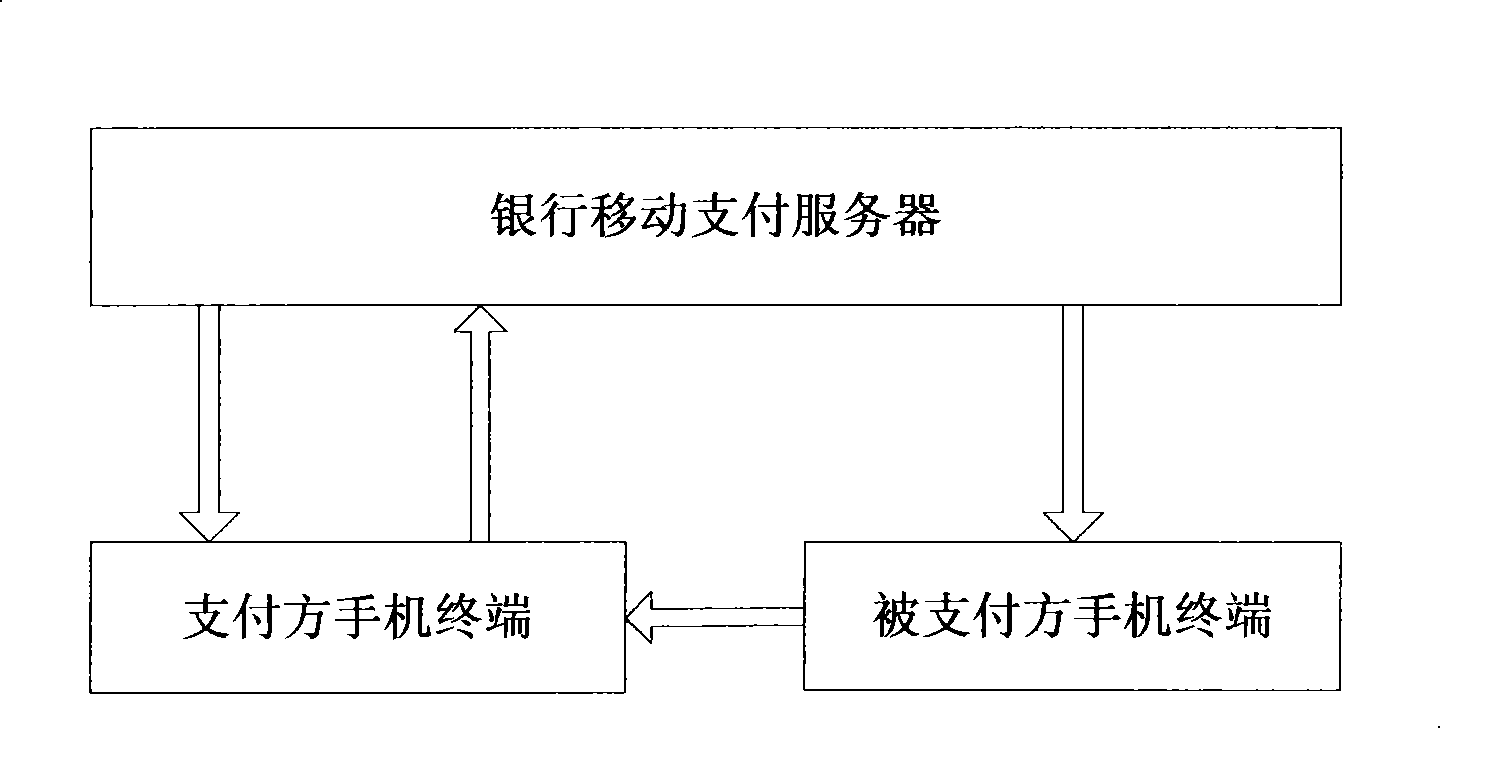

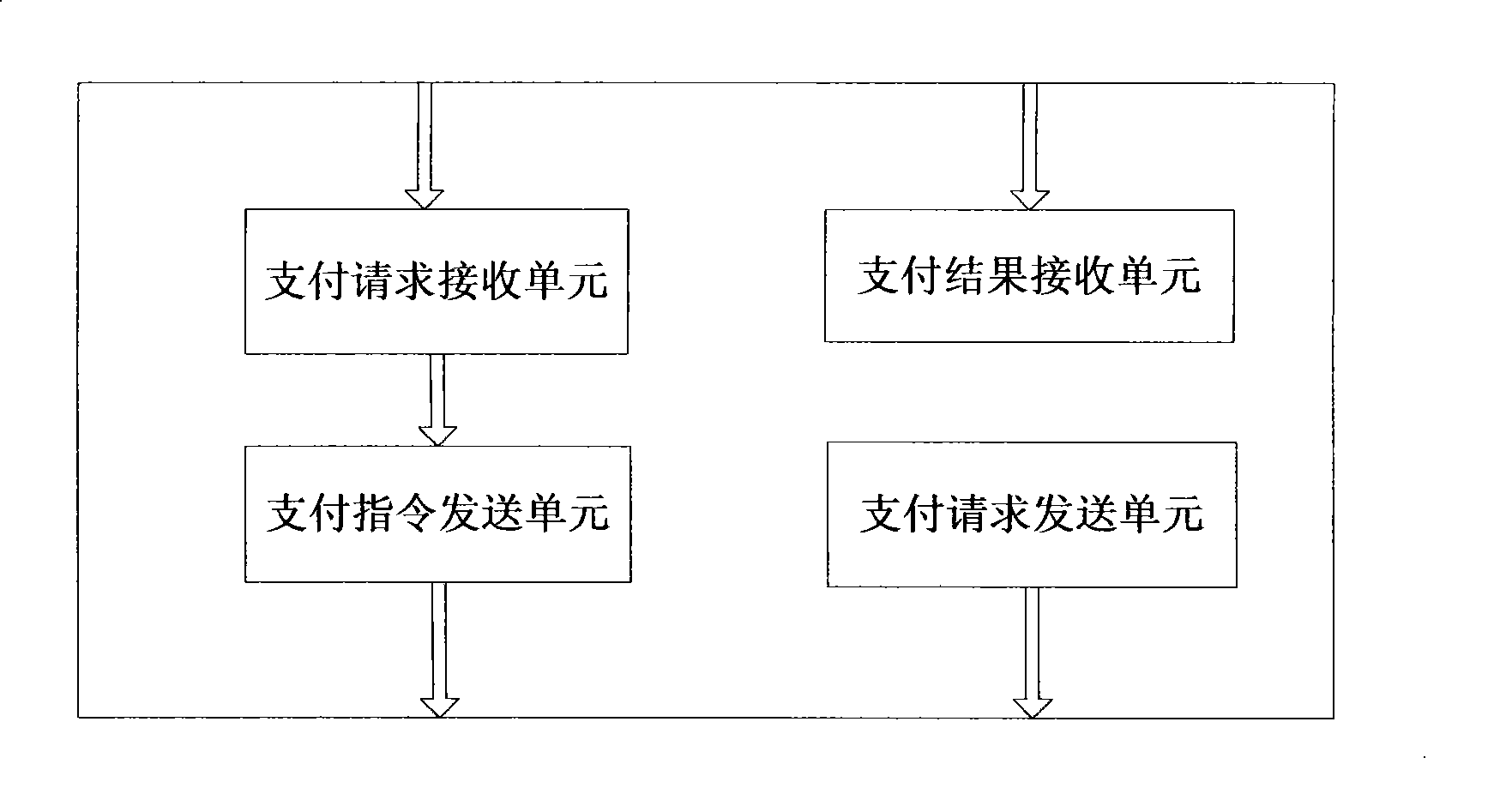

Bluetooth mobile payment terminal, payment method and system

InactiveCN101459903AInput less informationReduce the probability of errorAccounting/billing servicesNear-field systems using receiversTelecommunicationsPayment terminal

The invention discloses a Bluetooth cellular phone payment terminal, a payment method and a system thereof, which is designed for solving the problems of complicate payment and easy errors of an existing cellular phone payment mode. The system comprises a payer cellular phone terminal, a payment receiver cellular phone terminal and a bank mobile payment server, wherein the payment receiver cellular phone terminal is used for sending the payment request for the payer terminal through a Bluetooth, and the payer cellular phone terminal is used to receive the payment request and send the payment instruction for the bank payment server through the payment request, and the bank mobile payment server is used to receive the payment request, to process related financial information, and send the operation result to the payment receiver cellular phone terminal and the payer cellular phone terminal. The invention is applied to the consumption settlement between consumers and trade companies, also is applied to the transfer by payment between individuals.

Owner:BEIJING AIO TIME INFORMATION TECH

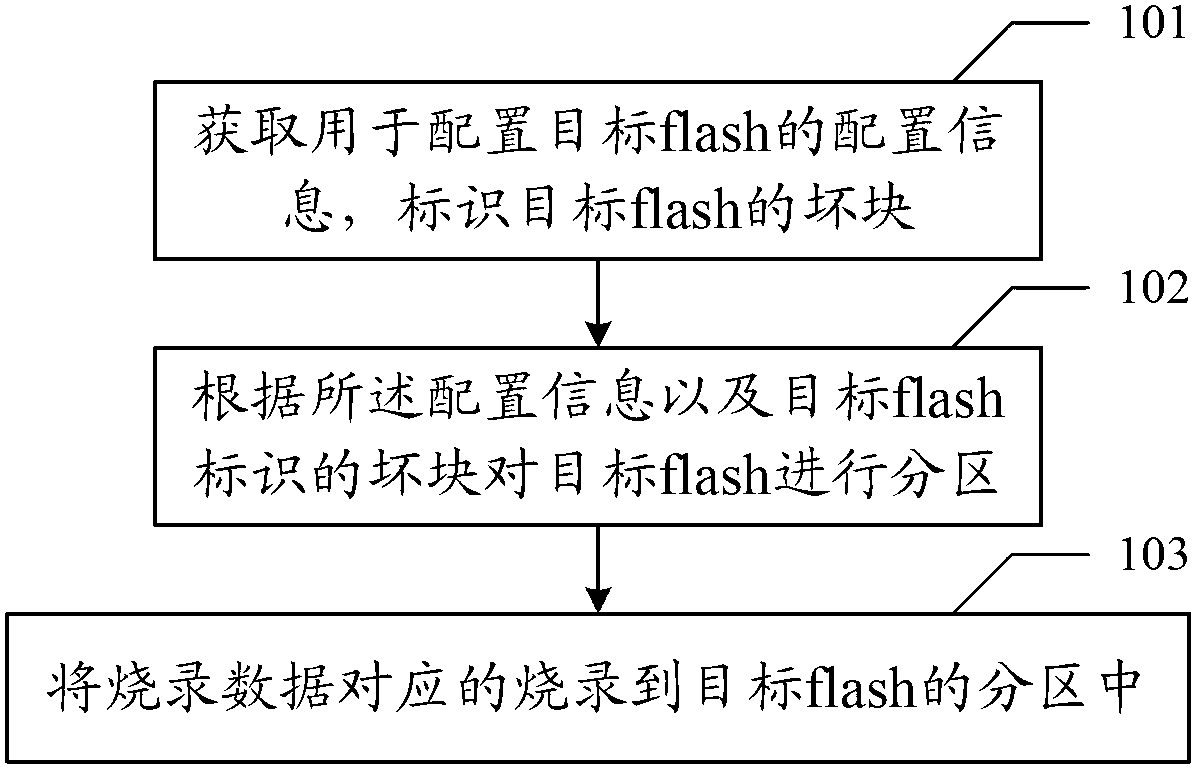

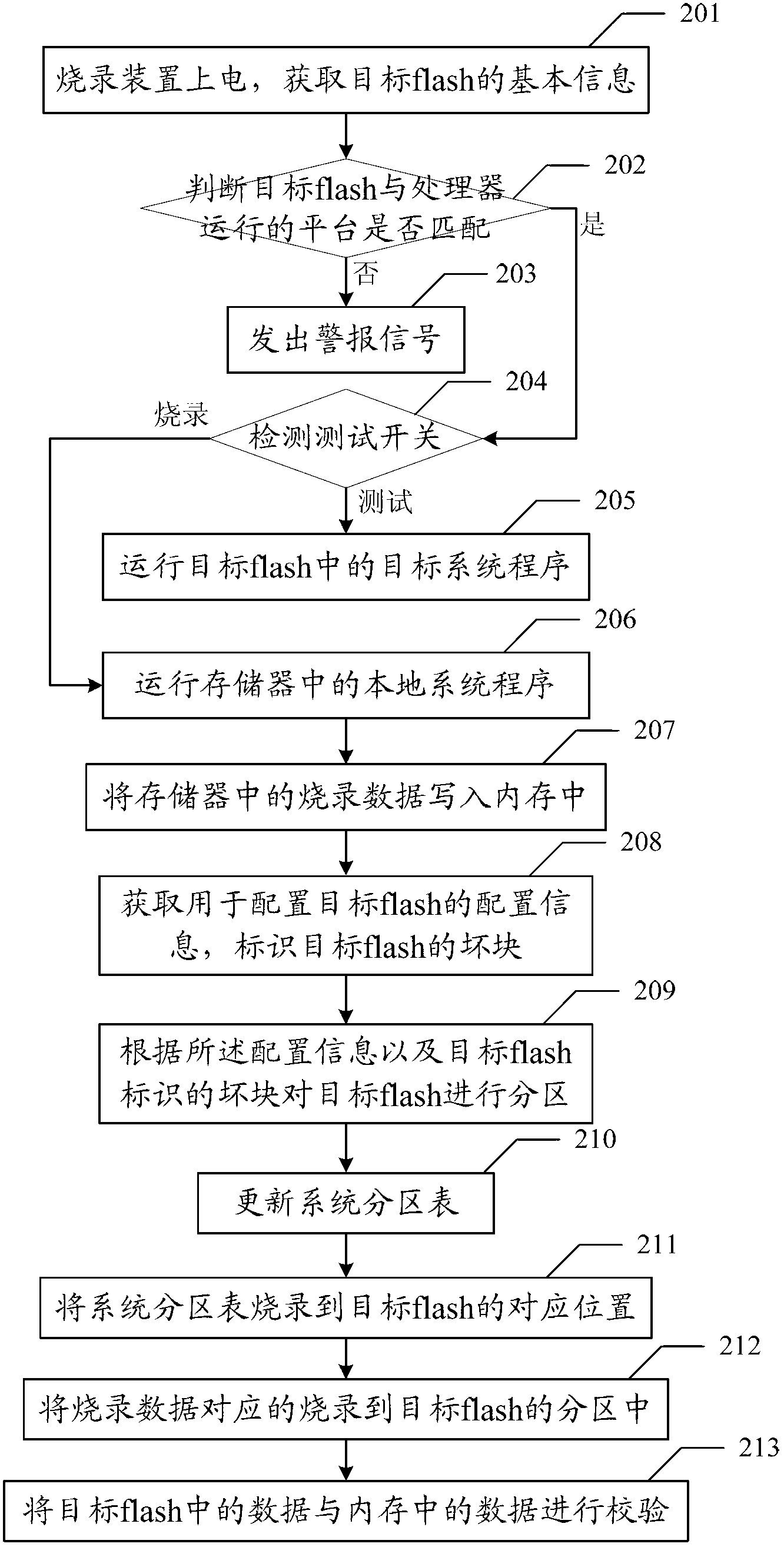

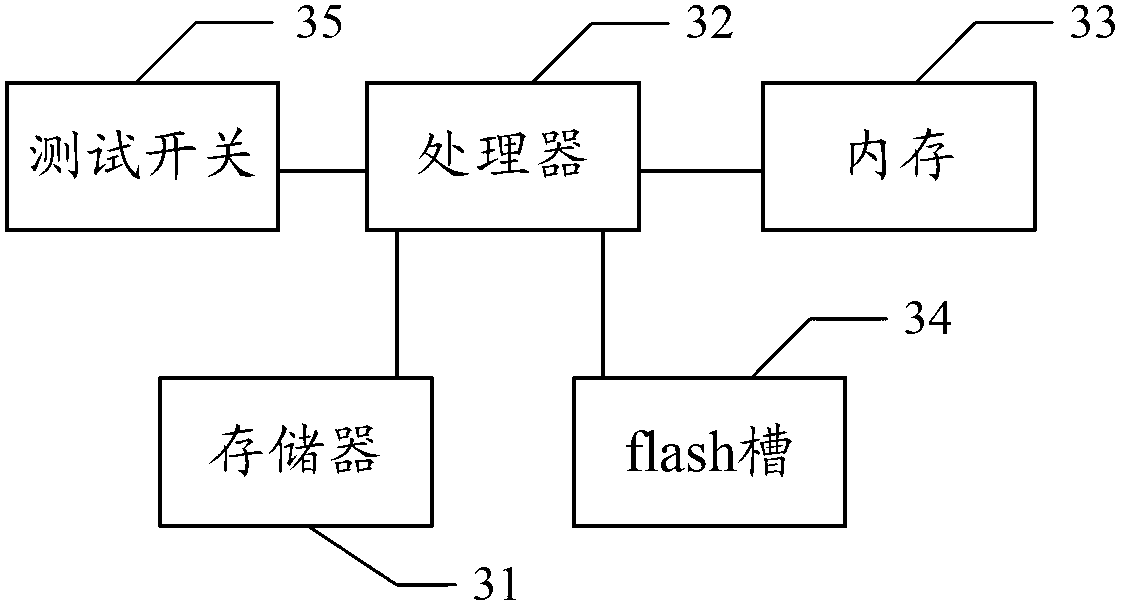

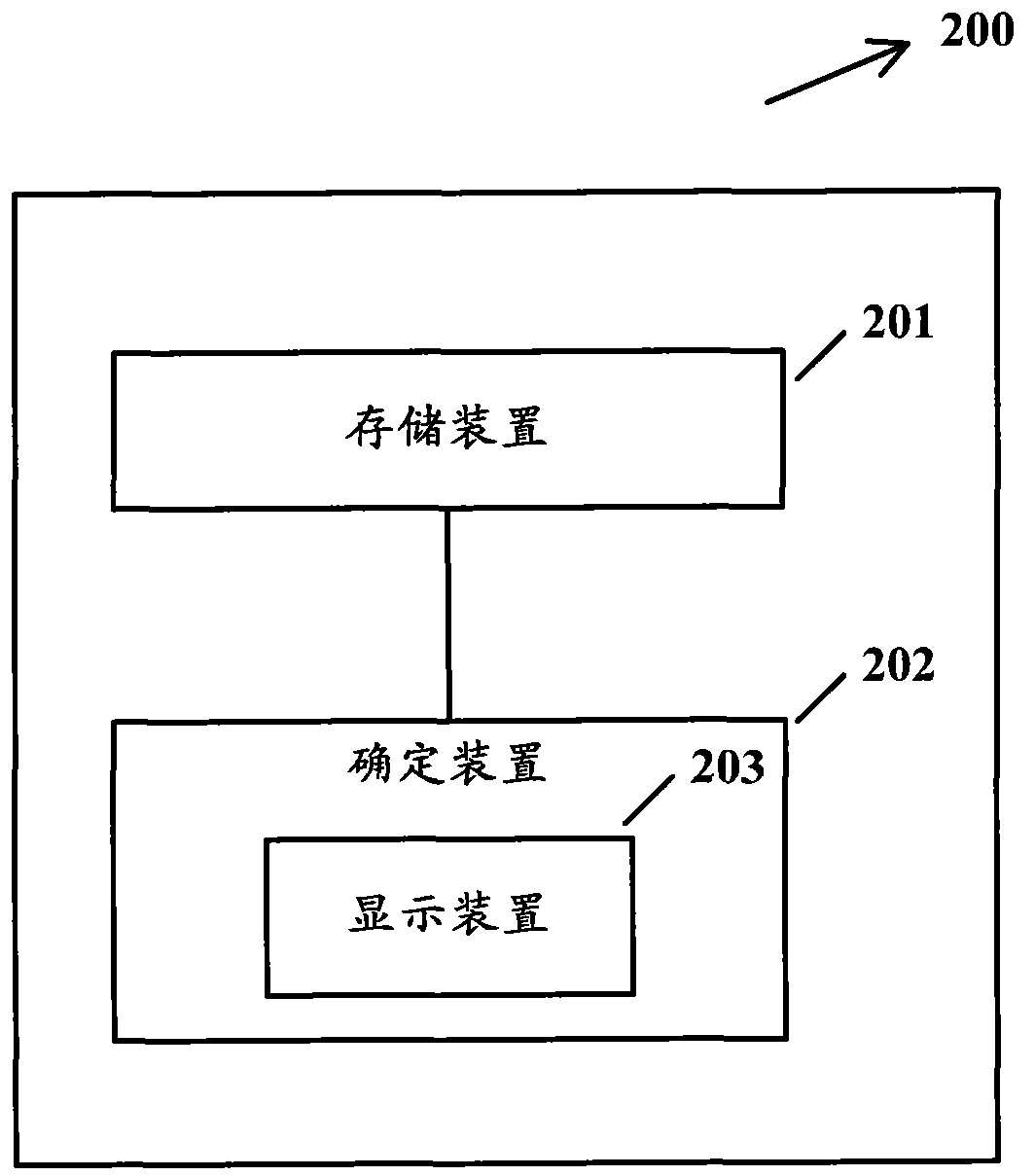

Flash programming method and device

ActiveCN103064710AReduce the probability of errorFlash programming method and device are stable and efficientProgram loading/initiatingElectronicsOperating system

An embodiment of the invention discloses a flash programming method and device. The method and the device are applied to the technical field of electronics. The flash programming method includes that configuration information for configuring a target flash is acquired, a bad block of the target flash is marked, and the configuration information includes partition area lengths of system partition areas; the target flash is subjected to area partition according to the configuration information and the marked bad block of the target flash, and thereby the quantity of non-bad blocks in the system partition areas acquired by the target flash corresponds to the partition area lengths of the system partition areas in the configuration information; and programming data are correspondingly programmed to the partition areas of the target flash. The flash programming method and device are stable and efficient.

Owner:SHENZHEN NOWADA TECH

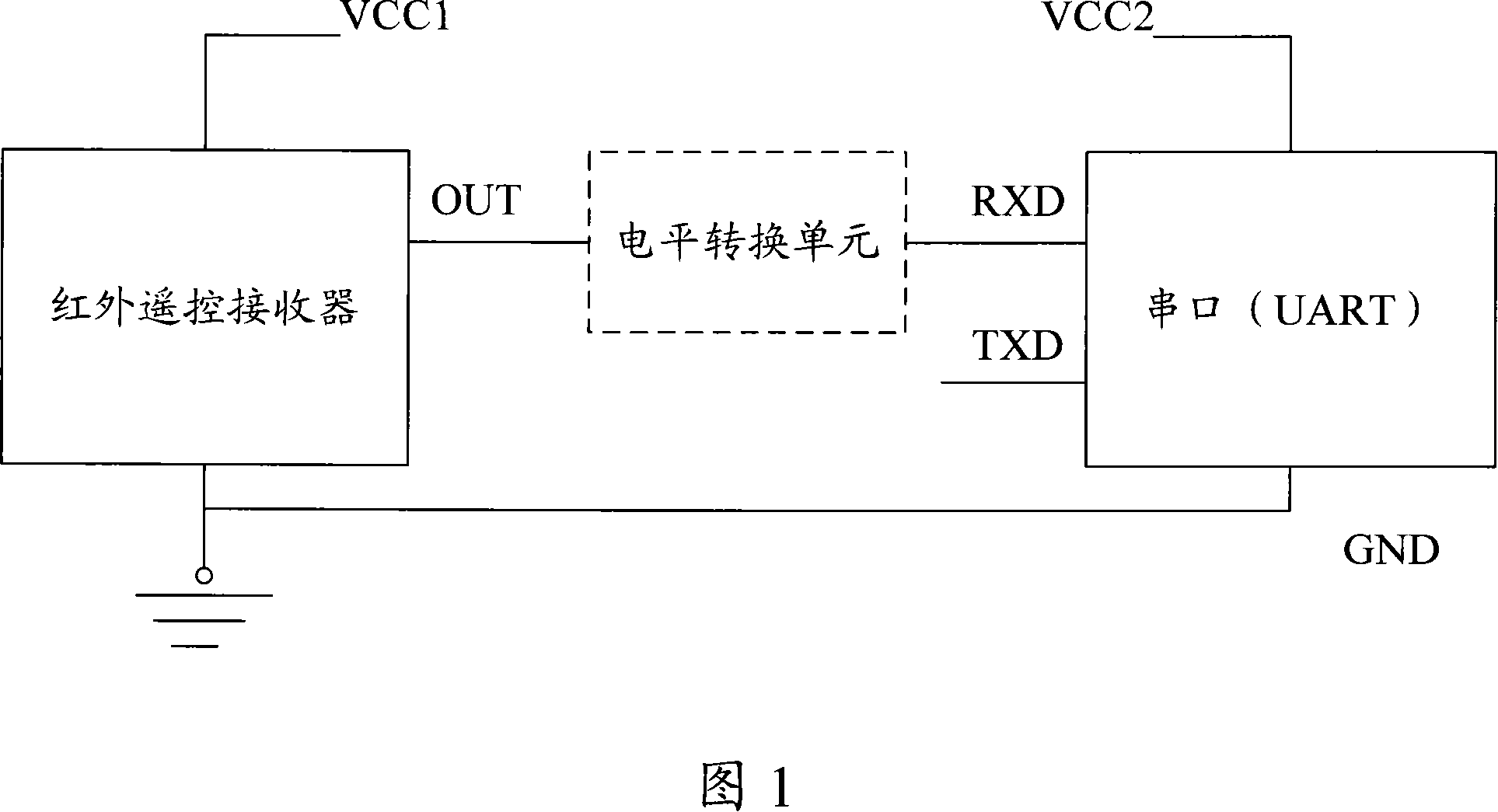

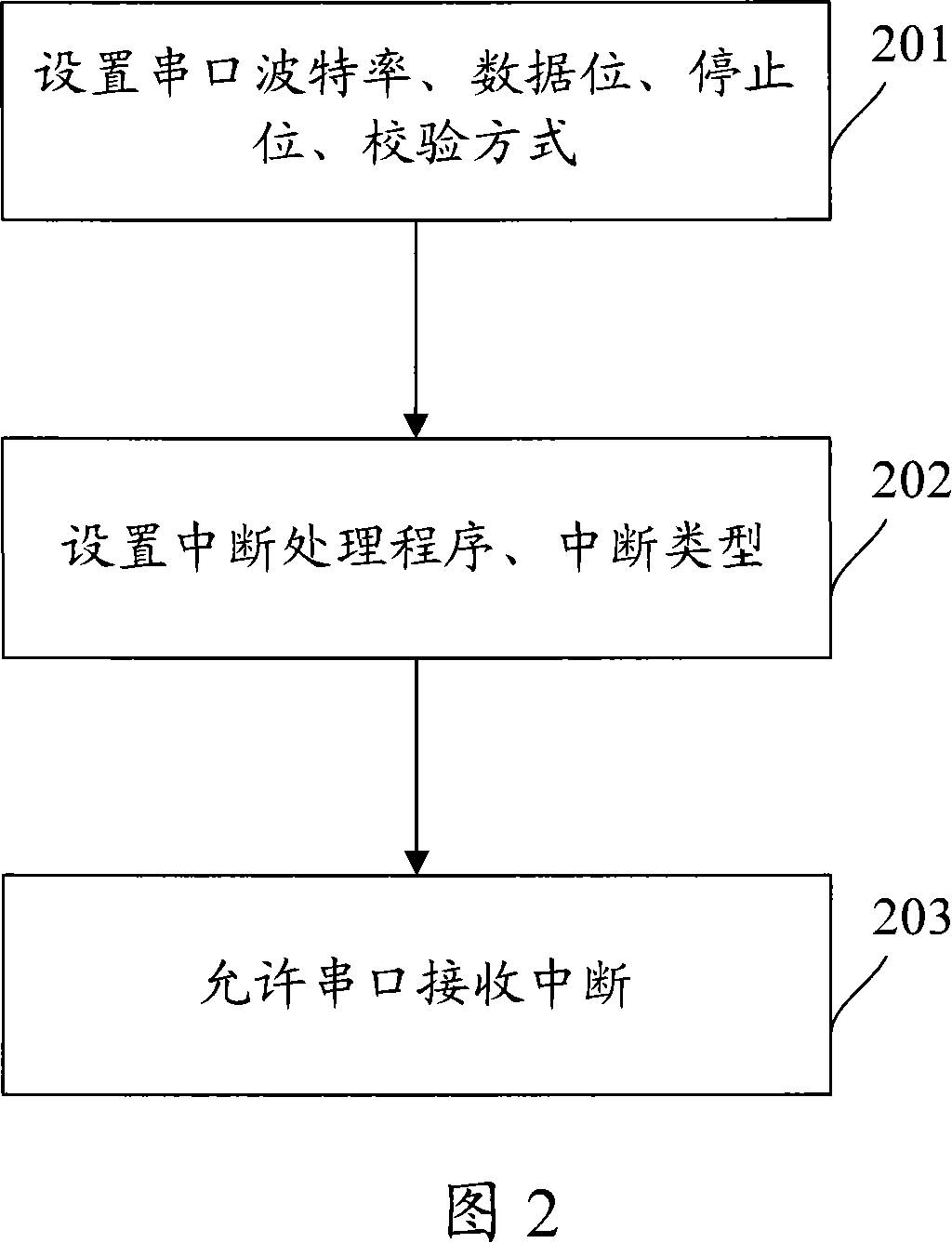

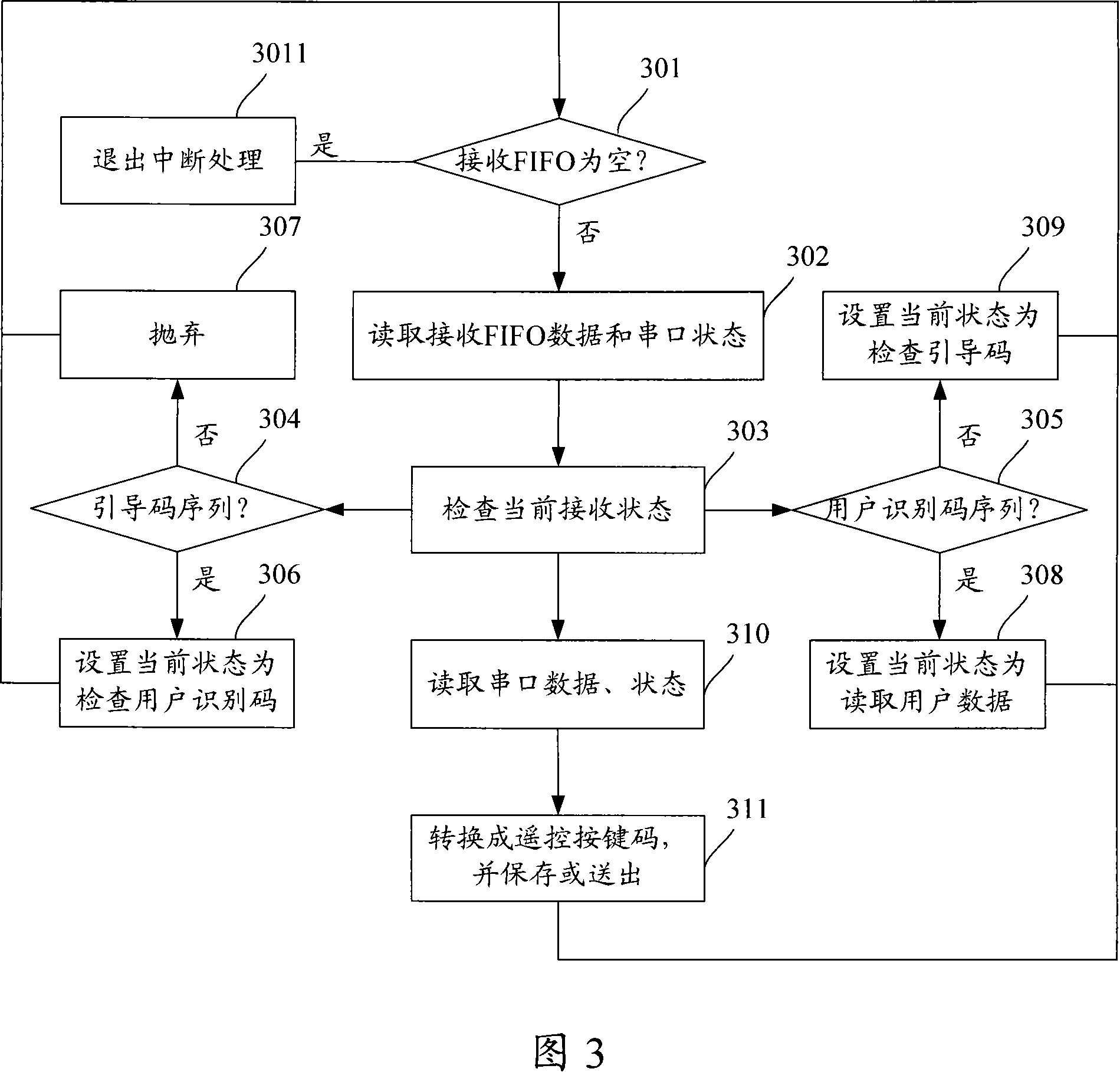

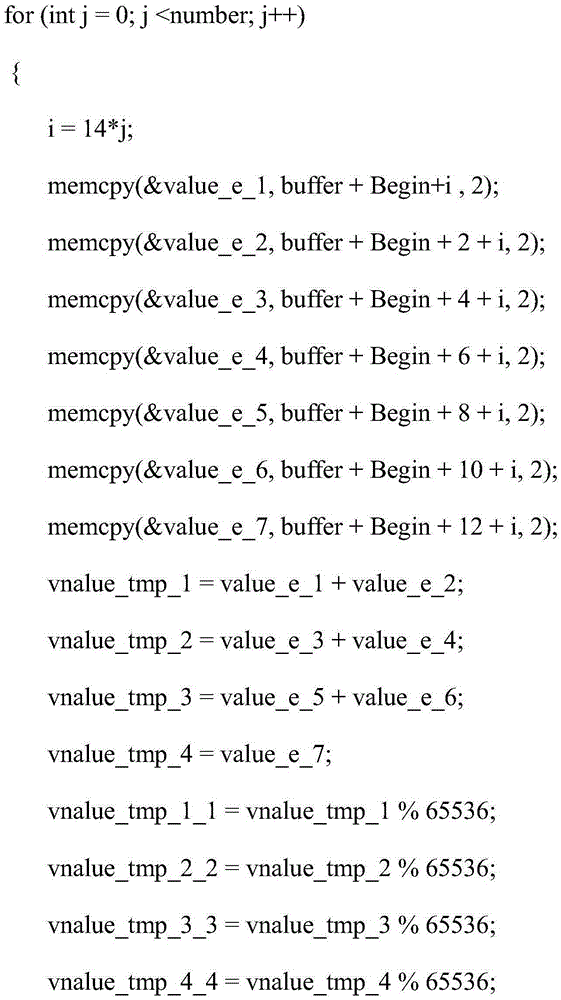

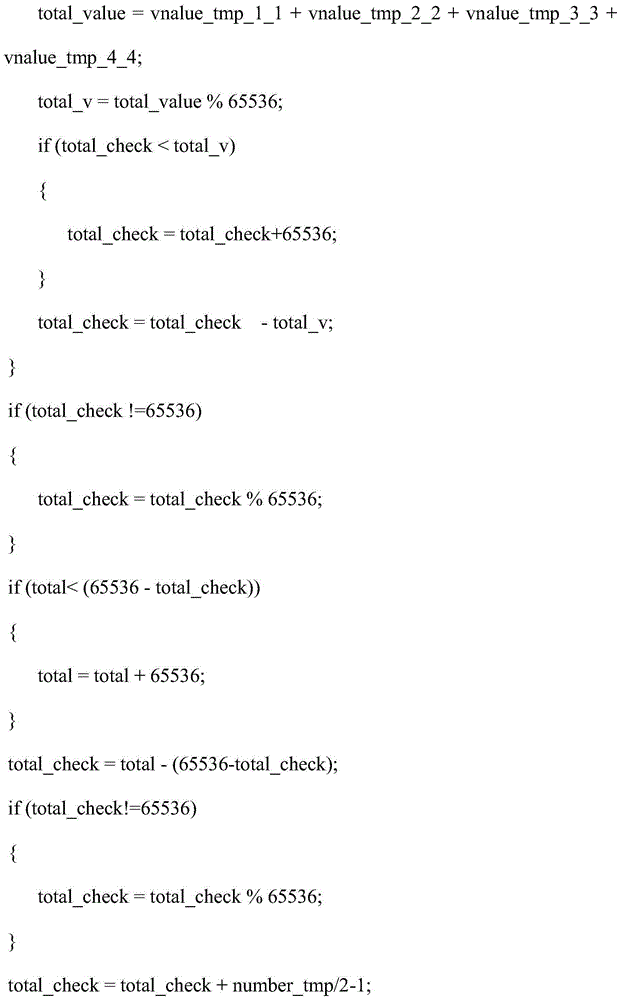

Method for receiving infrared remote control signal through serial port

InactiveCN101110159AReduce the probability of errorReduce occupancyNon-electrical signal transmission systemsEmbedded systemData conversion

The invention discloses a method for realizing software decoding remote control of signal pulse by receiving infrared remote control signal via a serial port, which is intended to reduce the additional external intermission resource of system occupied by software decoding. The invention is mainly characterized in that: connect an OUT pin of an infrared remote control receiver to a RXD pin of the serial port; calculate the serial port baud rate according to the pulse width of the remote controller currently in use; configure tribute of the serial port, comprising the serial port baud rate; acquire the serial port data that complies the lead code of the remote controller currently in use and a user identification code; save the value of the serial port data and a corresponding serial port status register; convert the serial port data into remote control key press value according to a remote controller key press map for the corresponding relation between the value of the remote control key press, the serial port and the serial port status register. Therefore, the invention does not occupy the additional external intermission resource of system and lowers down the possibility of mistake under great load of other intermission.

Owner:ZTE CORP

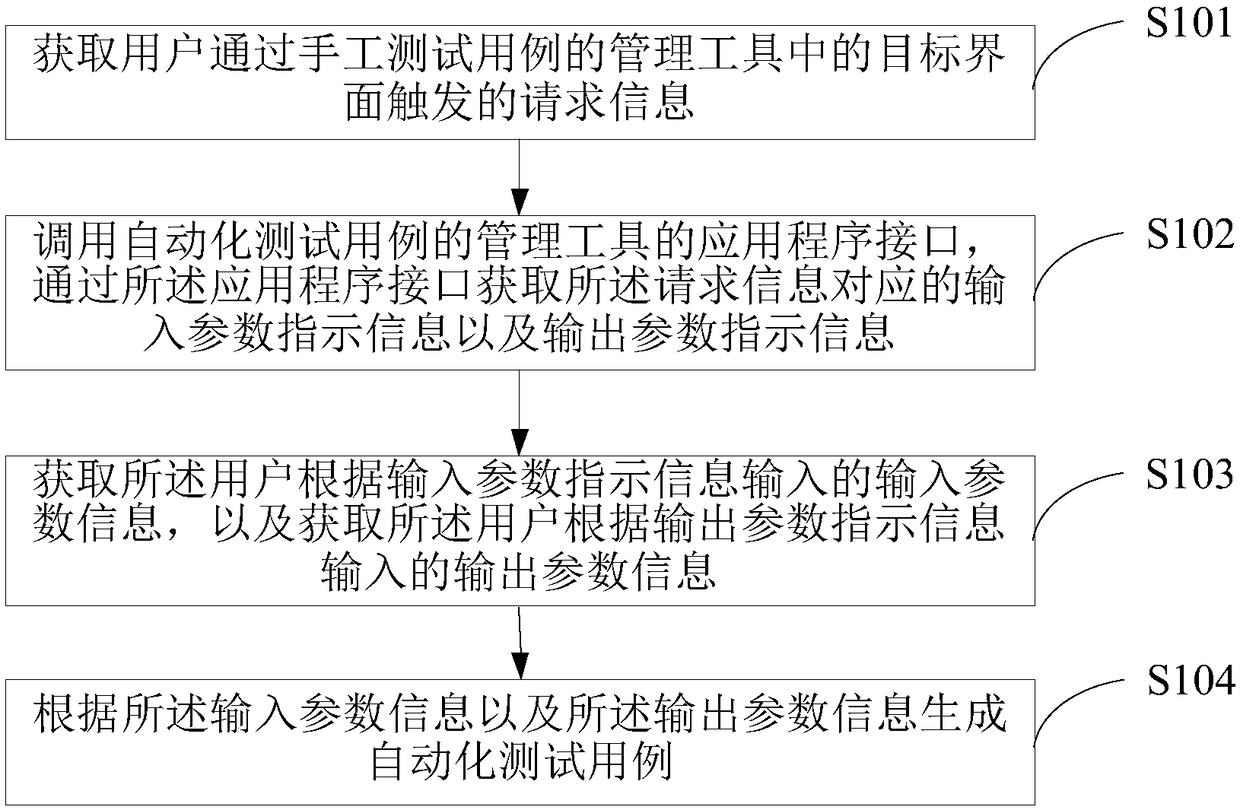

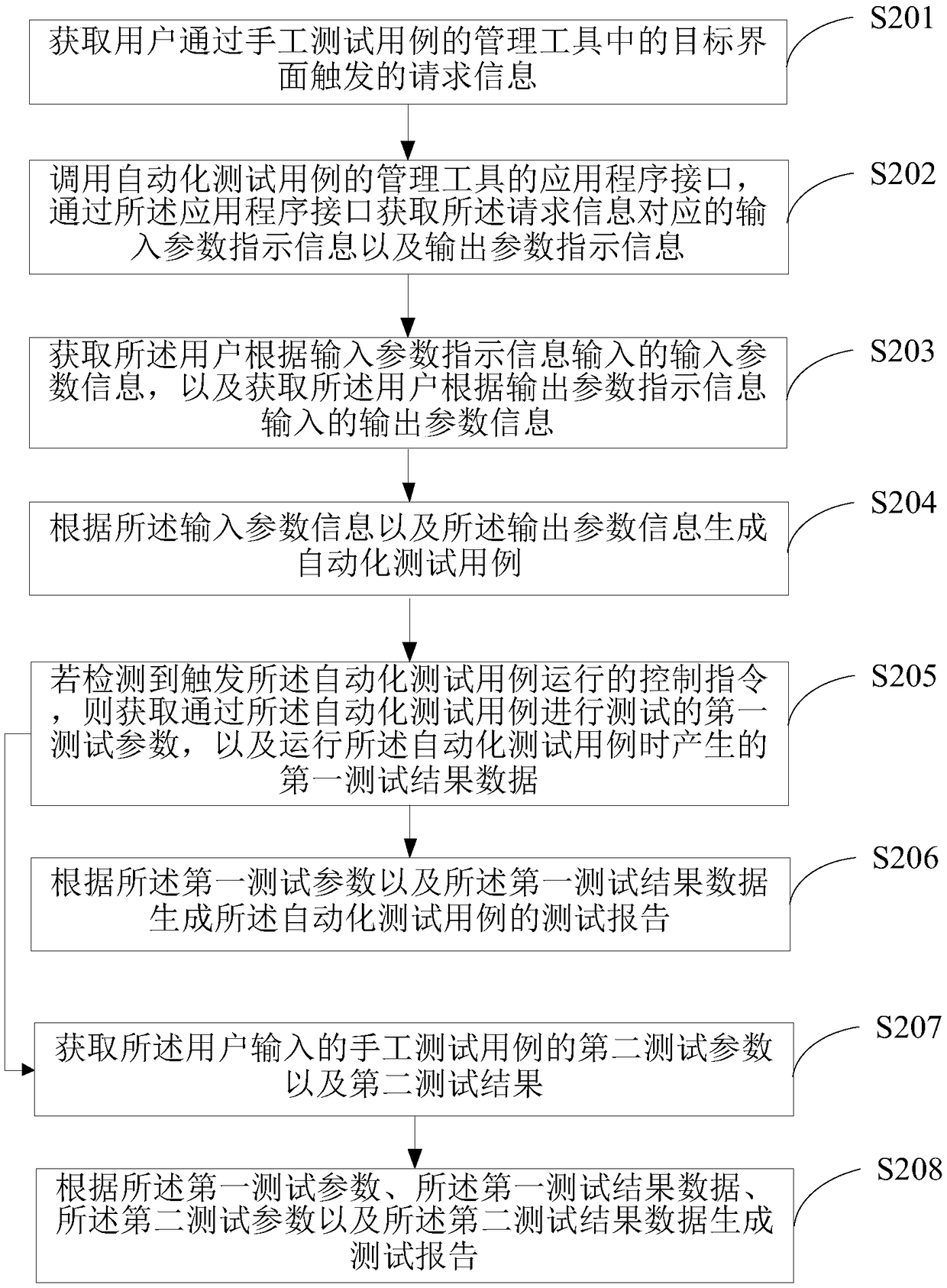

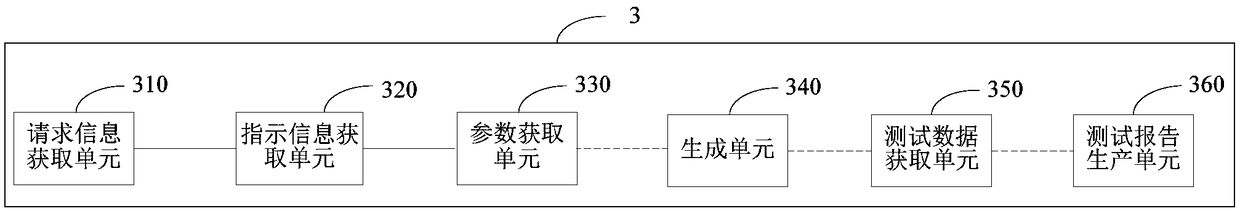

A method and a terminal device for generating an automated test case

PendingCN108984388AReduce the probability of errorSave time switching platformsSoftware testing/debuggingApplication softwareComputers technology

The invention is applicable to the field of computer technology, and provides a method and a terminal device for generating an automated test case. The method comprises the following steps: acquiringrequest information triggered by a user through a target interface in a management tool of a manual test case, wherein the target interface is an interactive interface for users to create automated test cases, and the request information is used to request the generation of automated test cases; calling an application program interface of the management tool of the automatic test case to obtain the input parameter indication information and the output parameter indication information corresponding to the request information through the application program interface; obtaining input parameter information inputted by the user according to the input parameter indication information and obtaining output parameter information inputted by the user according to the output parameter indication information; generating an Automated test case based on input parameter information and output parameter information. The invention does not need to switch the test platform, can save the time of the switching platform and can avoid the omission or redundancy of the requirement test, and realizes the purpose of improving the test efficiency.

Owner:PINGAN YIQIANBAO E COMMERCE CO LTD

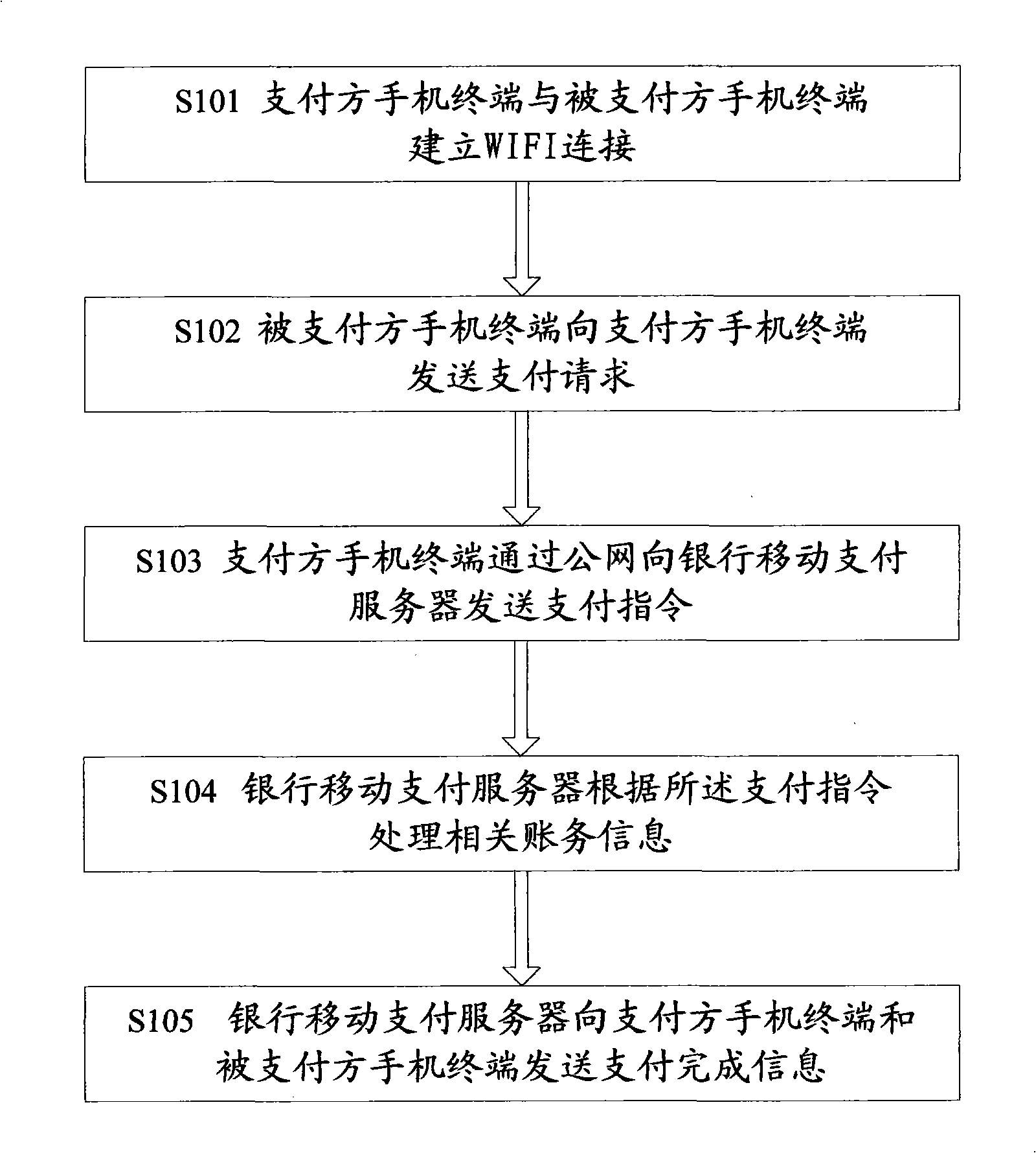

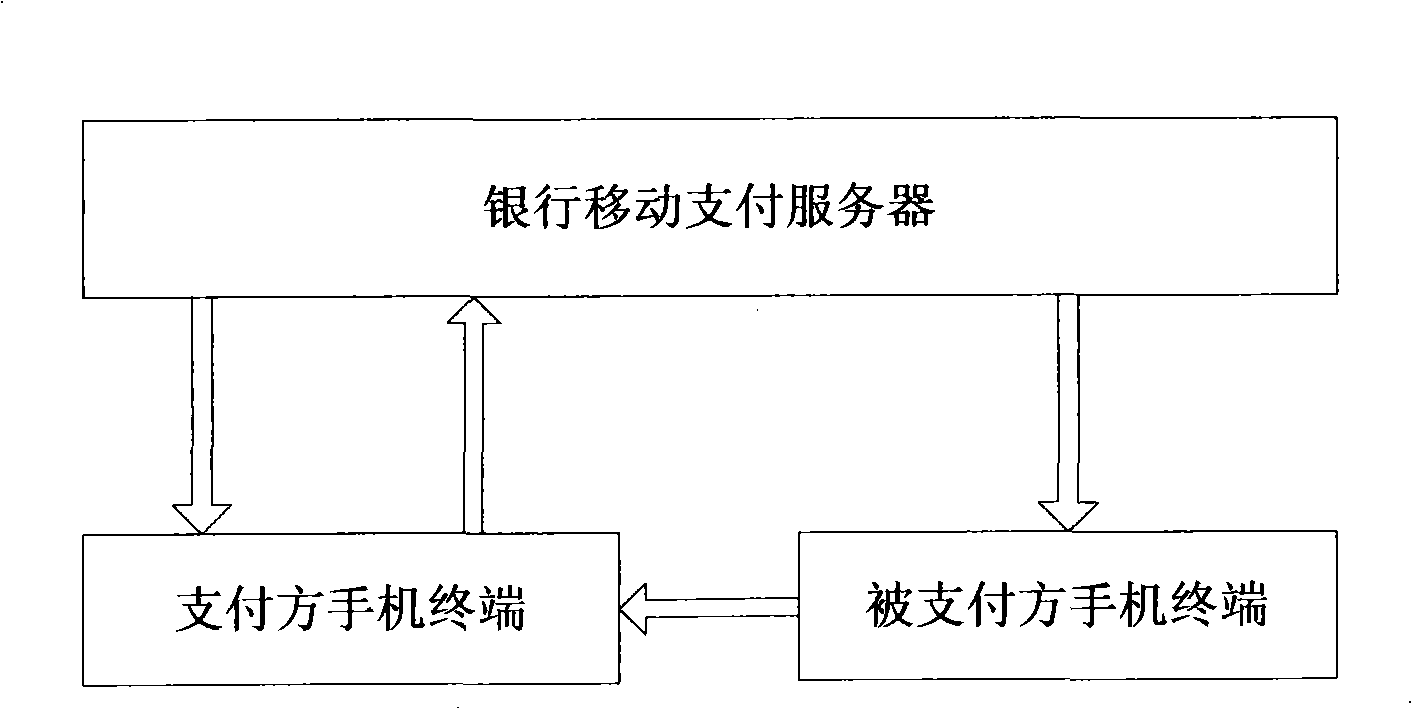

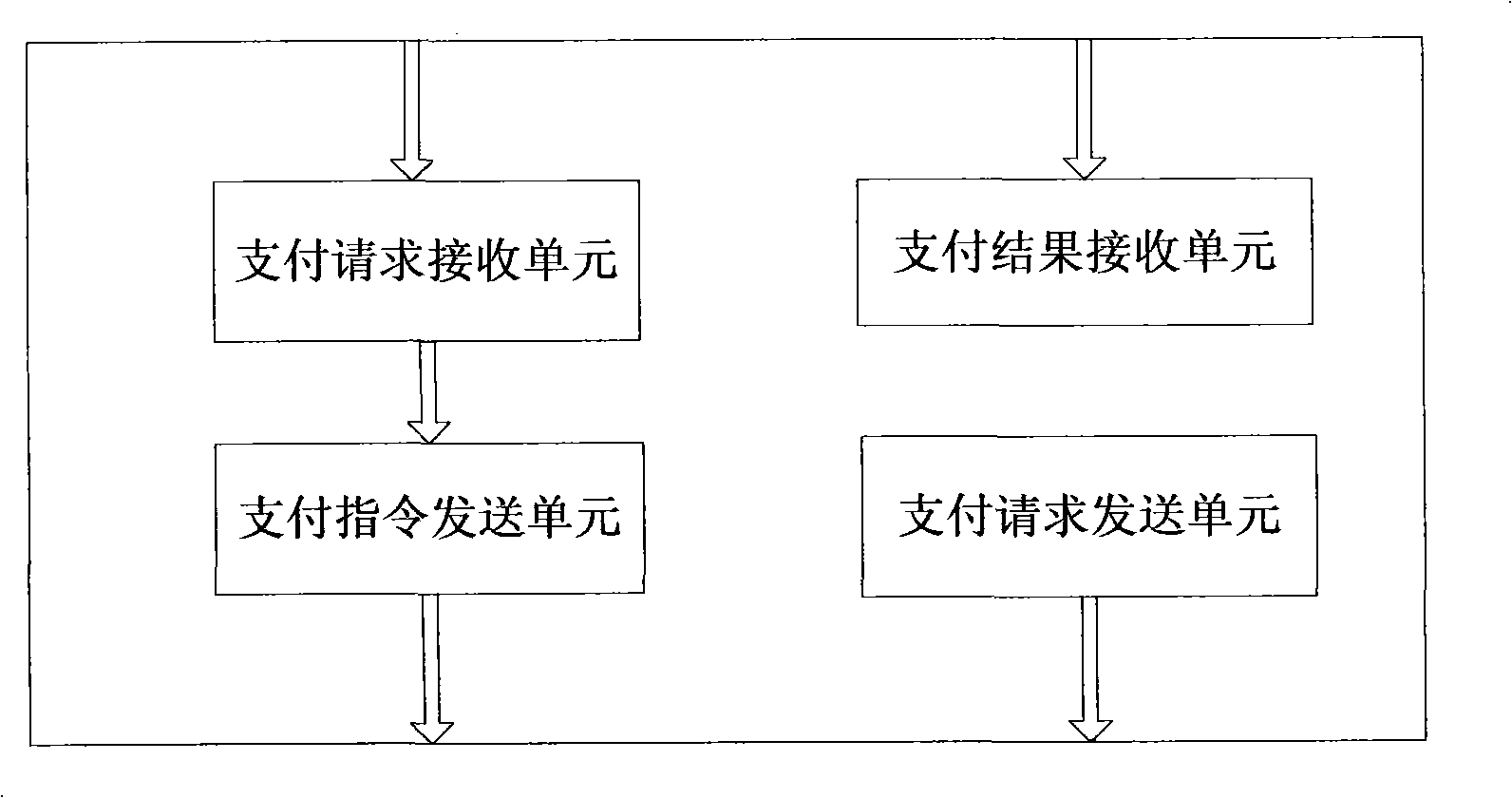

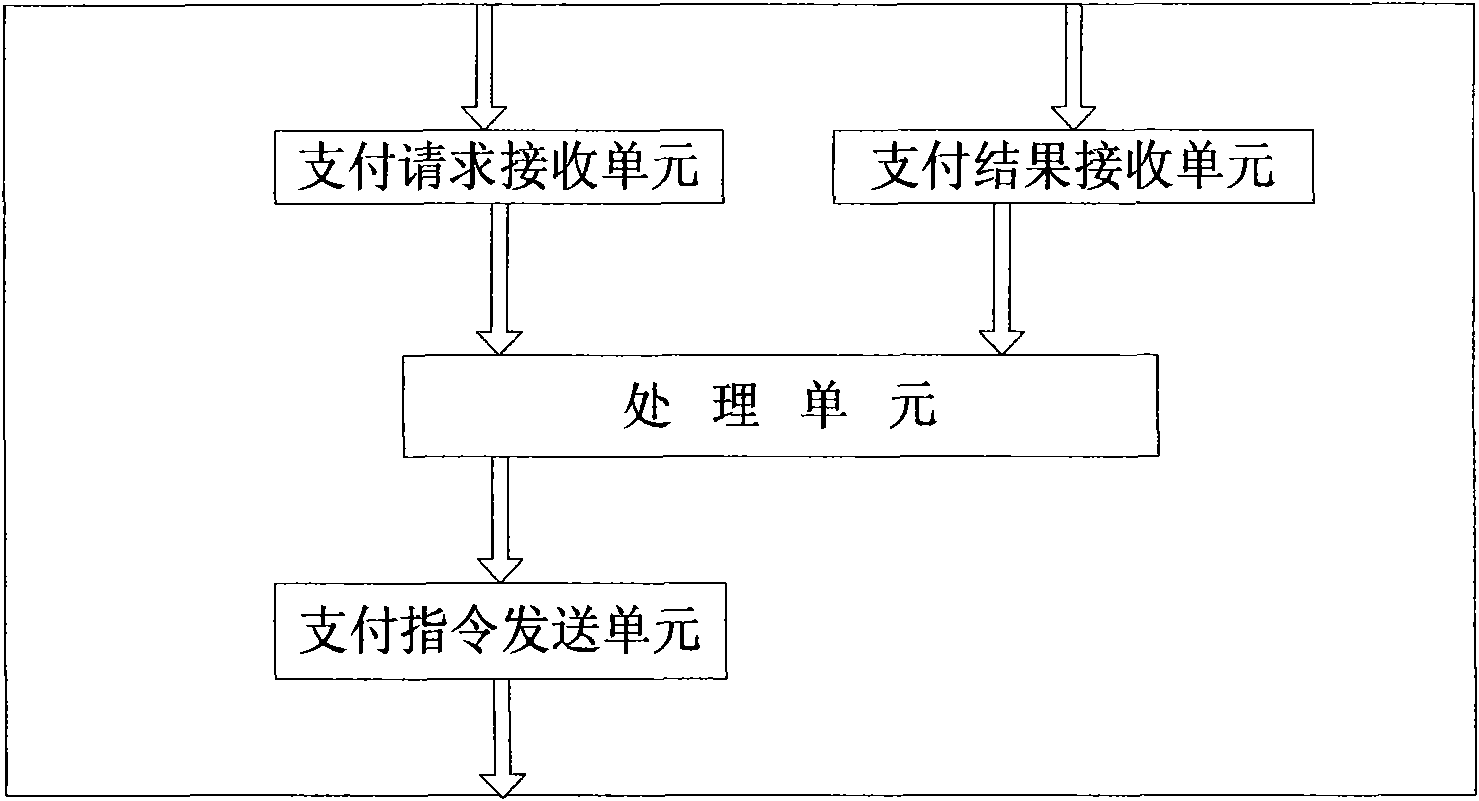

WIFI mobile phone payment terminal, method and system

InactiveCN101308559AInput less informationReduce the probability of errorData switching by path configurationPayment architectureHandsetPayment terminal

The invention discloses a WIFI handset payment terminal, a payment method and a system, designed to solve the problems that the existing handset payment mode is complicated in operation and can easily make a mistake. The system comprises a payer handset terminal, a payee handset terminal and a banking mobile payment server; the payee handset terminal is used to send payment request to the payer handset terminal through WIFI signals; the payer handset terminal is used to receive the payment request and send payment instruction to the banking mobile payment server according to the payment request; the banking mobile payment server receives the payment request and deals with the related account information, and then sends the operating results to the payee handset terminal and the payer handset terminal. The invention is applied to the settlement between consumers and merchants and is also suitable for payment transfer between two individuals.

Owner:BEIJING AIO TIME INFORMATION TECH

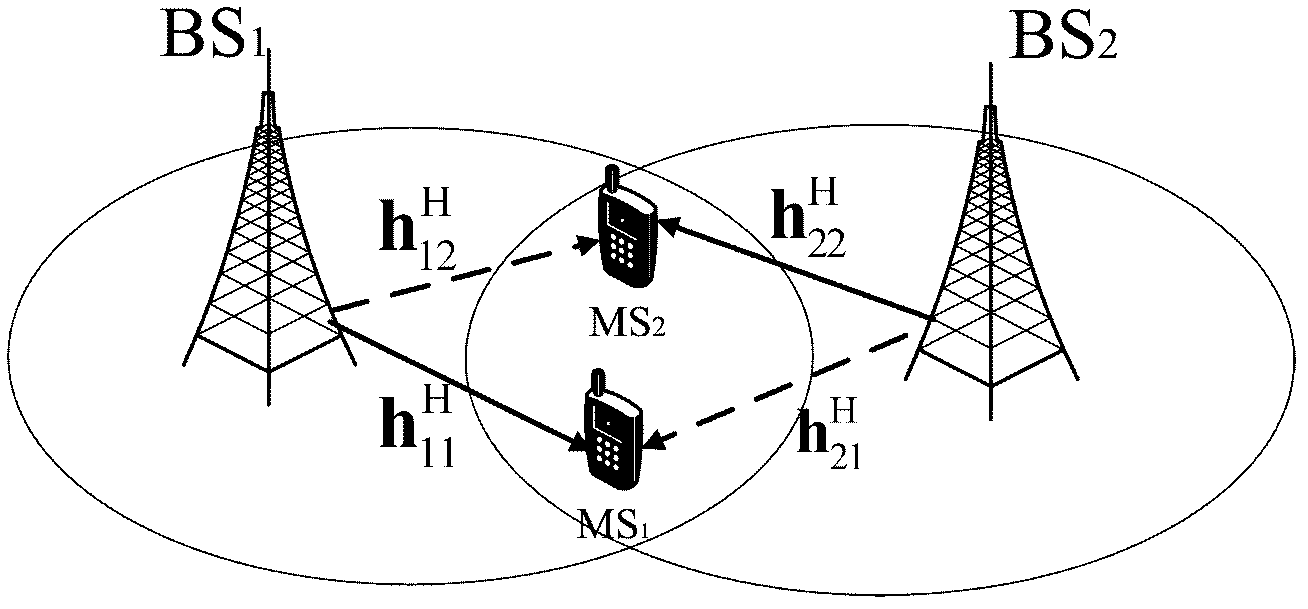

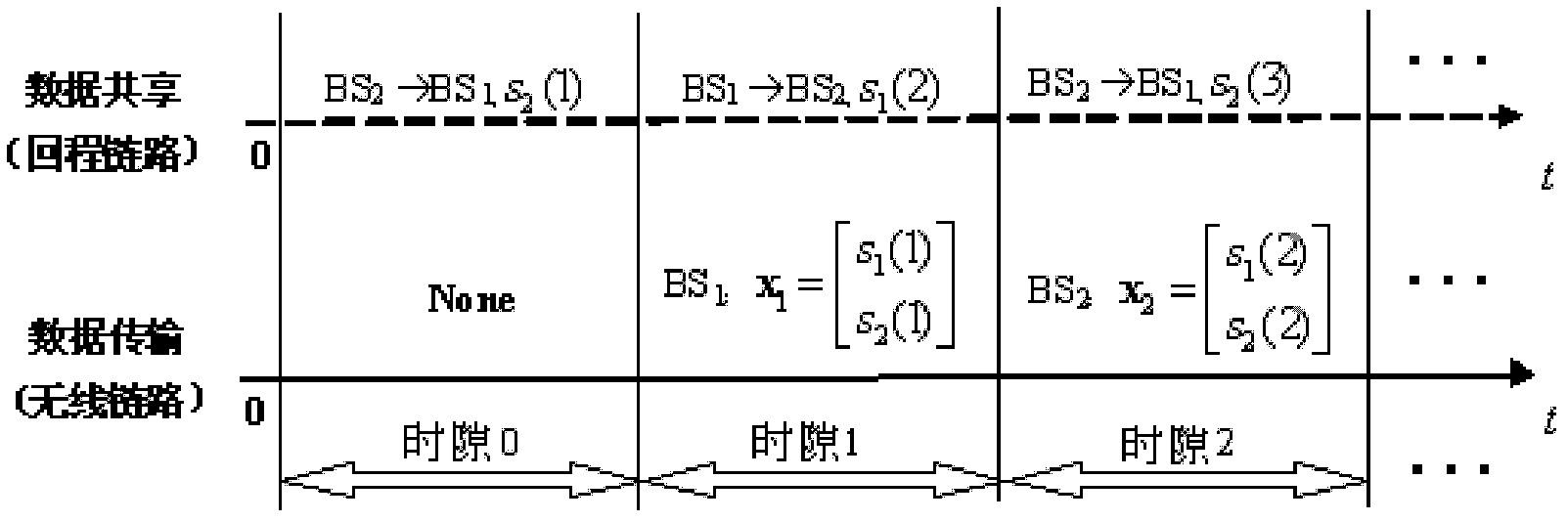

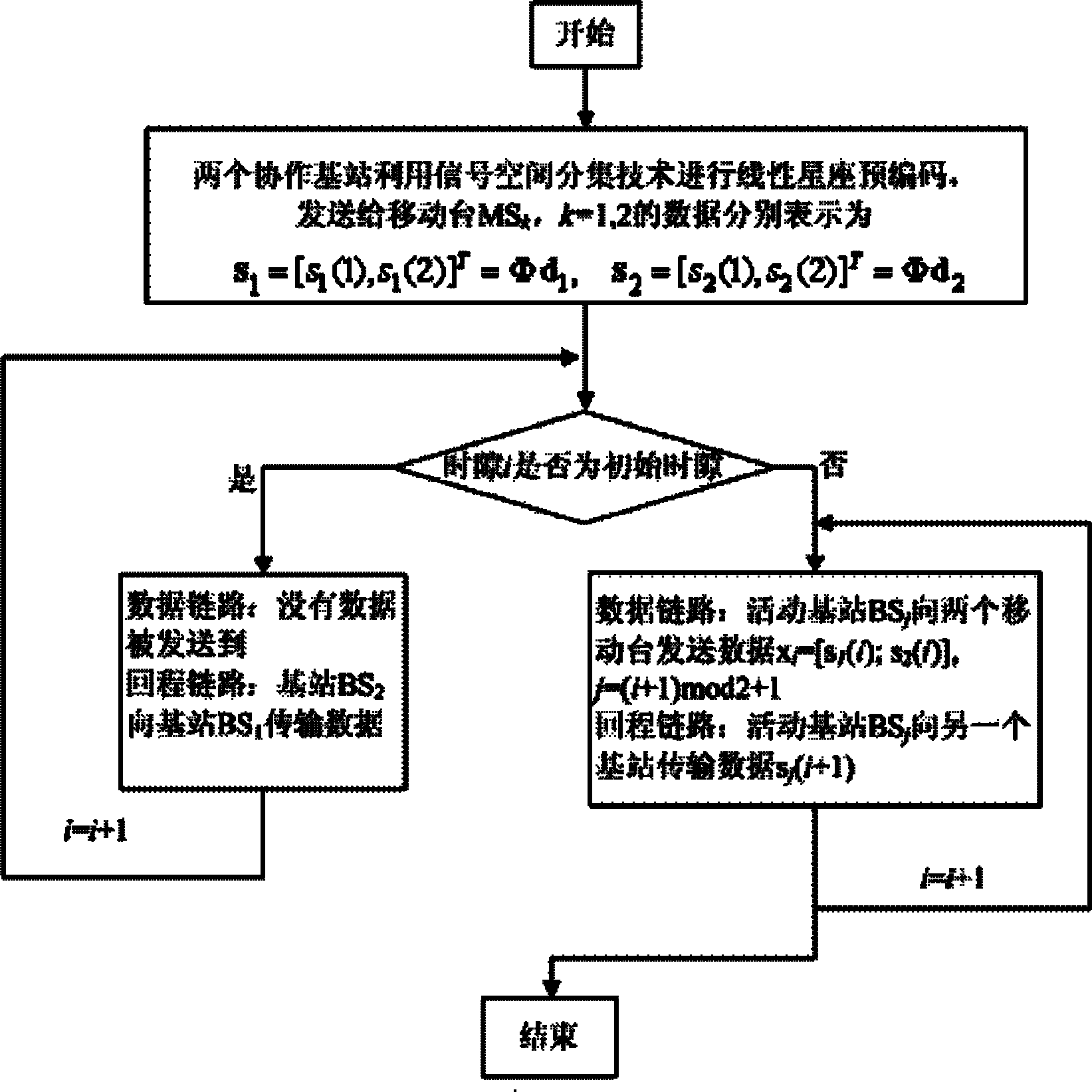

Scheduling transmission method for collaborative cells against cell edge users of downlink

InactiveCN102195700AReduce the probability of errorReduce error rateSpatial transmit diversitySignal-to-noise ratio (imaging)Data transmission

The invention discloses a scheduling transmission method for collaborative cells against cell edge users of a downlink. Under the transmission method provided by the invention, adjacent two base stations can collaboratively schedule the respective transmission based on an alternating data sharing protocol in which a signal space diversity technology is embedded, thereby enabling each base station to alternately perform data transmission and keep silence. Based on the realizable packet alternating data sharing way provided by the invention, inter-cell space diversity can be exploited and utilized in the form of the signal space diversity under the situation of local channel state information (CSI), thereby reducing the error probability of each data stream and further enabling an inter-cell link to turn from being harmful to being beneficial. By adopting the inter-cell collaborative scheduling scheme provided by the invention, the BER (bit error rate) performance of the two collaborative cells on the data downlink within a signal to noise ratio interval of actual work can be greatly upgraded.

Owner:XI AN JIAOTONG UNIV

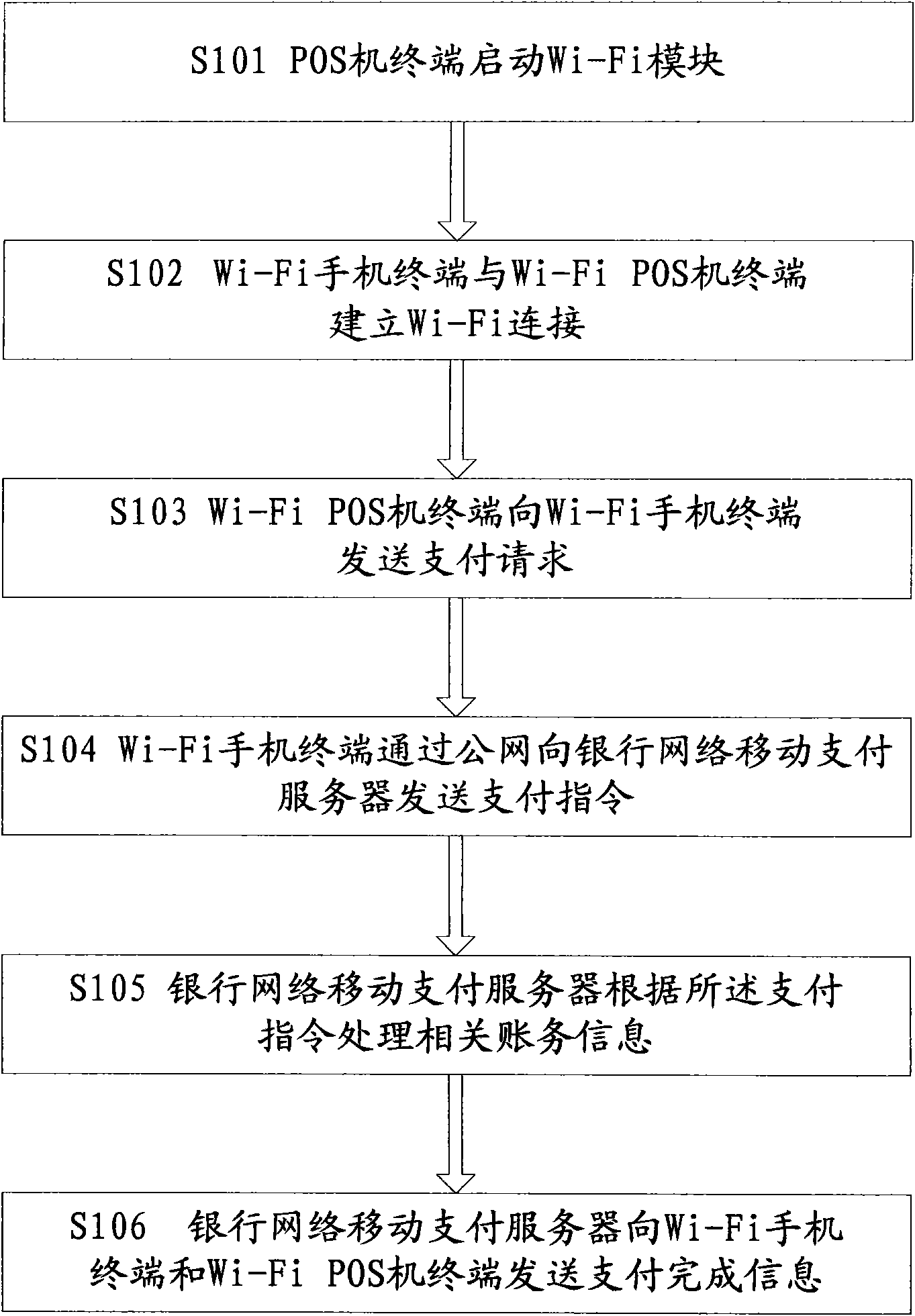

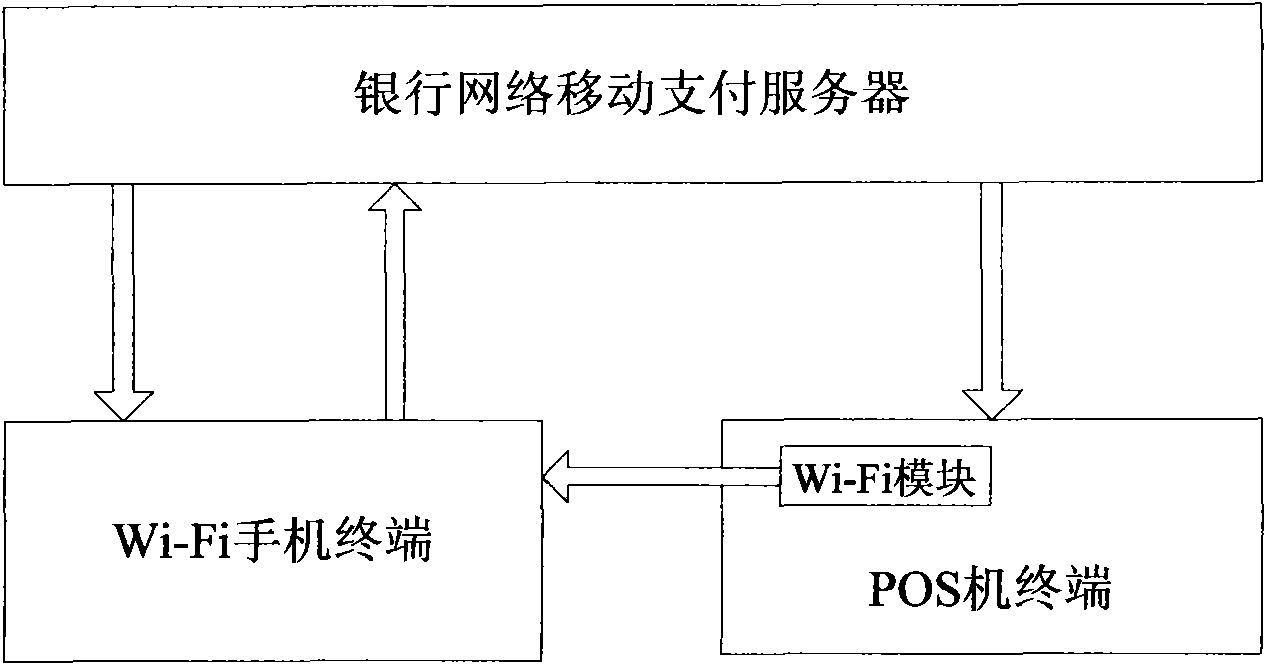

Method and system for payment of Wi-Fi mobile phone-POS machine

InactiveCN101567107AInput less informationReduce the probability of errorComplete banking machinesAccounting/billing servicesWi-FiMobile payment

The invention discloses a method and a system for payment of a Wi-Fi mobile phone-POS machine, which are designed to solve the problems of complicated operation and easy mistakes in the prior mobile phone payment mode. The system comprises a Wi-Fi mobile phone terminal, a Wi-Fi POS machine terminal and a bank network mobile payment server; the Wi-Fi POS machine terminal is used for sending a payment request to the Wi-Fi mobile phone terminal through Wi-Fi signals; the Wi-Fi mobile phone terminal is used for receiving the payment request and sending a payment instruction to the bank network mobile payment server according to the payment request; and the bank network mobile payment server receives the payment instruction, processes related financial information and sends an operation result to the Wi-Fi POS machine terminal and the Wi-Fi mobile phone terminal. The method and the system are suitable for consumption settlement between consumers and trade companies.

Owner:BEIJING AIO TIME INFORMATION TECH

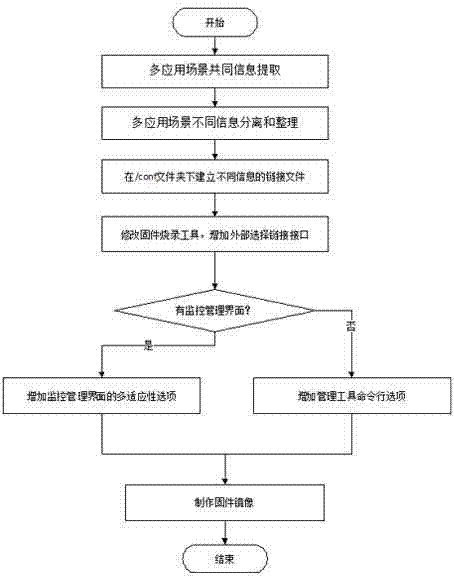

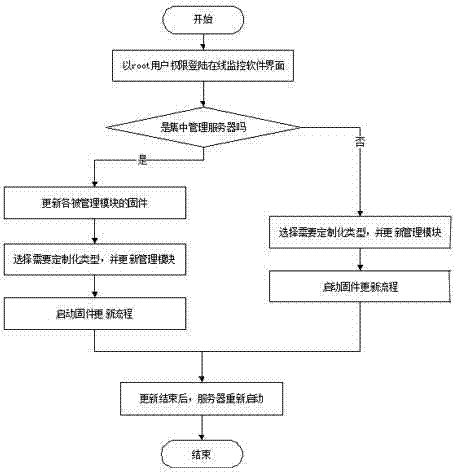

Manufacturing and implement method for multi-adaptive firmware of server

ActiveCN103490929AReduce the probability of errorImprove work efficiencyProgram loading/initiatingData switching networksMultiple applicationsInformation extraction

The invention provides a manufacturing and implement method for multi-adaptive firmware of a server. By means of the manufacturing and implement method, a multi-adaptive firmware mirror image for a monitoring and management system of the server can be manufactured. The manufacturing and implement comprises the specific steps that in the same firmware mirror image, the manufacturing and implement of the multi-adaptive firmware mirror can be achieved through the methods such as common information extraction of multiple application scenes, different information separation of the multiple application scenes, a selective information link algorithm, a revisable system starting loading selection mechanism, a firmware mirror image generation tool, and a firmware update connector command and interface. Meanwhile, the manufacturing and implement method is also suitable for occasions with large-scale server cluster management.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

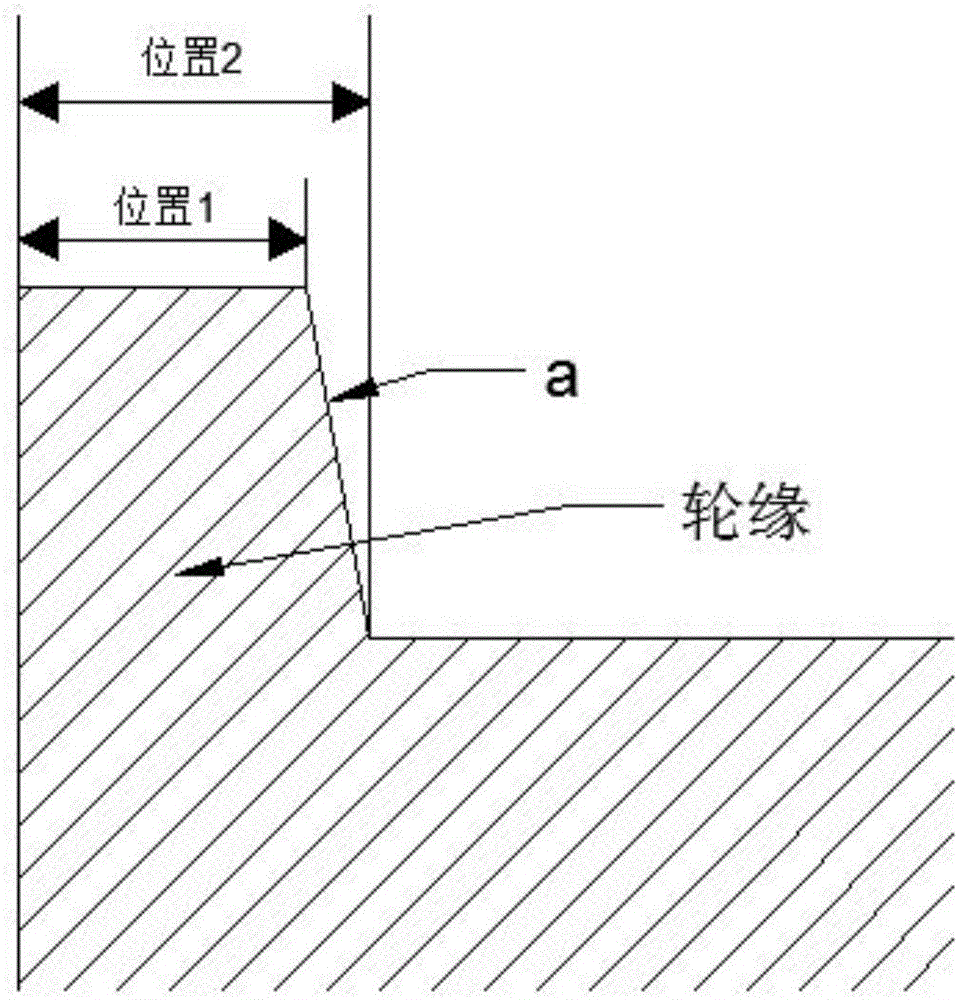

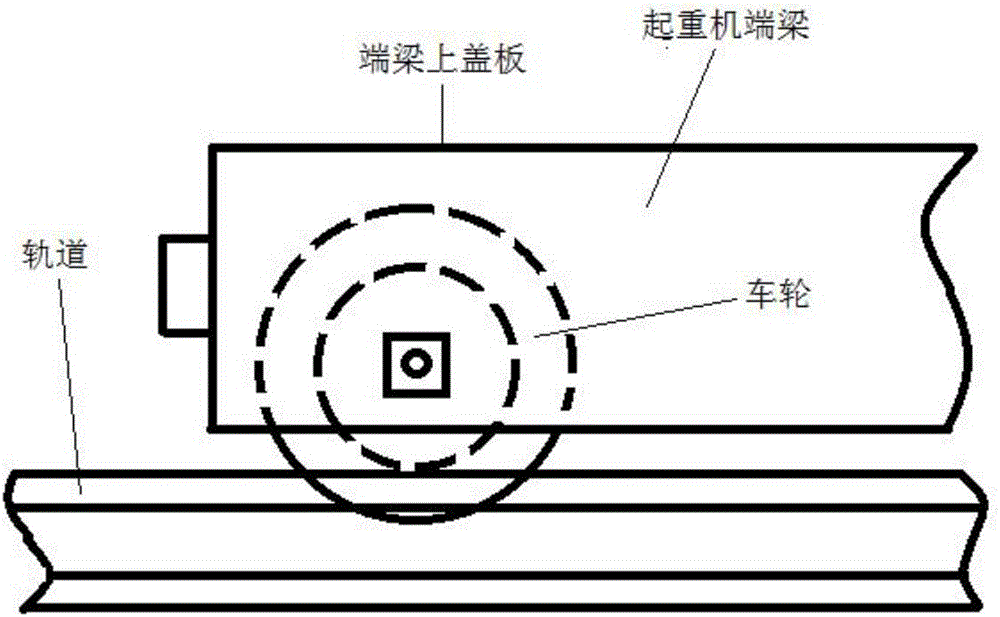

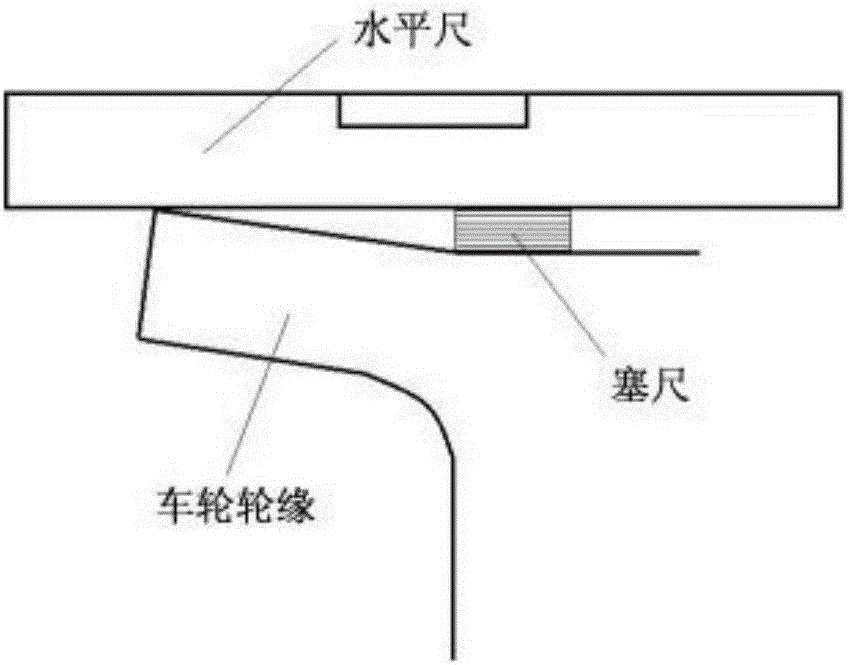

Crane part multidimensional comprehensive measuring tool

InactiveCN106403754AWide range of usesEasy to carryMechanical measuring arrangementsMultiple dimensionEngineering

The invention relates to a crane part multidimensional comprehensive measuring tool to achieve the goal that the provided measuring tool can accurately measure parameters such as vehicle wheel rim thickness, rim thickness bending deformation, tread diameter, tread roughness, vertical skew, excessive arc angle and is simple in structure, convenient for operation, and accurate in result, so that the safety of cranes is improved, accidents are reduced, and life and property safety are guaranteed. According to the technical scheme, the measuring tool comprises a ruler body, a main cursor in slide fit with the ruler body through a transverse slot, and a fixed measurement jaw arranged on an end of the ruler body. Transverse scales are arranged on the ruler body and the transverse slot. The measuring tool is characterized in that a vertical slot perpendicular to the transverse slot is produced in the main cursor; a main cursor measurement jaw for measuring part width is in slide fit with the vertical slot and is arranged in the vertical slot; and vertical scales are arranged on both the main cursor measurement jaw and the vertical slot.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST

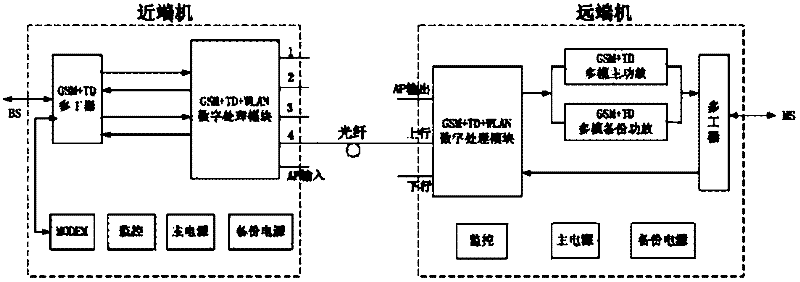

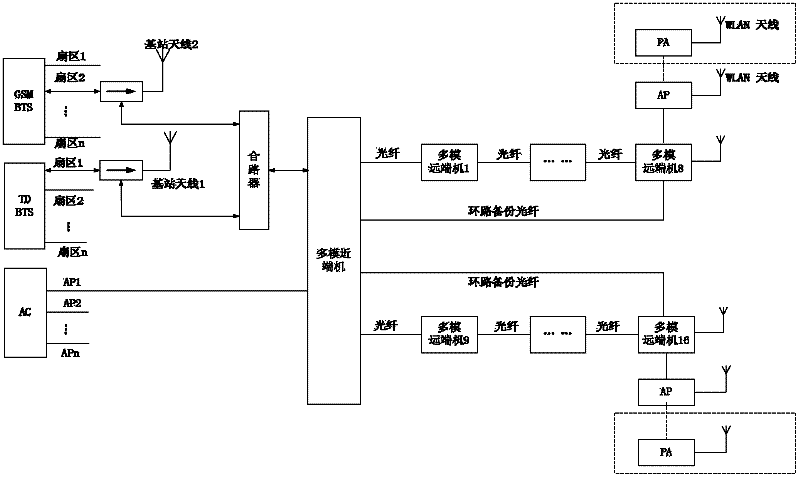

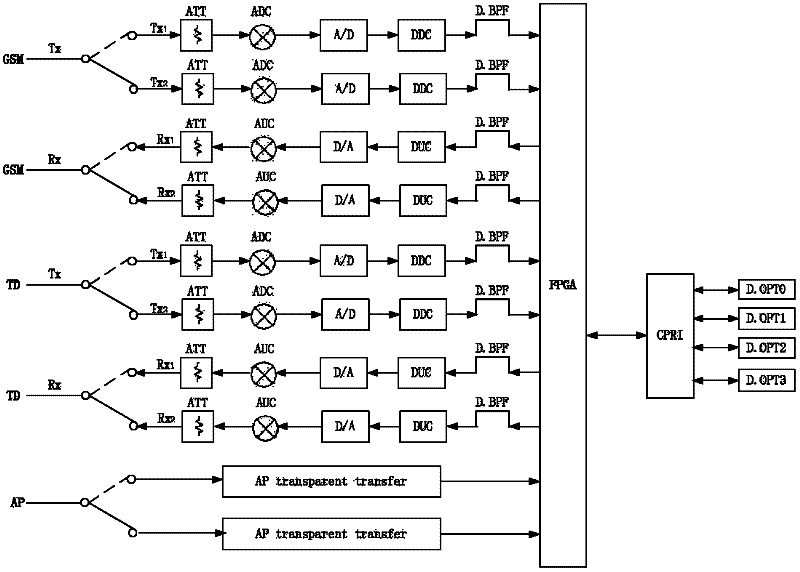

Three-mode digital optical fiber remote system

InactiveCN102333389AReduce the probability of errorImprove system reliabilityElectromagnetic repeatersWireless communicationVIT signalsDigital signal processing

The invention discloses a three-mode digital optical fiber remote system, which can process and transmit digital signals in global system for mobile communication (GSM) / distributed control system (DCS), time division-synchronous code division multiple access (TD-SCDMA) and wireless local area network (WLAN) modes. The system comprises a near-end machine and a far-end machine. The near-end machine comprises a near-end multiplexer, a GSM / DCS, TD-SCDMA and WLAN digital processing module comprising smart backup, an access point (AP) input module, a dual-power module and a monitoring module. The far-end machine comprises an AP output module, a GSM / DCS, TD-SCDMAD and WLAN digital processing module, a dual-GSM / DCS and TD multimode power amplifier, a multiplexer, a dual-power module and a monitoring module. The coverage of a plurality of modes of networks of a GSM / DCS, TD-SCDMA and WLAN wireless rapid access system can be realized in the same site by digital signal filters, digital signal processing modules and a digital signal processing algorithm.

Owner:XINMIN COMM EQUIP SHANGHAI

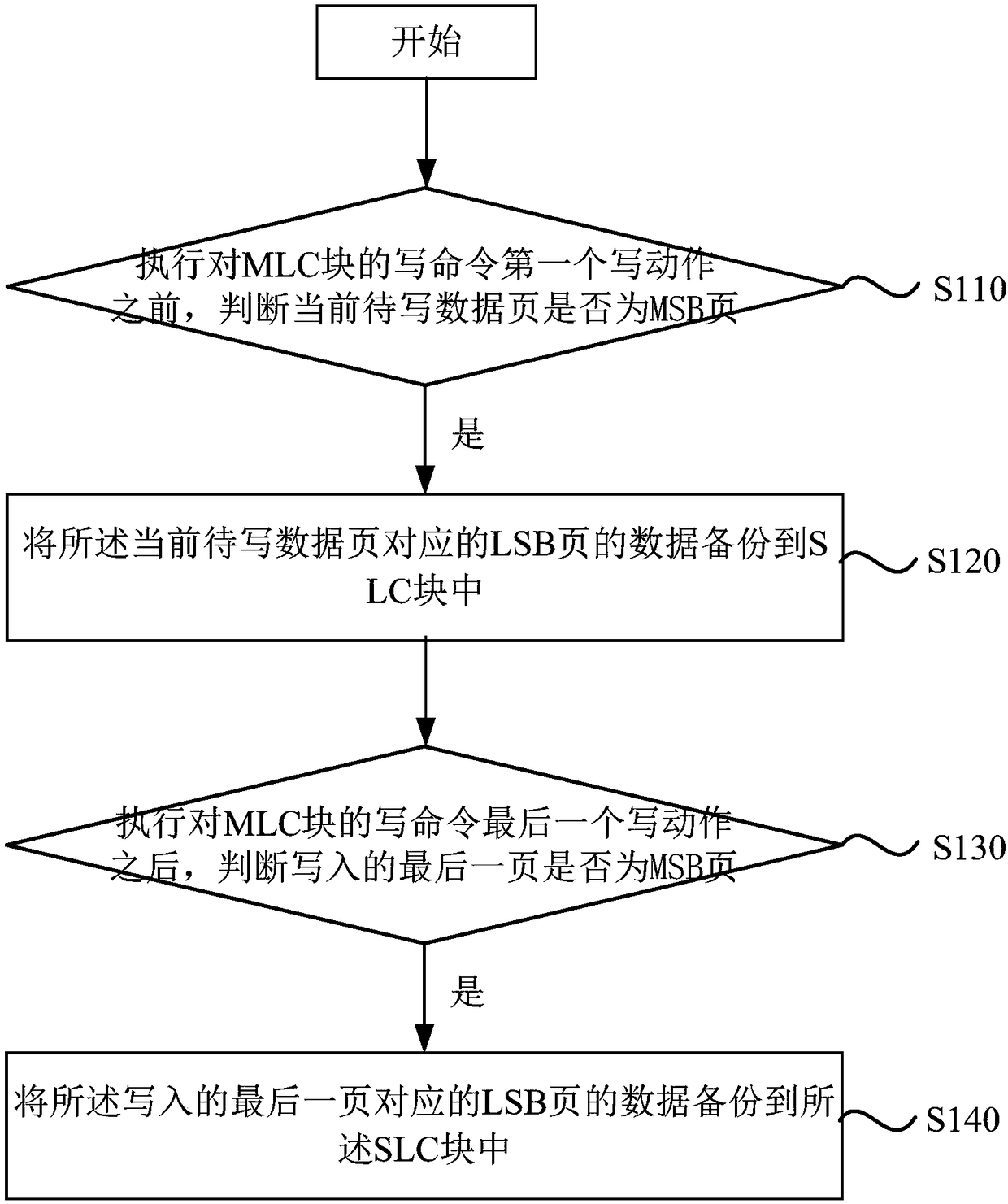

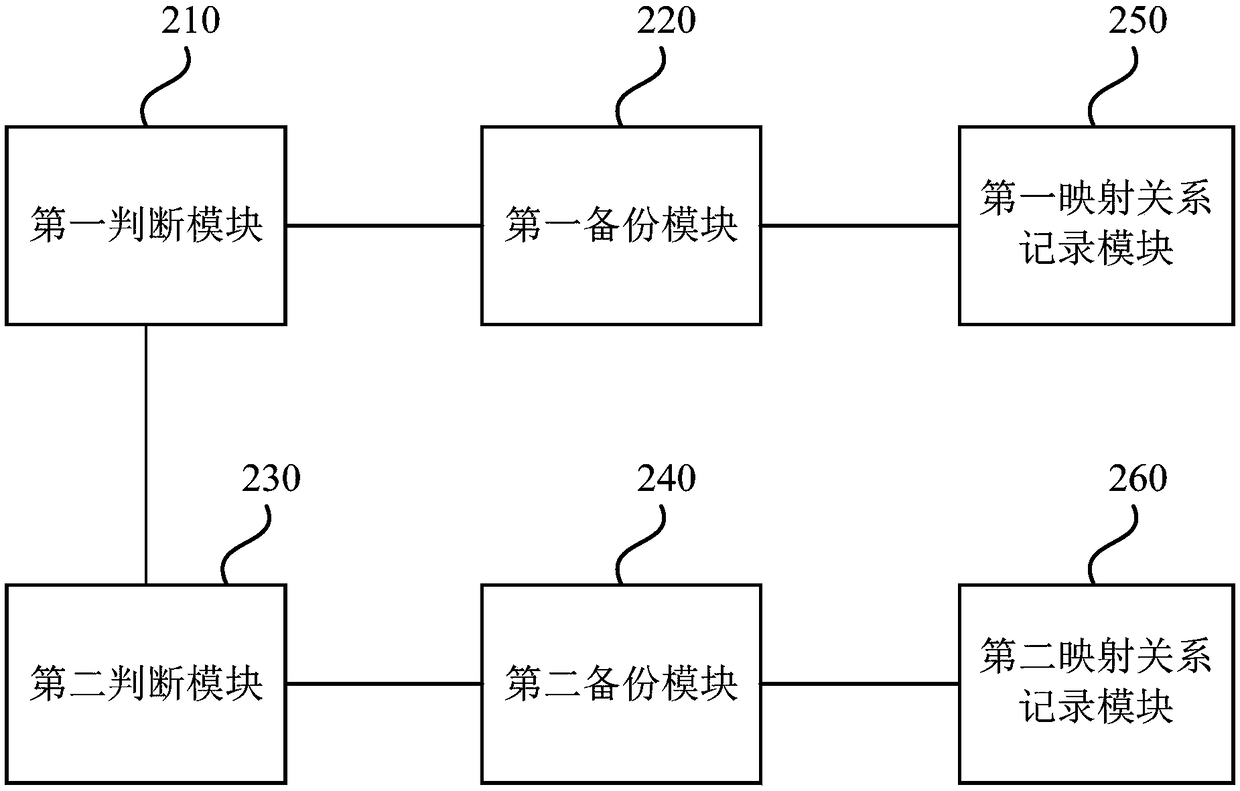

Method and device for power down protection based on NAND flash

ActiveCN108614744AReduce the probability of errorSolve the problem of reading errorsRedundant operation error correctionData pageOperating system

Embodiments of the invention disclose a method for power down protection based on NAND flash. The NAND flash comprises a MLC block and a SLC block. A data page of the MLC block comprises a MSB page and a LSB page corresponding to the MSB page. The method comprises: before executing first writing operation of a writing command on the MLC block, determining whether a current to-be-written data pageis the MSB page; when the current to-be-written data page is the MSB page is determined, backing up the LSB page corresponding to the current to-be-written data page in the SLC block; after executinglast writing operation of the writing command on the MLC block, determining whether the written-in last page is the MSB page; when the written-in last page is determined to be the MSB page, backing updata of the LSB page corresponding to the written-in last page in the SLC block. The method solves a problem of LSB page read errors caused by power down of the MSB page, realizes to ensure LSB datanot to be damaged, and reduces error probability in a data storage process.

Owner:GIGADEVICE SEMICON (BEIJING) INC

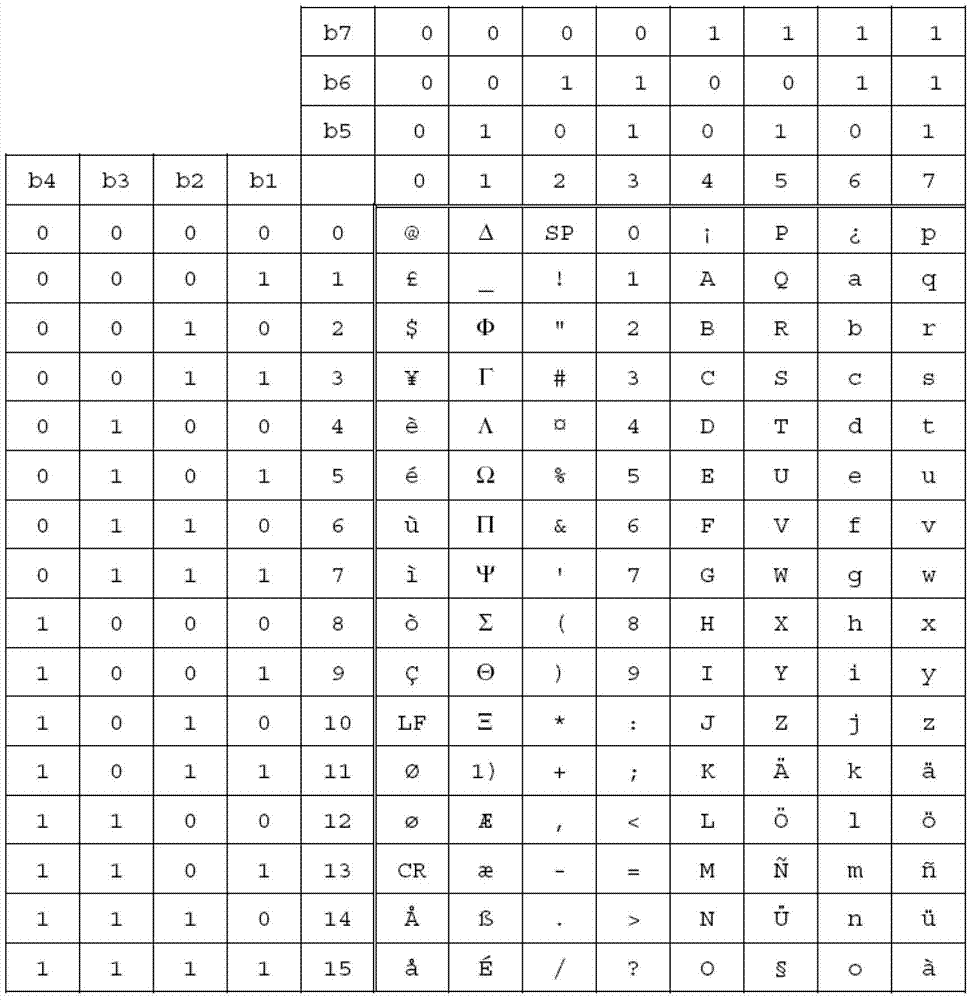

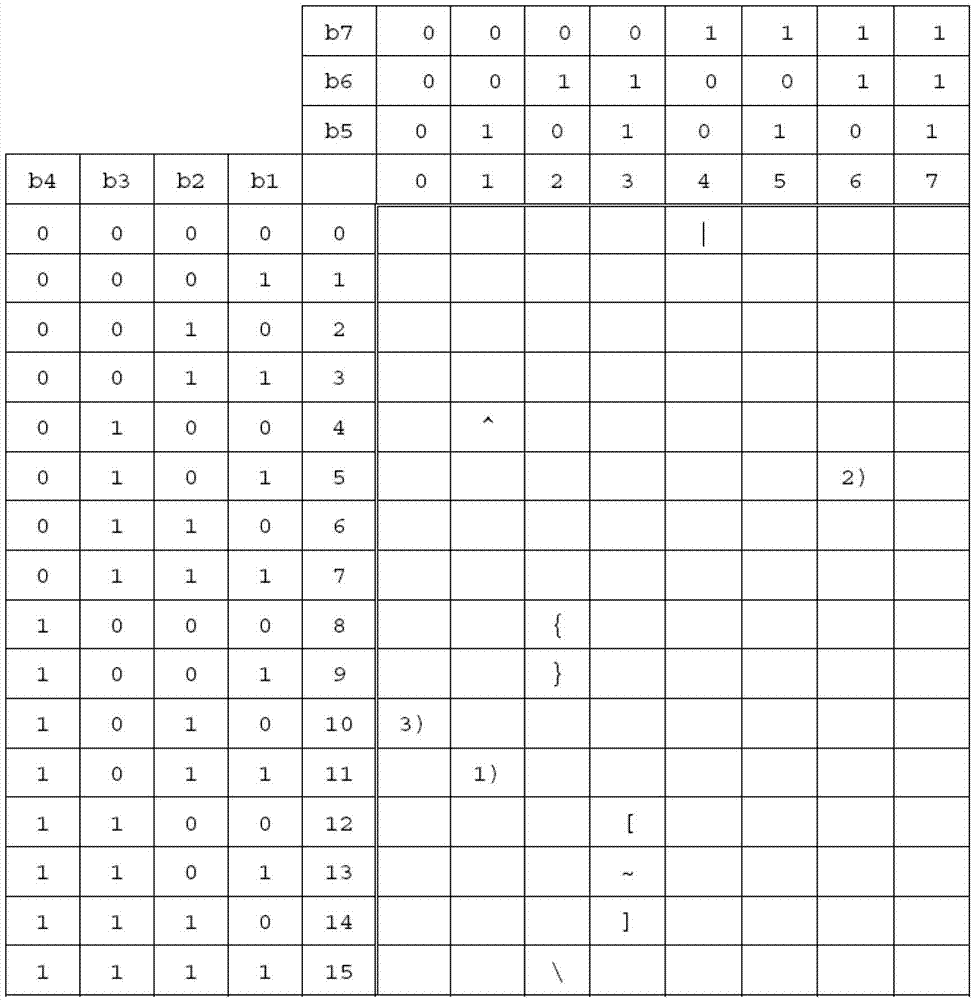

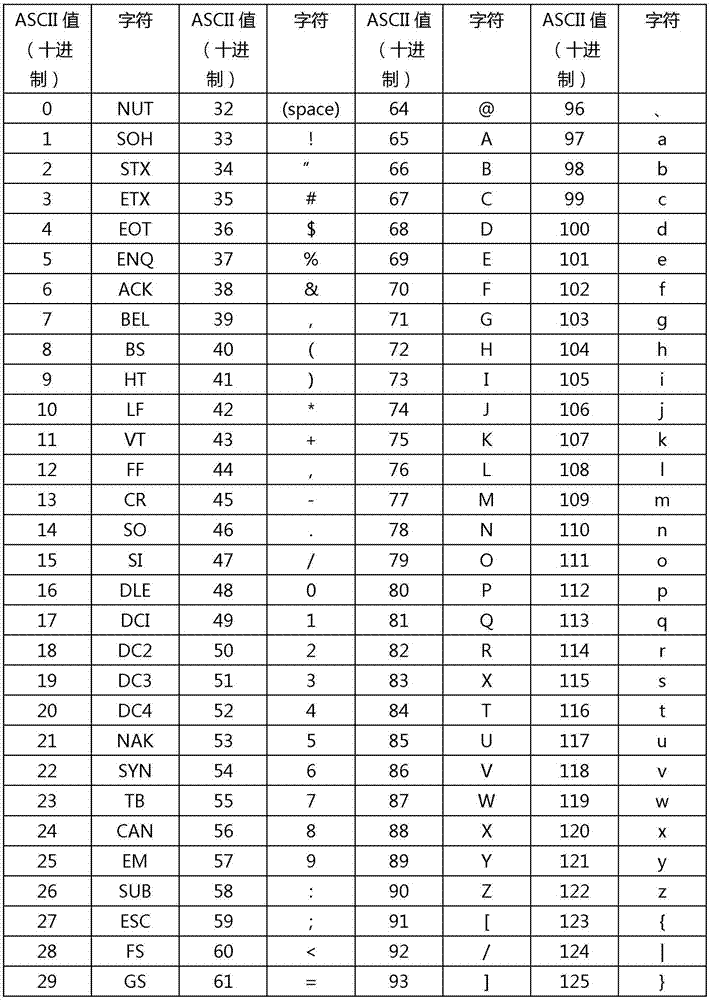

Method and device for code conversion of short messages

InactiveCN102970661AReduce the probability of errorAchieve conversionInformation formatContent conversionData conversionCode table

The invention discloses a method and a device for the code conversion of short messages. The method comprises: a code conversion driving table is stored in a short message center, and the corresponding relation of the code values of characters in an American standard code for information interchange (ASCII) code table and the code values of the same characters in a global system for mobile communications (GSM) code table is recorded in the code conversion driving table; and after the short message center receives the short message, when a sender and a receiver adopt different short message encoding types, the code value of the received short message is found out from the code conversion driving table according to the short message encoding type which is adopted by the sender, so that the code value, which corresponds to the code value of the short message, of the short message encoding type which is adopted by the receiver is obtained. The code conversion driving table is added in the short message center, custom code table conversion can be realized through the code conversion driving table no matter which country regions the short message center is used, and a new code table conversion function does not need to be temporarily developed.

Owner:ZTE CORP

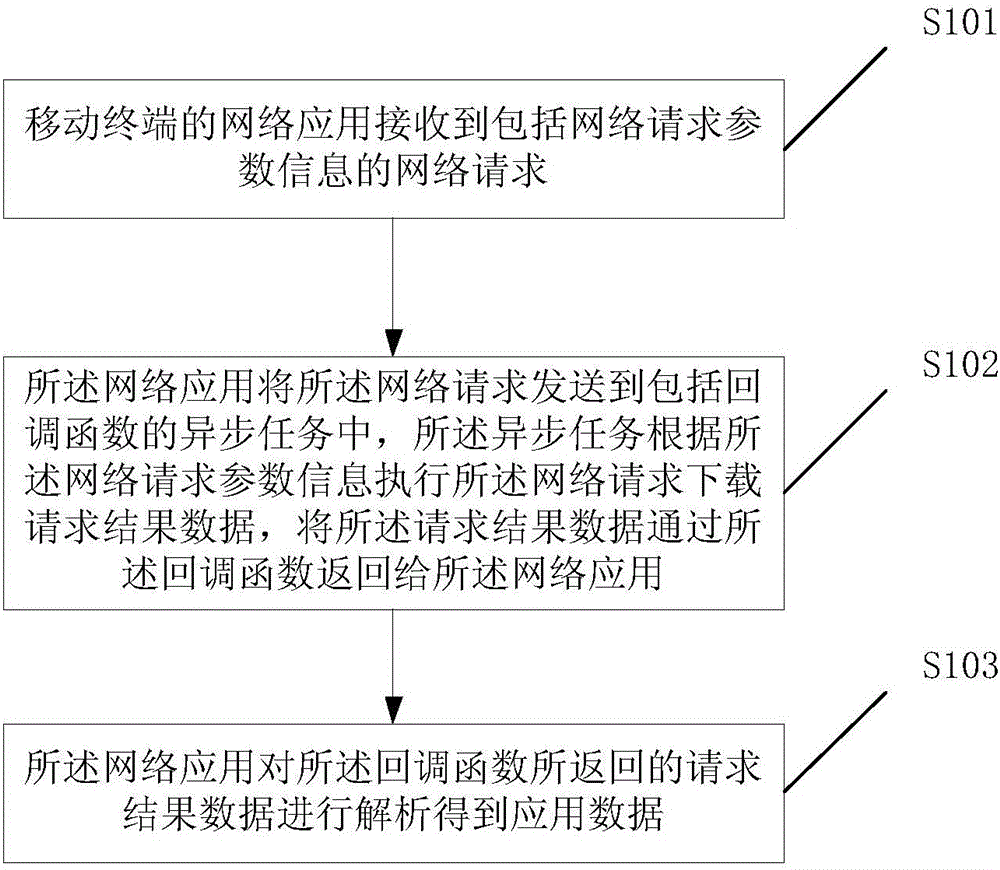

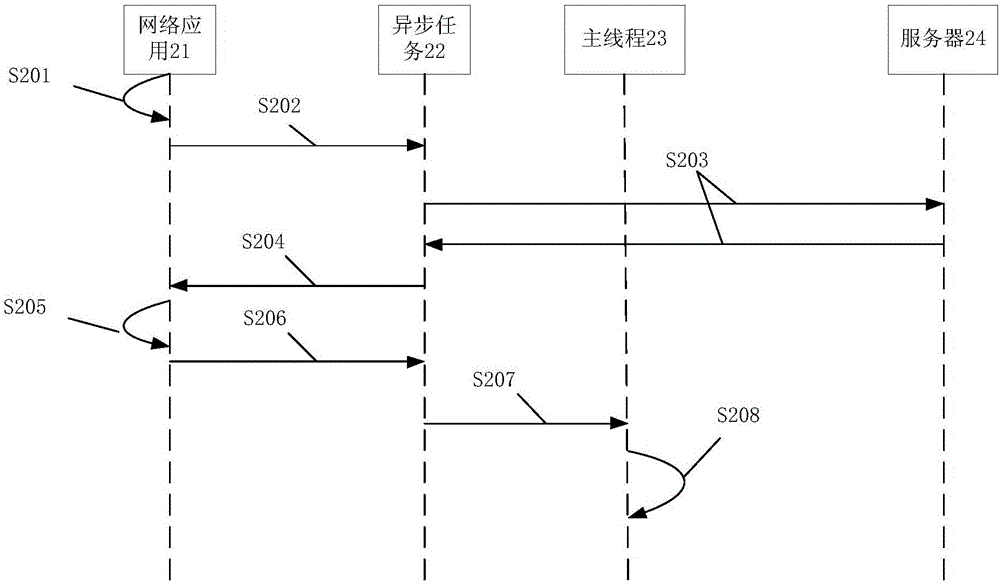

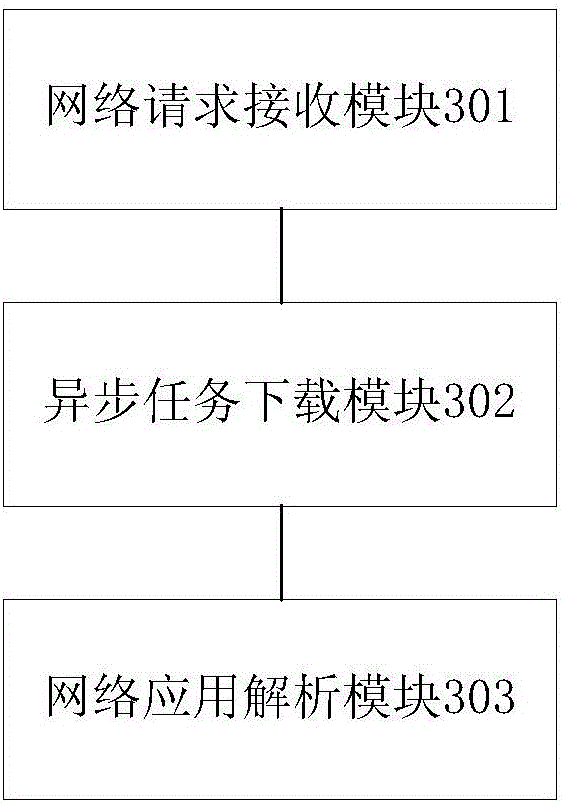

Mobile terminal network request method and system

InactiveCN105847319AReduce confusionReduce the probability of errorTransmissionNetwork Access DeviceDistributed computing

The invention discloses a mobile terminal network request method and system. The method comprises that network applications of a mobile terminal receives network requests comprising network request parameter information; the network applications sends the network requests to an asynchronous task comprising a callback function, wherein according to the asynchronous task, the network requests are executed and request result data is downloaded according to the network request parameter information, and the request result data is returned to the network applications by the callback function; the network applications analyze the request result data returned by the callback function, thus obtaining application data. According to the method and the system, the network requests sent by the network applications are received by the asynchronous task; according to the asynchronous task, network access is carried out uniformly; the network access is independent; multiple network applications are avoided from executing the network requests by themselves; the network requests of the mobile terminal can be managed uniformly; disorder is reduced; and the error probability is reduced.

Owner:LEMOBILE INFORMATION TECH BEIJING

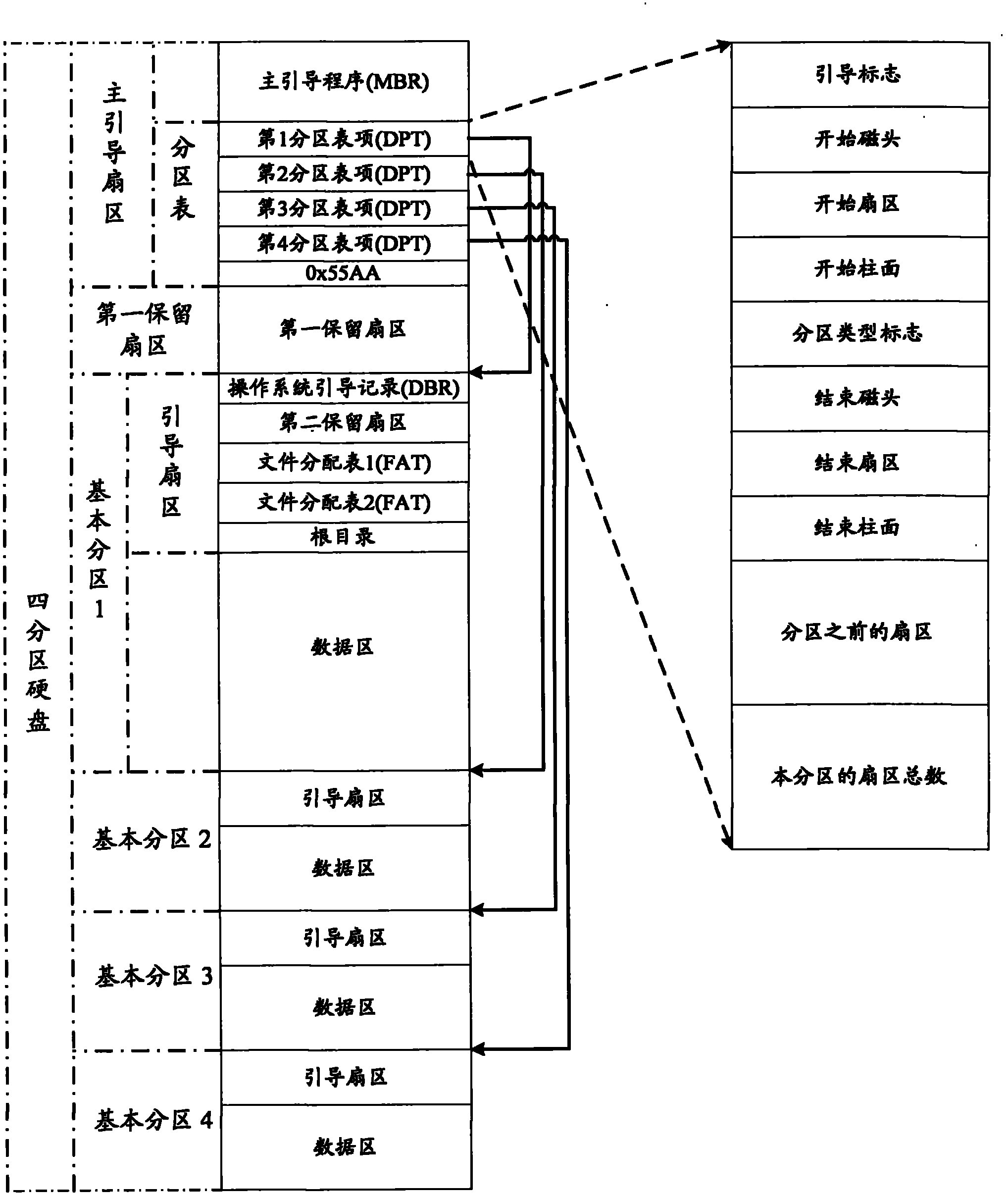

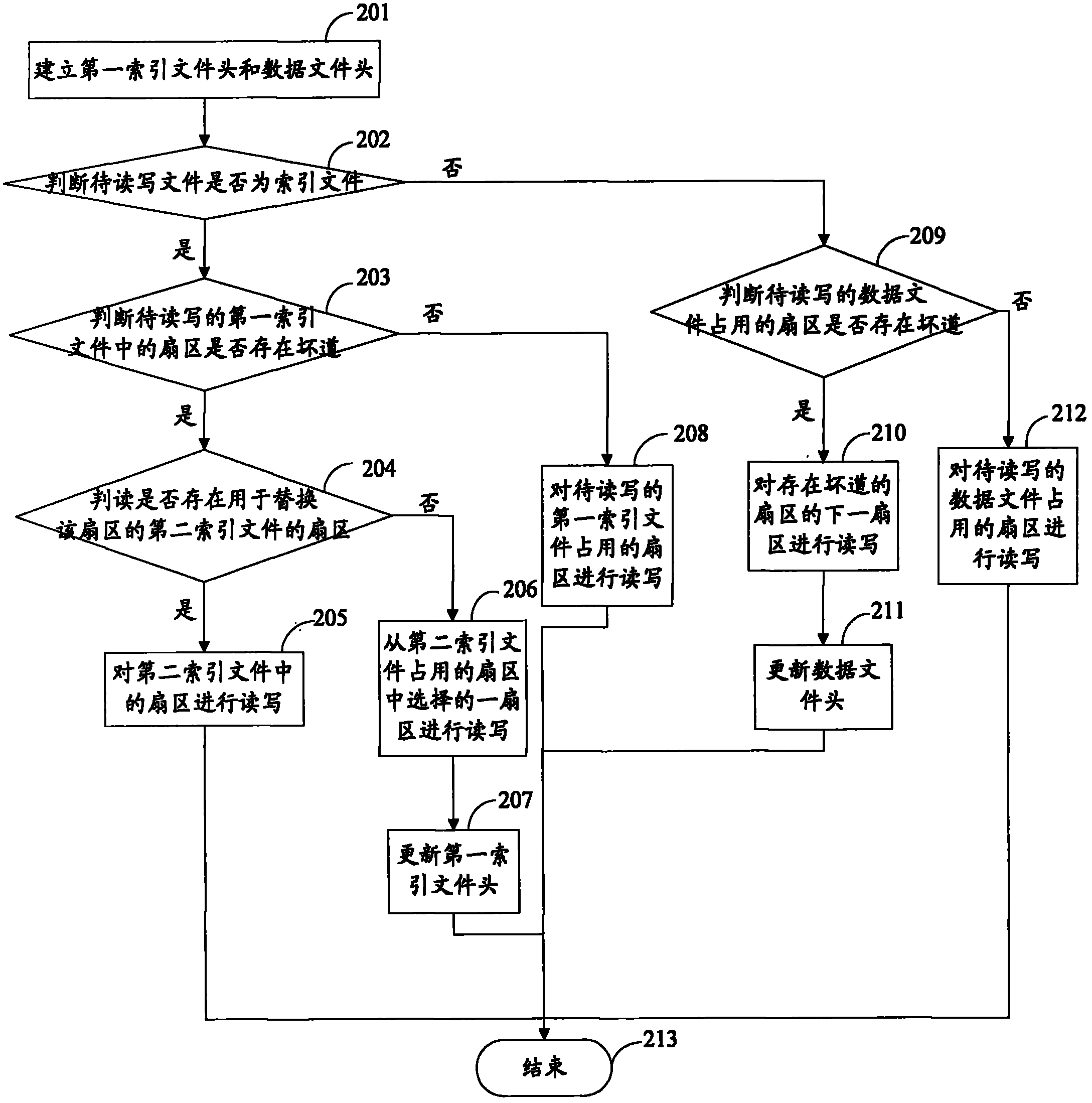

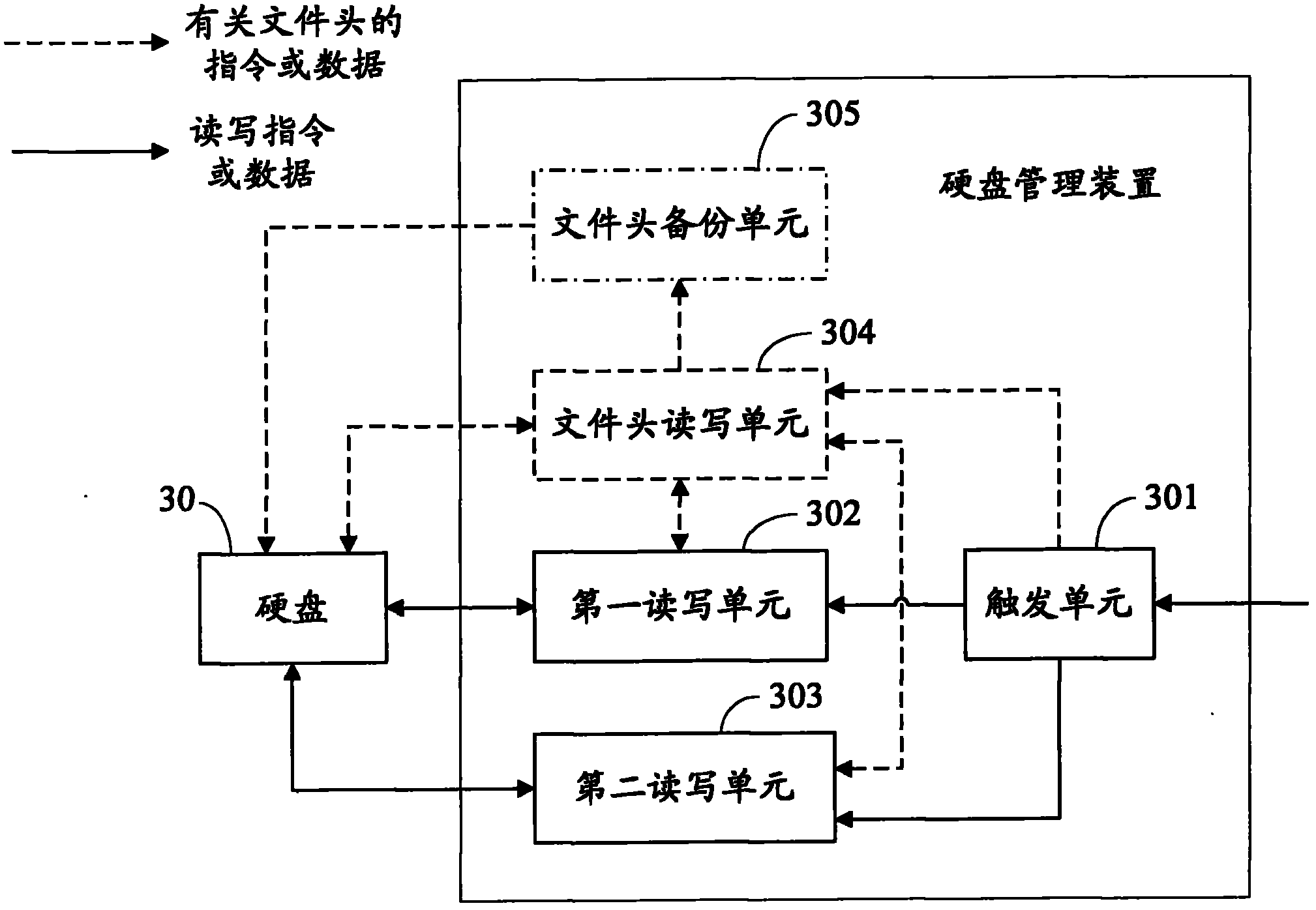

Hard disk management method and device

ActiveCN102063273AReduce the probability of errorRead and write normalInput/output to record carriersIndexed fileBackup

The invention provides a hard disk management method which is used for managing hard disk data fields and comprises the steps of: A, judging the type of a file to be read-written according to the attribute of the file to be read-written, determining the file as a first index file, executing the step B, determining the first index file as a data file and executing the step C, wherein the first index file is an index file used by a user; B, after the presence of a bad track in the sector of the first index file to be read-written is determined, selecting the alternative sector from a second index file to read and write, wherein the second index file is a vacant index file for backup; and C, after the presence of the bad track in the sector of the data file to be read-written is determined, performing read-write operation on the next section of the sector having the bad track. The invention further provides a hard disk management device. By adopting the method and the device provided by the invention, normal read-write can be performed on a hard disk under the situation that the hard disk has the bad track and is not formatted.

Owner:HANGZHOU HIKVISION DIGITAL TECH

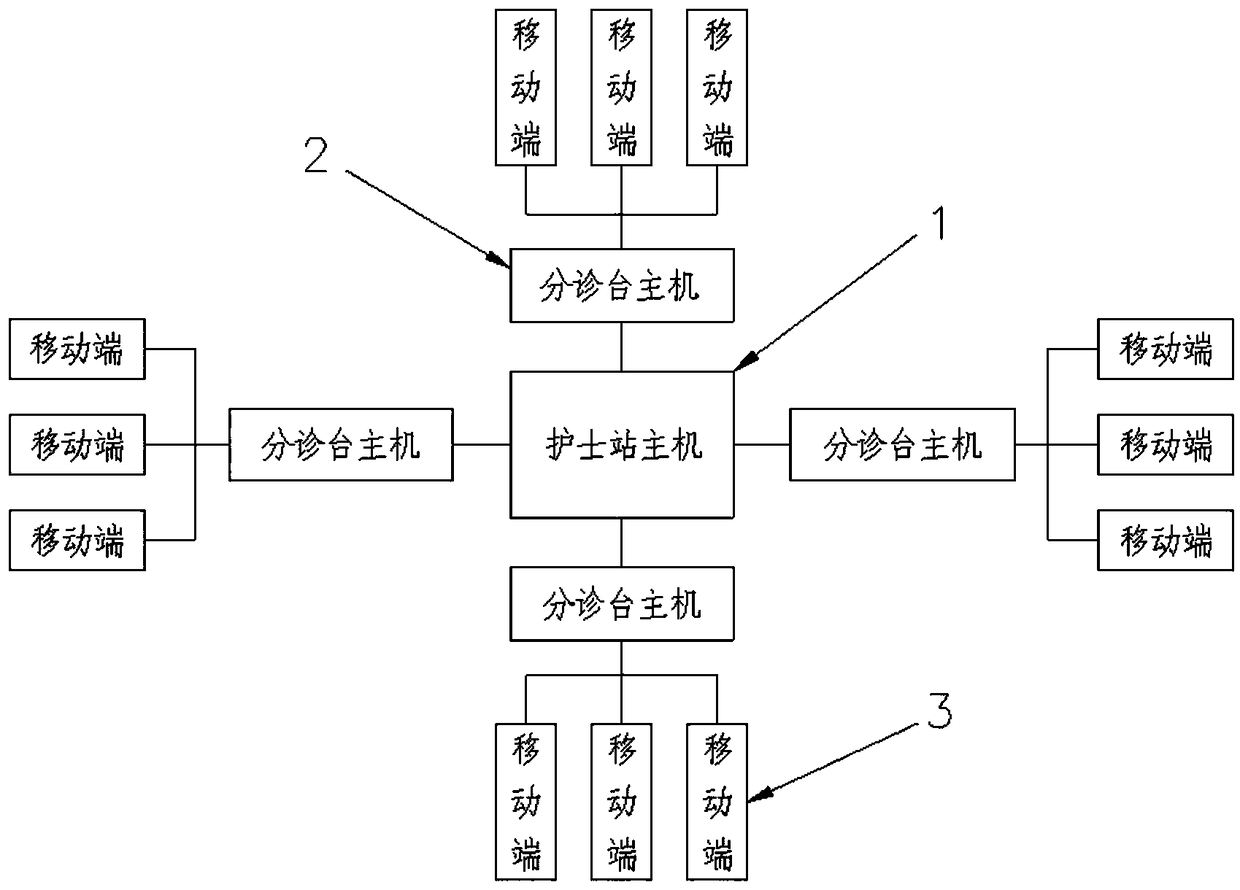

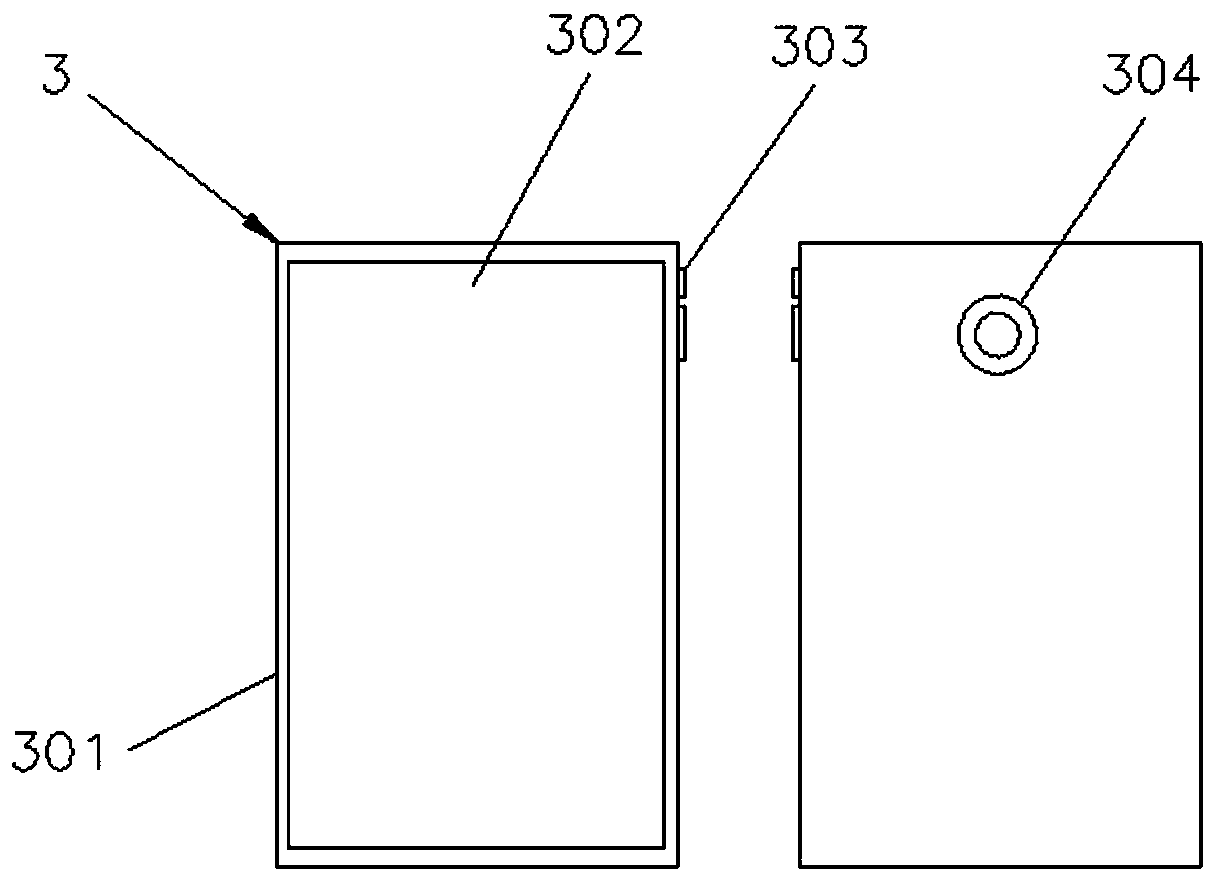

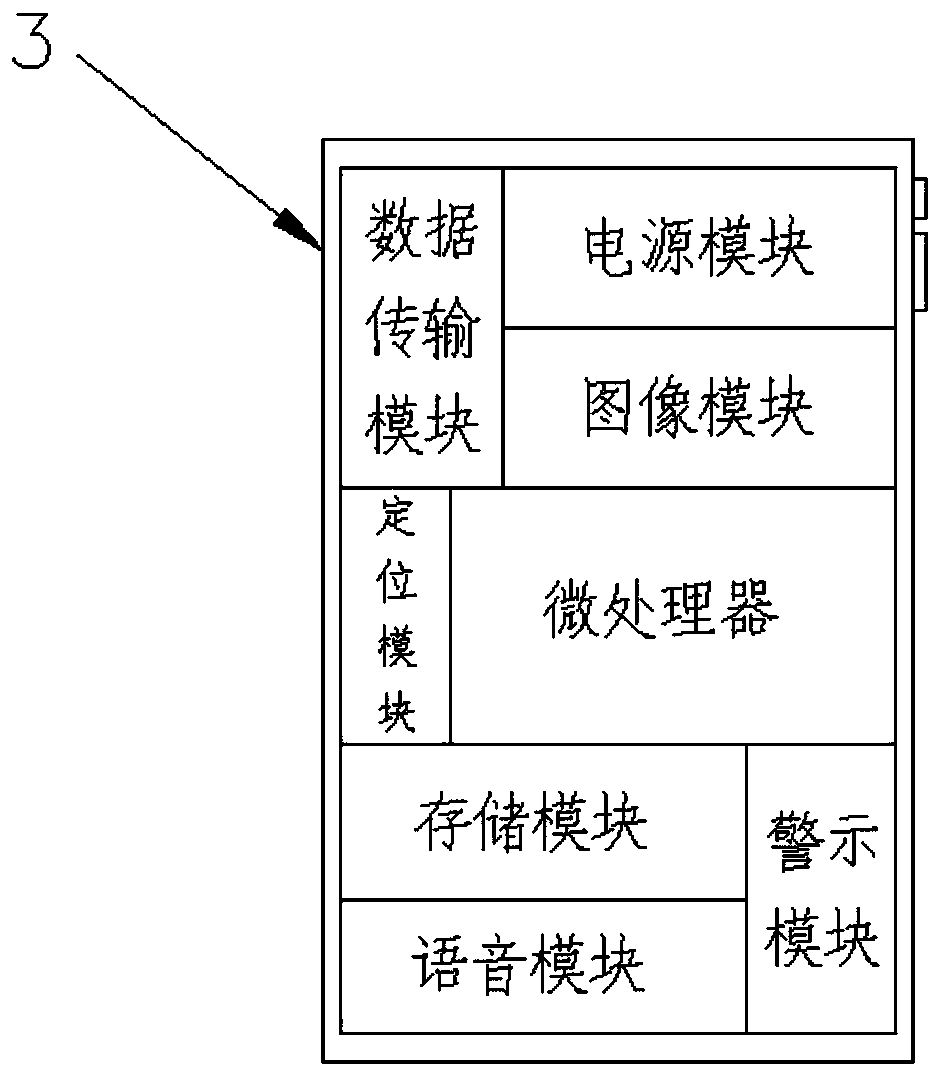

Emergency treatment shift system for improving quality and management level of emergency care

InactiveCN109411070AImprove quality of careImprove recording qualityHealthcare resources and facilitiesMedical recordTriage

The invention discloses an emergency treatment shift system for improving the quality and the management level of emergency care, and relates to the technical field of hospital quality management. Theemergency treatment shift system for improving the quality and the management level of emergency care includes a nurse station host, triage stage hosts and mobile terminals, wherein the nurse stationhost is connected to each of the triage stage hosts; each triage stage host is connected with a plurality of mobile terminals; the control unit of the nurse station host and the triage stage hosts isconnected to a display screen and a loudspeaker, and can share data with the mobile terminals. A case is input into the mobile terminal and the mobile terminal establishes a file and transmits the file to the nurse station host and the triage stage hosts. The system can easily achieve communication and management in an emergency ward care shifting process, facilitates quality control inspection,improves the quality of information records of nursing records, reduces the incidence of mistakes in shifts, improves the care quality and management level of emergency shift, and is suitable for emergency wards and other wards in medical institutions.

Owner:王瑞

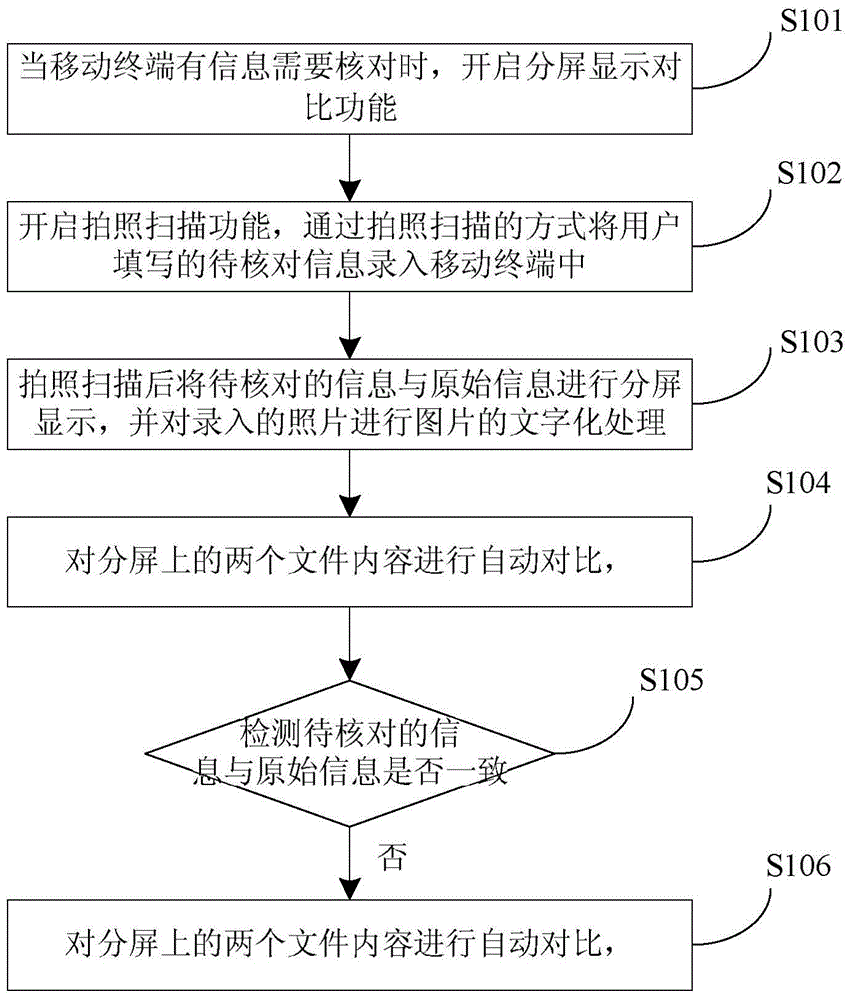

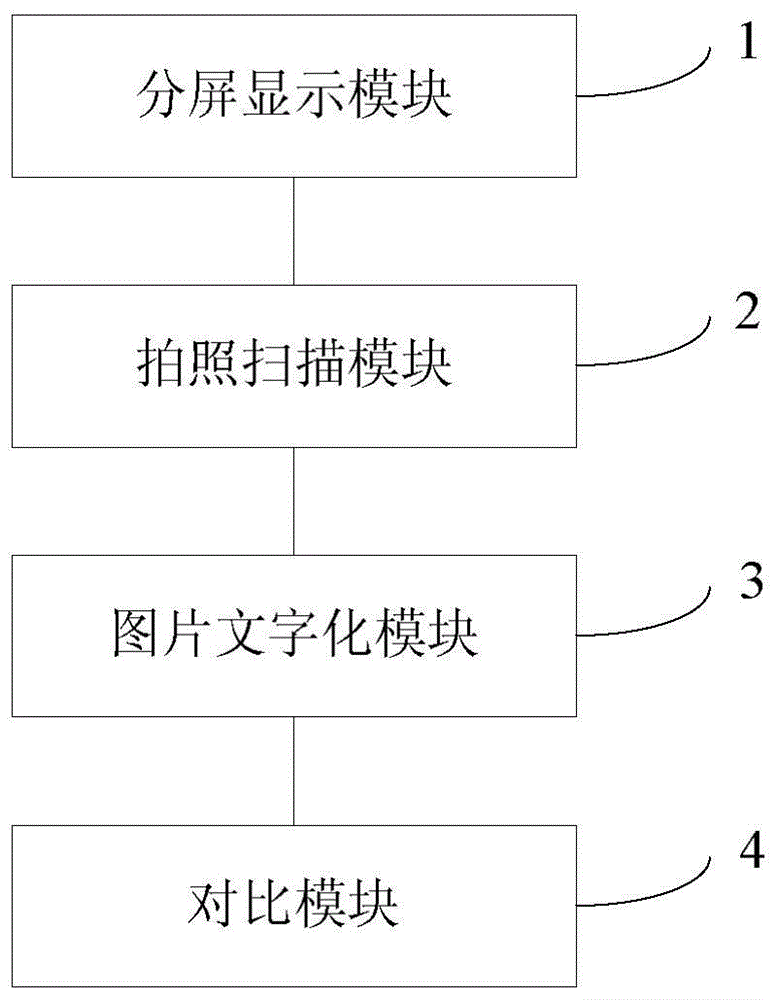

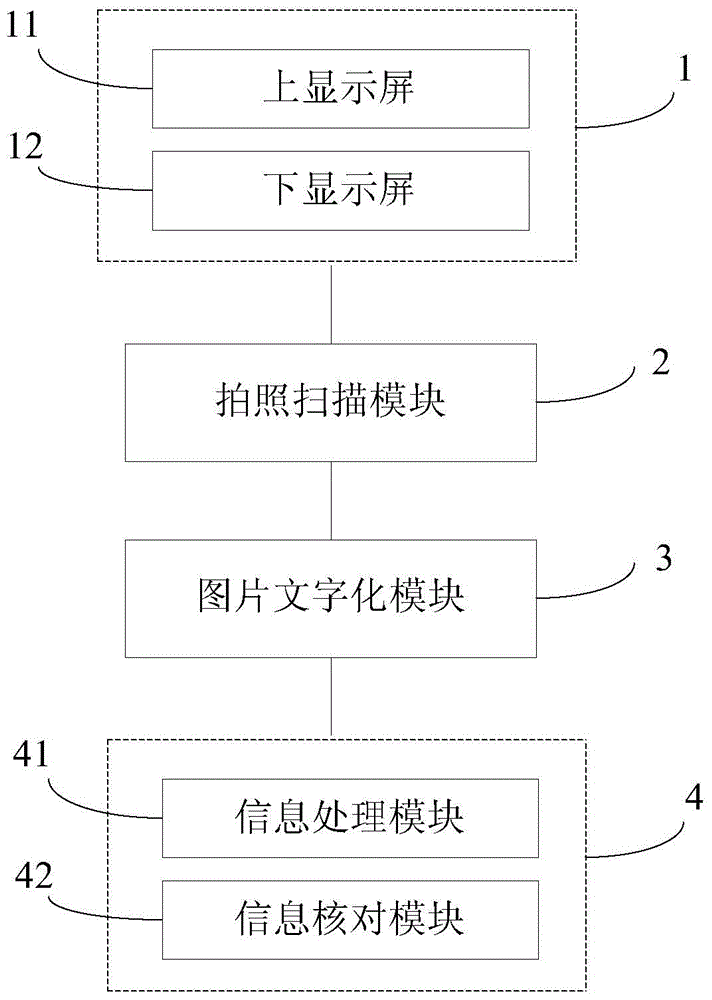

Method and system capable of preventing information input errors, and mobile terminal

ActiveCN104834924AImprove experienceReduce the probability of errorCharacter and pattern recognitionText processingComputer engineering

The invention discloses a method and a system capable of preventing information input errors, and a mobile terminal. The method comprises the following steps: a sub-screen display comparison function is turned on when a mobile terminal needs to check information; a photographic scanning function of the mobile terminal is turned on, to-be-checked information that is written by a user is input into the mobile terminal in a photographic scanning manner, and the mobile terminal displays the to-be-checked information obtained by photographic scanning and original information in sub screens and carries out image-to-text processing on the input picture; after the image-to-text processing, two contents in the sub screens are automatically compared, and upon the detection that the to-be-checked information and the original information are not identical, the mobile terminal marks the different characters and / or numbers with colors. According to the invention, the to-be-checked information and the original information are compared by photographic scanning, so that information input errors can be effectively prevented, the user experience is improved, and some special industries are provided with convenience.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

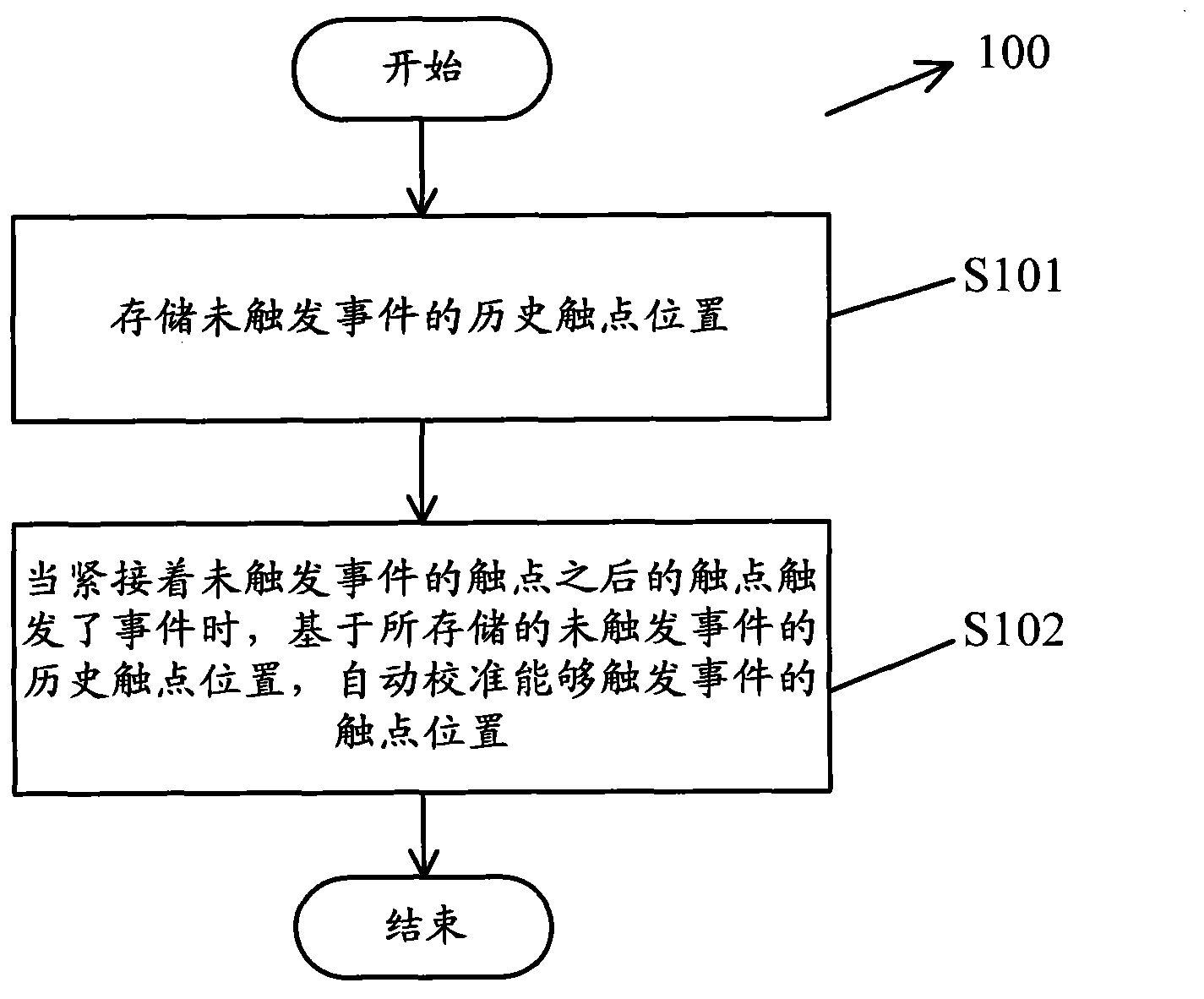

Automatic calibration method and equipment for contact position

InactiveCN103576964AReduce the probability of errorImprove user experienceInput/output processes for data processingContact positionComputer science

The embodiment of the invention discloses a method and equipment for automatically calibrating a contact position capable of triggering an event on a touch device. The method comprises the steps of storing historical contact positions of events which are not triggered; when a contact closely behind the contacts of the event which are not triggered triggers an event, automatically calibrating the contact position capable of triggering the event on the basis of the stored historical contact position of the events which are not triggered. The method and the equipment have the advantages that since the contact position capable of triggering the event can be automatically calibrated on the touch device, the contact position capable of effectively triggering the event is adjusted in real time, the error probability of a user during operation is reduced and the user experience is improved.

Owner:BEIJING OAK PACIFIC NETSCAPE TECH DEV

Method for repairing P table of Seagate hard disk

InactiveCN105354100AReduce the probability of errorShorten the timeNon-redundant fault processingCompilerSoftware engineering

The present invention discloses a method for repairing a P table of a Seagate hard disk. The method comprises the following steps: S101, reading a system file corresponding to a P table; S102, analyzing an effective data volume of the P table, and distinguishing abnormal entries; S103, removing the abnormal entries; S104, calculating an effect and writing the effect into the last two bytes of the P table; and S105, carrying out compiler reconstruction on the re-modified P table. The method has the following beneficial benefits that the abnormal defect entries of the P table can be directly modified, and the P table effect after modification can be calculated, so that the error probability of hard disk repair is reduced, time of hard disk repair is shortened, and the success rate of hard disk repair is improved.

Owner:XLY SALVATIONDATA TECHNOLOGY INC

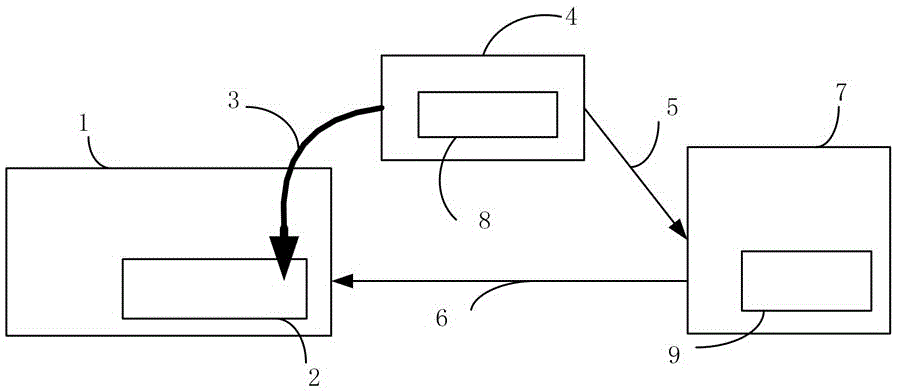

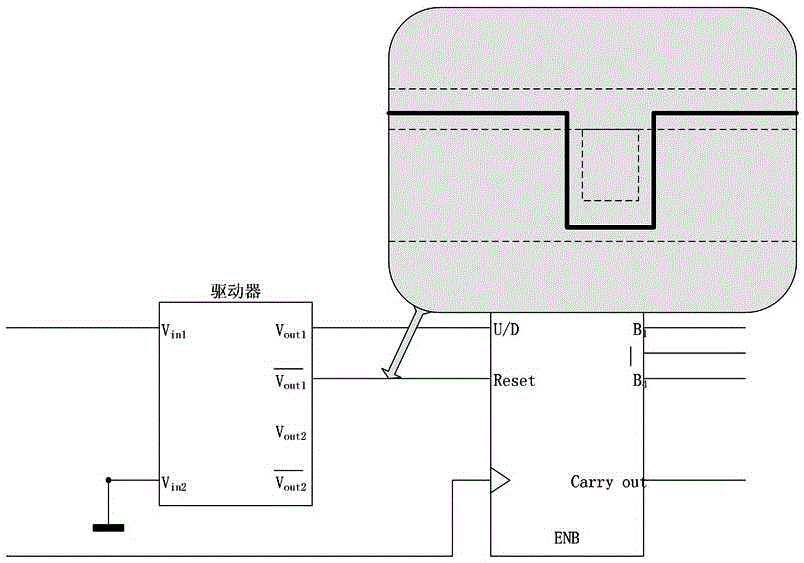

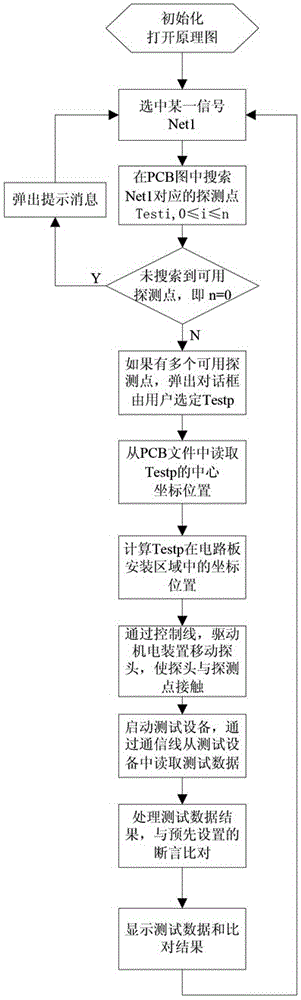

Device and method for printed circuit board detection based on schematic diagram assertion

InactiveCN105717442AImprove debugging efficiencyReduce the probability of errorPrinted circuit testingPrinted circuit boardTest facility

The invention discloses a device and method for printed circuit board detection based on a schematic diagram assertion. The device comprises a testing device, a control unit and a debugging mainframe, wherein the testing device comprises a finger test unit and an image colleting unit. The finger test unit comprises a finger test element and an electromechanical moving module. The finger test element is driven by the electromechanical moving module to move, so that a contact tip of the finger test element is in continuous contact with a designated location of a circuit board entity. The control unit is used for controlling the motion of the contact tip through the electromechanical moving module according to the distance between the contact tip and a test point on the circuit board entity. The debugging mainframe is used for sending to the control unit a control command of moving the contact tip and is used for reading data results, making a comparison between the data results and the assertion and displaying the results. The method is based on the detection device. The detection device has the advantages of being simple in structure, simple and convenient to operate and high in automation degree.

Owner:深圳市赛伦北斗科技有限责任公司

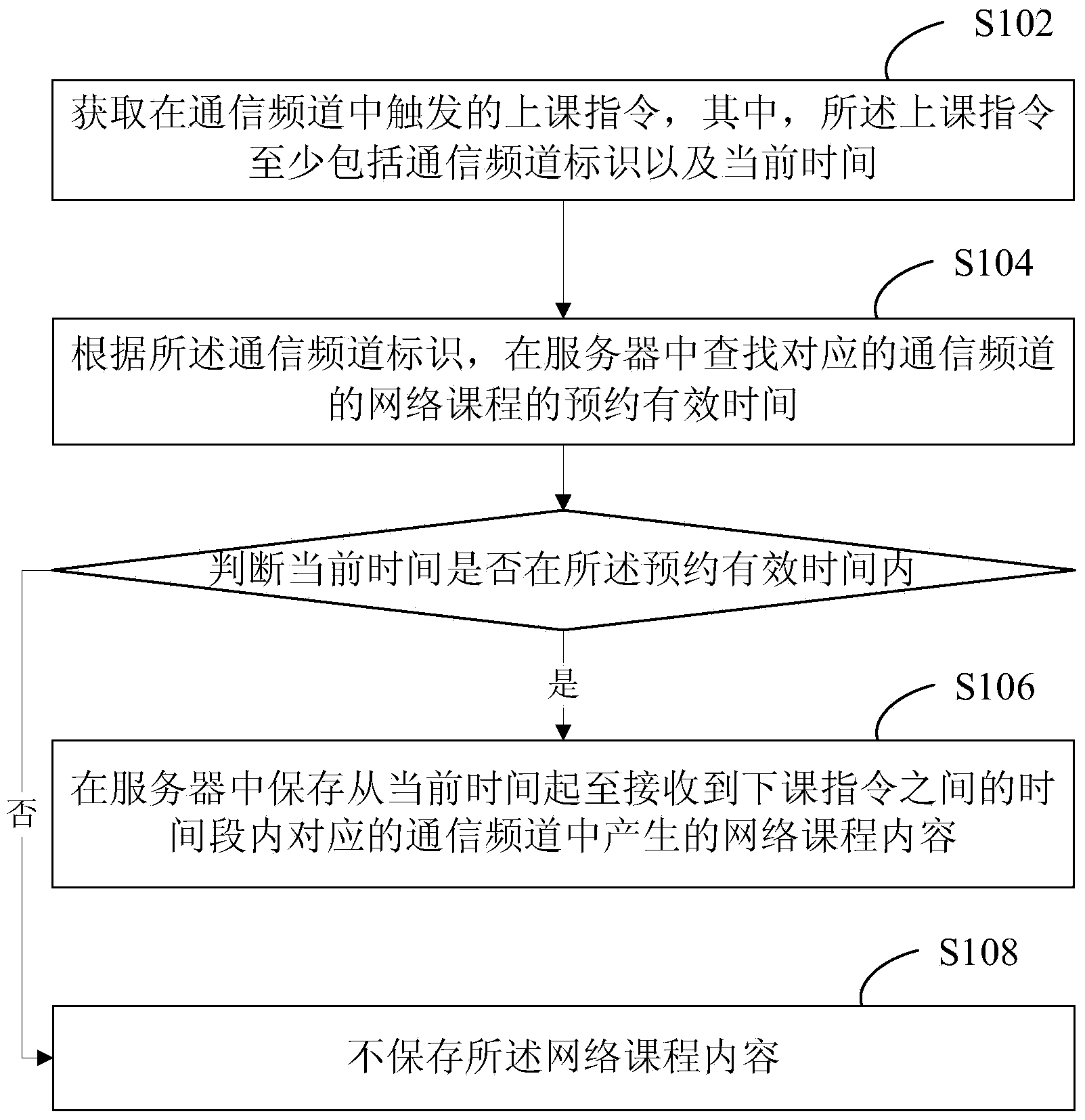

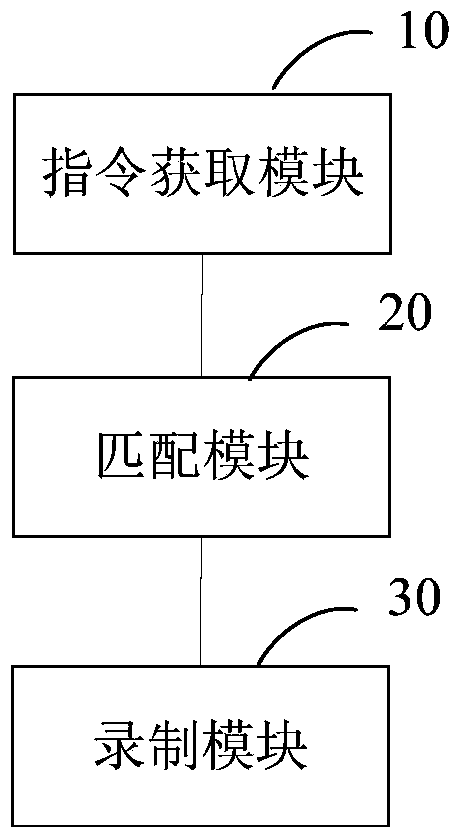

Method and system for automatically recording courses through communication software

ActiveCN103680257AReduce the probability of errorsReduce misuseTeaching apparatusTime rangeCommunications software

The invention provides a method and a system for automatically recording courses through communication software. The method includes acquiring a lesson-giving instruction triggered in communication channels, wherein the lesson-giving instruction at least includes a communication channel identity and current time; according to the communication channel identity, finding reservation valid time of network courses of corresponding communication channels in a server, and judging whether the current time is within the reservation valid time or not; if yes, storing network course content generated in the corresponding communication channels within a time range from the current time to a time point when a lesson-finishing instruction is received in the server; if not, not storing the network course content. By the method and the system, more convenience is brought to network course recording through the communication software, and manual triggering by a user is not needed; recording content can be automatically recognized, so that relevance between recorded content and related network courses can be improved.

Owner:广州欢聚时代信息科技有限公司

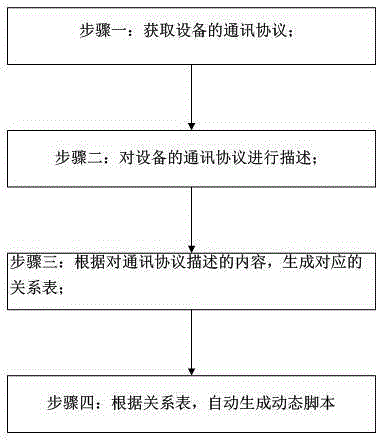

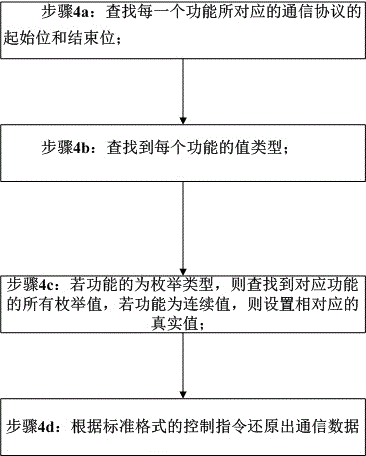

Dynamic script automatic-generating method

InactiveCN105335153AReduce the probability of errorReduce error rateSpecific program execution arrangementsCommunications protocolSoftware engineering

The invention discloses a dynamic script automatic-generating method comprising the following steps: 1, obtaining an equipment communication protocol; 2, describing the equipment communication protocol; 3, generating a corresponding relation table according to the content described by the communication protocol; 4, automatically generating a dynamic script according to the relation table. The method can describe the equipment functions according to the equipment communication protocol, and the relation table generated by the describing information can automatically form the script, thus parsing and processing a standard control order. Only describing operation is needed, and the describing work error rate is far lower than script development.

Owner:HANGZHOU BROADLINK ELECTRONICS TECH

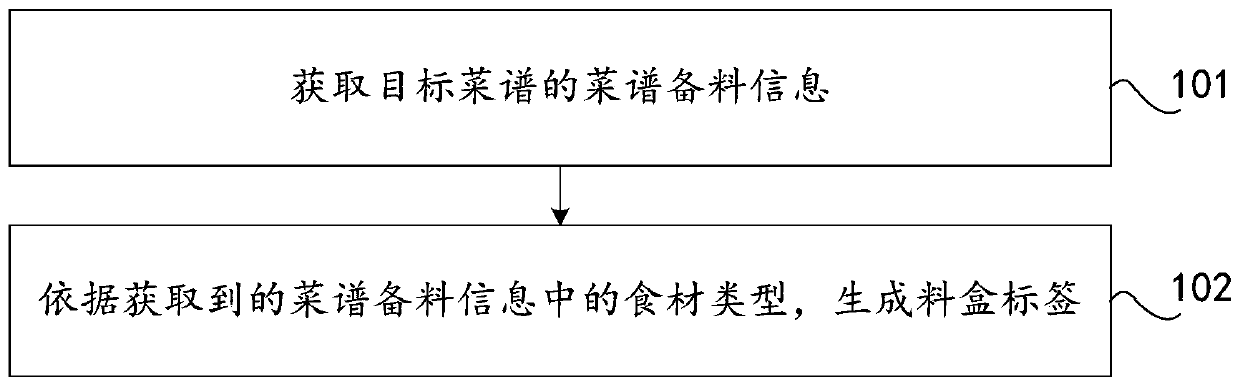

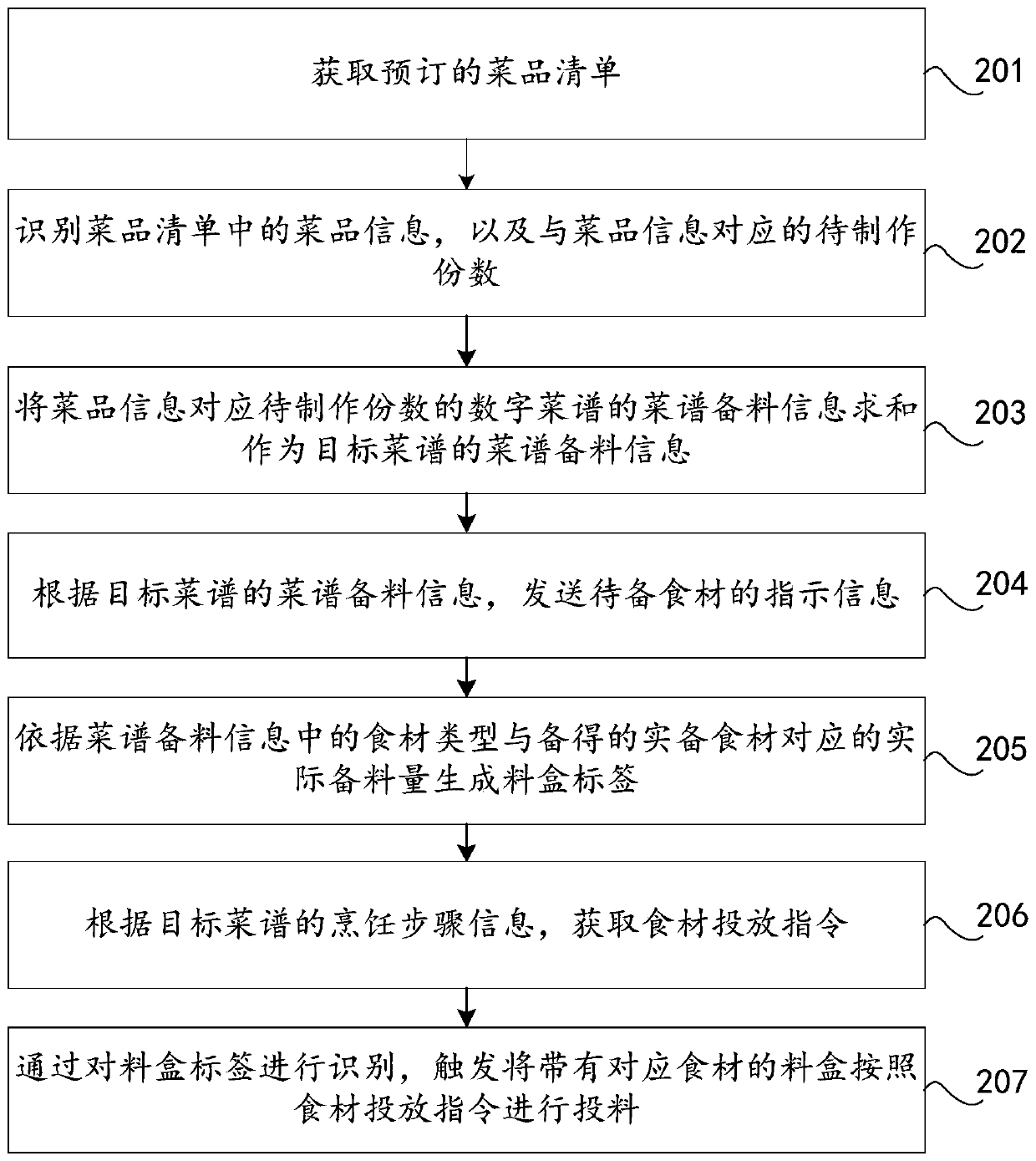

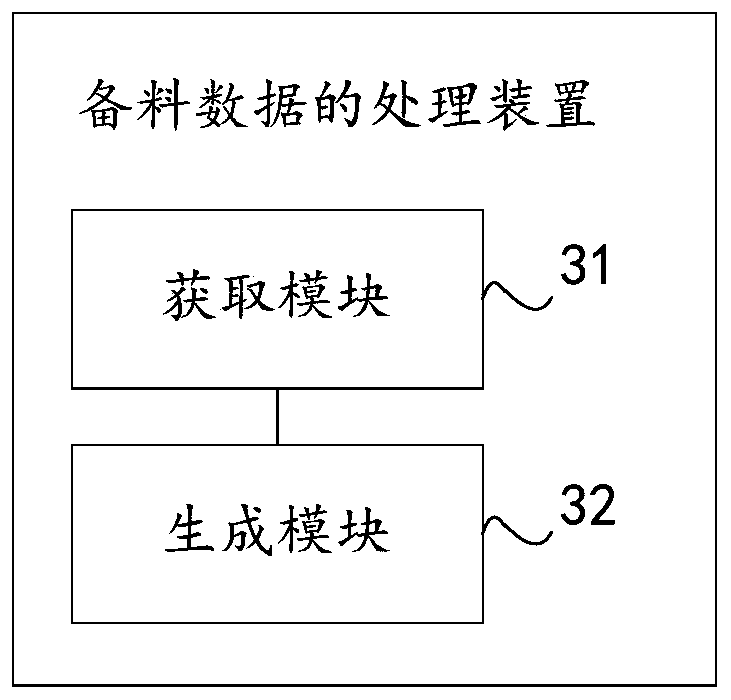

Material preparation data processing method, device and equipment

ActiveCN111103813AImprove efficiency and accuracyReduce the probability of errorProgramme control in sequence/logic controllersProcess engineeringManufacturing engineering

The invention discloses a material preparation data processing method, device and equipment, and belongs to the technical field of data processing. The method comprises the following steps: firstly acquiring menu material preparation information of a target menu; and then generating a material box label according to the food material type in the menu material preparation information, wherein the material box label is used for indicating the putting of a material box. The method can effectively help the user to prompt the content of the to-be-prepared food materials in the material boxes and improves the accuracy and the efficiency of food material preparation. In addition, after material preparation is completed, the material box label can further indicate material box putting operation, the user does not need to care about the placing sequence of the material boxes, the error probability in dish processing is reduced, and the accuracy of dish processing can be improved. The method issuitable for processing the material preparation data.

Owner:珠海优特智厨科技有限公司

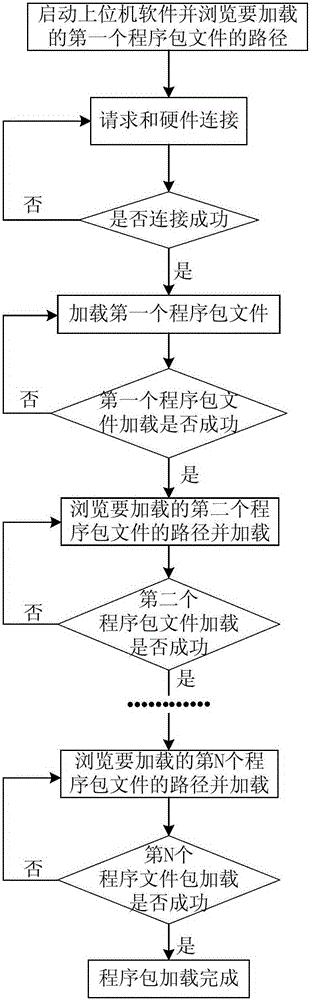

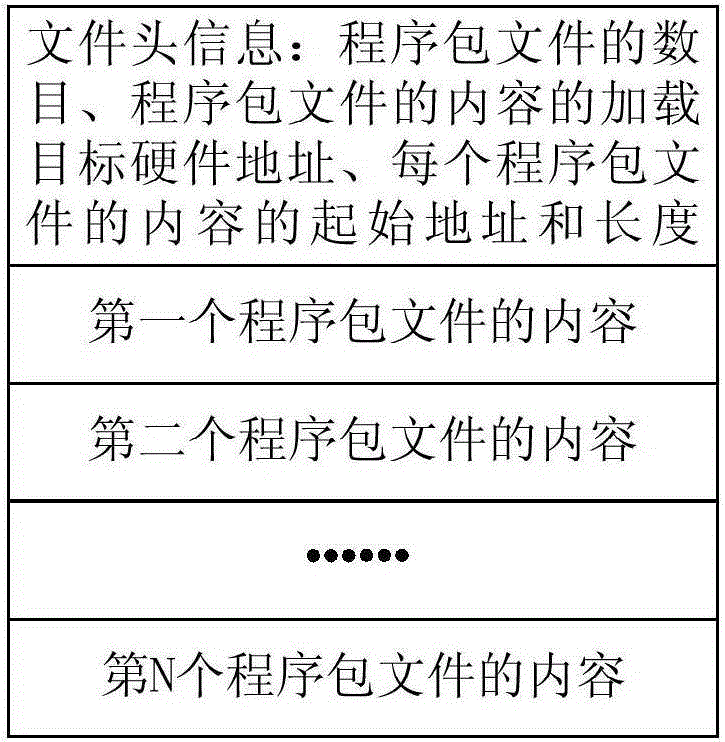

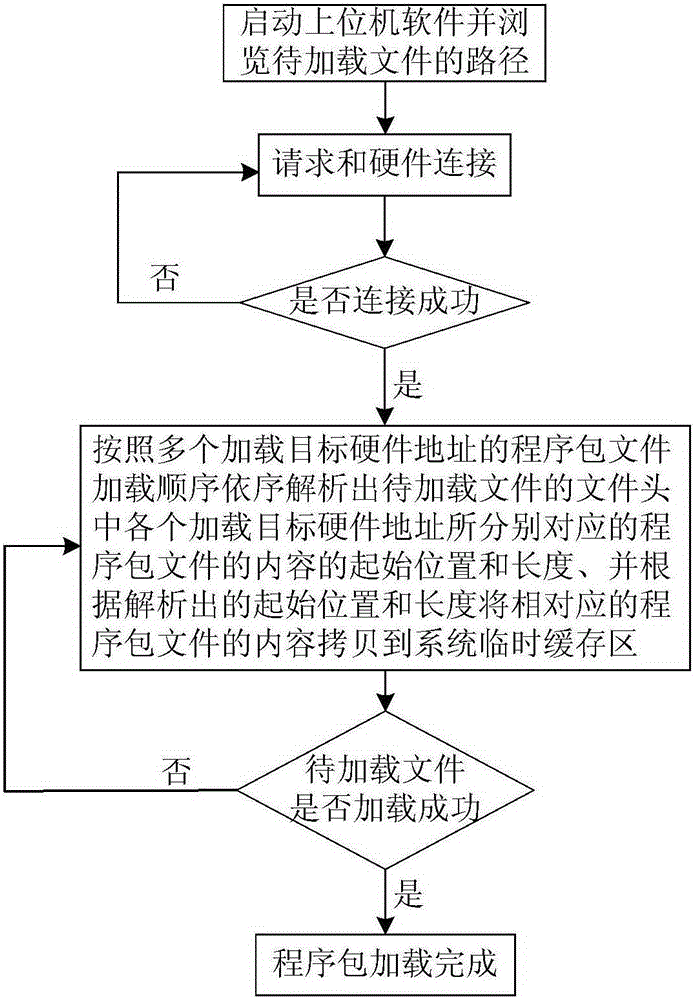

Program loading method

ActiveCN105224359AIncrease productivityReduce the probability of errorProgram loading/initiatingLoad fileProbability of error

The present invention relates to a program loading method. The method comprises: (a) acquiring a to-be-loaded file merged by multiple program package files, wherein a file header of the to-be-loaded file comprises the amount of the program package files, a loading target hardware address of contents of the program package files, and the starting position and length of the content of each program package file; (b) determining whether the connection between an upper computer and a lower computer is successful; and (c) based on a loading sequence of multiple loading target hardware addresses, sequentially analyzing the starting position and the length of the content of each program package file from the file header of the to-be-loaded file, and according to the analyzed starting position and length, storing the contents of the program package files into a temporary buffer zone of the upper computer, and releasing the contents from the temporary buffer zone after the contents are successfully loaded to the lower computer. Therefore, according to the method provided by the present invention, a program loading operation process can be simplified, thereby improving the production efficiency and reducing unnecessary error probability.

Owner:XIAN NOVASTAR TECH

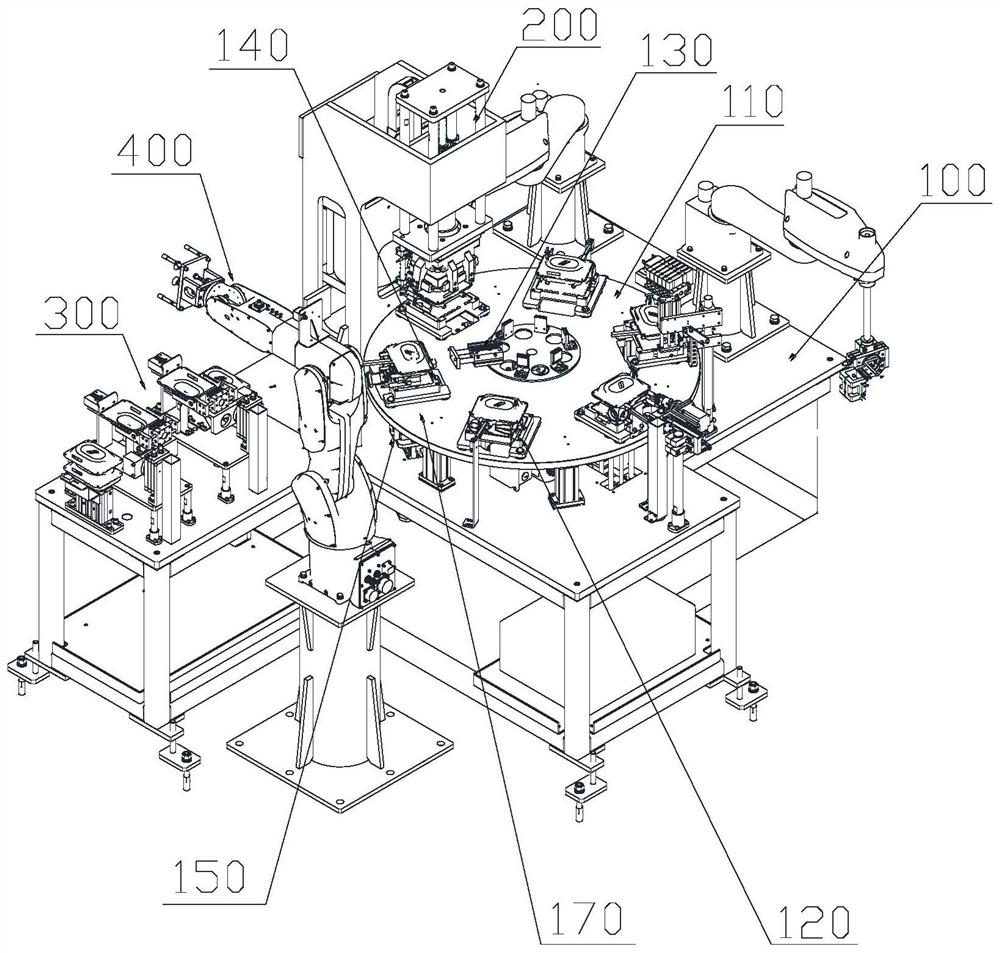

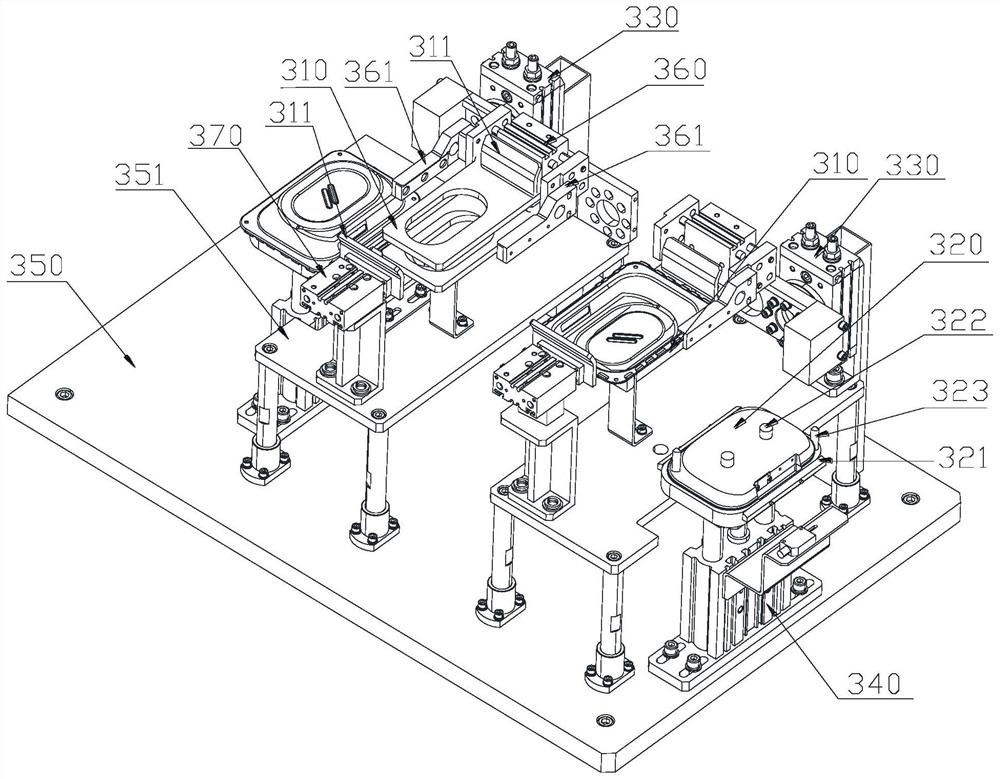

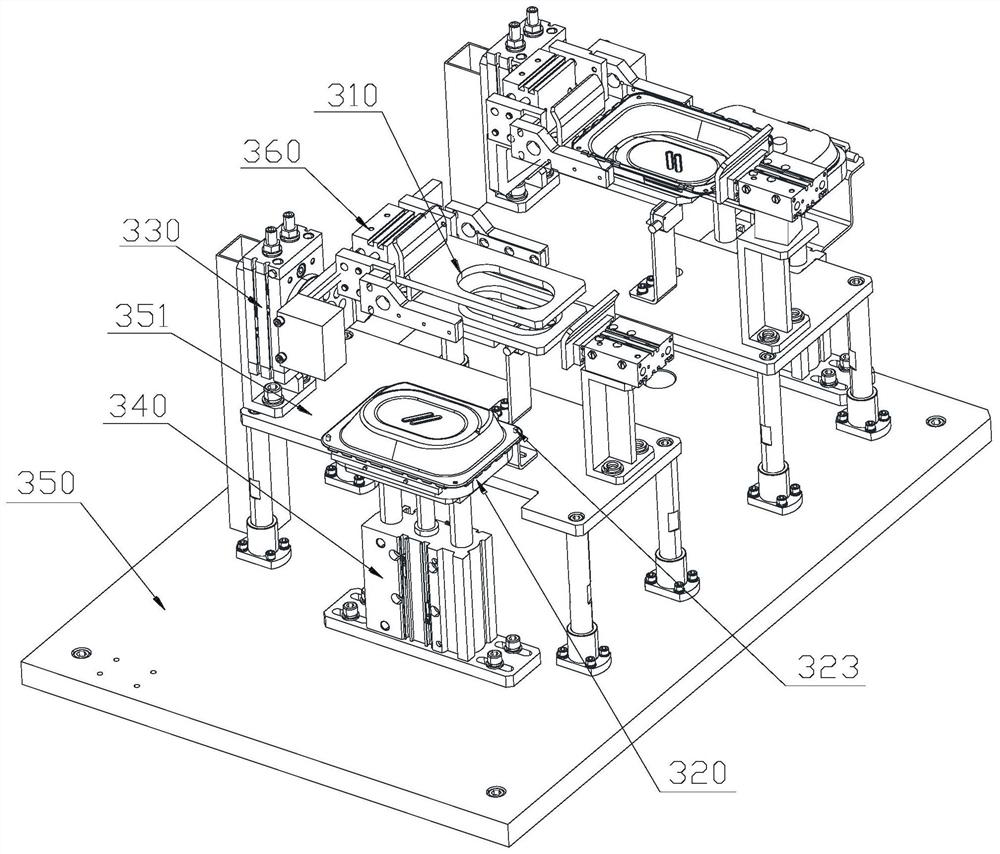

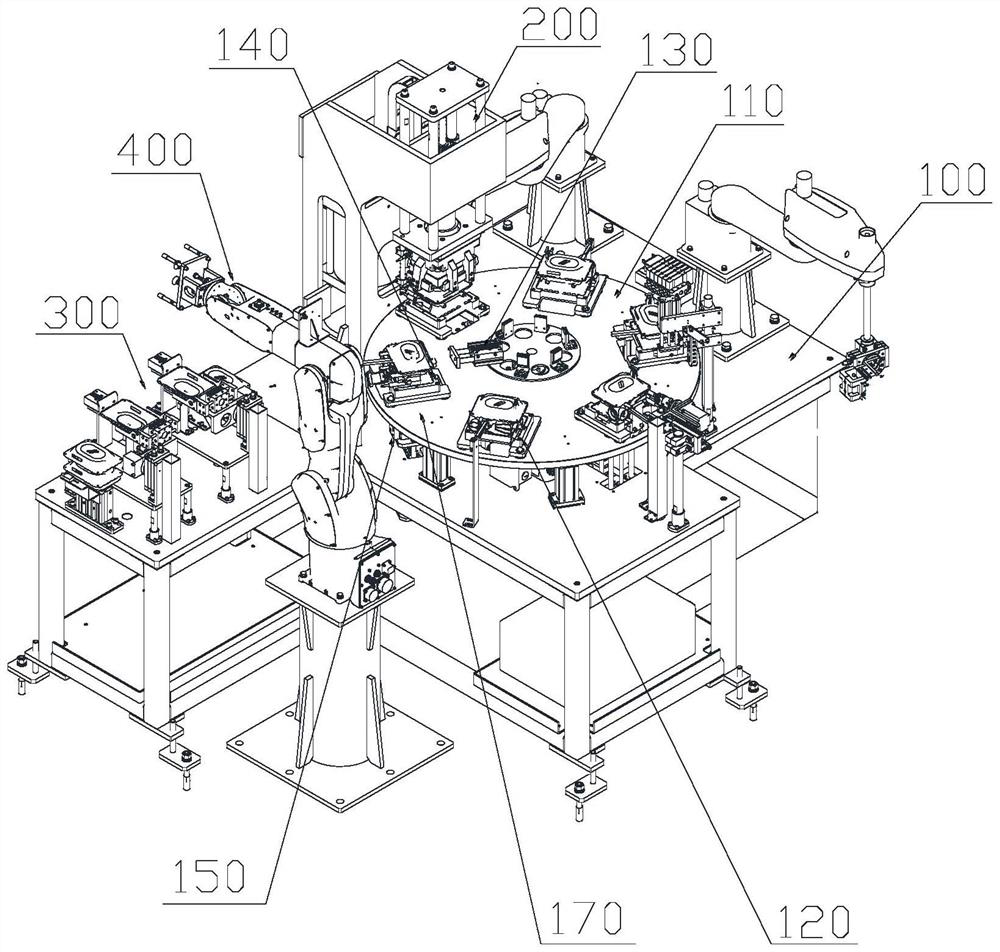

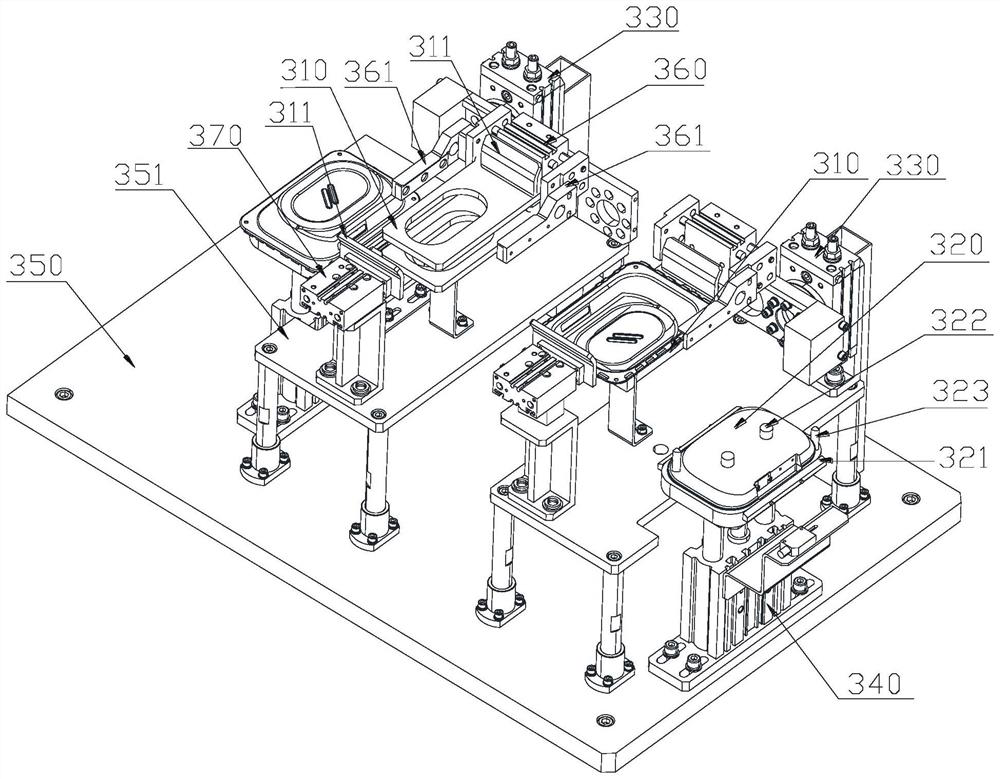

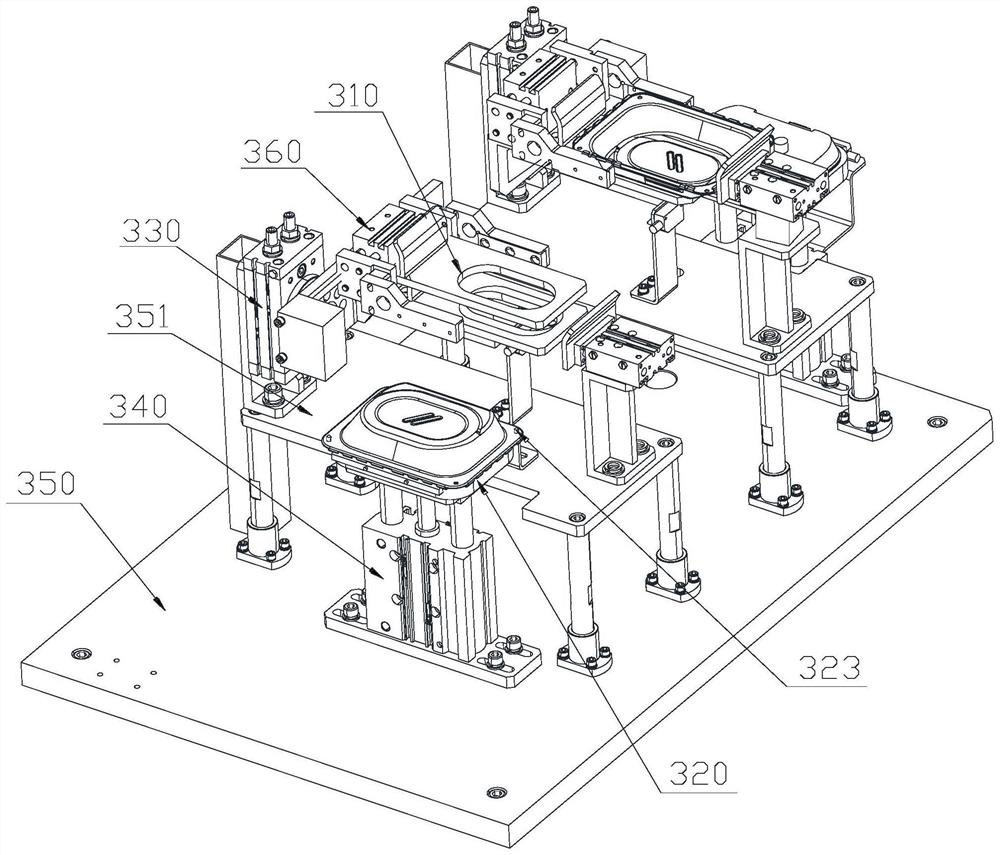

Diaphragm gas meter metering shell press seal and connecting rod assembly line

ActiveCN113953808AIncrease productivityImprove assembly alignment efficiencyMetal working apparatusProduction lineGas meter

The invention belongs to the field of gas meter production equipment, and discloses a diaphragm gas meter metering shell press seal and connecting rod assembly line. The diaphragm gas meter metering shell press seal and connecting rod assembly line comprises a metering shell press seal system and a connecting rod assembling system, wherein the metering shell press seal system comprises a secondary positioning mechanism, the secondary positioning mechanism comprises turnover plates and profiling tools which are arranged in a one-to-one correspondence mode, the connecting rod assembling system comprises a rack B, the rack B is provided with a station shifting mechanism, a pointer disc adjusting mechanism and a connecting rod assembling mechanism, the pointer disc adjusting mechanism and the connecting rod assembling mechanism are arranged corresponding to the station shifting mechanism, the station of the pointer disc adjusting mechanism is located on the upstream of the connecting rod assembling mechanism, and one side of the rack B is provided with a connecting rod feeding assembly corresponding to the connecting rod assembling mechanism. Two pre-adjusting structures are adopted, the buckling and even riveting press sealing efficiency of a metering shell and a movement and the connecting rod assembling efficiency are effectively improved, production line faults and errors are reduced, the production efficiency of the gas meter is improved, and the assembly line cost is reduced.

Owner:QIANWEI KROMSCHRODER METERS CHONGQING

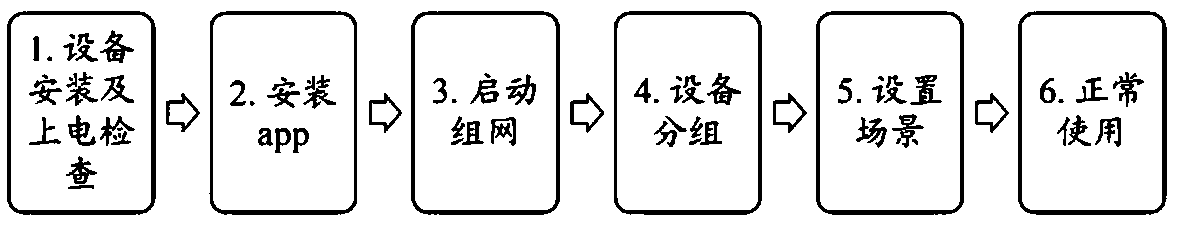

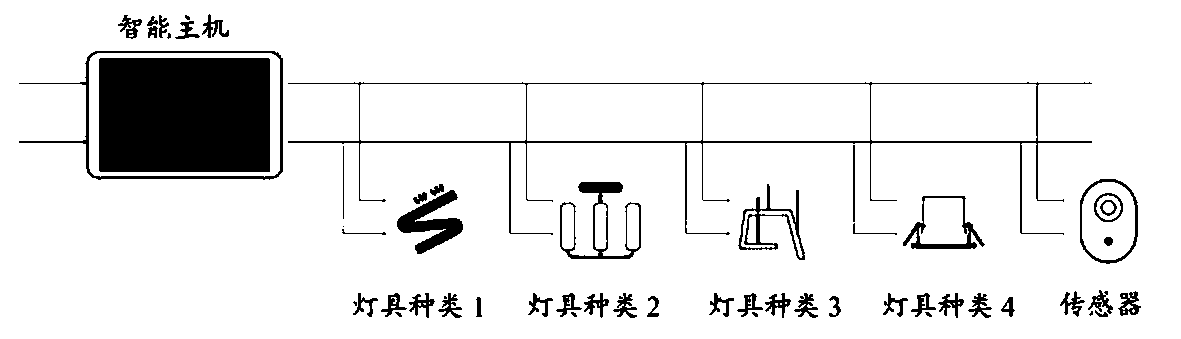

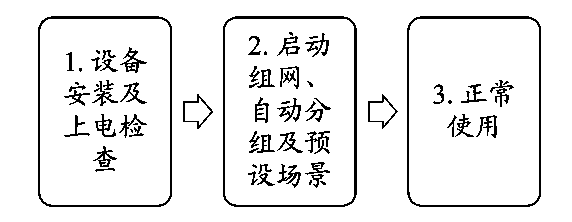

Lighting system realizing simple networking and configuration functions and method thereof

ActiveCN110784979AReduce the difficulty of operationReduce the probability of errorElectrical apparatusEnergy saving control techniquesEmbedded systemLighting system

The invention relates to a system for realizing simple networking and configuration functions. The system comprises a smart host and a number of smart devices. The smart host and the smart devices areconnected with the same mains branch. The smart host is used for establishing a wireless intelligent lighting system including the smart host and the smart devices, and controlling and operating thesmart devices. The smart devices are used to drive adapted lamps or electrical products. The invention further relates to a method for simple networking and configuration. According to the lighting system realizing simple networking and configuration functions and the method thereof, which are provided by the invention, the steps of automatic networking, grouping, scene setting and the like are carried out, which greatly reduces the difficulty of operation and the probability of errors; operation steps are reduced; the operating time is greatly shortened; daily use and maintenance are more convenient; and new equipment can be quickly added into the existing network, or faulty equipment can be replaced quickly.

Owner:SIMON ELECTRIC CHINA

Automatic assembly method and assembly line for movement of diaphragm gas meter

The invention belongs to the field of gas meter production equipment, and discloses an automatic assembly method and assembly line for a movement of a diaphragm gas meter. The assembly method mainly comprises the steps of automatic press sealing of a metering shell and automatic assembly of a connecting rod. In the automatic press sealing of the metering shell, secondary positioning of the metering shell and expansion of riveting teeth of the metering shell are conducted firstly; and then the metering shell with the expanded riveting teeth and a movement body are aligned and buckled and then are riveted in a press sealing manner. In the automatic assembly of the connecting rod, the position of a pointer disc assembled on the movement body is adjusted firstly, a fixing head of the connecting rod on the pointer disc is located on the side away from a rocker arm on the movement body, then after the pointer disc and the rocker arm are fixed, the two ends of the connecting rod are connected with the rocker arm and the pointer disc respectively, and the assembly line is mainly achieved on the basis of the assembly method. A pre-adjusting assembly concept is adopted, the buckling and even riveting and press sealing efficiency of the metering shell and the movement and the connecting rod assembly efficiency are effectively improved, production line faults and errors are reduced, the production efficiency of the gas meter movement is improved, and the assembly line cost is reduced.

Owner:QIANWEI KROMSCHRODER METERS CHONGQING

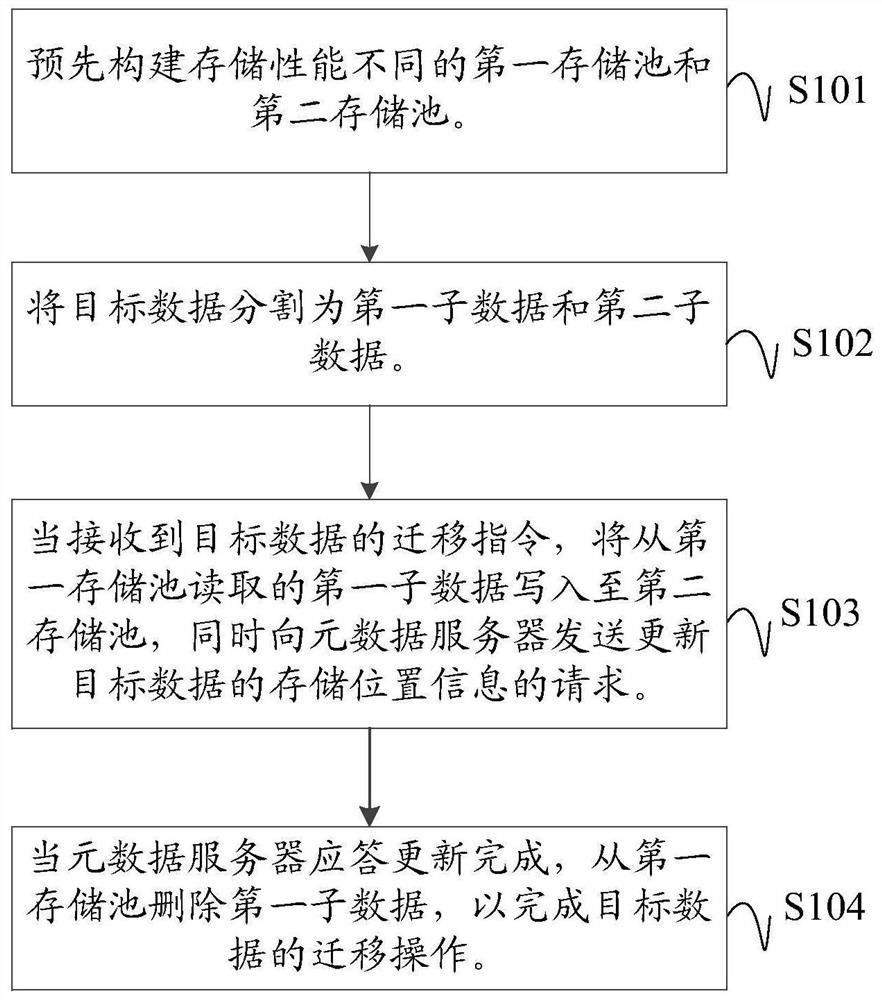

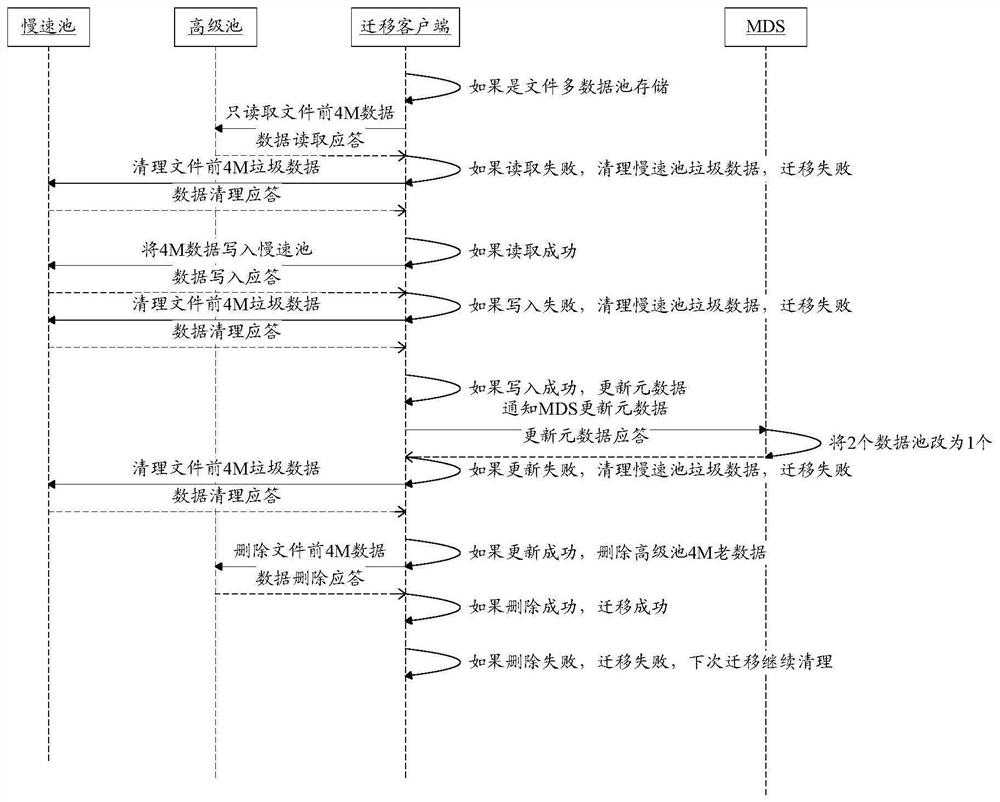

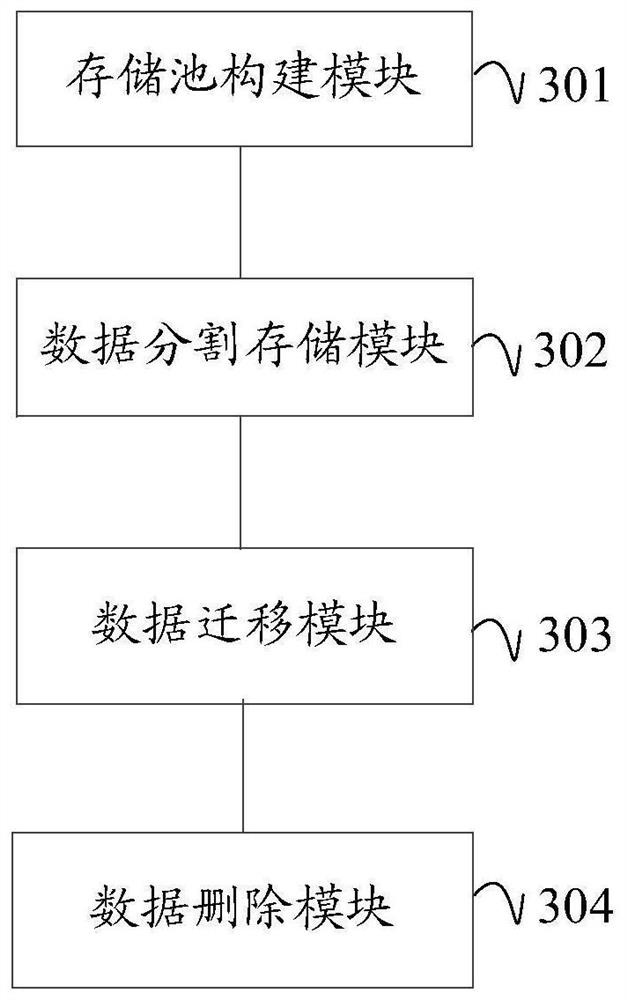

Data migration method, device, electronic equipment and readable storage medium

PendingCN113836116AImprove migration efficiencyReduce the probability of errorSpecial data processing applicationsDatabase design/maintainanceData migrationEngineering

The invention discloses a data migration method, a device, electronic equipment and a readable storage medium. The method comprises the steps that a first storage pool and a second storage pool which are different in storage performance are constructed in advance, and the storage performance of the first storage pool is superior to that of the second storage pool; segmenting the target data into first sub-data and second sub-data, storing the first sub-data into a first storage pool, and storing the second sub-data into a second storage pool; when a migration instruction of target data is received, writing first sub-data read from the first storage pool into a second storage pool, and sending a request for updating storage position information of the target data to a metadata server; when the metadata server responds to update completion, the first sub-data is deleted from the first storage pool to complete the migration operation of the target data, so that the file migration error probability can be reduced on the basis of improving the file migration efficiency.

Owner:济南浪潮数据技术有限公司

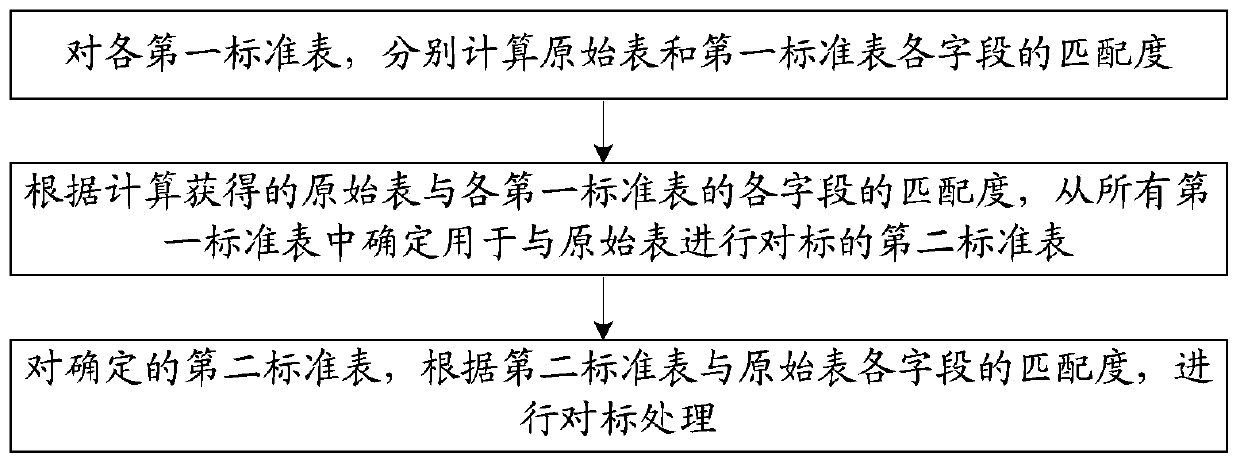

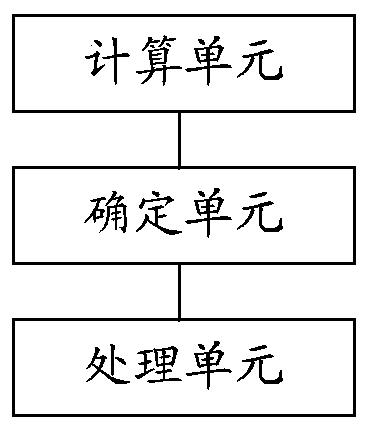

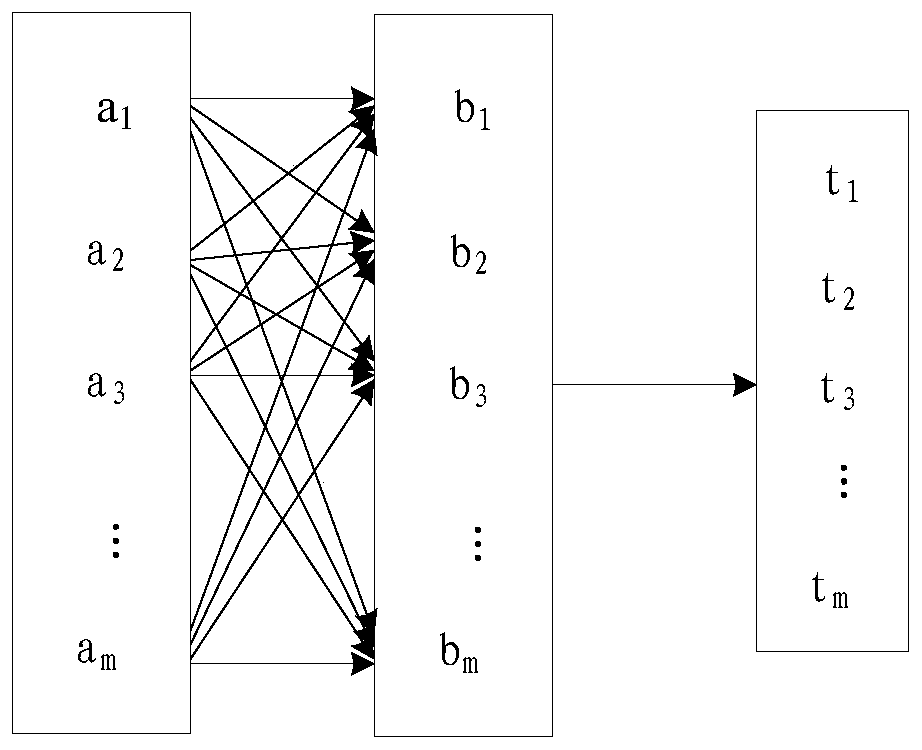

Benchmarking processing method and device, computer storage medium and terminal

InactiveCN109902083AImprove benchmarking processing efficiencyReduce the probability of errorSpecial data processing applicationsDatabase indexingData mining

The invention discloses a benchmarking processing method and device, a computer storage medium and a terminal, and the method comprises the steps: calculating the matching degree of each field of an original table and a first standard table for each first standard table; according to the calculated matching degree of each field of the original table and each first standard table, determining a second standard table used for carrying out benchmarking on the original table from all the first standard tables; and for the determined second standard table, performing benchmarking processing according to the matching degree of each field of the second standard table and the original table. According to the embodiment of the invention, the benchmarking processing is carried out according to the matching degree information, the benchmarking processing efficiency of the original table and the target table is improved, and the error probability during the benchmarking processing is reduced.

Owner:BEIJING MININGLAMP SOFTWARE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com