Diaphragm gas meter metering shell press seal and connecting rod assembly line

A membrane gas meter and assembly line technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of error-prone installation of measuring shell connecting rods, equipment errors and lower production efficiency, etc., so as to reduce the probability of equipment errors and improve Alignment efficiency, the effect of reducing the cost of the assembly line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the accompanying drawings.

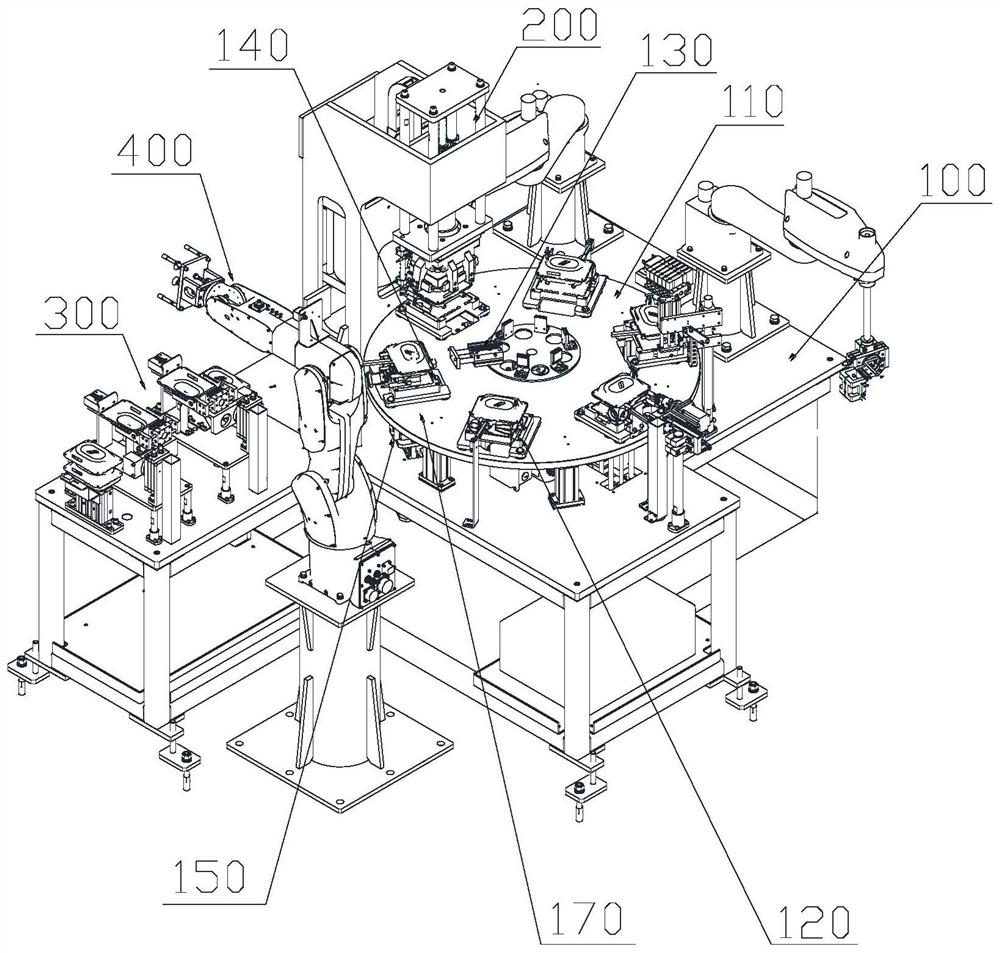

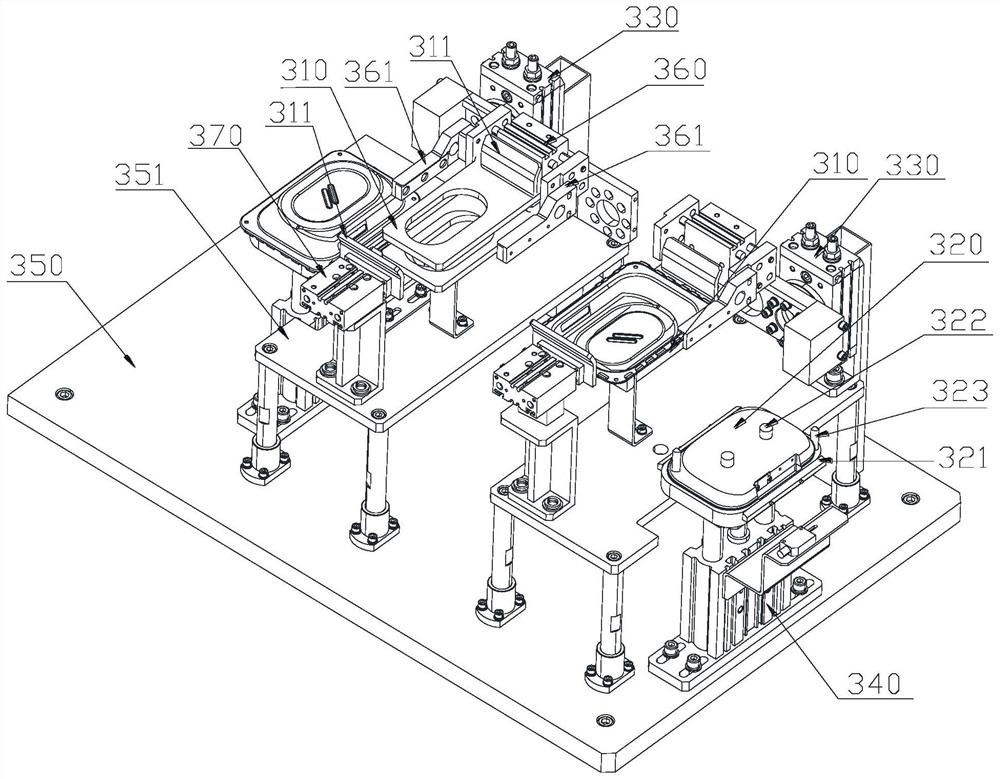

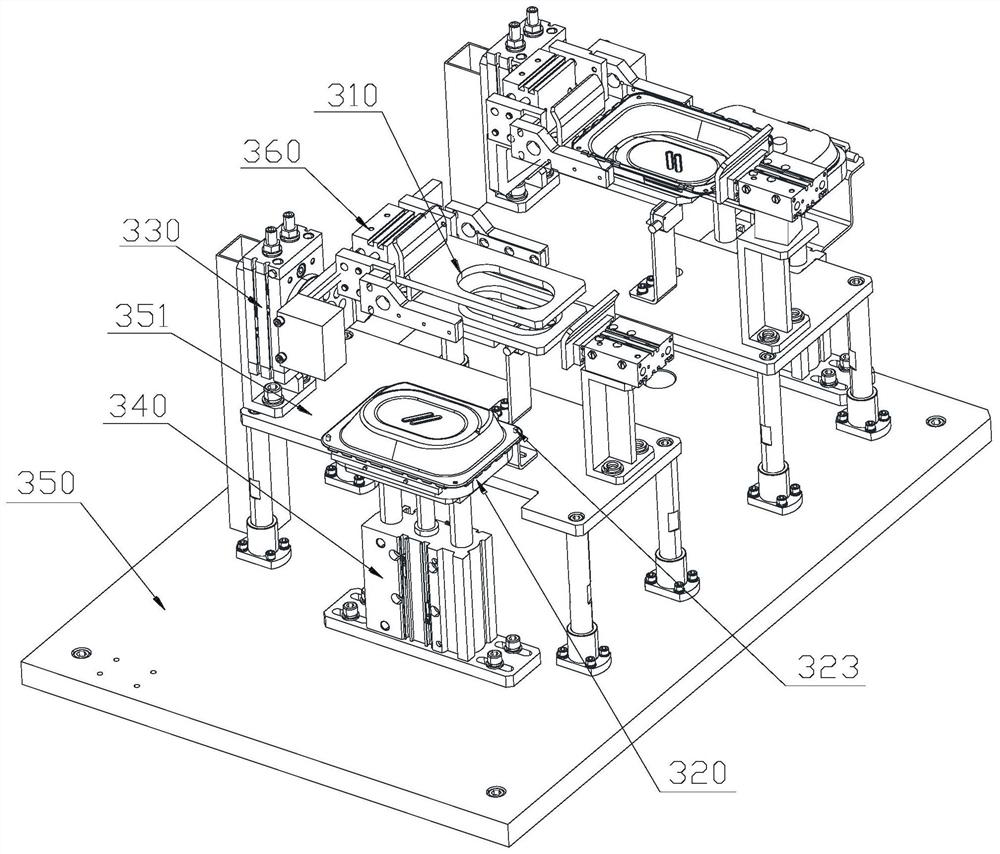

[0046] refer to Figure 1 to 25 The film-type gas meter measuring housing is compressed and the link assembly line, which mainly includes a metering shell compression system and a link assembly system in the same membrane gas meter production line. The present application mainly on the above-mentioned existing automation production line. Two systems are optimized to improve production efficiency throughout the production line.

[0047] The metering sealing system mainly includes a rack A100, and a rotary separator disk 110 disposed on the frame A100 and a pressurizing machine 200 that should be rotated to rotate the separation disc 110, and there is a rotational index disc 110. The rotation index disc 110 in the circumferential uniform distributed, the rotation index disc 110 is a conventional six-station degree-of-in-one, and each station has a motor core positioning seat 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com