Crane part multidimensional comprehensive measuring tool

A comprehensive detection and crane technology, applied in the field of measuring tools, can solve the problems of non-repetition and other problems, achieve the effects of fast detection speed, guarantee of life and property safety, and improve detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Such as Figure 6 , Figure 7 As shown, a multi-dimensional comprehensive detection measuring tool for crane components, the measuring tool includes a ruler body 1, a main vernier 2 slidingly fitted on the ruler body through a transverse groove 2-1, and a fixed measuring claw 11 arranged at the end of the ruler body (the fixed amount The claw and the ruler body are integrally formed), and the ruler body and the transverse groove are provided with horizontal scales. The transverse groove of the main vernier is provided with a locking screw 5, which can position the transverse groove on the ruler body. Such as Figure 9 As shown, the main vernier is also formed with a longitudinal groove 2-2 perpendicular to the transverse groove, and a main vernier claw 6 for measuring the width of the component is slidably fitted in the longitudinal groove. Both the main vernier claw and the longitudinal groove are provided with Vertical scale. Such as Figure 6 As shown, when the ...

Embodiment 2

[0070] Such as Figure 11 As shown, on the basis of Embodiment 1, the upper side of the fixed measuring jaw and the upper end of the main vernier measuring jaw are respectively provided with an inner diameter measuring jaw for measuring the inner diameter of the component. Combined with the principle of measuring the inner diameter of the vernier caliper, it can be used to measure the diameter of the axle hole of the wheel. In order to ensure the accuracy of depth measurement, it is necessary that the inner diameter measuring jaw of the main vernier measuring jaw can be aligned with the inner diameter measuring jaw on the upper side of the fixed measuring jaw, which requires that the inner diameter measuring jaw 8 on the upper side of the fixed measuring jaw be extended upwards (the inner diameter measuring jaw integrally formed with the ruler body), the main vernier measuring jaw 6 and its inner diameter measuring jaw 7 are integrally formed, when the vernier measuring jaw re...

Embodiment 3

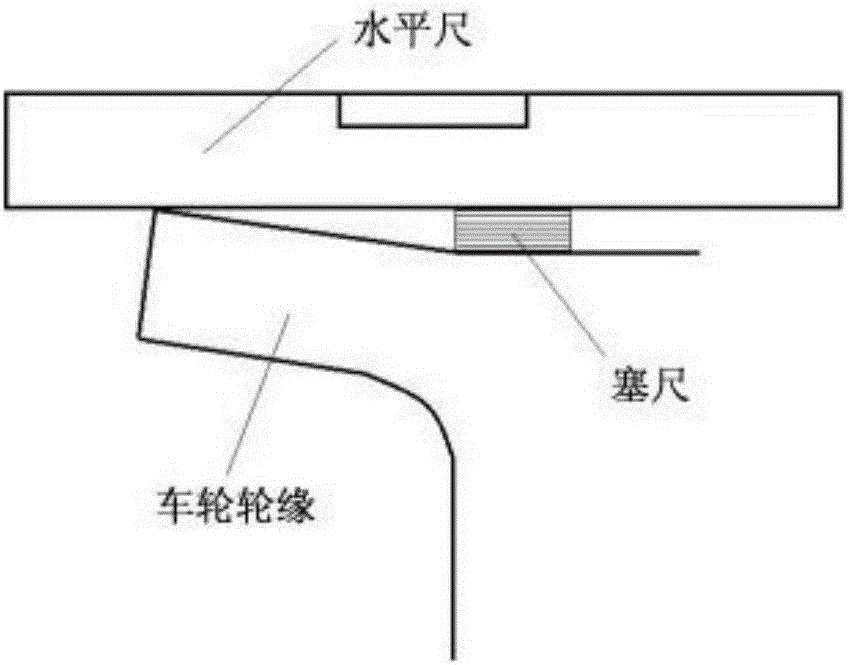

[0072] Such as Figure 13 As shown, on the basis of Embodiment 2, a horizontally arranged water bubble level 10 (generally located on the upper side of the fixed measuring claw) is also provided on the ruler body, and the inner diameter measuring claw on the upper side of the fixed measuring claw is provided with The bubble type spirit level 9 of vertical arrangement. When measuring, the water bubble level can be used to ensure that the ruler body is in a horizontal position and improve the measurement accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com