Automatic assembly method and assembly line for movement of diaphragm gas meter

A membrane gas meter and automatic assembly technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of easy error-prone assembly of measuring shell connecting rods, equipment error reporting and reducing production efficiency, etc., to reduce the probability of equipment error reporting, Improve alignment efficiency and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings.

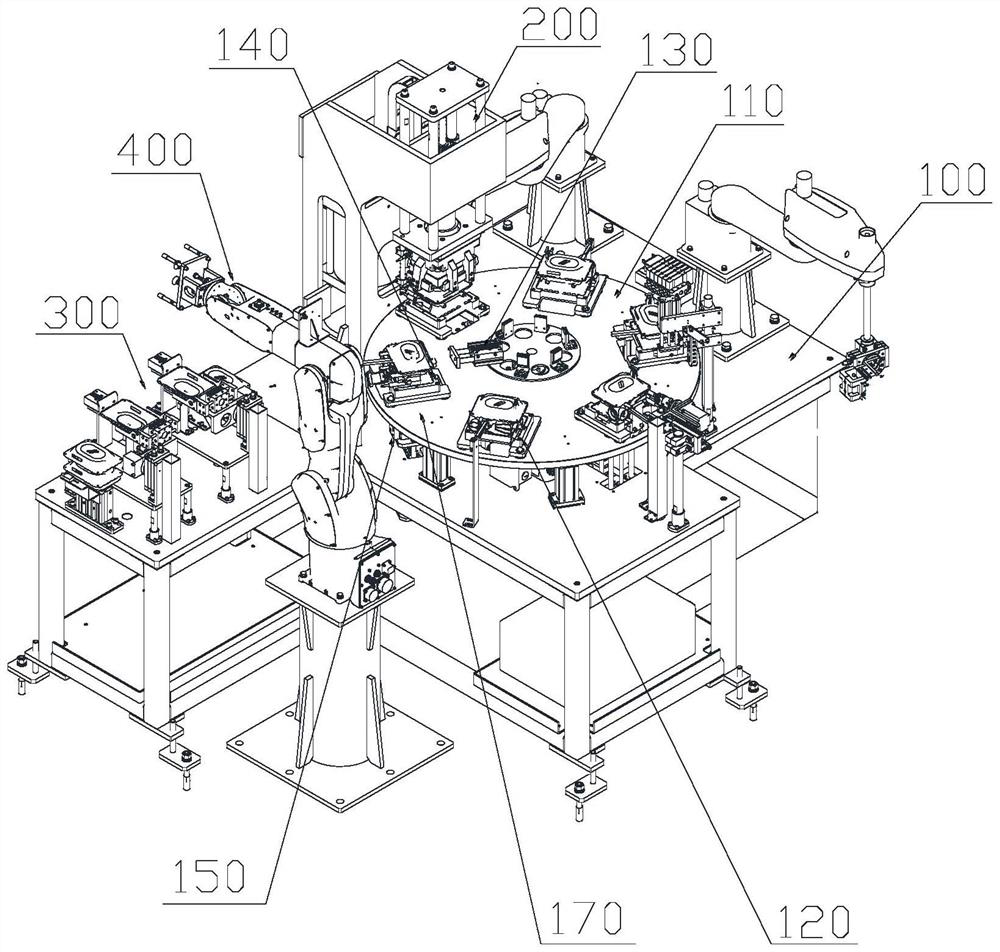

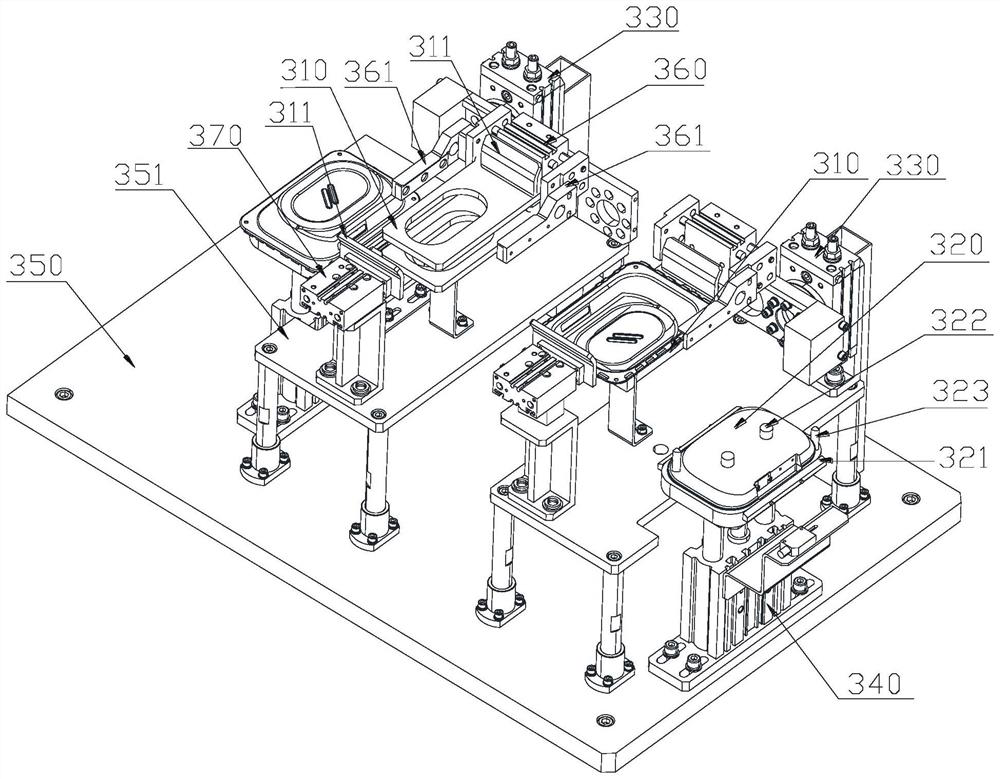

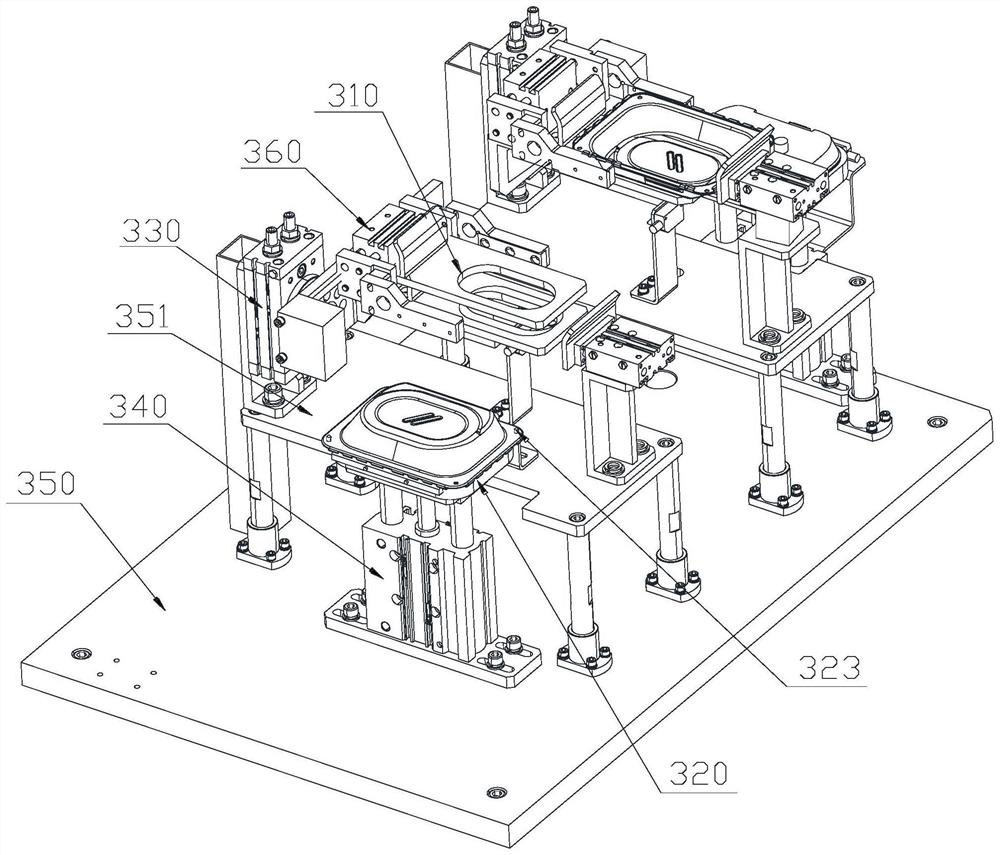

[0050] refer to Figure 1 to Figure 25 The automatic assembly line for the membrane gas meter movement shown mainly includes the metering case pressure sealing system and the connecting rod assembly system on the same membrane gas meter production line. This application mainly focuses on the above two systems in the existing automatic production line. Optimizing improvements to increase productivity across the production line.

[0051] Wherein the metering shell press-sealing system mainly includes a frame A100, a rotary index plate 110 arranged on the frame A100 and a press-sealing machine 200 corresponding to the rotary index plate 110, the rotary index plate 110 has a The core body positioning seat 120 evenly distributed in the circumferential direction, the rotating index plate 110 in this application is a traditional six-position index plate, each stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com