Patents

Literature

54results about How to "Promote mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

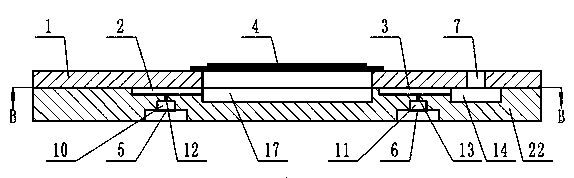

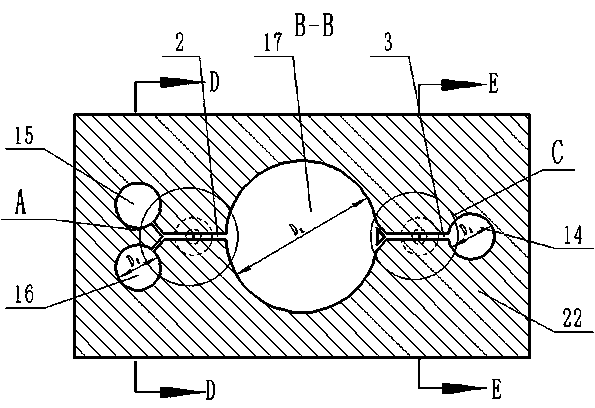

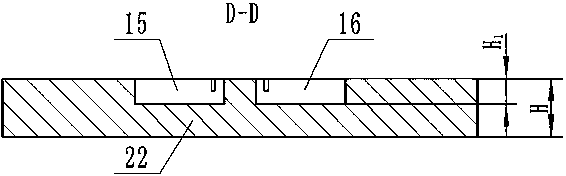

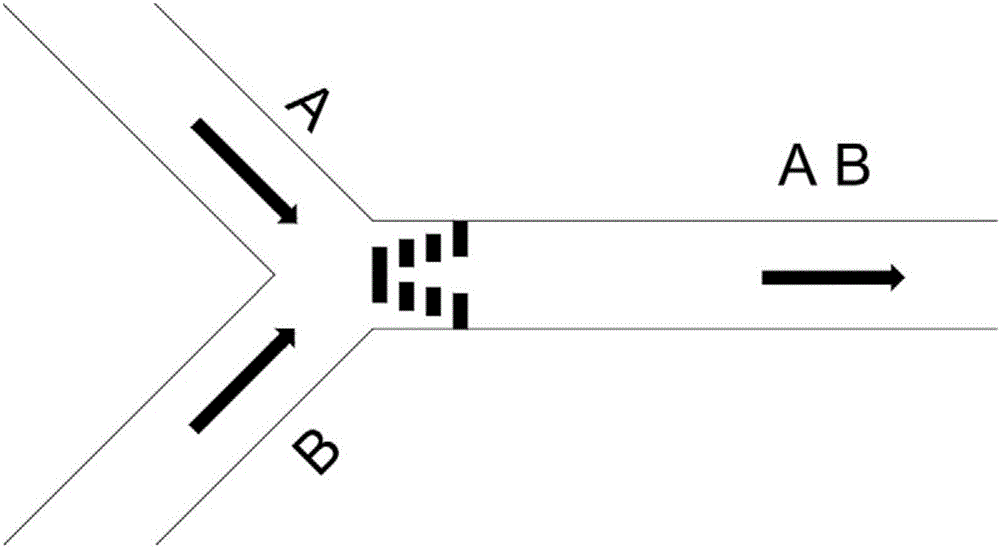

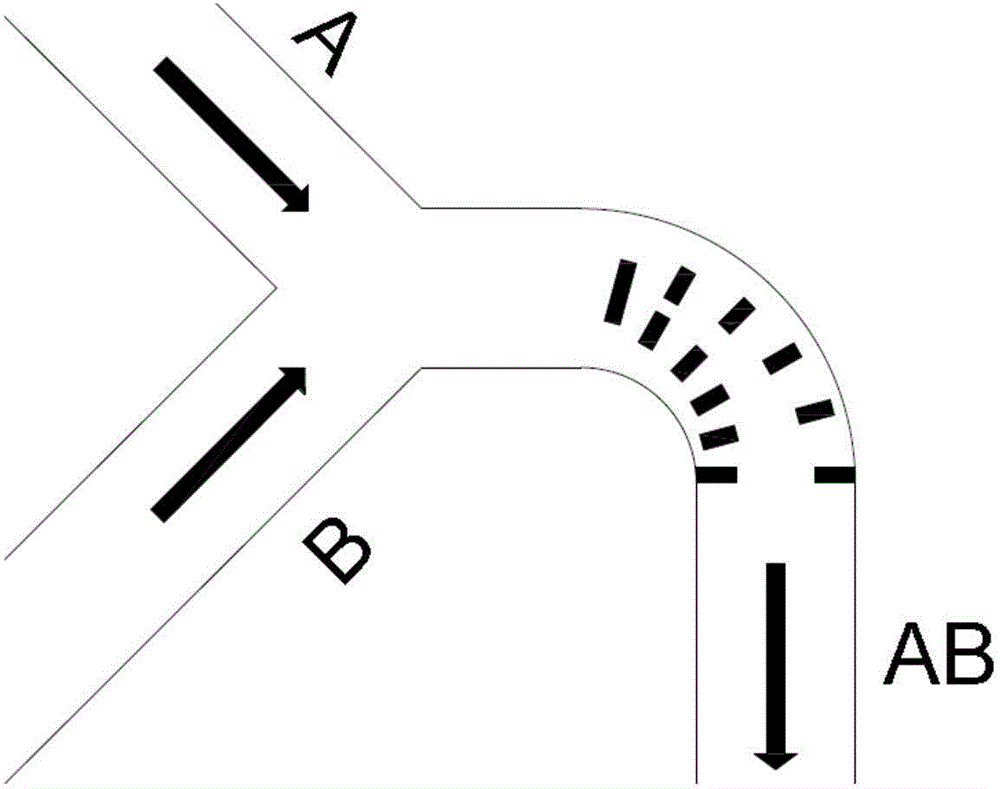

Valveless piezoelectric micromixer for synthesizing jet

The invention discloses a valveless piezoelectric micromixer for synthesizing jet, comprising a pump cover and a pump body which are bonded together, wherein two synthesis jet chambers are communicated with a relative inlet mixing flow path and a outlet mixing flow path, a first piezoelectric vibrator is fixed right above the pump cover, each of a second piezoelectric vibrator and a third piezoelectric vibrator is fixed right below the two synthesis jet chambers respectively, the inlet mixing flow channel and the outlet mixing flow channel are Y-type mixing flow channels each of which is composed of two shunting flow channels and a shunting flow channel, a jet synthesis exciter is arranged on the bottom of the mixing flow channel of the micromixer, fluid flow in the mixing flow channel is interfered by periodically ejecting and absorbing fluid by synthesis jet, and alternating voltage signal applied on the piezoelectric oscillator is regulated to implement large-range controllable mixing of mixed effect and mixed time.

Owner:JIANGSU UNIV

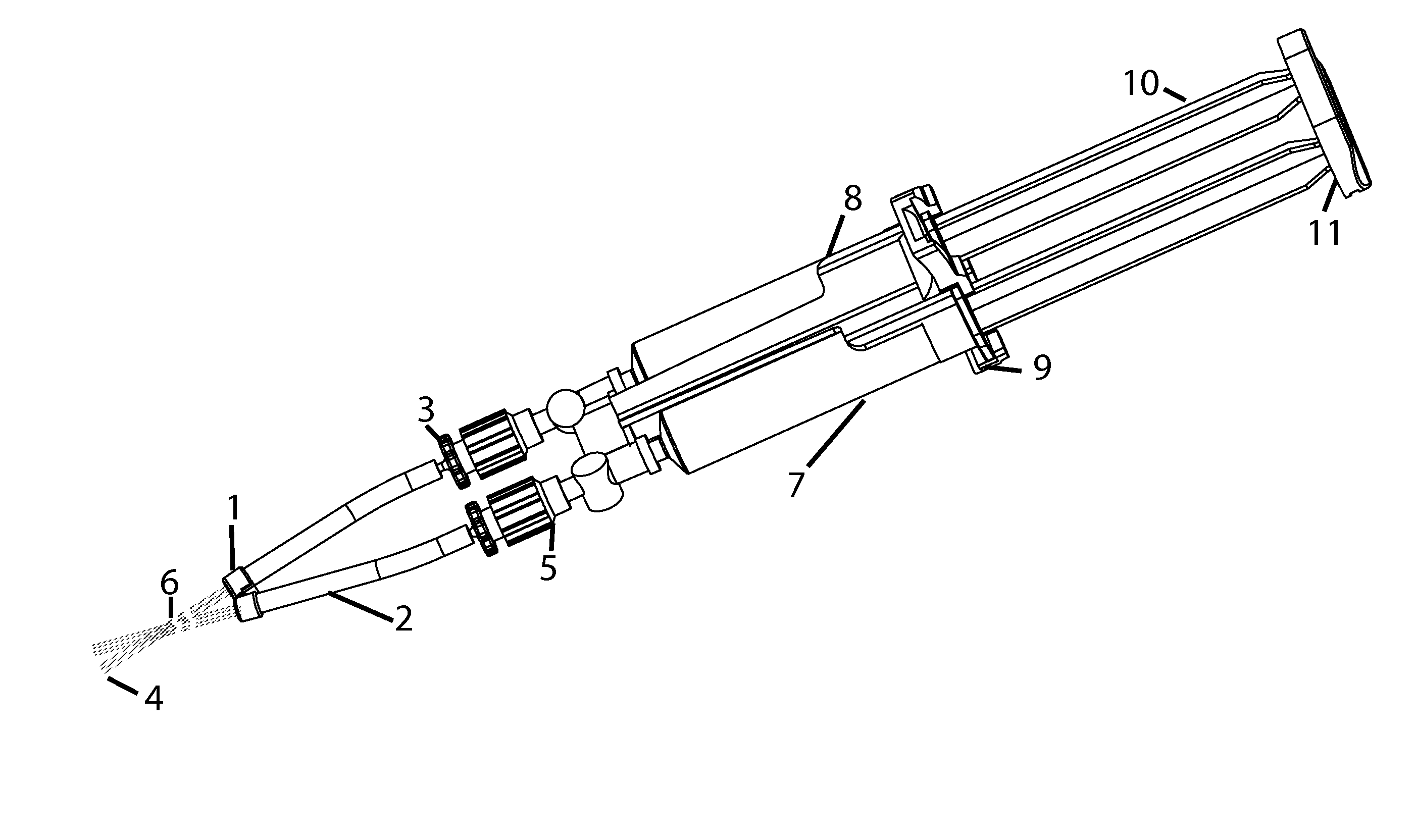

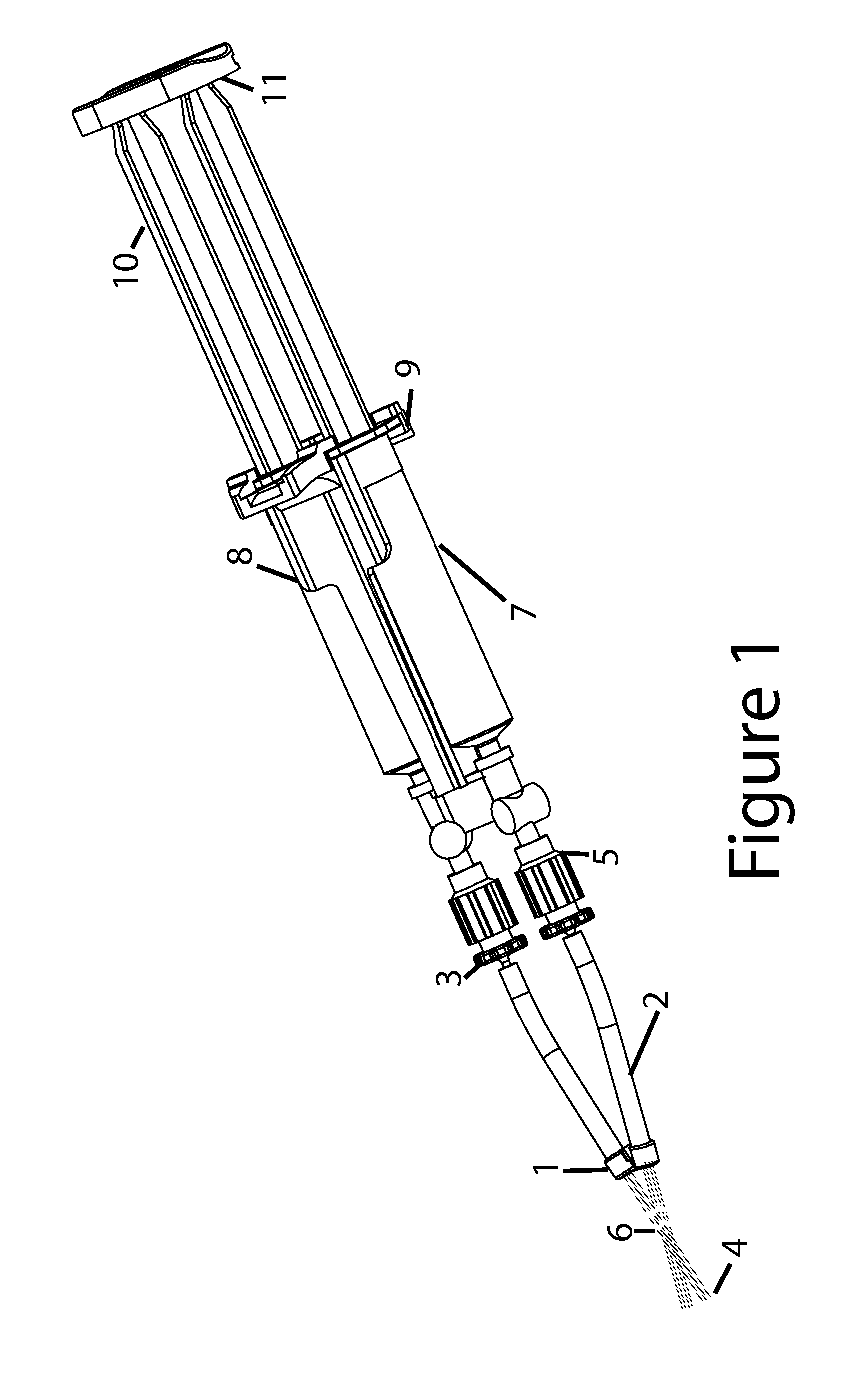

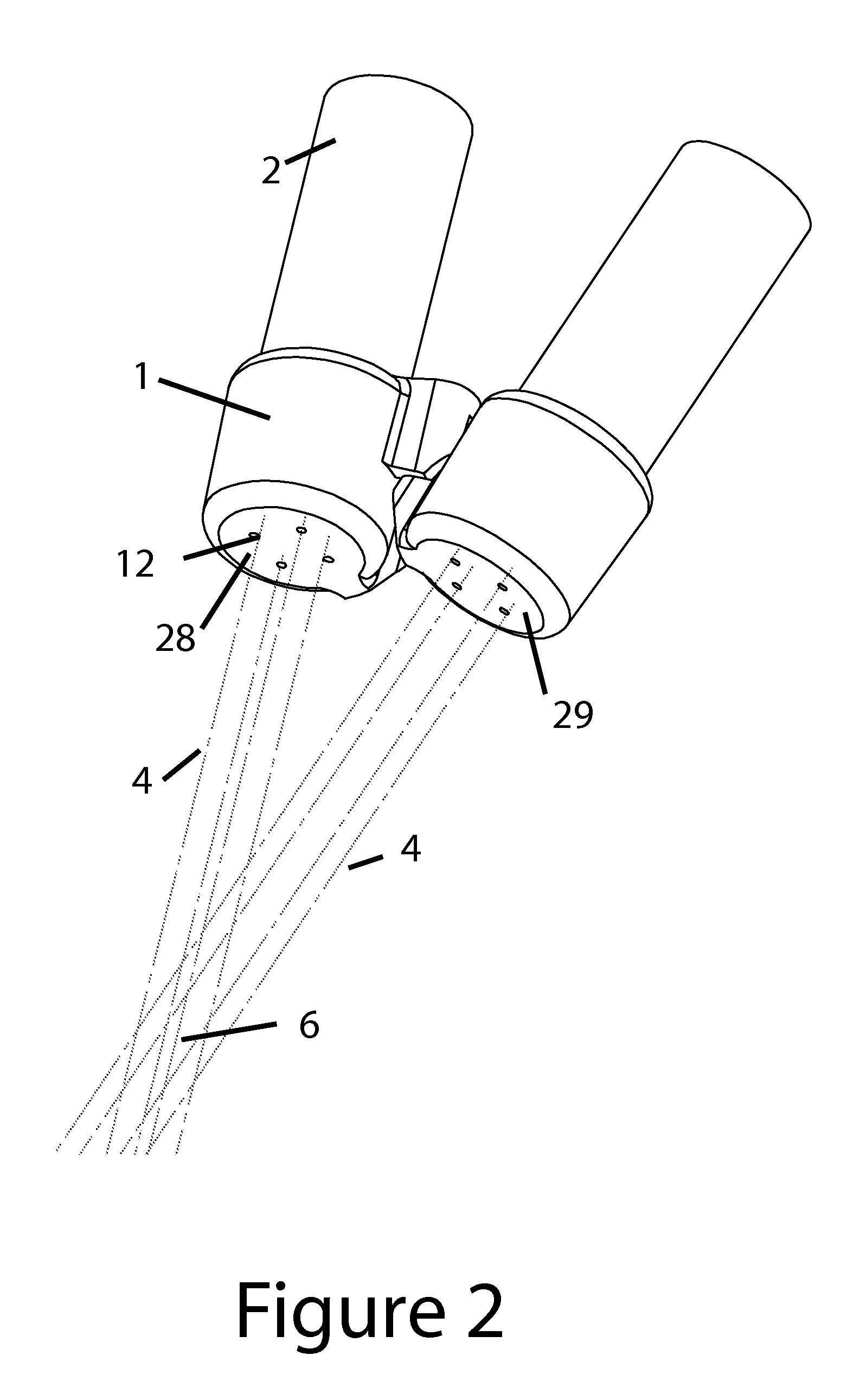

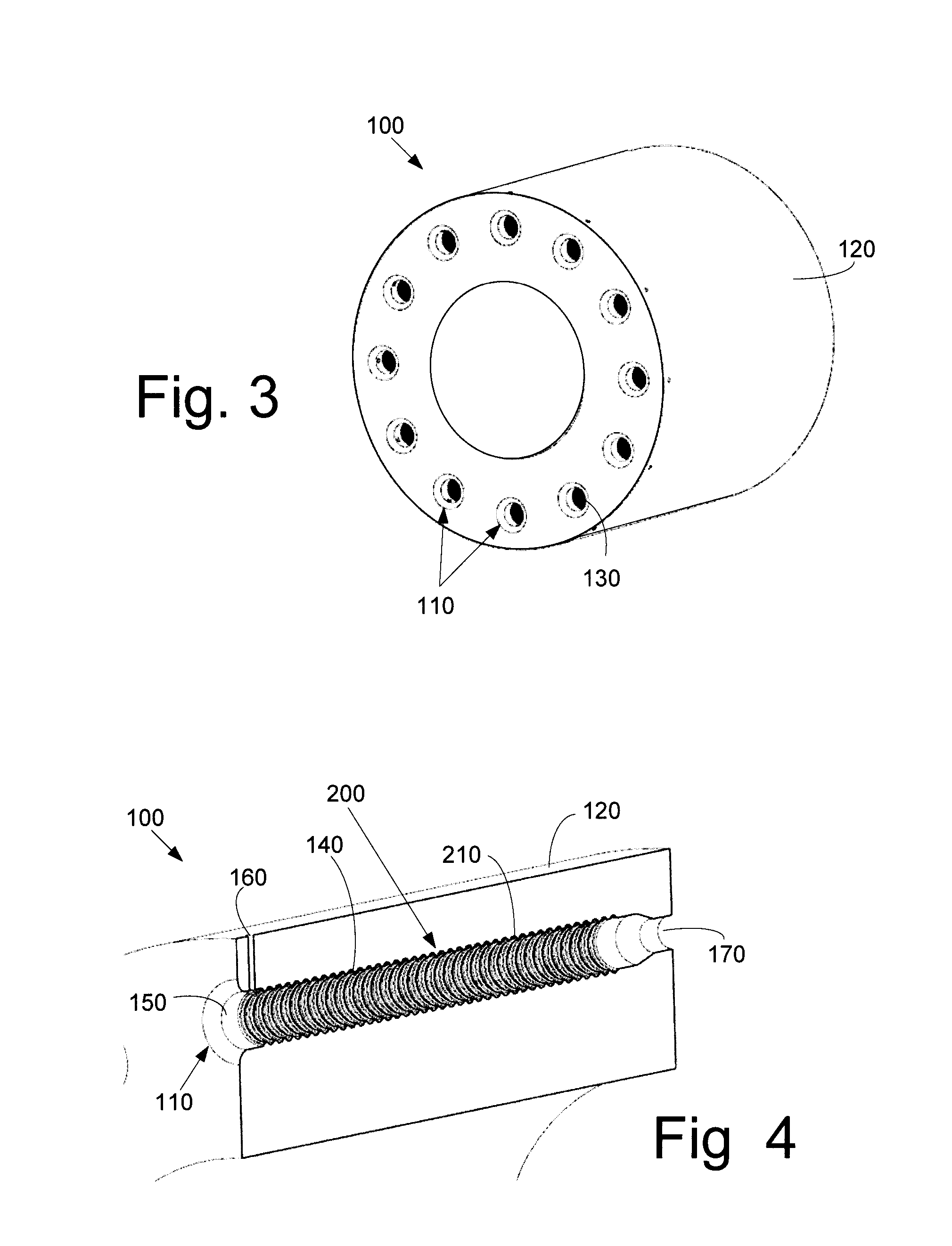

Non-Clogging Airless Spray for High Viscosity, High Surface Tension Fluids

InactiveUS20130325059A1Prevent tip clogPromote mixingLiquid surface applicatorsSpray nozzlesSyringeTissue adhesives

The invention describes a dispensing spray device coupled to a dual syringe device whose outlets terminate in a plurality of small holes of sufficient small size to induce high velocity jets in the fluid exiting each of the holes. The holes in two caps are forced into orientation with respect to each other at an angle governed by the included angle of the two caps. The two fluids exit in a plurality of discrete streams and combine in a shower pattern away from the caps. The liquids are preferably two components of a tissue sealant or tissue adhesive.

Owner:DEVICEGENERICS

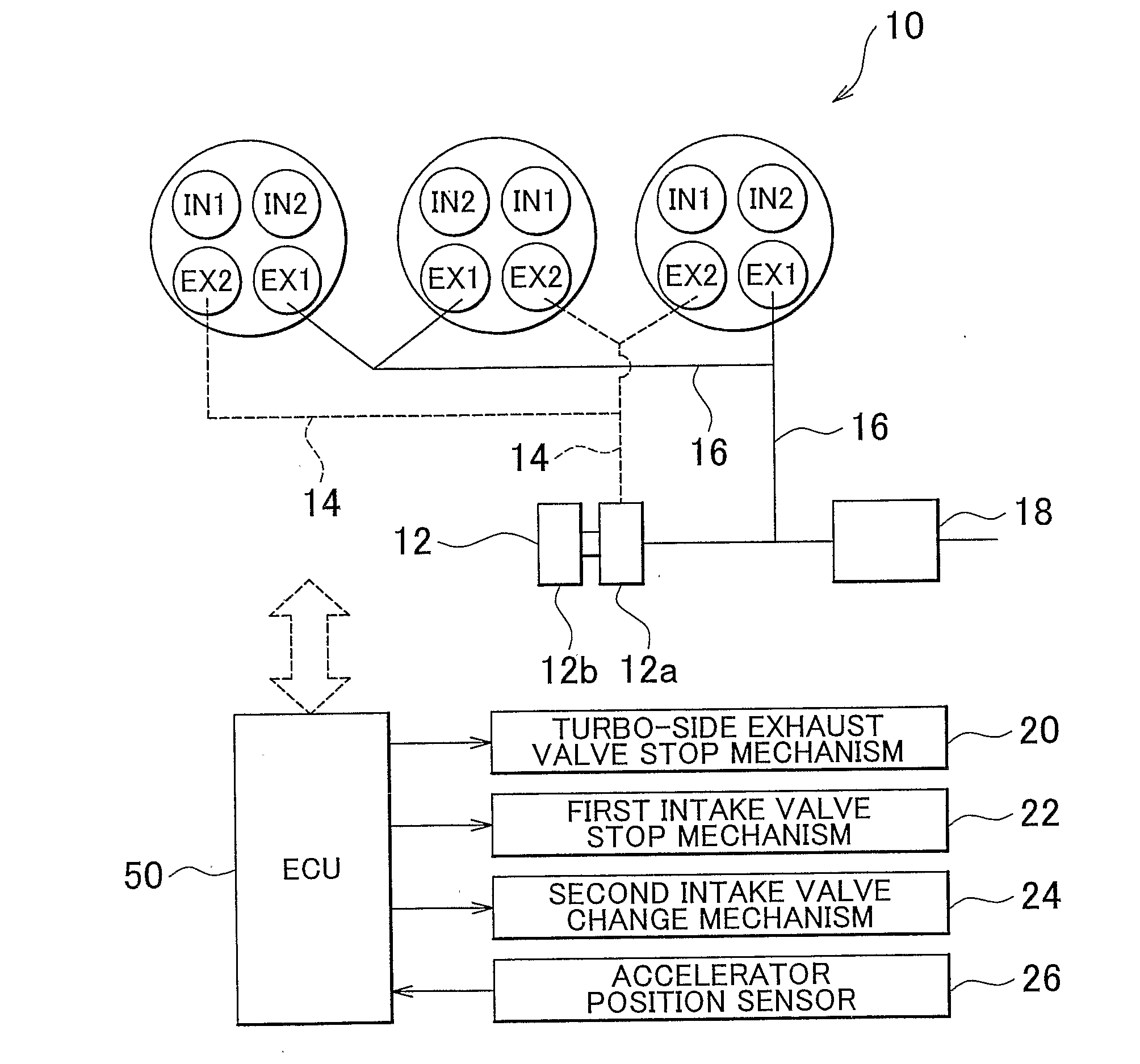

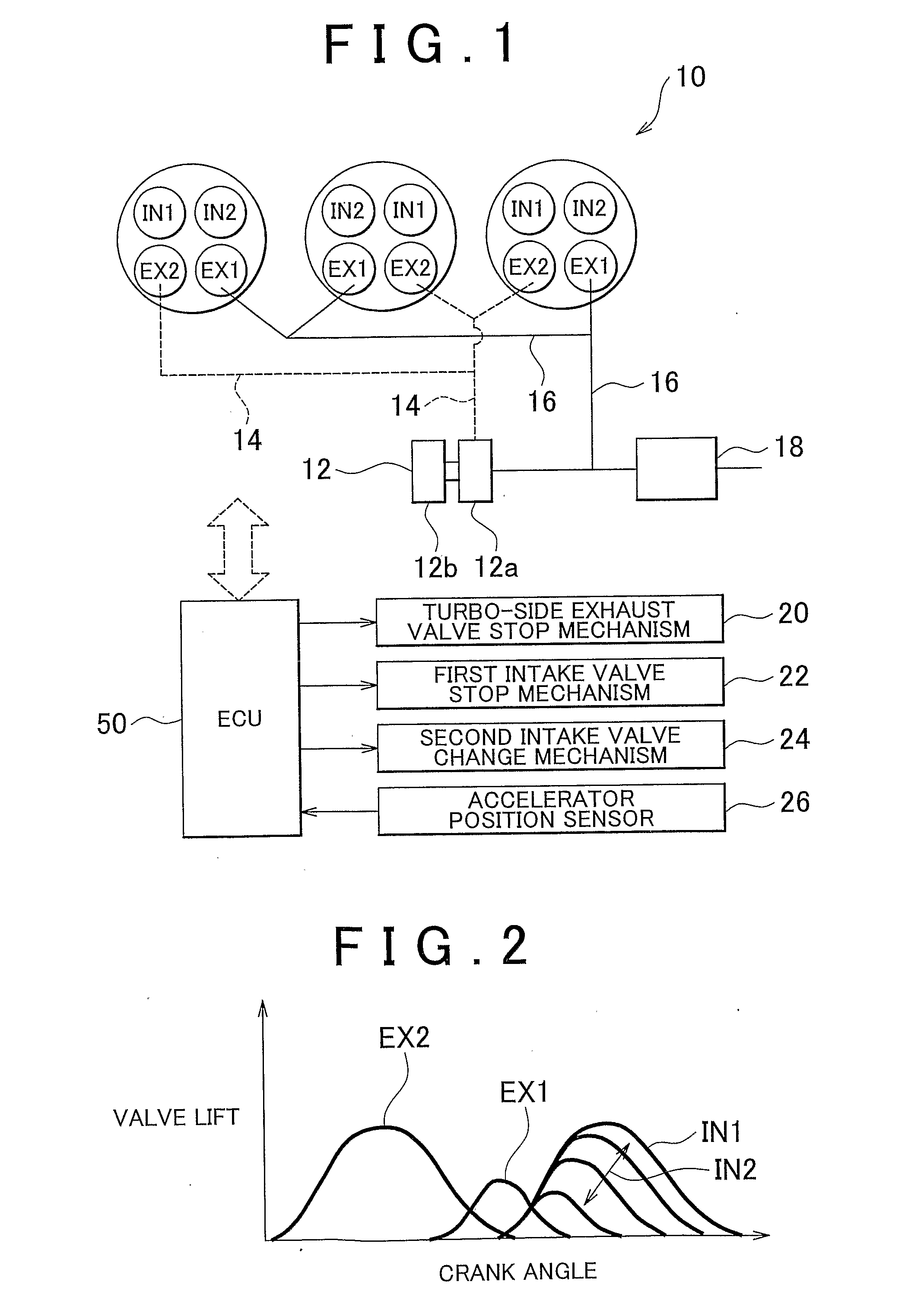

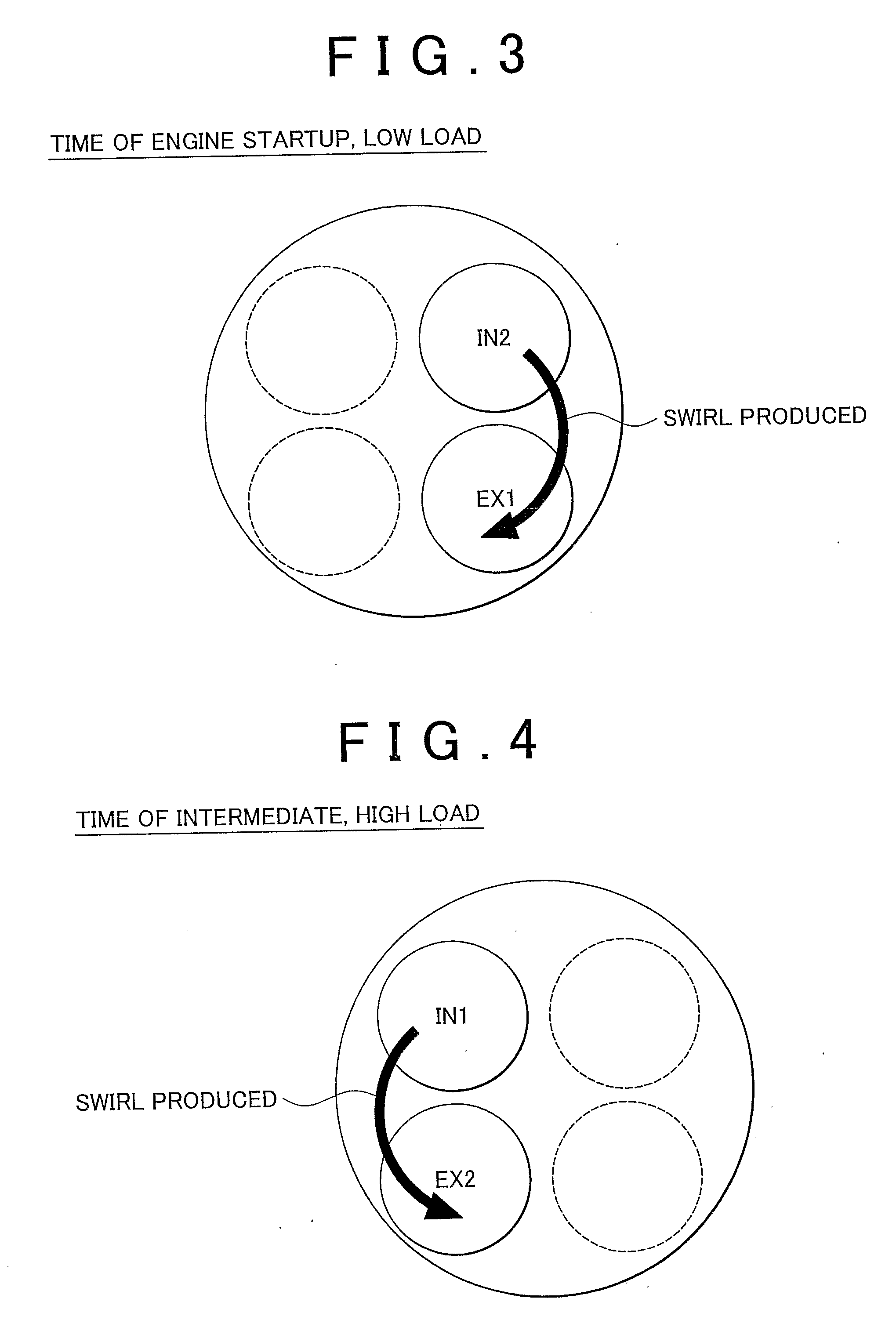

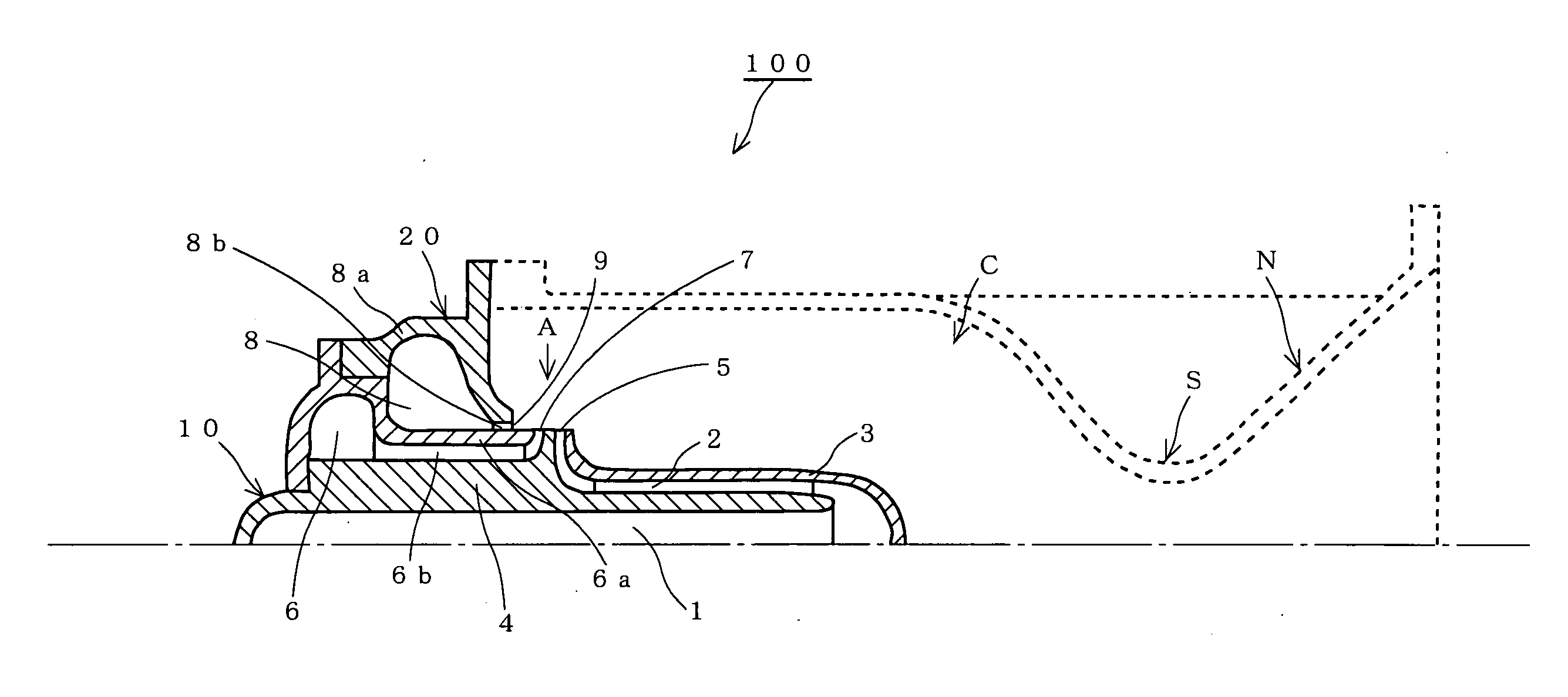

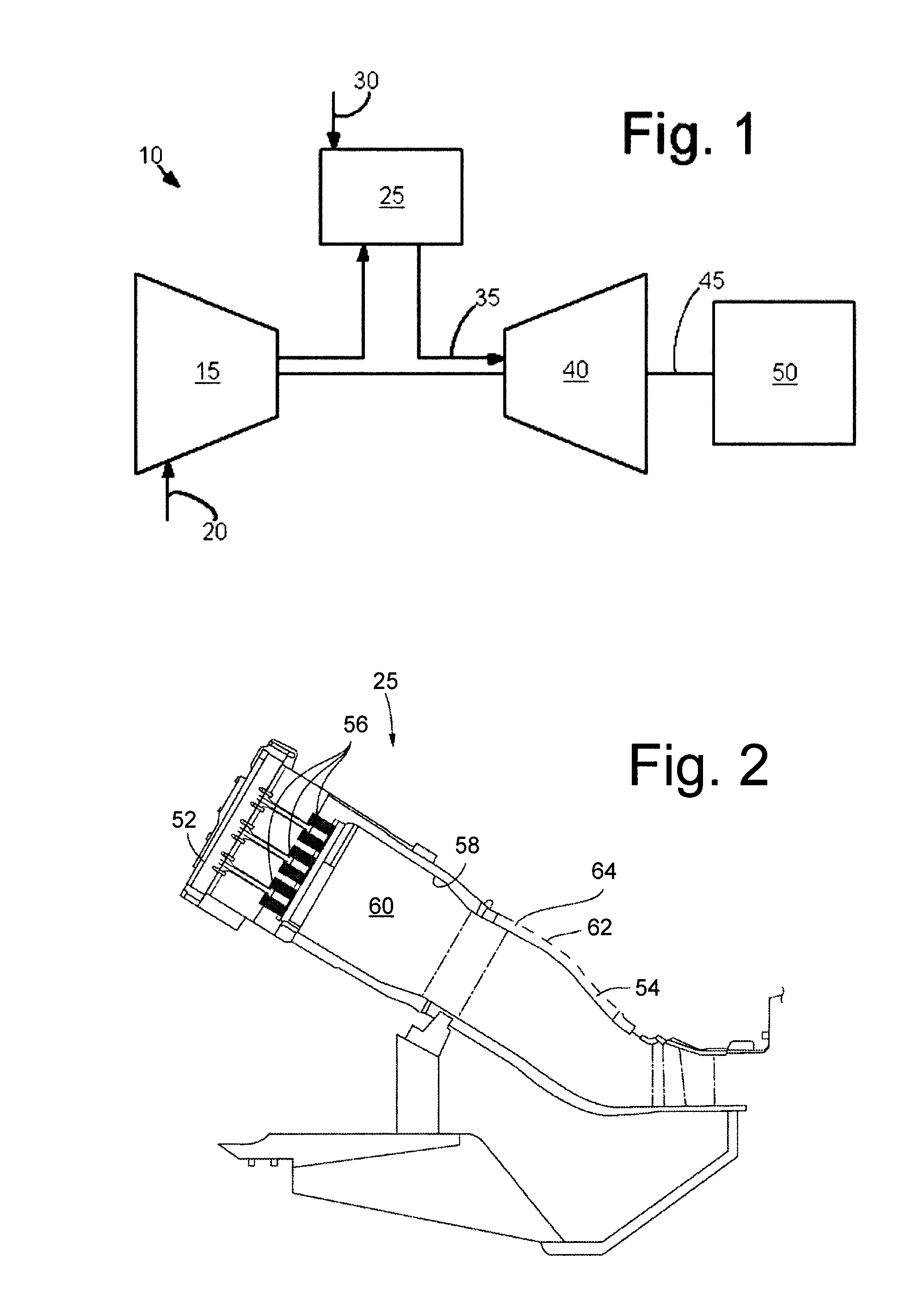

Control device and control method for internal combustion engine

InactiveUS20100192882A1Excellent effectPromote mixingValve arrangementsElectrical controlExternal combustion engineExhaust valve

A cylinder of an internal combustion engine is provided with a turbo-side exhaust valve that opens and closes an exhaust port that communicates with a turbo-side exhaust passageway that leads to a turbine inlet opening of a turbo-supercharger, a bypass-side exhaust valve that opens and closes an exhaust port that communicates with a bypass-side exhaust passageway that bypasses the turbine, a first intake valve disposed opposite to the turbo-side exhaust valve, and a second intake valve disposed opposite to the bypass-side exhaust valve. At the time of engine startup and / or the time of low engine load, the turbo-side exhaust valve and the first intake valve are stopped in the closed state.

Owner:TOYOTA JIDOSHA KK

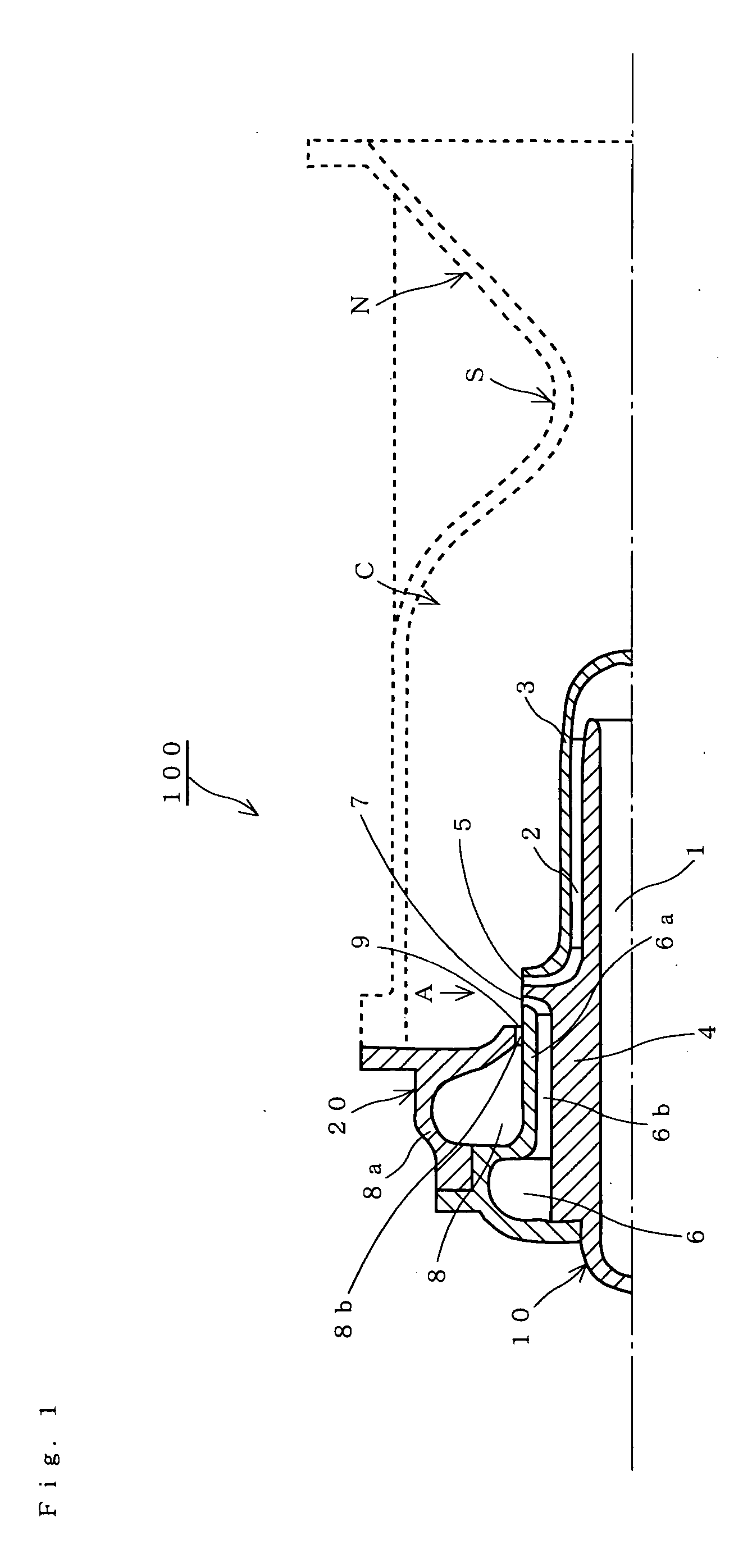

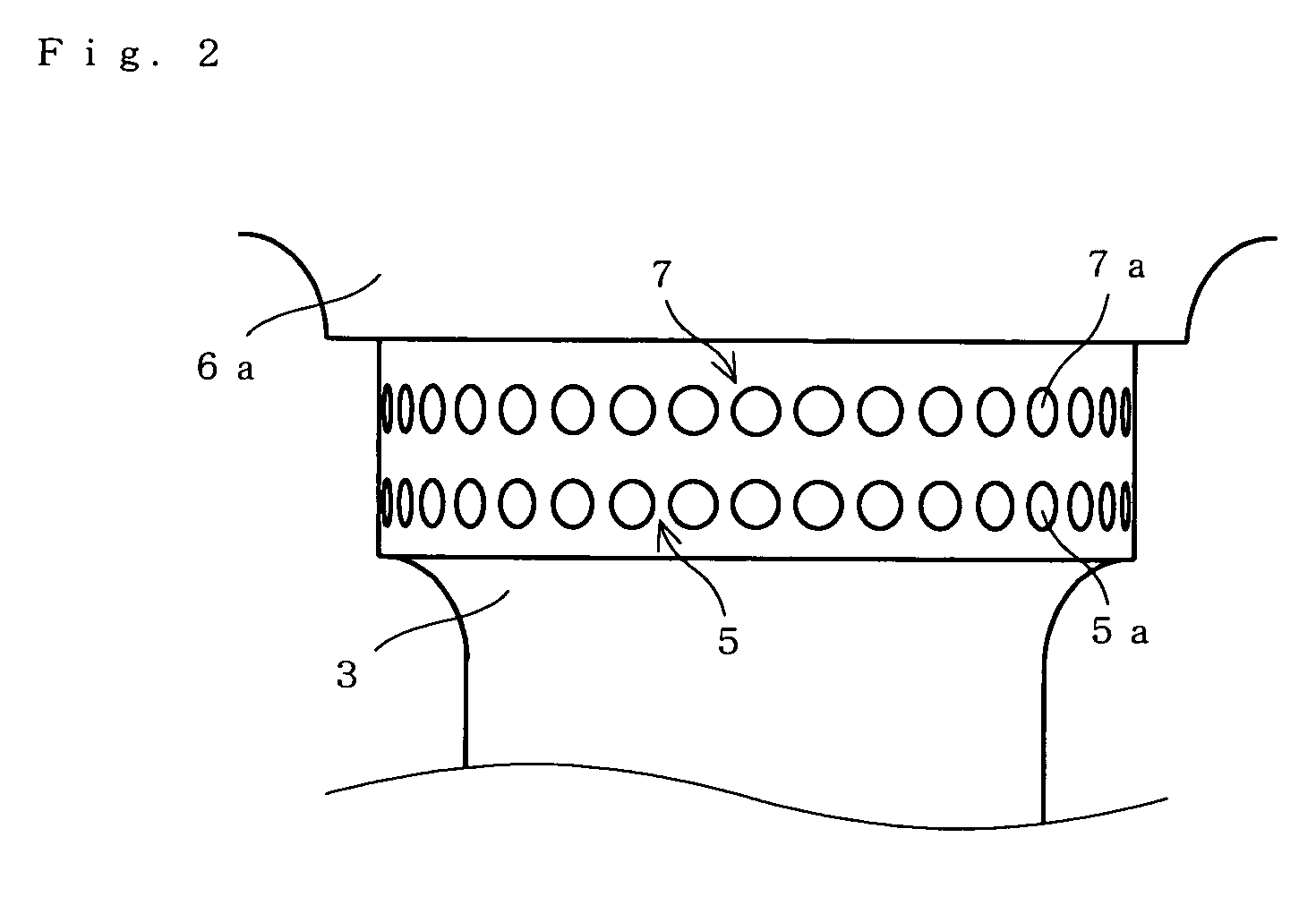

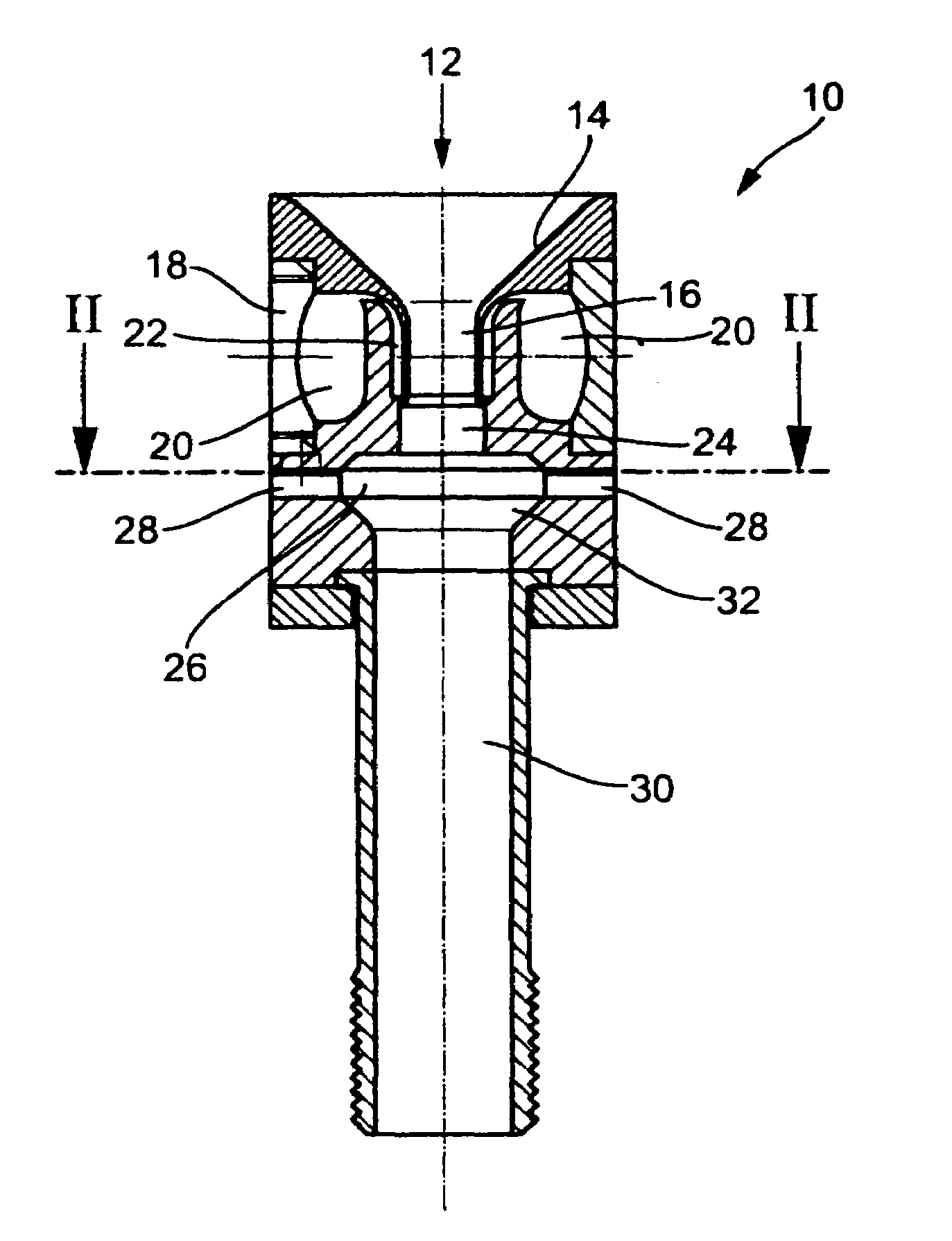

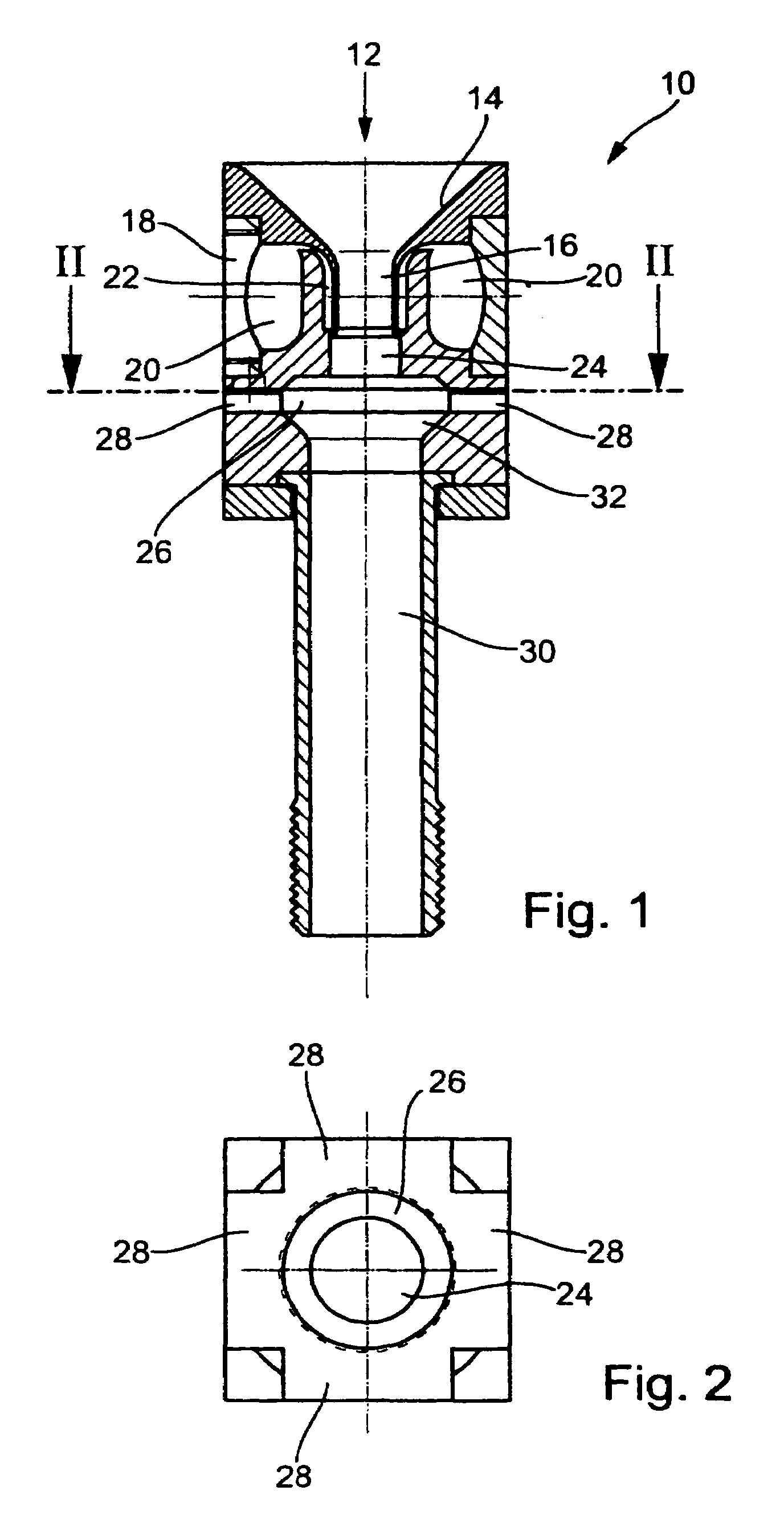

Pintle injector

InactiveUS20060230745A1Atomization mixing be promotePromote mixingBurnersContinuous combustion chamberRegenerative coolingInjector

To provide a simple structured and low cost pintle injector capable of uniformly atomizing and mixing fuel and oxidizer, and further improving the combustion efficiency of the combustion reaction in the combustion chamber. A pintle injector part having a first propellant channel forms a first injector flow path as a regenerative cooling path along the pintle external wall that projects into a combustion chamber, and high temperature fuel gas is injected from the first pintle injector port. On the other hand, an axial injector part is located upstream of the first pintle injector port, and injects comparatively low temperature liquid or gas fuel from an axial injector port via a third propellant channel and a third injector flow path. Oxidizer is injected from a second pintle injector port via a second propellant channel and a second injector flow path, and is atomized and mixed while being impinged on either by the high temperature fuel gas and the comparatively low temperature liquid or gas fuel. The fuel injected from the first pintle injector port and the fuel injected from the axial injector port may be the same type or a different type of fuel.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

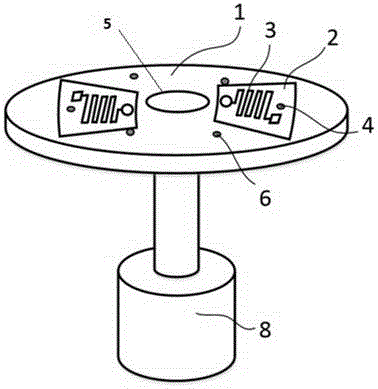

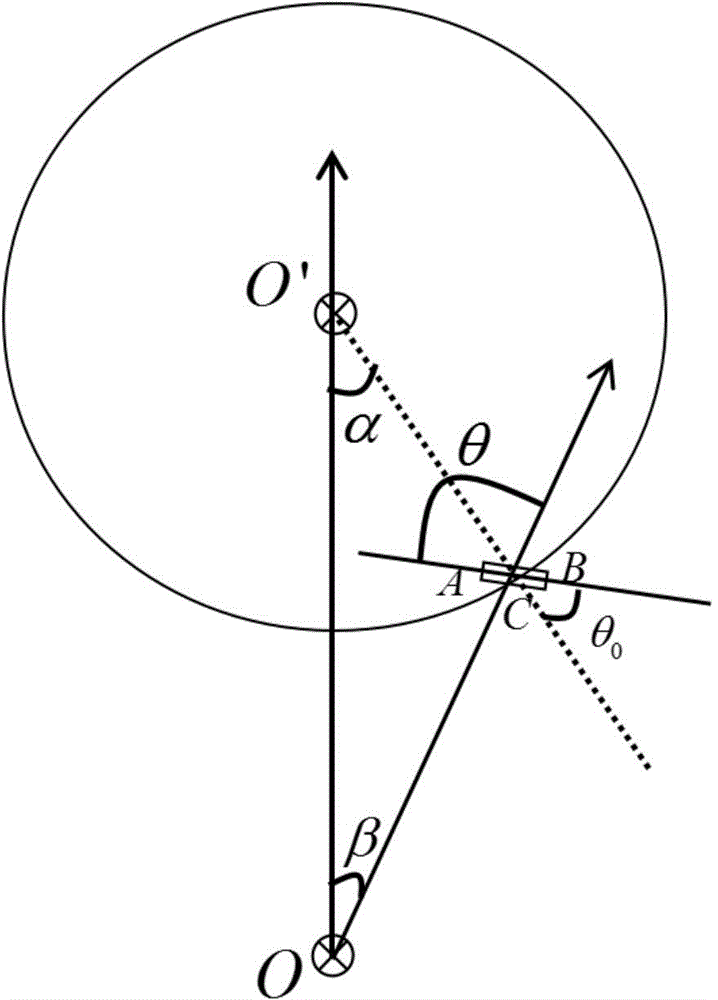

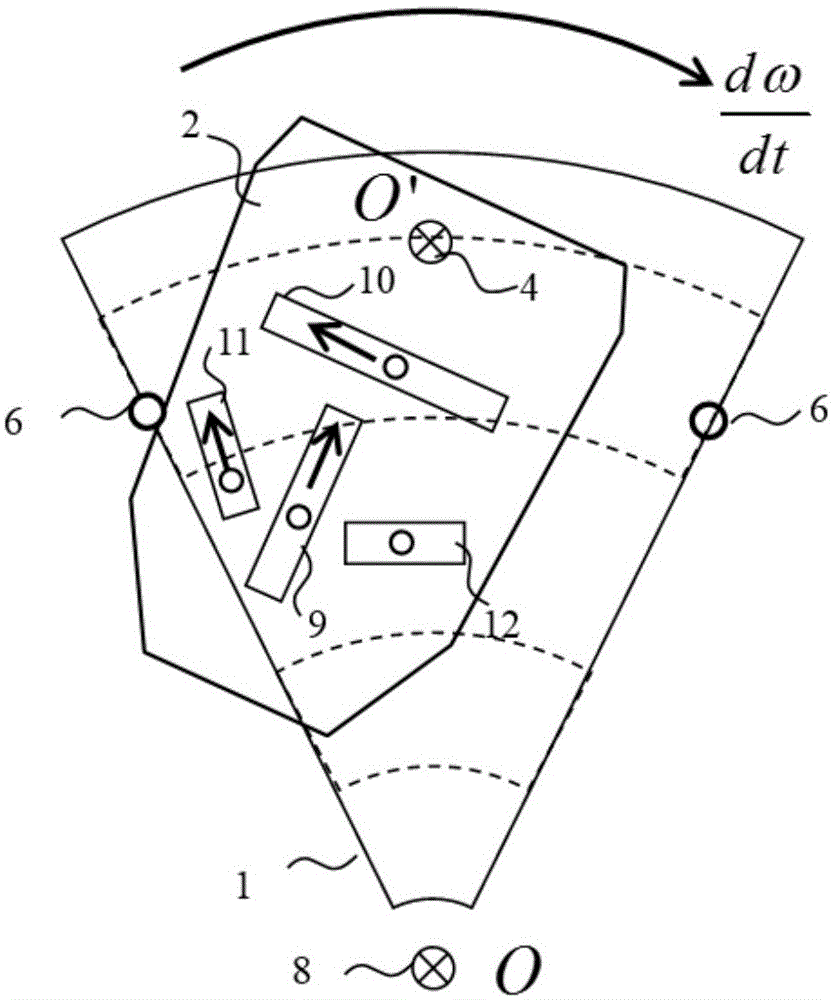

Logical control device of droplet on micro-fluidic chip

ActiveCN104155464AHighly integratedPromote mixingProgramme controlComputer controlMicro fluidicMicrofluidic chip

The invention discloses a logical control device of droplets on a micro-fluidic chip. The logical control device comprises a rotating platform with adjustable rotation speed, a micro-fluidic chip and at least one micro-flow pipes. The micro-flow pipes are S-shaped pipes or Y-shaped pipes. The logical control device also comprises auxiliary rotating shafts and two locking valves. The two locking valves are arranged at two sides of the micro-fluidic chip respectively. When the micro-fluidic chip rotates around the auxiliary rotating shafts, the micro-fluidic chip is locked on two states by the locking valves and adjusts included angles between micro-flow pipe directions and radial directions of the rotating platform through rotation acceleration of the rotating platform, so as to change droplet flow directions in the micro-flow pipes. The logical control device can control bi-directional flow of the droplets in the micro-flow pipes; and by introducing a binary logical control method, flow of the droplets in the micro-flow pipes can be controlled by using periodical timing sequence information, thereby mixing, reacting and detecting experimental samples more conveniently and quickly.

Owner:南京碟光生物科技有限公司

Low NOx fuel gas burner based on venturi tubes

InactiveCN103486572AReduce NOx formationPromote mixingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermal insulationEngineering

The invention disclose a low NOx fuel gas burner based on venturi tubes, which comprises a burner body, primary burners, secondary burners, a thermal insulation tile and the venturi tubes, wherein a first passage and a second passage are arranged on the thermal insulation tile; the thermal insulation tile is connected with the burner body; the first passage is communicated with a cavity of the burner body; necking mouths are formed in the first passage; primary fuel injection nozzles and secondary fuel injection nozzles are respectively arranged at the top ends of the primary burners and the secondary burners; the venturi tubes and the primary burners are arranged in the first passage; the secondary burners are arranged in the second passage; the top end surfaces of the primary fuel injection nozzles and the top end surfaces of the venturi tubes are parallel, and are arranged in the first passage respectively. Through the adoption of the design of the hierarchic arrangement of the venturi tubes, the necking mouths and the burners, the problem that local high temperature produced in a conventional fuel gas burner due to the nonuniform mixing of the fuel gas and combustion air in a furnace chamber can be overcome, meanwhile the flame stability of the burner is improved, and the generating of NOx is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

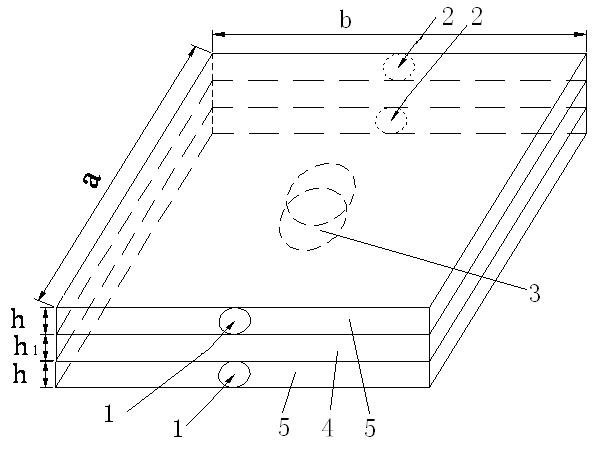

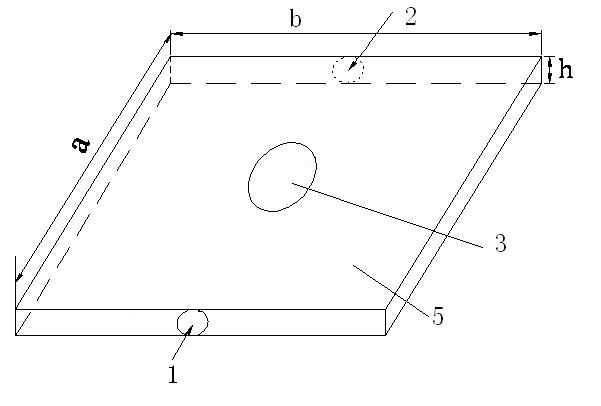

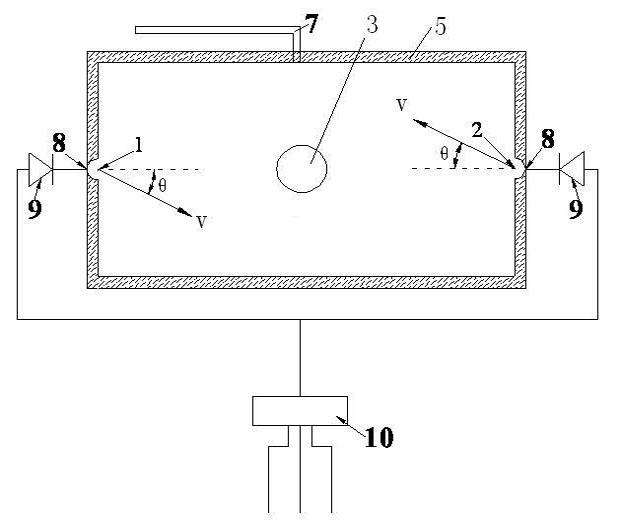

A double-nozzle flat-plate micro-combustion chamber based on hydrocarbon fuel

InactiveCN102278741AAchieve diffusivityPromote mixingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelExhaust gasCombustion chamber

The invention relates to the fields of micro-combustion and novel energy utilization, and relates to a double-nozzle flat type micro-combustion chamber based on hydrocarbon fuel. The double-nozzle flat type micro-combustion chamber comprises two same-structured cubic micro-combustion chambers. An outlet is arranged in the center of an upper surface of each micro-combustion chamber. A left inlet and a right inlet are arranged on the center of two opposite sidewalls of each micro-combustion chamber. The micro-combustion chambers are piled along a height direction with a clearance, and the outlets of the micro-combustion chambers are positioned face to face. The clearance between the two micro-combustion chambers forms a tail gas discharging cavity. An inlet incidence angle theta formed by a velocity direction of a fuel inlet and a central axis direction of the left inlet and the right inlet is 18 to 22 DEG. With the double-nozzle flat type micro-combustion chamber, spaces in micro-combustion chambers are fully utilized, large-flow high-efficiency combustion is realized in micro-scaled chambers, diffusivity of combustion is realized, combustion can be carried out with a relatively low flow, a limitation scope of micro-scaled combustion is improved, and combustion chamber apparatus can be further minimized.

Owner:JIANGSU UNIV

Method of Separating and Purifying Nucleic Acid

InactiveUS20080113356A1Promote recoveryPromote mixingSugar derivativesMicrobiological testing/measurementSolventSolid phases

A method for separating and purifying a nucleic acid comprising steps of: (1) adding a lysis solution to a biomaterial to prepare a sample solution containing a nucleic acid, and adding a water-soluble organic solvent or a solution containing a water-soluble organic solvent to the sample solution thereby preparing a sample solution containing the water-soluble organic solvent; (2) contacting the sample solution containing the water-soluble organic solvent with a solid phase thereby adsorbing the nucleic acid on the solid phase; (3) contacting a washing solution with the solid phase thereby washing the solid phase in a state where the nucleic acid is adsorbed on the solid phase; and (4) contacting a recovering solution with the solid phase thereby desorbing the nucleic acid from the solid phase, wherein, in the step (1), the water-soluble organic solvent or the solution containing the water-soluble organic solvent is added separately in at least two batches.

Owner:FUJIFILM CORP

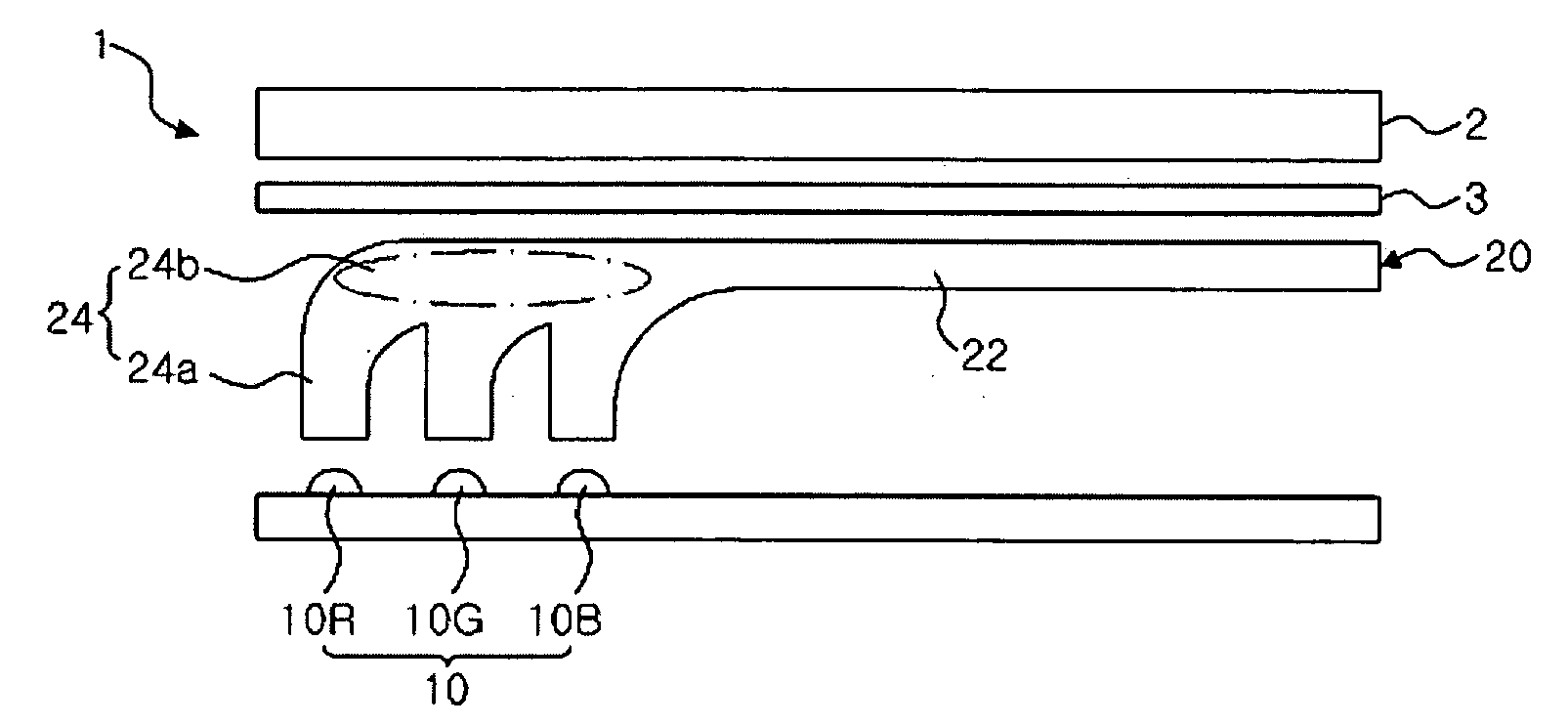

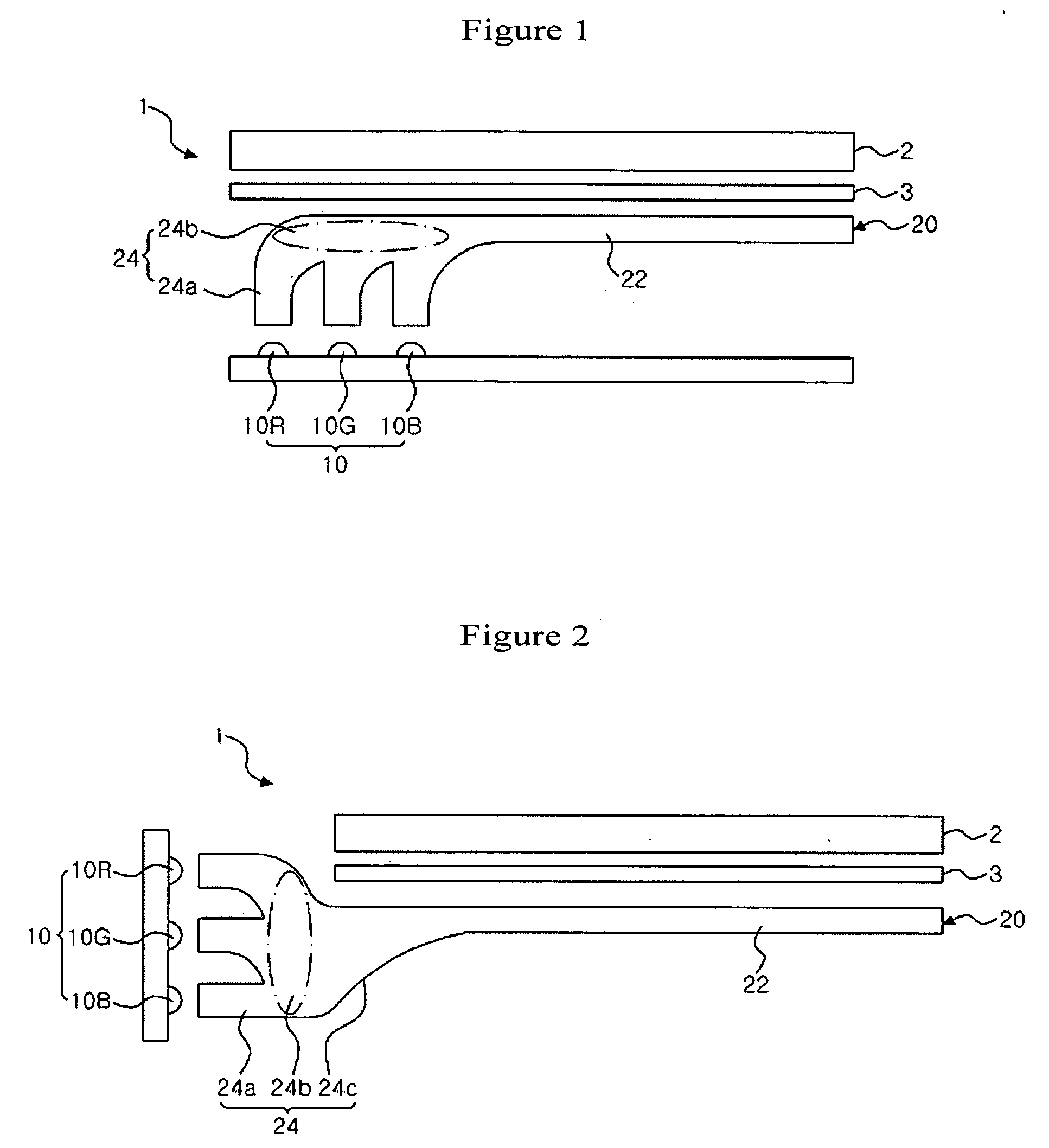

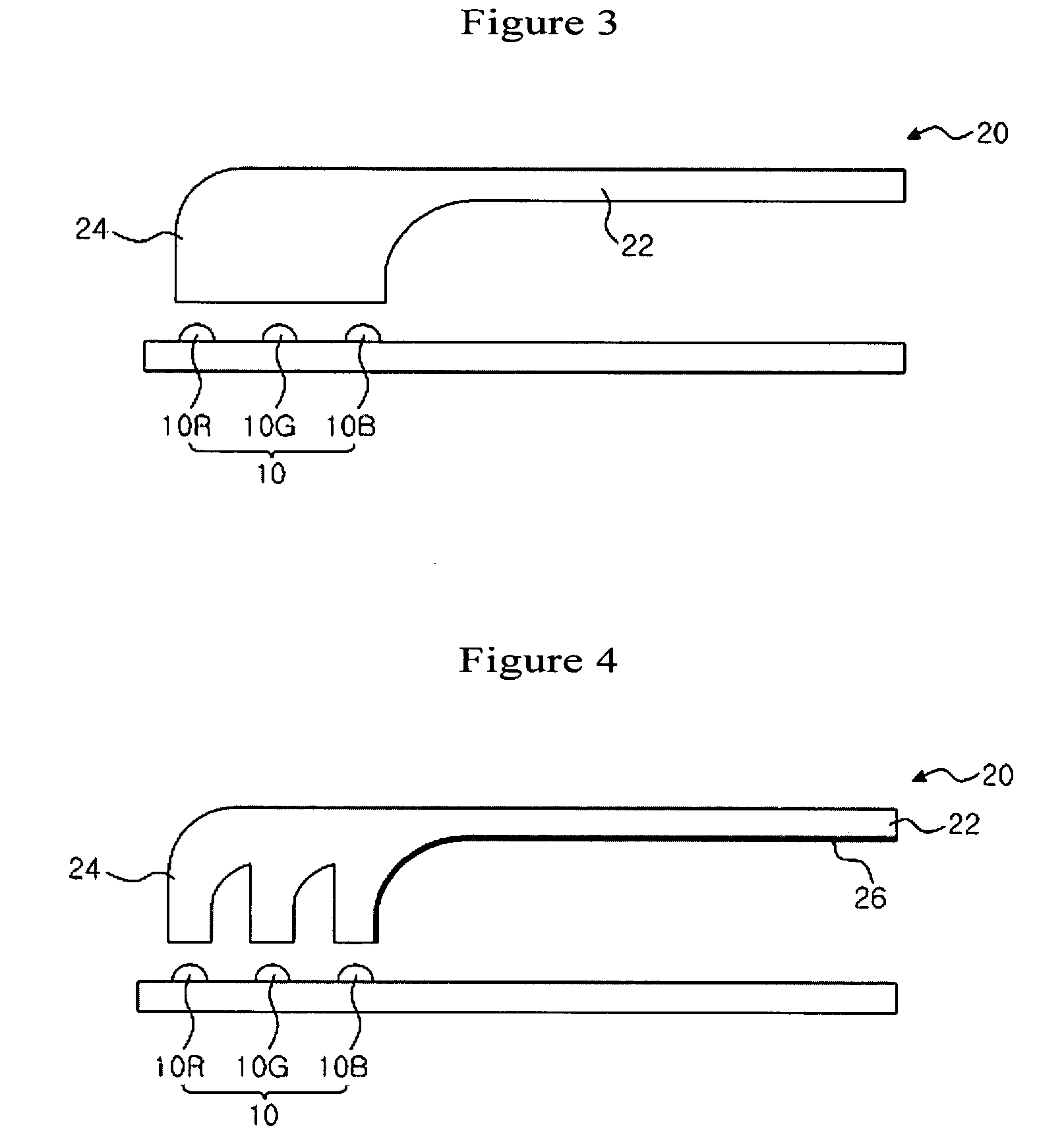

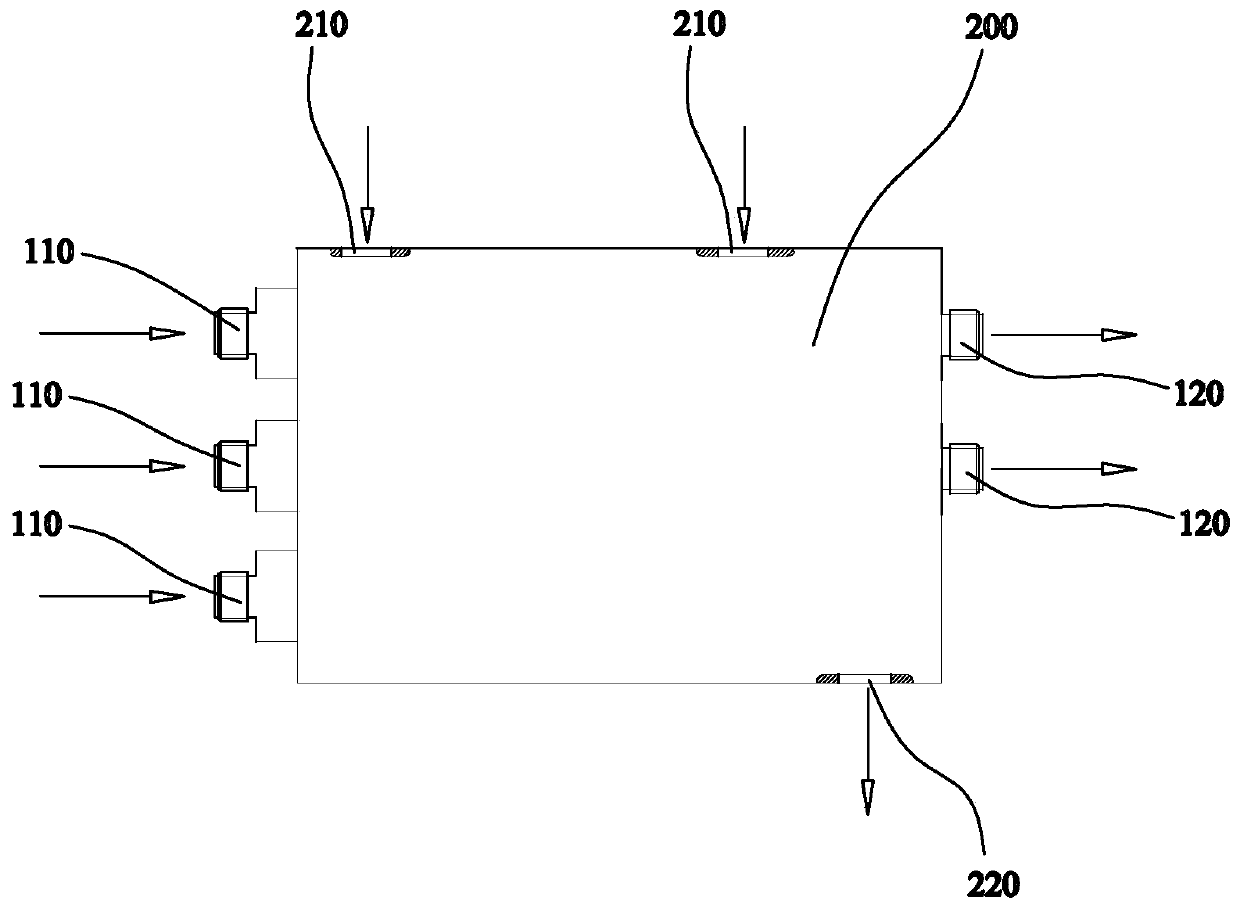

Light Guide Device and Back Lighting Module Comprising the Same

InactiveUS20090003015A1Promote mixingCompact displayPlanar/plate-like light guidesNon-linear opticsColored lightLight guide

A light guide device is used in a back light module that more uniformly mixes different colored light emitted from a plurality of LEDs and transfers the mixed light to a display panel, wherein a light loss can be minimized during the light mixing process and the light can be more uniformly mixed. A light guide device is disclosed for mixing different colored light emitted from a plurality of light emitting diodes (LEDs) and guiding the mixed light to a display panel, wherein the light guide device comprises a light guide portion in the form of a plate arranged at a rear of the display panel; and a light mixing portion formed integrally with the light guide portion and including a light incidence surface adjacent to the plurality of LEDs and a light mixing area for mixing the light with difference colors incident through the light incidence surface.

Owner:SEOUL SEMICONDUCTOR

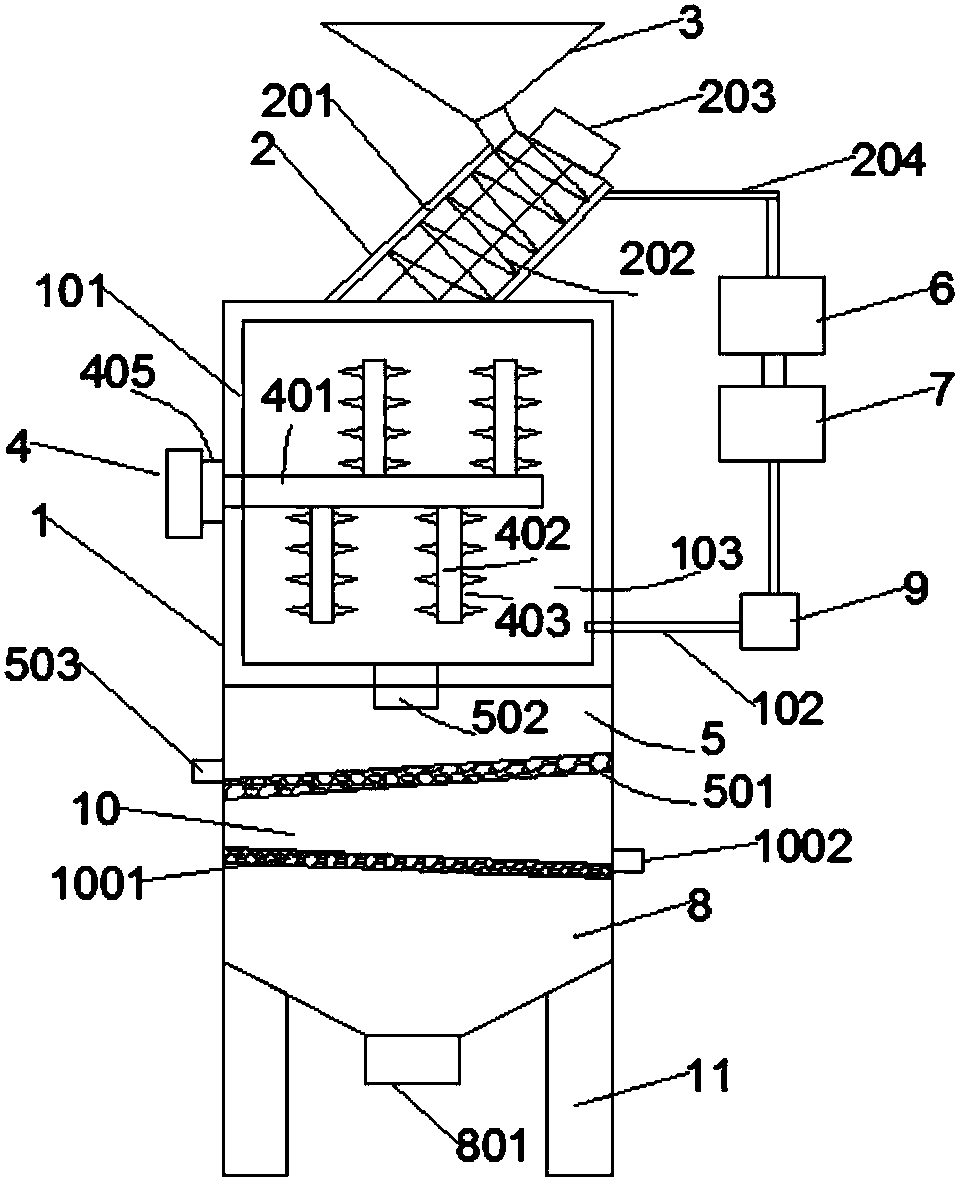

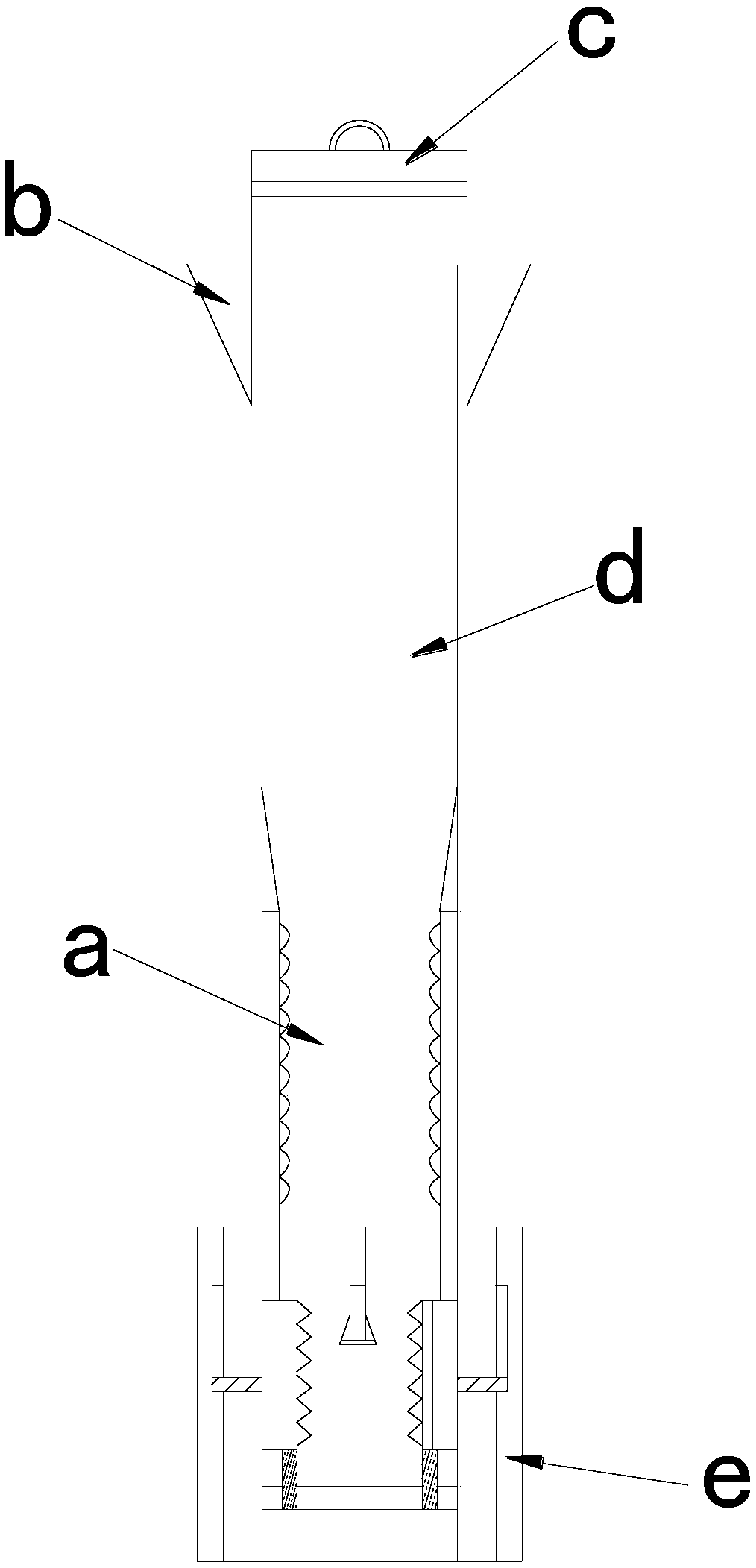

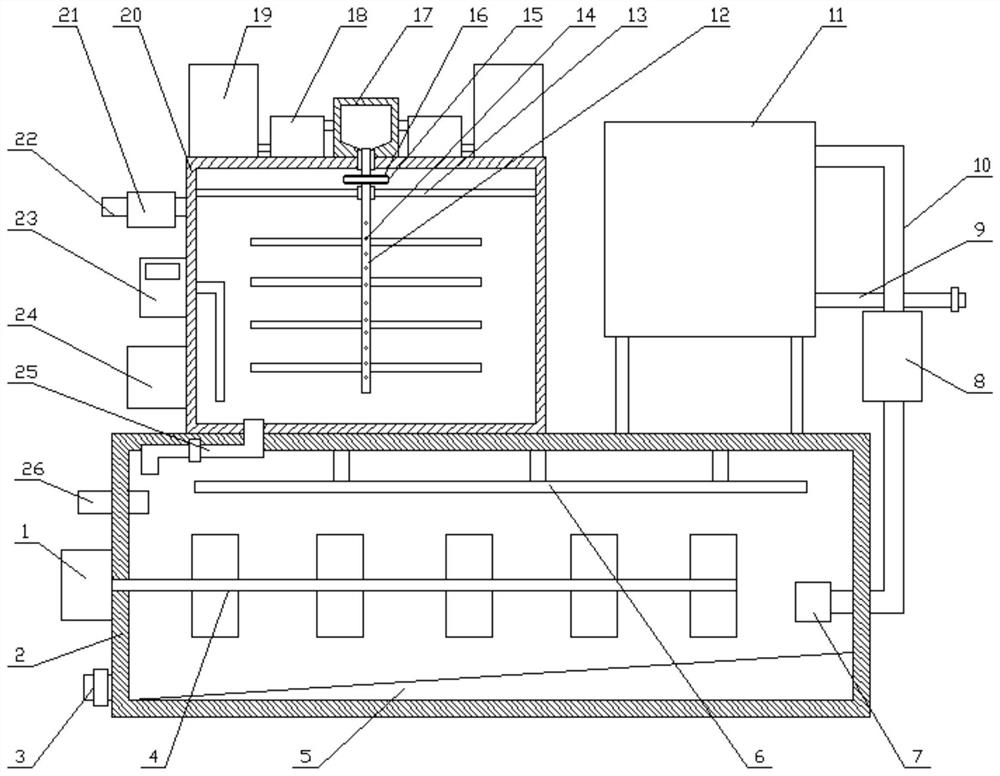

Feed mixing and filtering device

InactiveCN107837709APromote mixingExpand the scope of useFeeding-stuffRotary stirring mixersProcess engineeringMixed feed

The invention discloses a feed mixing and filtering device. The feed mixing and filtering device comprises a material feeding device, a mixing device, a first separating cavity, a second separating cavity and a material storage bin which are sequentially arranged from top to bottom, wherein the mixing device is provided with a mixing chamber; a transverse stirring device is arranged in the mixingchamber; an inclined coarse filter net is arranged at the bottom part of the first separating cavity; the first separating cavity is provided with an impurity outlet; an inclined fine filter net is arranged at the bottom part of a second separating cavity; a coarse particle outlet is arranged on the second separating cavity; a mixture outlet and a support column are arranged at the bottom part ofthe material storage bin. By adopting the scheme, the feed mixing and filtering device has the advantage that the mixed feed is filtered by two stages, so that the impurities can be removed, the large-size particle feed and the small-size particle feed can be separated, the quality of the feed is higher, and the requirements are met.

Owner:成都元始信息科技有限公司

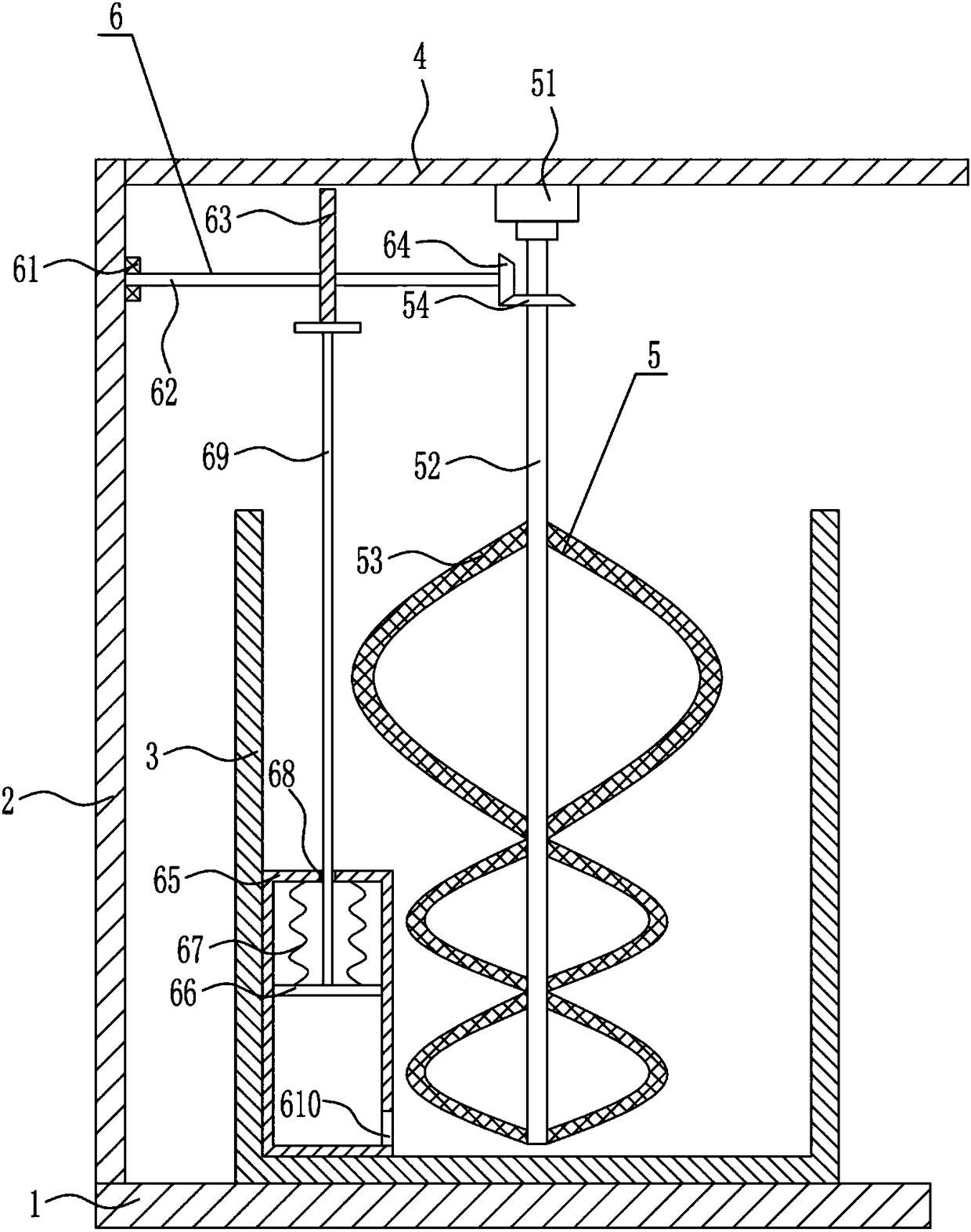

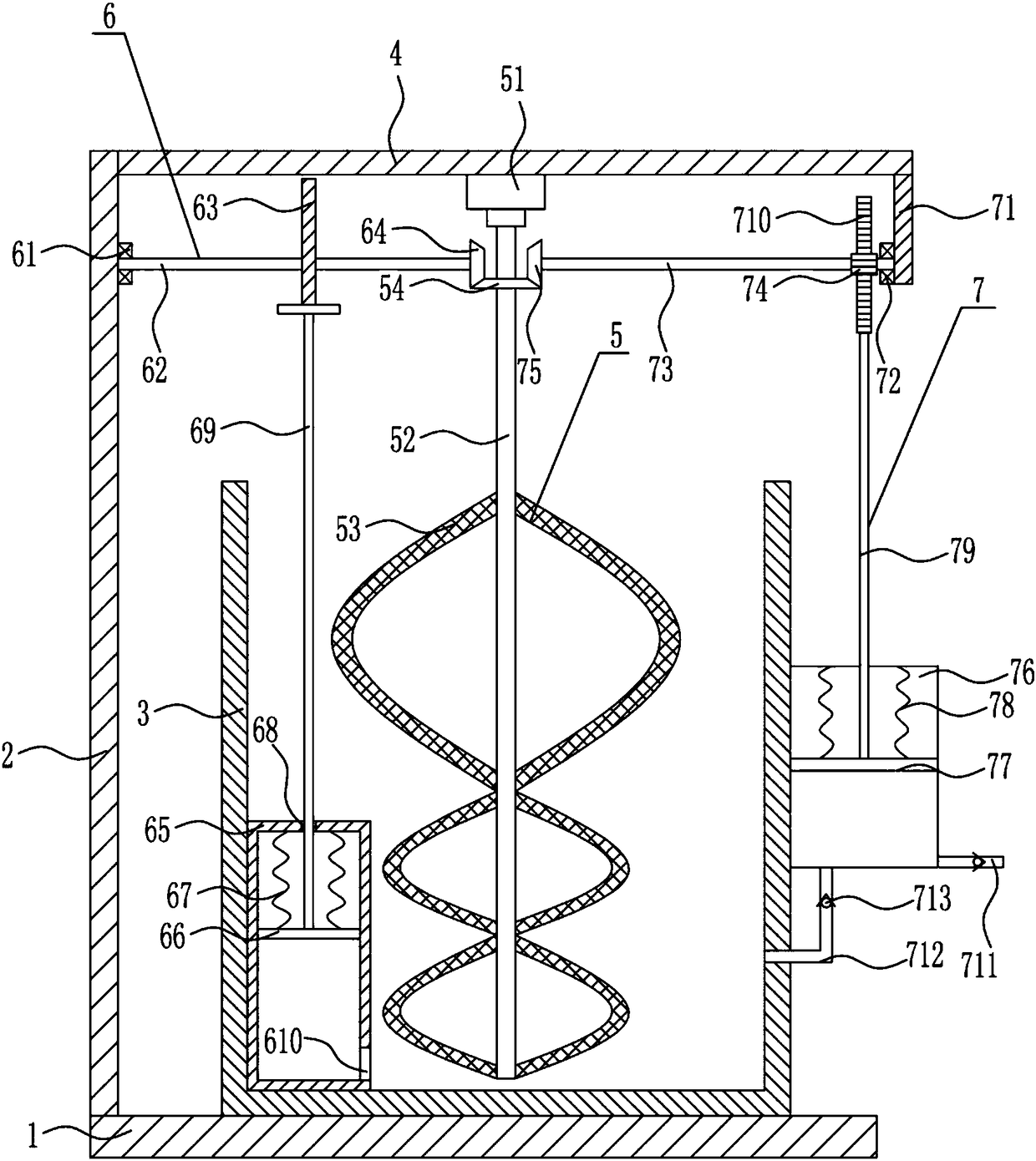

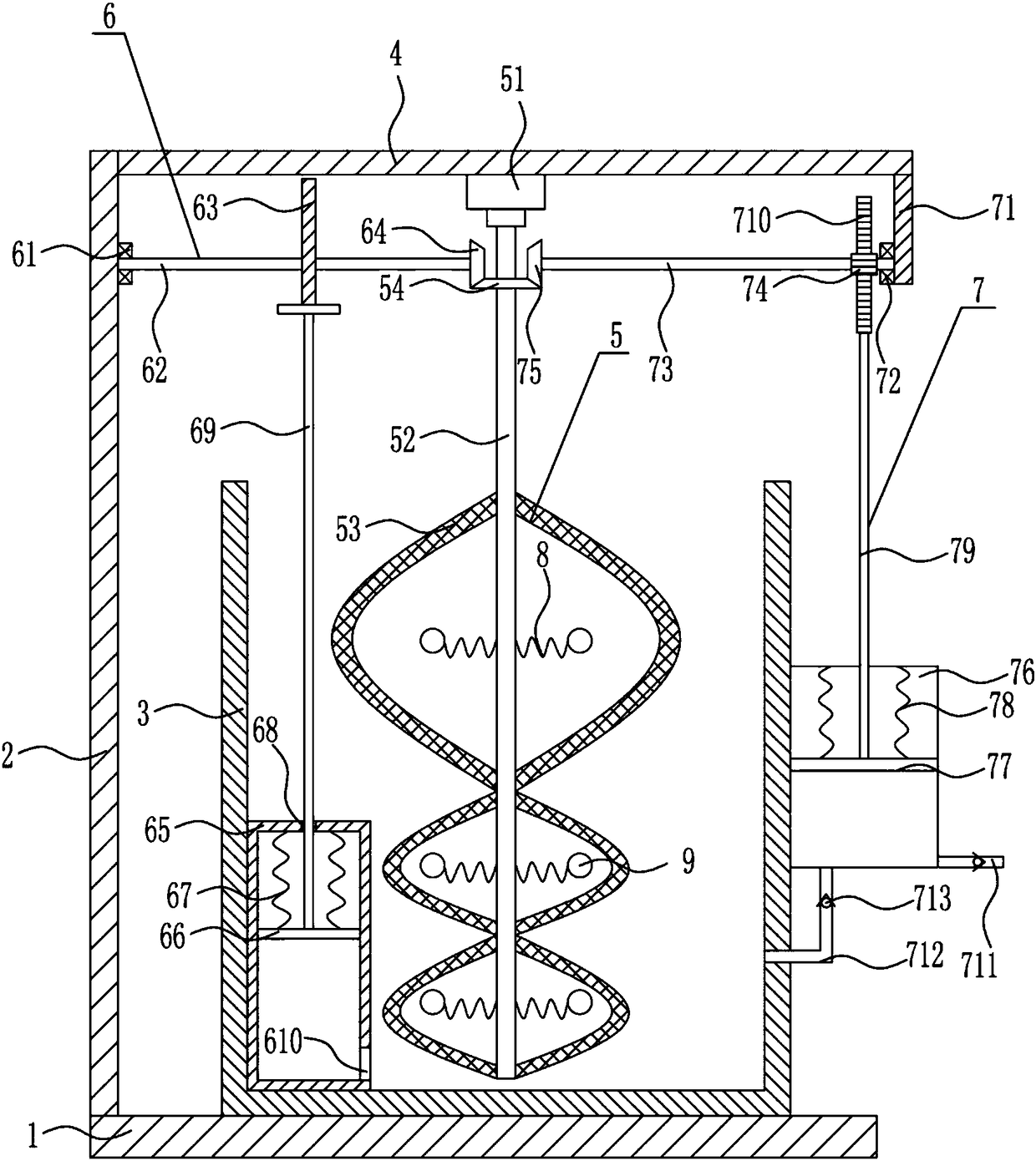

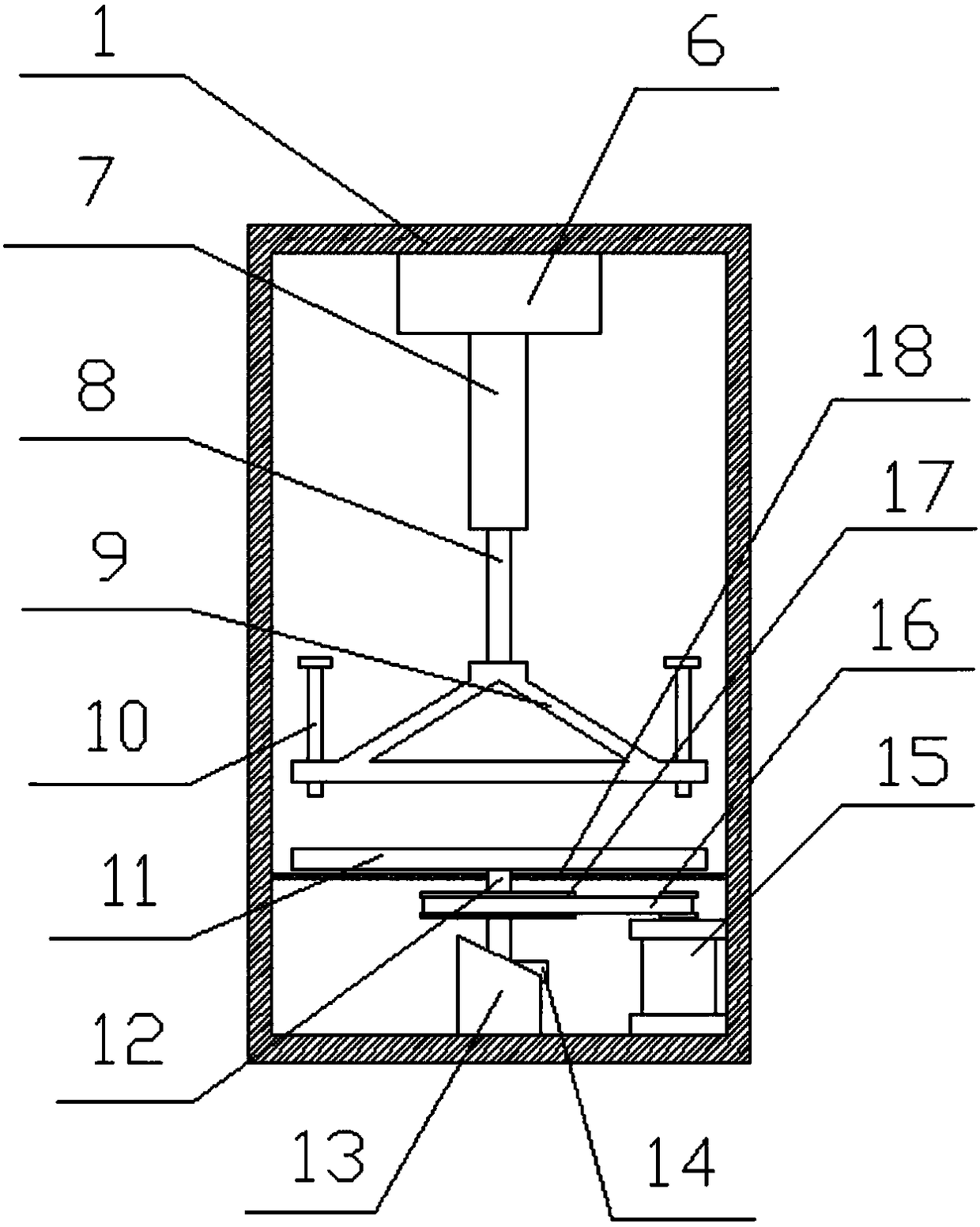

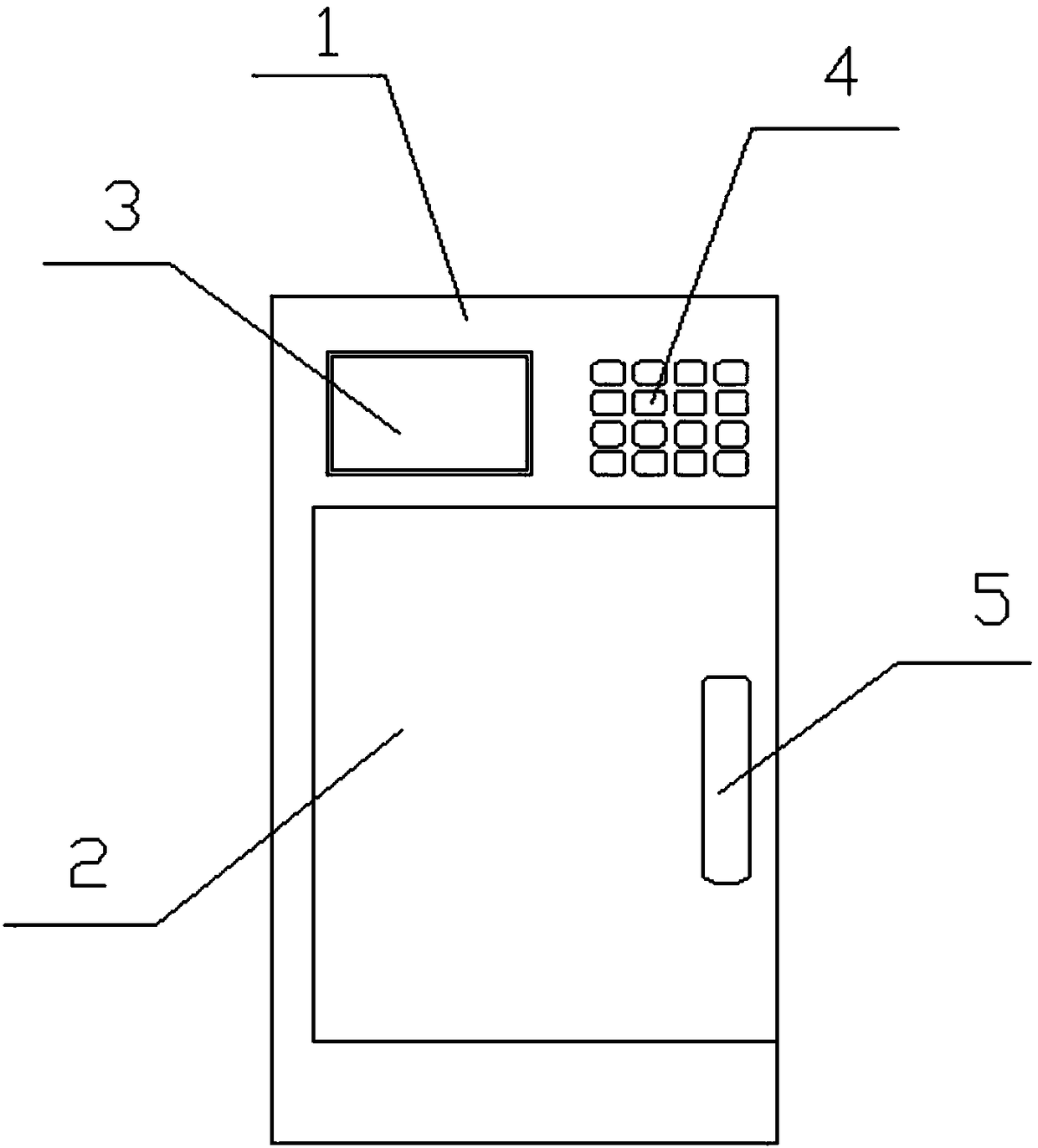

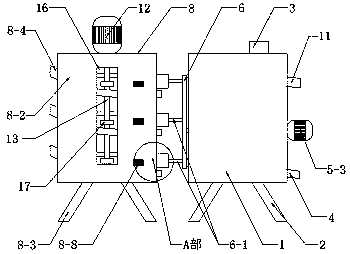

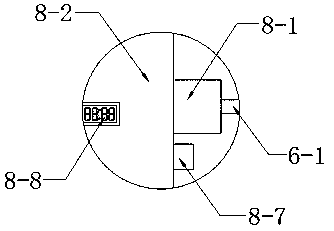

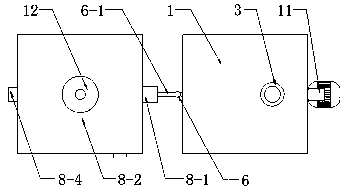

Coloring agent preparation machine for textile dyeing

InactiveCN108201831APromote mixingWell mixedShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringTextile dyeing

The invention relates to a coloring agent preparation machine, in particular to a coloring agent preparation machine for textile dyeing. Against the technical problem to be solved, the invention provides a coloring agent preparation machine for textile dyeing, which is high in mixing efficiency, performs mixing evenly and is simple to operate. In order to solve the technical problem, the inventionprovides such a coloring agent preparation machine for textile dyeing which includes a base plate and the like. A left side plate is disposed on the left side of the top of the base plate, a top plate is disposed on the right side of the top of the left side plate, the middle of the top of the base plate is provided with a box body, a stirring mechanism is arranged at the middle of the bottom ofthe top plate, and a mixing mechanism is arranged on the left side of the bottom of the box body. According to the coloring agent preparation machine for textile dyeing, raw materials are stirred through the stirring mechanism, the raw materials are sucked into a first cylinder body through the mixing mechanism and then sprayed out, the mixing between the raw materials is accelerated, and the mutual contact is more sufficient.

Owner:孙冲

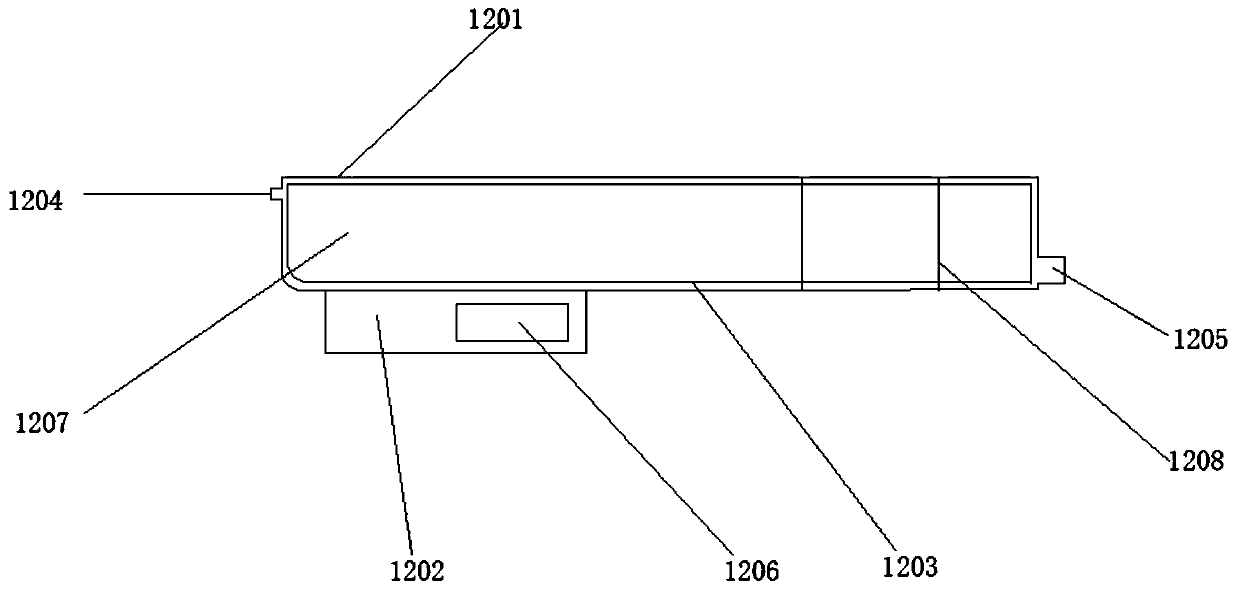

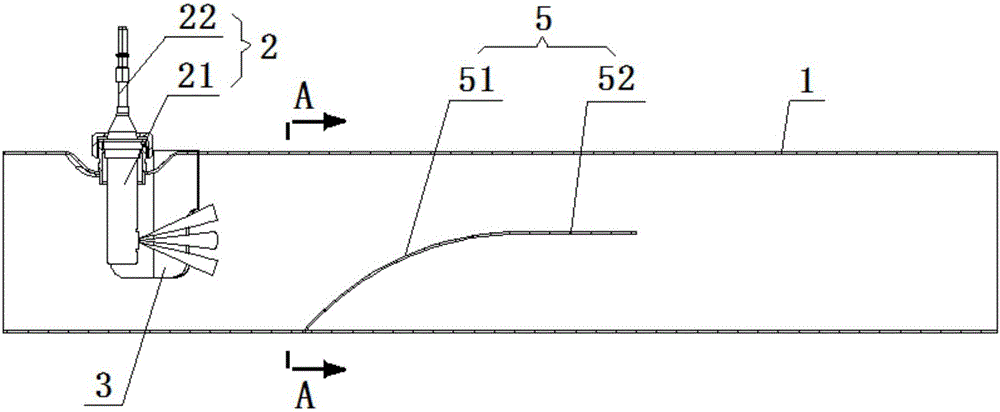

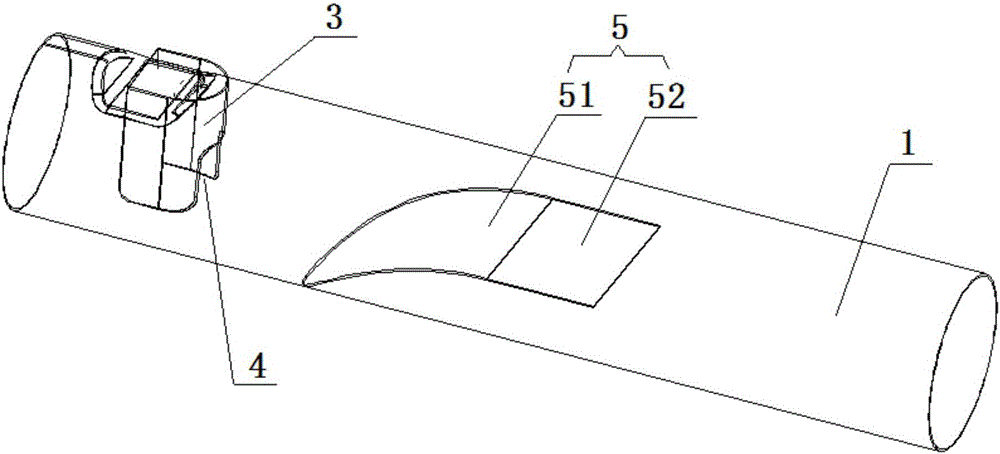

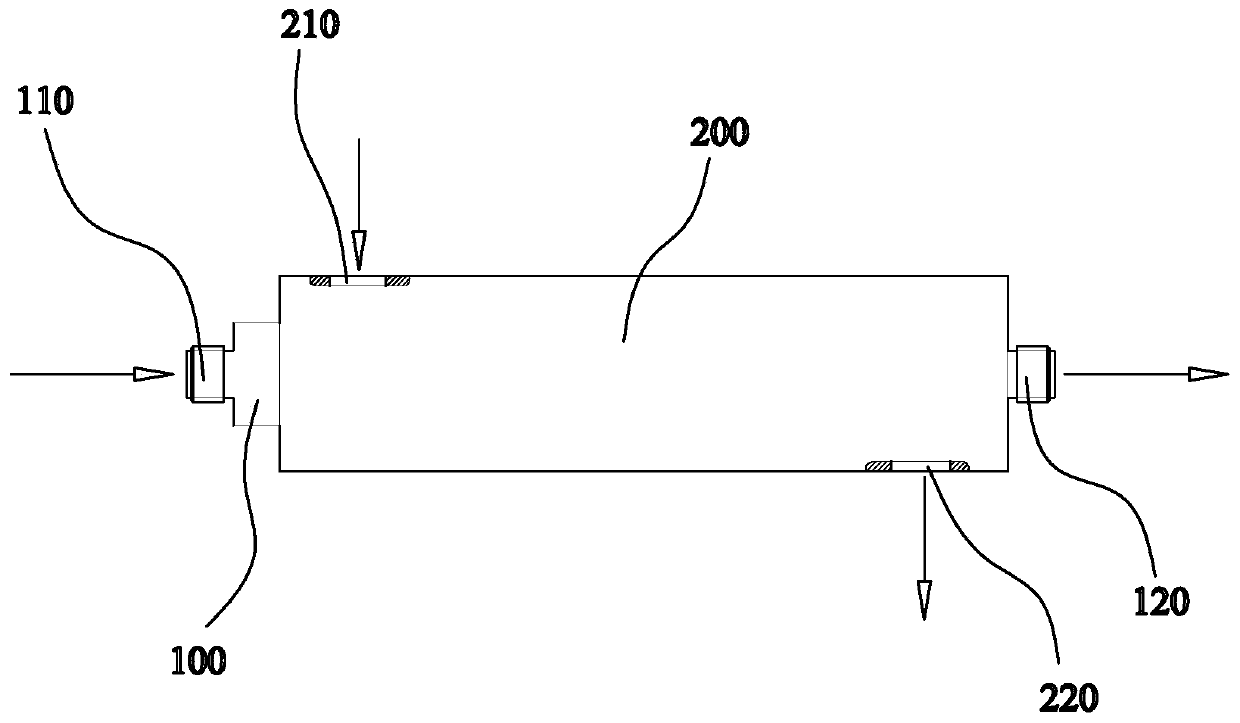

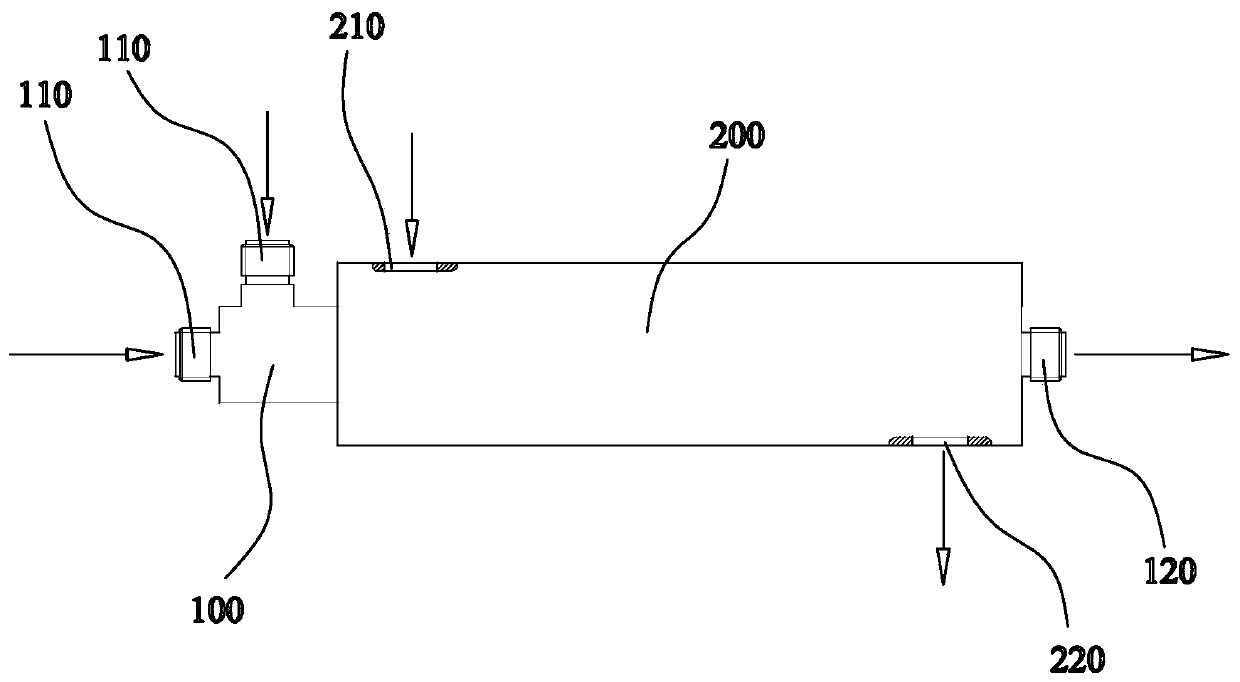

Quick uniform mixing device for gas

PendingCN107051241APromote mixingImprove mixing efficiencyFlow mixersTransportation and packagingProcess engineeringEngineering

Owner:YANCHENG CIVIL MACHINERY CO LTD

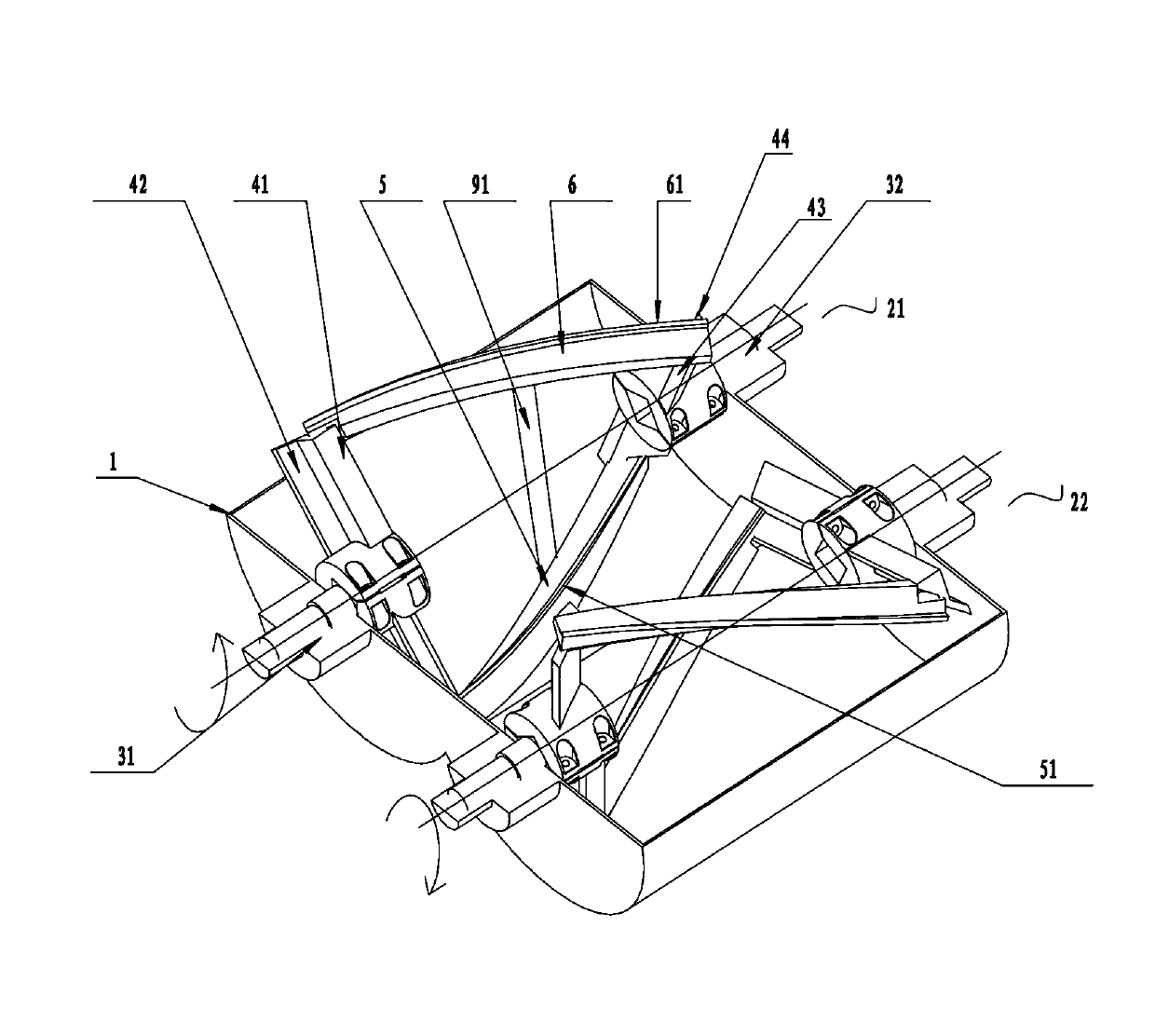

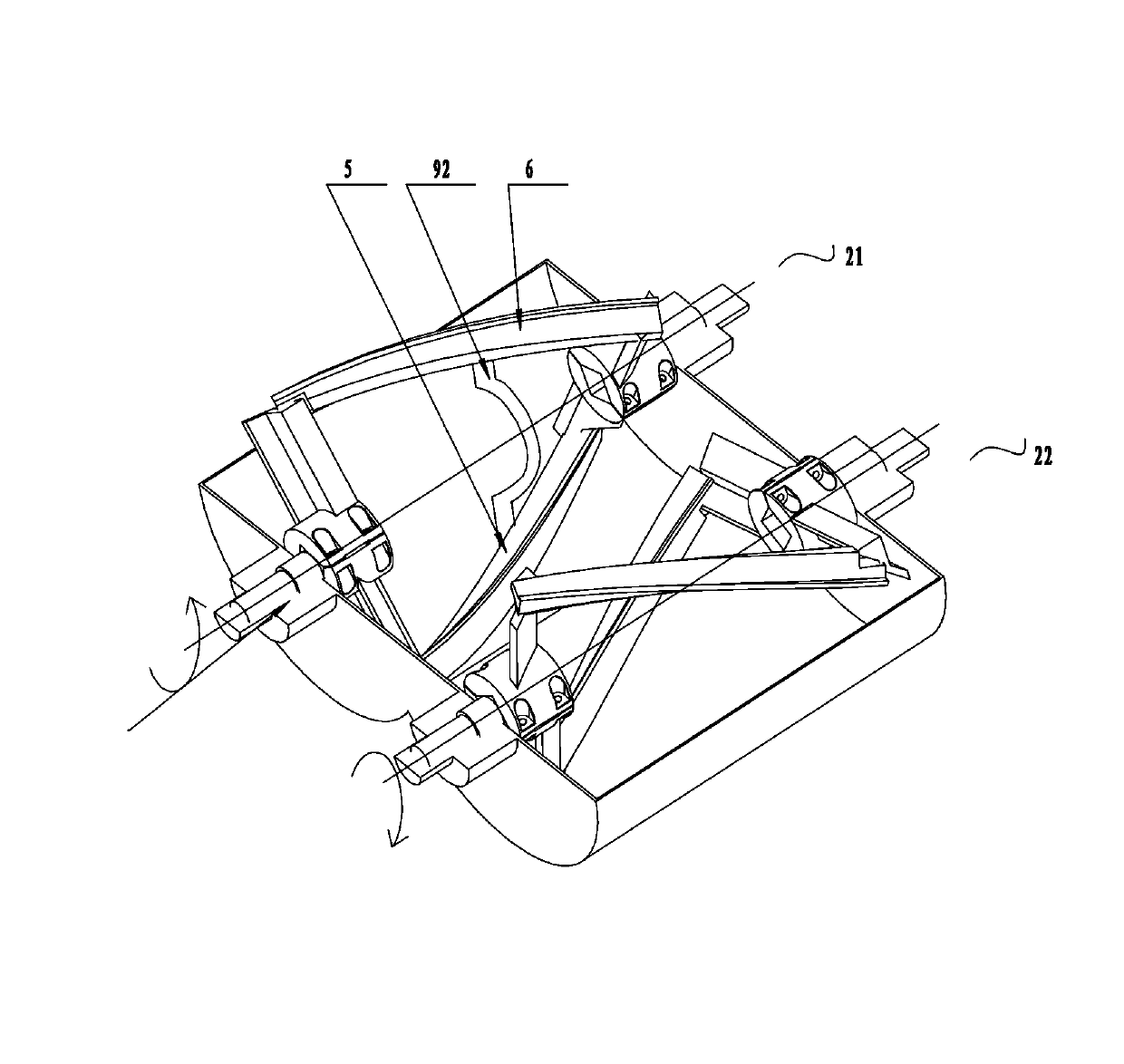

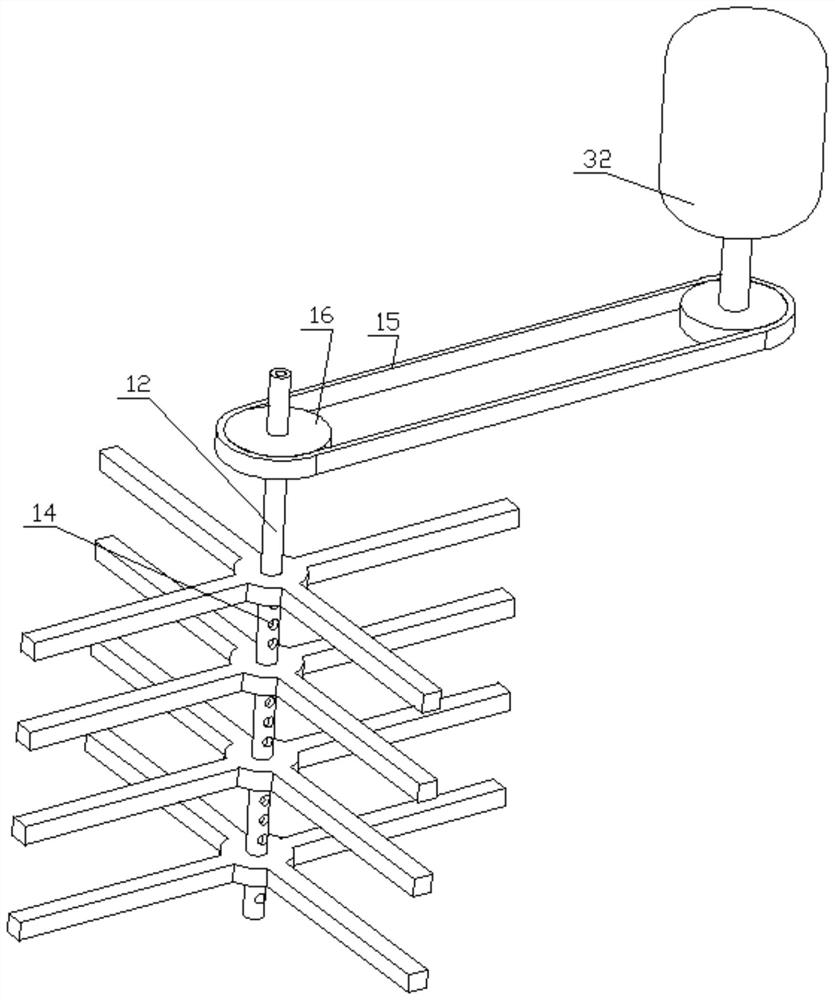

Multi-crankshaft concrete mixer

ActiveCN103128855APromote mixingImprove stirring efficiencyCement mixing apparatusEngineeringCrankshaft

The invention discloses a multi-crankshaft concrete mixer. The multi-crankshaft concrete mixer comprises more than one mixing device connected in a mixing barrel in a rotating mode, and the mounting directions and the rotating directions of two adjacent mixing devices are opposite. Each mixing device comprises a side feeding assembly, a side returning assembly and a mixing crankshaft assembly, wherein the side feeding assembly and the side returning assembly are respectively provided with a mixing arm connected with a main mixing shaft and a returning mixing arm connected with the main mixing shaft, vanes are arranged integrally or in a split mode on the mixing arm. The mixing crankshaft assembly comprises more than one feeding crankshaft, at least, the feeding crankshaft comprises two outer feeding crankshafts which are respectively connected with the feeding mixing arm and the returning mixing arm, and the spiral direction of the two outer feeding crankshafts are the same, and the two outer feeding crankshafts are connected on the mixing arm and distributed systematically. The multi-crankshaft concrete mixer resolves the problem that vibration is large due to large decentration in the prior art, and is stable in operation, low in energy consumption, and high in efficient due to the multi-crankshaft arrangement.

Owner:润桐(苏州)技术服务有限公司

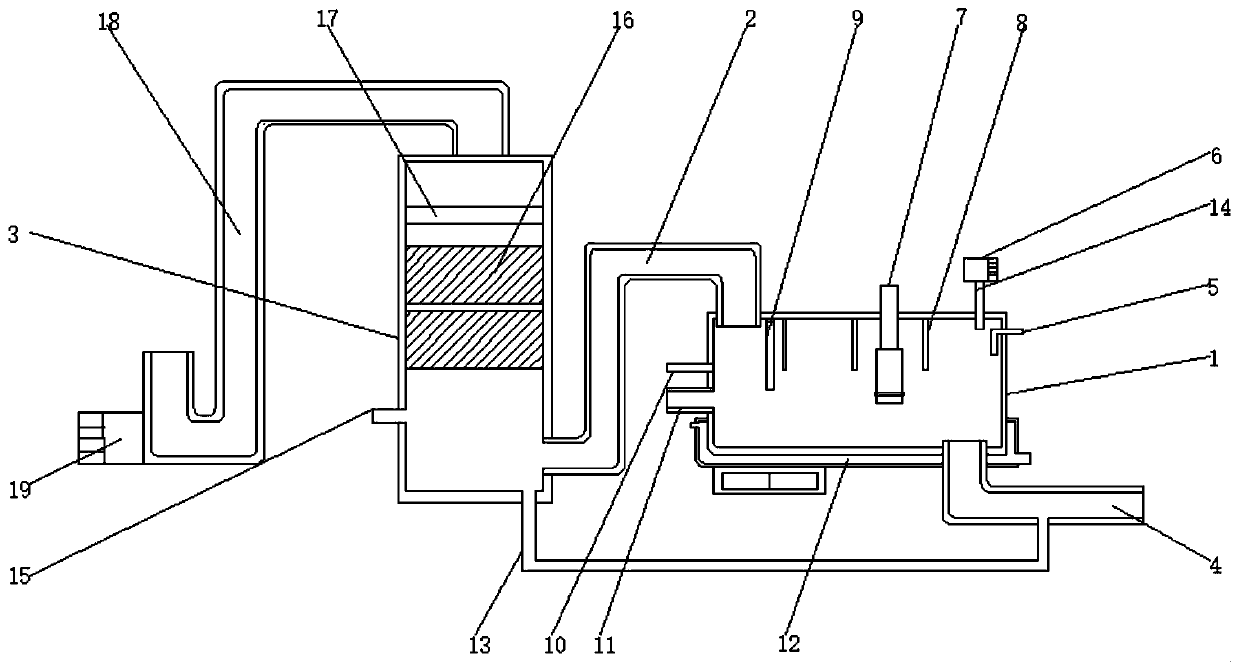

Waste gas and wastewater treatment device

InactiveCN110420545APromote mixingImprove processing efficiencyCombination devicesFatty/oily/floating substances removal devicesExhaust fumesTreatment effect

The invention discloses a waste gas and wastewater treatment device which comprises a wastewater treatment box, a waste gas treatment box and an air compressor, wherein a first waste gas pipe is fixedon one side of the top end of the wastewater treatment box; the waste gas treatment box and the wastewater treatment box are connected through the first waste gas pipe; a first waste liquid pipe is arranged on one side of the bottom of the wastewater treatment box; an adsorption liquid pipe is arranged on one side of the wastewater treatment box; and an air pressure pipe is arranged on the top end of one side close to the adsorption liquid pipe of the wastewater treatment box. The air compressor is connected with the wastewater treatment box through an air compression pipe, the middle part ofthe top end of the wastewater treatment box is provided with an air inlet pipe, and the inner side of the wastewater treatment box is fixed with a baffle. The waste gas and wastewater treatment device pretreats waste gas, so that the treatment effect of the waste gas is better, the mixing of wastewater and an adsorption liquid can be accelerated, the treatment efficiency is improved, and the wastewater treatment efficiency is prevented from being influenced by the change of reaction temperature.

Owner:孙灯成

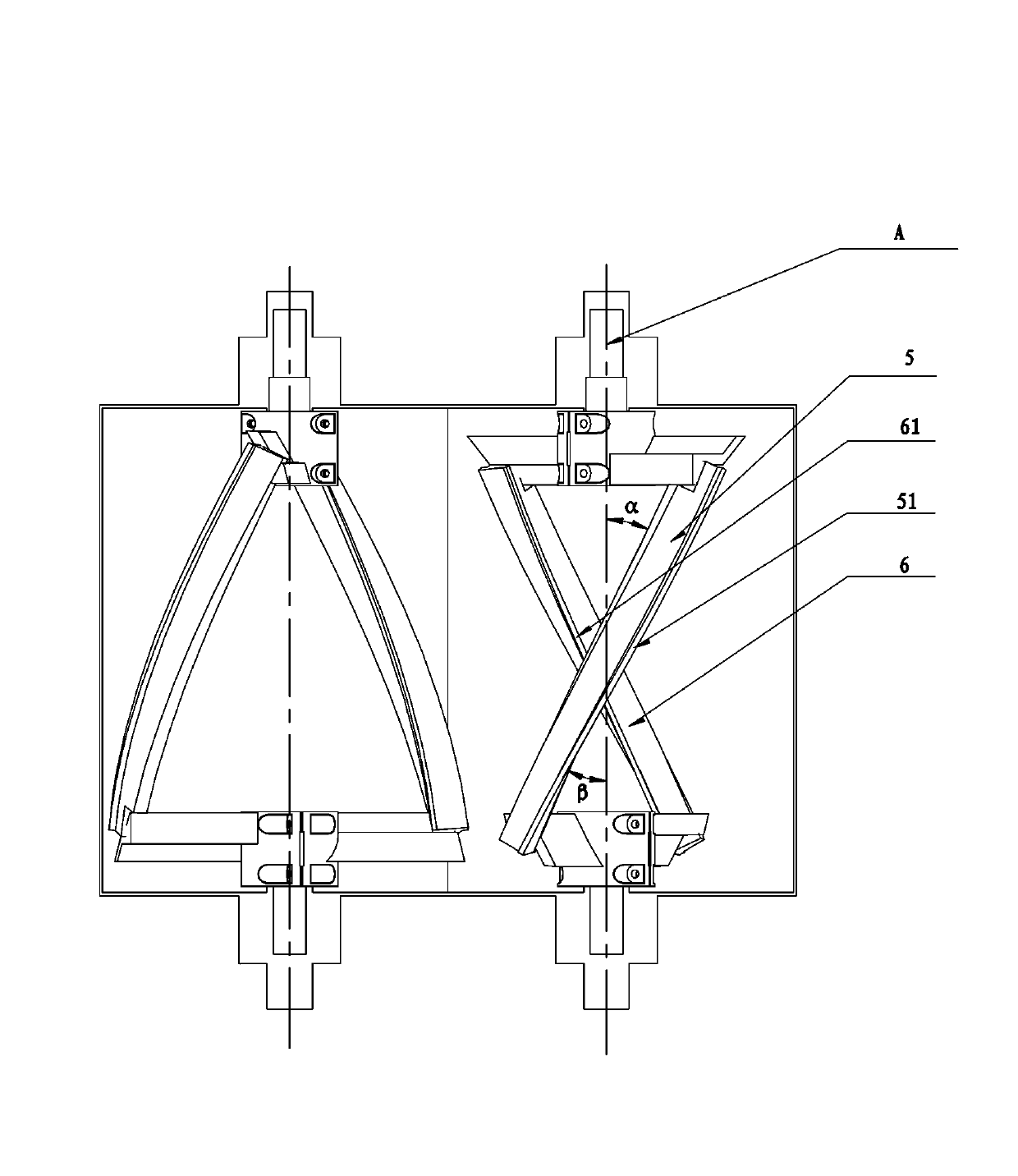

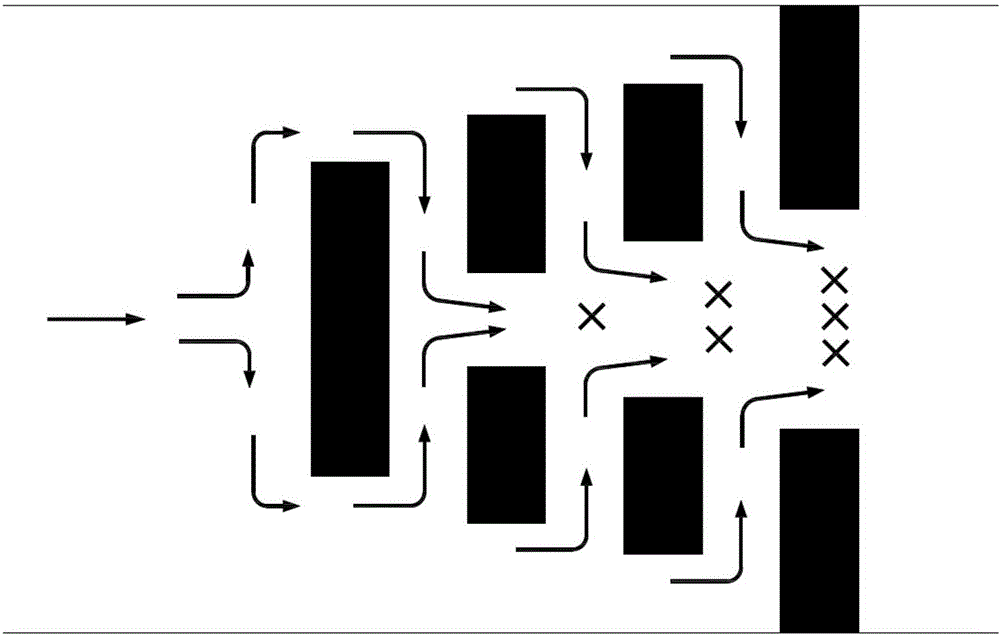

Inverted-V-shaped multi-stage mixed array structure for passive micromixer

ActiveCN106268472APromote mixingSimple structureTransportation and packagingMixersMicrofluidic chipMicromixer

Owner:苏州含光微纳科技有限公司

Device and method for the production of a powder-air mixture

The invention relates to a device for generating a homogeneous powder-air mixture comprising a pressure section and a suction section, wherein the two sections merge in an outlet, wherein the pressure section terminates in an orthogonal direction in the suction section in an ejector-like manner, the suction section being open towards the surroundings. The invention also relates to a method for generating a homogeneous powder-air mixture.

Owner:WEITMANN & KONRAD

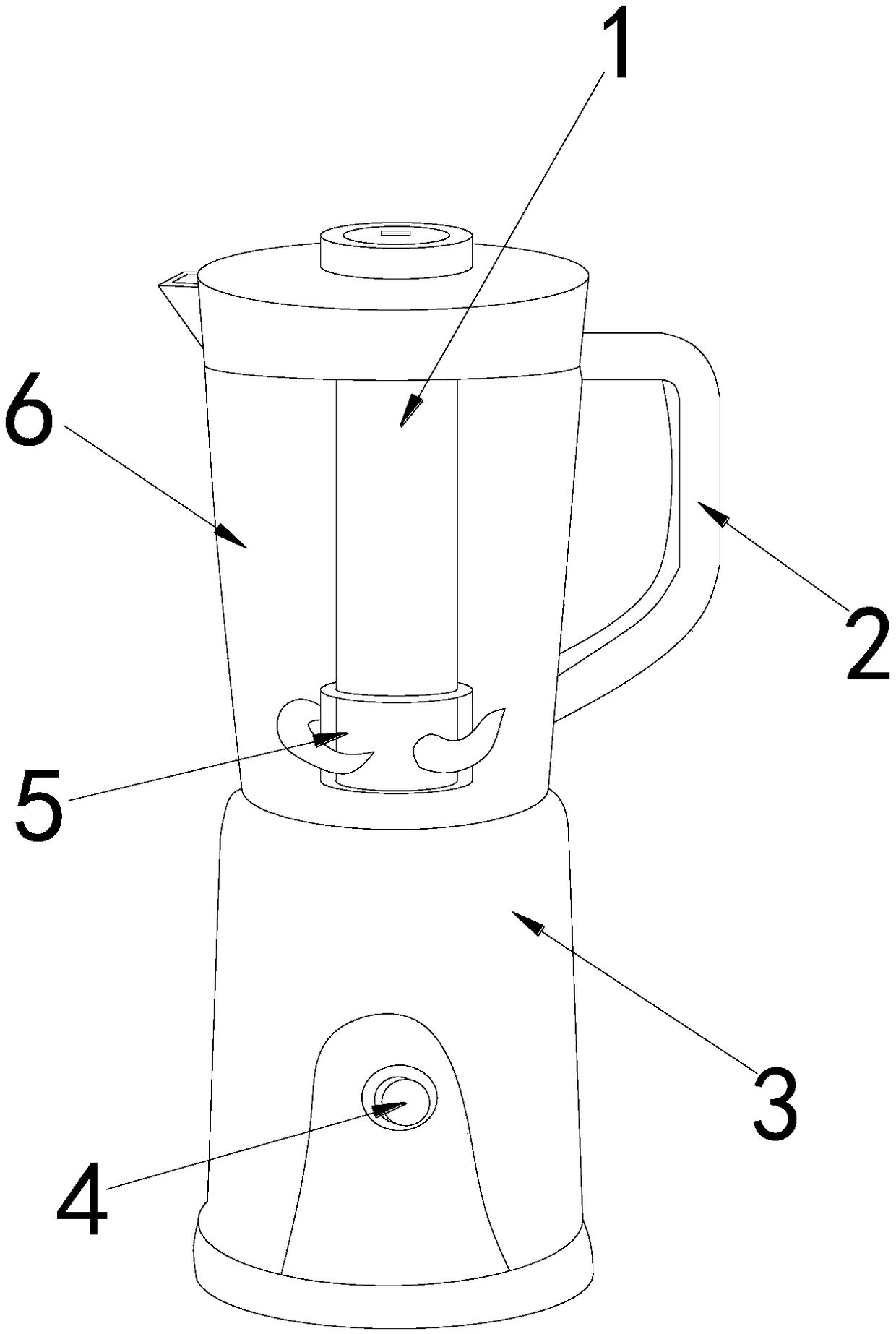

Juice extractor equipment for snow pear juice containing rock candy

The invention discloses juice extractor equipment for snow pear juice containing rock candy. The structure of the juice extractor equipment comprises a rock candy treatment embedded pipe, a handle, amotor device, a control handle, a reamer group and a pot body, wherein the handle is mounted on the right side of the pot body and is locked with the pot body; the rock candy treatment embedded pipe is arranged inside the pot body, and the pot body is connected with the rock candy treatment embedded pipe in a penetrating mode; the reamer group is arranged on the periphery of the bottom of the rockcandy treatment embedded pipe; the reamer group is in clearance fit with the rock candy treatment embedded pipe; and the reamer group is mounted above the motor device and is locked with the motor device. When the equipment is used, by the embedded treatment mechanism, the equipment can avoid the following problems: a cutter head is likely to block when the rock candy is directly put into the juice extractor to be mixed and stirred, the cutter head can be damaged when the blockage is serious, big noise can be generated, and time is wasted when the rock candy is ground and processed externallyfor the second time; and the equipment saves a secondary processing step of large rock candy, and the rock candy is ground by a specific embedded spline structure by the rotation of the juice extractor.

Owner:平邑县经发企业服务有限公司

Multi-stage premixed pipe for gas furnace head

InactiveCN110594792AGood mixing effectPromote mixingDomestic stoves or rangesGaseous fuel burnerProduct gasEngineering

The invention discloses a multi-stage premixed pipe for a gas furnace head. The multi-stage premixed pipe a pipe body, a first gas inlet, a second gas inlet and a mixed gas outlet, one end of the pipebody is provided with the first gas inlet and the second gas inlet correspondingly, the other end of the pipe body is provided with the mixed gas outlet, the pipe body is fixedly connected with a fixed plate, and two cavities are formed in the inner part of the pipe body through the fixed plate, the side wall of the fixed plate is provided with a communicating port which is in the horizontal direction, the two ends of the pipe body communicate through the communicating port, one end of the inner part of the pipe body is fixedly provided with a first conduit, and a second conduit is arranged on the outer part of the first conduit in the pipe body, the outer side of the first conduit is equidistantly provided with a first exhaust port, the outer side of the second conduit is equidistantly provided with a second exhaust port, and the other end of the pipe body is provided with a guide rod. The premixed pipe realizes multi-stage mixing of gas, the overall structure is simple, the design is reasonable, the mixing effect of gas is good, the utilization rate of gas is improved, and it is convenient to popularize and use.

Owner:广东炬鼎节能设备有限公司

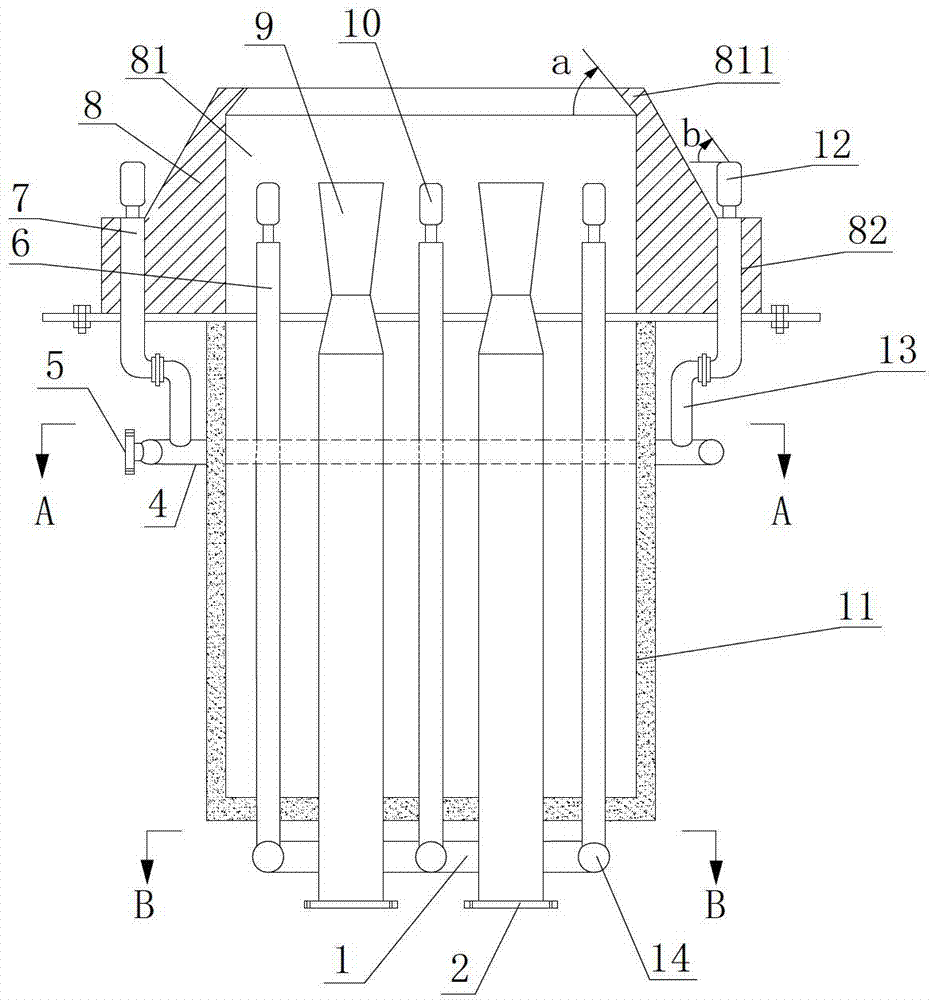

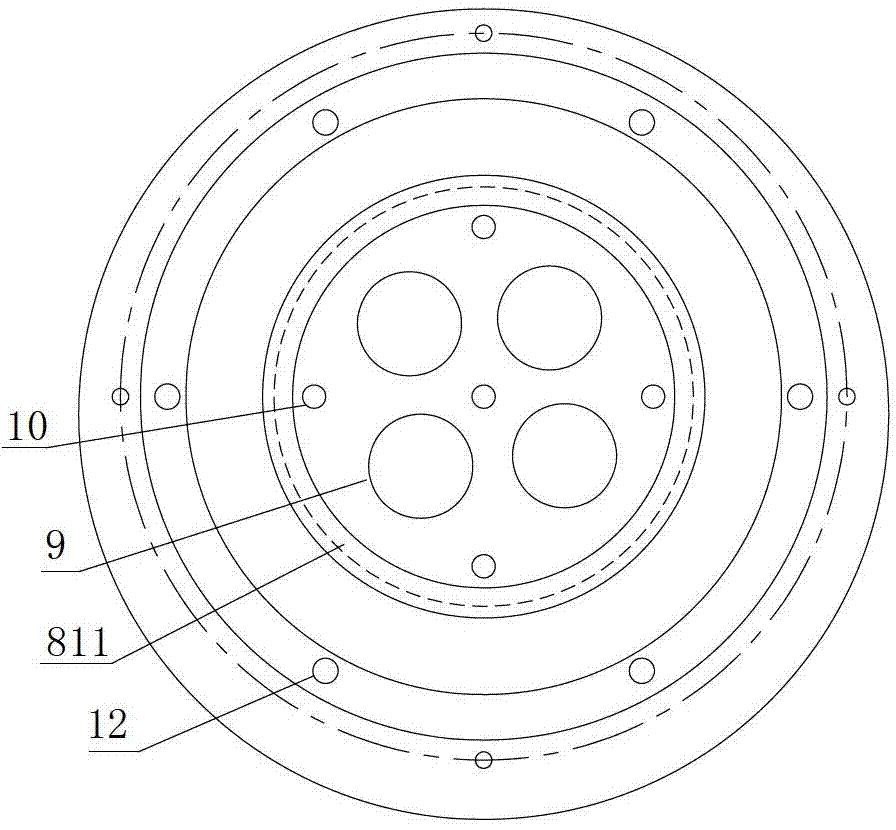

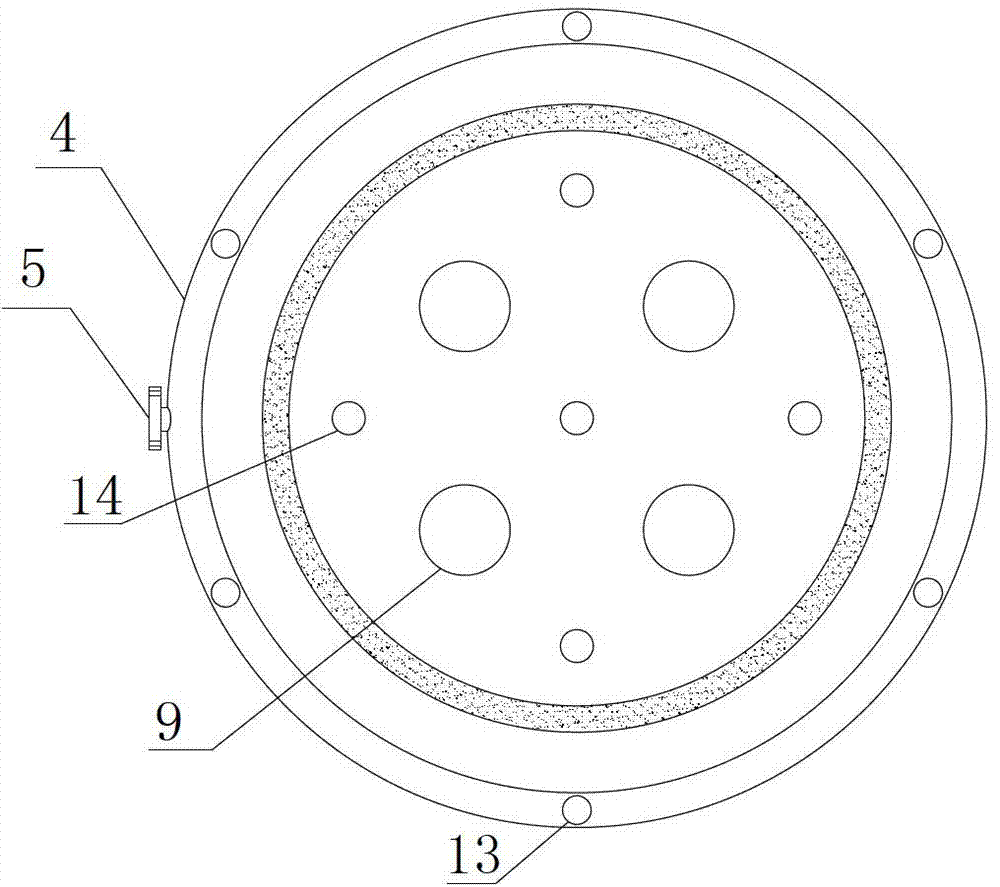

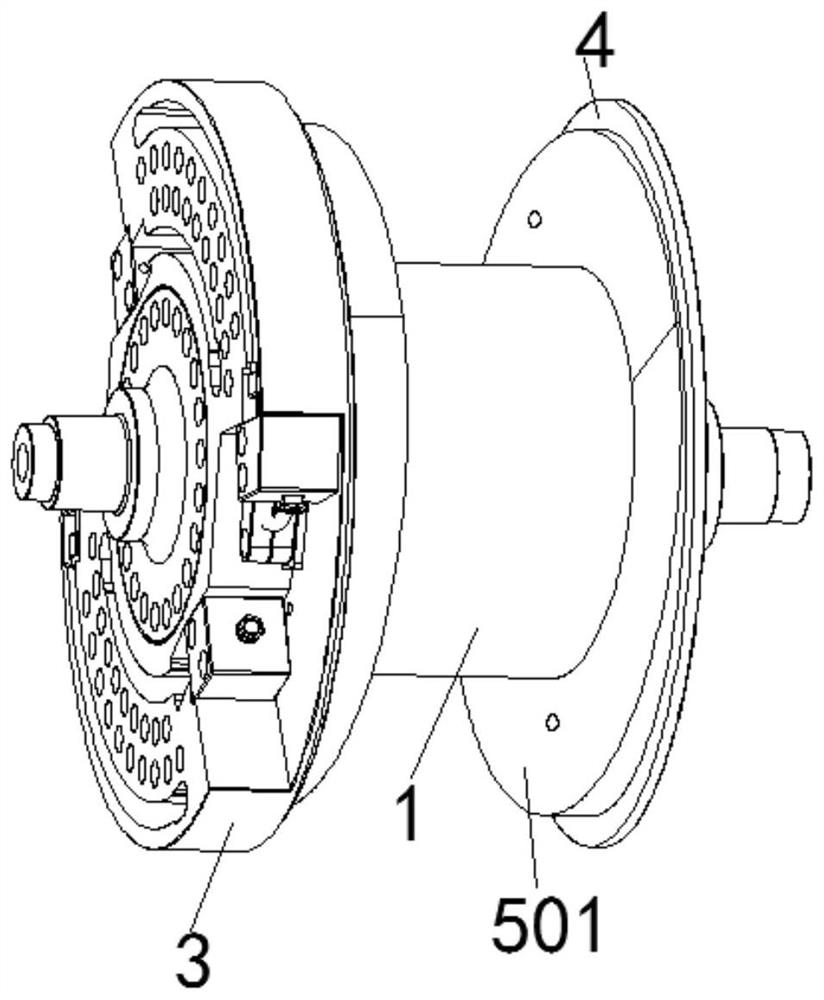

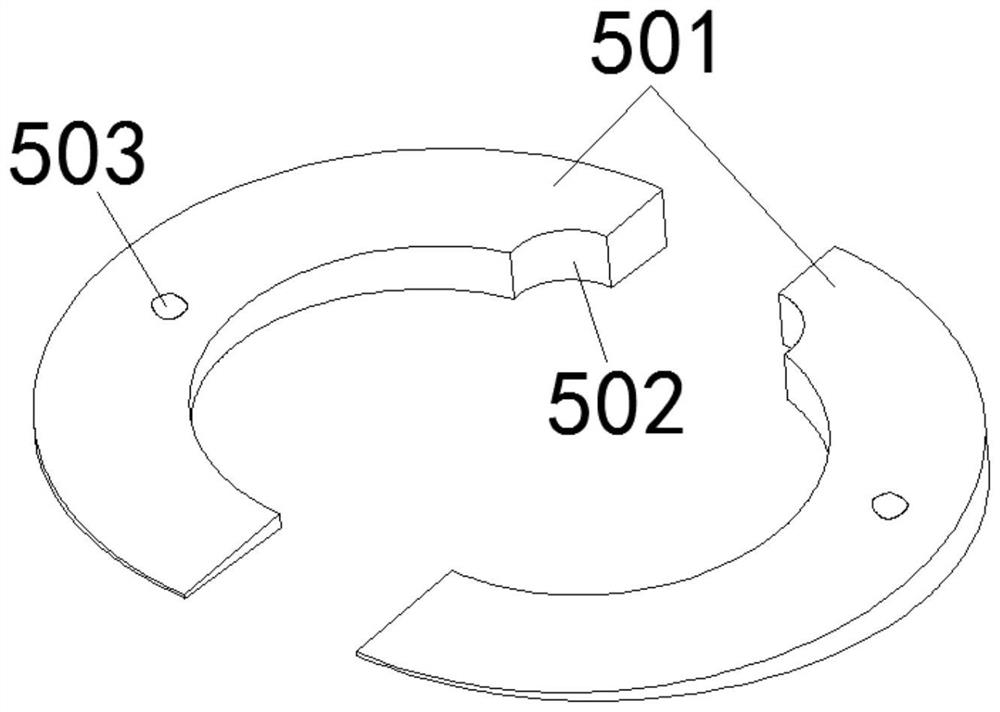

Spiral pipe structure for separation column of high-speed counter-current chromatograph

ActiveCN112245973AGuaranteed positioning accuracyPromote mixingSolid sorbent liquid separationCounter currentEngineering

The spiral pipe structure comprises the separation column, a spiral square pipe and two adjusting blocks, each adjusting block is of a circular ring structure, the separation column is sleeved with the hollow portion of each adjusting block, the end faces of the sides, close to each other, of the two adjusting blocks are inclined planes, and the two inclined planes are parallel to each other. Thespiral square pipe is spirally wound on the separation column and arranged between the two adjusting blocks, the two sides of the spiral square pipe abut against the two adjusting blocks respectively,a pipe inlet hole and a pipe outlet hole are formed in the first disc, and the two ends of the spiral square pipe extend out of the pipe inlet hole and the pipe outlet hole respectively; the end, extending out of the pipe inlet hole, of the spiral square pipe penetrates through the adjusting block close to one side of the first disc, the cross section of the spiral square pipe is of a rectangularstructure, the long edge of the rectangular structure is parallel to the axis of the separation column. By means of the device, the technical problems existing in the prior art can be solved: when atwo-phase interface in the circular tube is eccentric, radial mixing is insufficient, and the axial inclination of the spiral tube is difficult to control.

Owner:SICHUAN UNIV

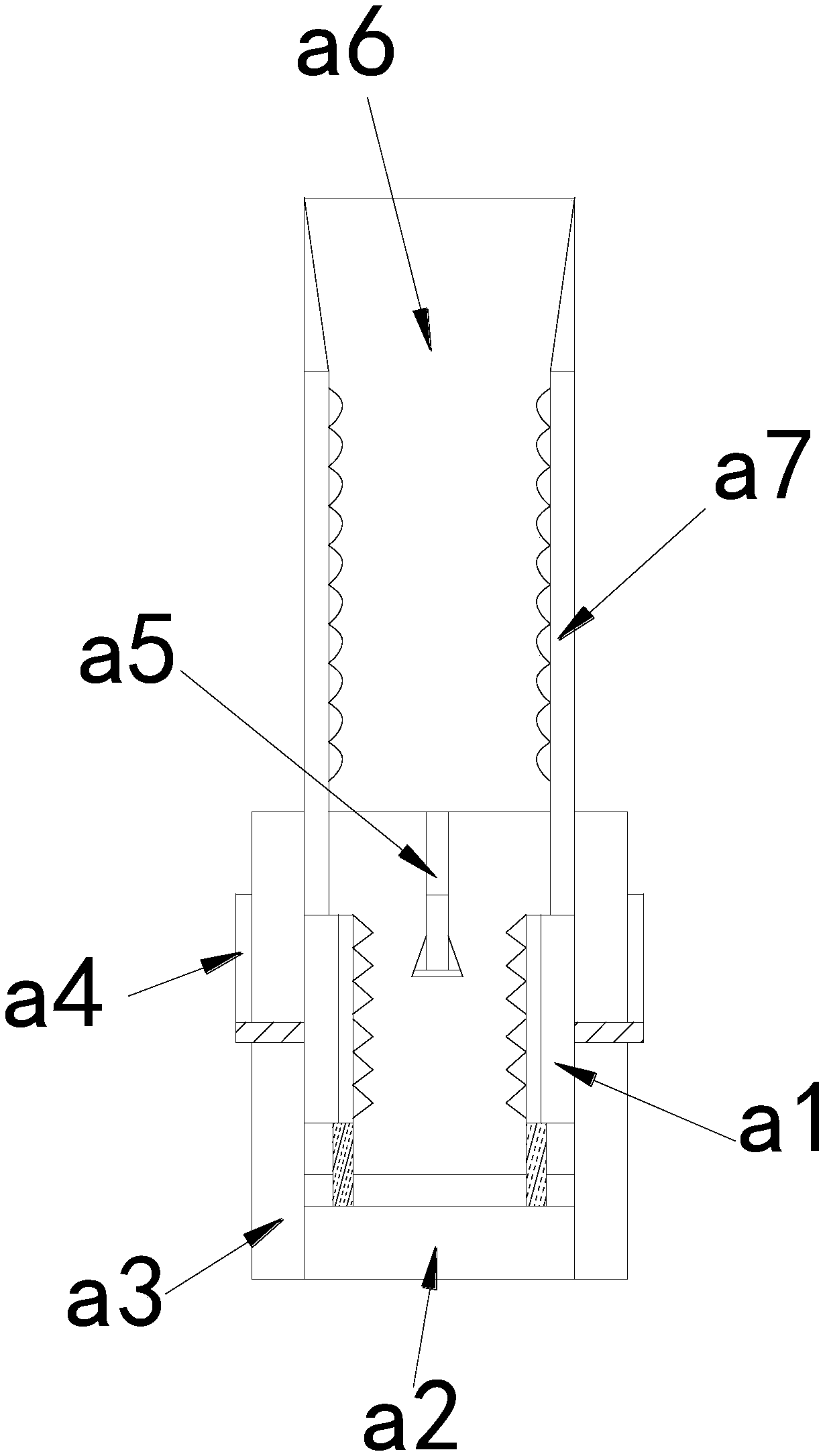

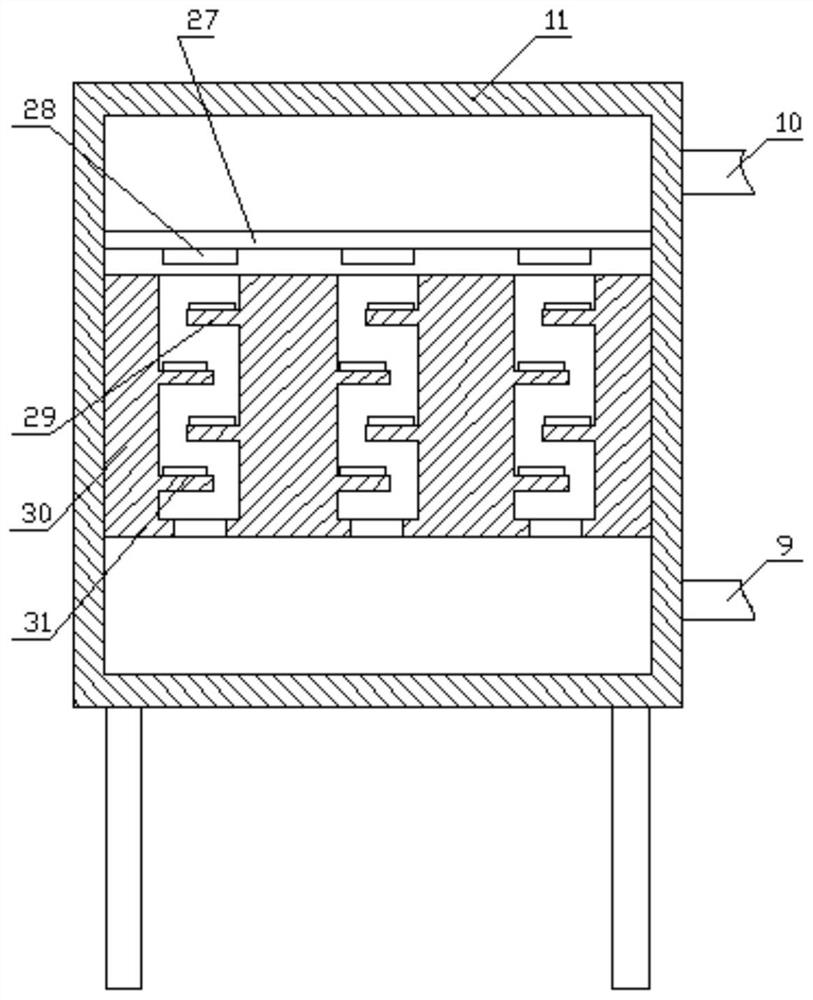

Medicinal liquid shaking device

InactiveCN108554283APromote mixingImprove efficiencyShaking/oscillating/vibrating mixersTransportation and packagingHollow cylinderEngineering

The invention discloses a medicinal liquid shaking device, and relates to the field of medicine production. The medicinal liquid shaking device comprises a casing, wherein an oscillating mechanism anda pressing mechanism are arranged inside the casing; the oscillating mechanism is arranged on the inner bottom surface of the casing, and comprises a turnplate, a rotating rod, a motor and a limitingcolumn; the rotating rod is fixedly connected to the bottom of the turnplate; a belt pulley is fixedly arranged on the rotating rod; the belt pulley is connected with the motor through a belt; the limiting column is a hollow cylinder, and the top end thereof is an inclined plane; the rotating rod is sleeved with the limiting column; a limiting block connected to the side wall of the limiting column in a clamping manner is arranged on the rotating rod; the pressing mechanism is arranged on the inner top surface of the casing, and comprises a connecting platform, a hollow tube, a telescopic rodand a triangular rack. The medicinal liquid shaking device can shake medicinal liquid up and down while rotation of the medicinal liquid is achieved, so that mixing of the medicinal liquid is more uniform and higher in efficiency.

Owner:WUHU NOKAN BIOTECH

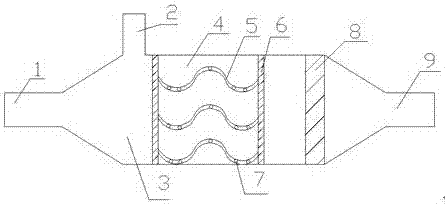

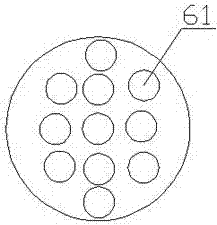

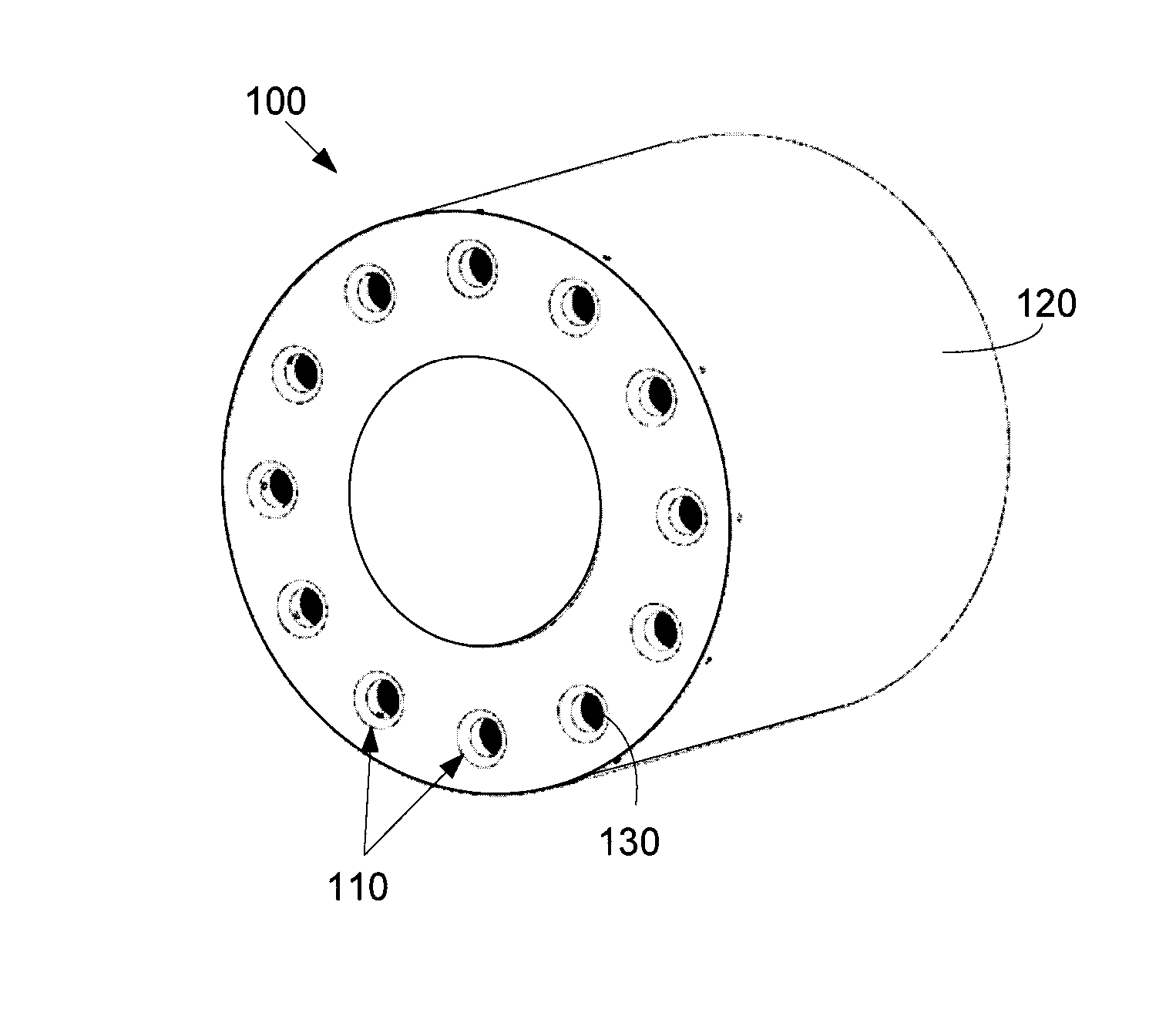

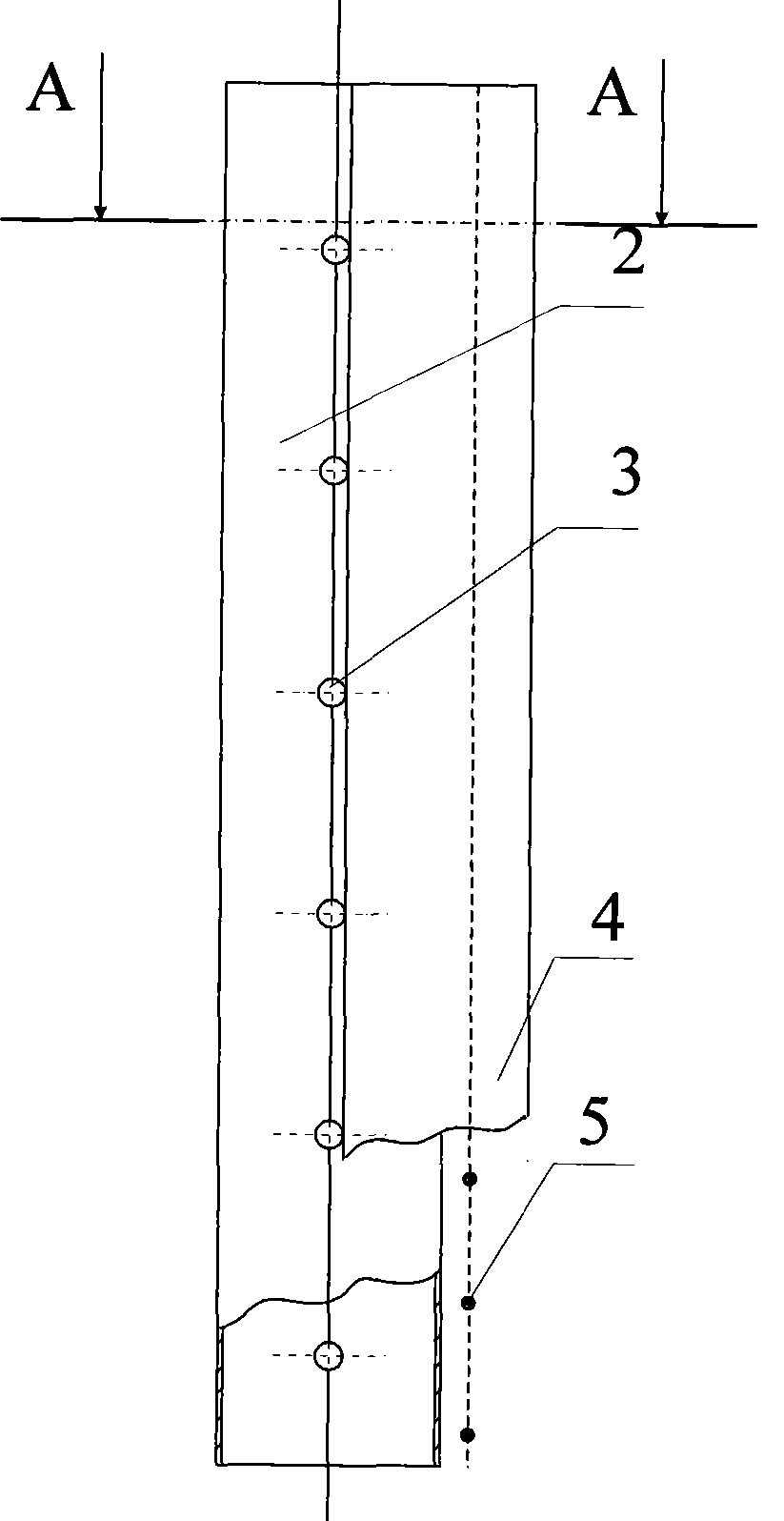

Enhanced Mixing Tube Elements

ActiveUS20150028133A1Promote mixingContinuous combustion chamberTurbine/propulsion fuel flow conduitsGas turbinesMixing zone

The present application provides a fuel nozzle for use with a flow of air and a flow of fuel in a gas turbine engine. The fuel nozzle may include a plenum, a mixing tube element positioned within the plenum, and an enhanced mixing feature positioned within the mixing tube element so as to promote mixing of the flow of air and the flow of fuel. The enhanced mixing feature may include a turbulated mixing zone.

Owner:GENERAL ELECTRIC CO

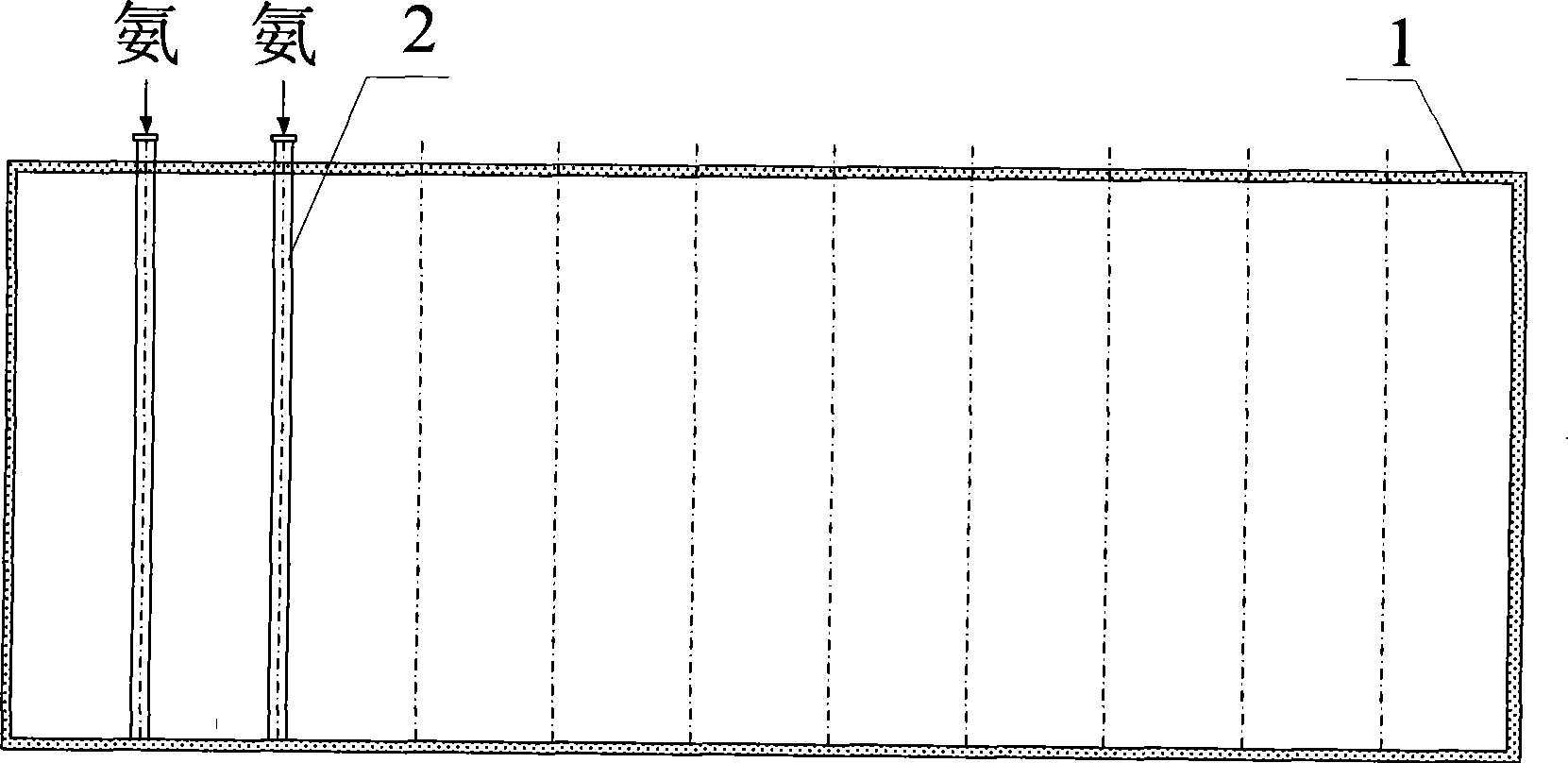

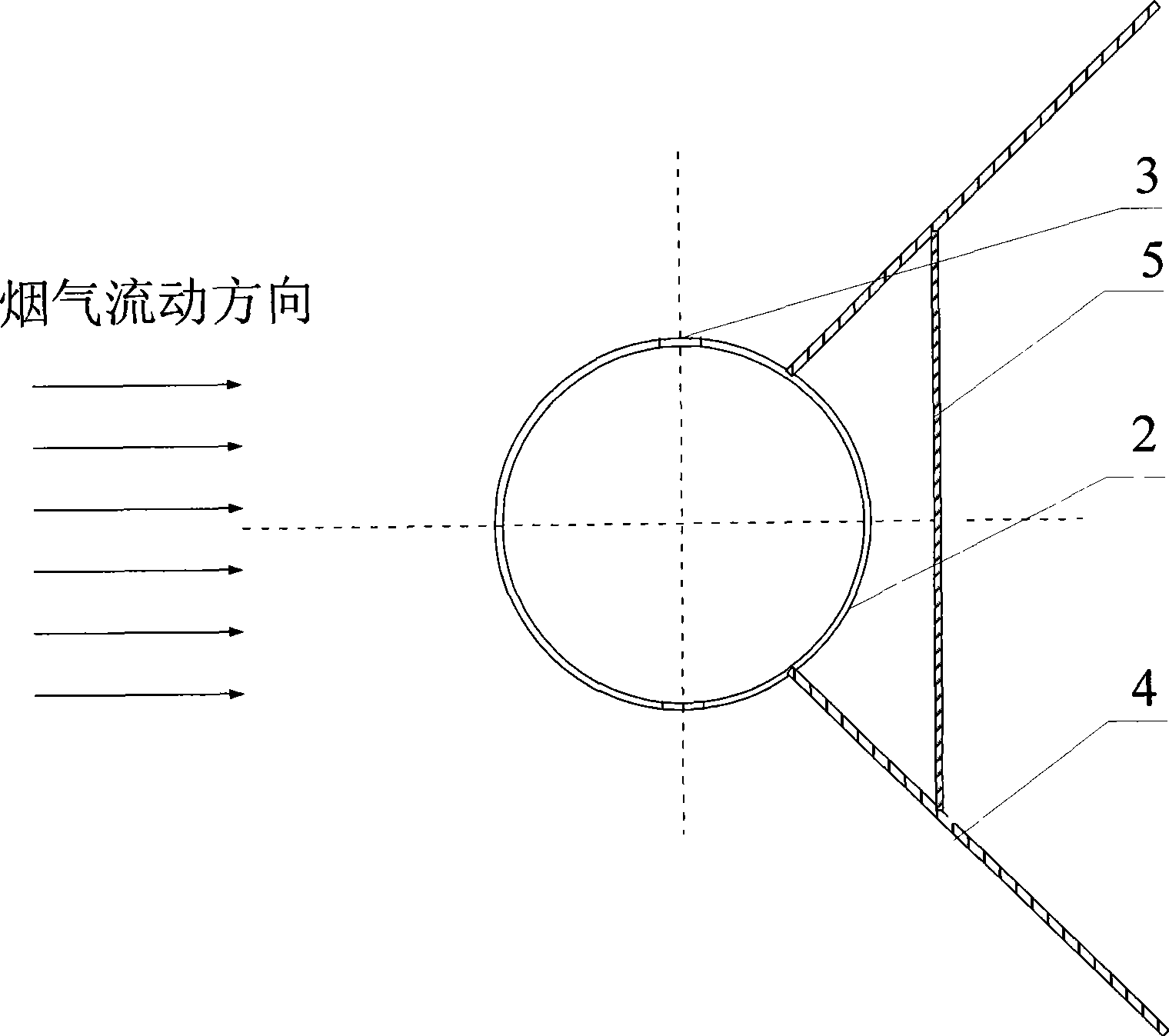

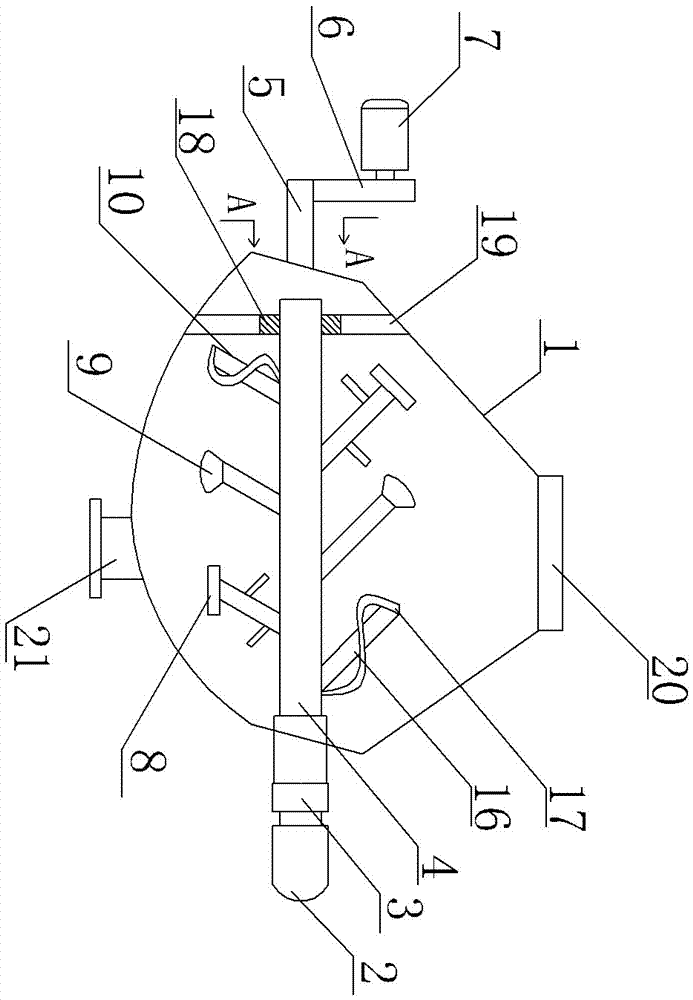

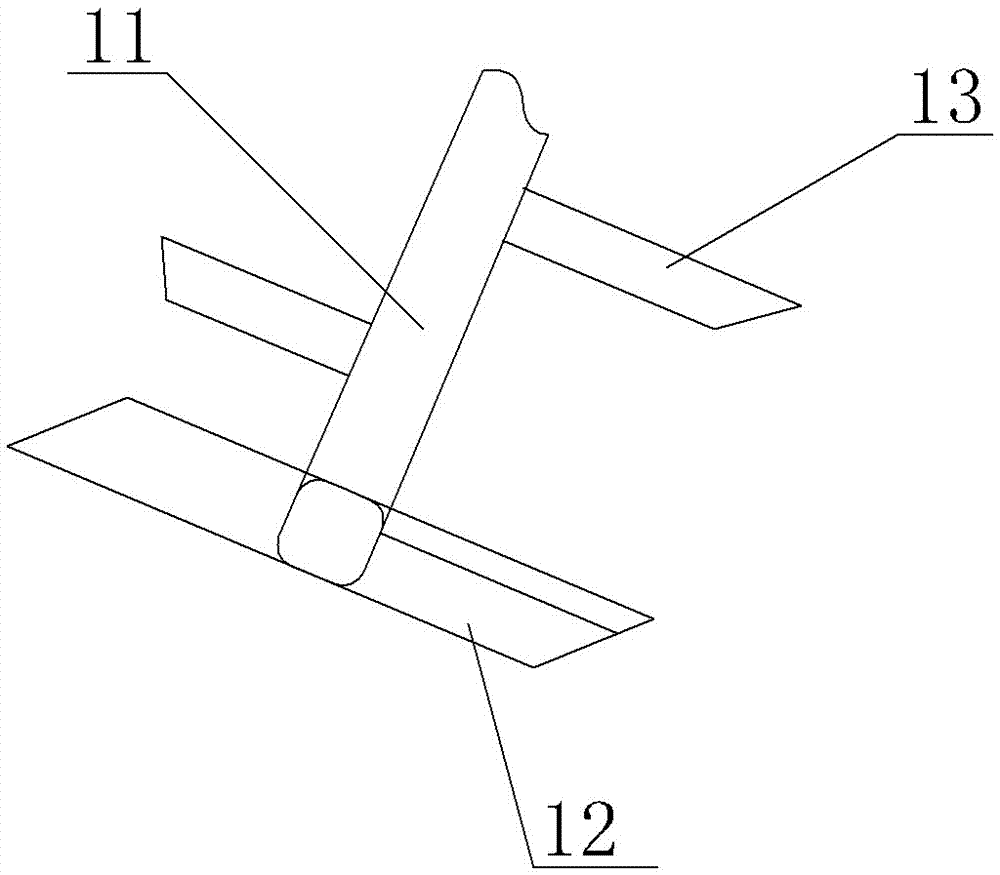

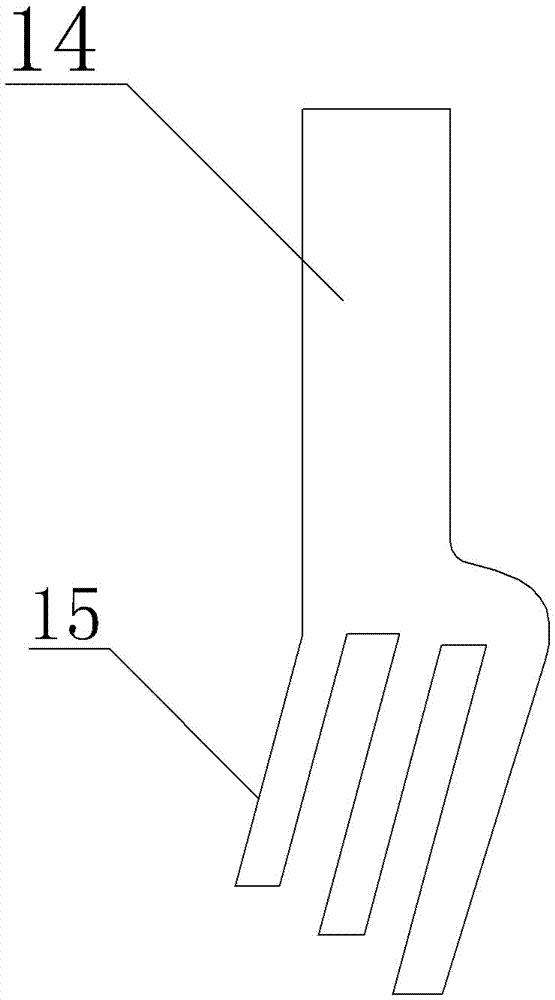

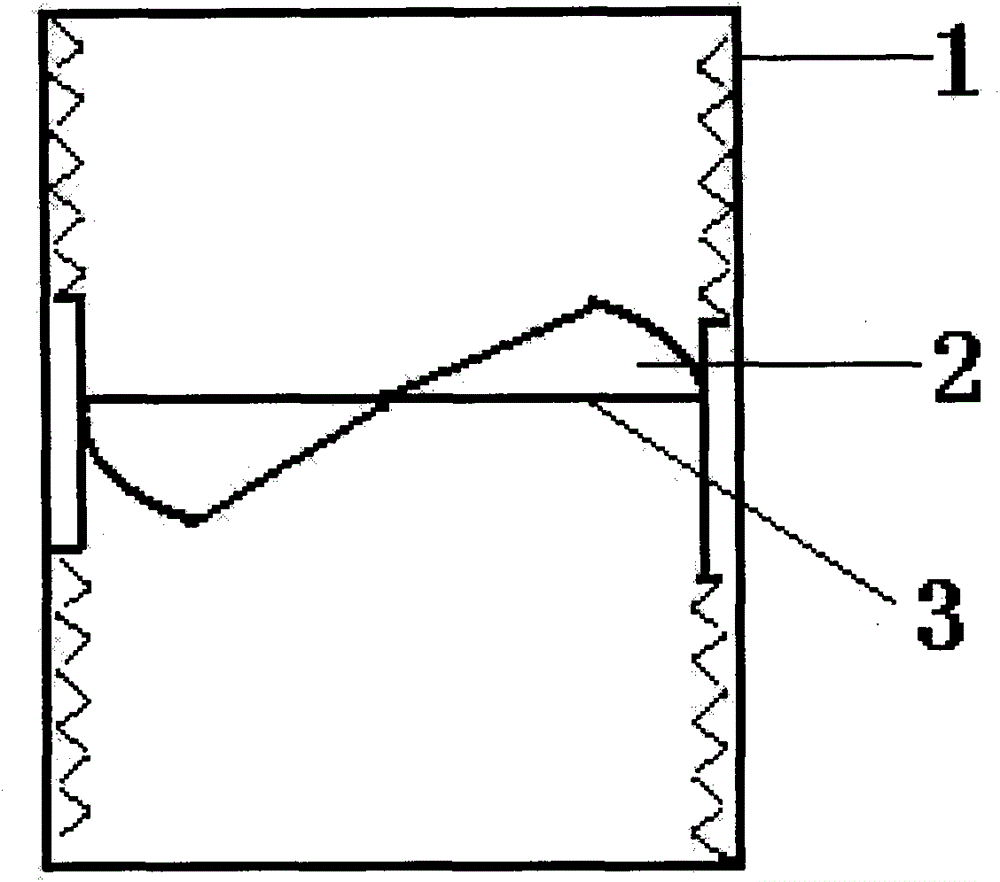

Flue-gas swirl strong mixing split filter board

InactiveCN101396637AEven flow distributionPromote mixingDispersed particle separationPower stationEngineering

A flue gas swirl strong mixing diversion filter board is used in a power station pulverized coal fired boiler at a grizzly screen for spraying ammonia of a flue gas selective catalyctic reduction (SCR) denitration device; the swirl strong mixing diversion filter board (4) are arranged along the outer surface of a metallic conduit (2) of the grizzly screen for spraying ammonia and is divided into an upper board and a lower board, the lengths of which are equal to or slightly longer than that of a spray pipe; the swirl strong mixing diversion filter board (4) installed on the metallic conduit (2) of the grizzly screen for spraying ammonia is close to an ammonia gas jet orifice (3) and forms the angle of 40-60 degrees, and the upper board and the lower board of the swirl strong mixing diversion filter board (4) are symmetrical and connected and supported with each other by a filter board support (5). The ammonia gas is gradually mixed with the flue gas in the process of flowing along the filter board (4) and gradually flows into flue gas flow field at rear along a round hole to be diverted by the round hole. The mixture of the ammonia gas and the flue gas form a great deal of swirl under the action of an ostiole of the filter board and the sawtooth edge of the filter board, and is rapidly mixed in the flow.

Owner:SOUTHEAST UNIV

Rotary type double-acting mixer

ActiveCN107261951APromote mixingPrevent unmixedRotating receptacle mixersTransportation and packagingLeather beltWheel and axle

The invention provides a rotary type double-acting mixer, which can be used for effectively solving the problems that a material cannot be sufficiently dispersed and the efficiency is low and guaranteeing product quality. The rotary type double-acting mixer comprises a barrel and a spindle motor, wherein the spindle motor is arranged on one side of the barrel; the spindle motor is connected with one end of a spindle, which stretches into the barrel in the horizontal direction, through a coupling; the spindle is provided with an agitation device; the other side of the barrel is provided with a belt wheel shaft; the belt wheel shaft is connected with a barrel motor through a belt transmission device; the upper part of the barrel is of a non-eudipleural double-cone structure; the lower part of the barrel is in a spherical-segment shape.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

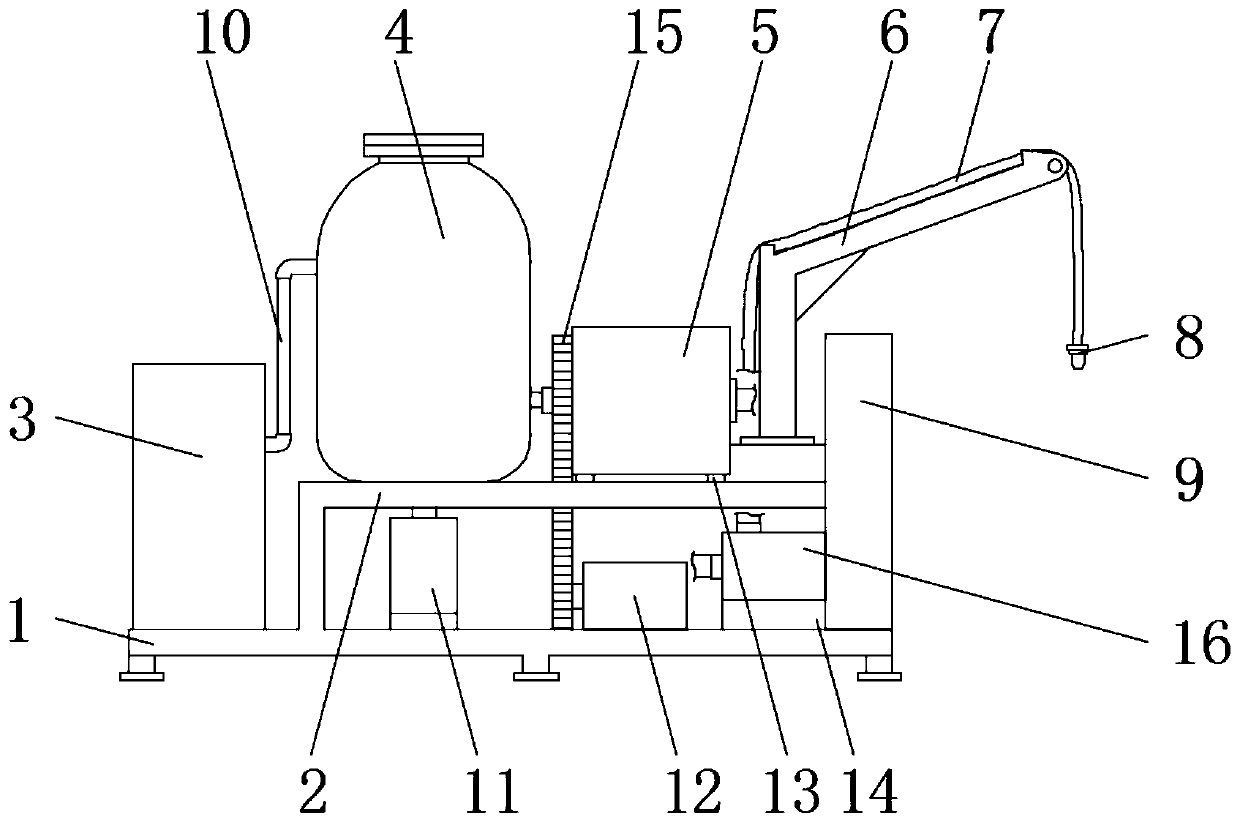

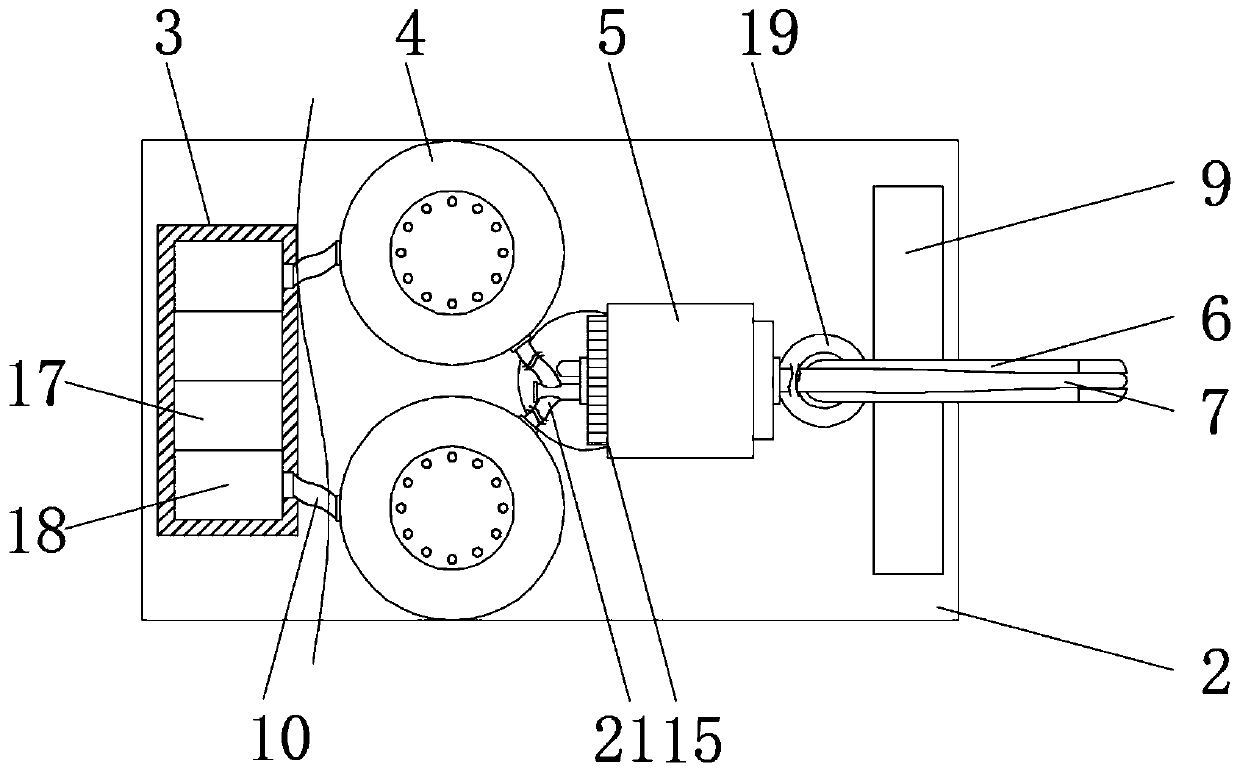

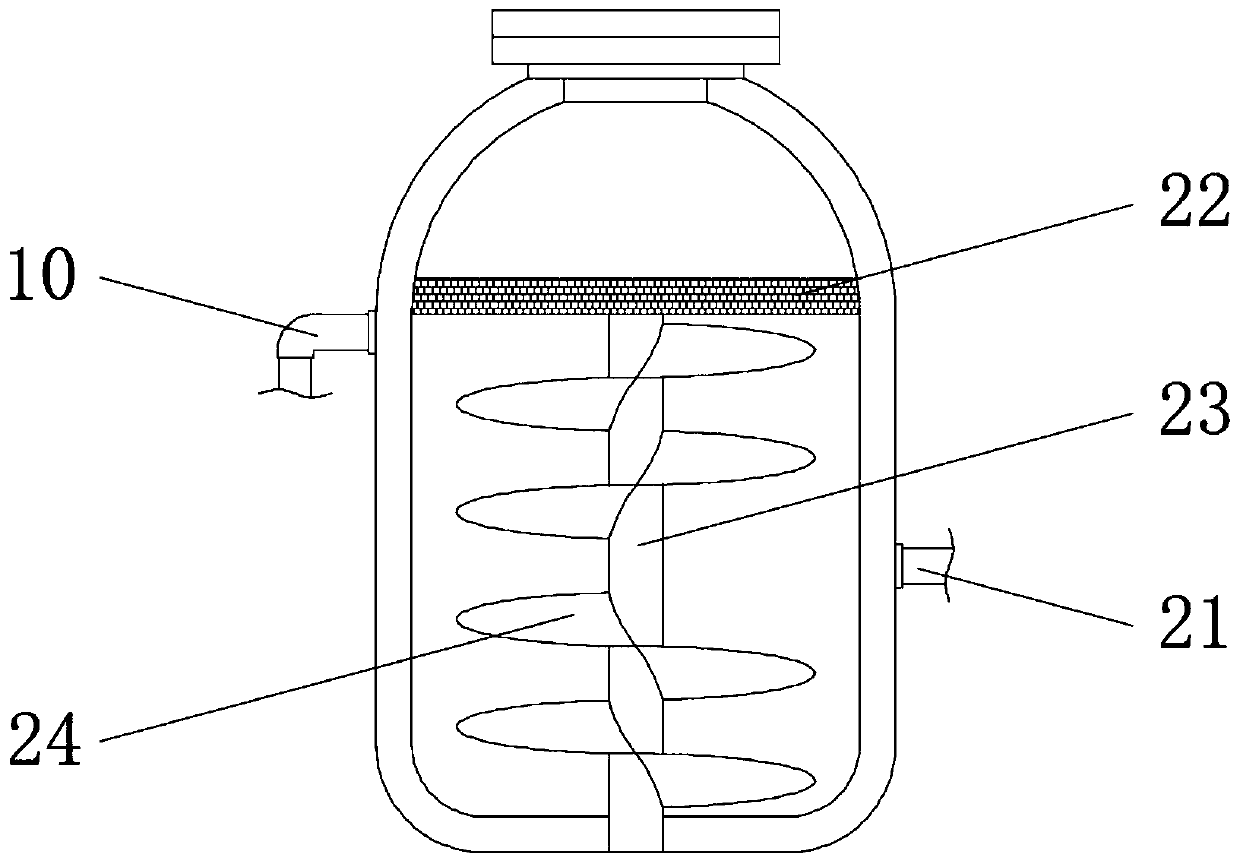

Precise high-pressure polyurethane foaming machine

The invention discloses a precise high-pressure polyurethane foaming machine. The foaming machine comprises a base, material bins and a mixing box; a first support is mounted at the top of the base; acontrol box is mounted at the top of the base; and the material bins are mounted at the top of the first support. According to the foaming machine, by the aid of a first pressure pump and a first pressure gauge which communicate with the mixing box as well as second pressure pumps and second pressure gauges which communicate with the two material bins, raw materials in the mixing box and the material bins can be stirred and pressurized respectively, the raw materials in the two material bins are stirred and pressurized preliminarily, are fluffy due to the internal gas, are conveyed into an inner barrel of the mixing box and are mixed for stirring and pressurizing again, the volumes of the two groups of fluffy raw materials are enlarged, the contact area of the raw materials is increased,mixing of the raw materials is promoted, meanwhile, the secondary pressure can be adjusted according to the state of the raw materials after preliminary pressurizing, by the aid of the foaming procedure of secondary pressurizing, the phenomenon of insufficient foaming can be avoided, the raw materials are ensured to be foamed completely, foam is fine and uniform, and the machine is suitable for wide popularization and use.

Owner:WENZHOU FEILONG POLYURETHANE ENG

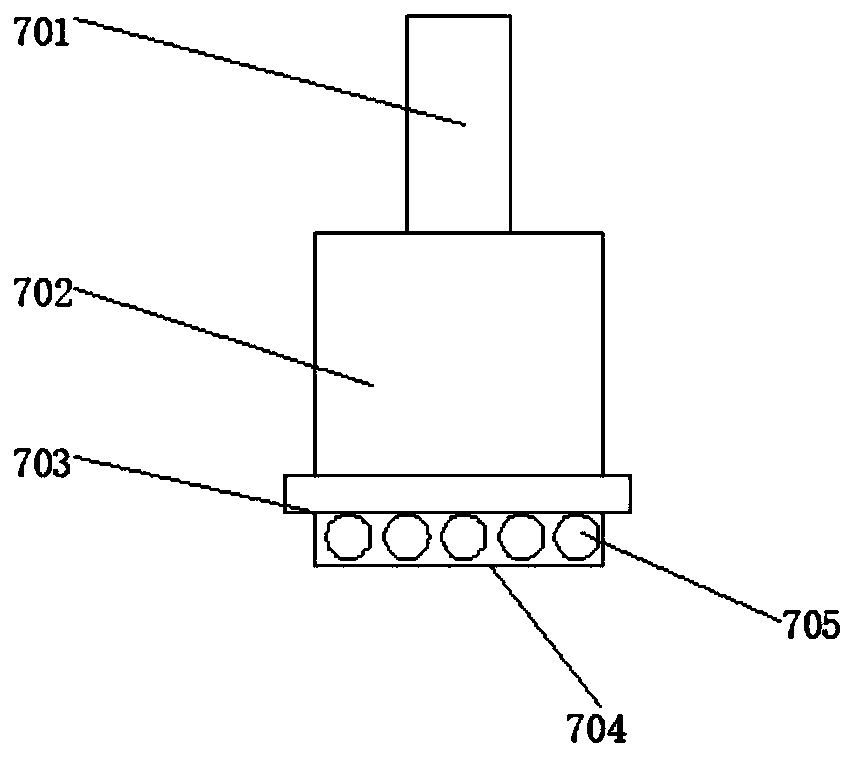

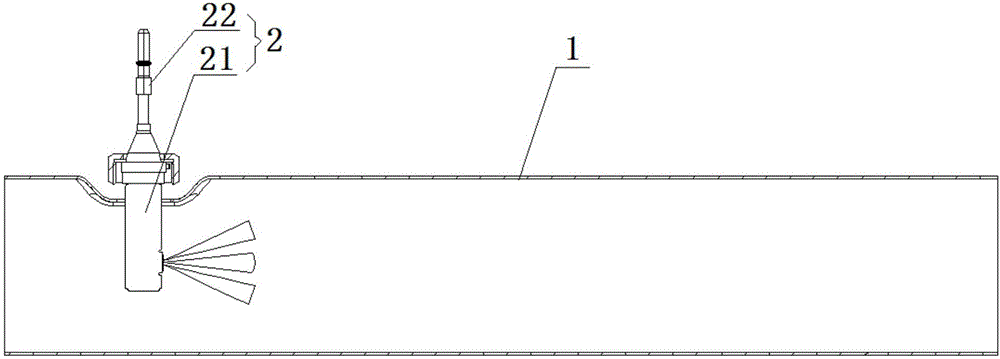

Novel urea mixer

ActiveCN106121792APromote mixingReduce cross-sectional flow areaExhaust apparatusSilencing apparatusSpray nozzleExhaust gas

The invention discloses a novel urea mixer. The novel urea mixer comprises a mixing pipe used for gathering urea and tail gas and a urea spraying nozzle vertically connected with one end of the mixing pipe in an inserted mode. A first baffle surrounding the urea spraying nozzle is arranged in the mixing pipe. A notch is formed in the lateral surface, opposite to the spraying direction of the urea spraying nozzle, of the first baffle. A second baffle opposite to the spraying direction of the urea spraying nozzle is further arranged in the portion, on one side of the first baffle, of the mixing pipe and is an arc baffle which extends upwards from the bottom of a turning surface of the mixing pipe, inclines in the direction away from the first baffle and then is gently bent in the tail gas flowing direction. The edges of two sides of the second baffle are in butt joint with the turning surface of the mixing pipe. An airflow passage for tail gas circulation is formed above the second baffle. The novel urea mixer is simple in structure, the problem of urea crystallization near the spraying nozzle and inside the mixer is solved, and the production cost is lowered.

Owner:GUANGXI YUCHAI MASCH CO LTD

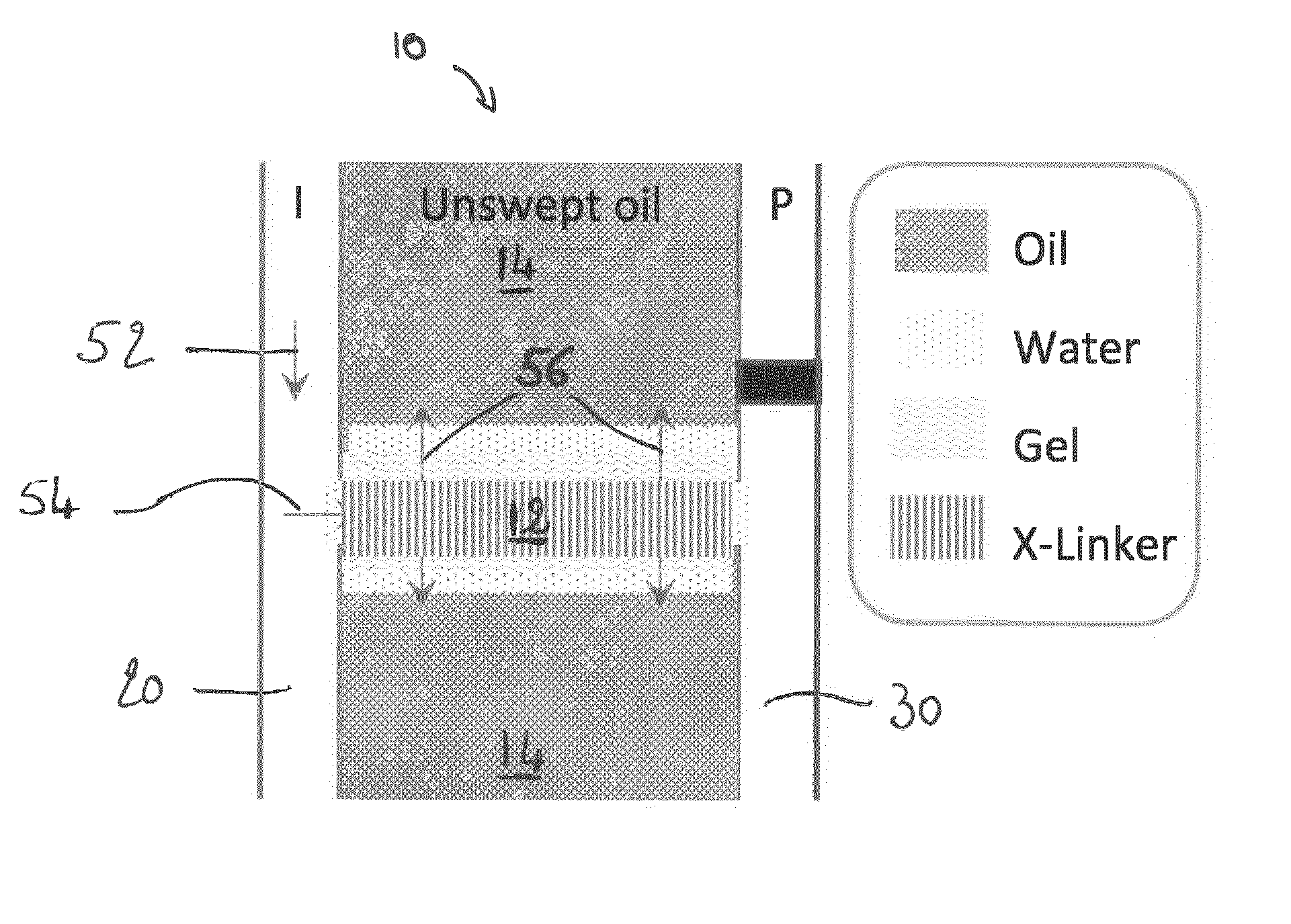

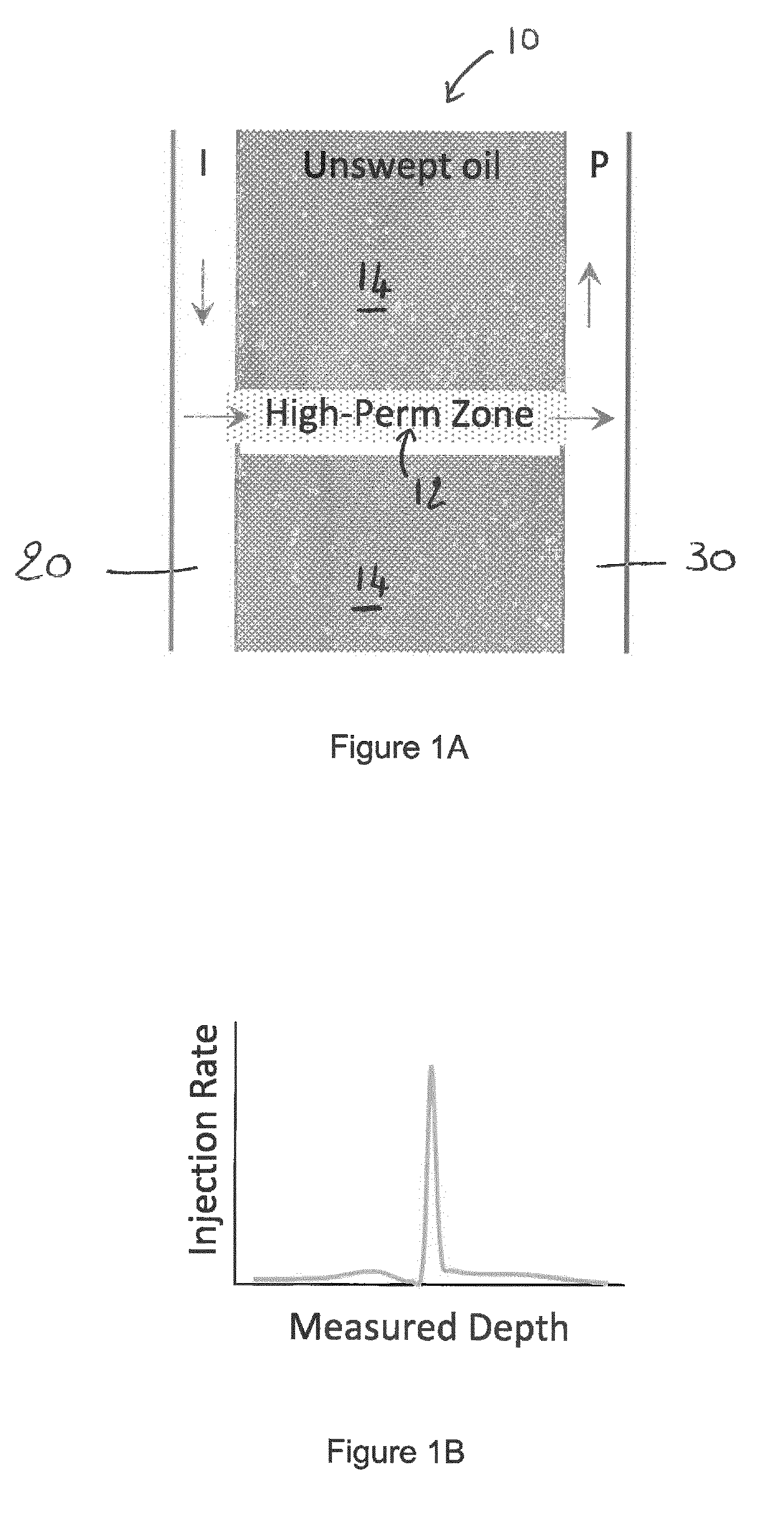

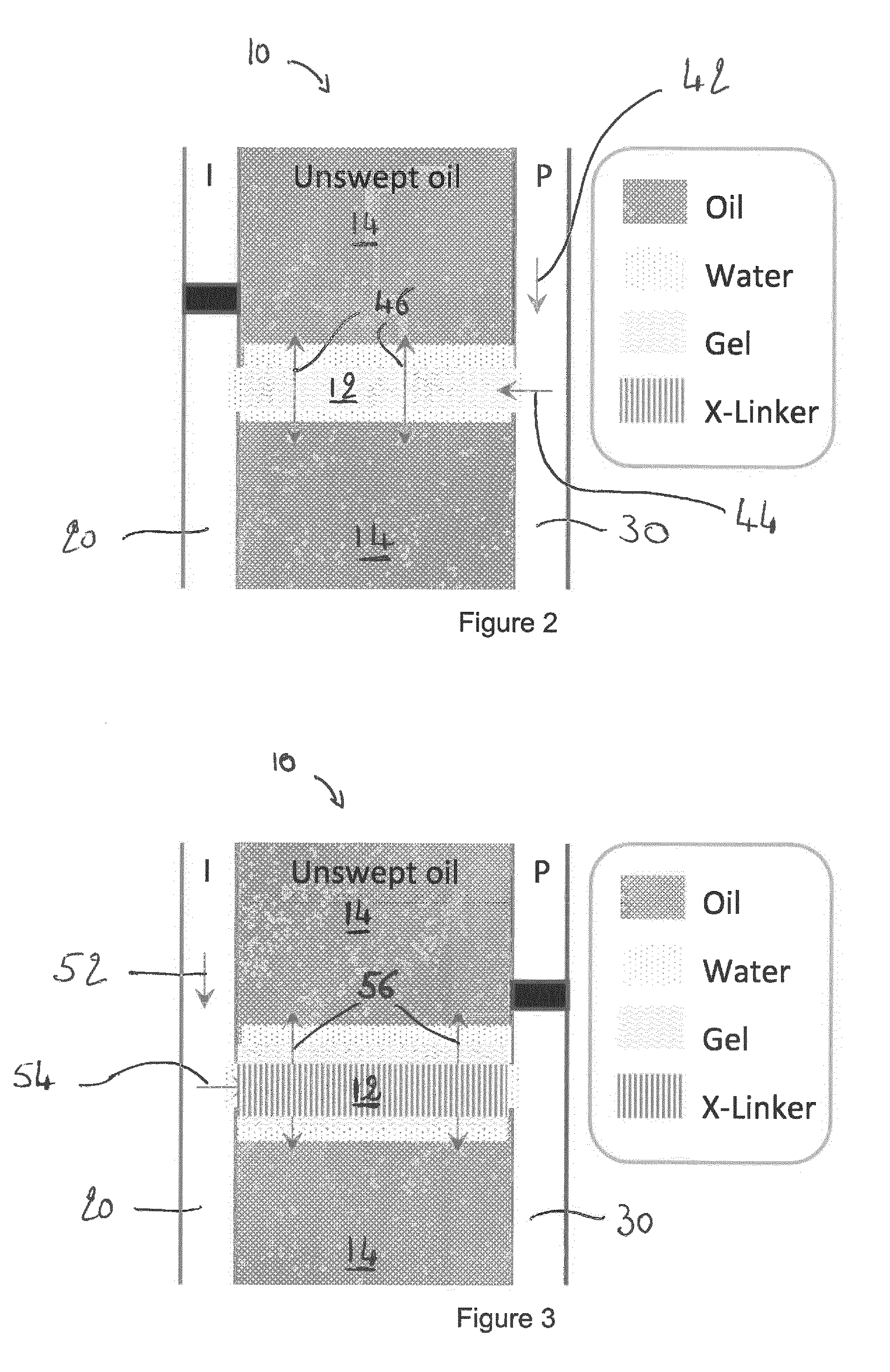

Controlled alternating flow direction for enhanced conformance

ActiveUS20160177662A1Promote mixingReduce permeabilitySurveyFluid removalEngineeringReaction product

Owner:MAERSK OLIE & GAS AS

Classified dosing device for sewage treatment

InactiveCN111422931APromote mixingNo overdose will occurRotary stirring mixersTransportation and packagingSewage treatmentSewage

The invention discloses a classified dosing device for sewage treatment, belonging to the technical field of sewage treatment. According to the invention, a stirring mechanism is arranged in a sewagetank; two ends of a stirring shaft in the stirring mechanism are respectively screwed with the left and right side walls of the sewage tank through sealing bearings; a conveying pipe is inserted intoone end of the stirring shaft and is screwed with the stirring shaft through a sealing bearing; the other end of the conveying pipe penetrates through one side wall of the sewage tank and then is inserted and fixed to the outer ring wall of a connecting pipe; a plurality of first hoses are inserted into the other side of the outer ring wall of the connecting pipe at an equal interval; the other ends of the first hoses are connected with a plurality of water suction pumps in a medicine distribution mechanism; and the medicine distribution mechanism is arranged on one side of the sewage tank. Different medicines are respectively separated through separation plates, and a second hose on the upper side of each separation plate is connected with one water suction pump, so the different medicines can be pumped into the sewage tank for mixing through the water suction pumps at different time periods; and thus, the phenomenon of excessive addition of medicines cannot occur. The classified dosing device of the invention has the advantages of reasonable arrangement, low production cost and the like.

Owner:湖南洞庭环保科技有限公司

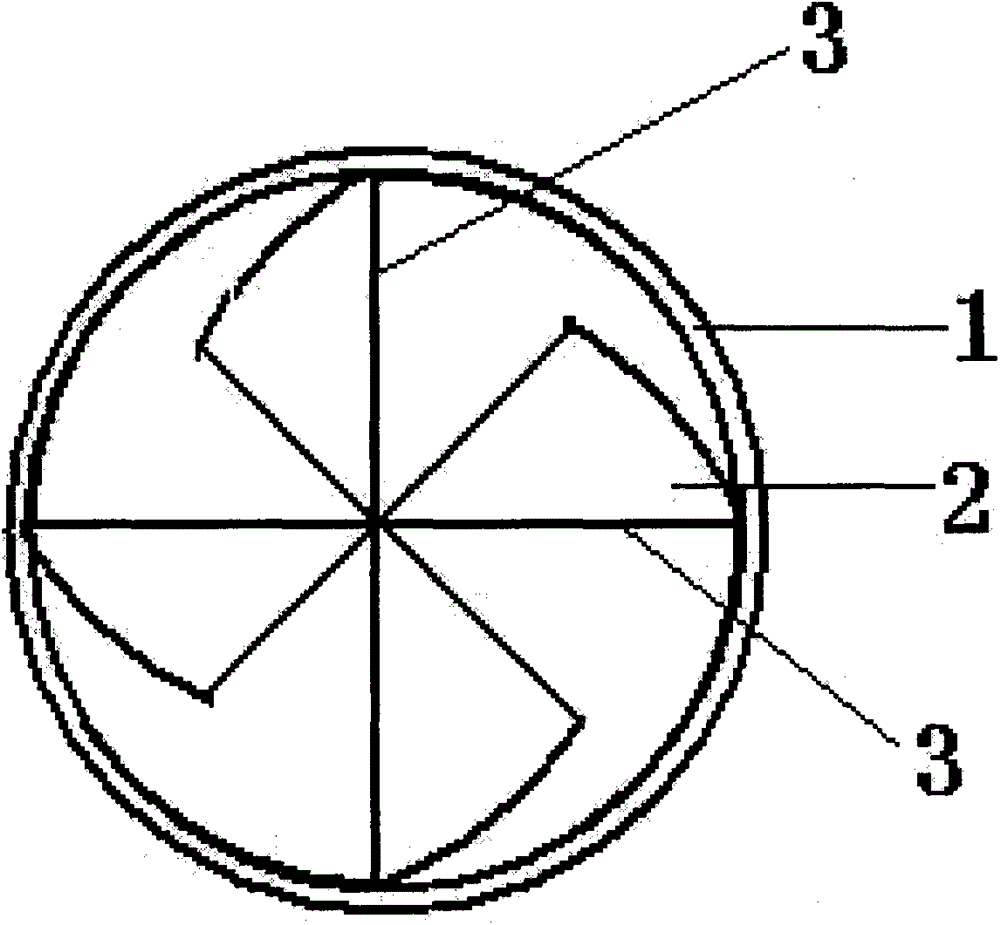

Combustion-supporting wind rotator of gas stove

The invention discloses a combustion-supporting wind rotator of a gas stove. The combustion-supporting wind rotator of the gas stove is composed of a connecting barrel, a fan blade and a fixing rod. When combustion-supporting wind output from a blast blower arrives at the rotator through a wind pipe of the blast blower, the linear moving combustion-supporting wind is guided to change the move direction by the fan blade, because the fan blade is composed of four blades which incline in the same direction, the combustion-supporting wind moves along the inclination direction of the fan blade to form rotating flow. The rotating move combustion-supporting wind enters a premixing chamber to rotationally and transversely push scattered fuel gas to maximize the combustion-supporting wind and fuel gas mixing.

Owner:王丽君

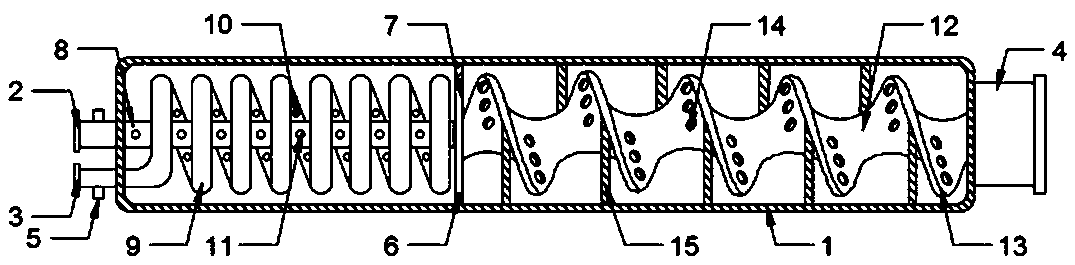

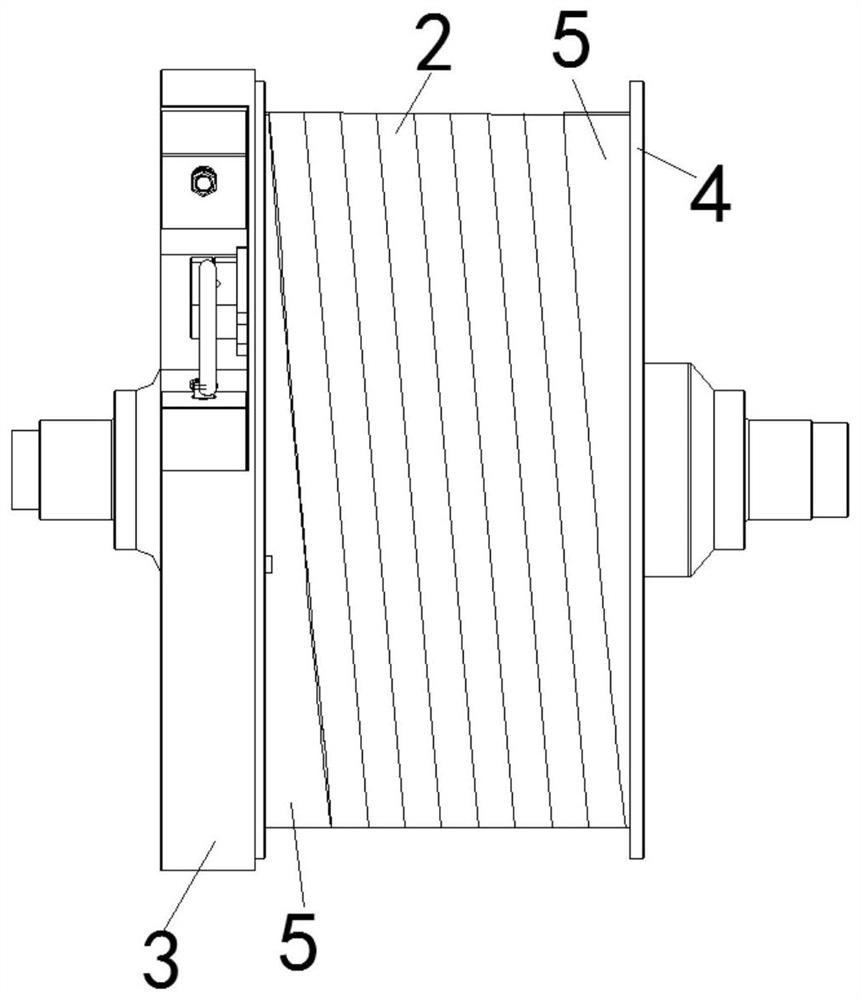

Pressure bearing fluid mixing apparatus

PendingCN110433682APromote mixingIncrease the heat transfer surface areaPreparation from carboxylic acid halidesFlow mixersEngineering

The invention discloses a pressure bearing fluid mixing apparatus, which comprises an inner bushing and an outer bushing, wherein a first channel is arranged in the inner bushing, and comprises a plurality of unit channels, the adjacent unit channels are communicated, a flow blocking member is fixed on the unit channel, the inner bushing is provided with a plurality of first inlets and a pluralityof first outlets, a second channel is arranged in the outer bushing, the outer bushing is provided with a plurality of second inlets and a plurality of second outlets, and the inner bushing is fixedon the second channel. According to the present invention, by organically combining the inner bushing and the outer bushing, the efficient mixing and heat exchange effect of different fluids is achieved; and compared with the conventional fluid stirring device, the technical scheme of the present invention has advantages of continuous and stable mixing reaction, safety and high efficiency.

Owner:欧志安

Environment-friendly laboratory wastewater treatment device

InactiveCN112110584APromote mixingImprove settlement efficiencyWater treatment parameter controlWater/sewage treatment by irradiationElectric machineryWater treatment

The invention relates to the technical field of wastewater treatment, and discloses an environment-friendly laboratory wastewater treatment device. The device comprises a first motor, a pH detector, asecond motor, a controller and a settling tank, wherein a neutralization reaction tank is arranged on the left side of the upper end of the settling tank; a deodorization device is arranged on the right side of the upper end of the settling tank; a plurality of ultraviolet lamp tubes are arranged at the inner upper end of the settling tank; the left side of the settling tank is rotationally connected with a first stirring rod; the left end of the first stirring rod is fixedly connected with the output end of the first motor; a right side pipeline of the settling tank is connected with a firstwater conveying pipe; an upper side pipeline of the first water conveying pipe is connected with the deodorization device; a first pump machine is arranged on the first water conveying pipe; an upperside pipeline of the settling tank is connected with a second water conveying pipe; and the other end of the second water conveying pipe is connected with the neutralization reaction box. The laboratory wastewater treatment device is simple in structure, capable of conducting multiple distribution treatment on laboratory wastewater and efficiently removing harmful substances in the laboratory wastewater, low in manufacturing cost and capable of effectively protecting environmental sanitation, and has usage value in the field of wastewater treatment.

Owner:ZIBO CREATION OF MECHANICAL & ELECTRICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com