Inverted-V-shaped multi-stage mixed array structure for passive micromixer

An array structure, micro-mixer technology, applied in mixers, chemical instruments and methods, dissolution and other directions, can solve the problems of destroying the liquid flow state, low mixing efficiency of passive micro-mixers, etc., to enhance the mixing effect and shorten the mixing time. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described through specific embodiments and drawings below.

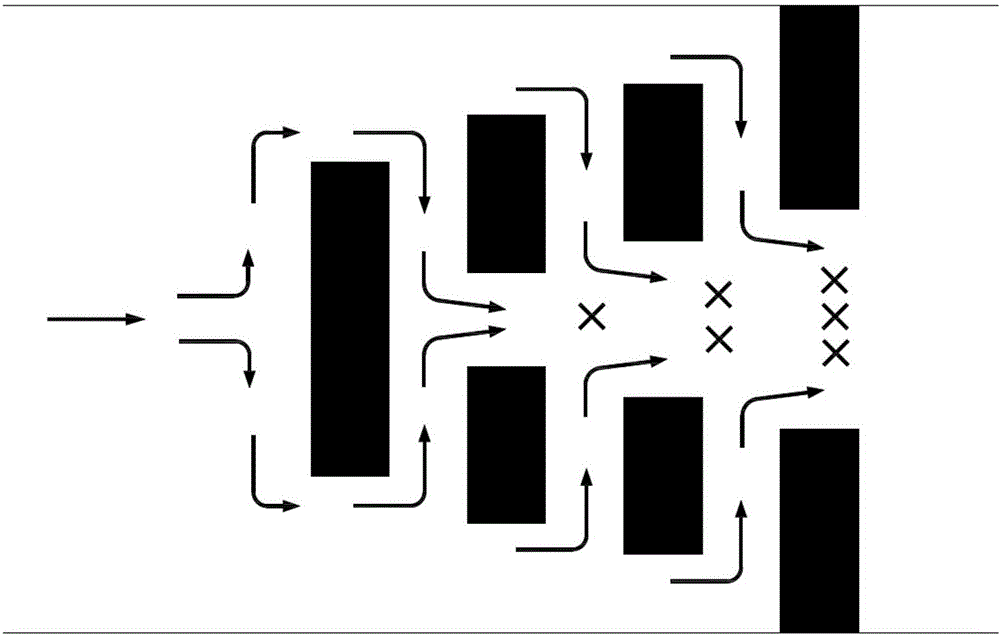

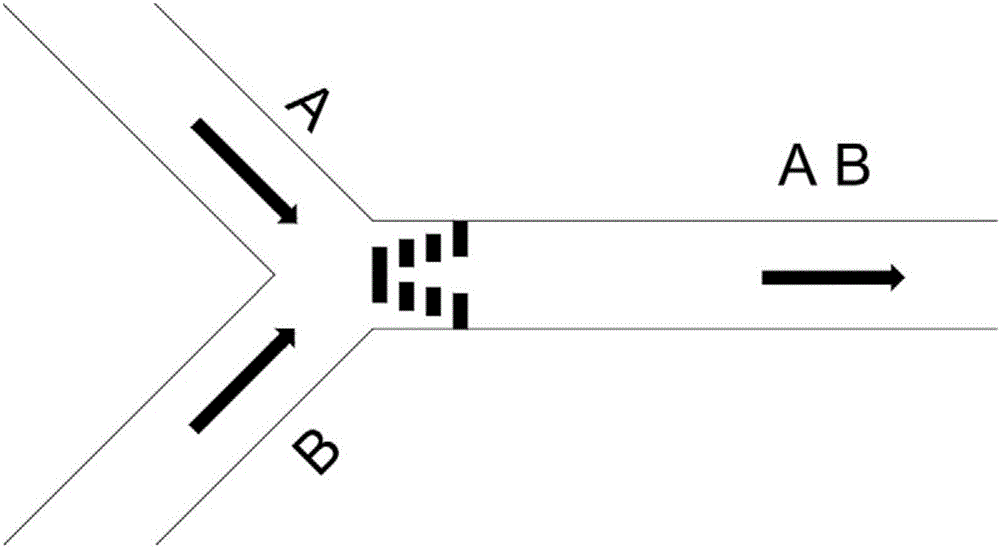

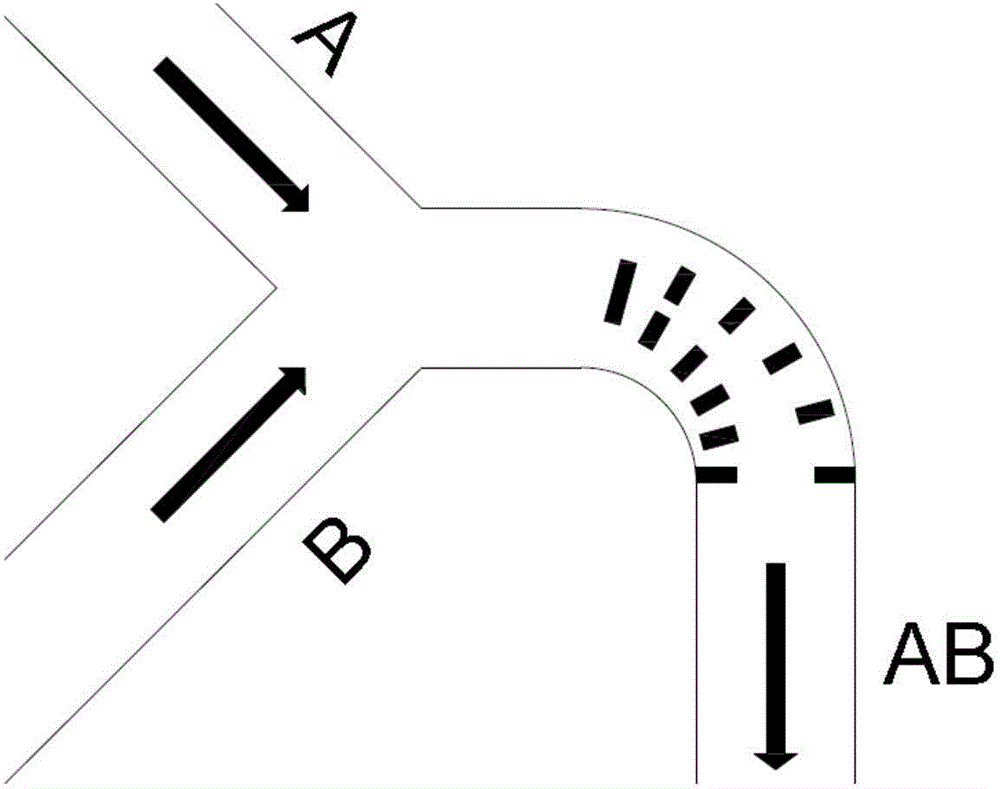

[0024] figure 1 It is a schematic diagram of the inverted V-shaped multi-stage hybrid array structure of the present invention and the flow mode of the microfluid in the structure. The specific description of the structure is as follows:

[0025] 1. The inverted V-shaped multi-stage hybrid array structure used in the passive micro-mixer is arranged in the flow channel in an inverted V shape by rectangular baffles, and the opening direction of the V-shaped structure is opposite to the fluid flow direction. The baffle in the present invention is preferably rectangular, which has a good mixing effect, but the present invention is not limited by this. In other embodiments, baffles of other shapes can also be used. In the inverted V-shaped multi-level baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com