A double-nozzle flat-plate micro-combustion chamber based on hydrocarbon fuel

A micro-combustion chamber and hydrocarbon fuel technology, which is applied in the direction of burning various fuels, gas fuel burners, block fuels and liquid fuels, etc. It can solve the problems of difficult processing and promotion, and increased complexity of the combustion chamber. problems, to achieve the effects of miniaturization, diffusion, and complete diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

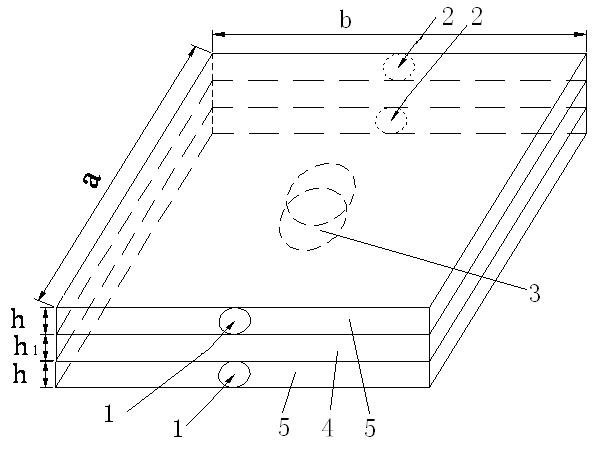

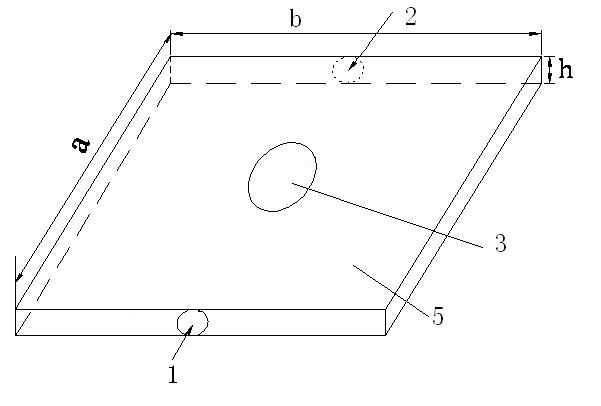

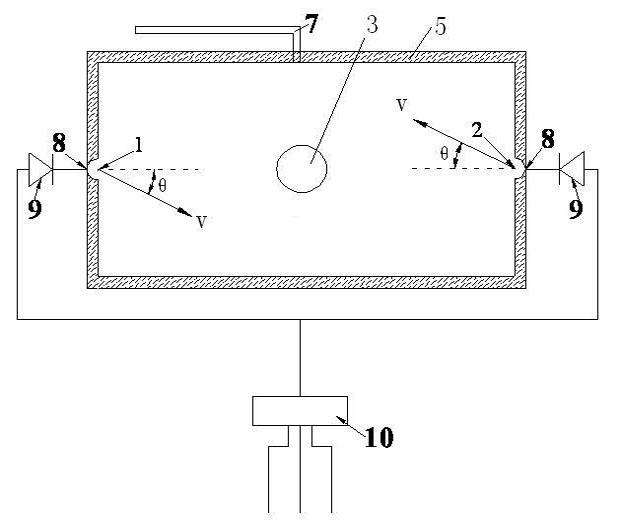

[0015] Such as Figure 1-2 , the present invention is made up of two identical micro-combustion chambers 5, and the micro-combustion chamber 5 adopts high-temperature-resistant materials, such as Sic, Al 2 o 3 Wait. The micro-combustion chamber 5 is a cube structure, and the length, width and height of the cavity inside the cube a, b, and h are usually 10mm, 10mm, 0.6mm or 8mm, 8mm, 0.6mm, and the wall thickness of the micro-combustion chamber 5 is generally 0.20~0.35mm. In the middle of an upper wall surface of the micro-combustion chamber 5, there is an outlet 3, and the axial direction of the outlet 3 is consistent with the height h direction of the micro-combustion chamber 5. There are respectively a left inlet 1 and a right inlet 2 in the middle of the opposite side walls of the micro-combustion chamber 5, and the left inlet 1 and the right inlet 2 communicate with the micro-combustion chamber 5 and the external environment. The radii of the left inlet 1 and the right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com