Patents

Literature

125results about How to "Even flow distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

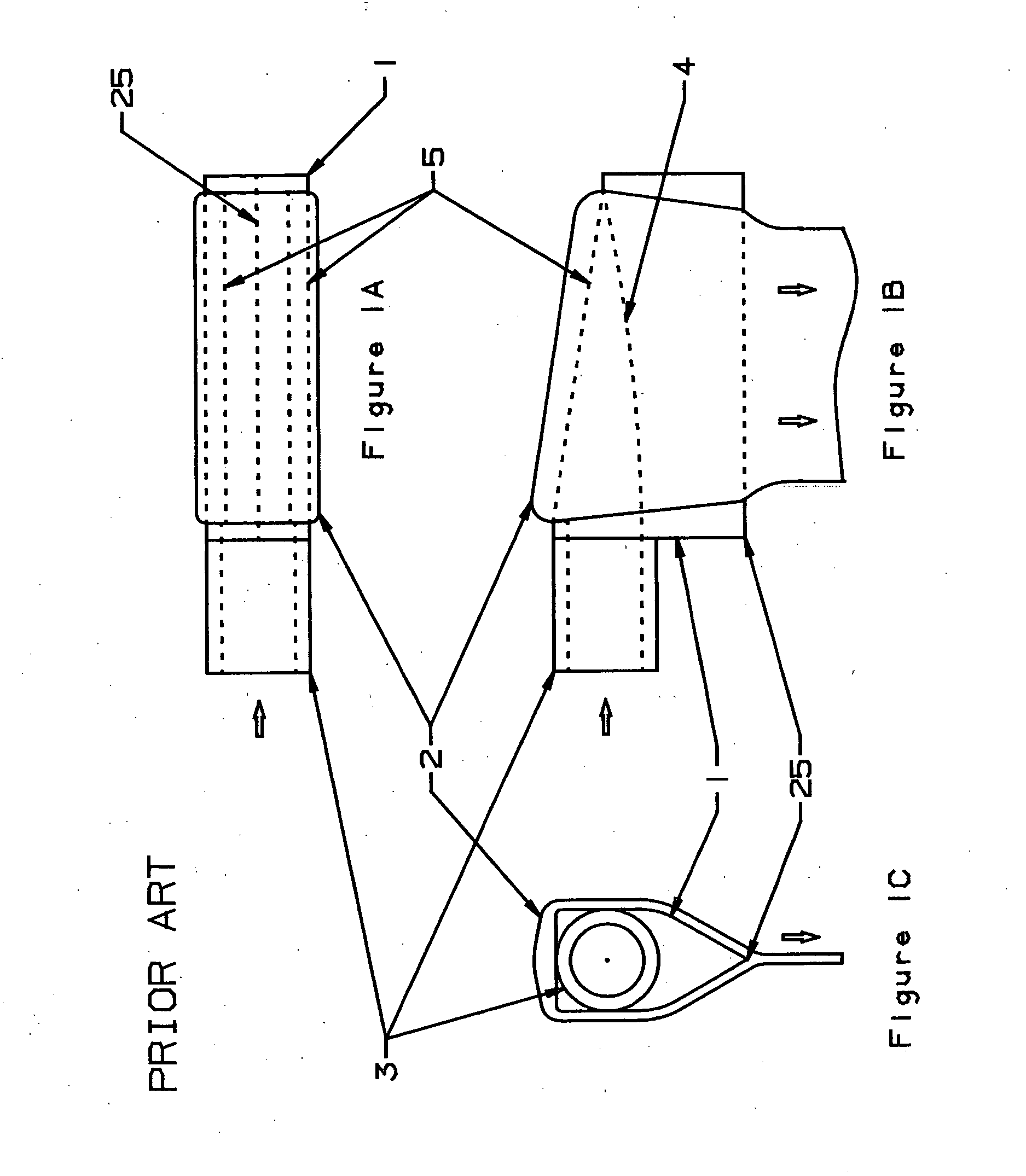

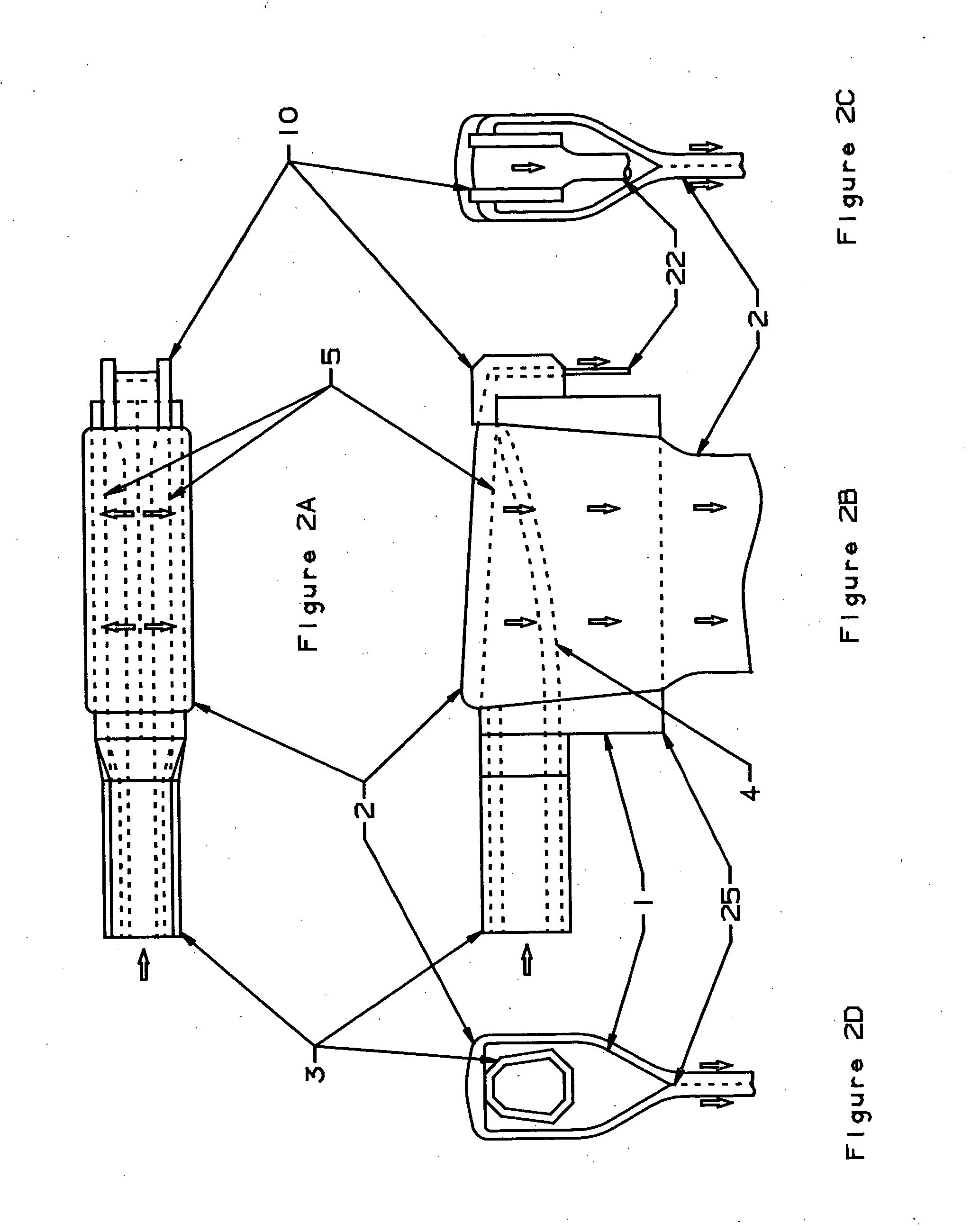

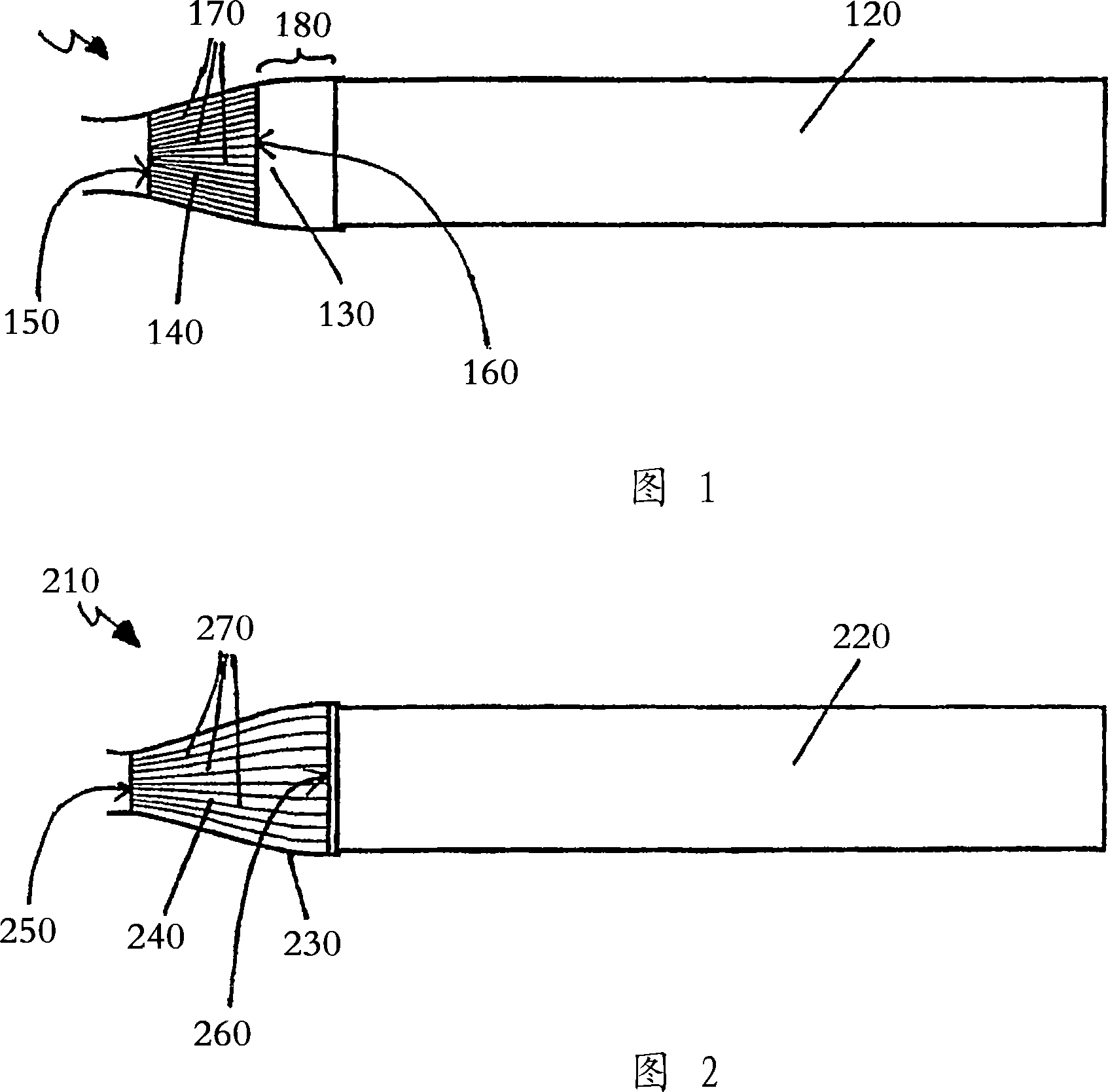

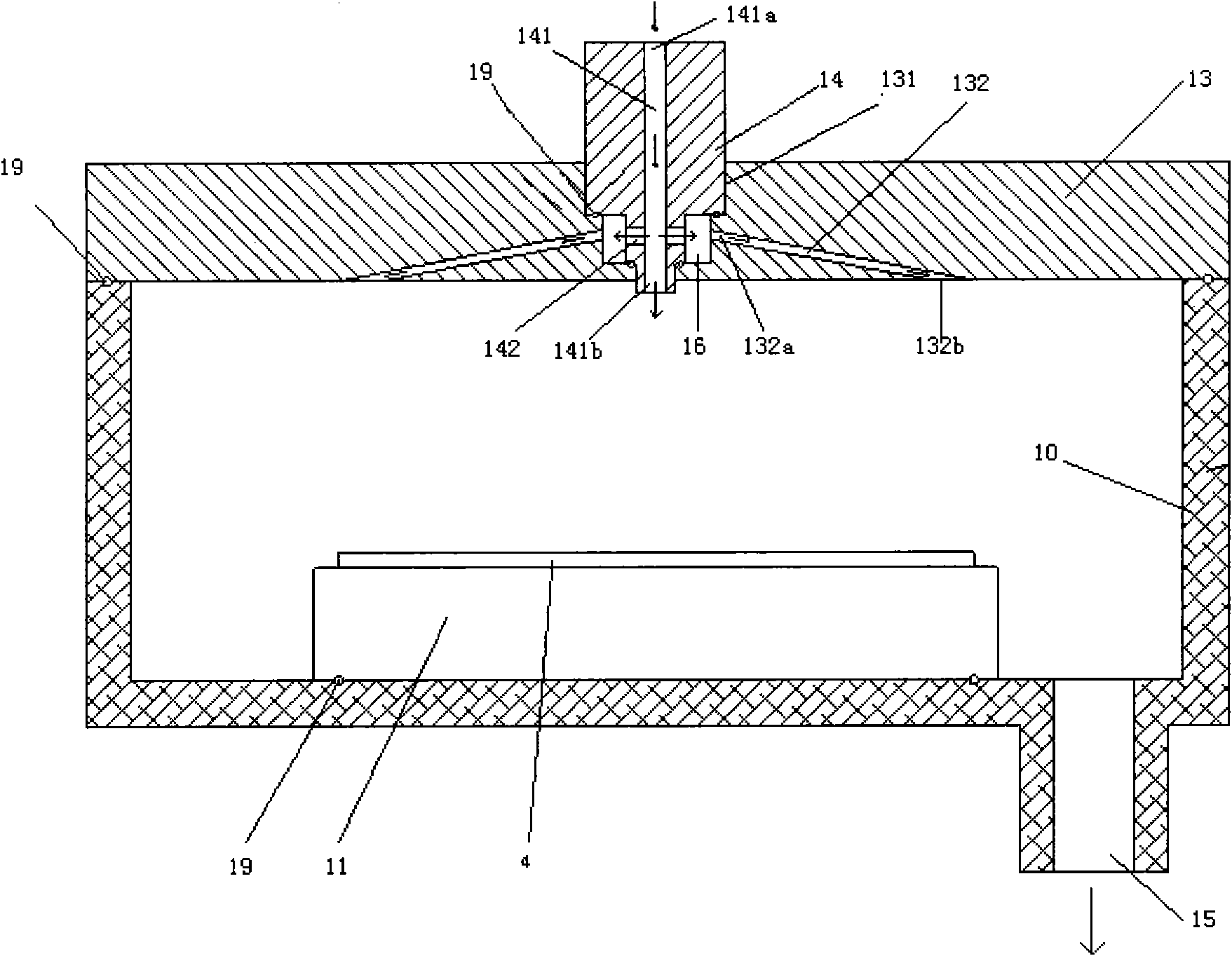

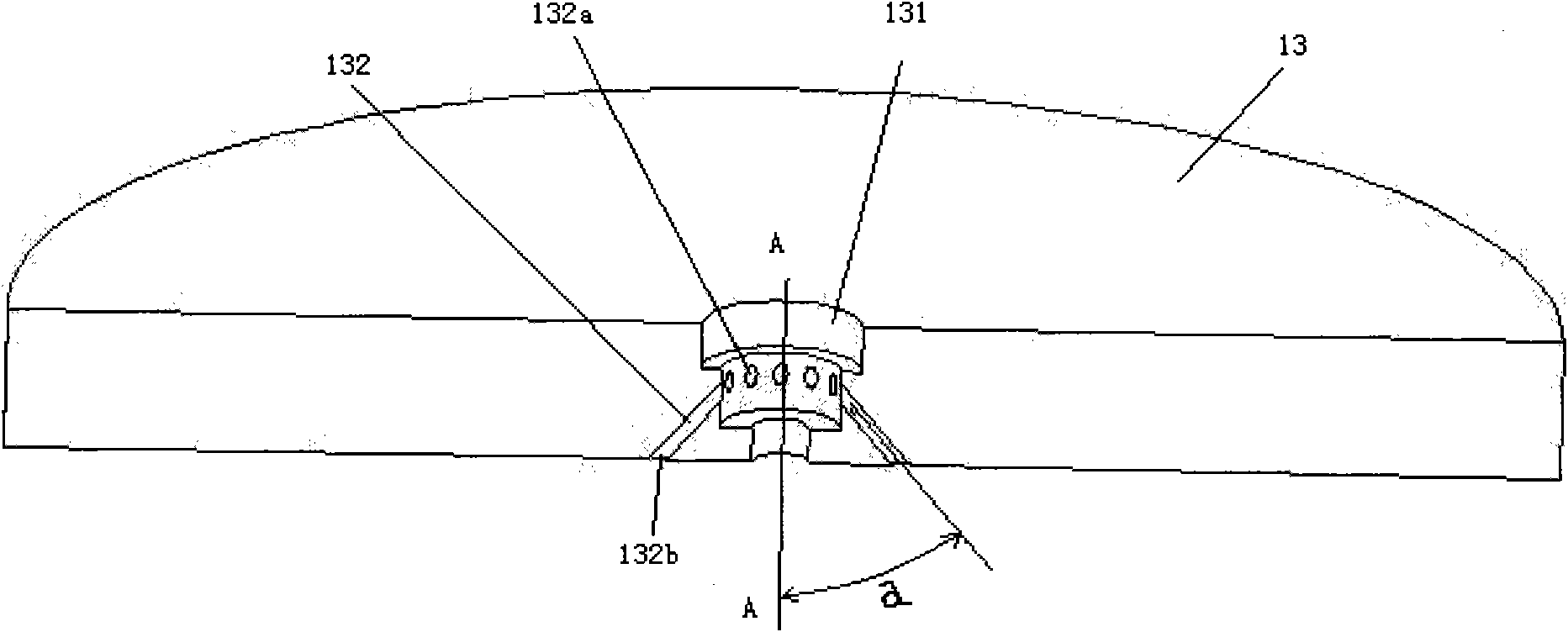

Overflow downdraw glass forming method and apparatus

InactiveUS6997017B2Facilitate faster and uniform flowIncrease rangeGlass furnace apparatusGlass drawing apparatusEngineeringFlow augmentation

The forming apparatus of the present invention preferably includes an orifice on top of the trough. The uniquely shaped orifice substitutes for the weirs as the controlling entity for glass thickness. The orifice is designed such that as it deforms, it maintains a linear flow characteristic with respect to its length. As the orifice is made larger by the applied stress, the percentage width increase is the same over its length and consequently the percentage flow increase is the same over the length of the orifice. In another embodiment, the present invention provides an adjustment to change the flow characteristics of the trough to compensate for the degradation of the forming trough during an extended production run. A flow control plug can be inserted into the trough, such that flow dynamics can be altered during hot operation by insertion, removal or position adjustment of the flow control plug.

Owner:CORNING INC

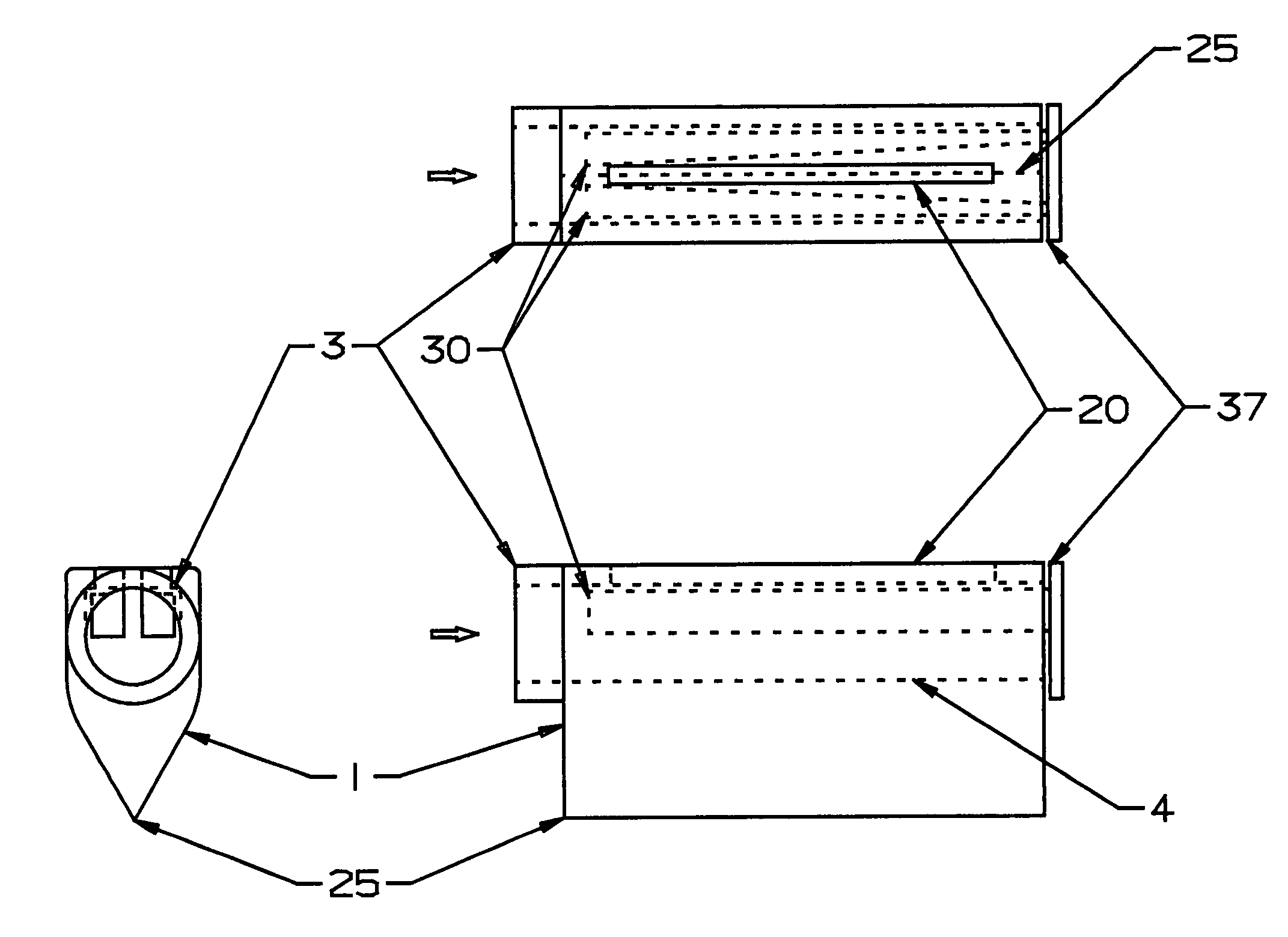

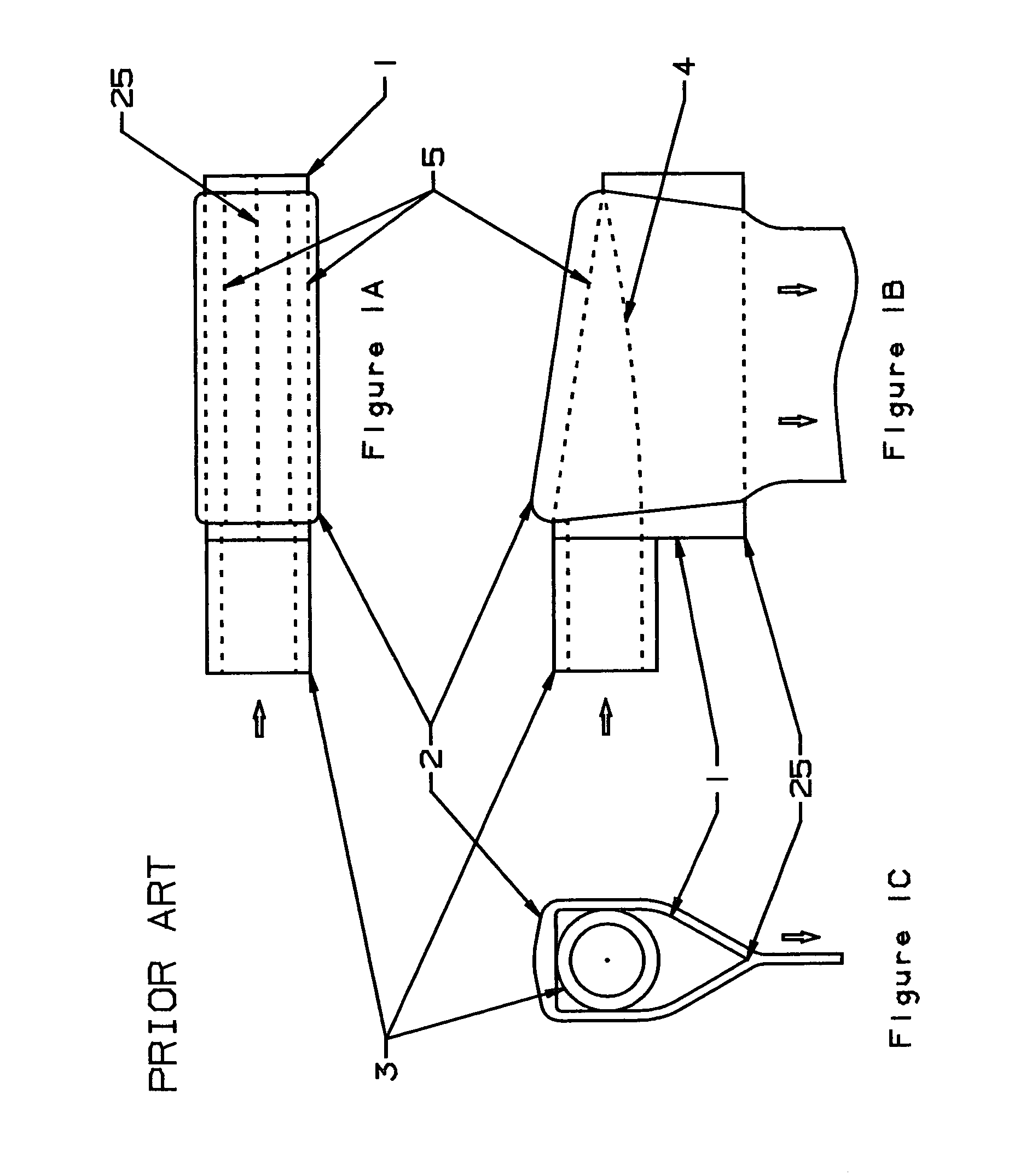

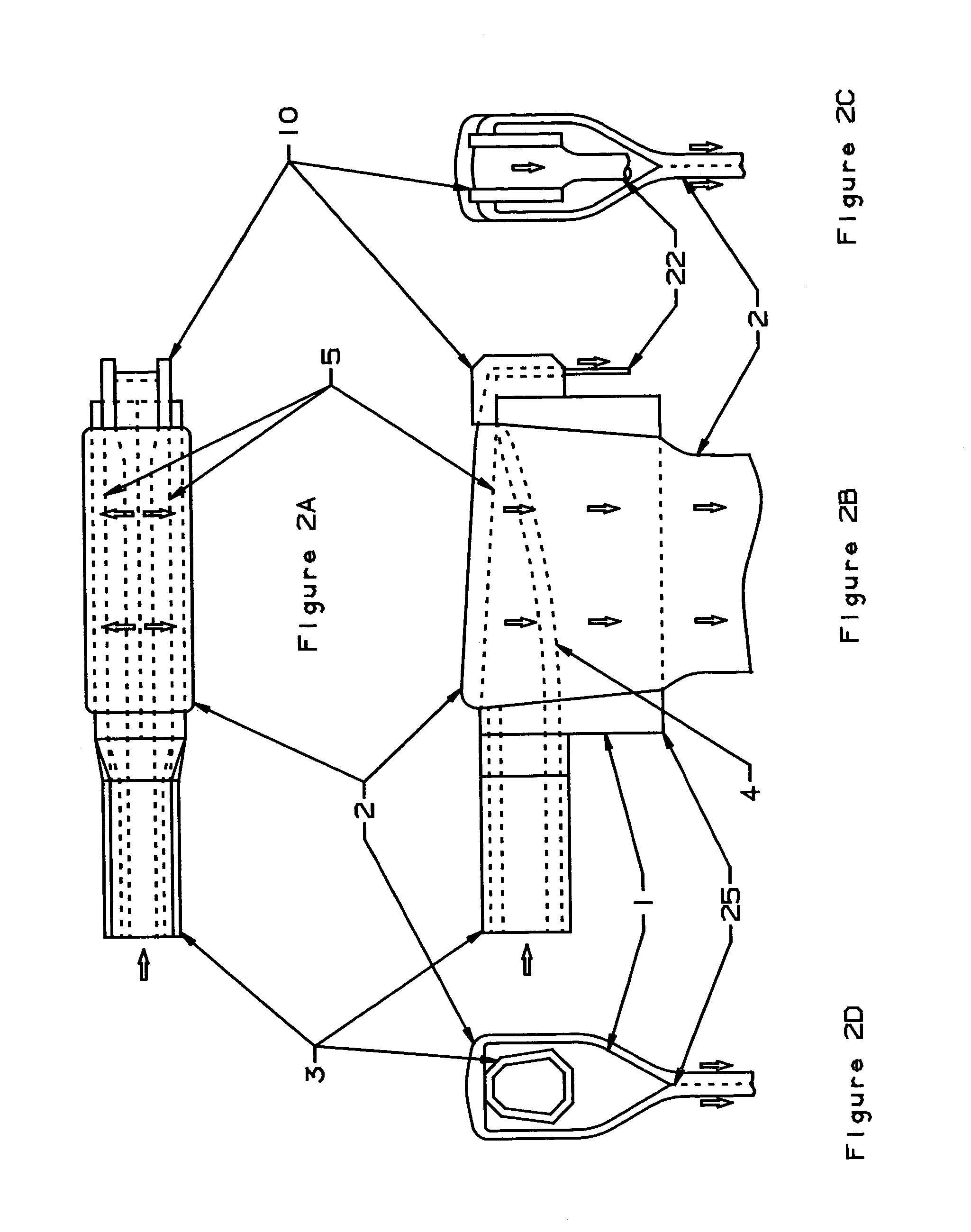

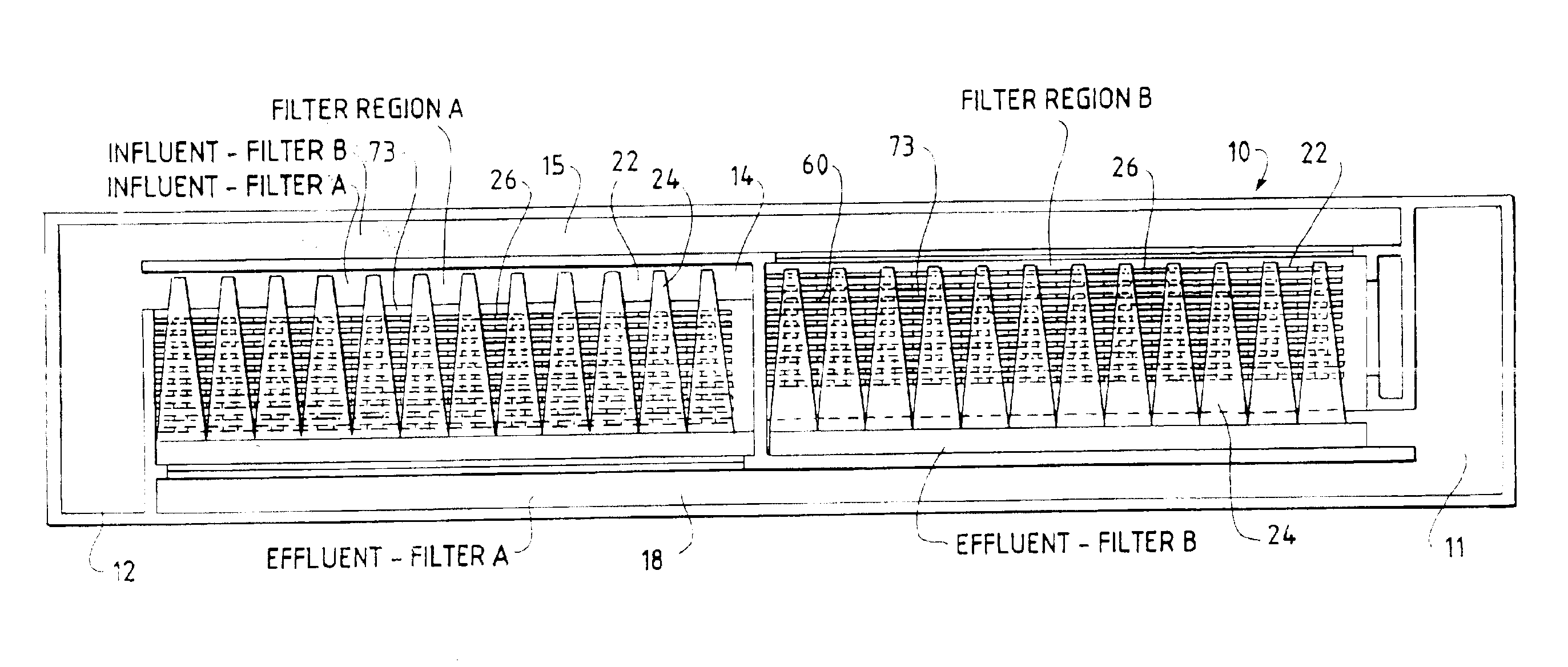

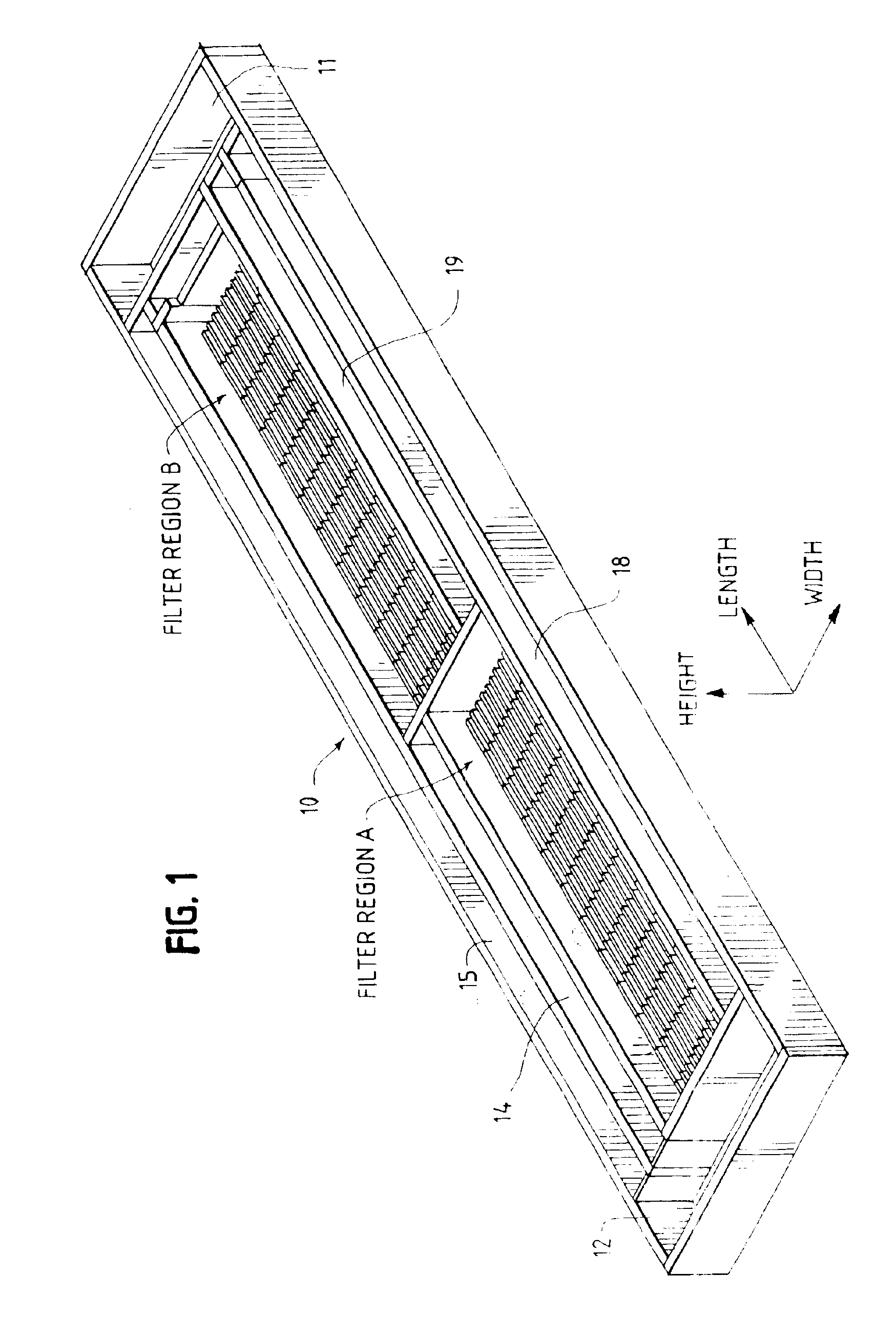

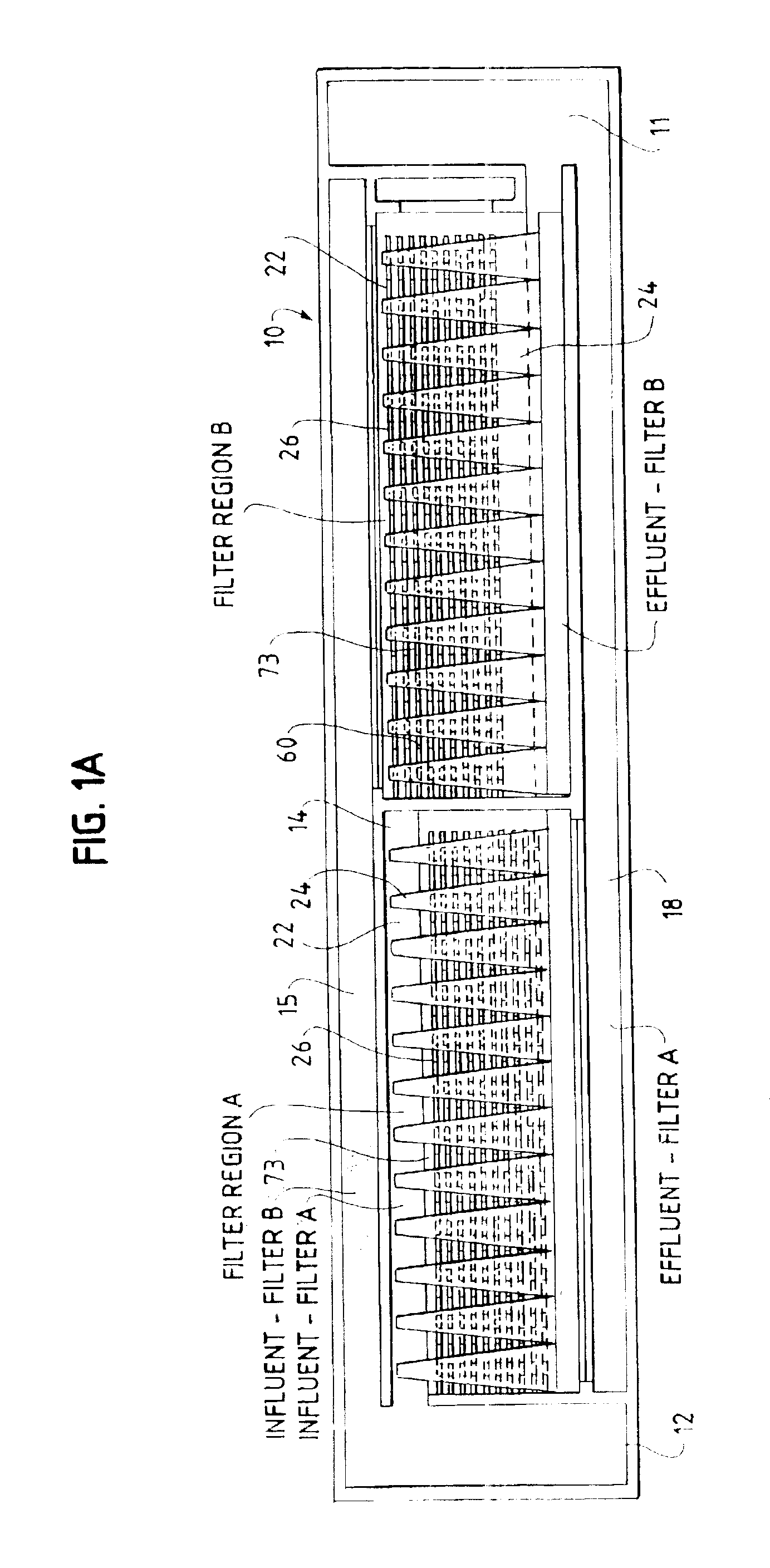

Processes and devices for water and wastewater treatment, including stationary cloth media filtration

InactiveUS6858140B2Quality improvementLow cost advantageSettling tanks feed/dischargeWater/sewage treatmentFiltrationMedia filter

The present invention relates to stationary cloth media filtration systems and devices, as well as processes and devices for uniform flow distribution and improved cloth media filter backwashing.

Owner:AQUA AEROBIC SYST

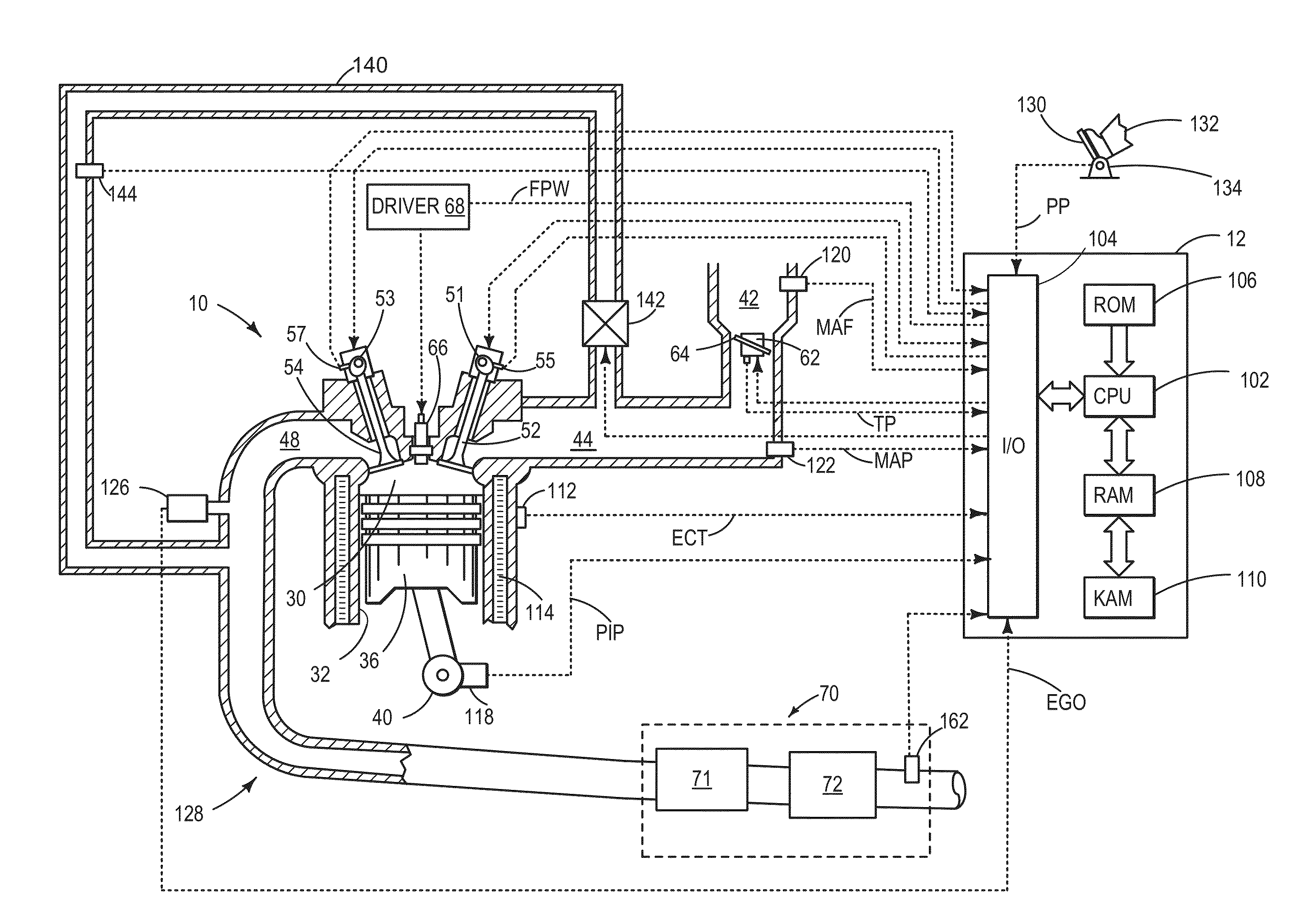

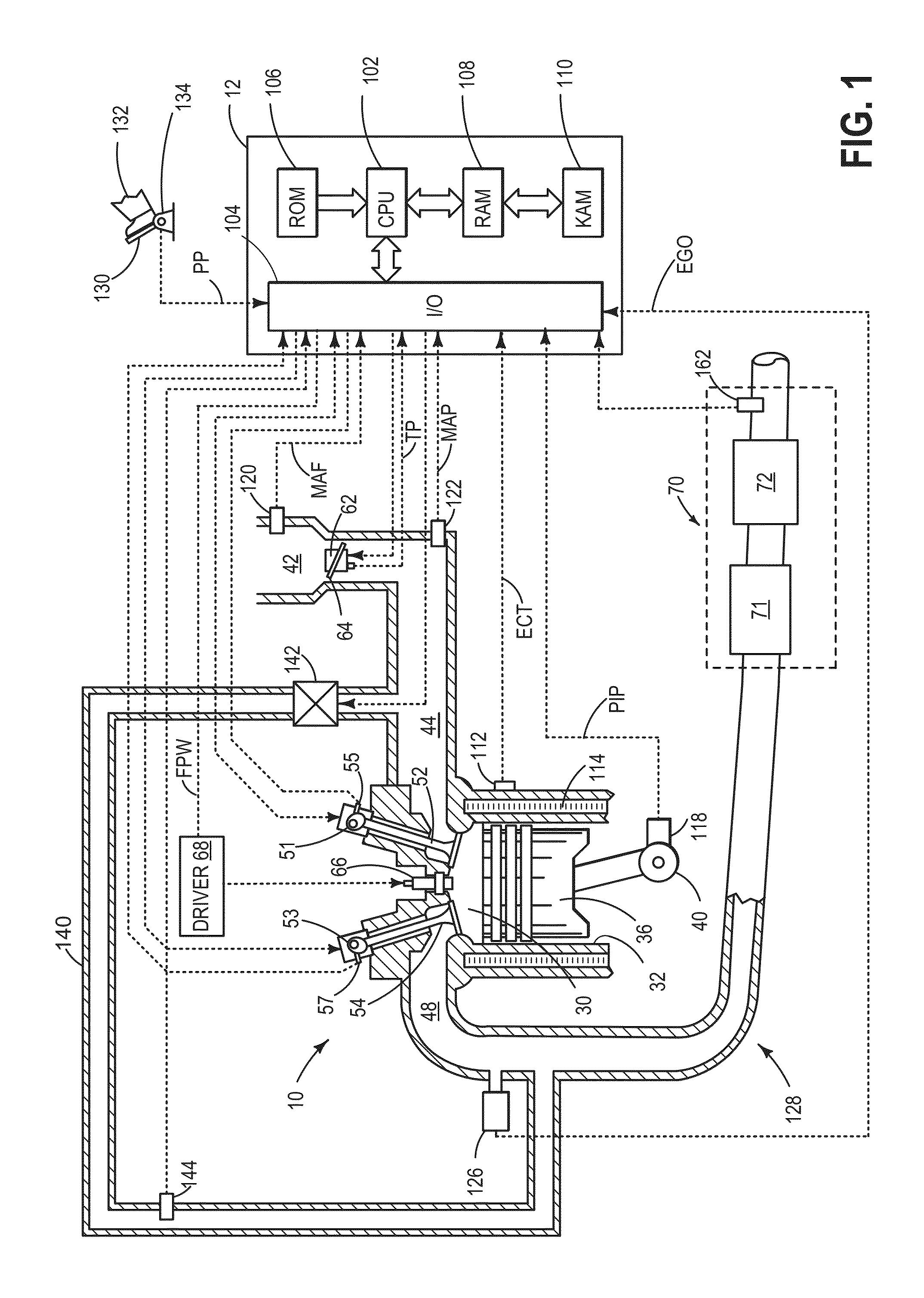

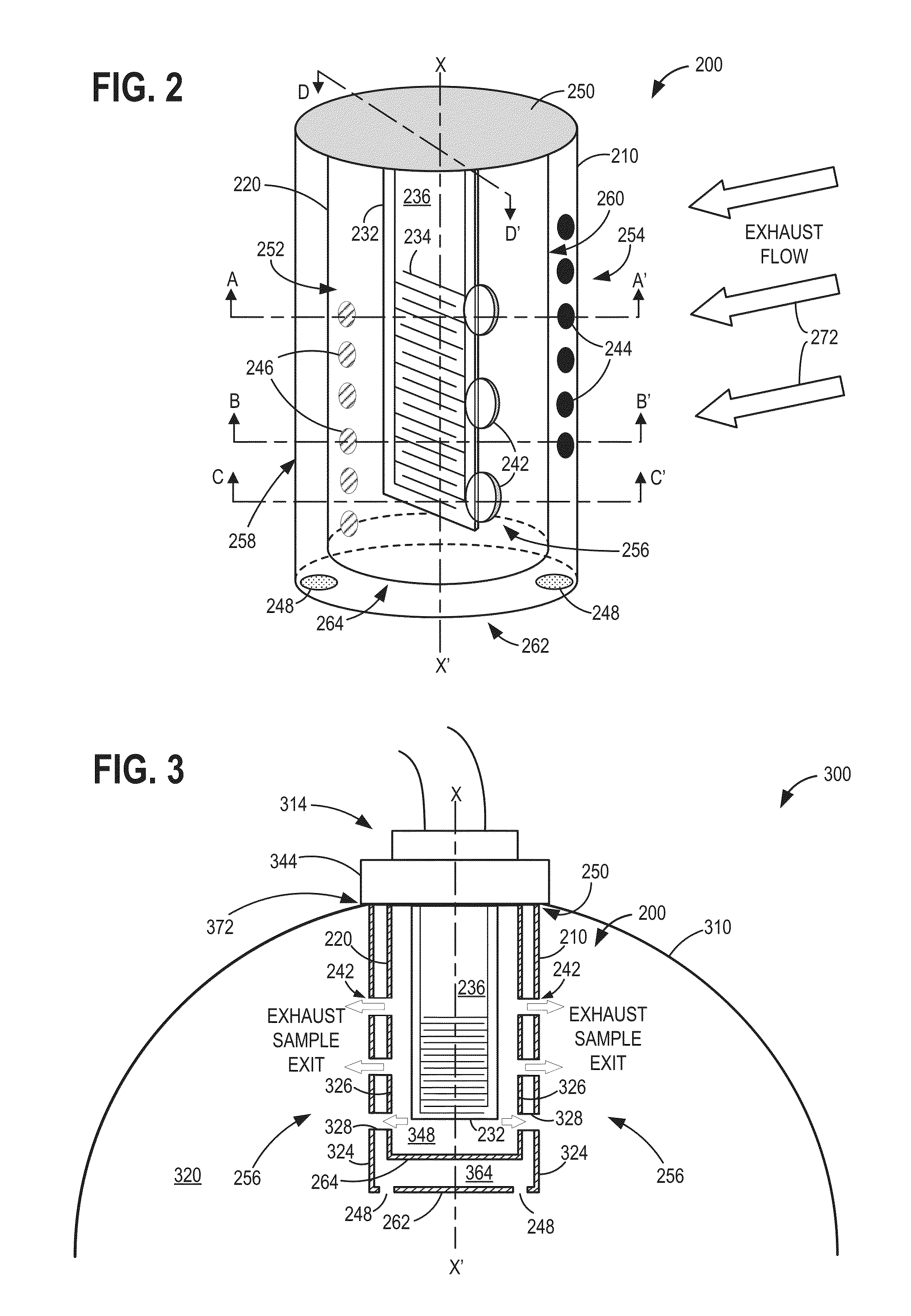

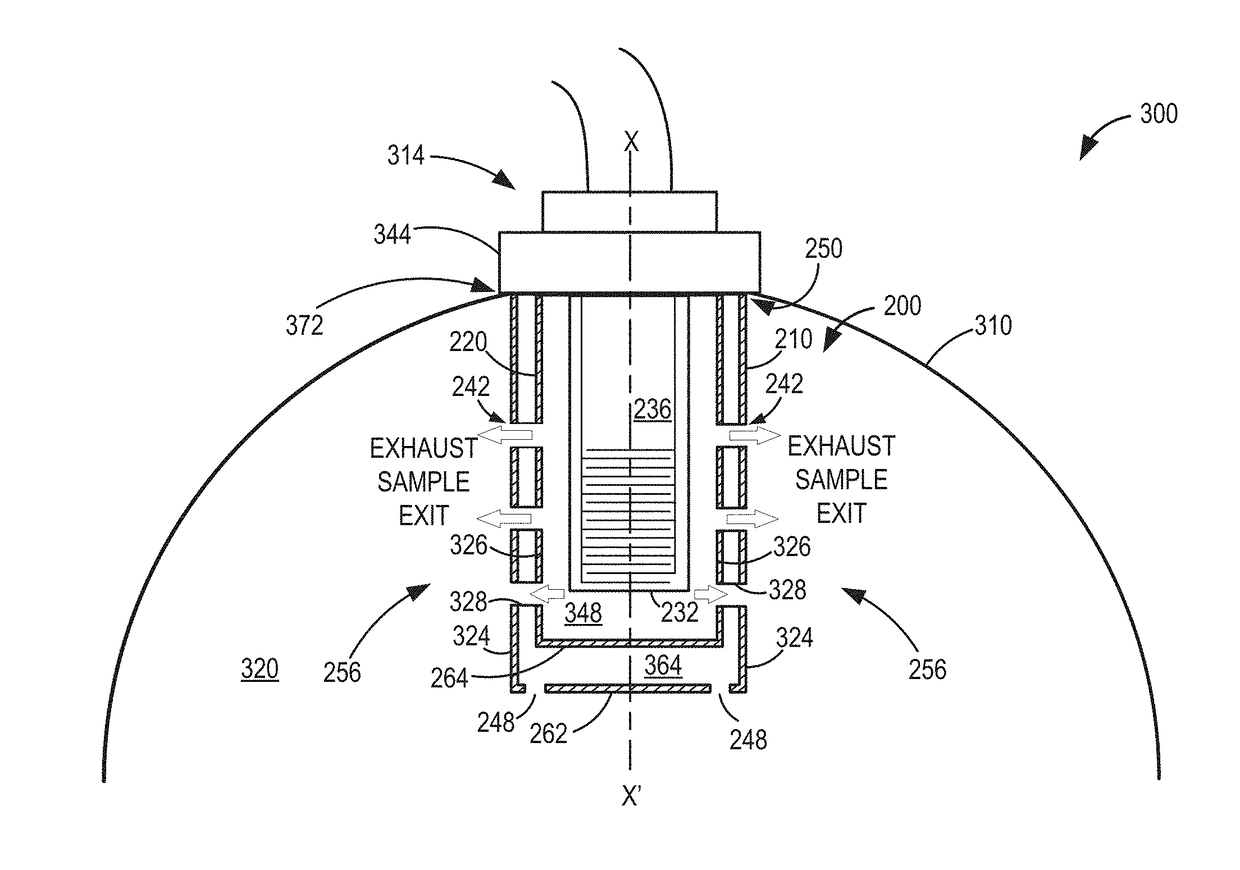

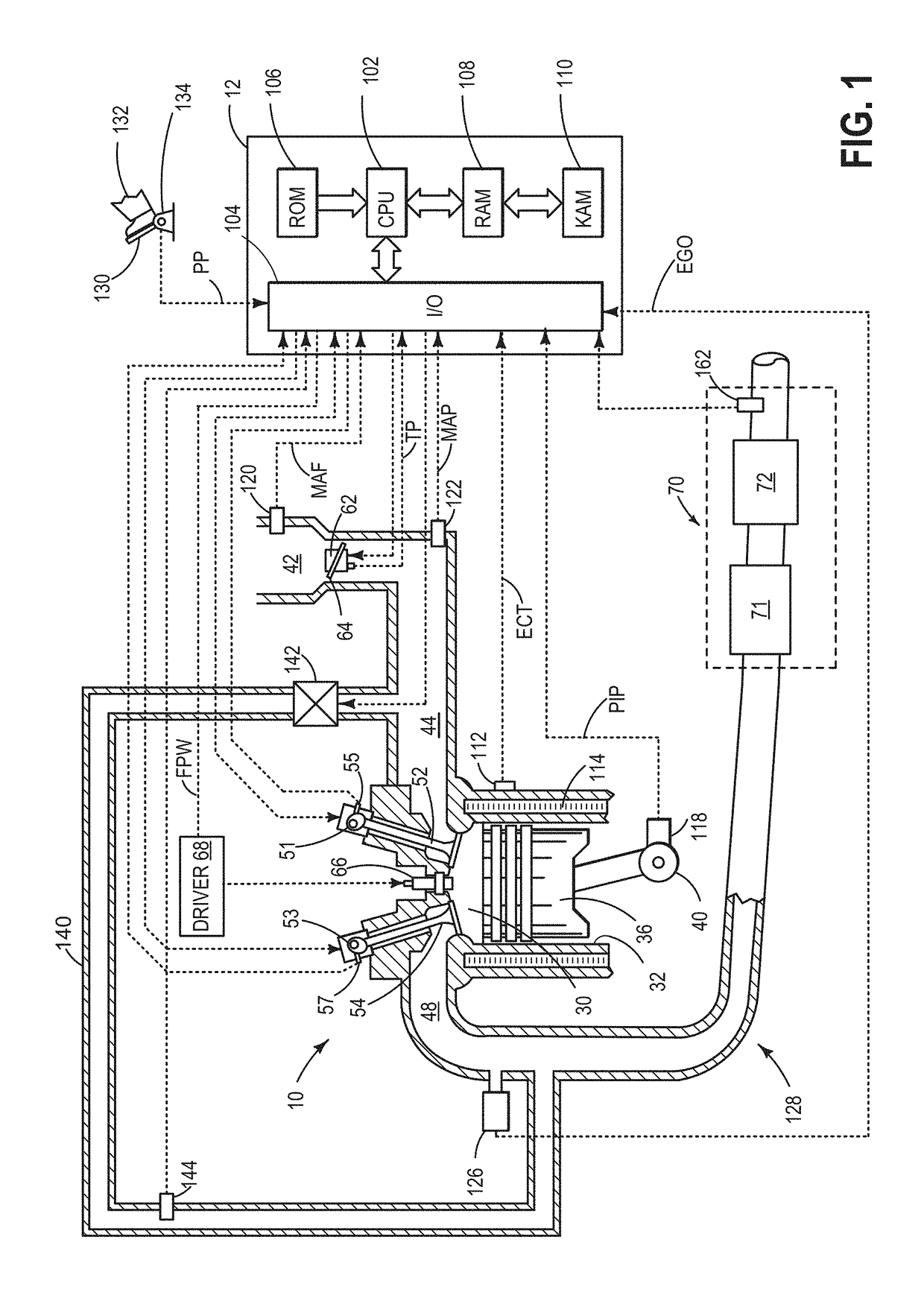

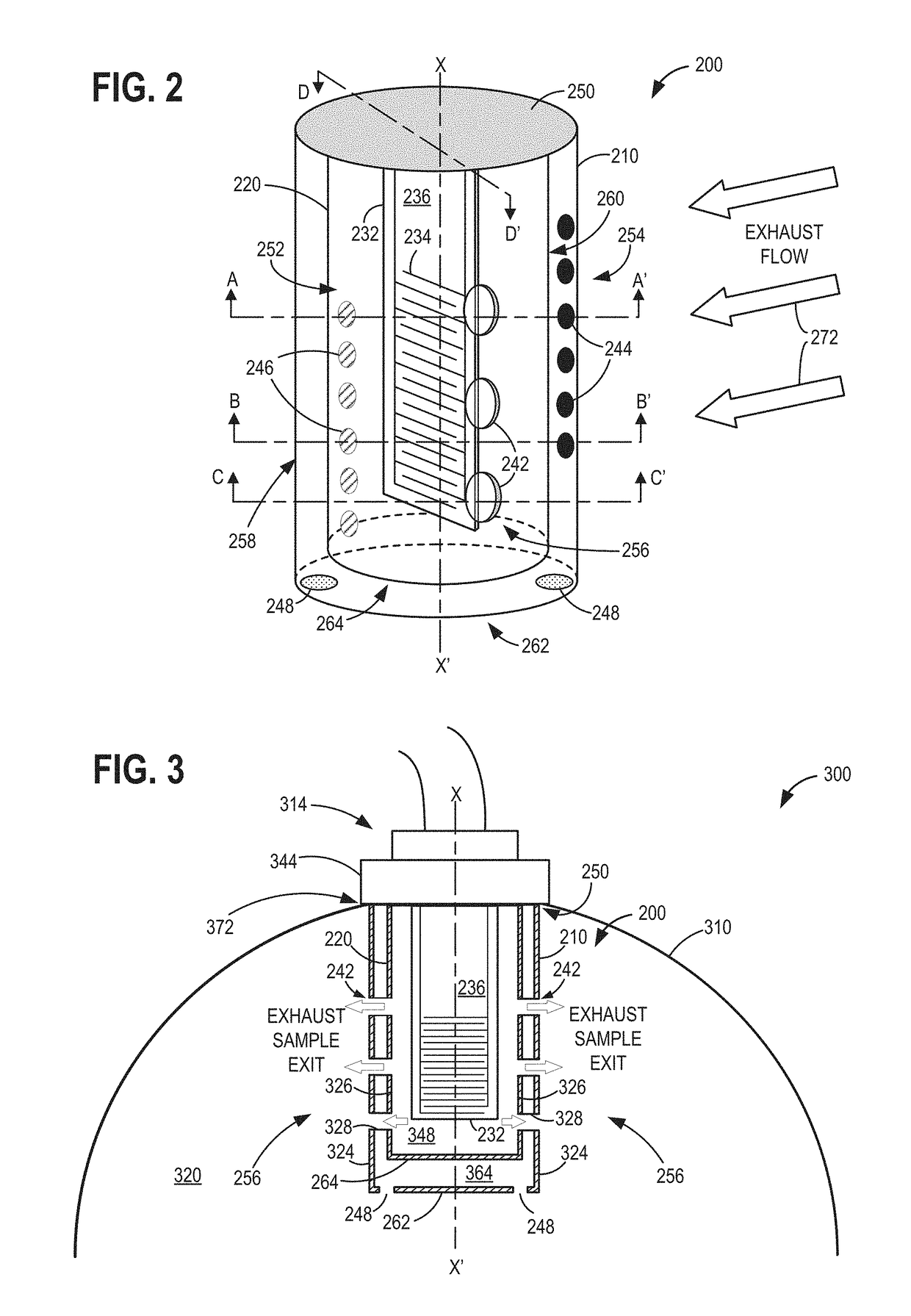

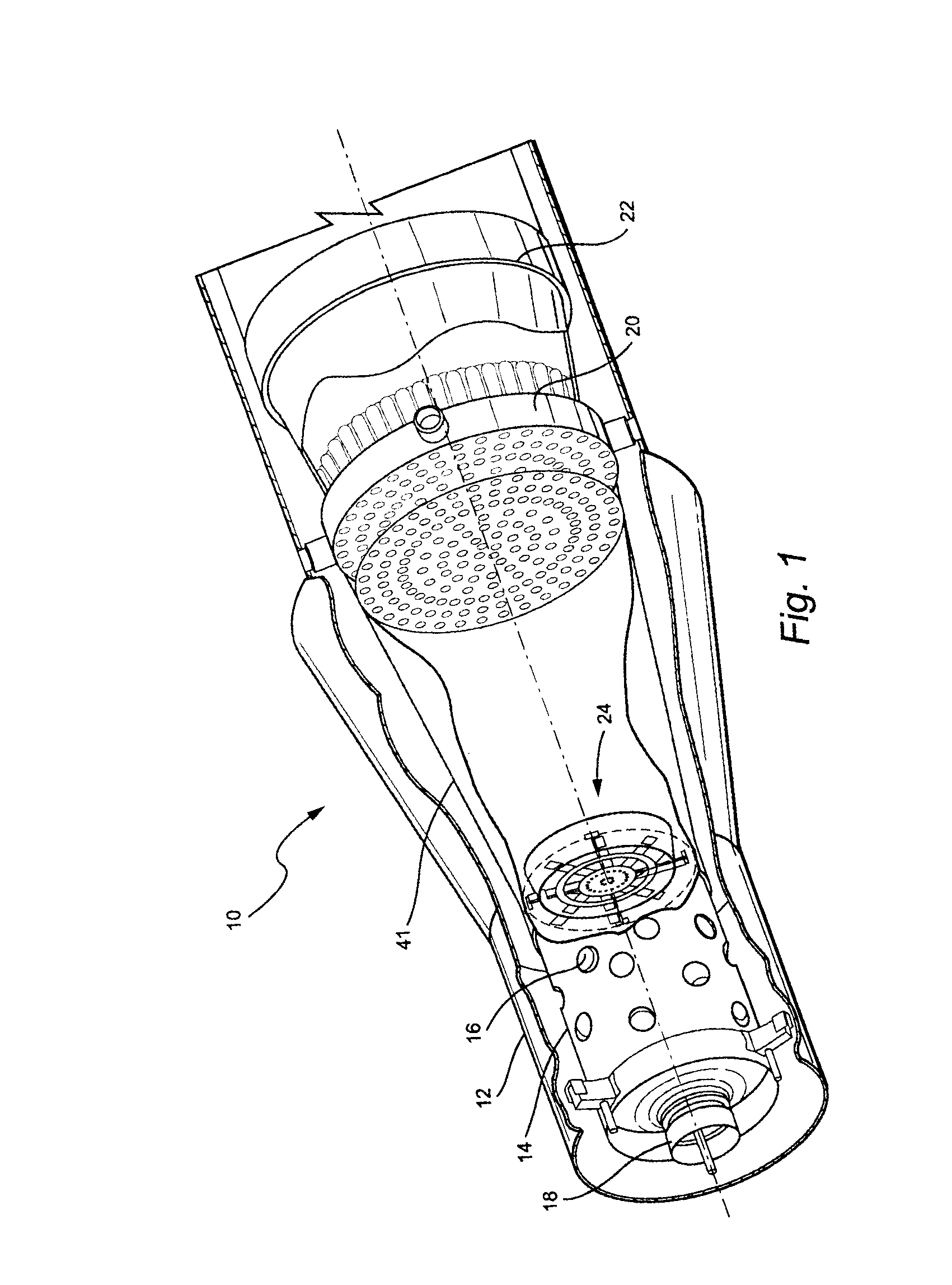

System for sensing particulate matter

InactiveUS20150355066A1Reduce heat lossUniform depositionInternal-combustion engine testingExhaust apparatusEngineeringParticulate matter sampler

Systems and methods are described for sensing particulate matter in an exhaust system of a vehicle. An example system comprises a first outer tube with a plurality of intake apertures on an upstream surface, a second inner tube with a plurality of intake apertures on a downstream surface, and a particulate matter sensor placed within the second inner tube. The second inner tube may be positioned within the first outer tube such that a central axis of the second inner tube is parallel to a central axis of the first outer tube.

Owner:FORD GLOBAL TECH LLC

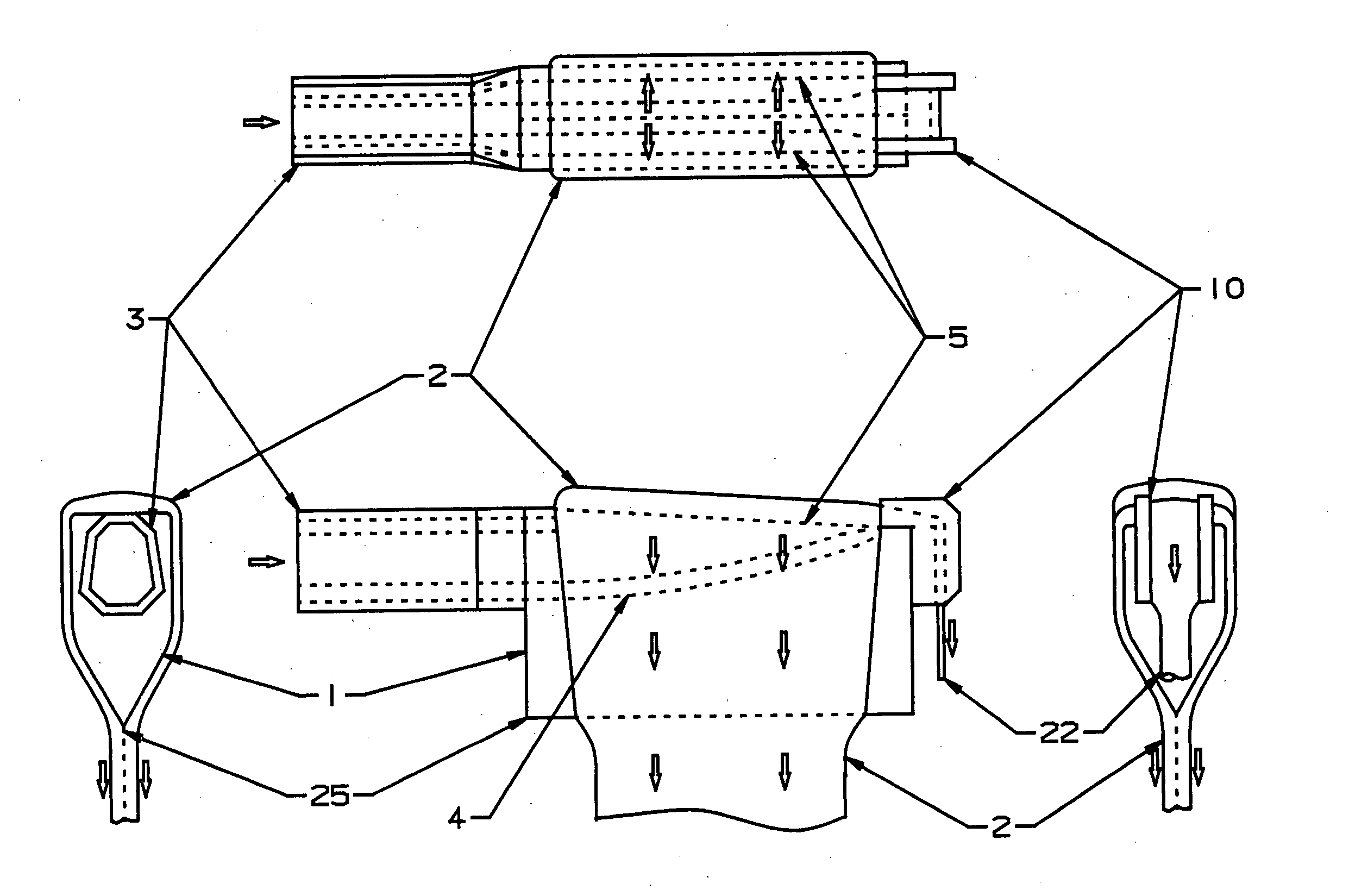

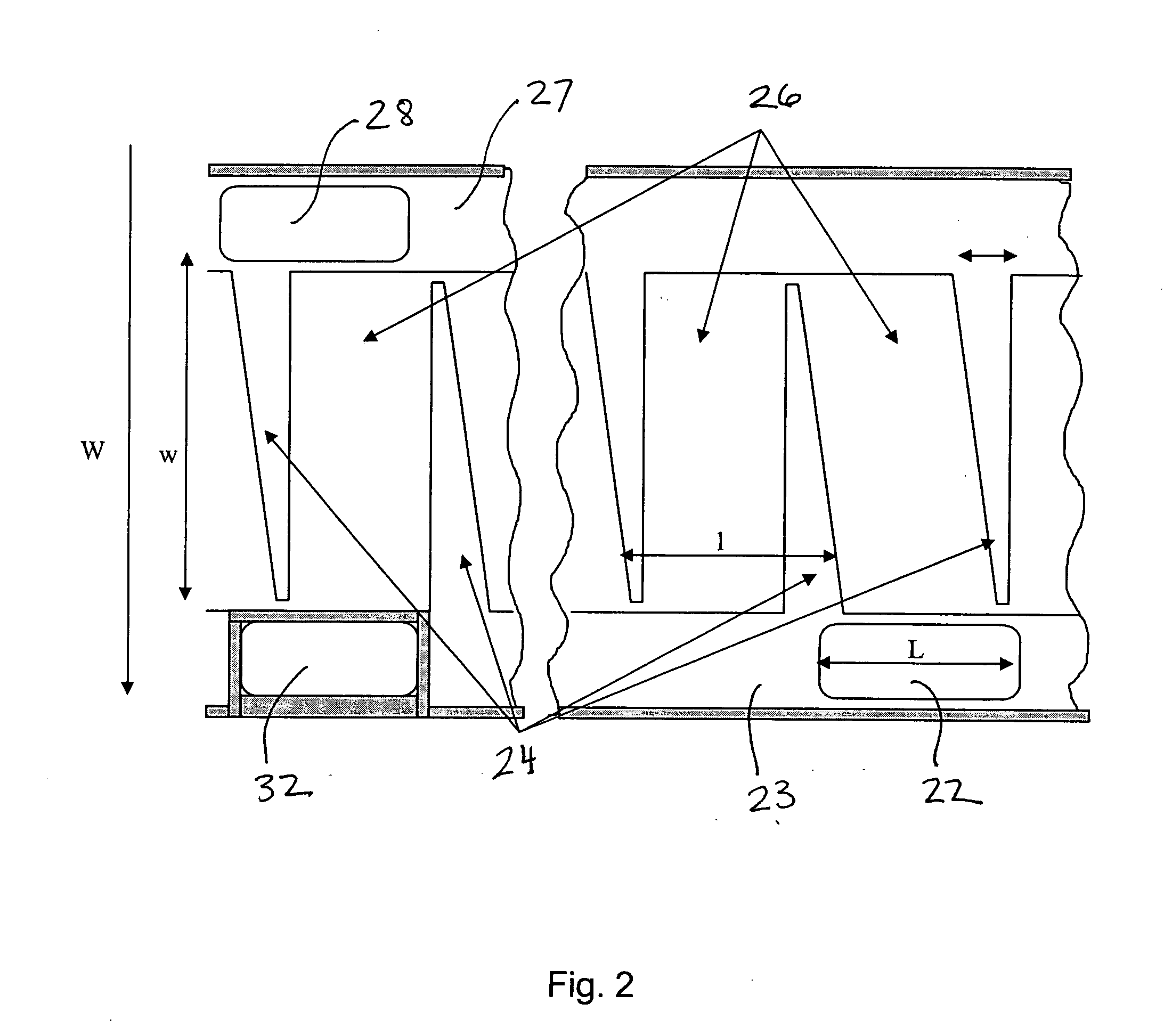

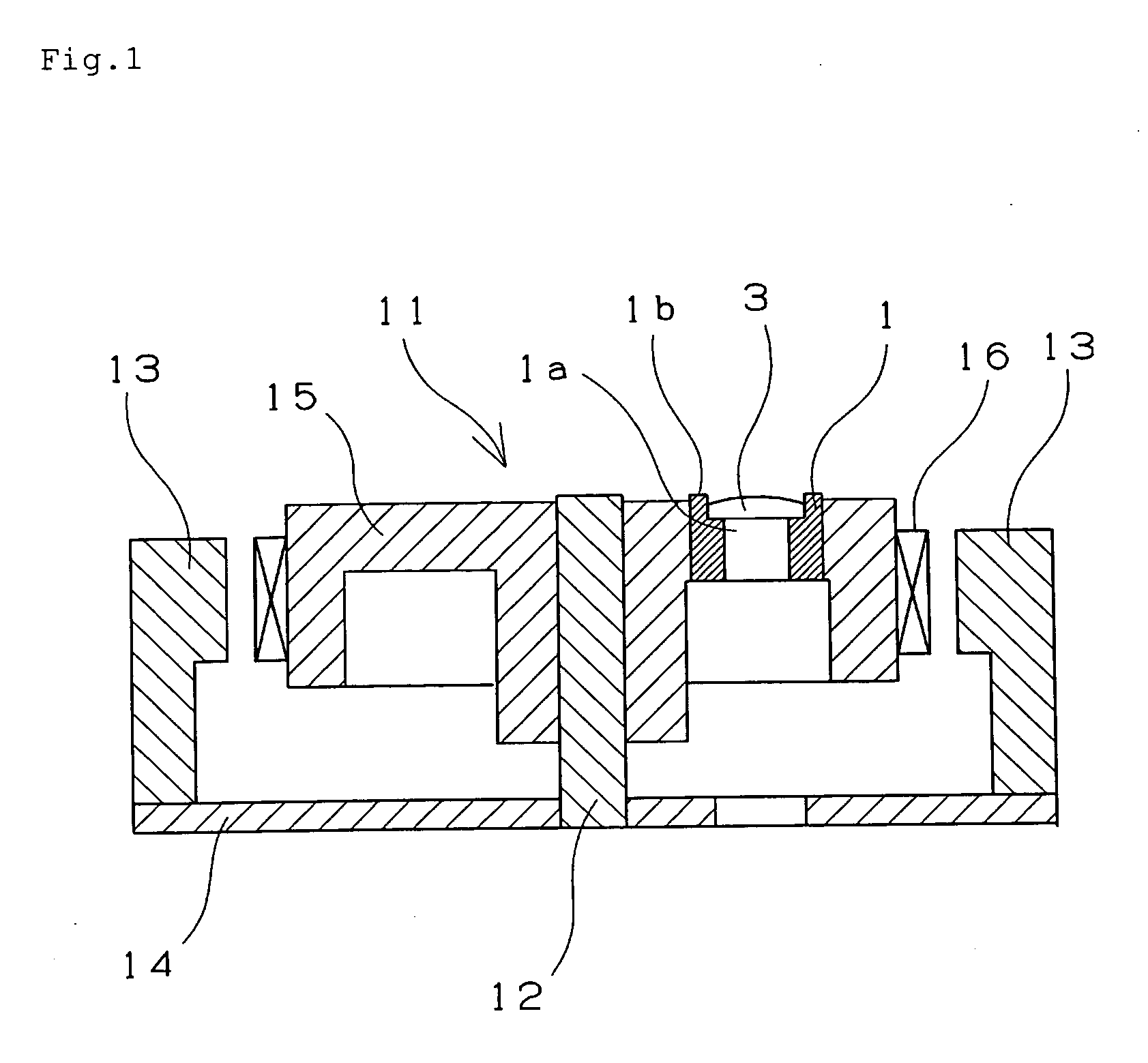

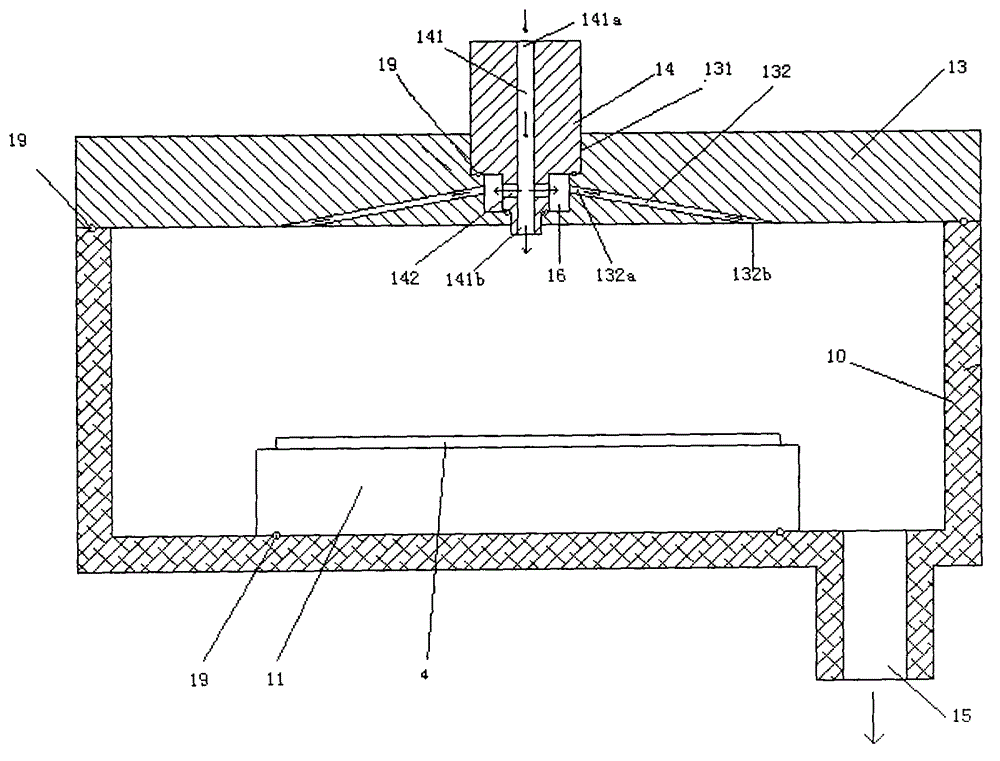

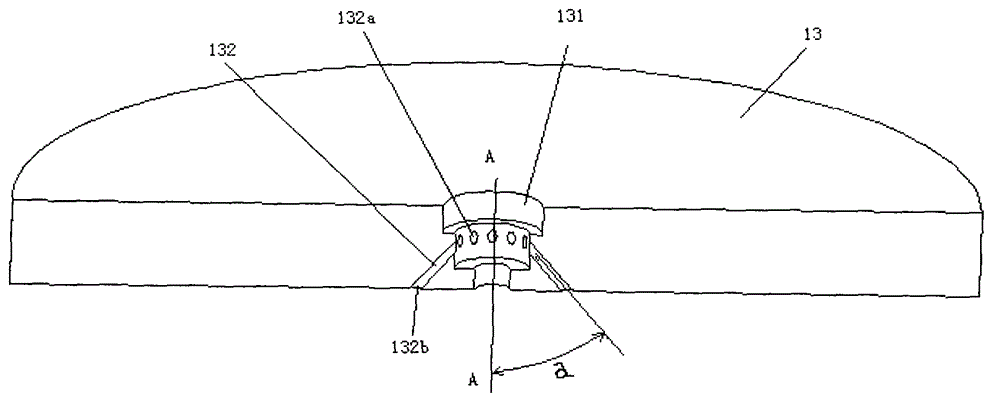

Sheet glass forming apparatus

InactiveUS20050076677A1Facilitate faster and uniform flowAdjustable thicknessGlass furnace apparatusGlass drawing apparatusFlat glassLinearity

The forming apparatus of the present invention preferably includes an orifice on top of the trough. The uniquely shaped orifice substitutes for the weirs as the controlling entity for glass thickness. The orifice is designed such that as it deforms, it maintains a linear flow characteristic with respect to its length. As the orifice is made larger by the applied stress, the percentage width increase is the same over its length and consequently the percentage flow increase is the same over the length of the orifice. In another embodiment, the present invention provides an adjustment to change the flow characteristics of the trough to compensate for the degradation of the forming trough during an extended production run. A flow control plug can be inserted into the trough, such that flow dynamics can be altered during hot operation by insertion, removal or position adjustment of the flow control plug.

Owner:CORNING INC

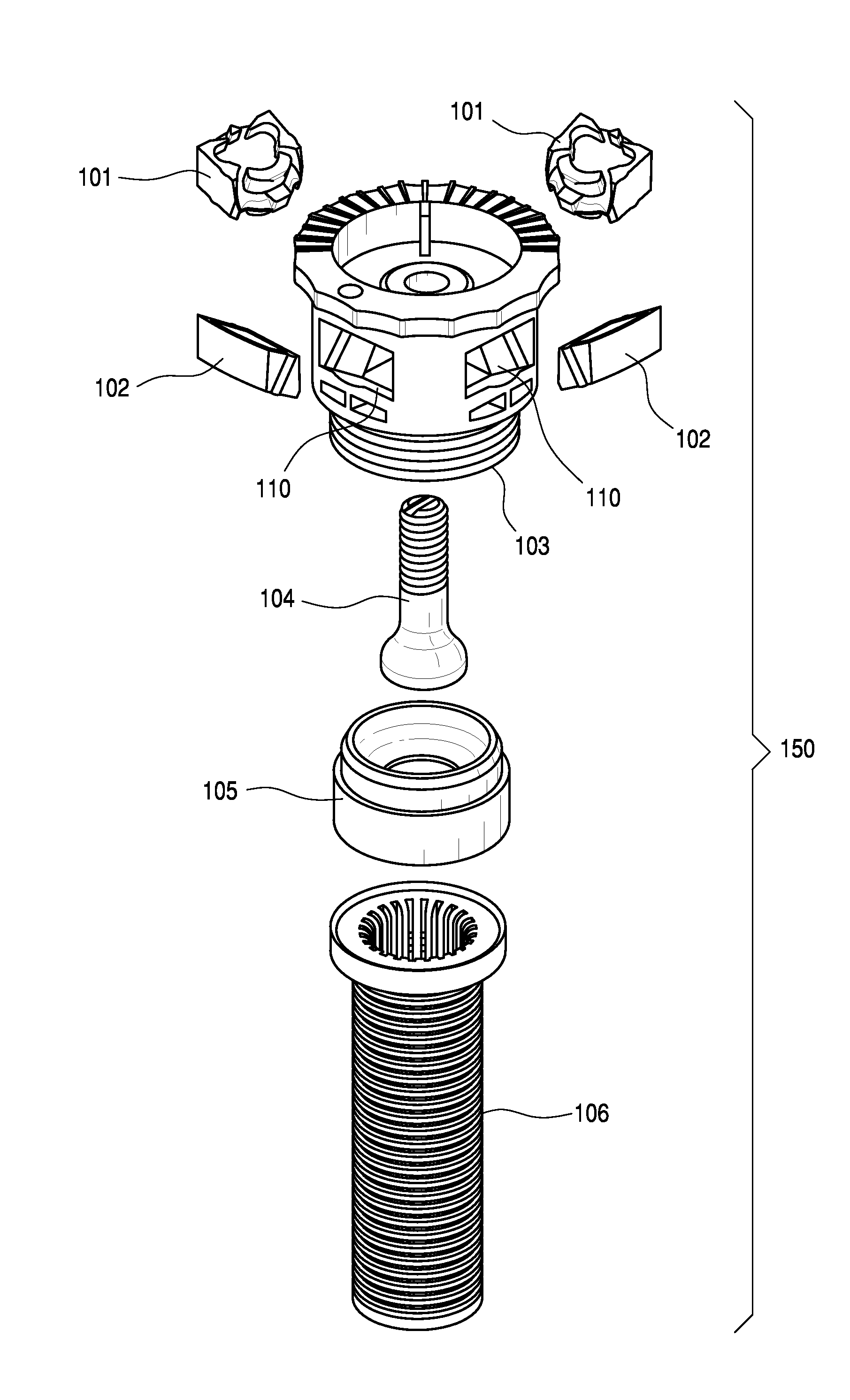

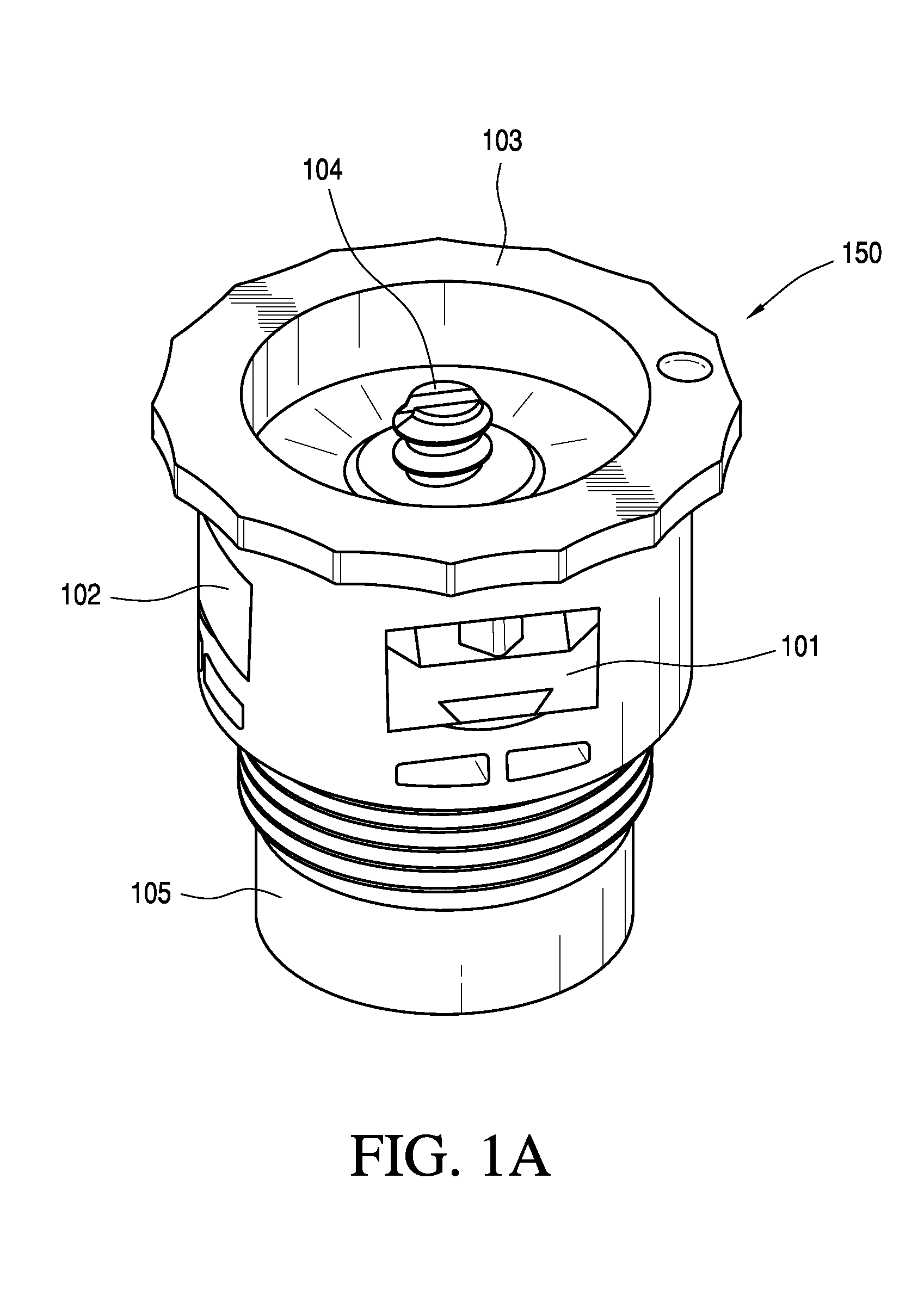

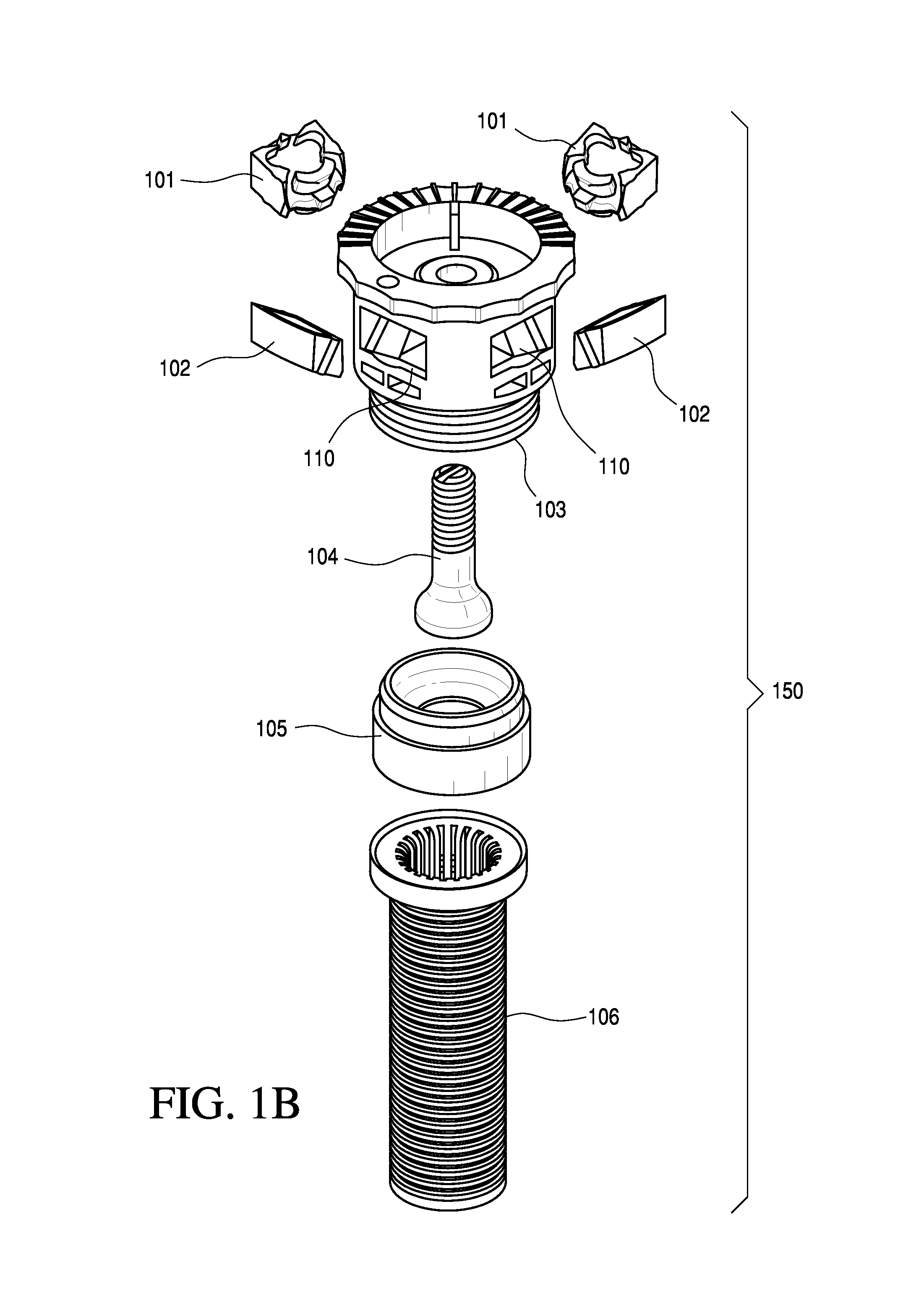

Fluidic circuit with bump features for improving uniform distribution of fluidic sprays

InactiveUS20100090036A1Improve performanceEvenly distributedWriting implementsMetal-working apparatusLiquid jetFluidic oscillator

A fluidic circuit or oscillator is provided with one or more small raised bumps or protrusions near the outlet or exhaust of a fluidic circuit to alter the spray pattern by re-distributing heavy areas of flow, resulting in a more uniform spray. The fluidic oscillator enclosure operates on a pressurized liquid flowing through the oscillator to generate a liquid jet that flows from said oscillator and into a surrounding environment to form an oscillating spray of liquid droplets, where the oscillator generates a stream of liquid droplets. The outlet or throat structure includes at least one bump or protuberance configured to project into the oscillating spray.

Owner:ALLEN KERRIE +2

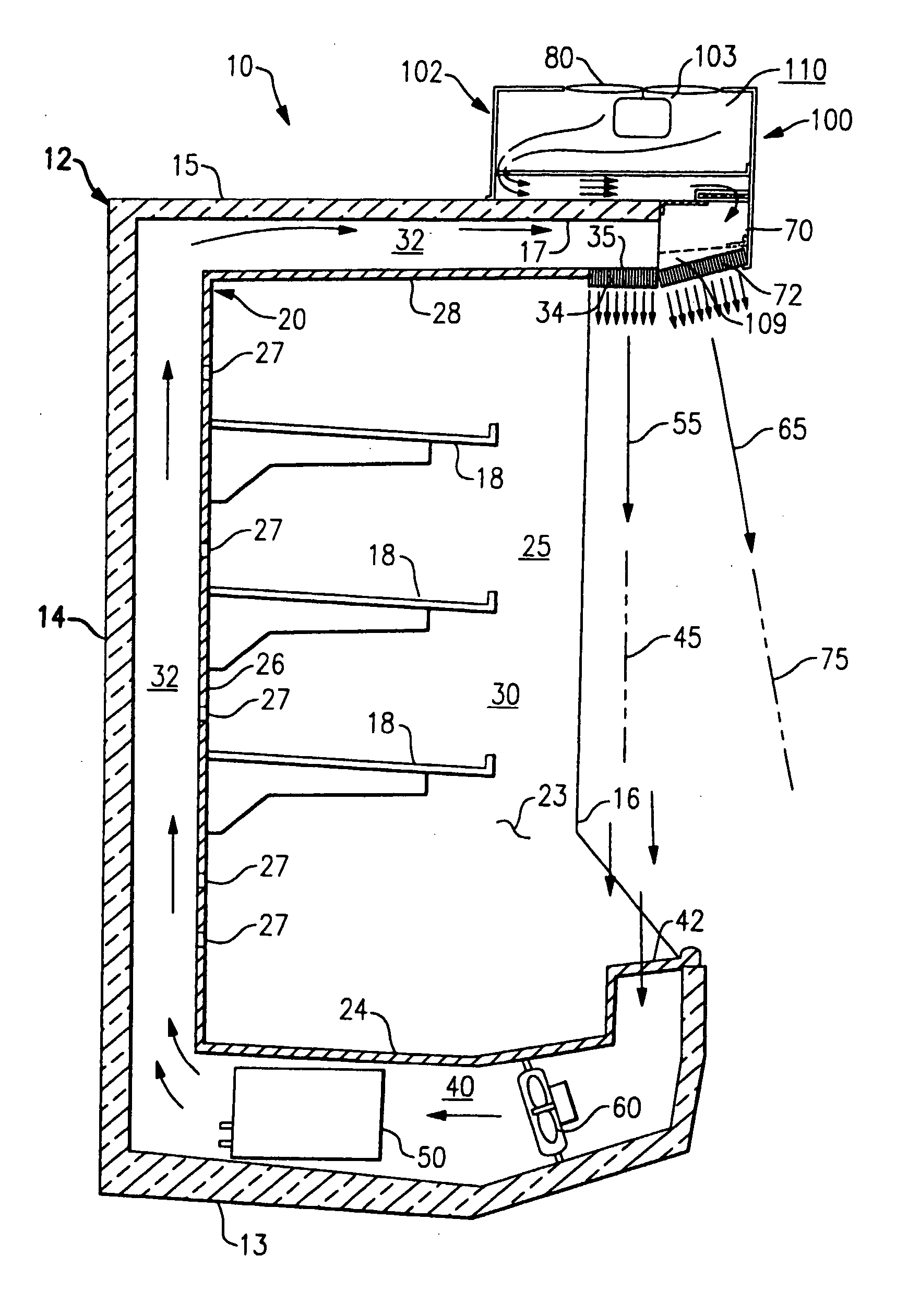

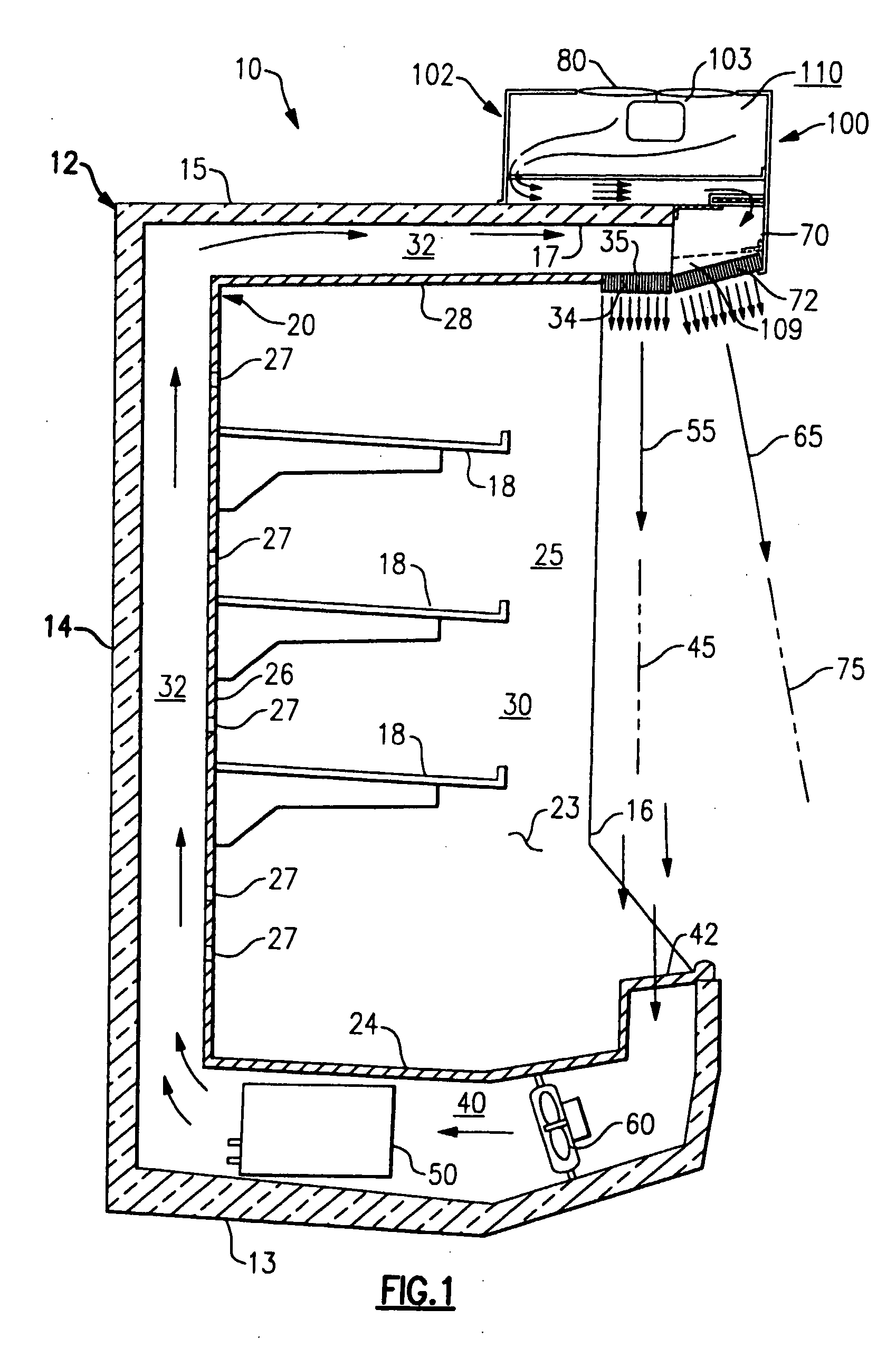

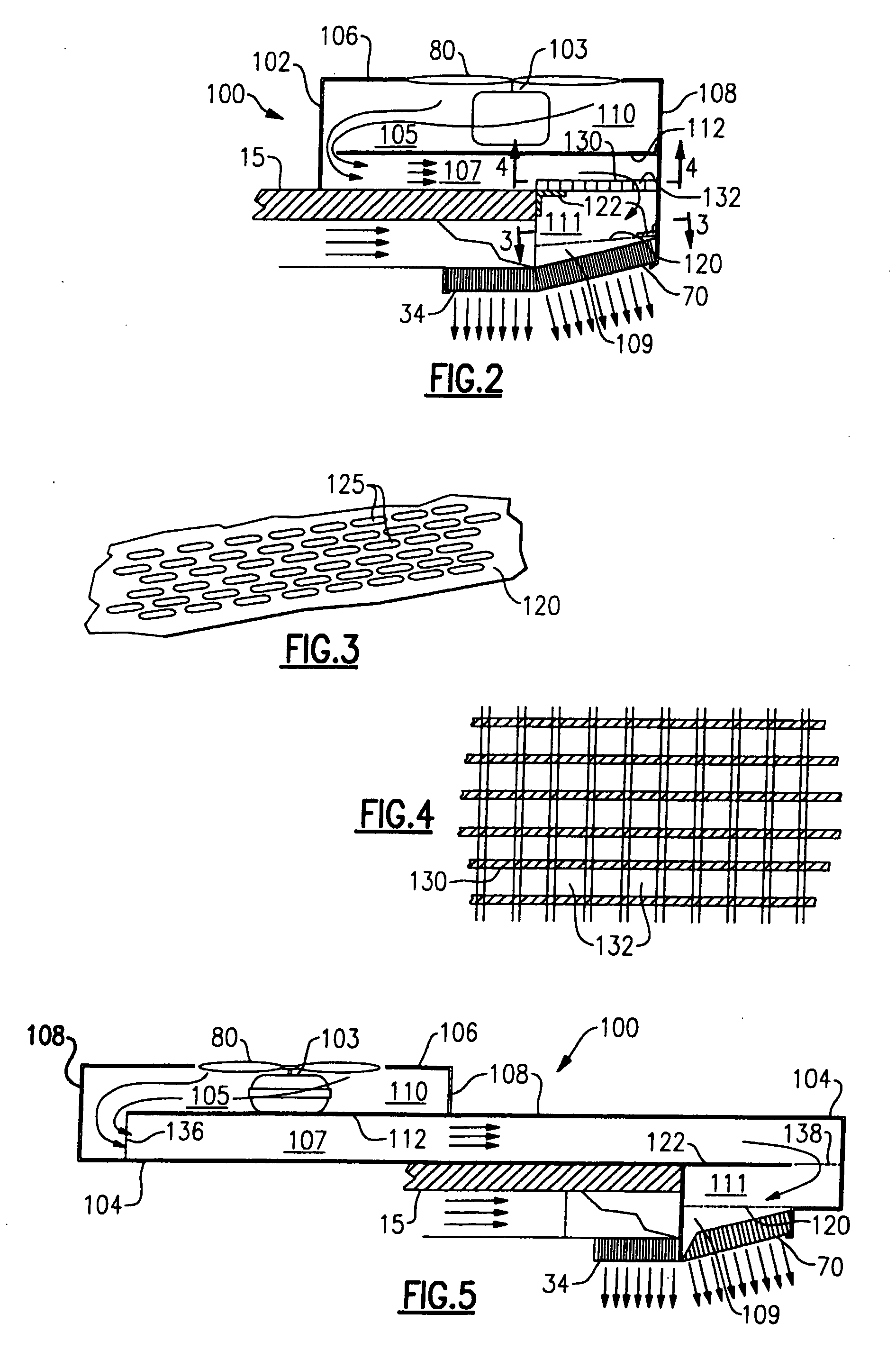

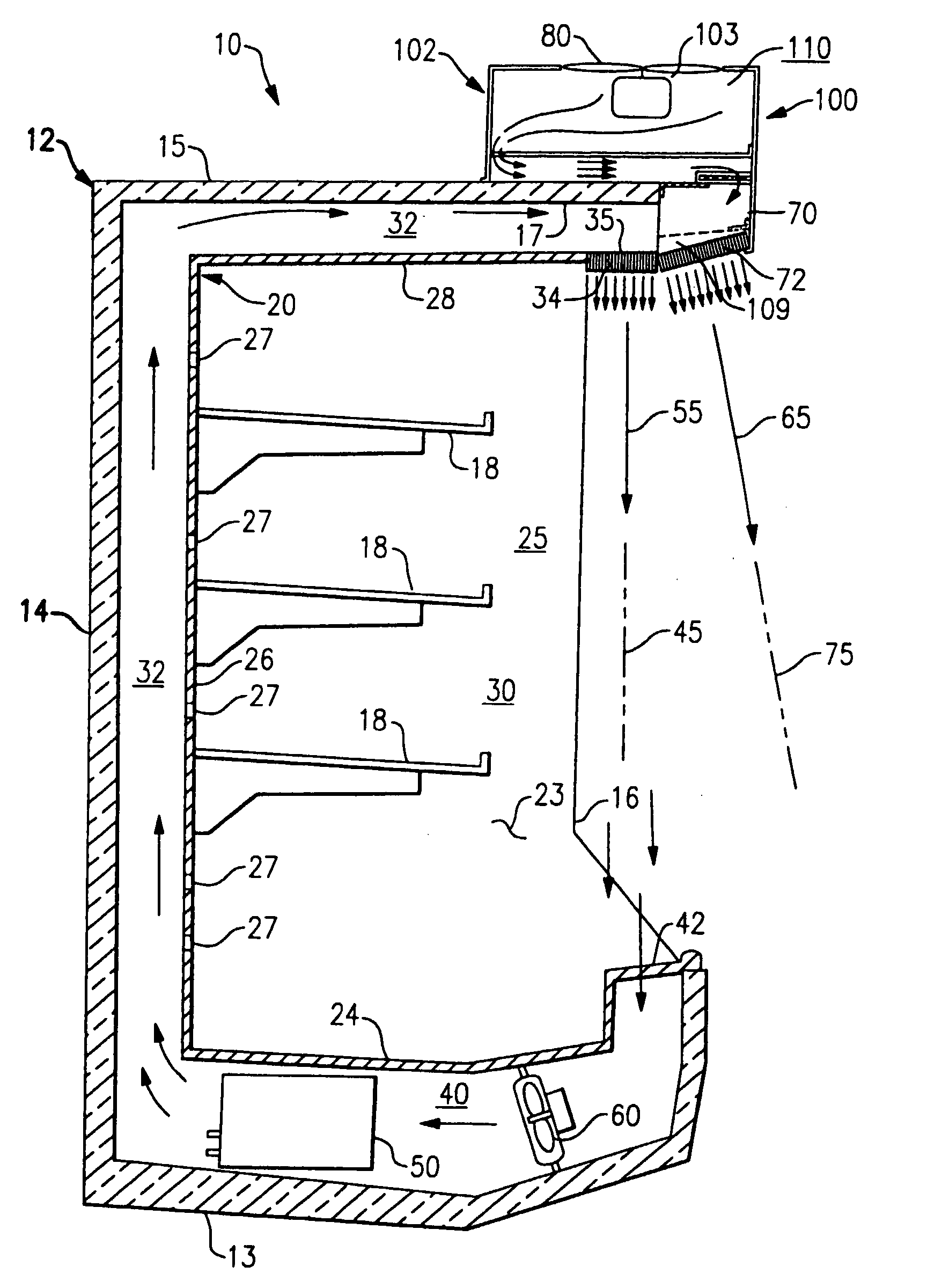

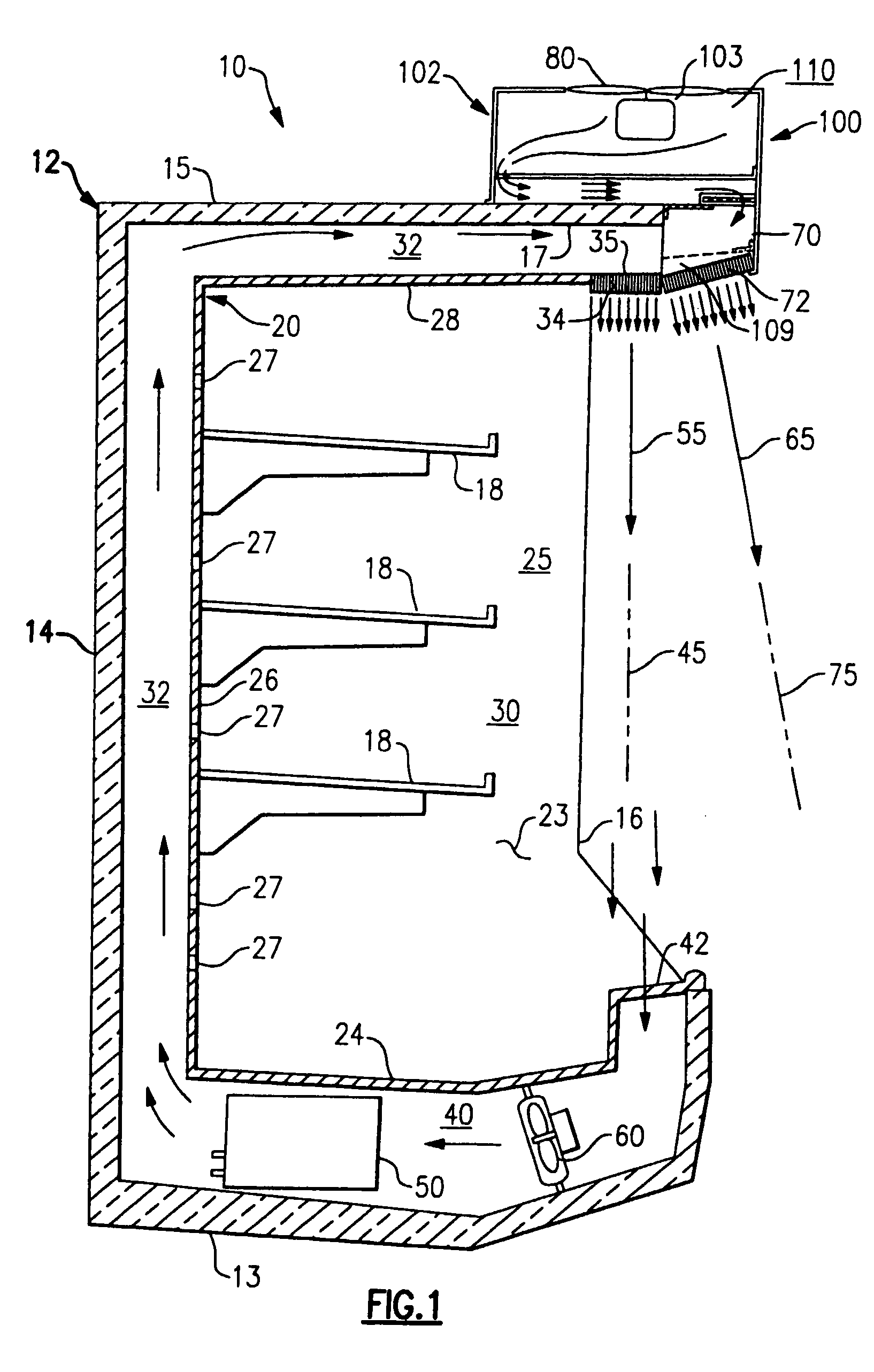

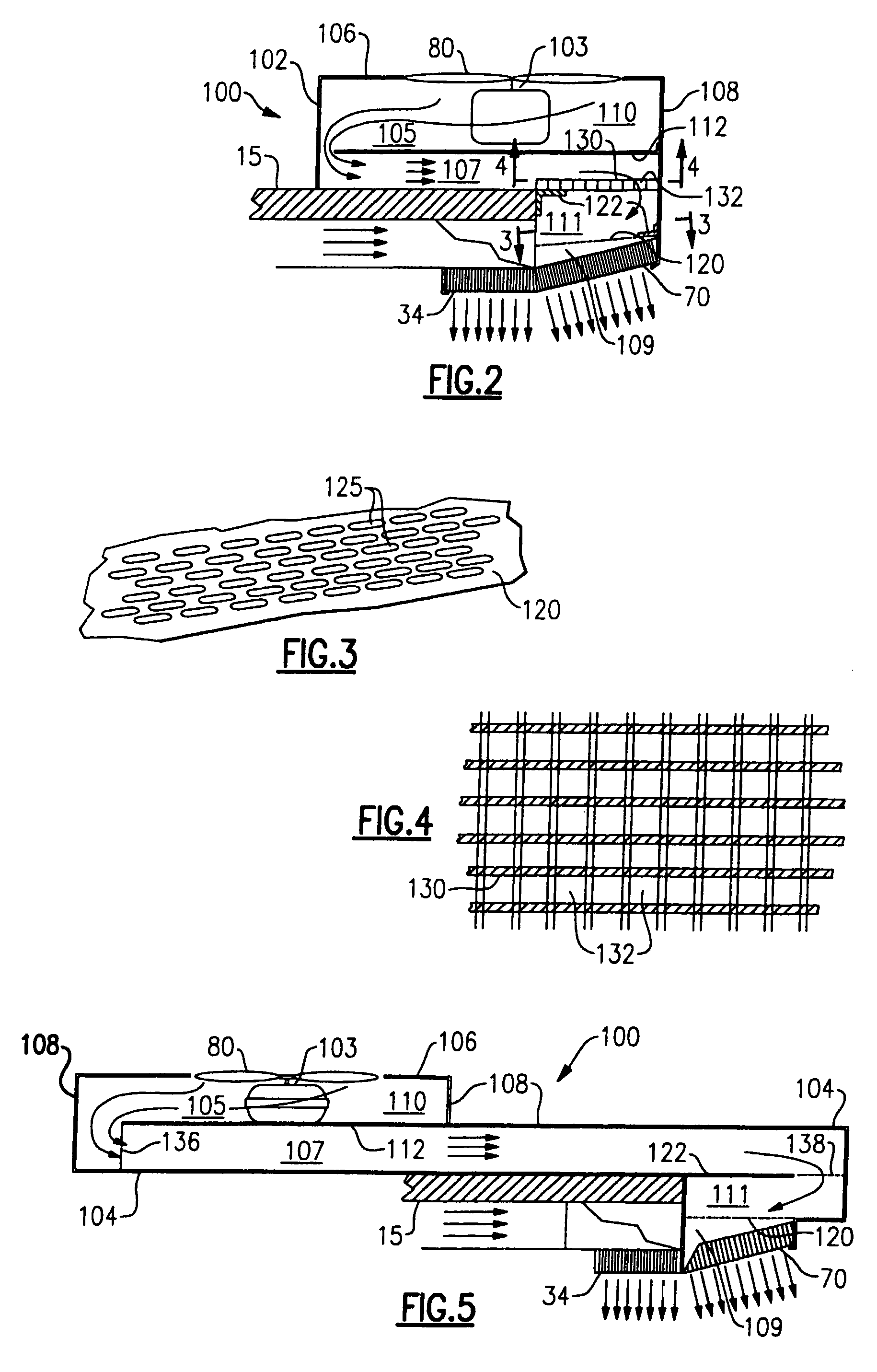

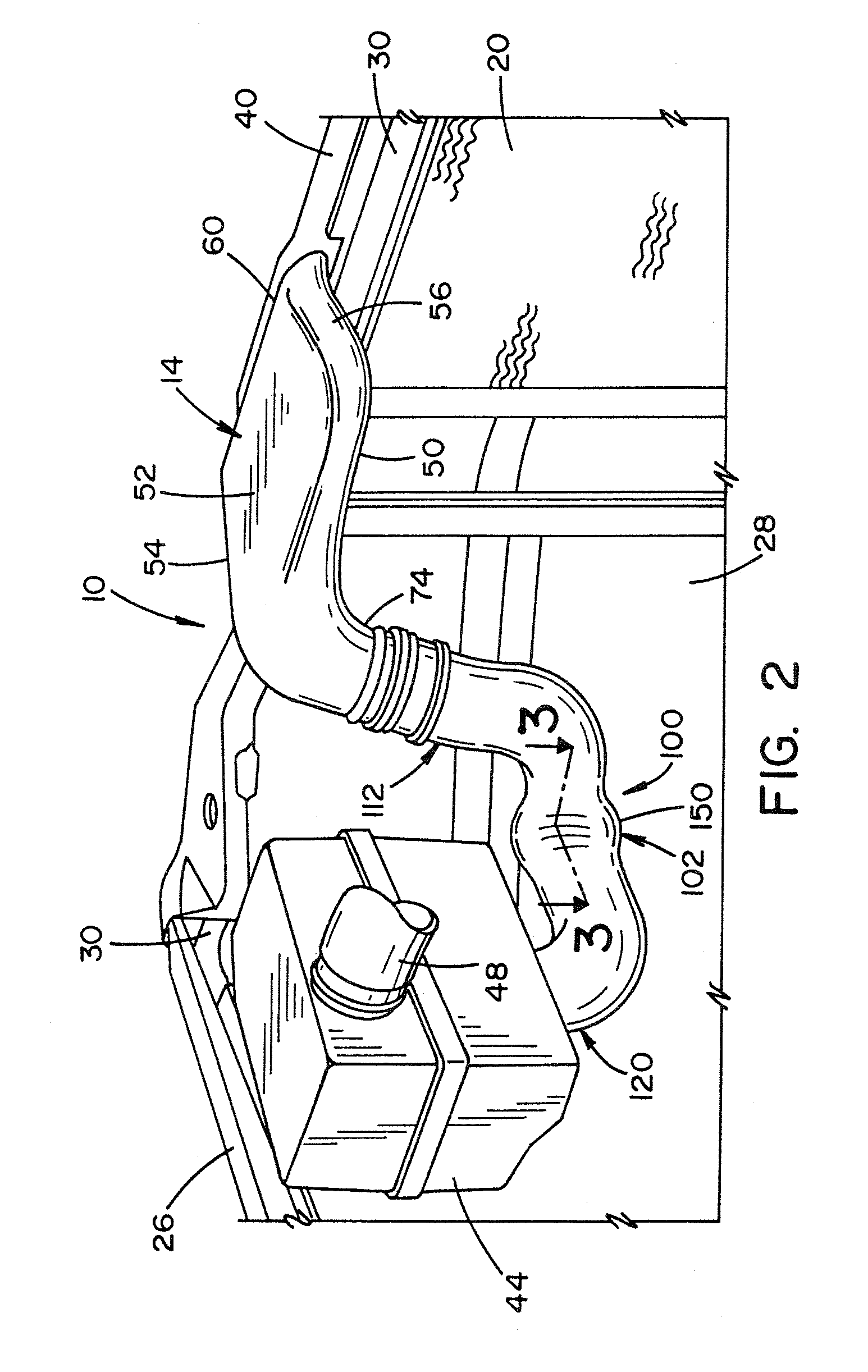

Curtain Air Admission Assembly

A refrigerated merchandiser includes a display case defining a product display region having an open-front isolated from the ambient air of the store by means of a downwardly directed inner air curtain of relatively cold refrigerated air and a downwardly directed outer air curtain of relatively warmer air established via an improved curtain air admission assembly. The curtain air admission assembly defines a plenum atop the refrigerated display through which the flow of air substantially reverses direction when passing from a first flow passage to a second flow passage. This reversal of flow direction serves to distribute the air flow more uniformly along the length of the display case.

Owner:HILL PHOENIX

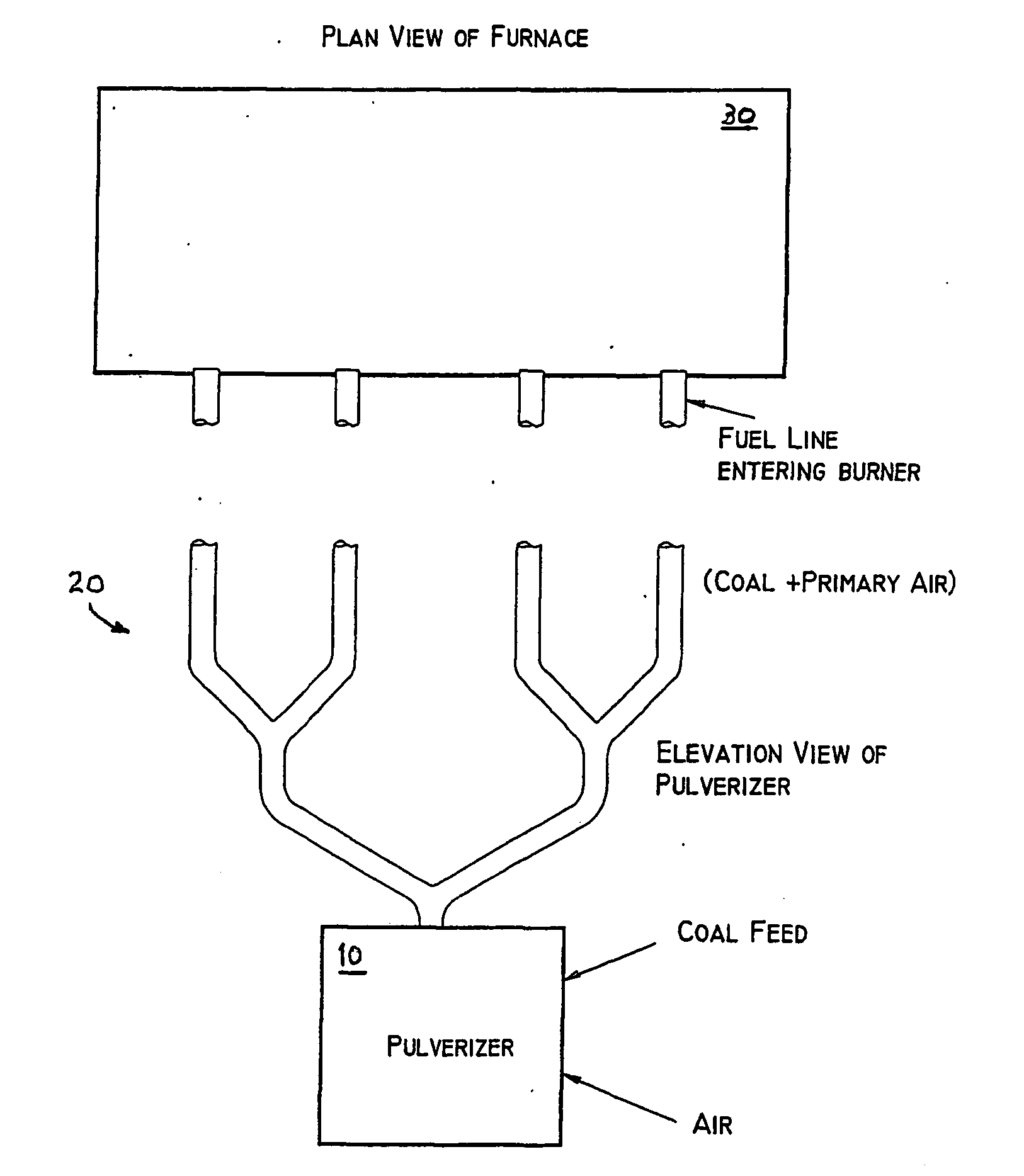

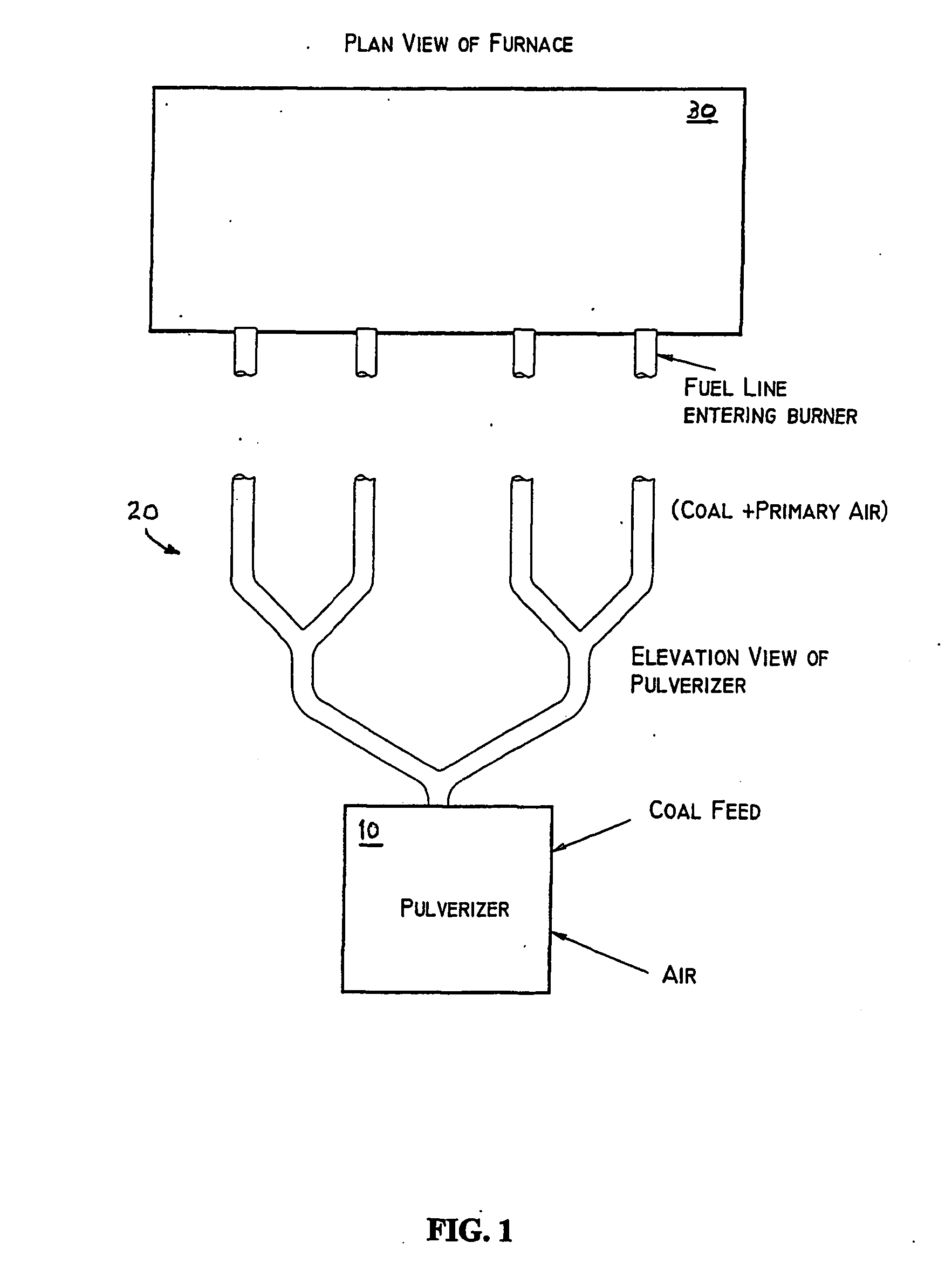

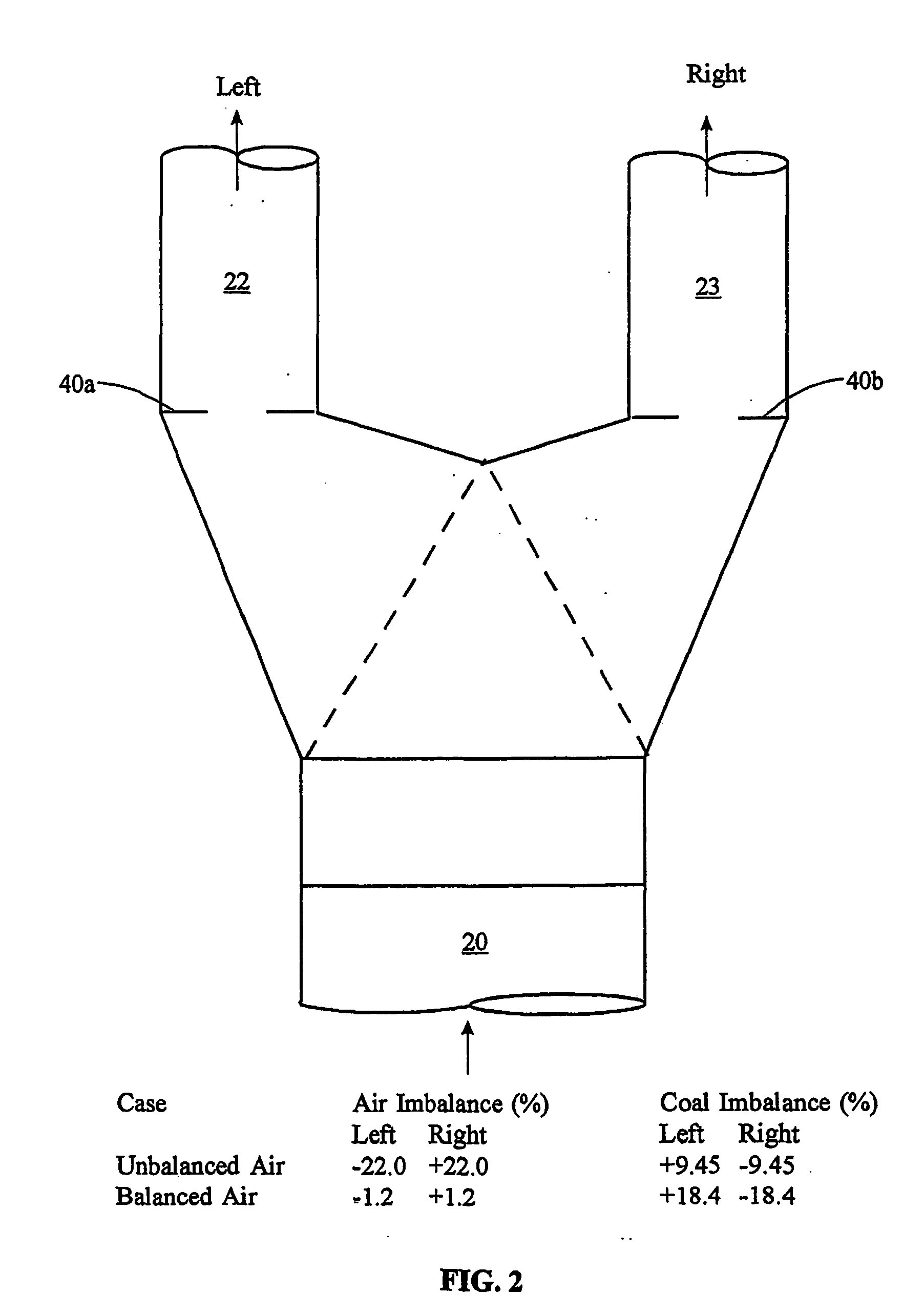

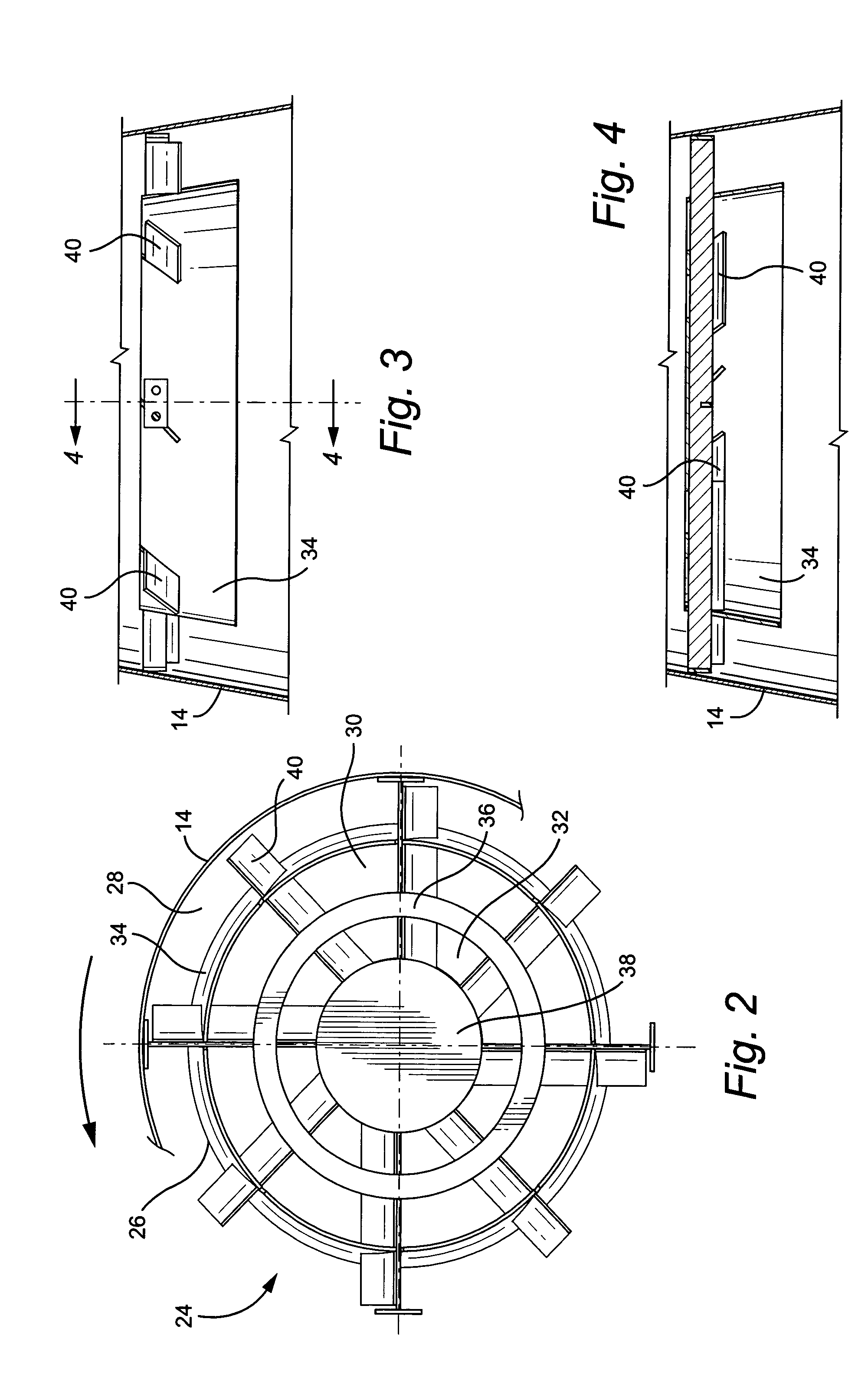

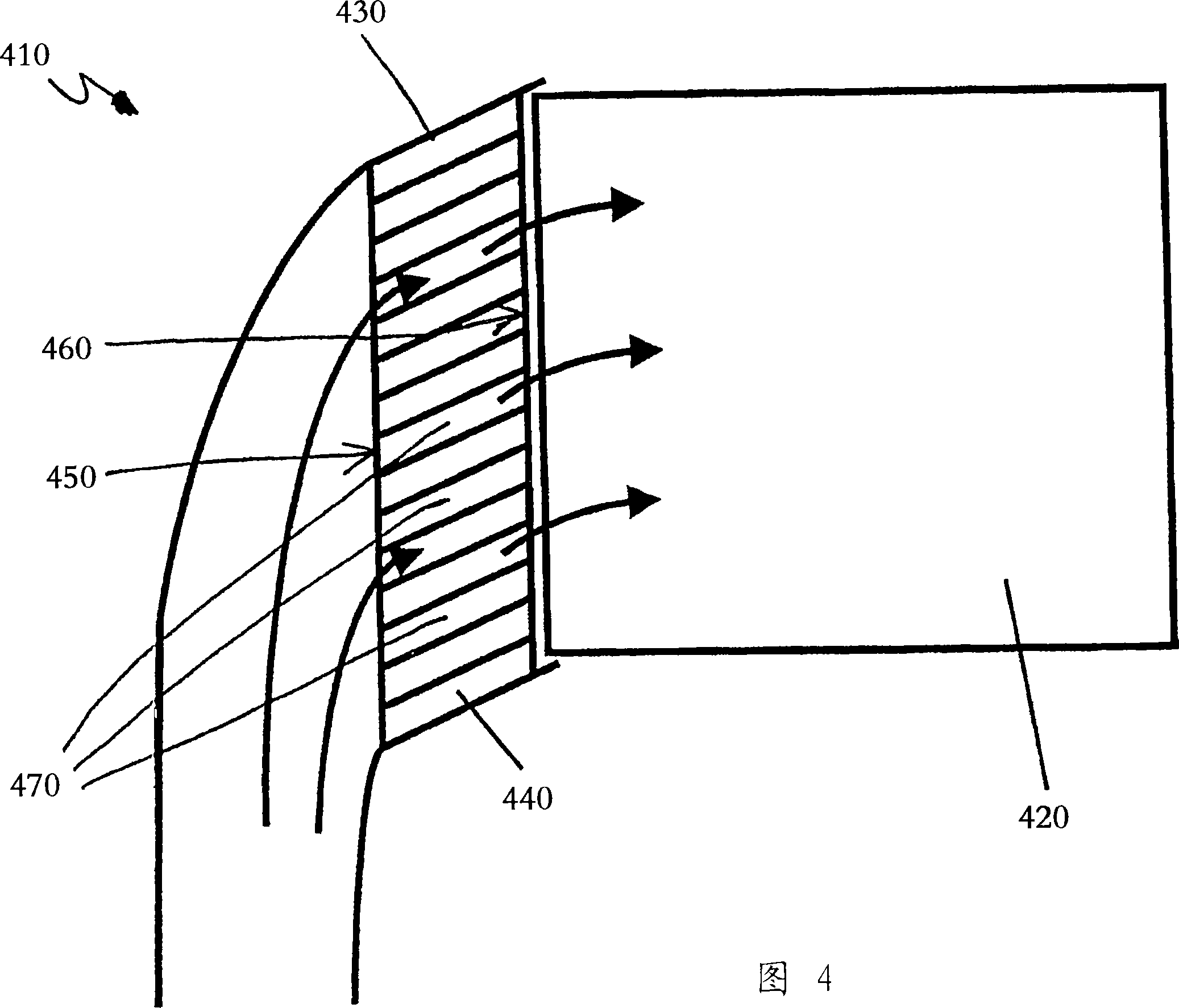

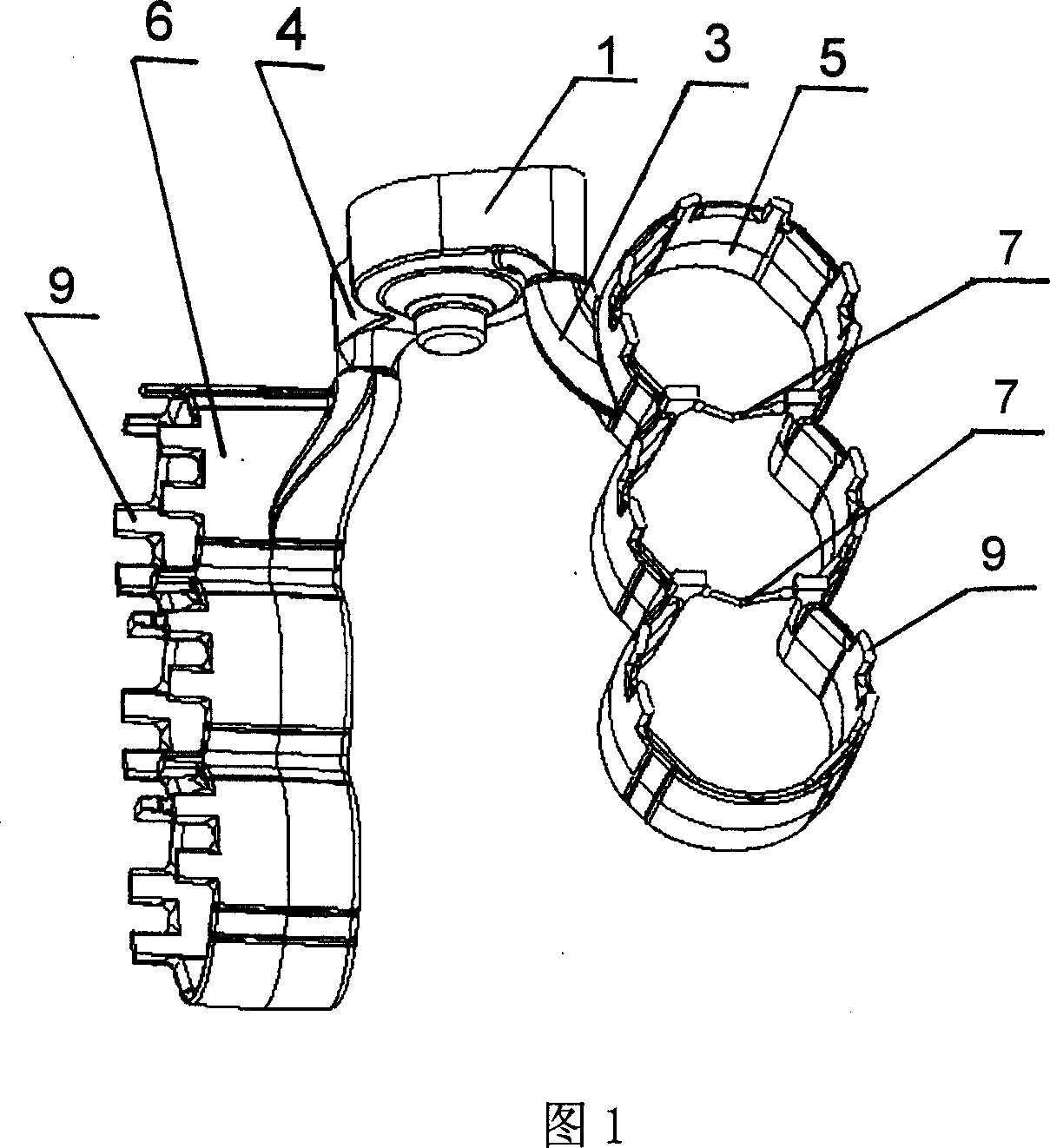

Adjustable air foils for balancing pulverized coal flow at a coal pipe splitter junction

InactiveUS20050042043A1Coal flow imbalanceIncreasing and decreasing flowFuel feeding arrangementsDamper arrangementPollutant emissionsCoal

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of wake inducing airfoils (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each wake-inducing airfoil has a cross-section defined by a width W that varies along its length H for creating upstream turbulence, and a particle wake that preferentially diverts the coal flow to one of the outlet pipes at the splitter junction without affecting primary air flow. For example, each wake inducing airfoil may comprise a rounded convex edge leading to straight tapered sides. The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers. In addition, conventional fixed or variable orifices may be used in combination with the wake inducing airfoils for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air, resulting in closely balanced coal flow, reduced pollutant emissions and improved combustion efficiency.

Owner:LEVY EDWARD KENNETH +3

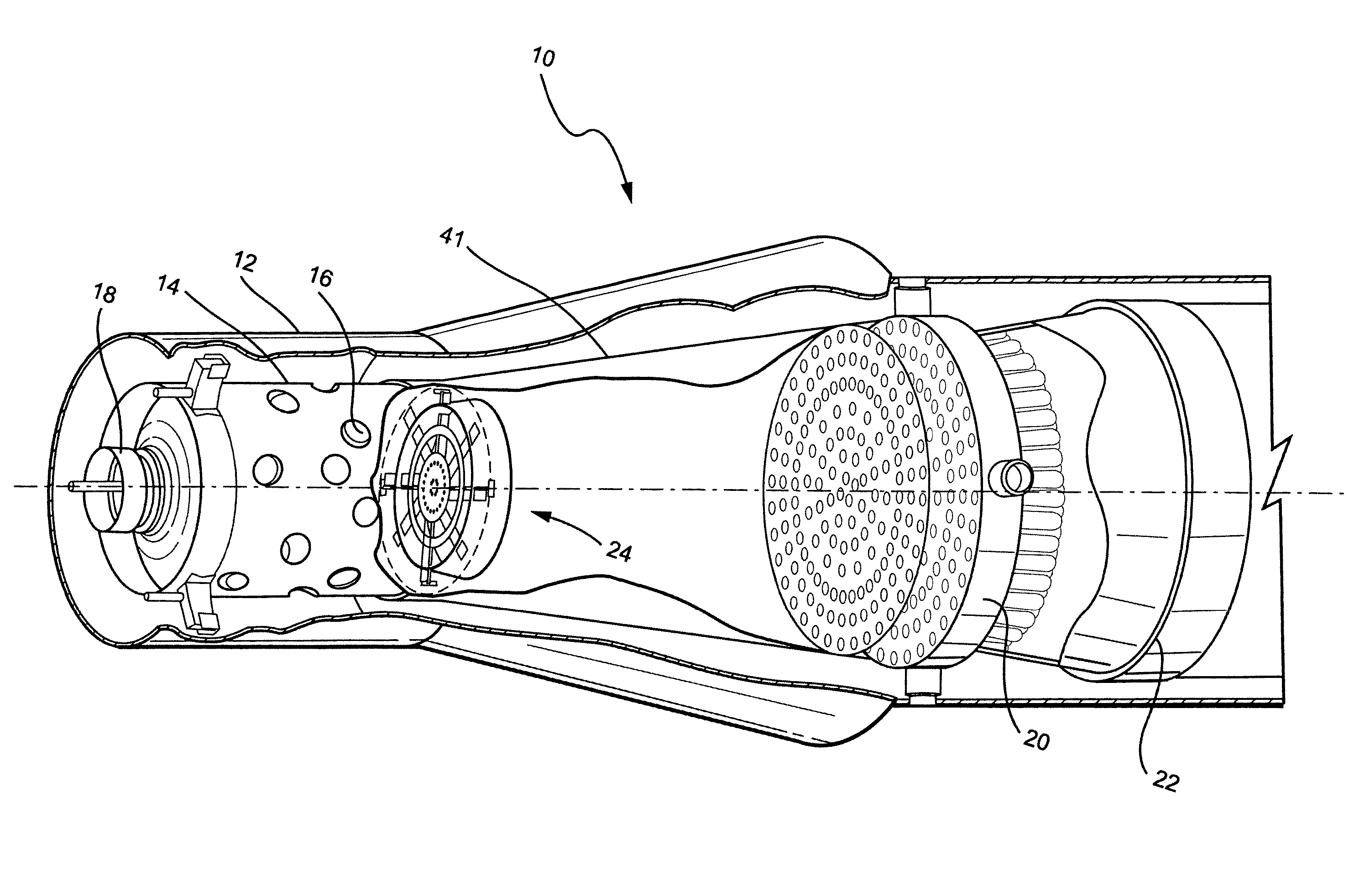

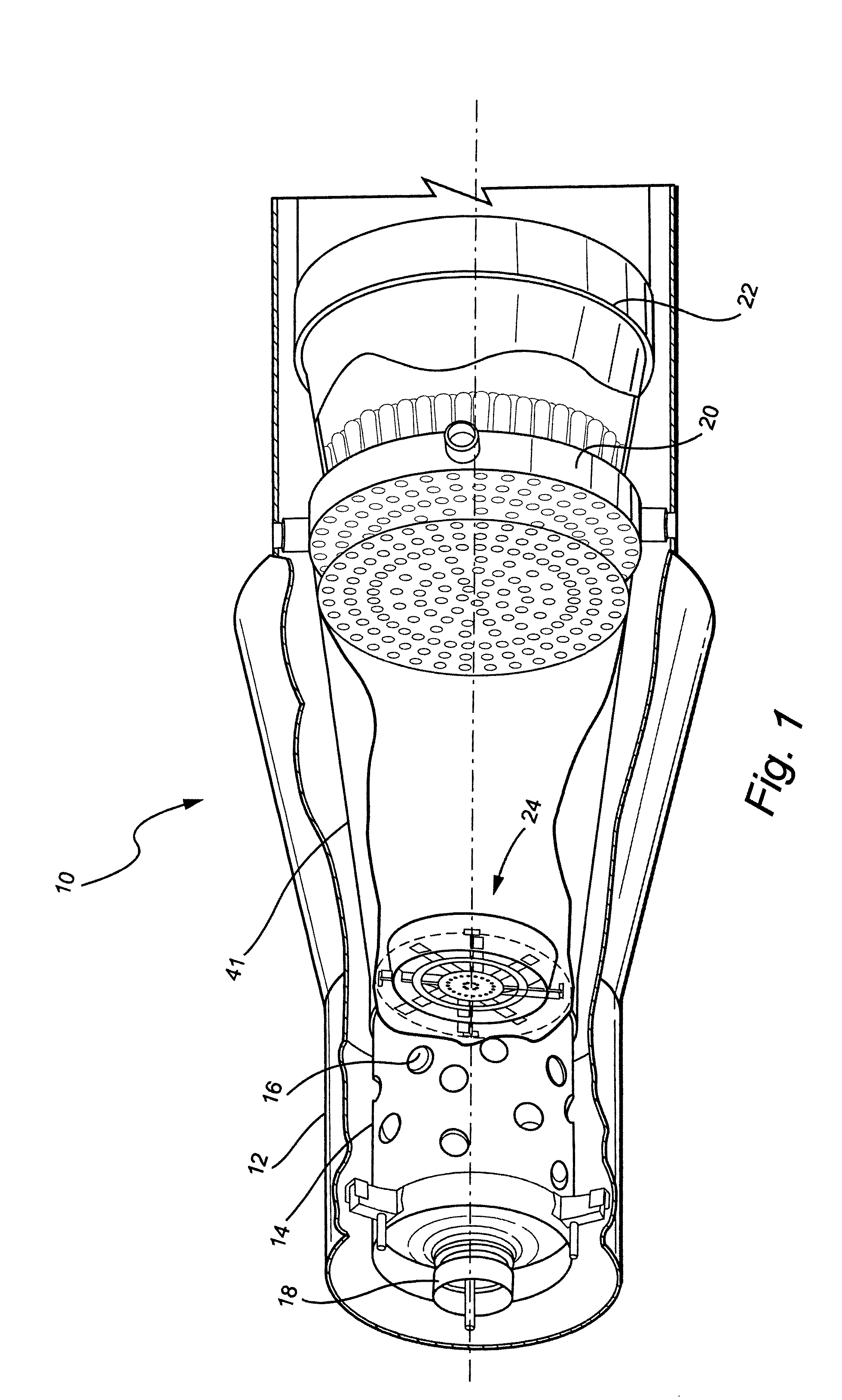

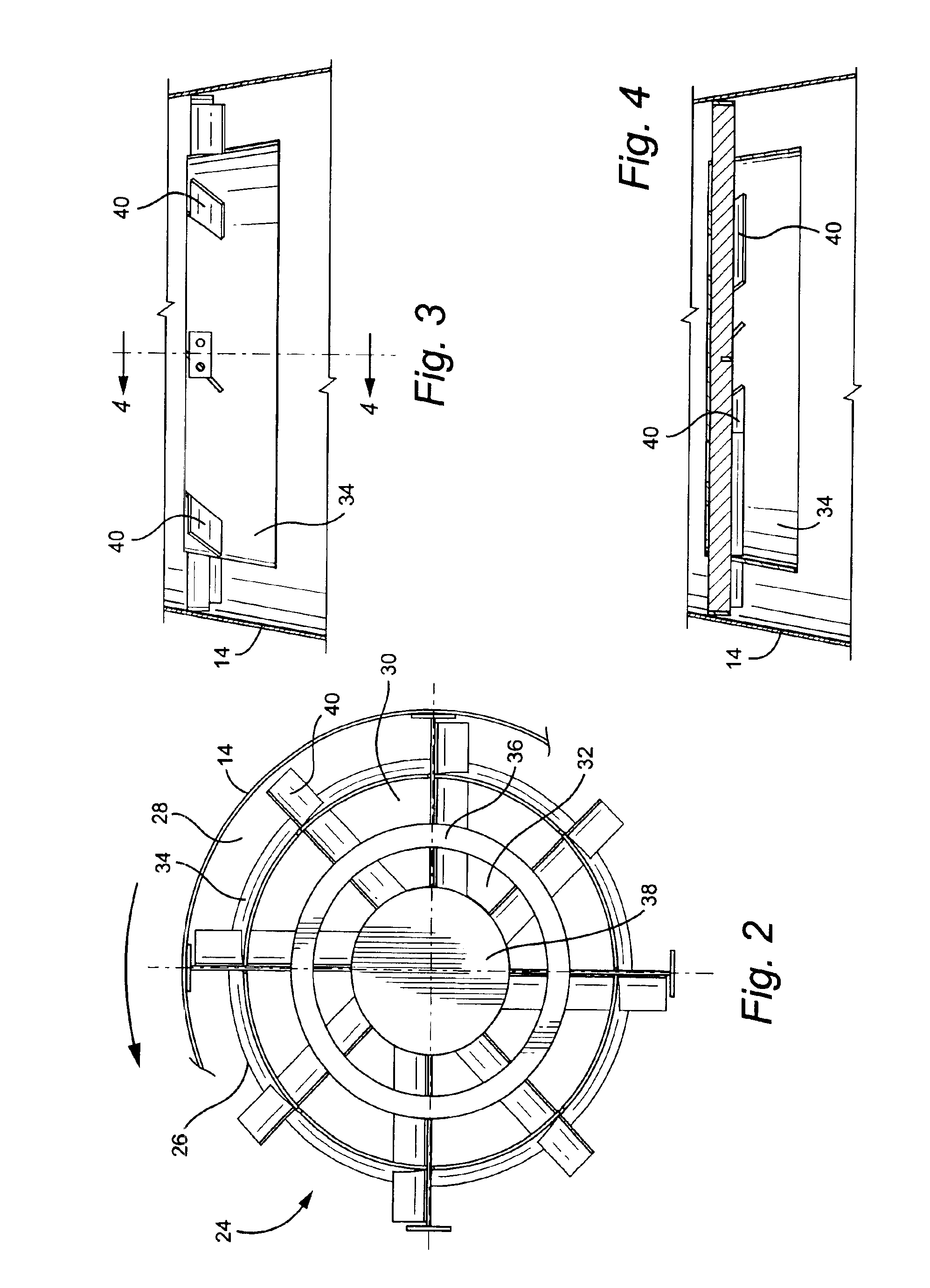

Flow controller for gas turbine combustors

InactiveUS20050044842A1Uniform flow distributionUniform flowContinuous combustion chamberFurnace componentsInjectorGas turbines

A flow controller is disposed between a preburner section in a diffuser and prior to the main fuel injector and catalytic sections in a turbine combustor. The flow from the burner section is typically not uniform in temperature and velocity and the flow splitter renders the flow substantially uniform at the fuel injector and catalyst inlet. The flow splitter comprises substantially equal mass annular flow areas defined by a first outer frustoconical element and the diffuser wall, a second element defining with the first element a second annular area and a central bluff disk defining with the second element the interior annular area. Vanes are provided on the flow splitter to enhance turbulent flow and substantially preclude swirling flow. As a result, flow uniformity at the catalyst inlet and main fuel injection is achieved.

Owner:GENERAL ELECTRIC CO

Evaporative fuel vapor emission control systems

ActiveUS20180363594A1Low volumeCost-effective manufacturingGas treatmentNon-fuel substance addition to fuelParticulatesControl system

The present disclosure describes an evaporative emission control canister system that includes: one or more canisters comprising at least one vent-side particulate adsorbent volume comprising a particulate adsorbent having microscopic pores with a diameter of less than about 100 nm; macroscopic pores having a diameter of about 100-100,000 nm; and a ratio of a volume of the macroscopic pores to a volume of the microscopic pores that is greater than about 150%, and having a retentivity of about 1.0 g / dL or less. The system may further include a high butane working capacity adsorbent. The disclosure also describes a method for reducing emissions in an evaporative emission control system.

Owner:INGEVITY SOUTH CAROLINA

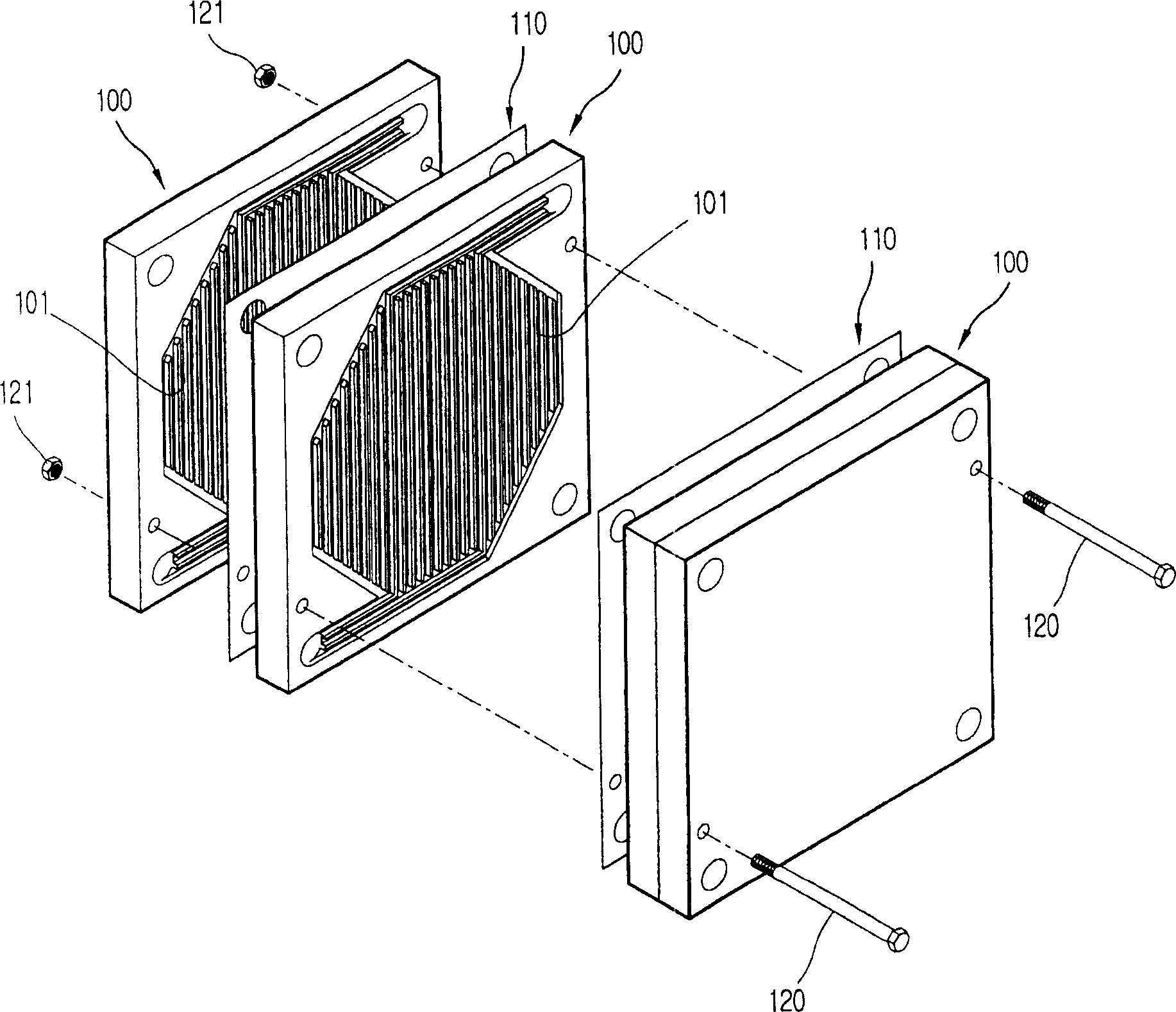

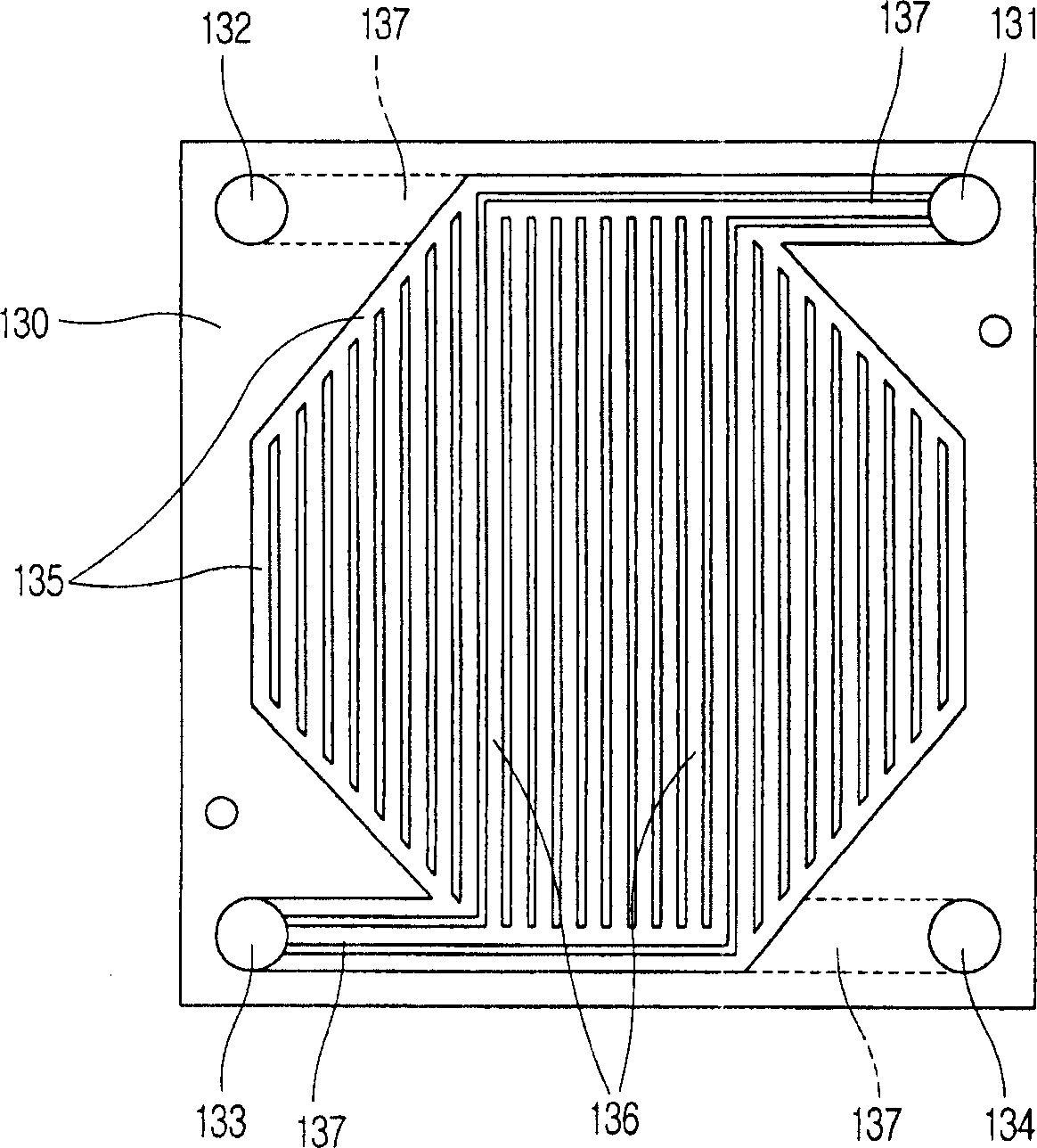

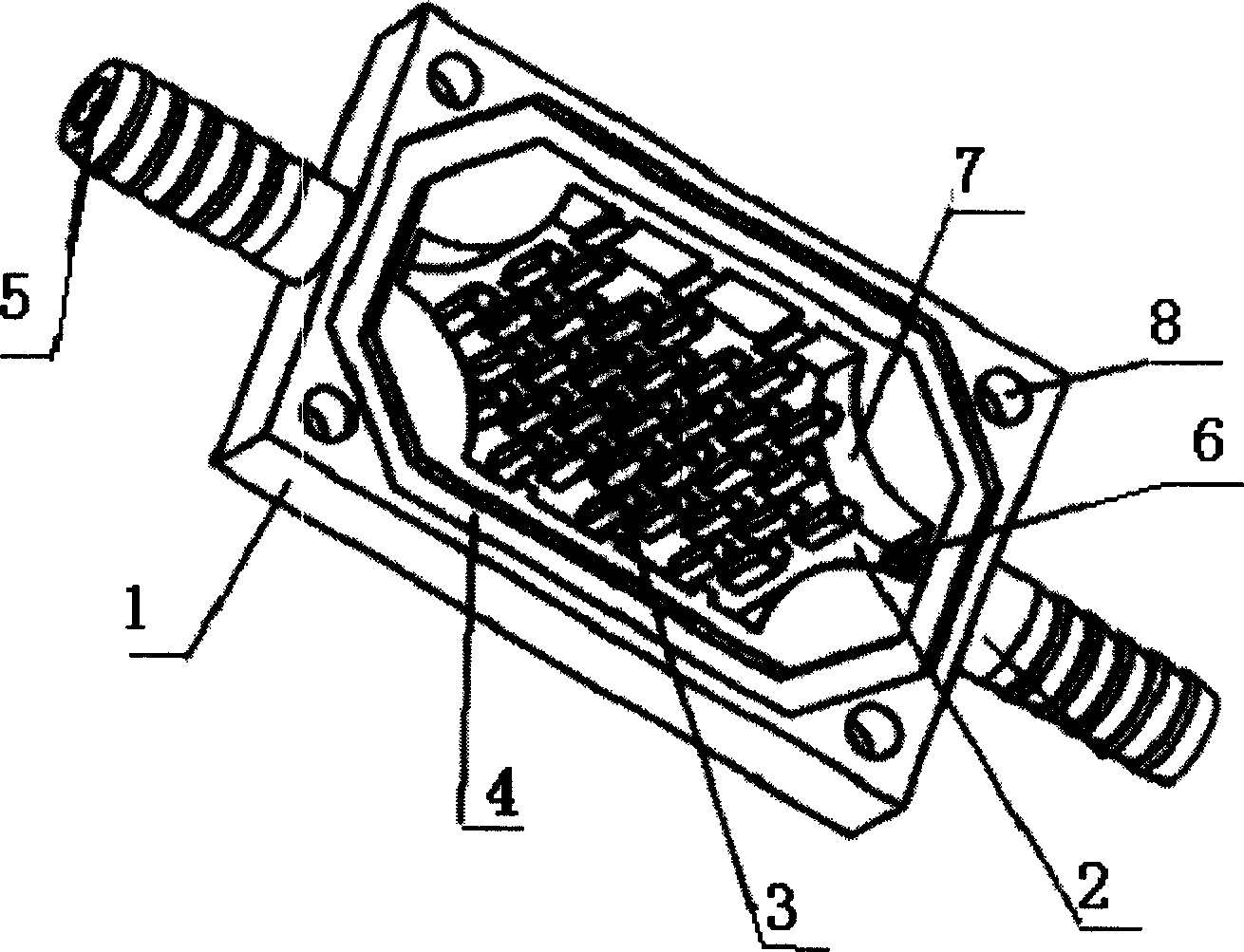

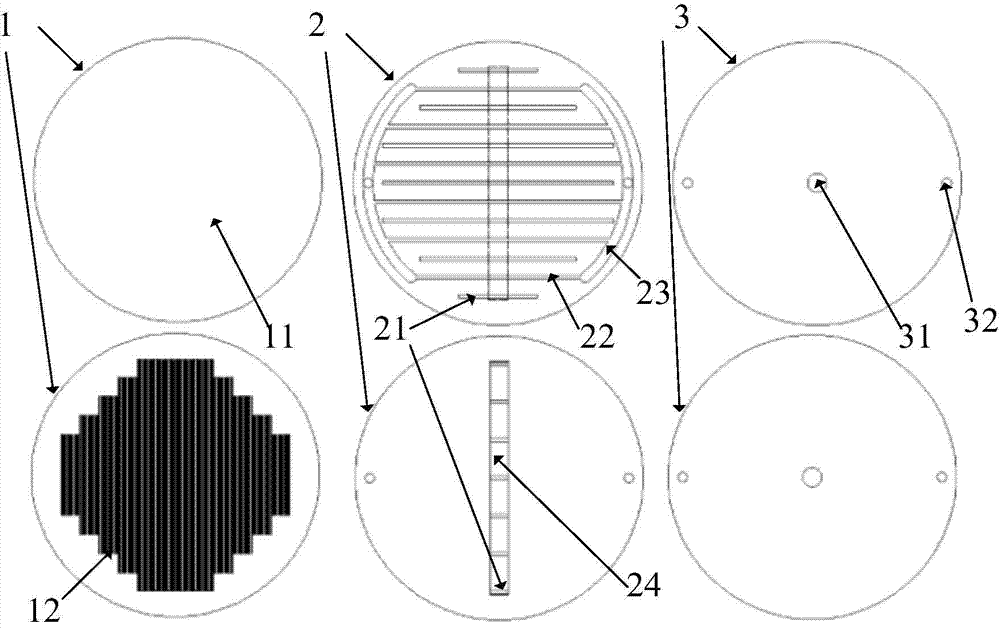

Bipolar plate of fuel cell

InactiveCN1692515ALow flow resistanceEven flow distributionFuel cell auxillariesCollectors/separatorsFuel cellsEngineering

In a bipolar plate of a fuel cell including a plate having a certain area and thickness; inflow and outflow buffer grooves respectively formed at both sides of the plate so as to have a certain area and depth; plural channels for connecting the inflow buffer groove and the outflow buffer groove; plural buffer protrusions formed in the inflow and outflow buffer grooves so as to have a certain height; an inflow path formed on the plate so as to be connected to the inflow buffer groove; and an outflow path formed on the plate so as to be connected to the outflow buffer groove, it is possible to uniformize flux distribution and reduce flow resistance of fuel and air respectively flowing into a fuel electrode and an air electrode of a fuel cell.

Owner:LG ELECTRONICS INC

Curtain air admission assembly

A refrigerated merchandiser includes a display case defining a product display region having an open-front isolated from the ambient air of the store by means of a downwardly directed inner air curtain of relatively cold refrigerated air and a downwardly directed outer air curtain of relatively warmer air established via an improved curtain air admission assembly. The curtain air admission assembly defines a plenum atop the refrigerated display through which the flow of air substantially reverses direction when passing from a first flow passage to a second flow passage. This reversal of flow direction serves to distribute the air flow more uniformly along the length of the display case.

Owner:HILL PHOENIX

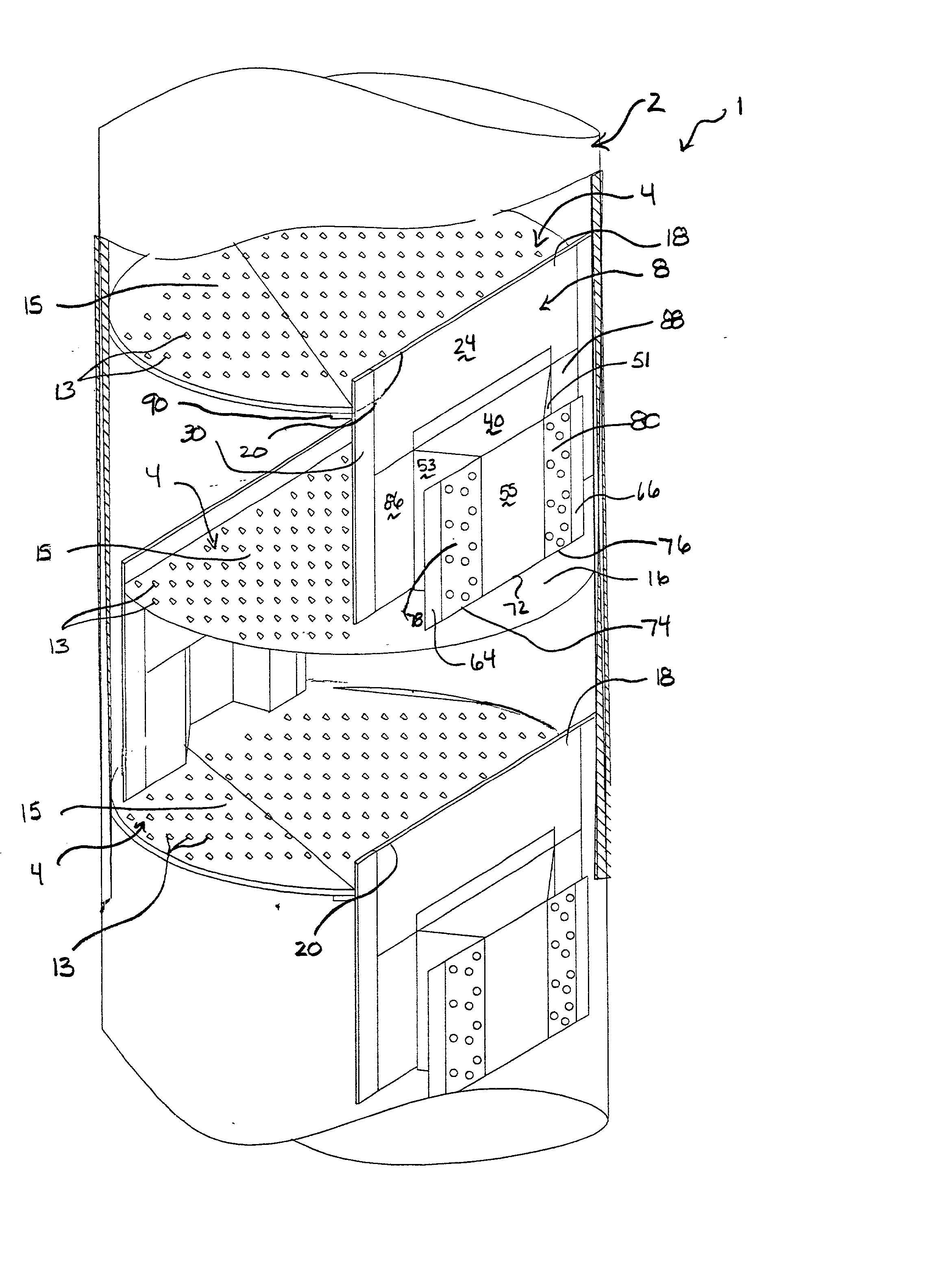

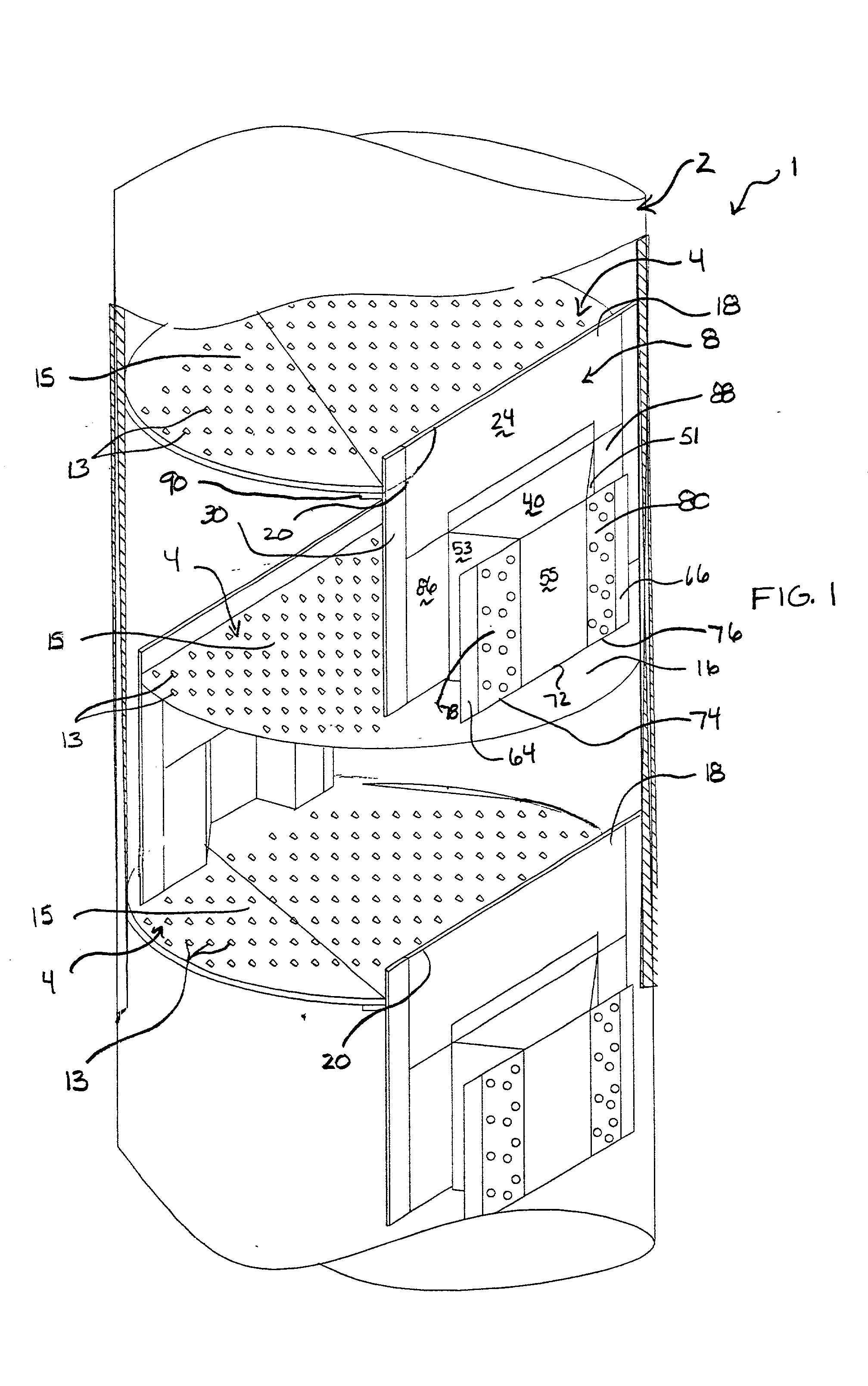

Stepped downcomer apparatus and vapor-liquid contact apparatus with same

A stepped downcomer apparatus for use in a vapor-liquid contact apparatus having an intermediate level step platform with a preferred tri-edge peripheral edge and corresponding step panels extending down from that edge to form a sealing step panel wall. As a preferred support device, extensions extend in chordal fashion out from the interior vertical edge of the opposite side step wall panels and either directly or indirectly by way of support bars into a supporting relationship with a tower of the vapor-liquid contact apparatus. A main panel extends up from the interior edge of the platform and up to the above positioned tray. A weir may extend above the above positioned tray that is an extension of the main panel. This main panel is attached to the support bars and supports the step platform and walls and extensions either alone or with added support members. A tray support ledge extends inwardly from the downcomer to provide support to the upper tray. The liquid-vapor mix contacts the step platform after passing over the weir, and off from which fluid travels both along the central axis of flow and obliquely off the opposite side panels. At opposite ends of the weir, the liquid flows directly into contact with the inlet region of the lower tray, by-passing the platform. The opposite side panel walls can slope outward to vary the downcomer lower pass through volume. An embodiment features chordal wing extensions with pressure equalization openings that extends out from opposite sides of the step wall panel also into a support relationship with the tower. The lower edge of the panels of the wall and the lower edge of the extensions control the flow of fluid as it travels under the lower edging from the inlet side of the downcomer apparatus to the active area of the tray. The relative level of the lower edges can be varied to suit the intended use. Additional or replacement downcomer structural supports include vertical support members extending from a step panel to a lower tray either in the form of support brackets or tiplet extensions.

Owner:SULZER MANAGEMENT AG

Water cooling type CPU radiator

InactiveCN1588267AEven flow distributionAvoid physical damageDigital data processing detailsWater flowDistilled water

It is a water cooling type CPU heat dissipater. It contains heat dissipater body with admitting pipe and exhaust pipe on two stage, a cavity joined with admitting pipe and exhaust pipe inside the heat dissipater body and crossbar interfluent feather array in the cavity. This invention uses distilled water as water cooling type heat dissipater of cooling working substance and quickly transmits CPU's heat to condenser and into the air by this water cooling type heat dissipater; in the mean time, on one hand, crossbar interfluent feather array increases area of dissipation and on the other hand, when water flows through columnar feather array, the columnar feather array has turbulent effect, increases heat emission effect and makes water flows even in the cavity. In this way, great stress raised by great temperature gradient on the CPU's surface can be avoided and CPU's physical damage can also be avoided.

Owner:XI AN JIAOTONG UNIV

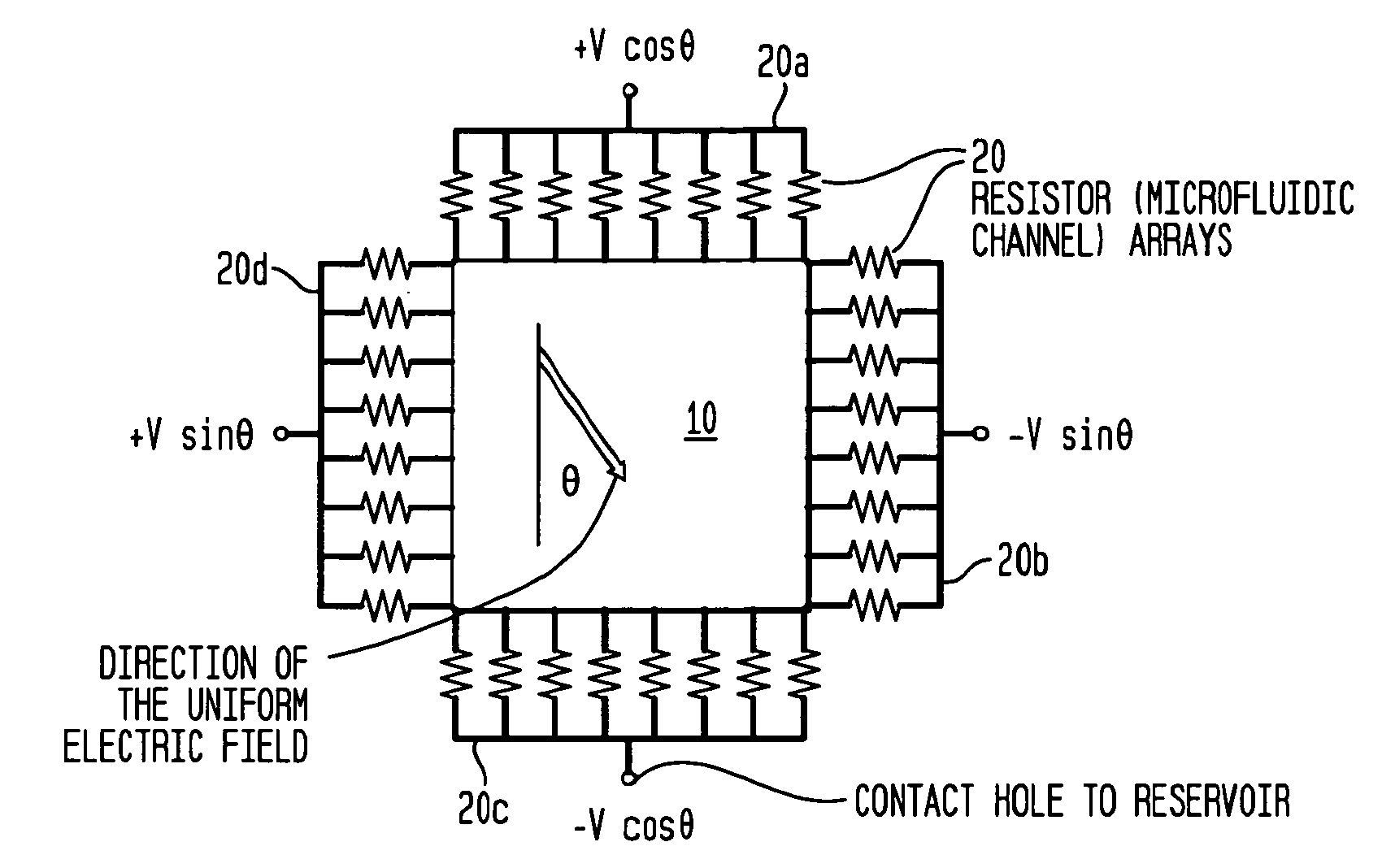

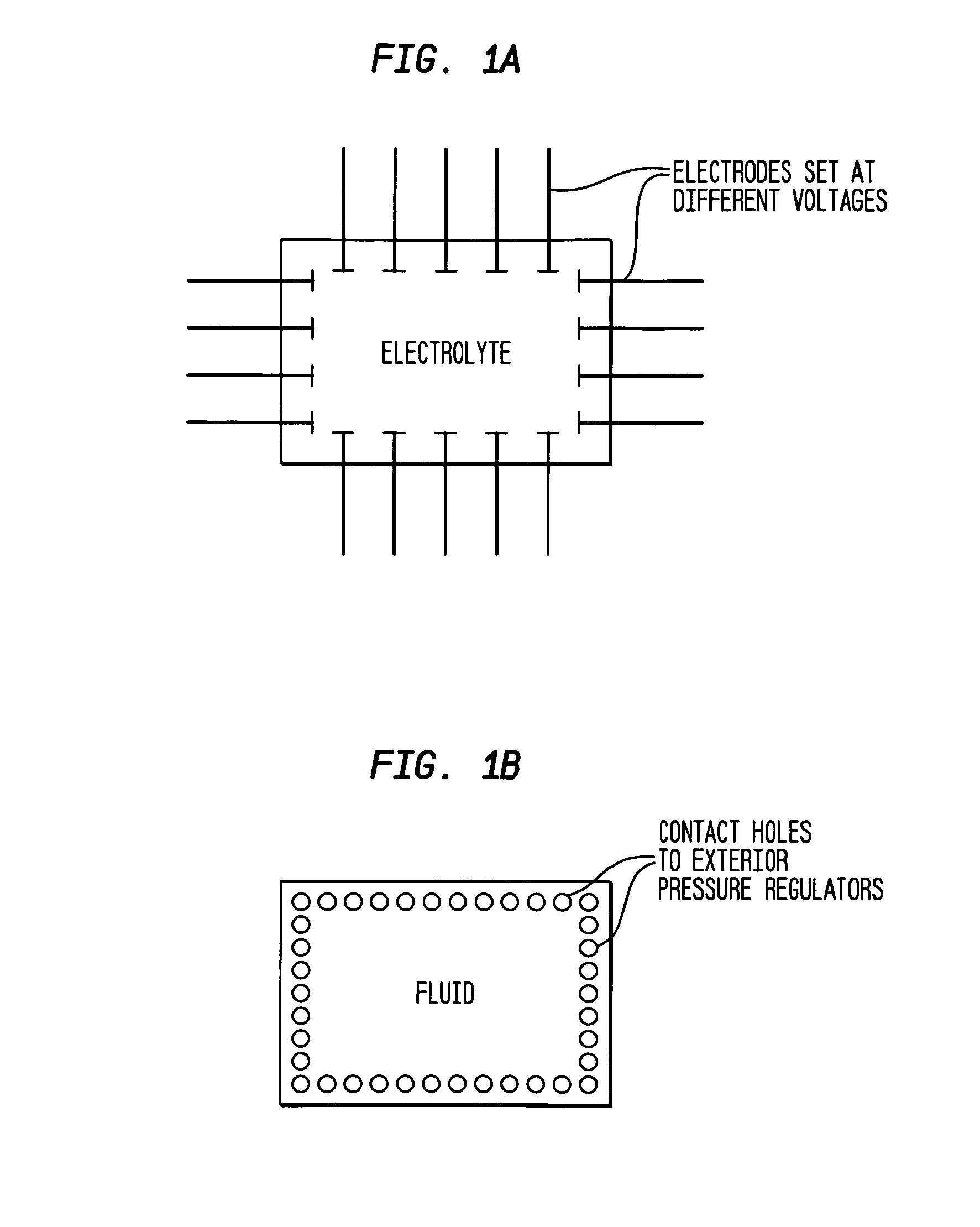

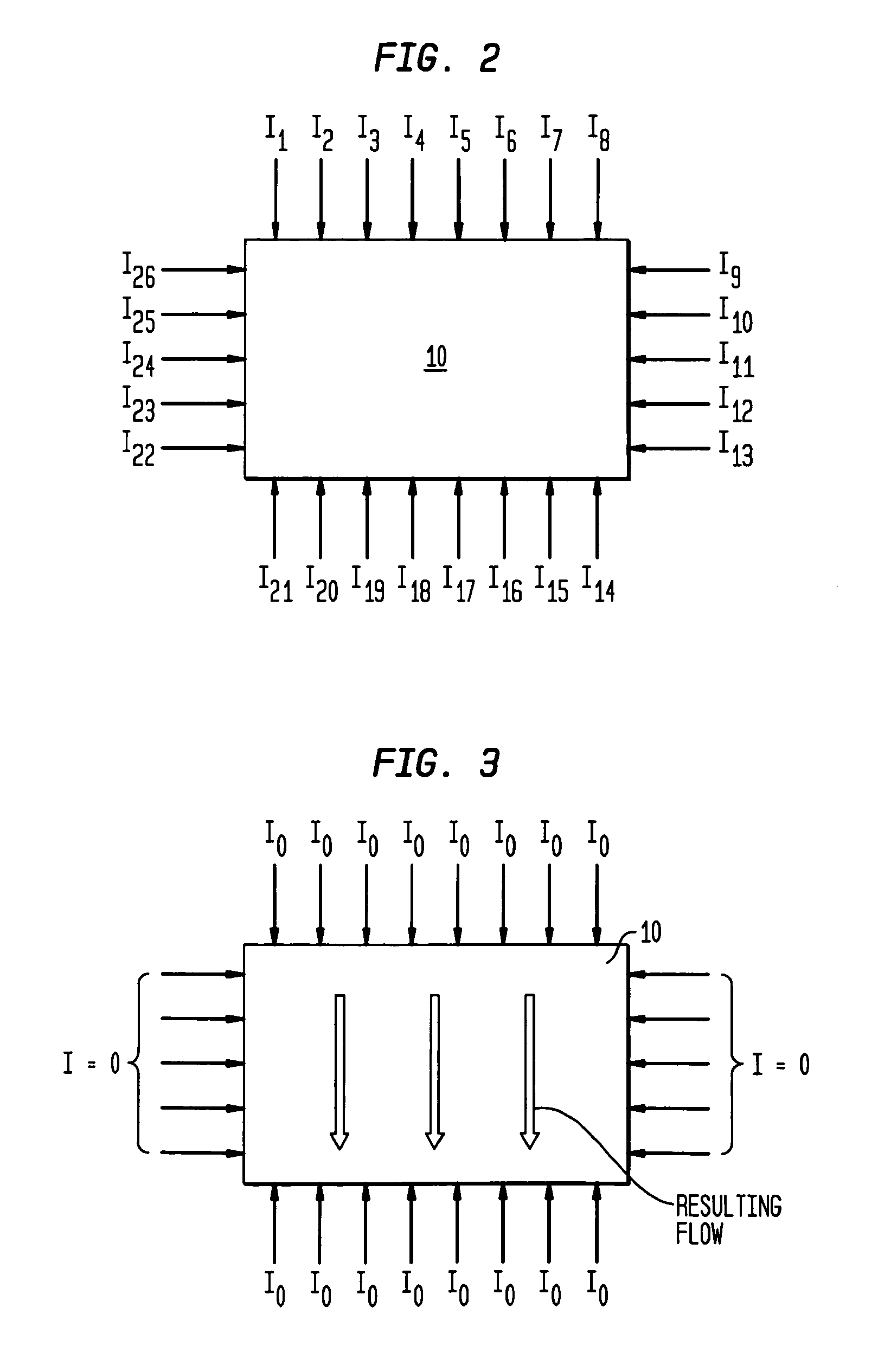

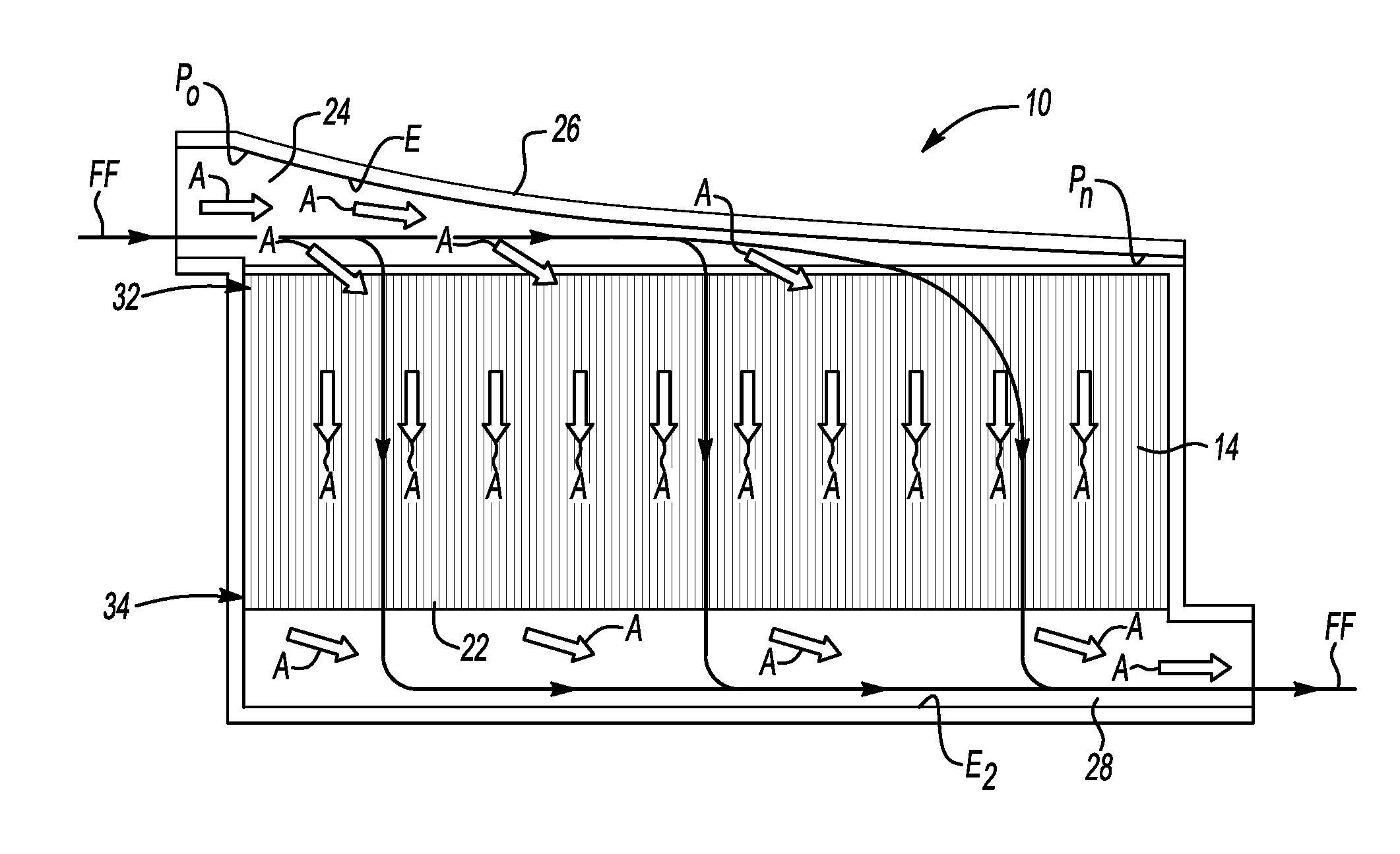

Method and apparatus for generating electric fields and flow distributions for rapidly separating molecules

InactiveUS7597791B2Easy to separateUniform fieldSludge treatmentVolume/mass flow measurementDNAStreamflow

A method and apparatus for generating tunable, uniform electric fields in fluidic applications for rapid separation of molecules, such as DNA, is provided. A region receives the molecules to be separated, the molecules being injected into the region by an injection channel connected thereto. Fluidic microchannels or resistor arrays connected to sides of the region inject currents into the region and produce electric fields in the region that can be oriented at any angle. The electric fields can separate the molecules according to size, and can be used to move or manipulate the molecules within the region. Further, the molecules can be separated by controlling fluid flows within the region to manipulate the molecules. One or more reservoirs can be attached to the fluidic microchannels for collecting the molecules after separation, movement, or manipulation.

Owner:THE TRUSTEES FOR PRINCETON UNIV

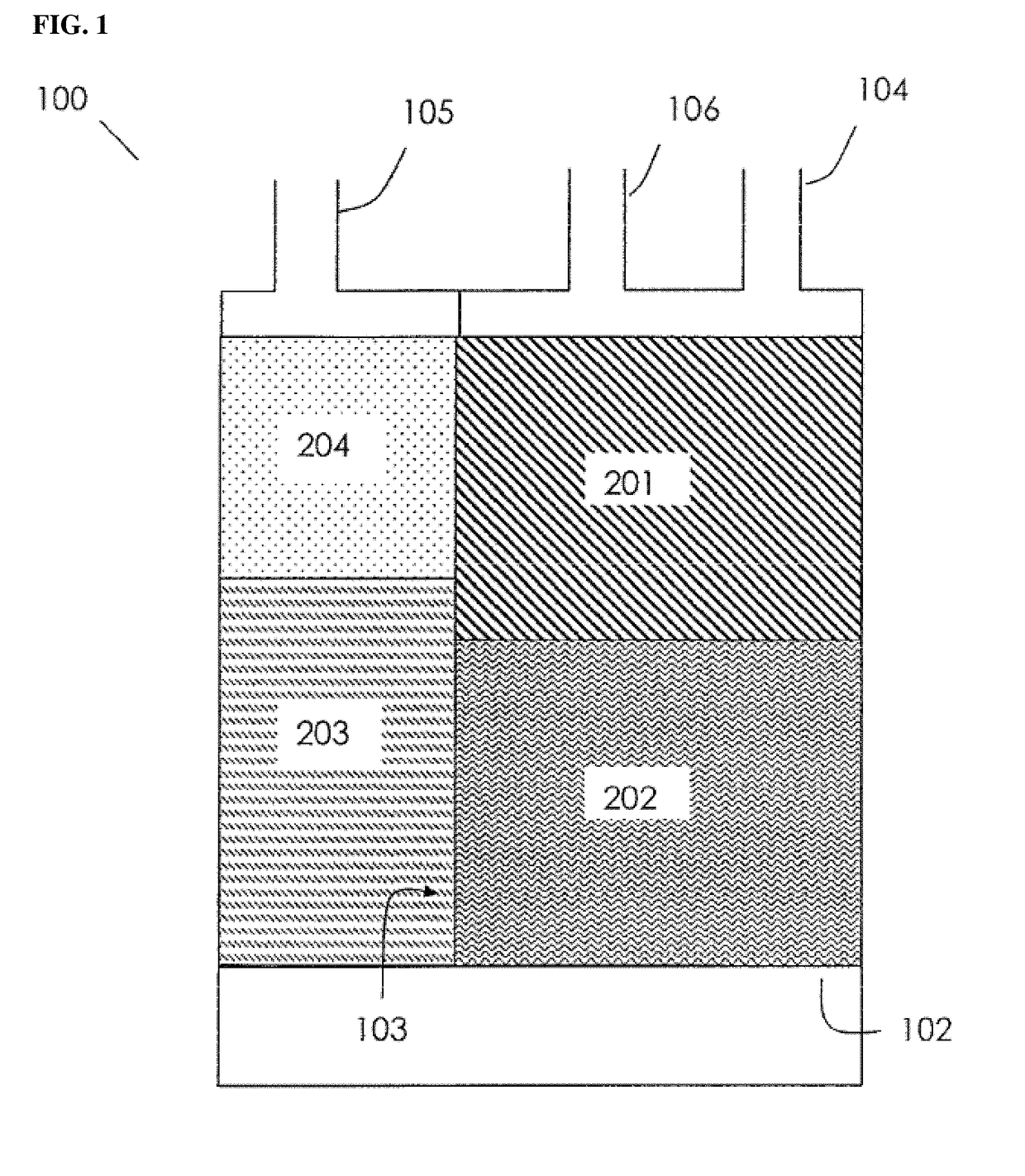

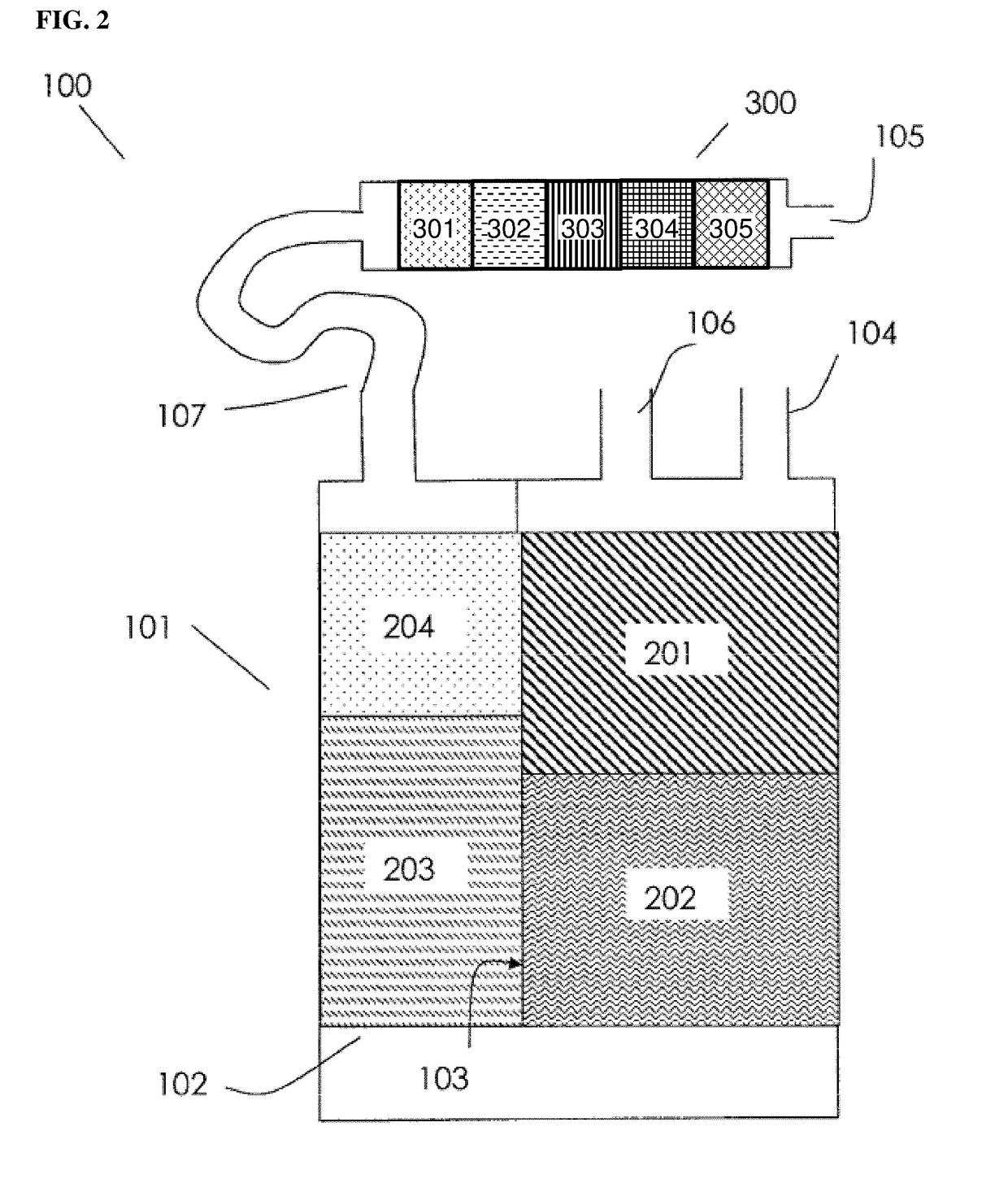

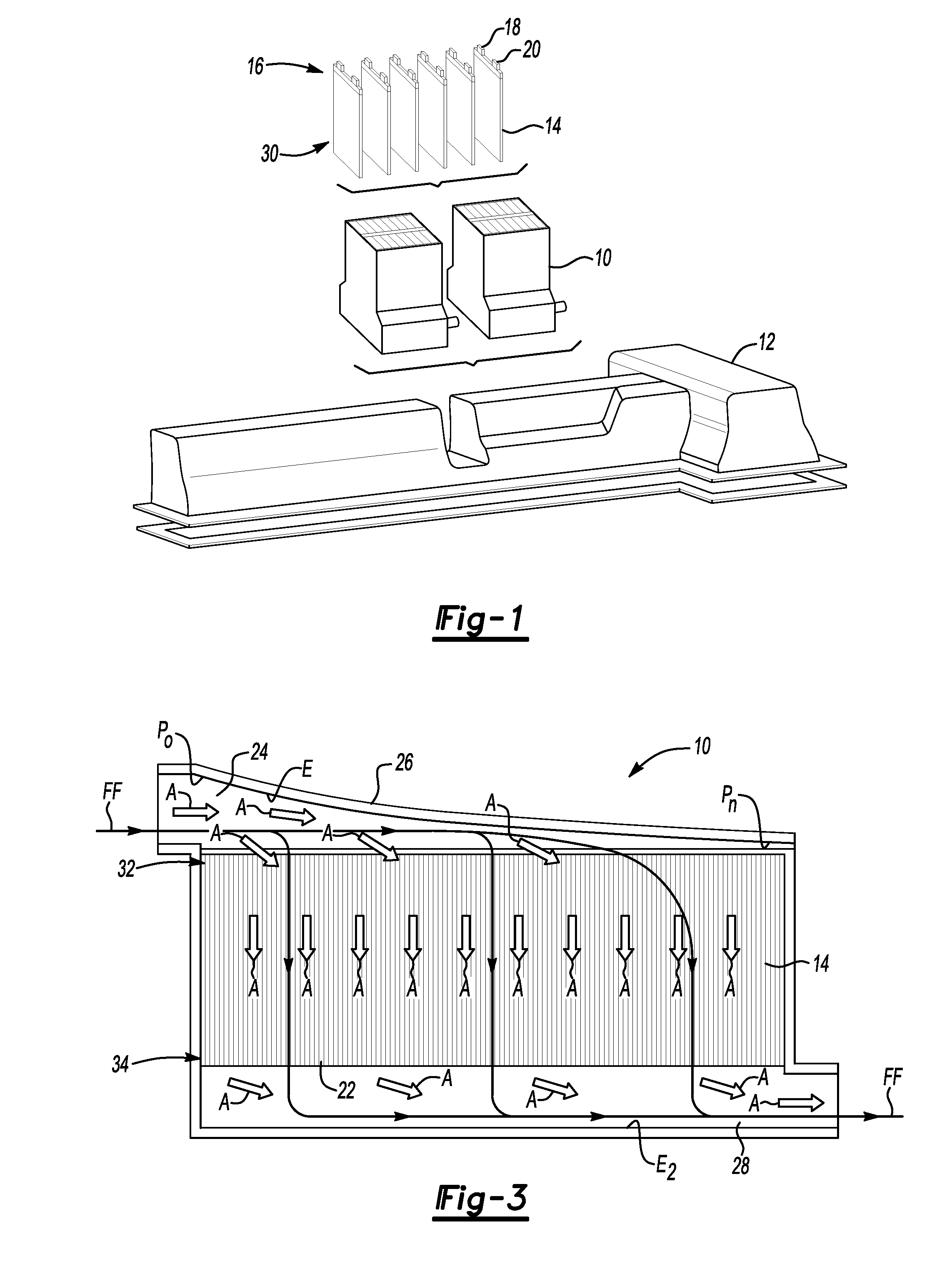

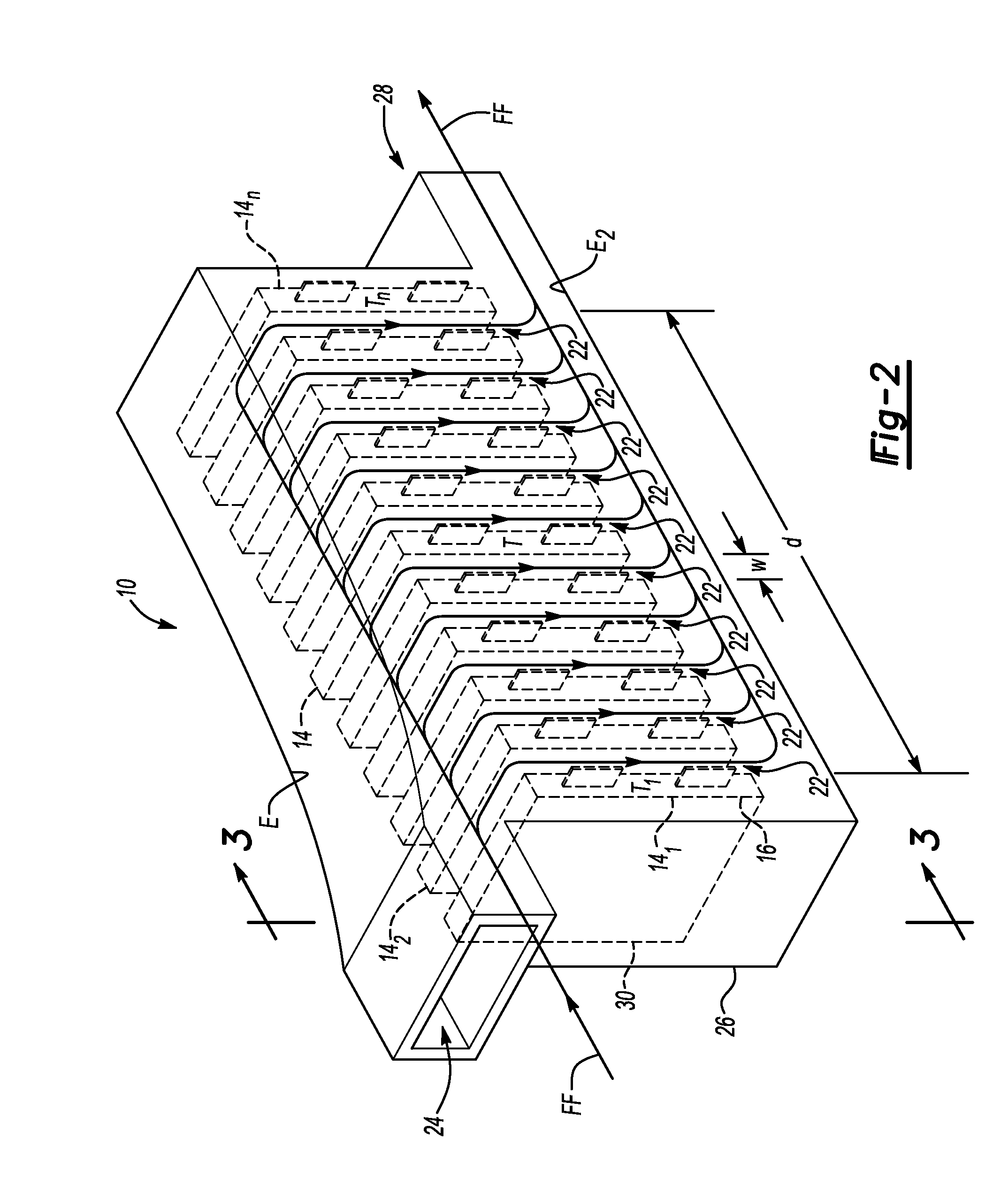

Secondary battery module

ActiveUS20110244295A1Easy temperature controlMinimizes non-uniform coolingCell temperature controlCell component detailsThermal energyInlet channel

A secondary battery module includes a plurality of secondary battery cells each having a measureable temperature and each spaced apart from an adjacent one of the cells to define a cooling channel therebetween. The plurality of cells includes a first one of the cells having a measureable first temperature, and a terminal one of the cells having a measureable terminal temperature and separated from the first one of the cells by at least one other of the cells. The module includes a fluid flowable within each of the cooling channels and in thermal energy exchange relationship with each of the cells. The module includes a housing having a surface defining an inlet channel disposed in fluid flow communication with each of the cooling channels and configured for directing the fluid flow to each of the cooling channels. The surface has a shape defined by a spline.

Owner:GM GLOBAL TECH OPERATIONS LLC

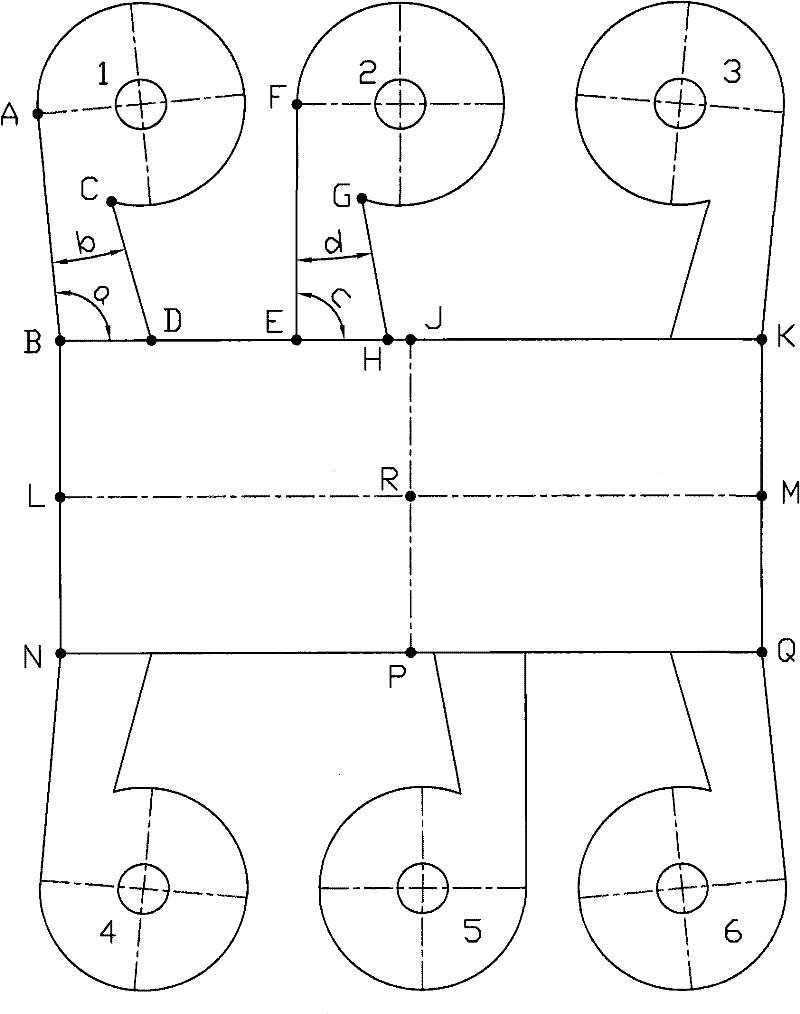

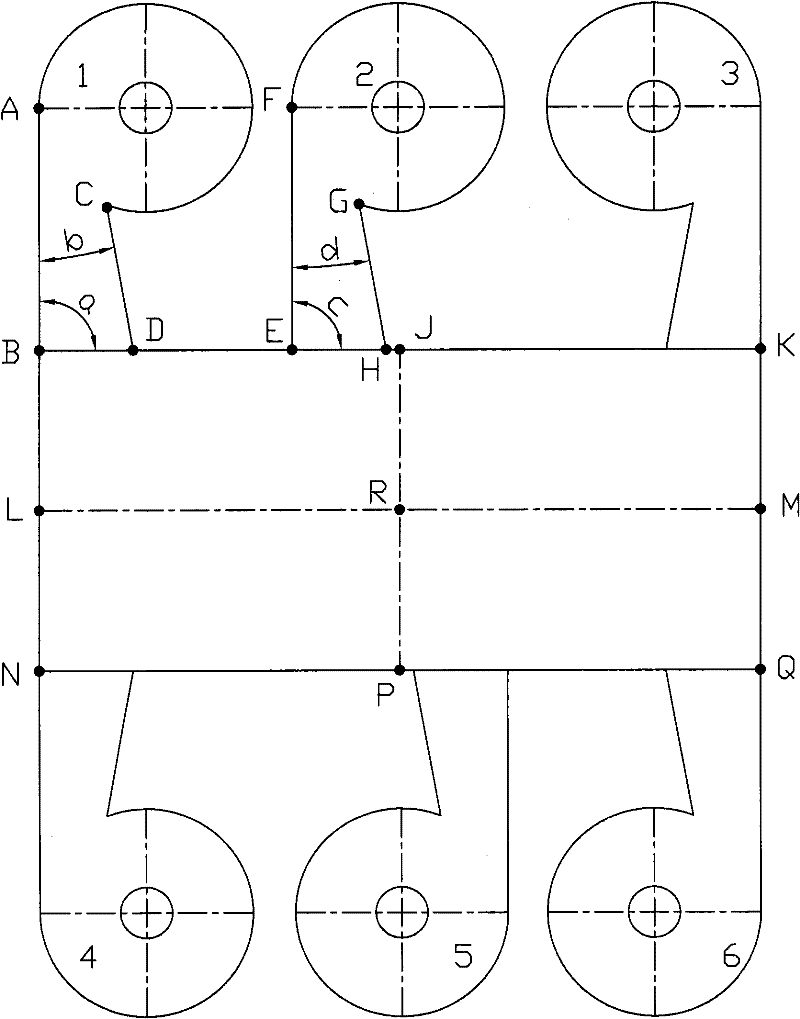

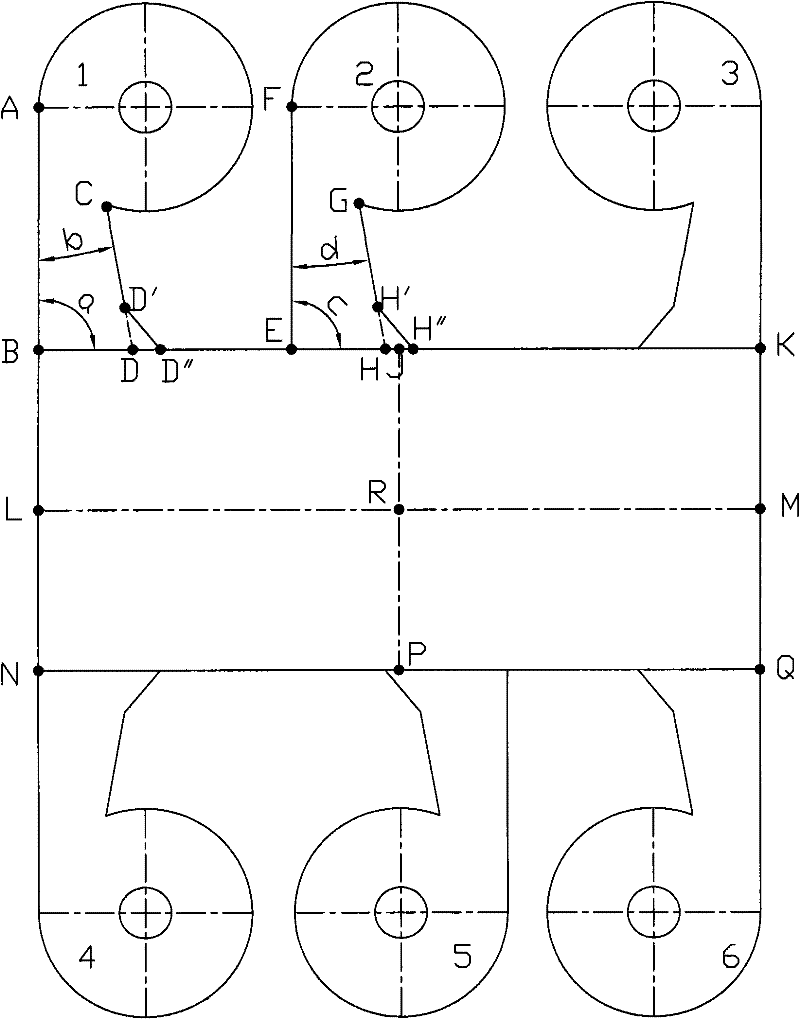

Connection between cyclone separators and hearth of large-scale circulating fluidized bed boiler

ActiveCN102235665AConsistent performanceEven flow distributionFluidized bed combustionApparatus for fluidised bed combustionCycloneFlue gas

The invention discloses connection between cyclone separators and a hearth of a large-scale circulating fluidized bed boiler. The hearth is connected with six cyclone separators. A cross section of the hearth is rectangular, wherein upper portions of two wider side walls of the hearth are provided with three flue gas outlets respectively. The six cyclone separators are divided into two sets equally and are fixedly connected with the two wider side walls. Each flue gas outlet is communicated with an inlet flue of the cyclone separator. Cylindrical shell structure and dimension of the six cyclone separator are same. In the two set of cyclone separators on the two side walls, inlet flue cross section of each cyclone separator of each set and inlet flue cross section of each cyclone separator of the other set form central symmetry relative to a central point of the hearth. Inlet flue cross sections of two outboard cyclone separators of the sets form axial symmetry relative to a center line of the hearth. According to the connection provided in the invention, flow of flue gas in the hearth is distributed uniformly, flue gas flux of each cyclone separator is distributed uniformly, particle concentration of a vertical cross section of the inlet flue is in reasonable distribution, thus performance consistency of each cyclone separator is ensured.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

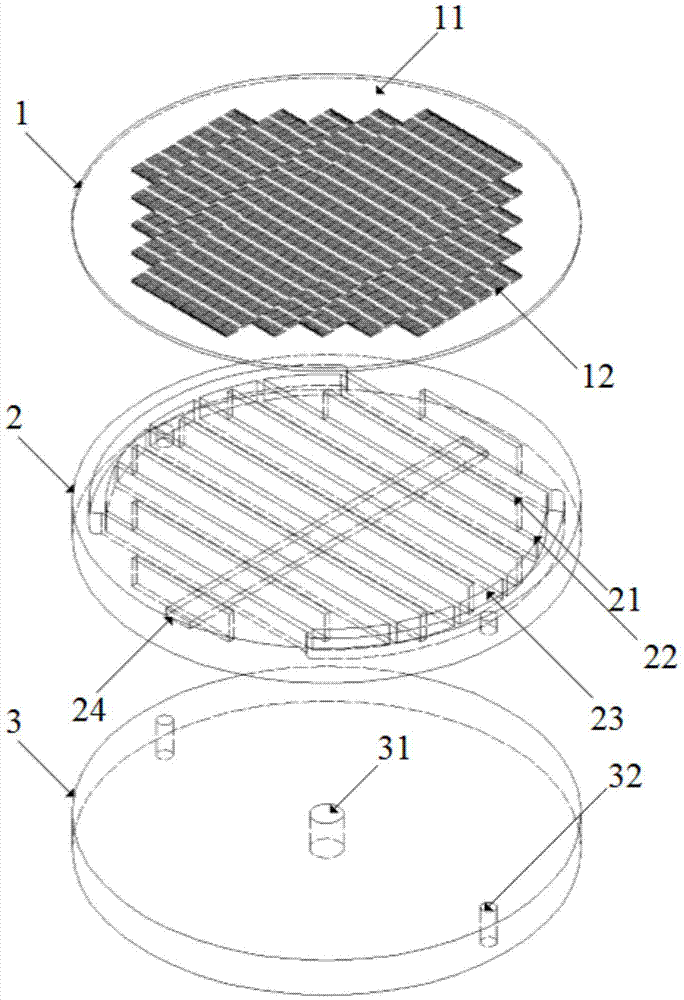

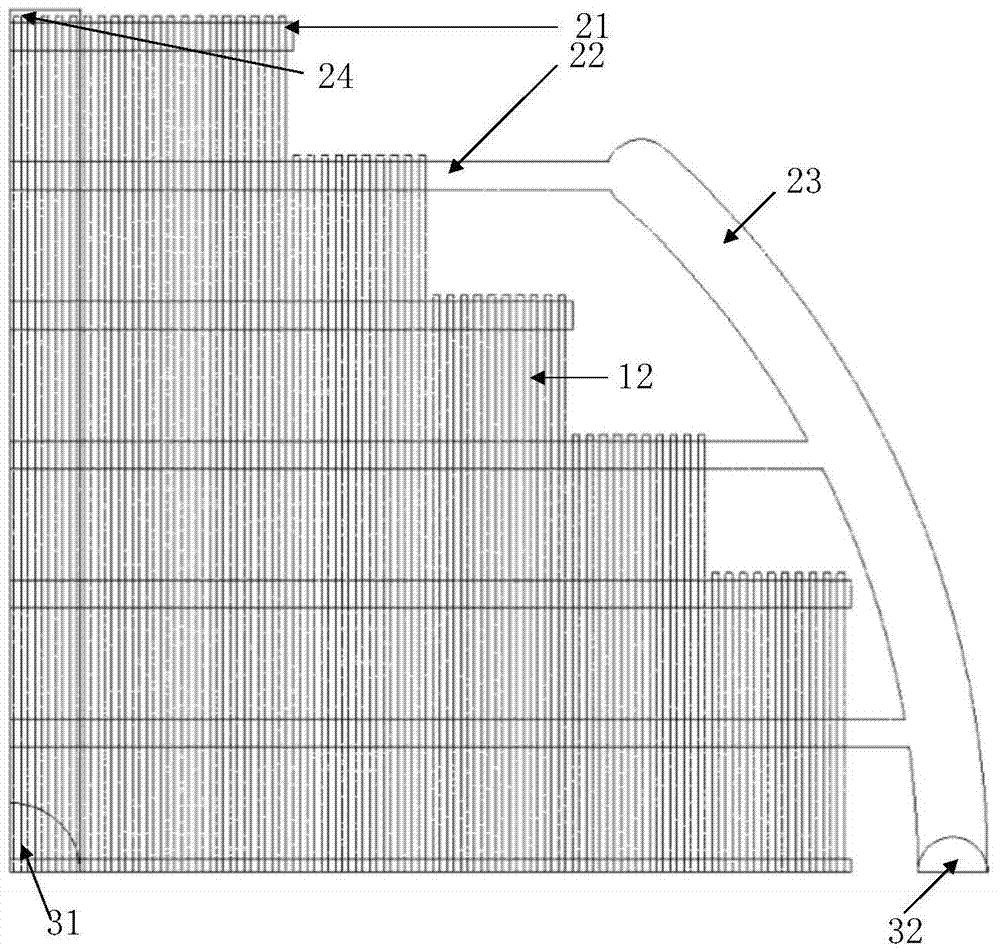

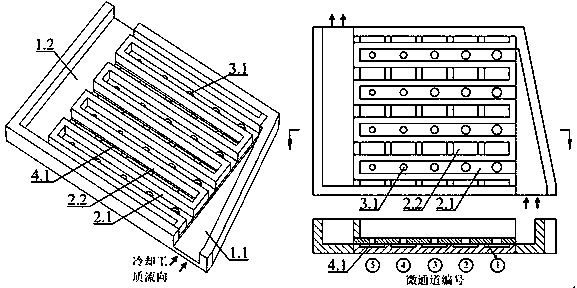

Large-diameter laser liquid cooling mirror structure

InactiveCN104852257AUniform distribution of pressure and flowEven heat dissipationMountingsLaser cooling arrangementsBackplaneEngineering

The invention discloses a large-diameter laser liquid cooling mirror structure, which comprises a reflection panel, a distribution plate and a back plate, wherein the back face of the distribution plate is provided with water inlet first-level flow channels and water outlet first-level flow channels; the front face of the distribution plate is provided with water inlet second-level flow channels and water outlet second-level flow channels distributed parallelly; a plurality of water inlet holes and water outlet holes are arranged in the back plate; and the front face of the reflection panel is a reflection face, and the back face is provided with third-level flow channels. By adopting a multilevel cooling flow channel structure based on interdigitated flow channels, cooling liquid with a large flow can be provided for transferring reflection face sedimentary hot under small water through pressure, pressure and flow of the cooling liquid inside each micro flow channel can be distributed comparatively uniformly, uniform cooling is realized on the reflection face, and over large thermal distortion of the large-diameter endoscope can be restrained. Adjacent second-level flow channels are communicated with the water inlet first-level flow channels and the water outlet first-level flow channels respectively and stacked with the third-level flow channels vertically, liquid does not need to flow through the whole section of the thin third-level flow channel, and flow resistance is greatly reduced.

Owner:DALIAN UNIV OF TECH

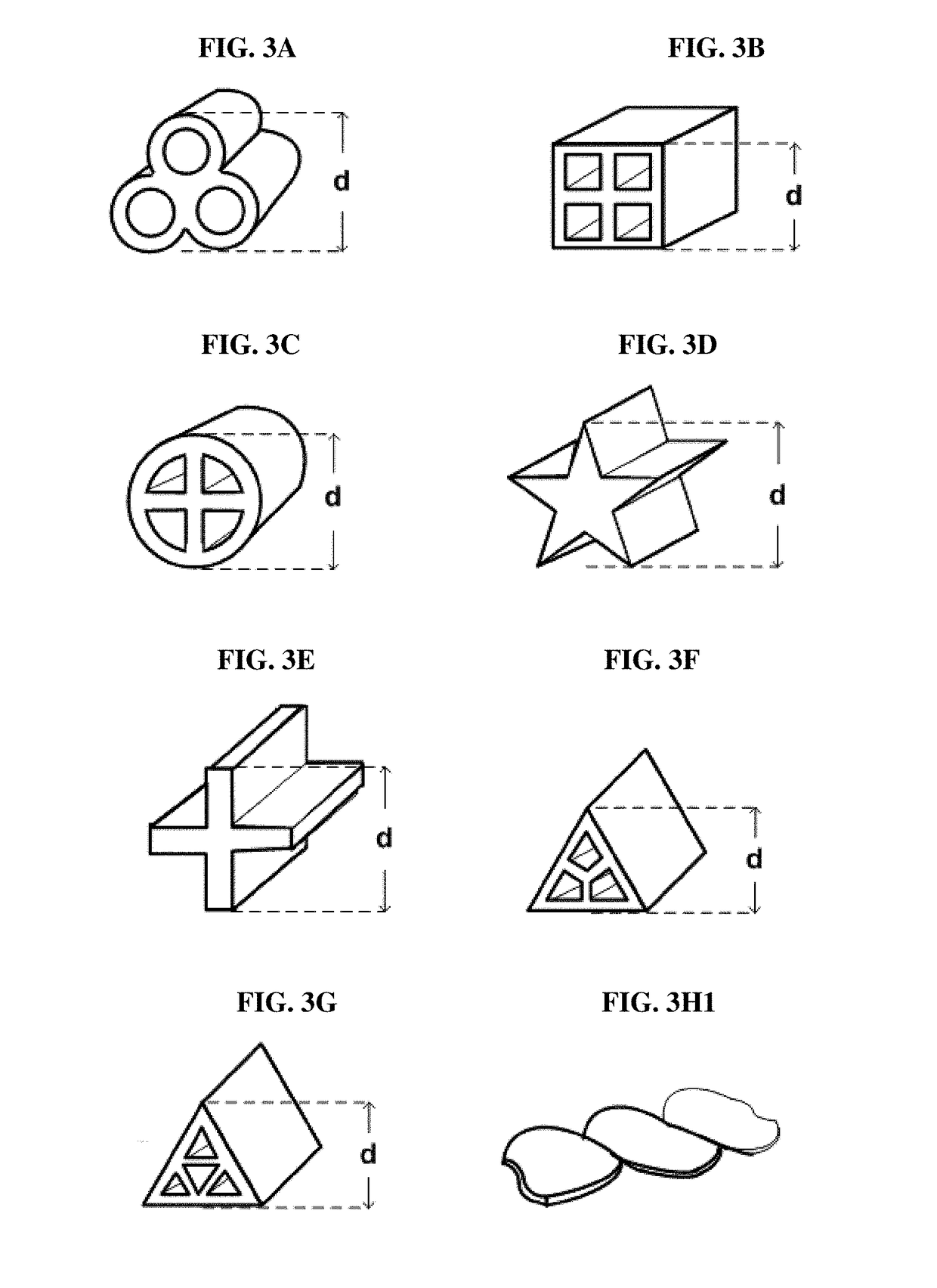

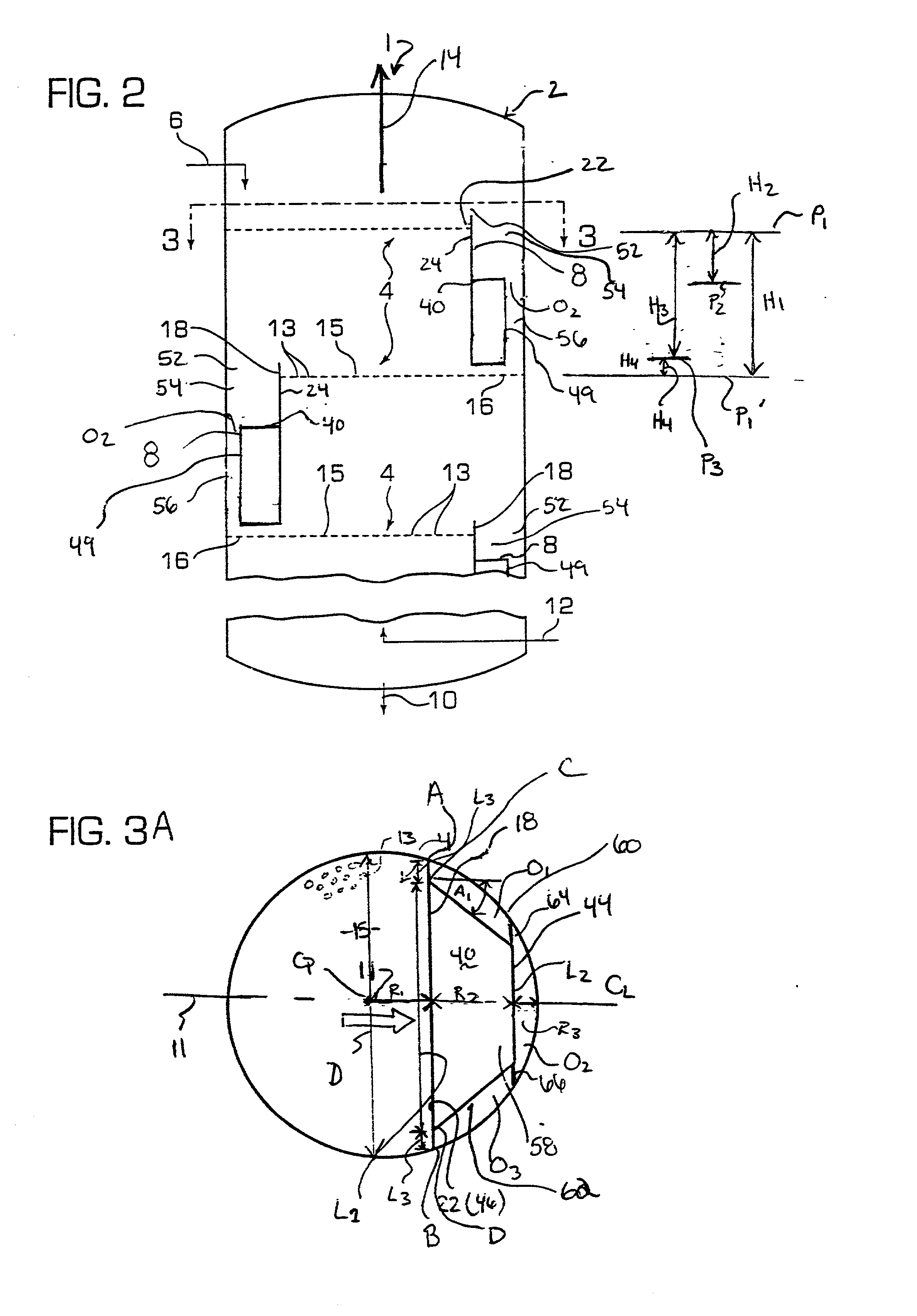

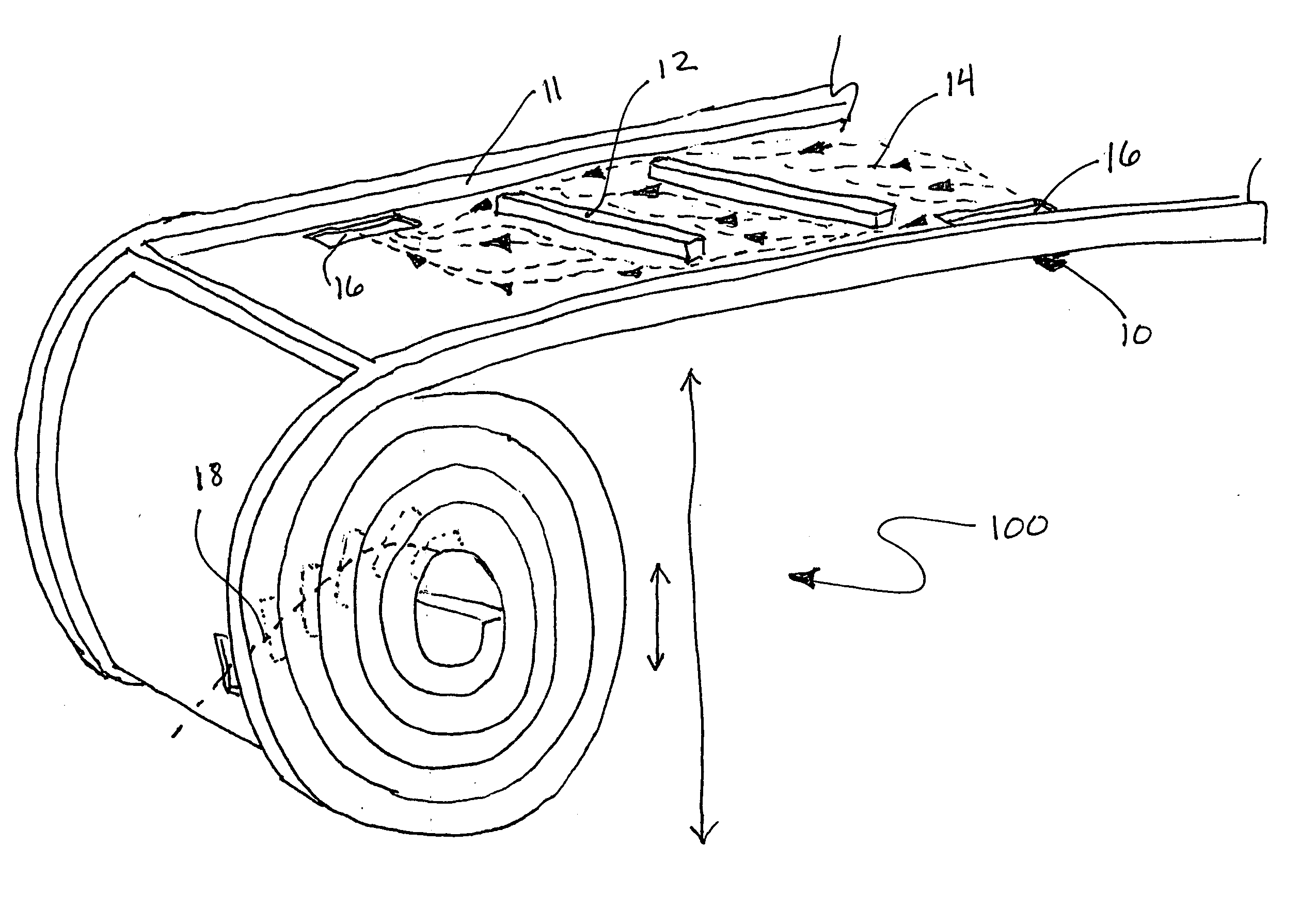

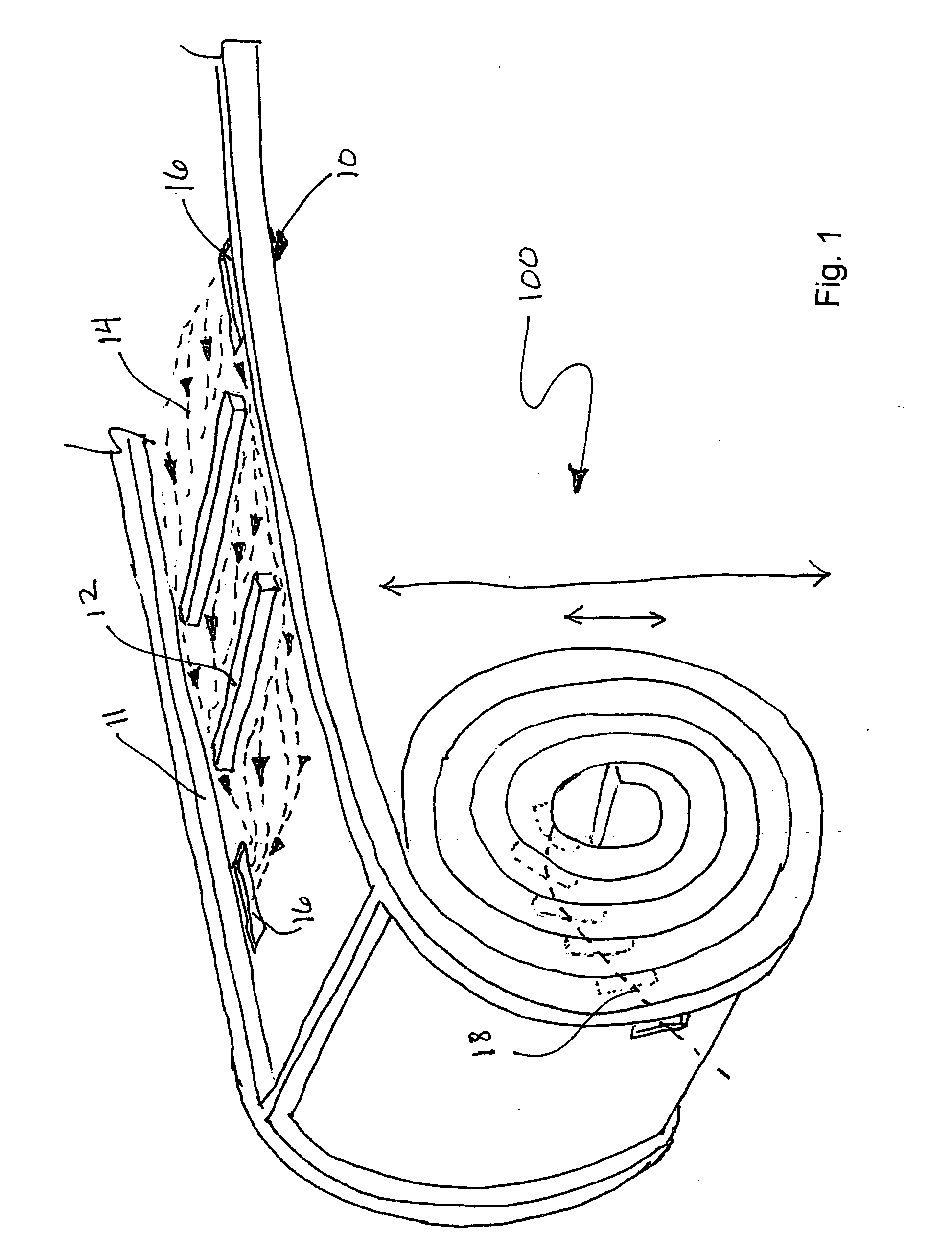

Biomimetic 3-dimensional scaffold with metabolic stream separation for bioartificial liver device

InactiveUS20060035376A1Even flow distributionArtificial cell constructsVertebrate cellsBioartificial liver deviceEngineering

A bio-artificial organ comprises a substrate comprising a roll of a substrate material, and a plurality of cells adhered to the substrate, the roll being formed from a sheet rolled to form a plurality of layers that include spacers and spaced openings such that at least a first set of parallel chambers is formed when the roll is formed, the chambers being manifolded to a first inlet and a first outlet. The bio-artificial organ may further include at least a second chamber, the second chamber being isolated from the first set of chambers by at least a cell barrier. A method for assembling a bio-artificial organ comprises a) providing a substrate for cell culture capable of forming a roll, the substrate having a surface, b) patterning the surface of the substrate, c) seeding cells onto the substrate, and d) reeling the substrate into a cylindrical roll.

Owner:RICE UNIV

System for sensing particulate matter

InactiveUS9778160B2Uniform depositionReduce heat lossInternal-combustion engine testingExhaust apparatusEngineeringParticulate matter sampler

Owner:FORD GLOBAL TECH LLC

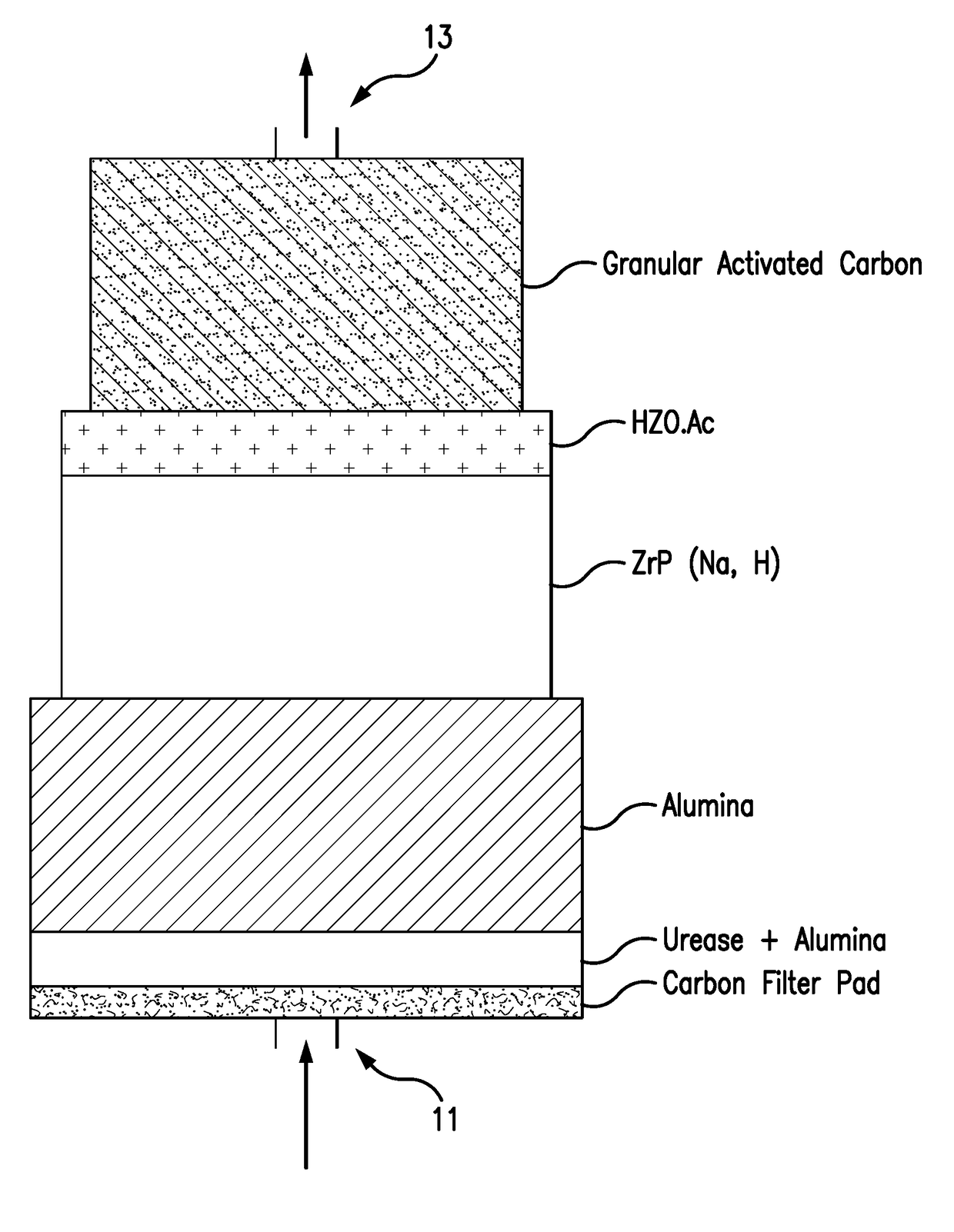

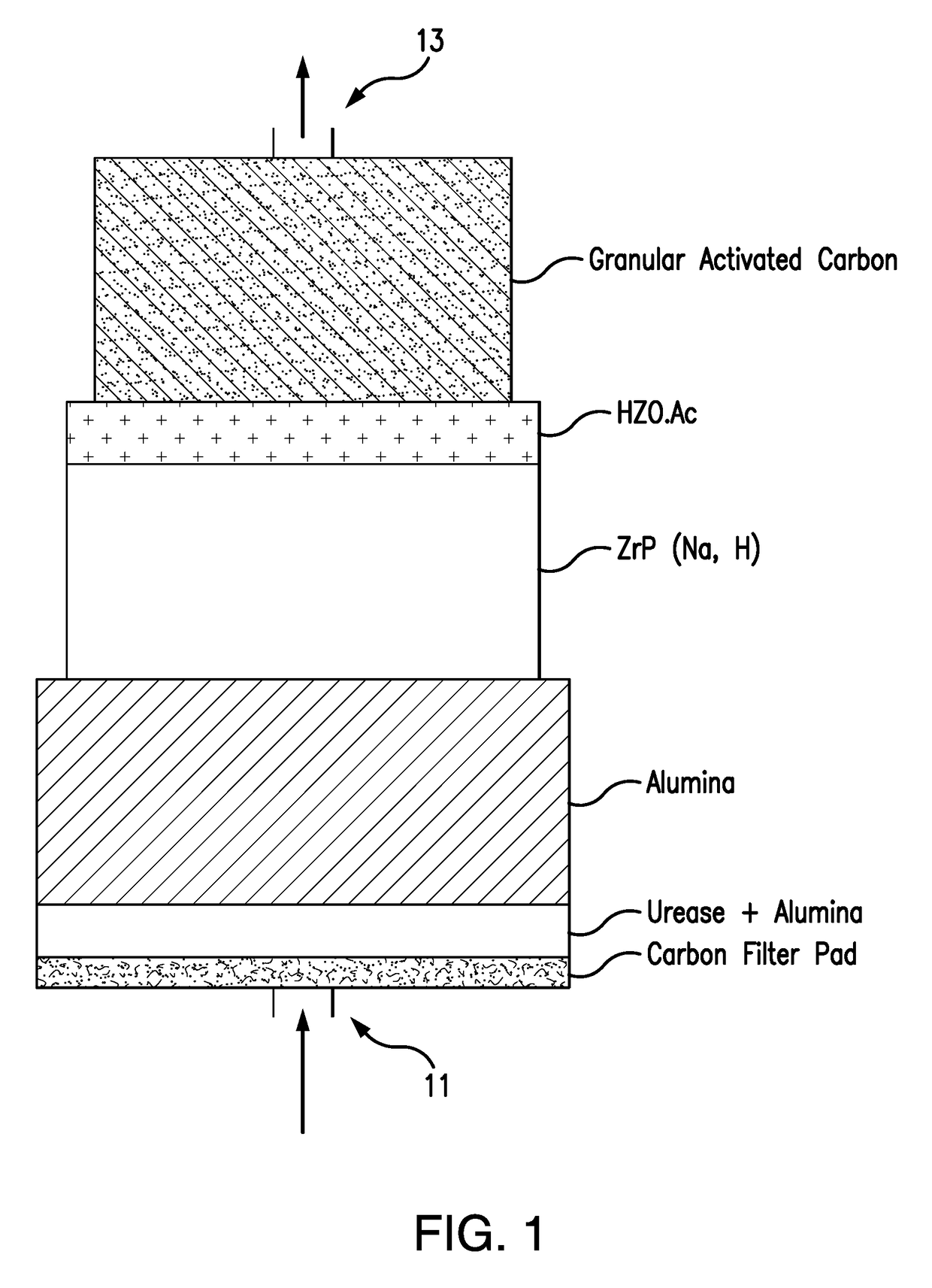

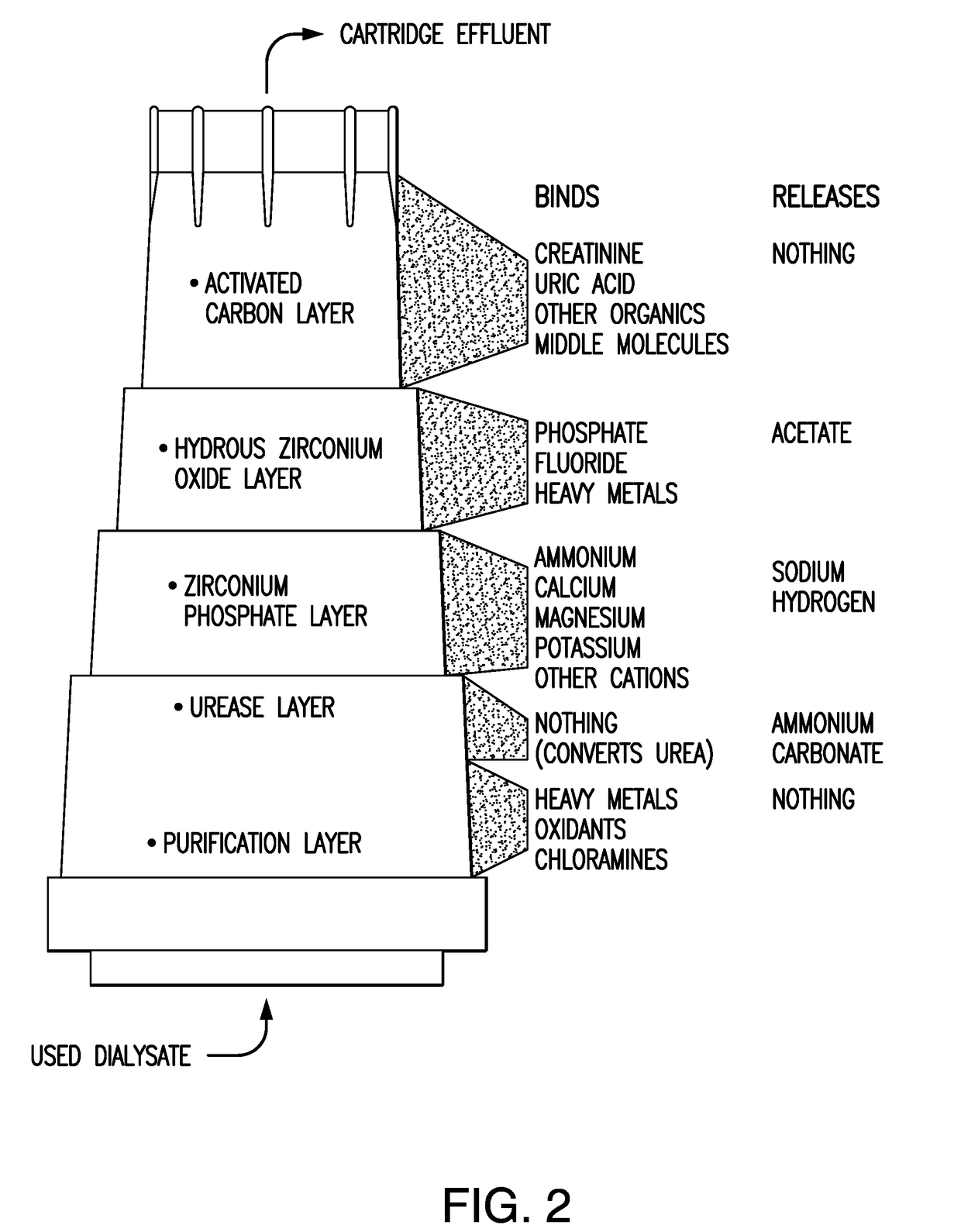

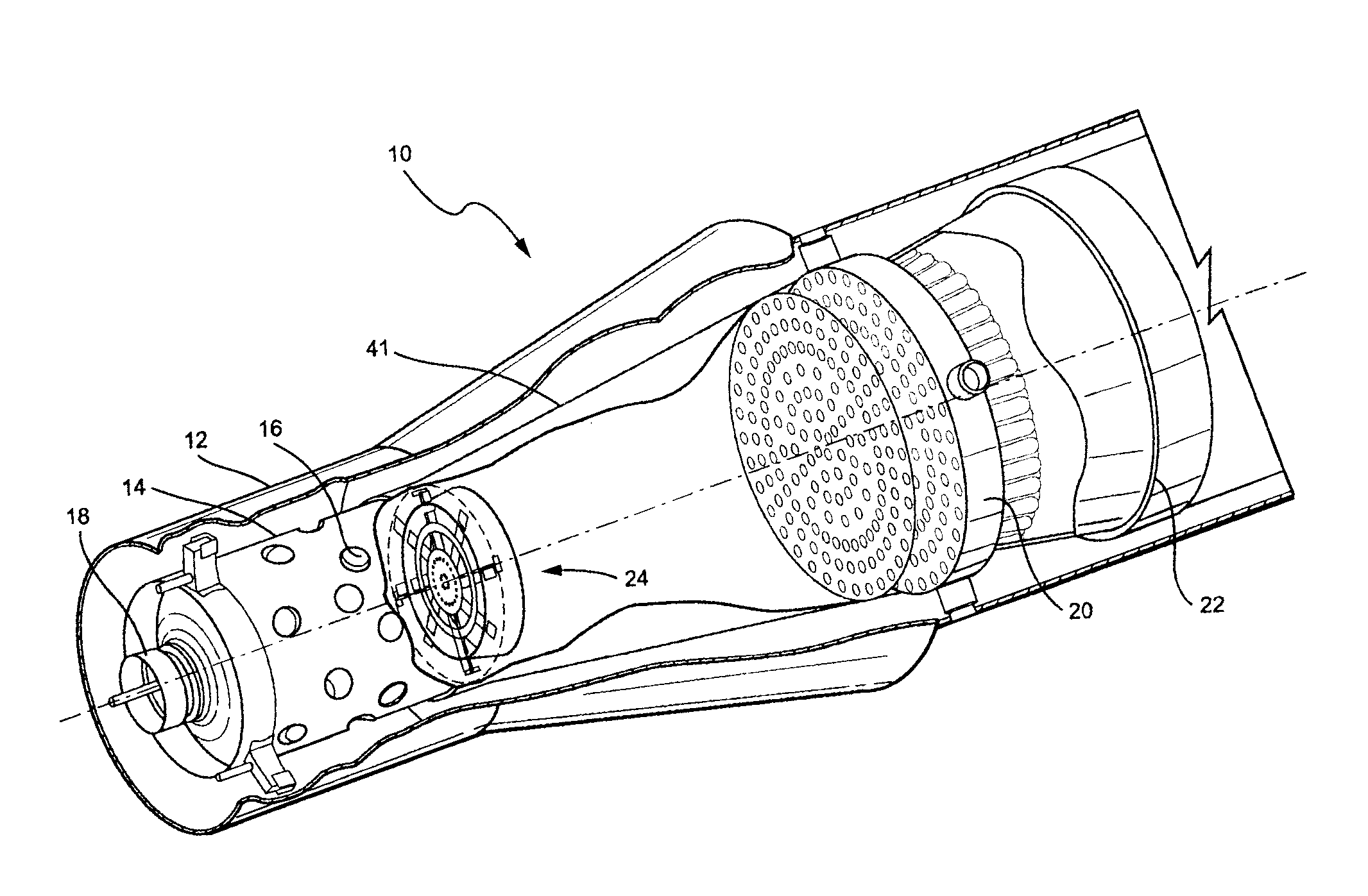

Cartridge Systems Useful In Cleaning Dialysis Solutions

ActiveUS20170189598A1Improve traffic distributionEven flow distributionIon-exchange process apparatusOther chemical processesBiochemistryMedicinal chemistry

Owner:FRESENIUS MEDICAL CARE HLDG INC

Flow controller for gas turbine combustors

InactiveUS6996990B2Improve flow uniformityMinimizes and eliminates for flow separationContinuous combustion chamberFurnace componentsCombustorCombustion chamber

A flow controller is disposed between a preburner section in a diffuser and prior to the main fuel injector and catalytic sections in a turbine combustor. The flow from the burner section is typically not uniform in temperature and velocity and the flow splitter renders the flow substantially uniform at the fuel injector and catalyst inlet. The flow splitter comprises substantially equal mass annular flow areas defined by a first outer frustoconical element and the diffuser wall, a second element defining with the first element a second annular area and a central bluff disk defining with the second element the interior annular area. Vanes are provided on the flow splitter to enhance turbulent flow and substantially preclude swirling flow. As a result, flow uniformity at the catalyst inlet and main fuel injection is achieved.

Owner:GENERAL ELECTRIC CO

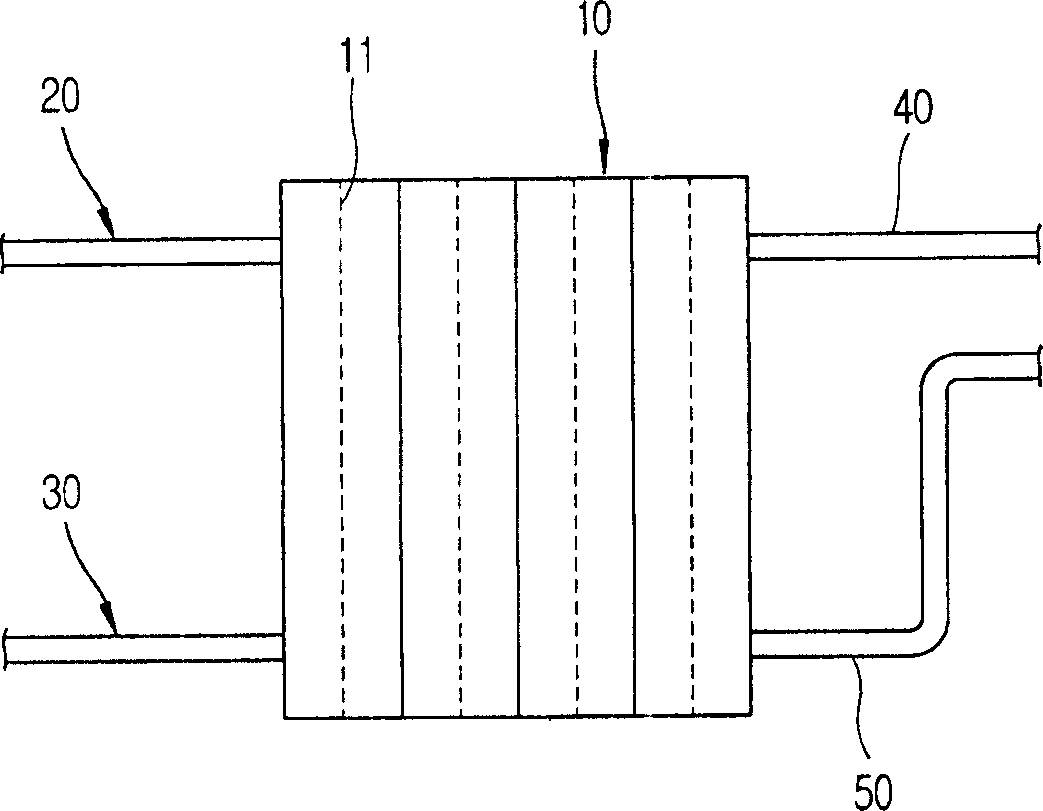

Exhaust gas heat exchanger, in particular an exhaust gas cooler for exhaust gas recirculation in a motor vehicle

ActiveCN101147039AEven flow distributionNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesExhaust gas recirculation

The invention relates to an exhaust gas heat exchanger, in particular, to an exhaust gas cooler for exhaust gas recirculation in a motor vehicle comprising heat exchanging conduits which are passed through by exhaust gases, surrounded by a coolant and linked to a distributing and / or collecting chambers comprising a flux guiding device which is provided with the exhaust gas input and output sides and a plurality of channels extending therebetween and inclined to each other.

Owner:BEHR GMBH & CO KG +1

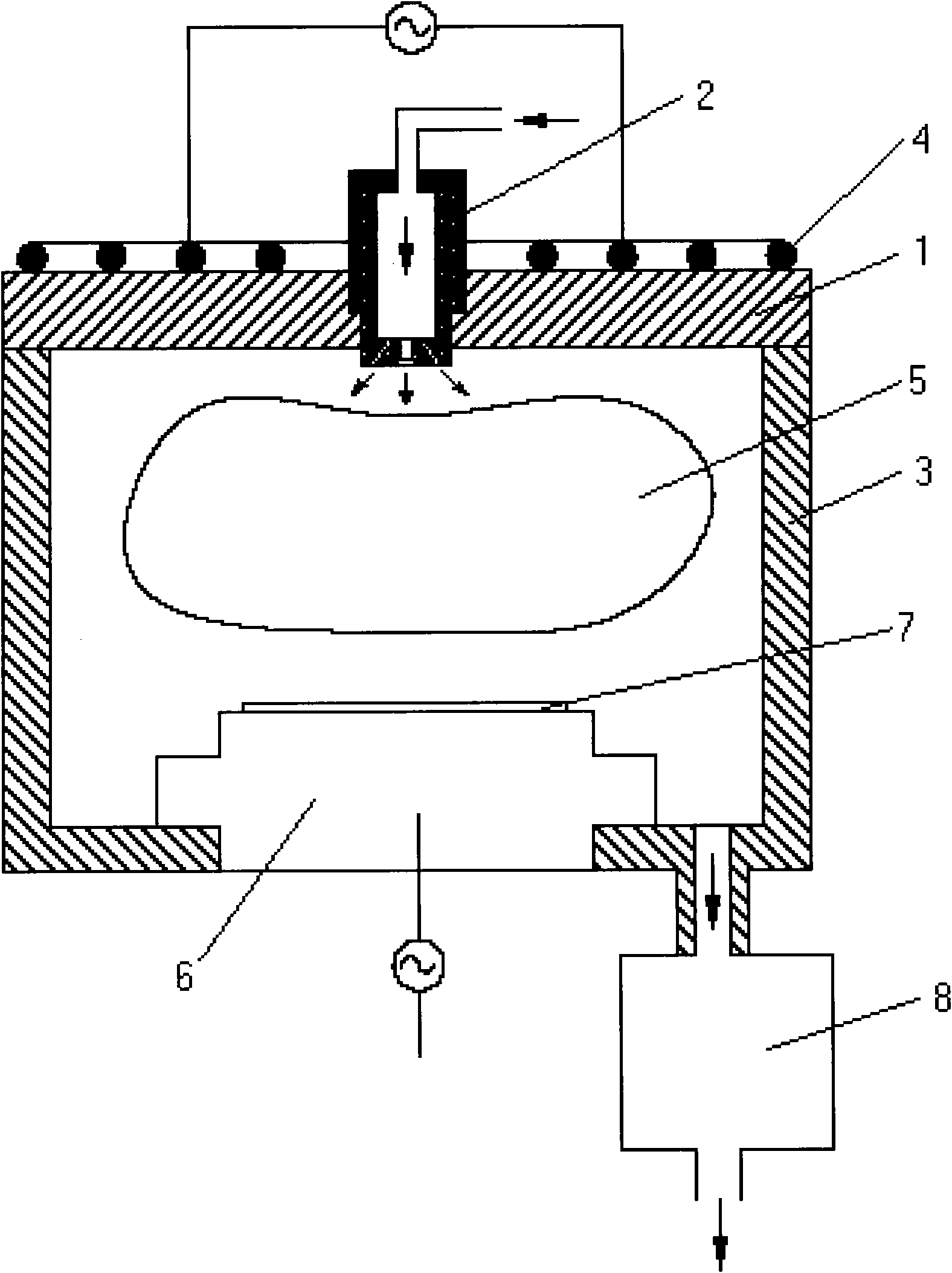

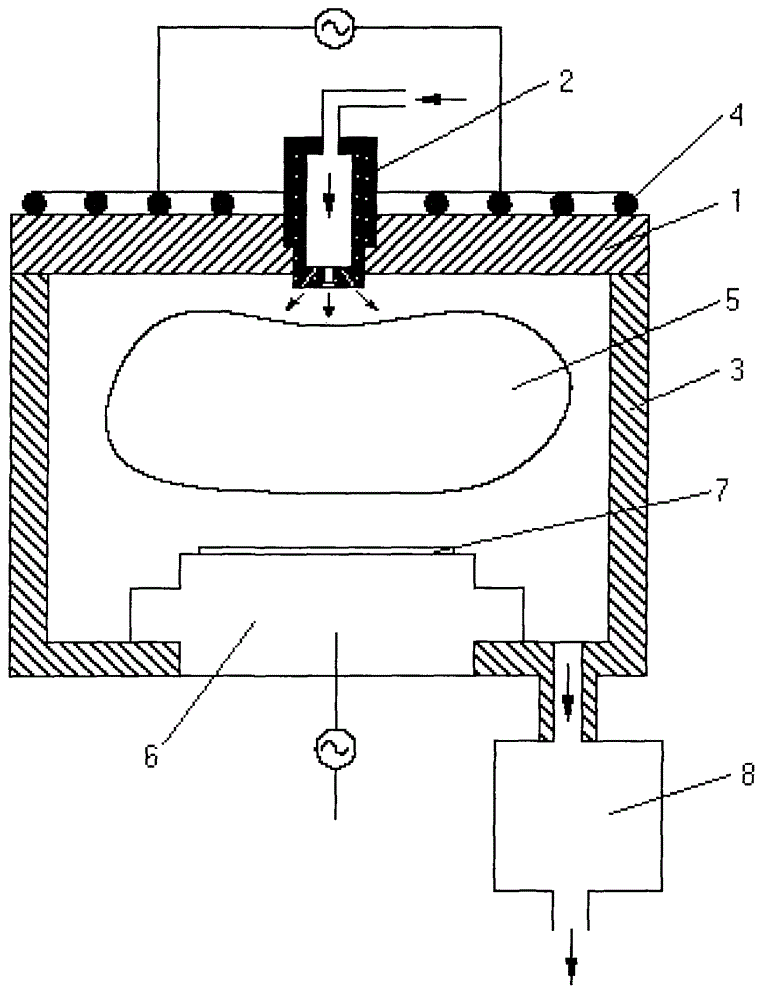

Gas input device and plasma processing equipment

InactiveCN101930889AUniform pressureEven flow distributionElectric discharge tubesEtchingEngineering

The invention provides a gas input device and plasma processing equipment. The gas input device comprises a nozzle and a cover plate, wherein, the nozzle is provided with a first channel and a nozzle bypass communicated with the first channel; the cover plate is provided with a groove and a plurality of second channels, the groove is basically arranged at the central position of the cover plate, and the plurality of the second channels are uniformly distributed in the cover plate around the center line of the groove; and the nozzle is embedded into the groove, the air outlet end of the first channel stretches out of the cover plate from the bottom part of the groove, and the air inlet ends of the plurality of the second channels are communicated with the nozzle bypass. The gas input device and the plasma processing equipment can obtain uniform air flow distribution above the whole surface of a processed wafer so as to effectively avoid non-uniform etching or deposition caused by non-uniform gas distribution from the center to the edge above the wafer surface, thus promoting the etching or deposition rate of points on the whole wafer surface to be more similar.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

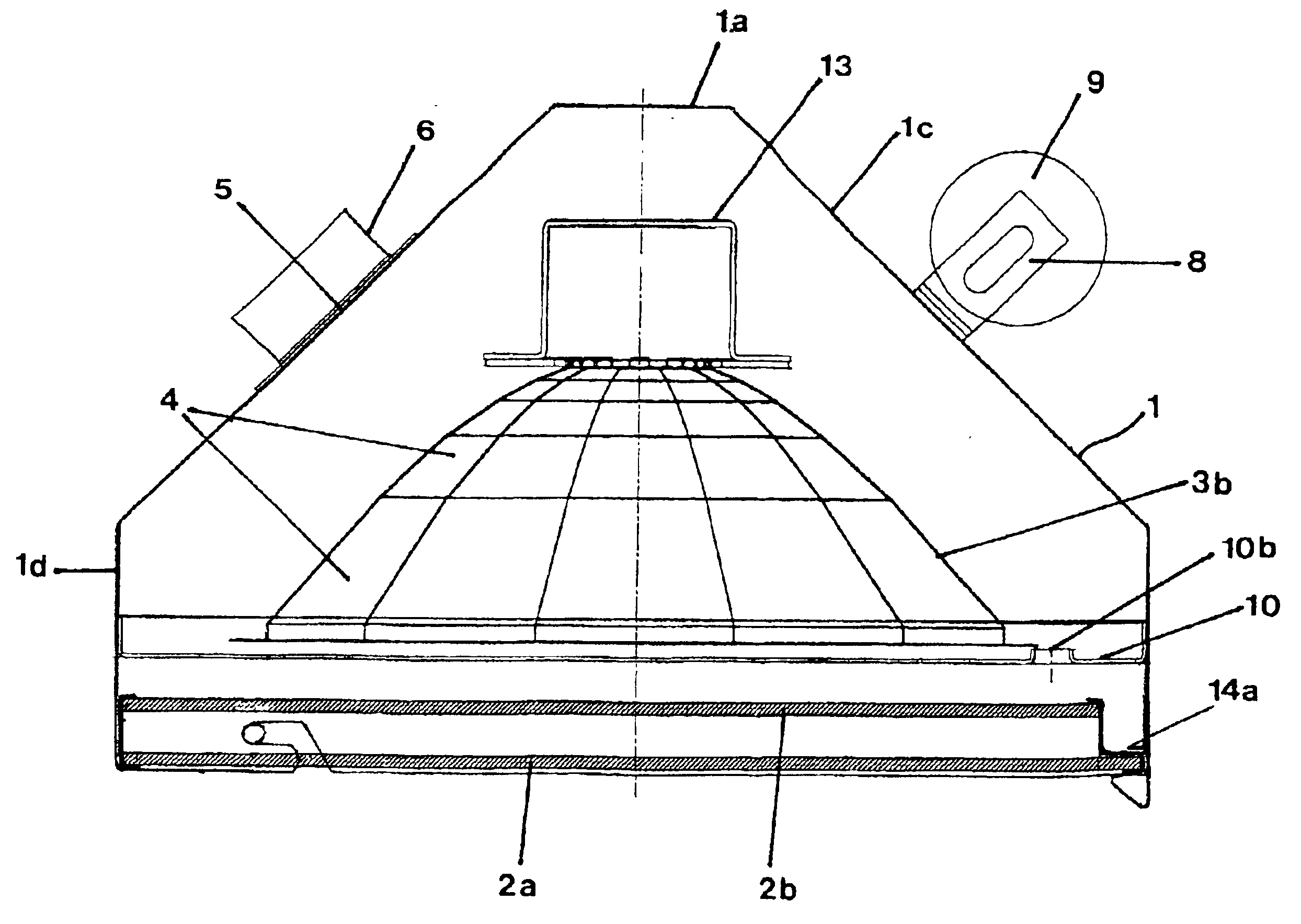

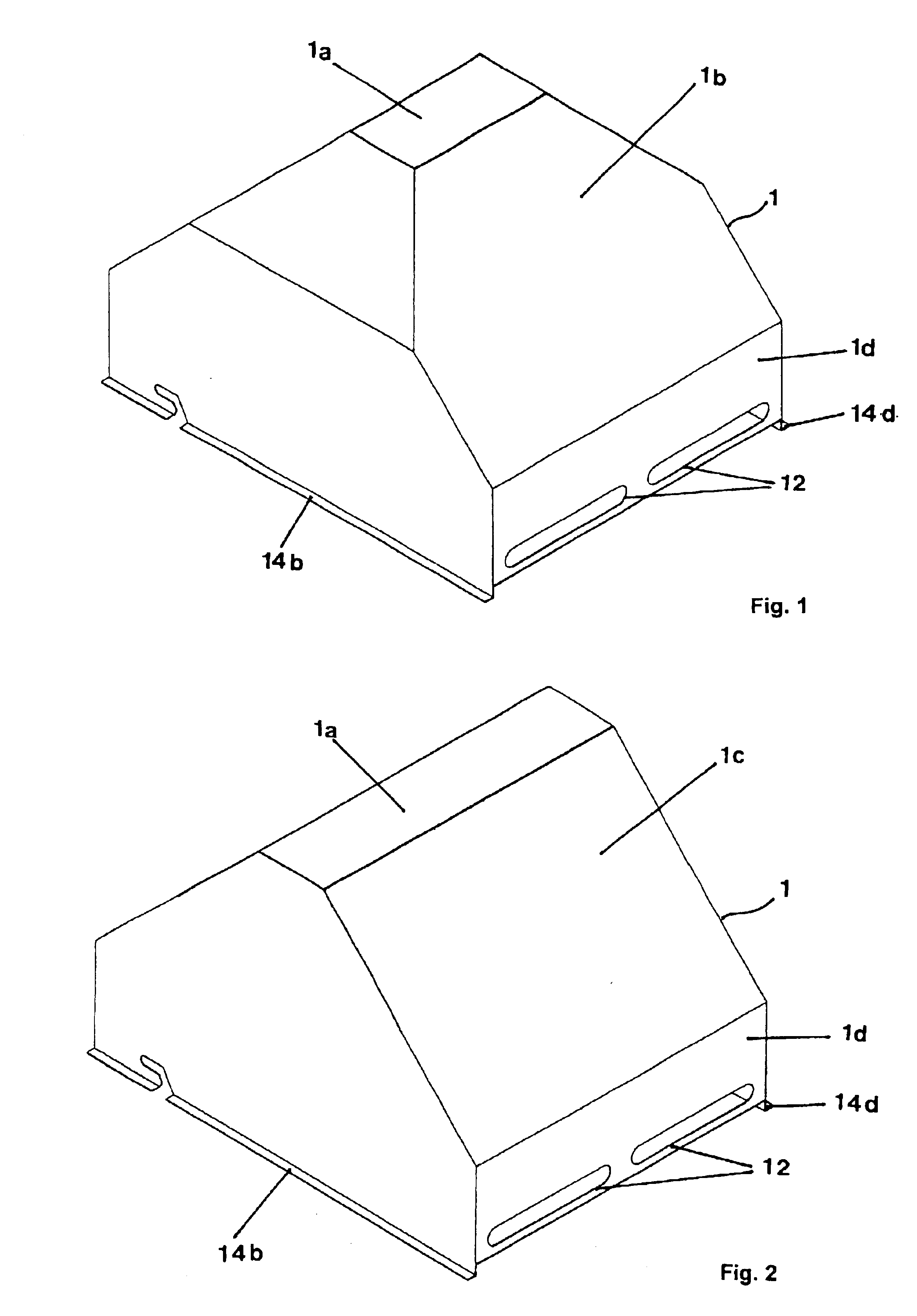

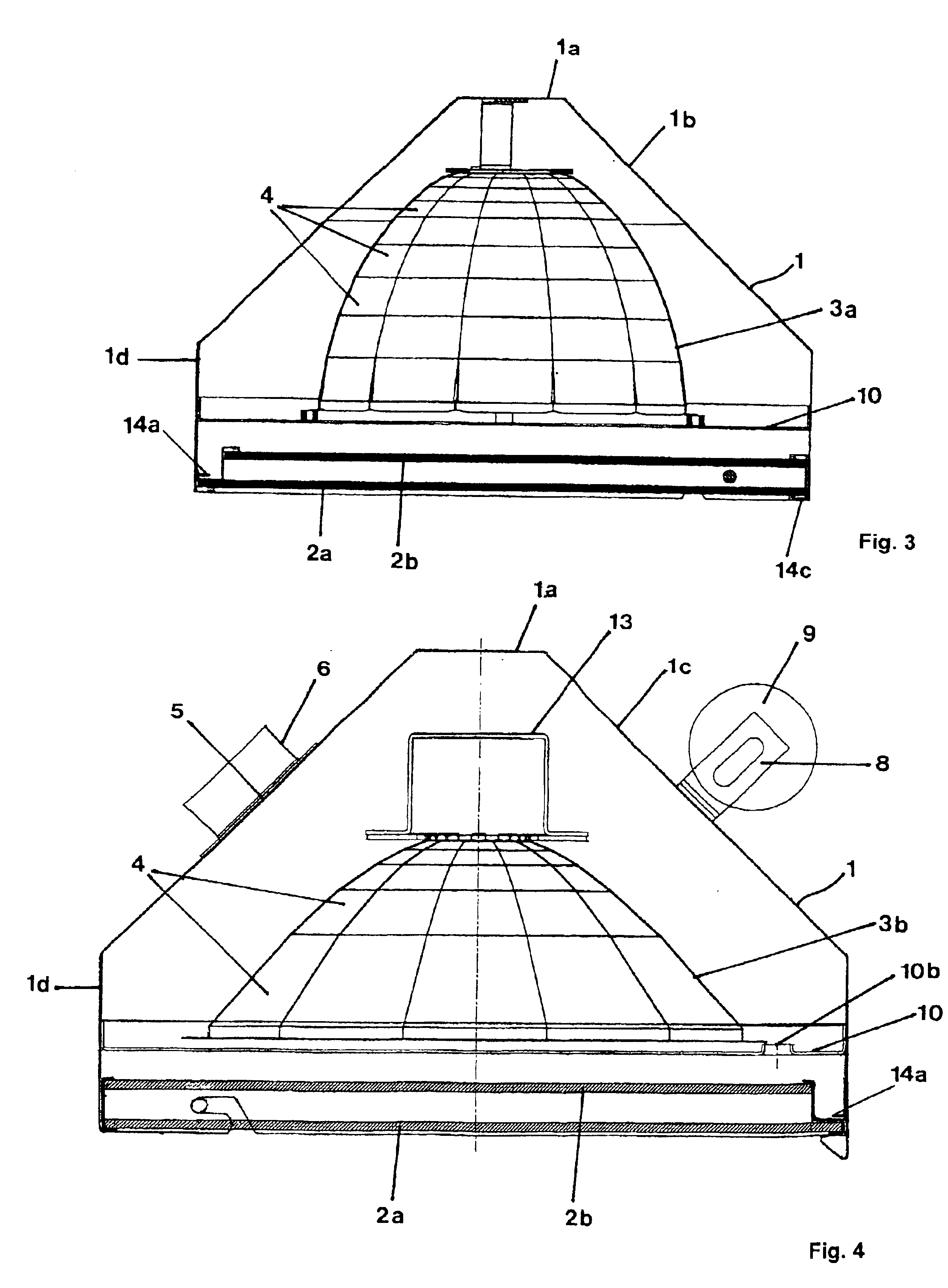

Tanning module with housing

InactiveUS6837900B2Significant positive effectEven flow distributionLighting support devicesVehicle interior lightingEngineeringGable roof

The invention relates to a tanning module with optimized guidance of the cooling air, having a housing, a three-dimensional reflector, and at least one windowpane-shaped radiation filter. The housing has on the side of the housing opposite the radiation filter the shape of a gable roof, a hip roof, or a false hip roof, the roof ridge being flattened and facing away from the radiation filter.

Owner:HERAEUS NOBLELIGHT GMBH

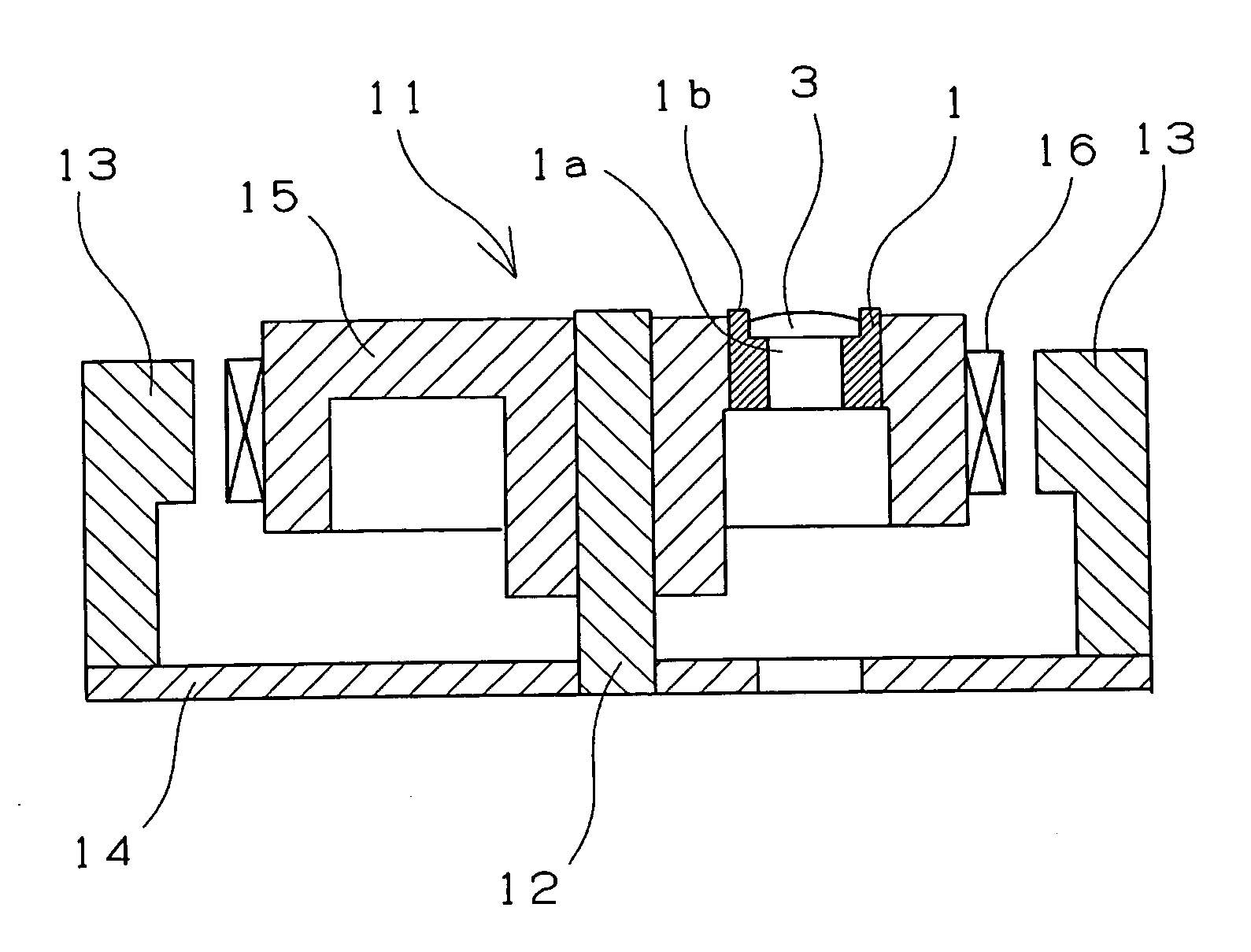

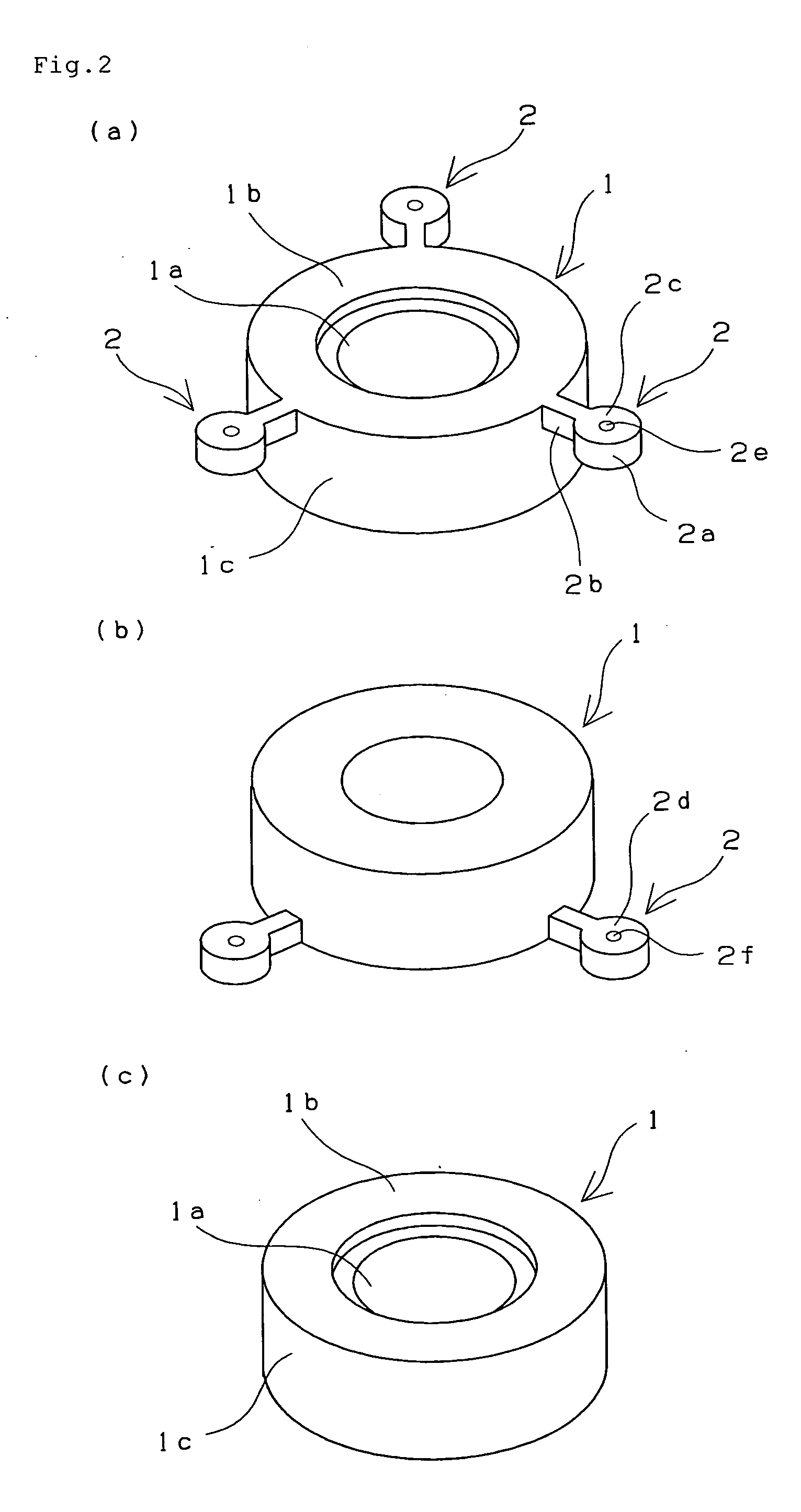

Lens holder and lens protector for use in optical pick-up and method of manufacturing same

InactiveUS20050073755A1High dimensional accuracyImprove balanceOptical head protectionOptical articlesEngineeringInjection moulding

The present invention provides a lens holder and a lens protector having little burrs and no gate marks formed on a surface thereof confronting an optical disc and a method of manufacturing the lens holder and the lens protector. The lens holder is formed in integration with a boss by injection-molding and has a hole capable of holding an objective lens on a surface of the lens holder confronting an optical disc. The boss having a gate and a contact portion which contacts a ejector pin is formed on a peripheral side surface of the lens holder when the injection molding is performed and cut off from the lens holder after the injection molding finishes.

Owner:NTN CORP

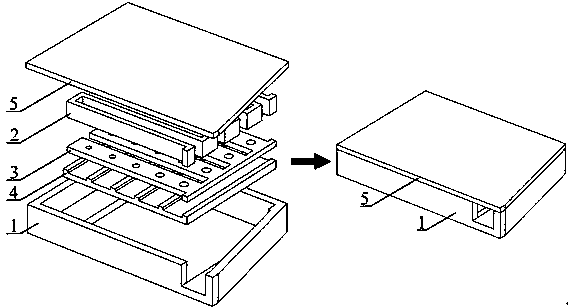

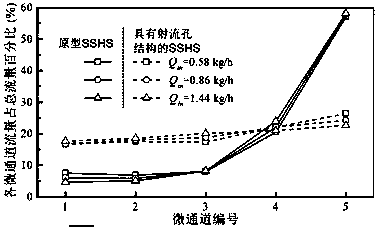

Self-similarity micro-channel heat sink with jet flow structure

ActiveCN108807309AEvenly distributedEven flow distributionSemiconductor/solid-state device detailsSolid-state devicesJet flowEngineering

The invention discloses a self-similarity micro-channel heat sink with a jet flow structure. The heat sink comprises a main inflow and outflow structure, a shunt layer, a jet flow pore plate layer, amicro-channel (overflow channel) layer and a top cover plate. A plurality of jet flow holes are formed in the jet flow pore plate layer below the shunt layer, and the forming positions are arranged along the flowing directions of shunt sub-channels. A sub-channel layer is positioned below the jet flow pore plate layer and is composed of a plurality of microgrooves arranged in parallel, and the intermittent micro-channel (overflow channel) structure is formed by the microgrooves and the bottom surface of the jet flow pore plate layer. A main inflow channel adopts a cross section reduced structure to guarantee uniform distribution of a cooling working medium towards the shunt sub-channels. The diameters of jet flow holes in the jet flow pore plate below the shunt layer are reduced along theflow, so that the micro-channels (overflow channels) below the shunt sub-channels obtain similar flow, and the uniformity of heat exchange is improved. The cooling working medium vertically impacts the bottom surfaces of the overflow channels after passing through the jet flow holes, a certain jet flow impact effect is formed, and heat transfer enhancement is achieved.

Owner:SICHUAN UNIV

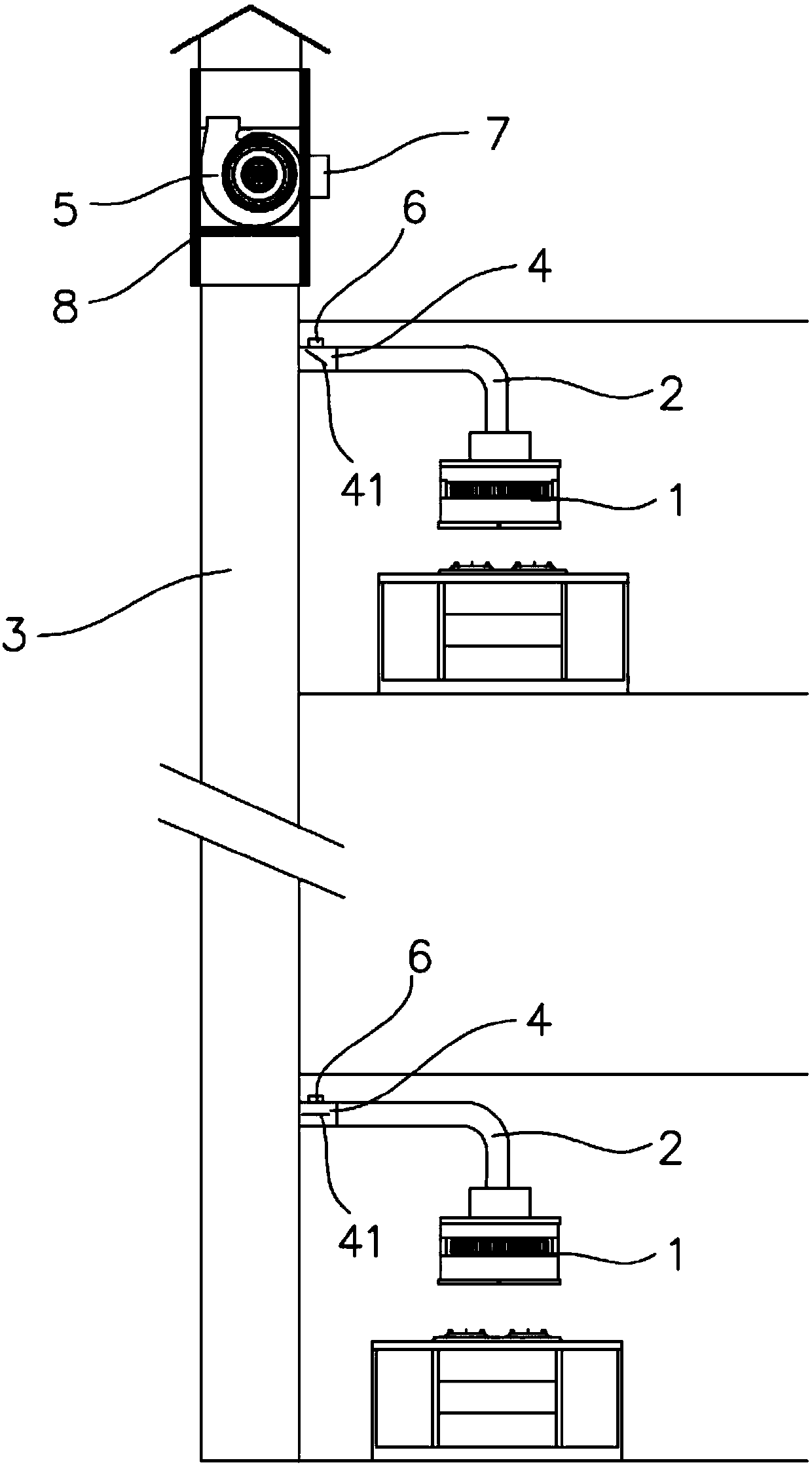

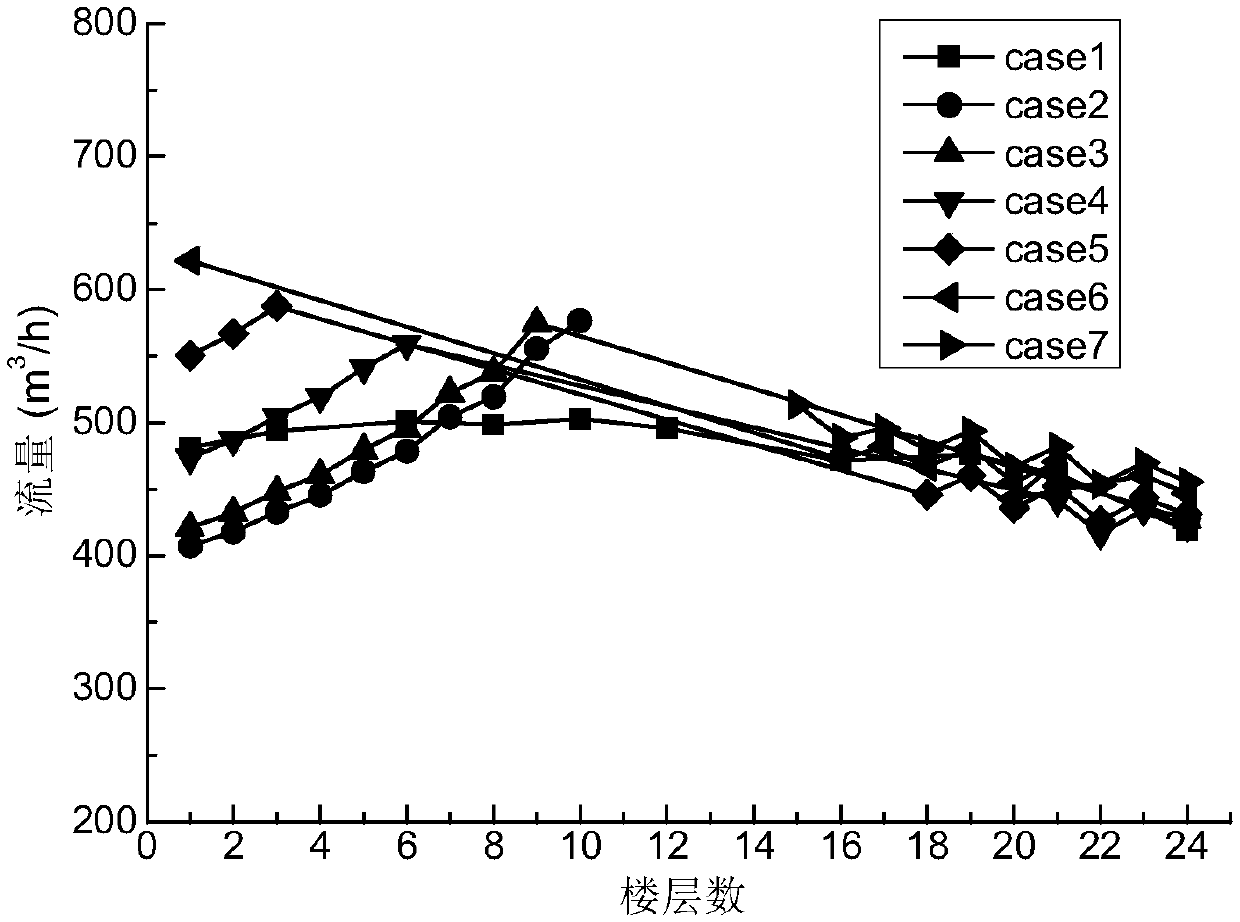

Central flue system and uniform flow distribution method thereof

InactiveCN111076249AEven flow distributionSimple adjustment processDomestic stoves or rangesLighting and heating apparatusFlueProcess engineering

The invention discloses a central flue system. The central flue system comprises range hoods, an outdoor control system and a check valve control system, wherein an air outlet of each range hood is incommunication with a public flue through a respective smoke pipe, an adjustable check valve is mounted in each smoke pipe, a flue fan is mounted in the public flue, the range hoods are unpowered range hoods, the outdoor control system is used for controlling the rotating speed or frequency of the flue fan, the check valve control system is used for adjusting the opening angle of a valve plate ofthe adjustable check valve, and the check valve control system and the outdoor control system can communicate with each other. The invention further discloses a flow uniform distribution method of thecentral flue system, an extractor hood of the central flue system is an unpowered extractor hood, the rotating speed or frequency of the flue fan is adjusted through the outdoor control system, the opening angle of the valve plate is controlled through the check valve control system, the flow uniform distribution method only needs to preset the preset angles of the valve plate under two differentstarting rates, uniform flow distribution can be ensured through judgment of the startup rate, and the adjustment process is simple and efficient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Gas filling device and plasma processing equipment

InactiveCN102945783AUniform pressureEven flow distributionElectric discharge tubesSpray nozzlePlasma processing

The invention provides a gas filling device and plasma processing equipment. The gas filling device comprises a nozzle and a cover plate, wherein the nozzle is provided with a first passage and a nozzle bypass communicated with the first passage; the cover plate is provided with a groove and a plurality of second passages; the groove is basically positioned at the center position of the cover plate; the second passages are uniformly distributed in the cover plate around the central line of the groove; the nozzle is embedded in the groove; an air outlet end of the first passage extends out of the cover plate from the bottom of the groove; air inlet ends of the second passages are communicated with the nozzle bypass; and the second passages are formed into a multi-layer structure. Uniform air flow distribution can be obtained on the whole surface of a processed wafer by the gas filling device and the plasma processing equipment, so that the phenomenon of etching or uneven deposition caused by uneven air distribution from the upside center of the surface of the wafer to the edge can be effectively avoided, and the etching or deposition rates of each point on the surface of the whole wafer are more approximate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

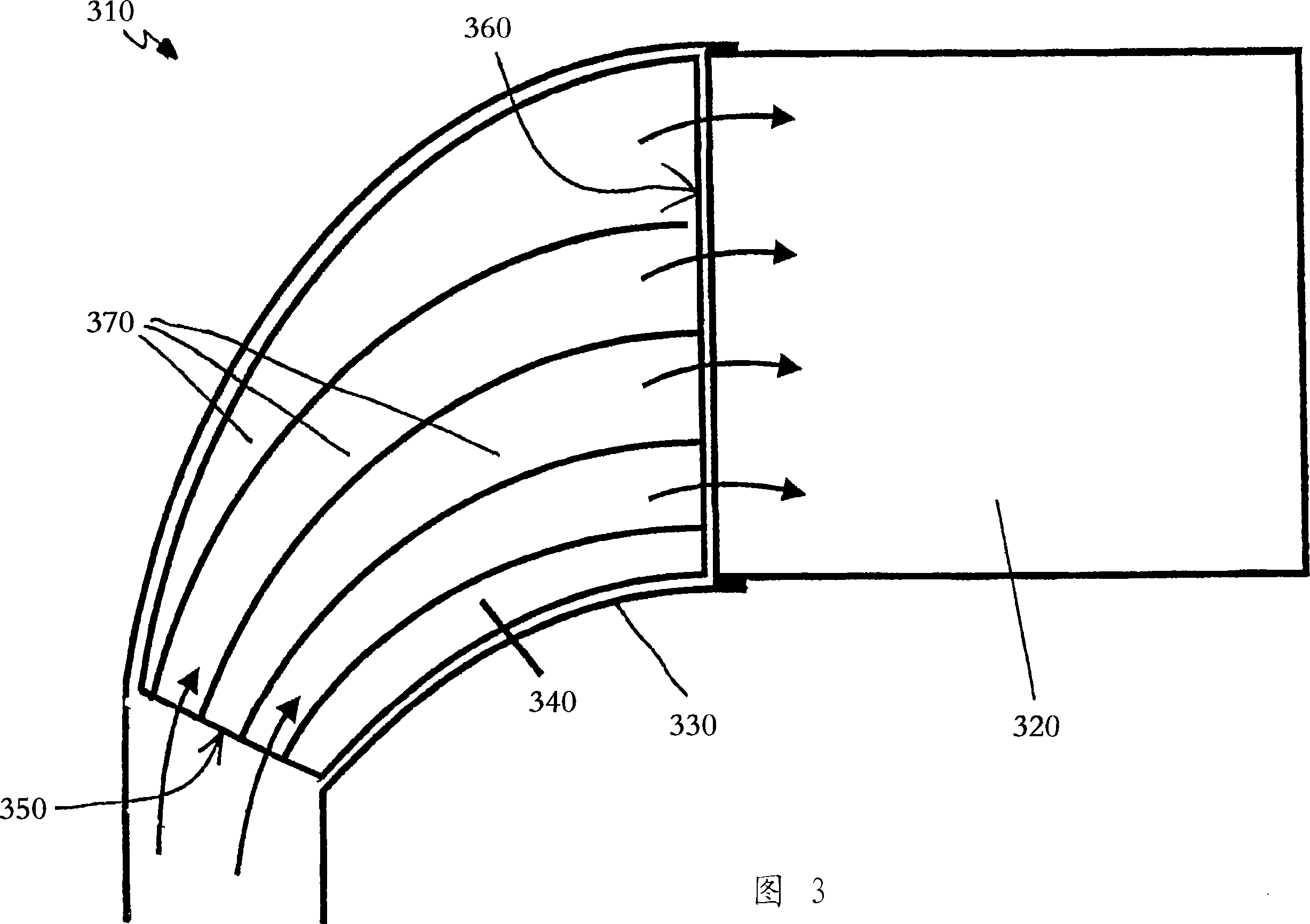

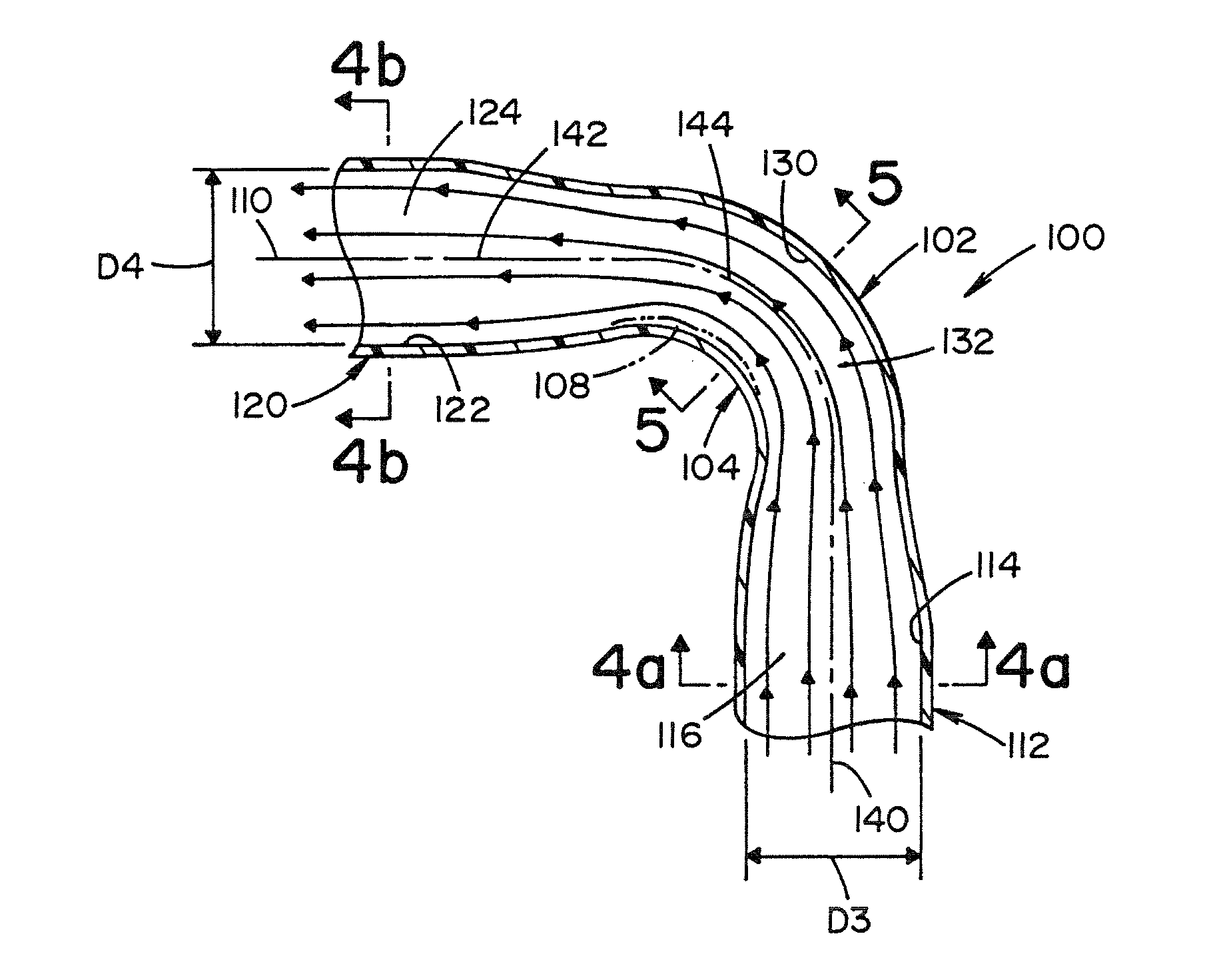

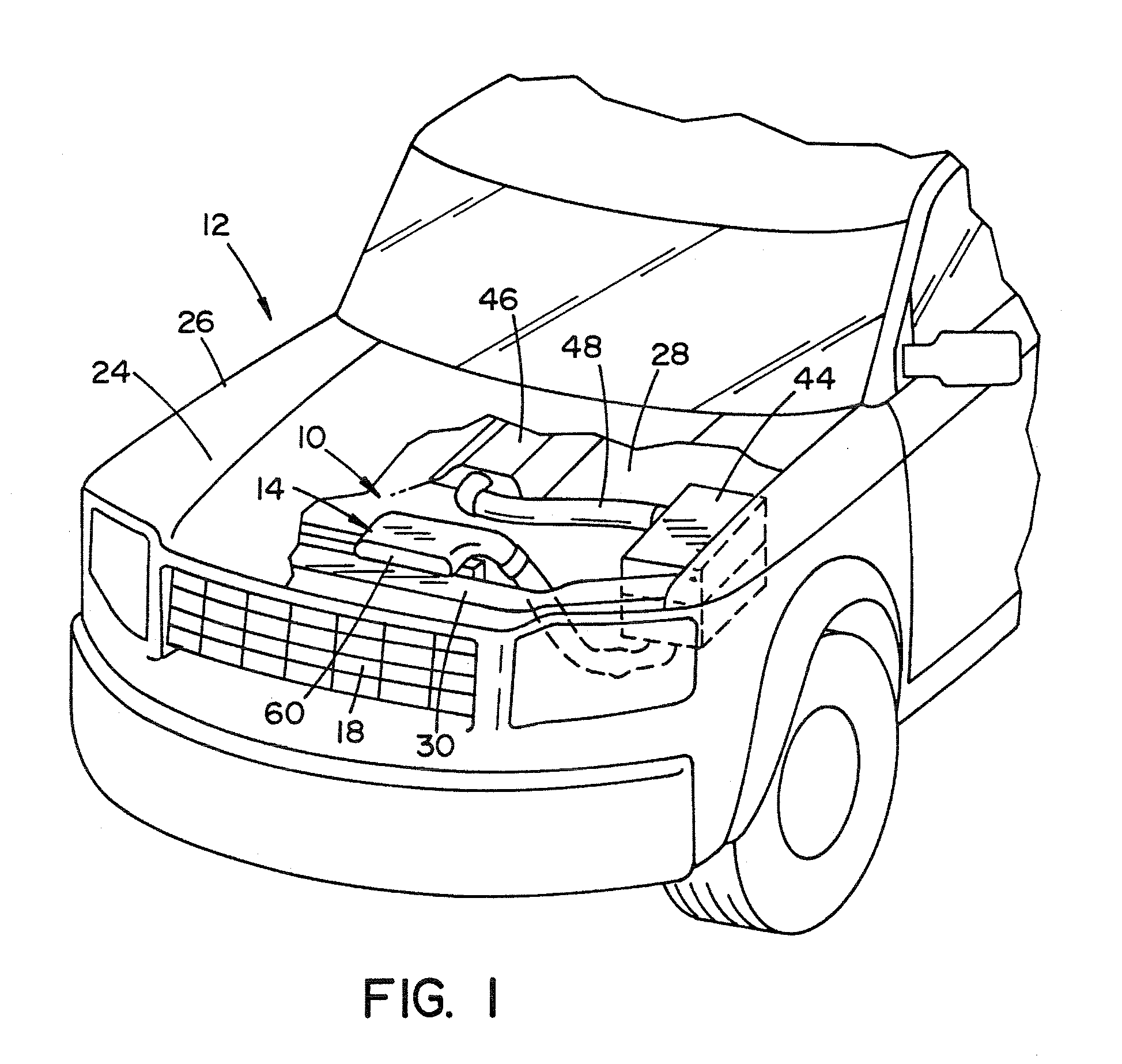

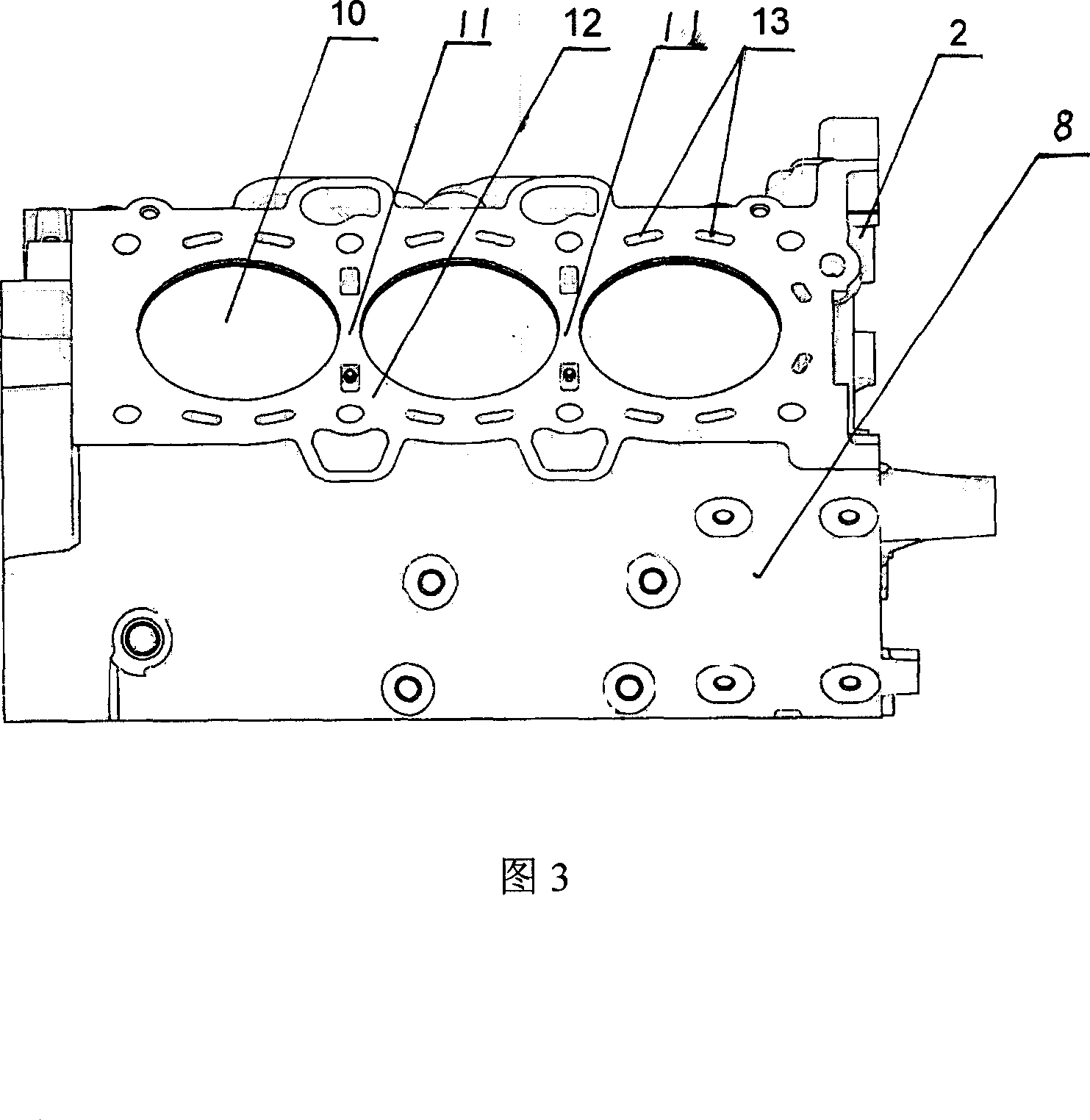

Intake system for a vehicle

InactiveUS8516986B2Minimum separationIncrease flow rateDispersed particle filtrationMachines/enginesEngineeringInlet manifold

An intake tube for an air intake system of a vehicle is provided. The air intake system is located upstream of an intake manifold and includes an intake enclosure and an air precleaner. The intake tube directs a flow of air from the intake enclosure to the air precleaner. The intake tube comprises a first end section, a second end section and a curved section. The first end section is connected to the intake enclosure and has a first longitudinal axis. An inner surface of the first end section defines a first section air passage. The second end section is connected to the air precleaner and has a second longitudinal axis. The inner surface of the second end section defines a second section air passage. The curved section is located between the first and second end sections. The curved section has a third longitudinal axis. An inner surface of the curved section defines a curved air passage. The curved section includes a compressed portion having a minor dimension and a major dimension. The major dimension is greater than the minor dimension so that the flow of air through the curved air passage has minimal separation which increases flow rate into the air precleaner.

Owner:HONDA MOTOR CO LTD

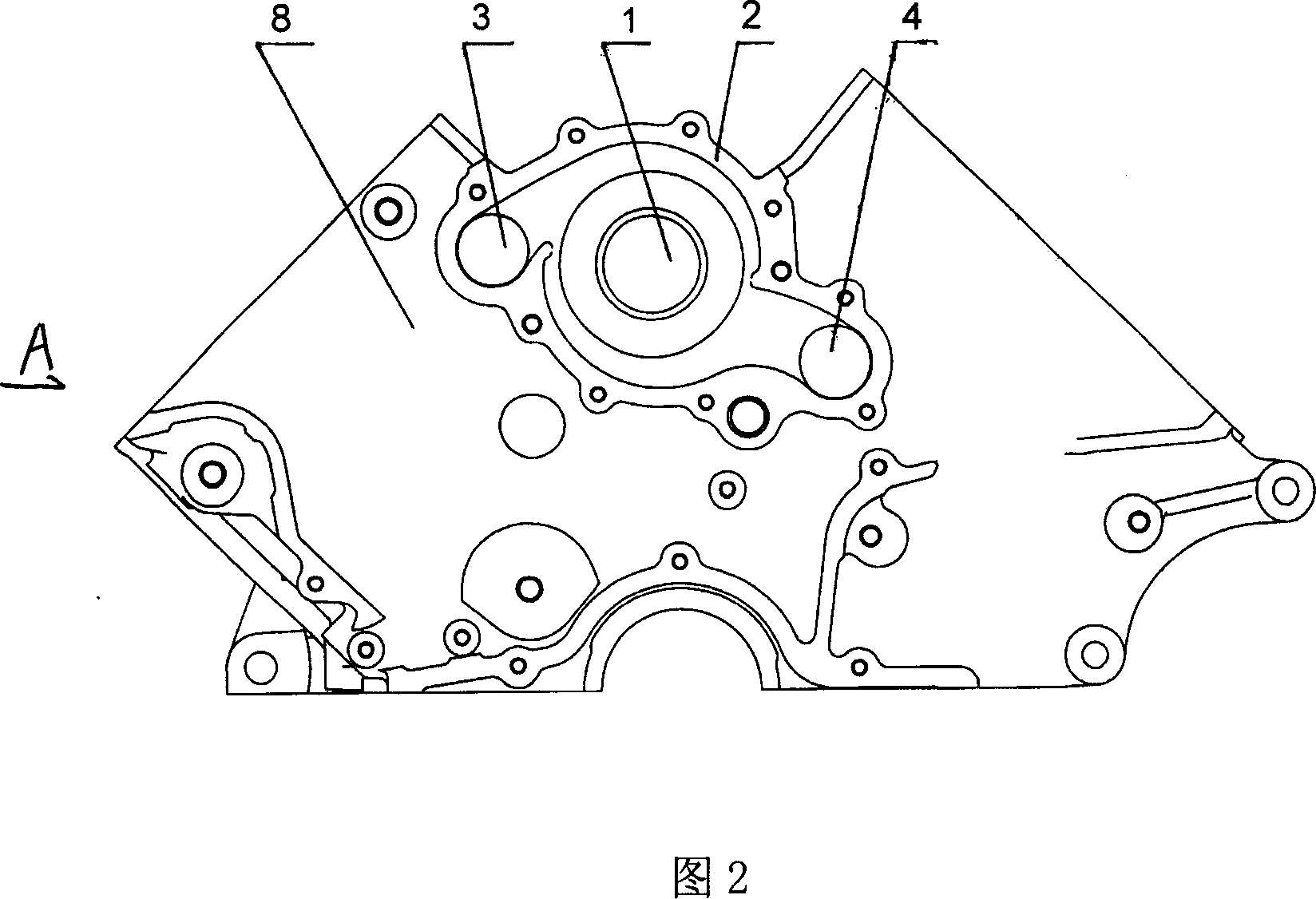

Assembly of water jacket and water pump cylinder body in V type engine

A water-jacket and water-pump assembly of cylinder on engine in V form consists of two sets of water-jackets and water-pumps distributed at periphery of cylinder hole on said cylinder. It is featured as setting water-pump at V angle position in side-middle portion of said cylinder, arranging water channel opening at each side of water-pump and connecting these said opening separately to two sets of water-jackets distributed at periphery of cylinder hole.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com