Water cooling type CPU radiator

A radiator, water-cooled technology, used in instruments, electrical digital data processing, digital data processing components and other directions, can solve problems such as large noise, increase the size of the radiator, and achieve the effect of avoiding stress and avoiding physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

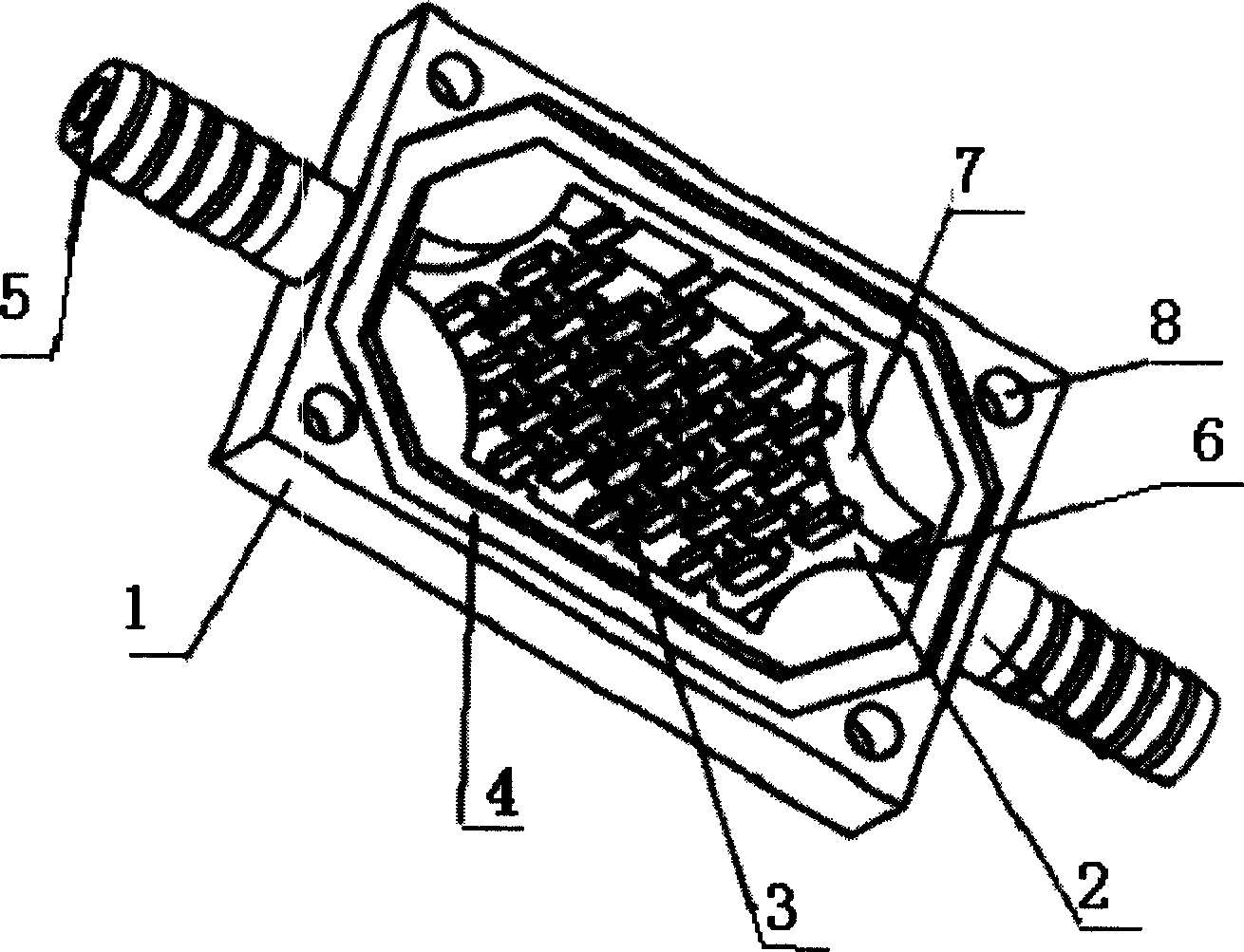

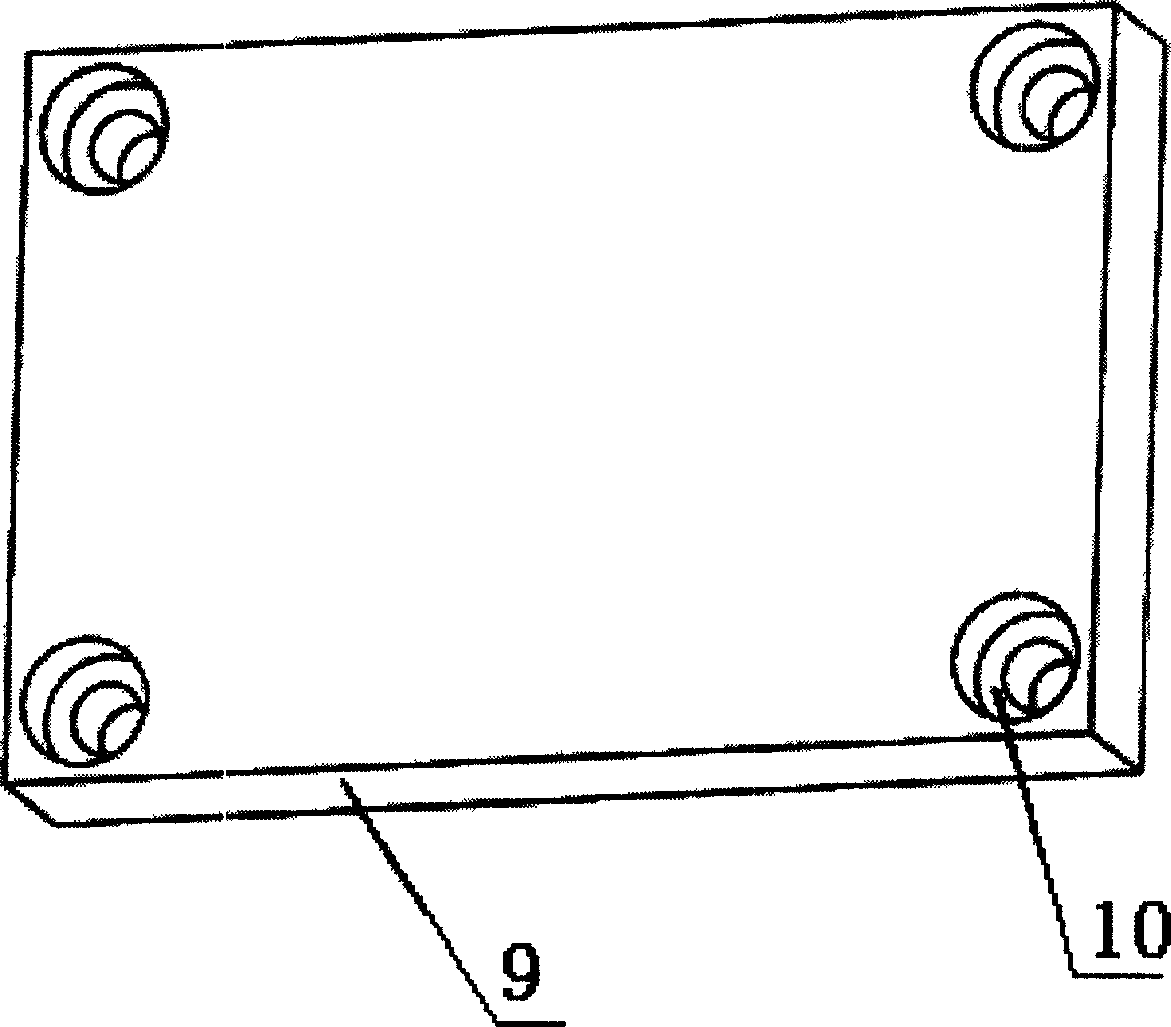

[0010] see figure 1 , 2. The present invention includes a radiator body 1 and an upper cover 9. A cavity 2 is cut inside the radiator body 1, and a criss-cross columnar fin array 3 is evenly distributed in the cavity 2. The fin array 3 is connected with the heat dissipation The radiator body 1 is an integrated design. There is a channel 4 with a rectangular cross section on the outside of the cavity 2. An O-shaped sealing ring is placed in the channel 4. The two ends of the radiator body 1 are provided with water inlet and outlet pipes 5 connected to the cavity 2. 6. The water inlet and outlet pipes 5 and 6 are integrated with the radiator body 1. There are countersunk screw holes 8 at the four corners of the radiator body 1, and countersunk holes 10 are opened at the four corners of the upper cover 9. The rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com