Assembly of water jacket and water pump cylinder body in V type engine

A technology of engine cylinder and cylinder water jacket, which is applied in the direction of engine cooling, engine components, machines/engines, etc., and can solve the problems of large water pressure loss, good cooling effect, and small convective heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

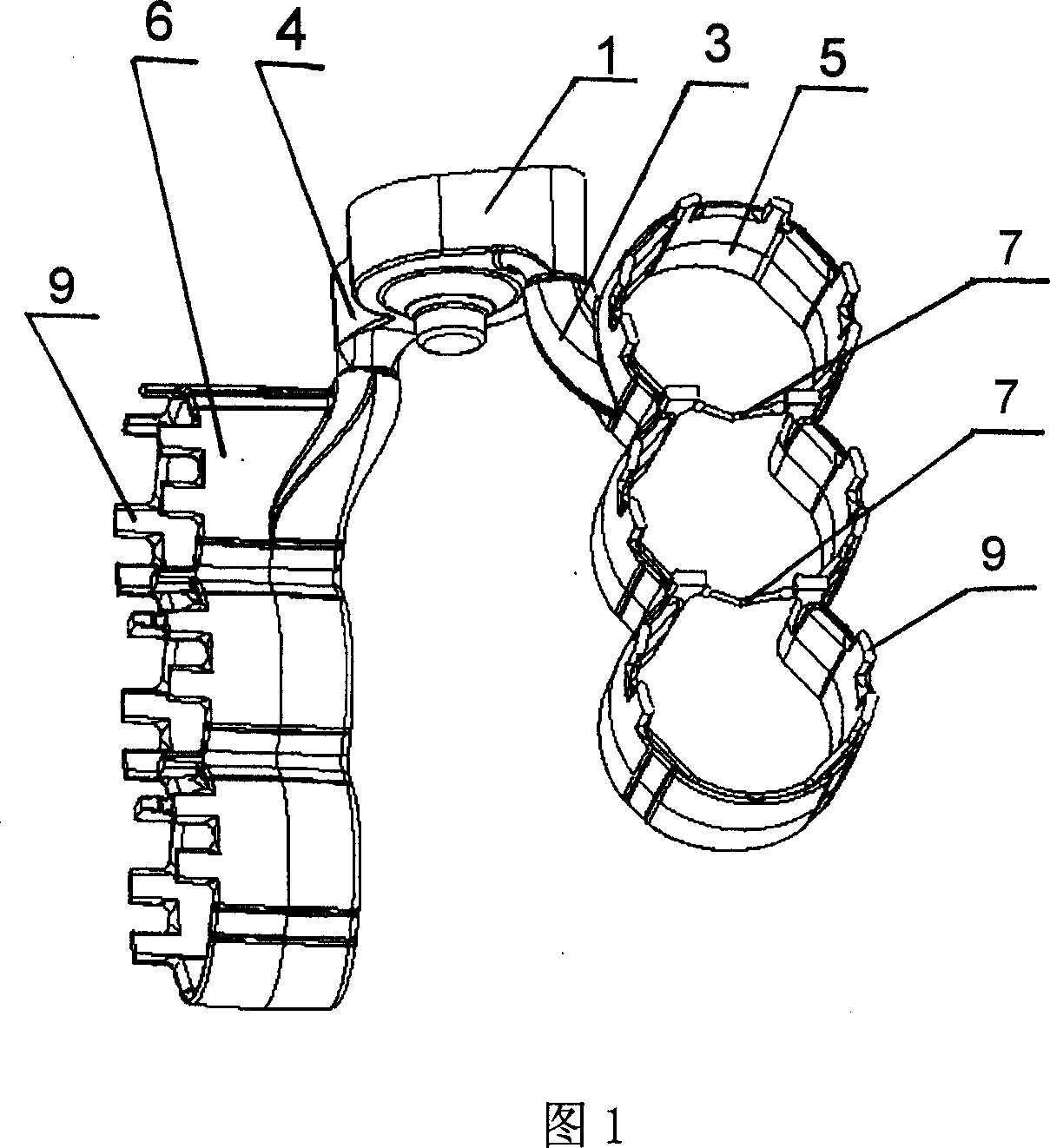

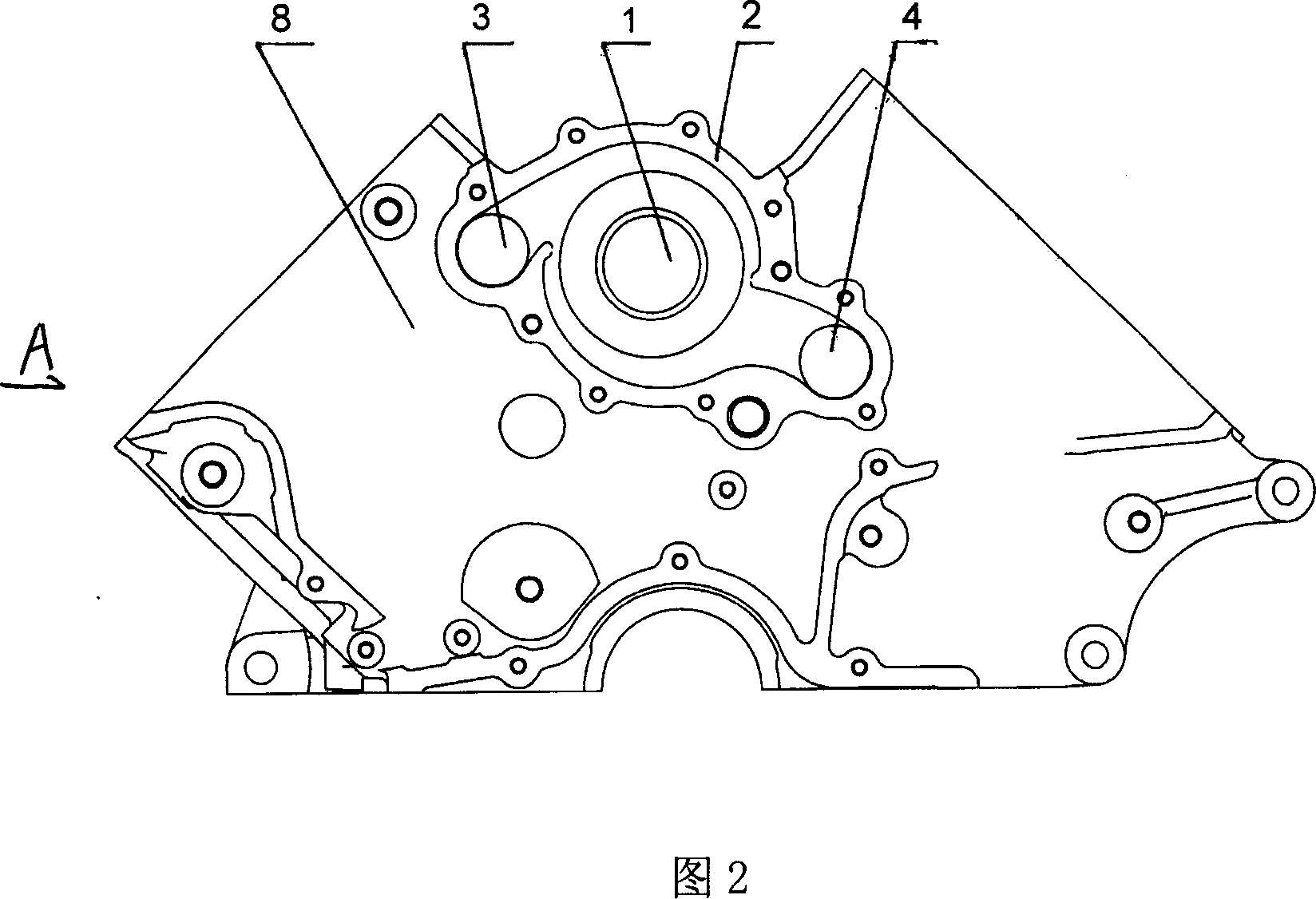

[0014] As shown in Fig. 1 and Fig. 2, there is a water pump volute 2 integrated with the cylinder body by casting at the V angle in the middle of one side of the V-shaped engine cylinder block 8. The water pump 1 is installed in the water pump volute 2, and the two parts of the water pump 1 The left water channel port 3 of the water pump and the right water channel port 4 of the water pump are respectively connected to each other. Port 3 is slightly higher than water pump right channel port 4. The water jacket 5 on the intake side and the water jacket 6 on the exhaust side are composed of three connected cylinders of the same diameter, and the upper parts of the two cylinders have X-shaped water channels 7 connected at corners and the upper edges of the cylinders have interval distribution. The extension part 9 is formed.

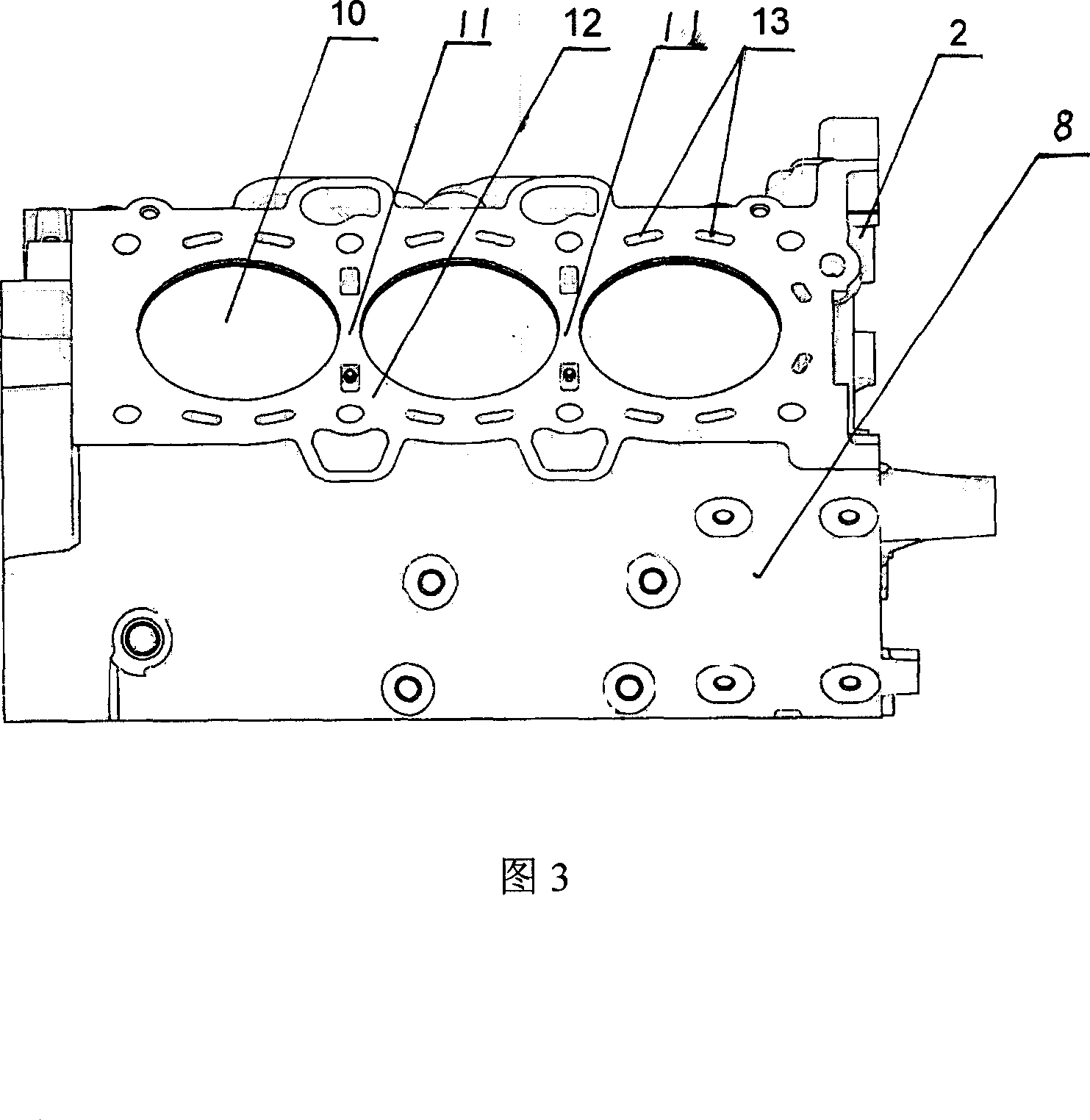

[0015] As shown in Figure 3, between every pair of cylinder bores of the three cylinder bores 10 is the nose bridge area 11, and each cylinder bore 10 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com