Large-diameter laser liquid cooling mirror structure

A large-diameter, laser technology, applied in the field of laser optics, can solve the problem of small flow resistance of cooling liquid, and achieve the effects of uniform pressure and flow distribution, small flow resistance, and high heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

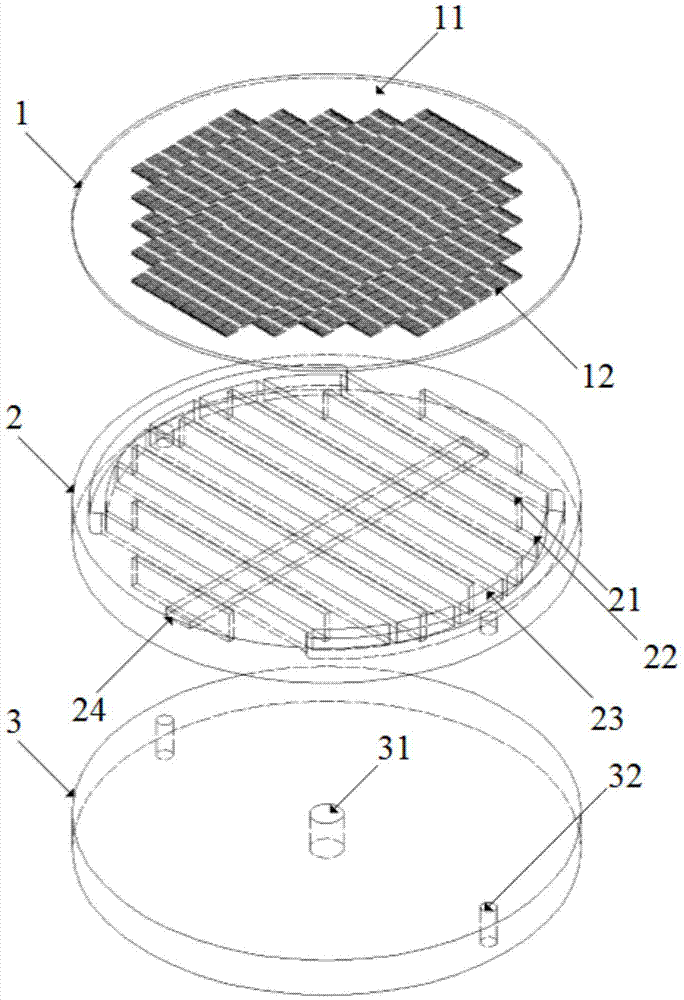

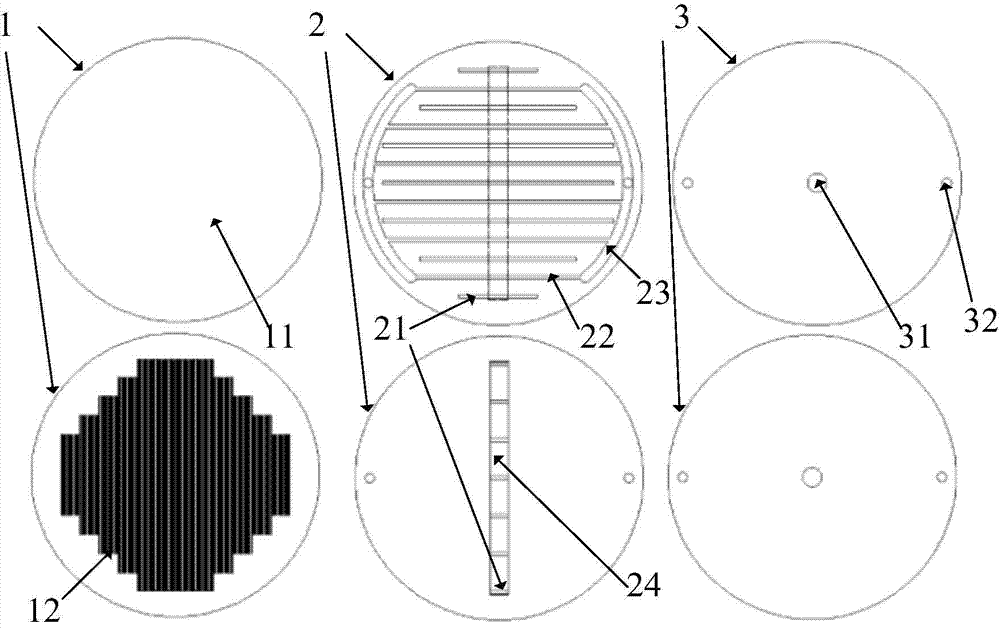

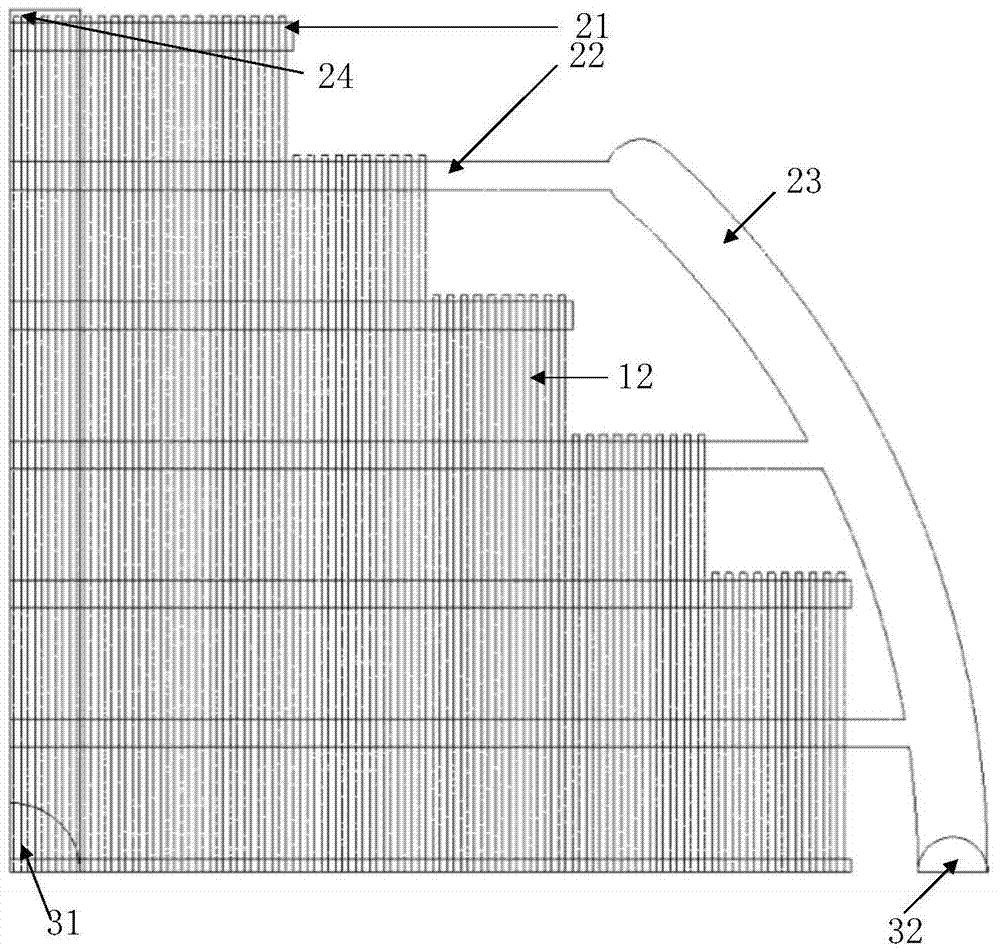

[0024] The present invention will be further described below in conjunction with accompanying drawing. In the design scheme of the present invention, on the basis of retaining the fine channel cooling structure of the traditional direct-flow liquid-cooled mirror, an interdigitated channel structure is added to reduce the flow resistance of the mirror body, and improve the uniformity of the flow field and heat dissipation. Excessive thermal distortion of the entire reflective surface is avoided.

[0025] Such as Figure 1-3 As shown, the reflective surface 11 and the micro-channel heat dissipation structure are designed on the same panel, that is, the reflective panel 1 . The front side of the reflective panel 1 is plated with a high-reflection film as the reflective surface 11 for reflecting laser light, and the three-stage flow channels 12 made on the back are some fine straight channels for cooling the mirror body. The front of the distribution plate 2 is made with large c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com