Patents

Literature

39results about How to "Reduce the incidence of cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cr-Mo alloyed steel round billet produced by arc continuous casting machine and technique thereof

The present invention relates to one kind of round Cr-Mo alloy steel billet produced in a bow-type continuous casting machine and its production process. The molten steel for the round Cr-Mo alloy steel billet contains P not more than 0.012 wt% and S not more than 0.002 wt%, and has Mn / S weight ratio not smaller than 200. The present invention features that the continuous casting process has the second cooling with specific cooling water amount of 0.47-0.53, the first region cooling water amount accounting for 35-45 %, the second region cooling water amount accounting for 22-32 %, the third region cooling water amount accounting for 14-24 %, the fourth region cooling water amount accounting for 9-19 %, and Mn / S content ratio in steel not smaller than 200. The present invention can produce continuously cast round low carbon alloy steel billet without crack, shrinkage hole and other defects.

Owner:BAOSHAN IRON & STEEL CO LTD

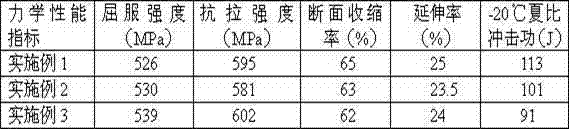

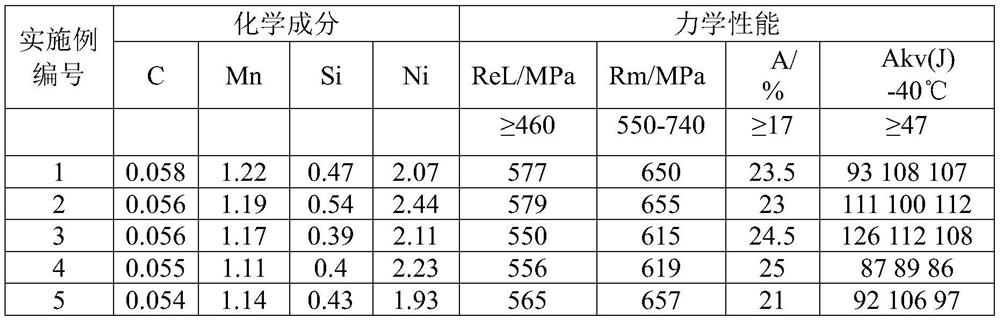

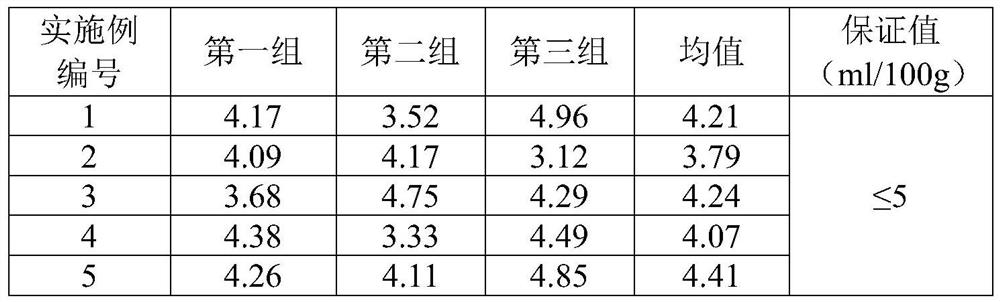

Low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel and preparation method of low-hydrogen high-toughness seamless flux-cored wire

ActiveCN109623193AImprove impact toughnessLow melting pointWelding/cutting media/materialsSoldering mediaSilicon alloyMagnetite

The invention discloses a low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel. The seamless flux-cored wire is composed of low-carbon steel strip skin and flux core powder and used for welding of the low-temperature steel adopted in a LPG ship and a liquefied petroleum storage tank. The low-hydrogen high-toughness seamless flux-cored wire is formed by mixing, by mass percentage, 30-40% of rutile, 0.5-1% of sodium fluoride, 10-16% of manganese-silicon alloy, 1-2% of zircon sand, 5-9% of rare earth silicon iron, 10-12% of nickel powder, 3-5% of magnesium powder, 0.3-0.6% of ferroboron, 1-5% of titanium powder, 2-4% of potassium titanate, 0.5-1% of magnesia, 1-2% of magnetite and 12-14% of iron powder. The seamless flux-cored wire is high in impact toughness at thelow temperature, applicable to all-position welding, good in welding manufacturability and meanwhile good in seawater corrosion resistance and ultralow in diffusible hydrogen; and the low-hydrogen high-toughness seamless flux-cored wire is mainly applied to welding of the low-temperature steel of the LPG ship, the liquefied petroleum storage tank and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A production process of high-strength x80 steel plate for bent pipe

InactiveCN102286705AFluctuation of liquid level is smallReduce the incidence of cracksTemperature control deviceTemperature controlEngineering

The invention relates to a production process of high-strength bent pipe steel, which is a production process of high-strength X80 steel plate used for bent pipes. Composition: C: 0.015-0.080%, Mn: 1.50-1.80%, Si: ≤0.30% , S: ≤0.0030%, P: ≤0.015%, Nb: 0.04~0.15%, Ti: 0.005~0.030%, V: ≤0.120%, Alt: ≤0.060%, N: ≤0.010%, Mo: 0.10~0.60 %, Cu: 0.10~0.50%, Ni: 0.10~0.50%, Cr: 0.10~0.30%, Ca: ≤0.01%, the rest is iron; in the slab reheating process, the slab heating temperature: 1100~1200℃; In the controlled rolling process, the termination temperature of controlled rolling in the recrystallization zone: 1000-1080°C, the start temperature of controlled rolling in the non-recrystallization zone: 900-980°C, the termination rolling temperature: 760-880°C; In the cooling process, the termination cooling temperature: 300-550°C, and the cooling rate: 3-40°C / s. The product of the invention has good comprehensive properties, especially excellent performance in low-temperature impact toughness, and can still maintain a Charpy impact energy of about 300J at about -30°C.

Owner:NANJING IRON & STEEL CO LTD

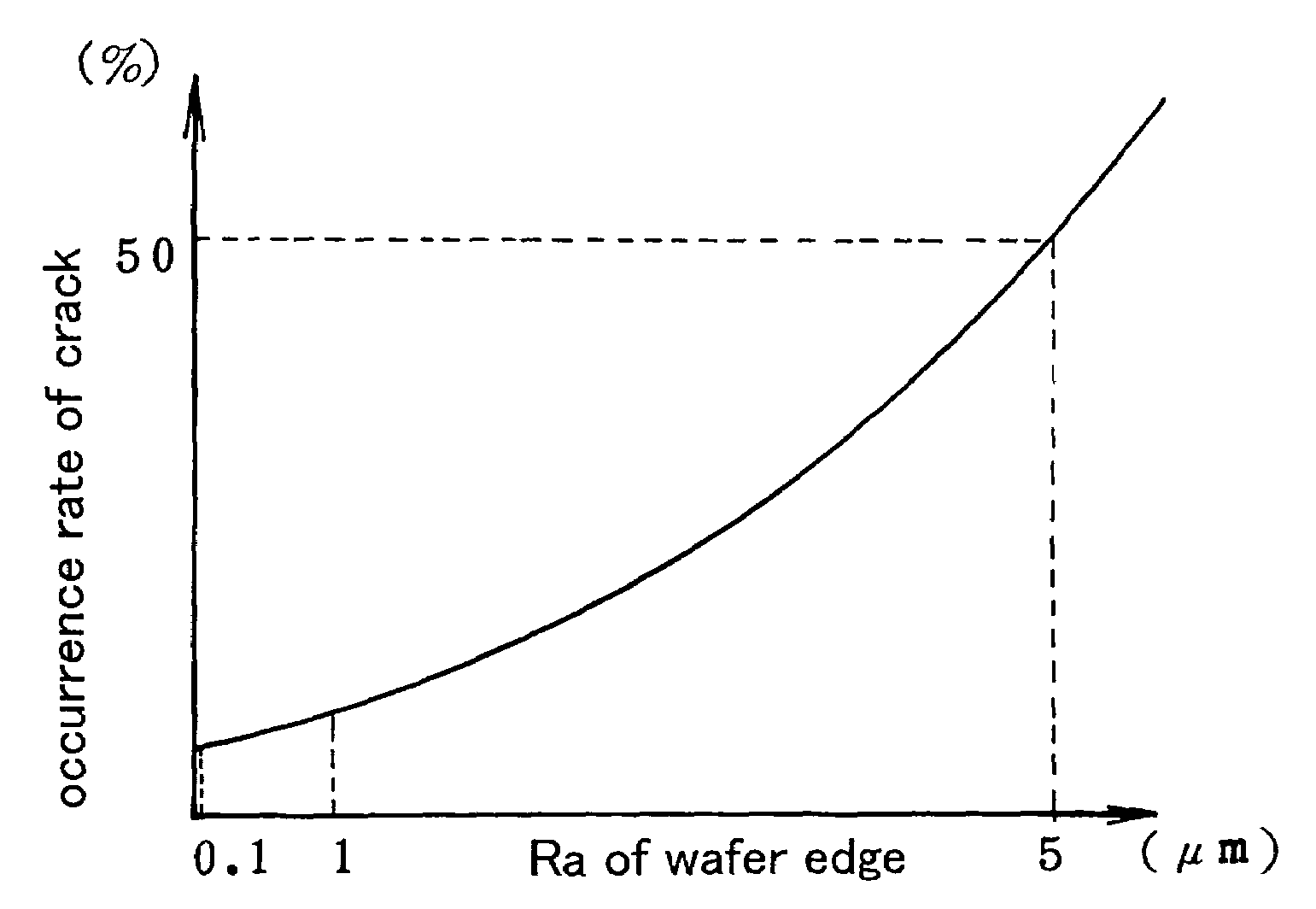

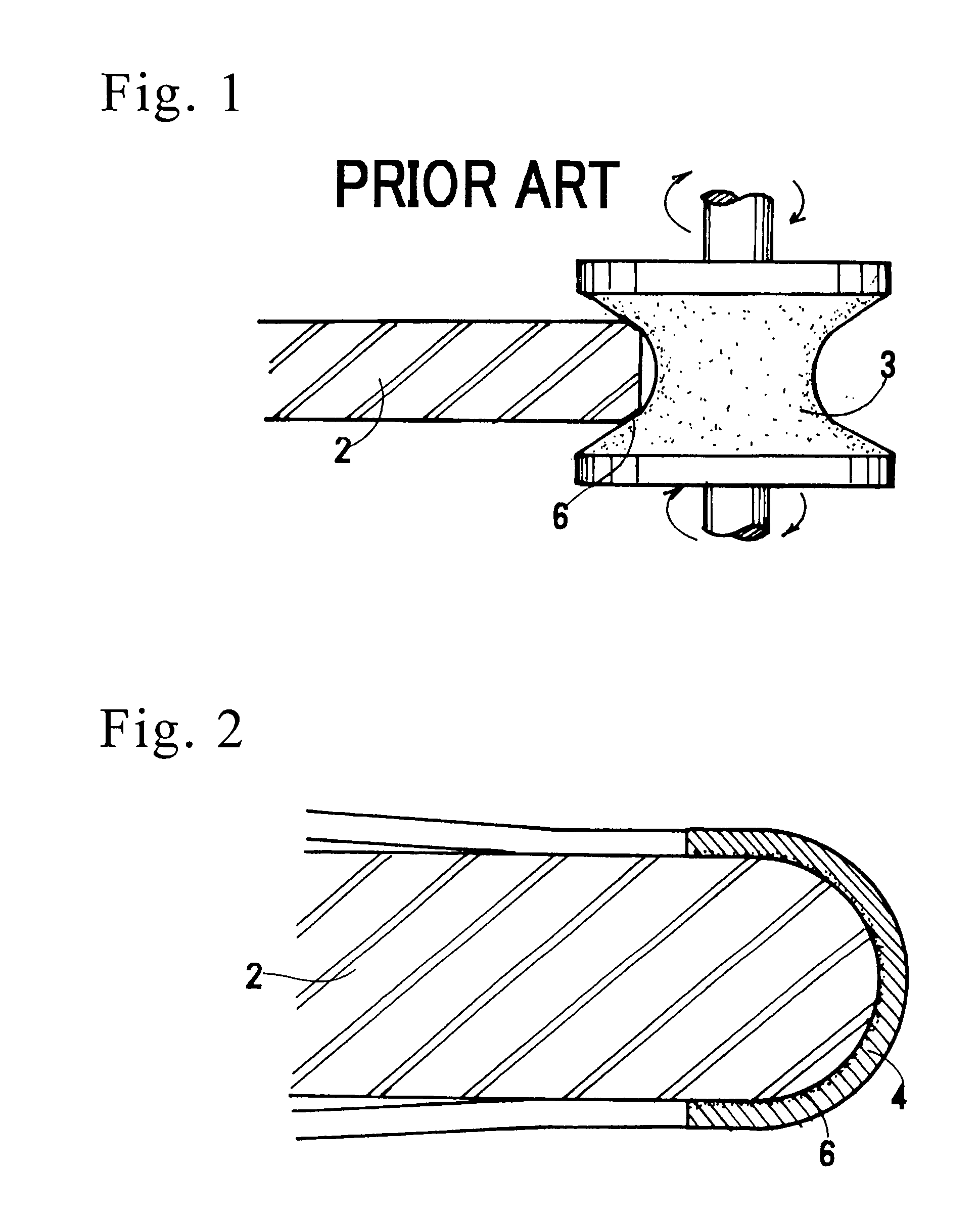

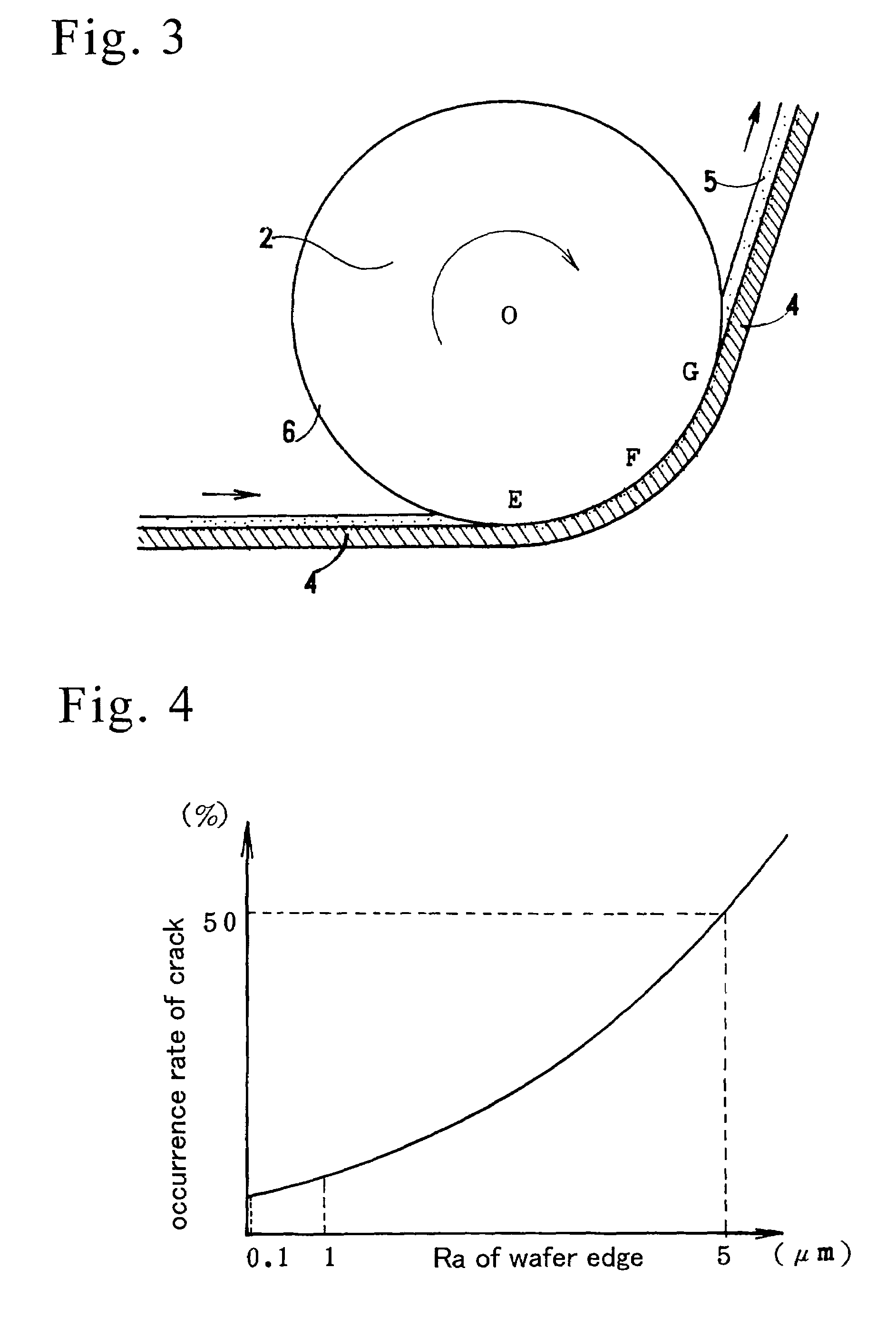

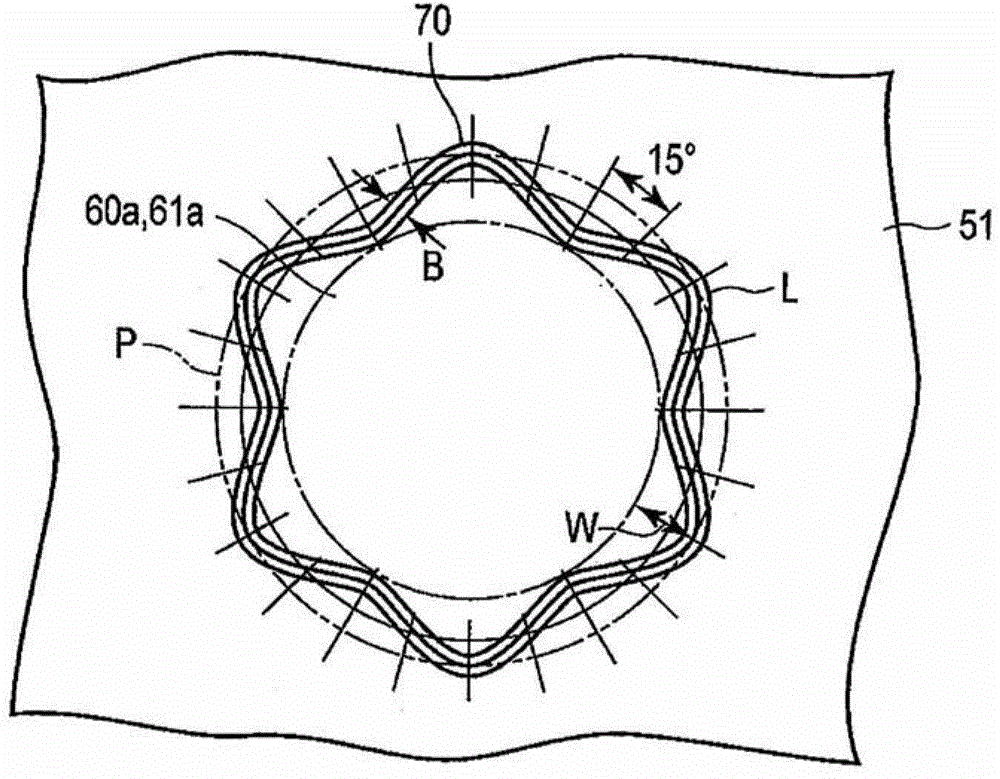

Chamfered freestanding nitride semiconductor wafer and method of chamfering nitride semiconductor wafer

InactiveUS7195545B2Reduce the incidence of cracksEdge grinding machinesSemiconductor/solid-state device detailsEngineeringGallium nitride

Owner:SUMITOMO ELECTRIC IND LTD

Method for fabricating seamless tube welding wire containing rutile cored powders by mild-carbon steel strip

ActiveCN103753055AReduce the incidence of cracksImprove porosity resistanceWelding/cutting media/materialsSoldering mediaCopper platingManganese

Disclosed is a method for fabricating a seamless tube welding wire containing rutile cored powders by a mild-carbon steel strip. The method includes that by weight, 30%-50% of rutile, 2%-5% of dehydrated feldspar, 5%-10% of silicon iron, 1%-8% of ferrotitanium, 5%-15% of manganese metal, 2%-5% of zircon sand, 3%-8% of mineral magnesia, 2%-6% of quartz, 0.5%-2% of zirconium metal and the balance iron powders are fully and uniformly stirred to form the rutile cored powders, and the rutile cored powders are stored in a feeding device for stand-by, the mild-carbon steel strip is rolled to form a U-shaped steel strip, the cored powders are filled in the U-shaped steel strip at a rolling speed of 2-10m / s, the filling rate is controlled within 14%-18%, then a seamed tube in the diameter of D is formed by rolling, a seamless tube welding wire tube blank is formed by on-line welding of a laser-beam welding machine or a high-frequency welding machine, the seamless tube welding wire tube blank is subjected to high frequency annealing at 500-1200 DEG C, then the diameter of the seamless tube welding wire tube blank is reduced by a cold-drawn machine to form a D1 seamless tube welding wire, and then the D1 seamless tube welding wire is copperized so as to form the seamless tube welding wire containing the rutile cored powders.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

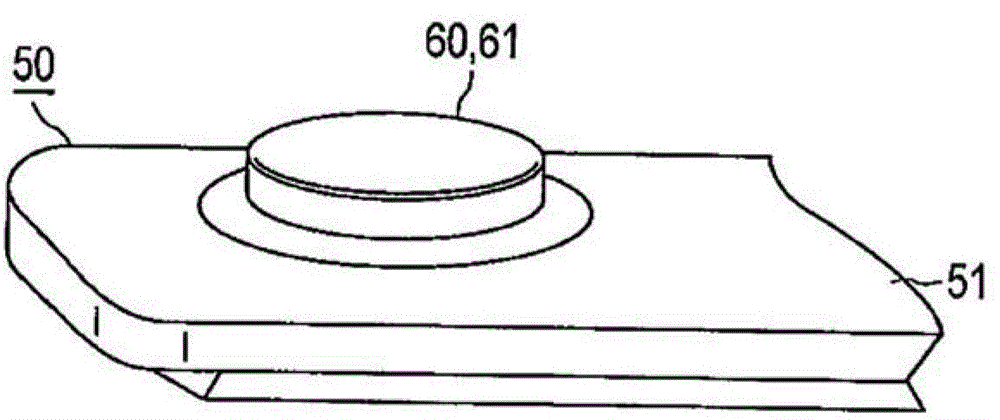

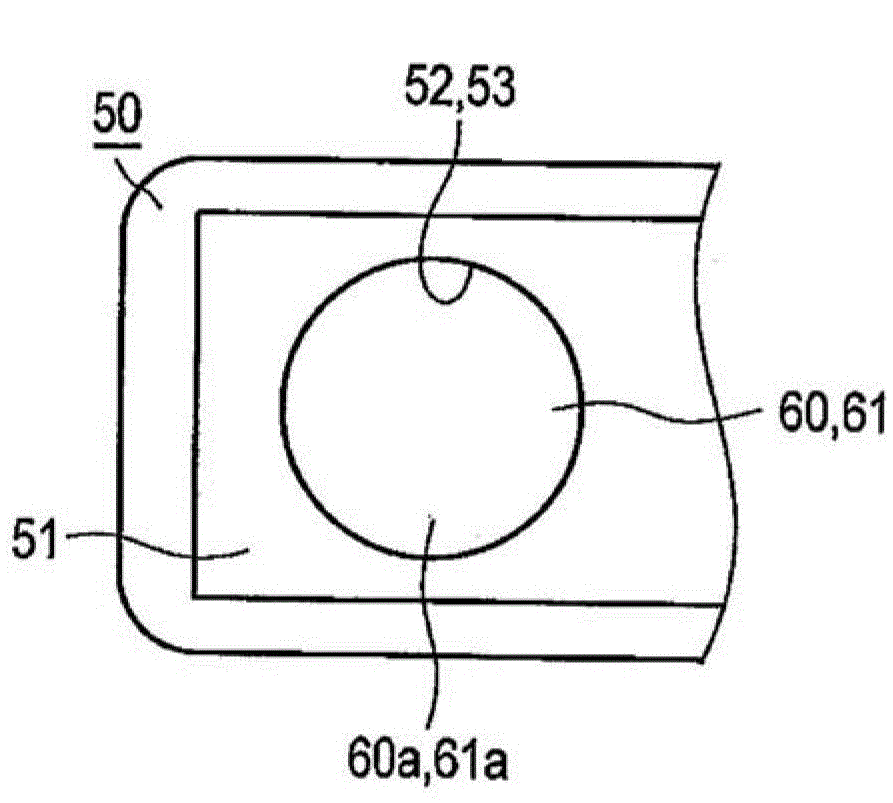

Welding method of sealed storage battery, sealed storage battery, and cap body

ActiveCN103594723AReduce the incidence of cracksWeld firmlyFinal product manufactureSmall-sized cells cases/jacketsEngineeringReference line

Provided is a welding method of a sealed storage battery, which is provided with a casing configured to encase therein electrodes and an electrolyte, a cap body configured to cover the casing, and two terminals inserted into holes provided in the cap body, connected to a pair of electrodes, and formed of a material including a composition different from a material of the lead. The welding method includes crushing and spreading the distal end side of each of two terminals along a cap body, and carrying out continuous welding along a boundary line between a circumference of the distal end side of the terminal, and the cap body, and alternately and repetitively by way of a position on the terminal side of the boundary line regarded as a reference line, and a position on the cap body side of the boundary line.

Owner:KK TOSHIBA

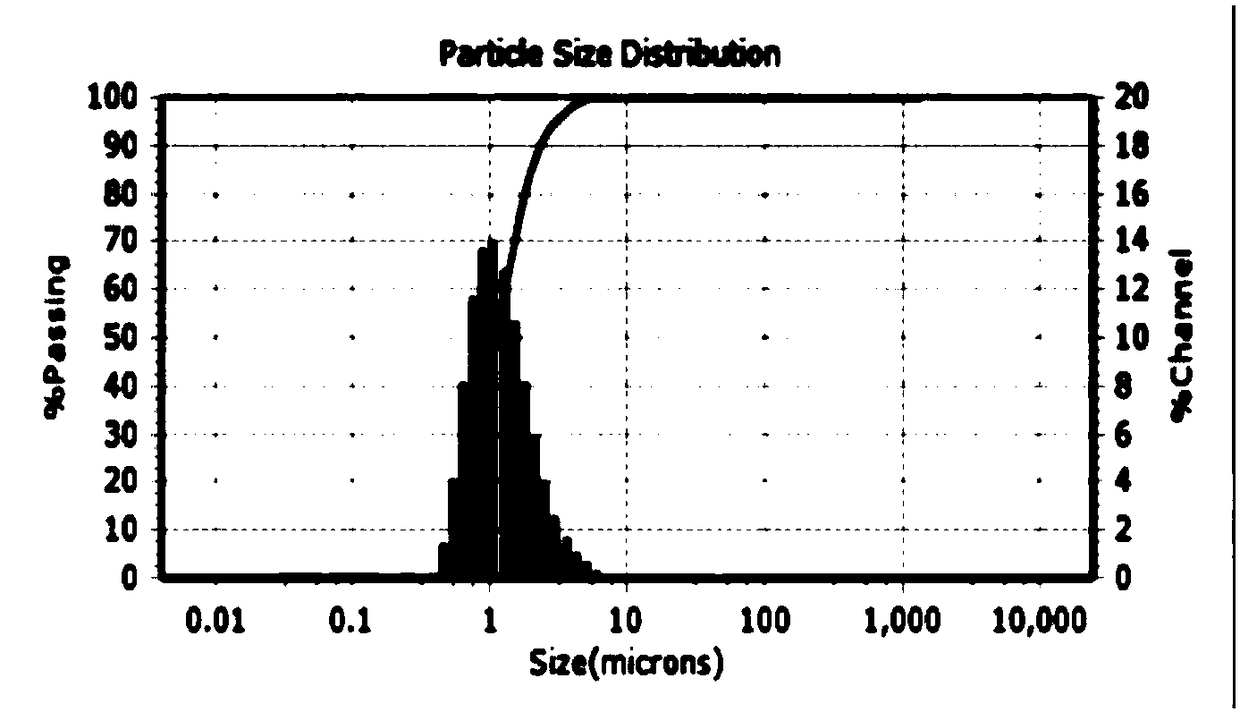

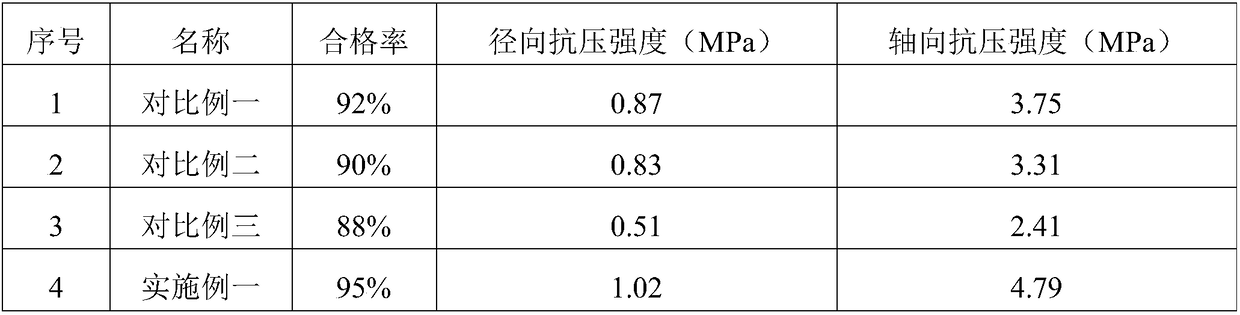

Honeycomb-like SCR denitration catalyst and preparation method thereof

InactiveCN108404902AReduce the incidence of cracksHigh mechanical strengthGas treatmentHeterogenous catalyst chemical elementsFiberGeneration rate

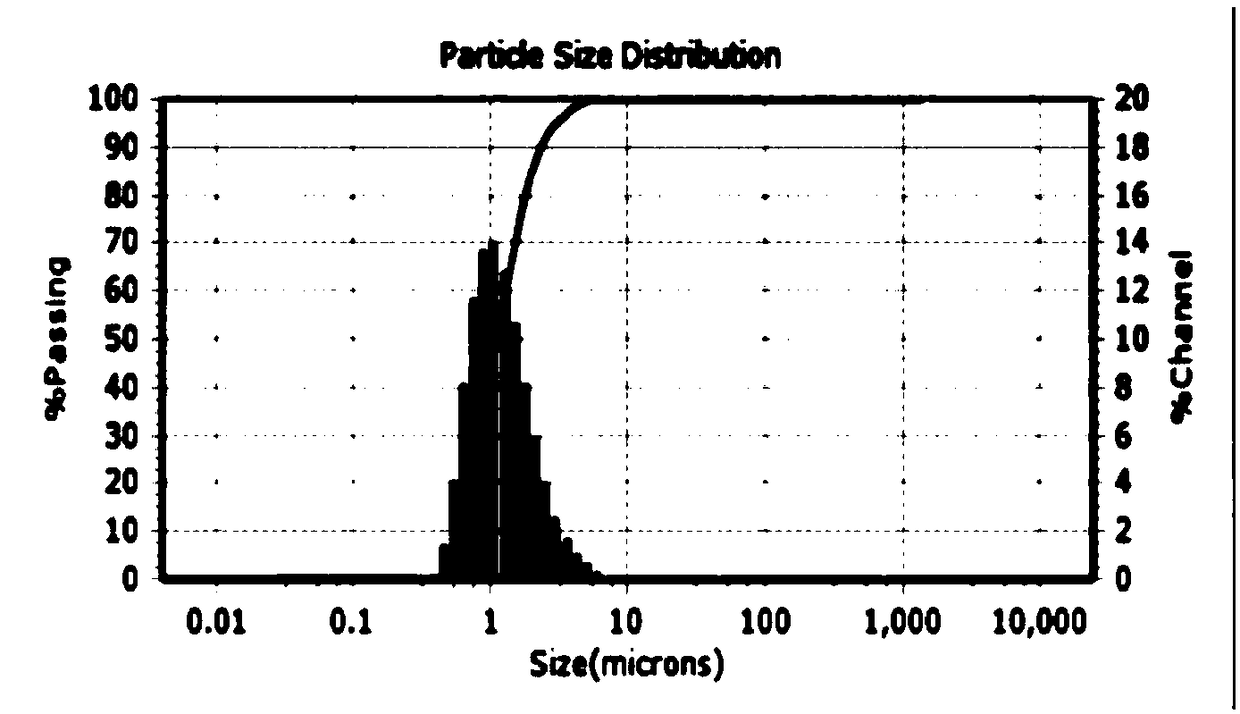

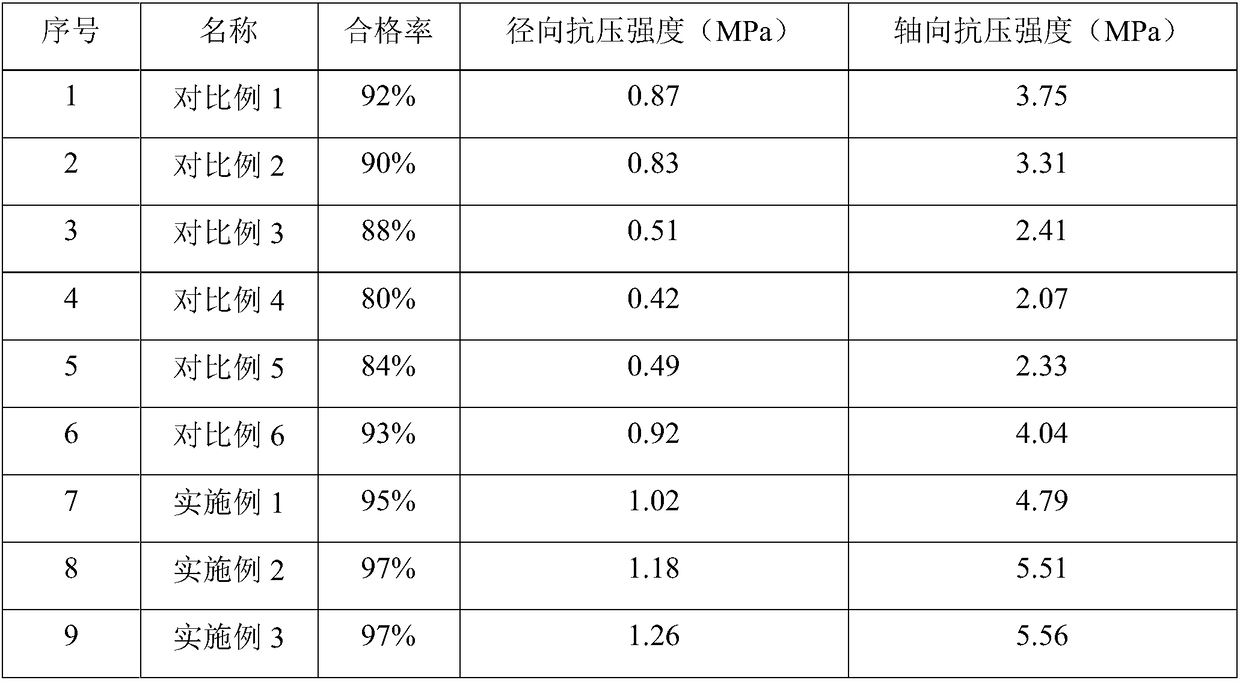

The invention relates to a honeycomb-like SCR denitration catalyst and a preparation method thereof, and belongs to the technical field of SCR catalysts. The honeycomb-like SCR denitration catalyst isprepared from the following raw materials: titanium dioxide, carboxymethyl cellulose, polyethylene oxide, fiber, deionized water, ammonium metavanadate, ammonium metatungstate, aqueous ammonia, lactic acid, cerium nitrate hexahydrate and praseodymium nitrate hexahydrate; wherein the relationship between the diameter R of the fiber and the average particle size d50 of the titanium dioxide is R=3 to 8d50; the relationship between the fiber length L at the diameter R and the particle size d of the titanium dioxide is L=5000 to 6000d, the value range of d is d10 to d90; the ratio of the added mass m1 of the fiber to the added mass m2 of the titanium white is m1: m2 = 0.06 to 0.15:1. The crack generation rate in the drying process of the honeycomb-like SCR denitration catalyst prepared by fiber optimization selection is significantly reduced, and the mechanical strength of the finished product is remarkably improved.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

Method for in-situ reducing residual stress of titanium-based composite material prepared through selective laser melting

InactiveCN110405209AReduce residual stressImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesRare-earth element

The invention discloses a method for in-situ reducing the residual stress of a titanium-based composite material prepared through selective laser melting. The method includes the steps that titanium-based composite material powder is prepared, wherein the titanium-based composite material powder comprises a combination of titanium or a titanium alloy and chemical substances generating reinforcingbodies, and the chemical substances comprise one or more of a B (boron) element, a C (carbon) element and rare earth elements; one or more layers of the titanium-based composite material powder is laid on a base plate of a selective laser melting device, and selective laser melting is performed; and one or more times of laser remelting is performed on the surface solidified after the selective laser melting; and operation is repeated till a titanium-based composite material component is prepared. According to the method, after laser remelting is performed on the surface solidified after selective laser melting, the local heat effect caused by scanning a powder layer by using high-energy laser beams as a heat source is lowered, the reaction of the reinforcing bodies can be more thorough, precipitation of the reinforcing bodies is thinner and smaller, the residual stress in the component preparing process is lowered, and the performance of the material is changed.

Owner:SHANGHAI UNIV OF ENG SCI

Continuous casting method of high-carbon steel plate blank

The invention relates to the technical field of steel and iron smelting, in particular to a continuous casting method of a high-carbon steel plate blank. The method comprises the following steps: the casting superheat degree of the high-carbon steel plate blank is controlled within 10-20 DEG C by low superheat degree; the low-pulling-speed continuous casting is performed for the high-carbon steel plate blank, and the pulling speed is controlled within 0.9-1.1 m / min; the aerial fog cooling is performed for the high-carbon steel plate blank; the taper of a crystallizer is controlled according to variable taper, wherein the alkalinity of covering slag in the crystallizer is controlled within 0.93-0.99; the melting point of the covering slag is not higher than 1050 DEG C; and the viscosity of the covering slag is not higher than 0.140 pa.s. The method reduces the large surface and angle stress, enhances the solidification uniformity of a blank shell, reduces the surface crack generation rate of the plate blank, and improves the center segregation level.

Owner:SHOUGANG CORPORATION

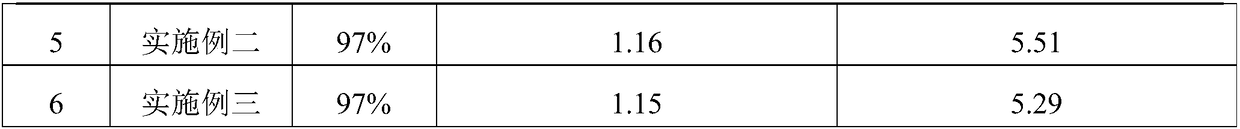

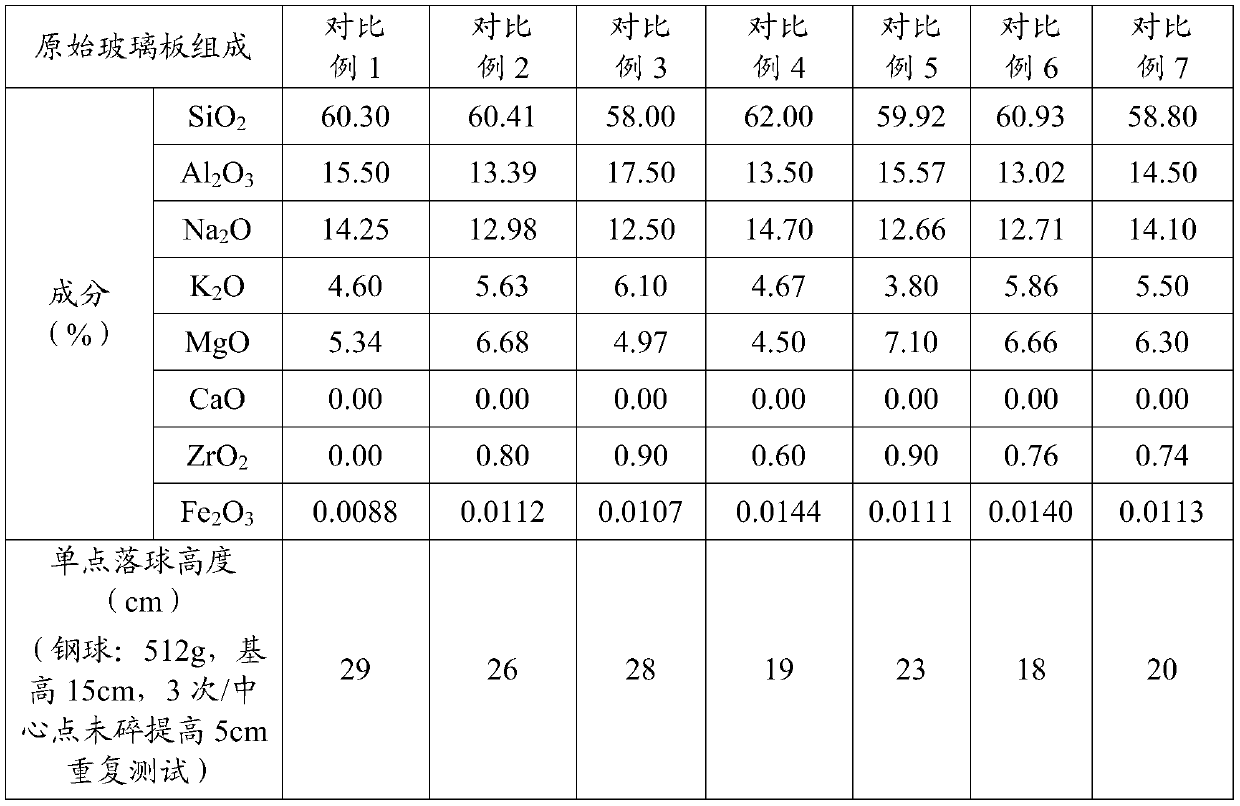

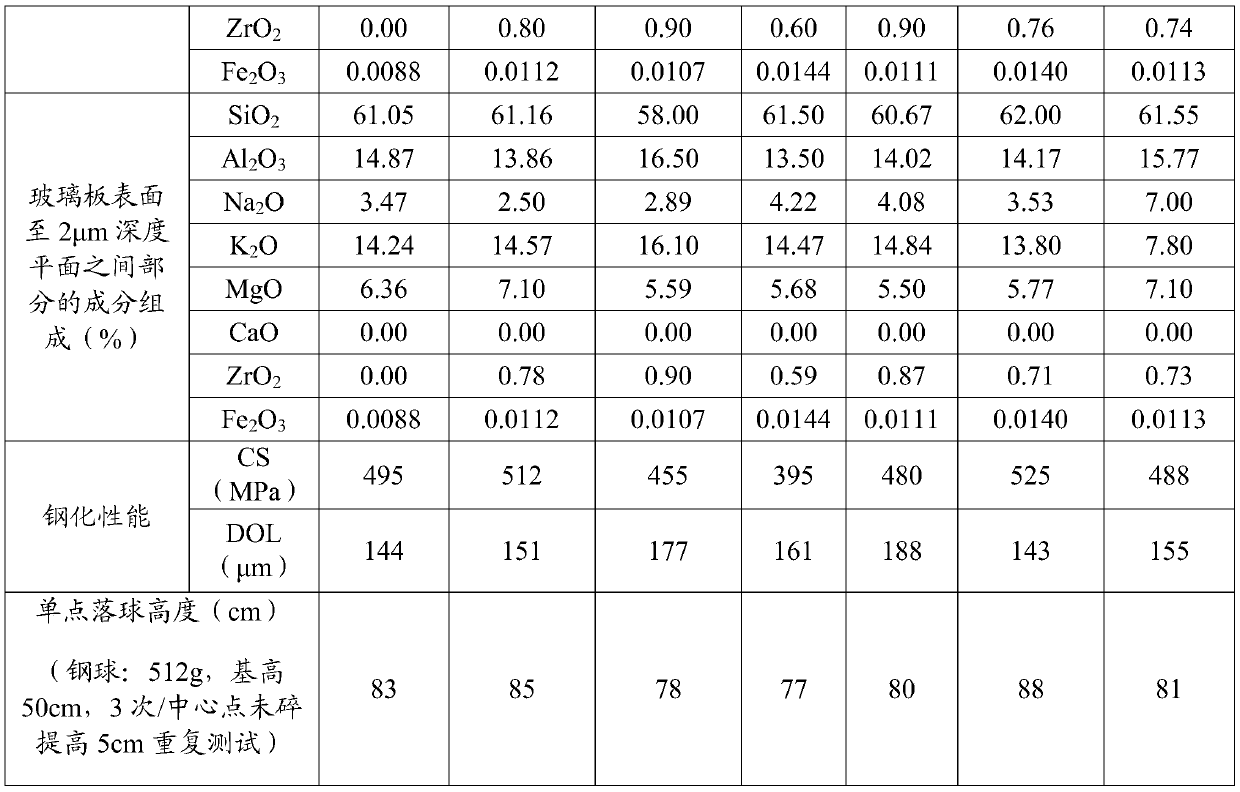

Chemically strengthened glass plate and preparation method thereof

InactiveCN109694186AImprove crystallization abilityFast hardeningGlass severing apparatusGlass sheetChemically strengthened glass

The invention discloses a chemically strengthened glass plate comprising a surface compressive stress layer and a base layer; the compressive stress layer consists of an outer layer and an inner layer, the inner layer is located between the outer layer and the base layer; the outer layer satisfies the requirements: the outer layer comprises, by the weight percentage based on oxides in the outer-layer, 58-62% of SiO2, 13-16.5% of Al2O3, 2.5-7% of Na2O, 7.8-16.1% of K2O, 5.5-7.1% of MgO, 0-0.9% of ZrO2, 0.005-0.015% of Fe2O3, and 0% of CaO. The inner layer satisfies the requirements: the inner layer comprises, by the weight percentage based on oxides in the inner layer, 58-62% of SiO2, 13-17.5% of Al2O3, 2.5-14.7% of Na2O, 3.8-16.1% of K2O, 4.5-7.1% of MgO, 0-0.9% of ZrO2, 0.005-0.015% of Fe2O3, and 0% of CaO. The base layer satisfies the requirements: the base layer comprises, by the weight percentage based on oxides in the base layer, 58-62% of SiO2, 13-17.5% of Al2O3, 12.5-14.7% of Na2O, 3.8-6.1% of K2O, 4.5-7.1% of MgO, 0-0.9% of ZrO2, 0.005-0.015% of Fe2O3, and 0% of CaO.

Owner:四川虹科创新科技有限公司

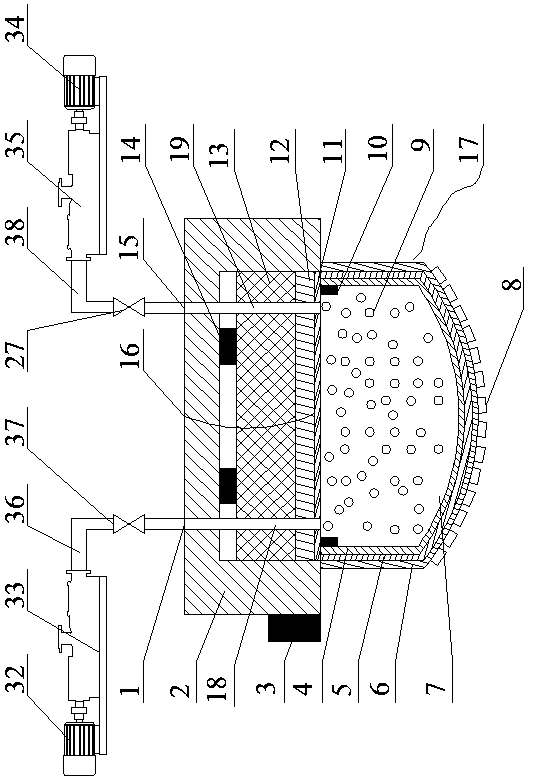

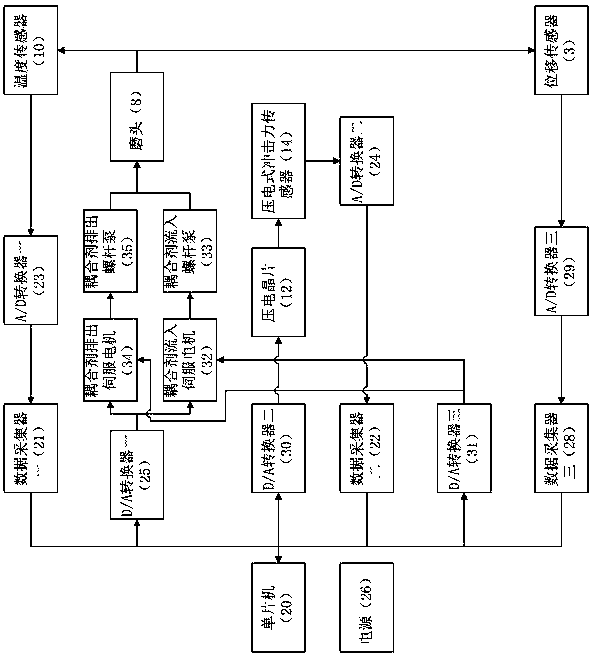

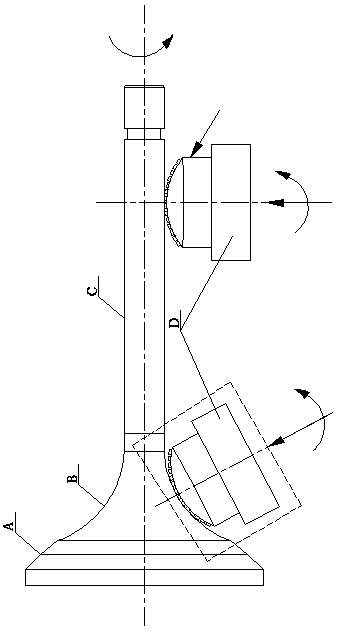

Ultrasonic combined adaptive anti-fatigue precision machining system and method of multi-curvature curved surface

ActiveCN108481138AImprove polishing efficiencyImprove fatigue lifeGrinding machine componentsGrinding machinesCouplingEngineering

The invention discloses an ultrasonic combined adaptive anti-fatigue precision machining system and method of a multi-curvature curved surface, and belongs to the field of mechanical precision machining common technologies. The ultrasonic combined adaptive anti-fatigue precision machining system and method of the multi-curvature curved surface aim to solve the technical problem of how to machine acurved surface of a key part with the multi-curvature curved surface while guaranteeing that the part has the anti-fatigue performance of a part with the multi-curvature curved surface. According tothe adopted technical scheme, the ultrasonic combined adaptive anti-fatigue precision machining system structurally comprises a flexible grinding head device and a control unit. The control unit is electrically connected with and has control over the flexible grinding head device, an ultrasonic coupling agent circulation structure and an impact vibration structure. The flexible grinding head device is used for machining the multi-curvature curved surface of the part. The control unit is used for having control over the working state of the flexible grinding head device. The flexible grinding head device comprises a flexible adjustment box body, the ultrasonic coupling agent circulation structure and the impact vibration structure. The impact vibration structure is arranged in the flexibleadjustment box body. The interior of the flexible adjustment box body communicates with the ultrasonic coupling agent circulation structure. The invention further discloses the ultrasonic combined adaptive anti-fatigue precision machining method of the multi-curvature curved surface.

Owner:QILU UNIV OF TECH

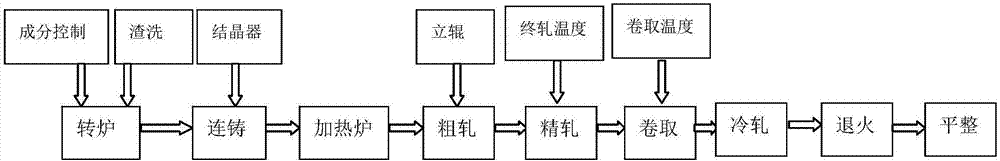

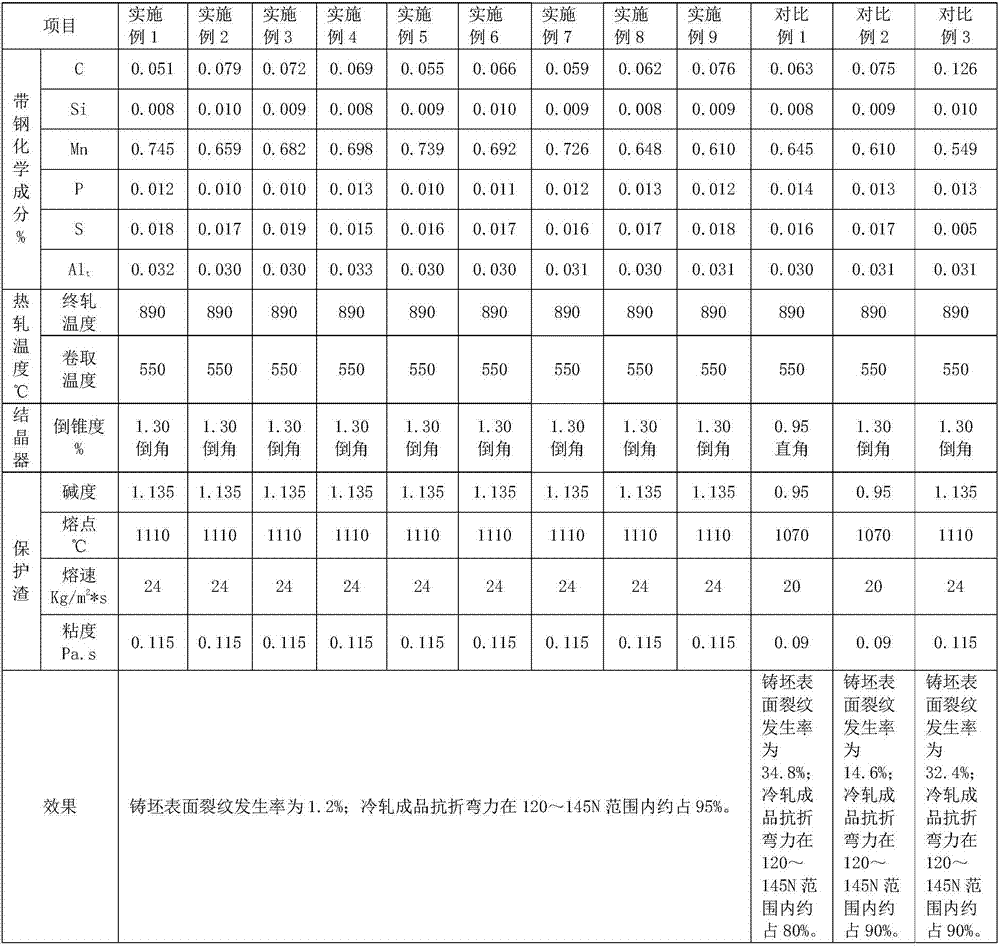

Tinplate base material used for low-defect-rate bottle cap and reduction production technology

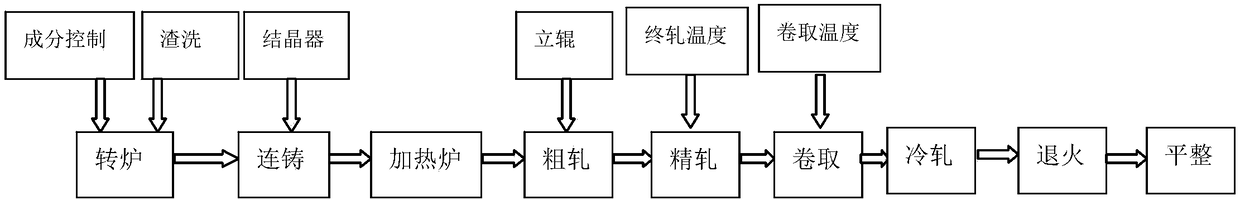

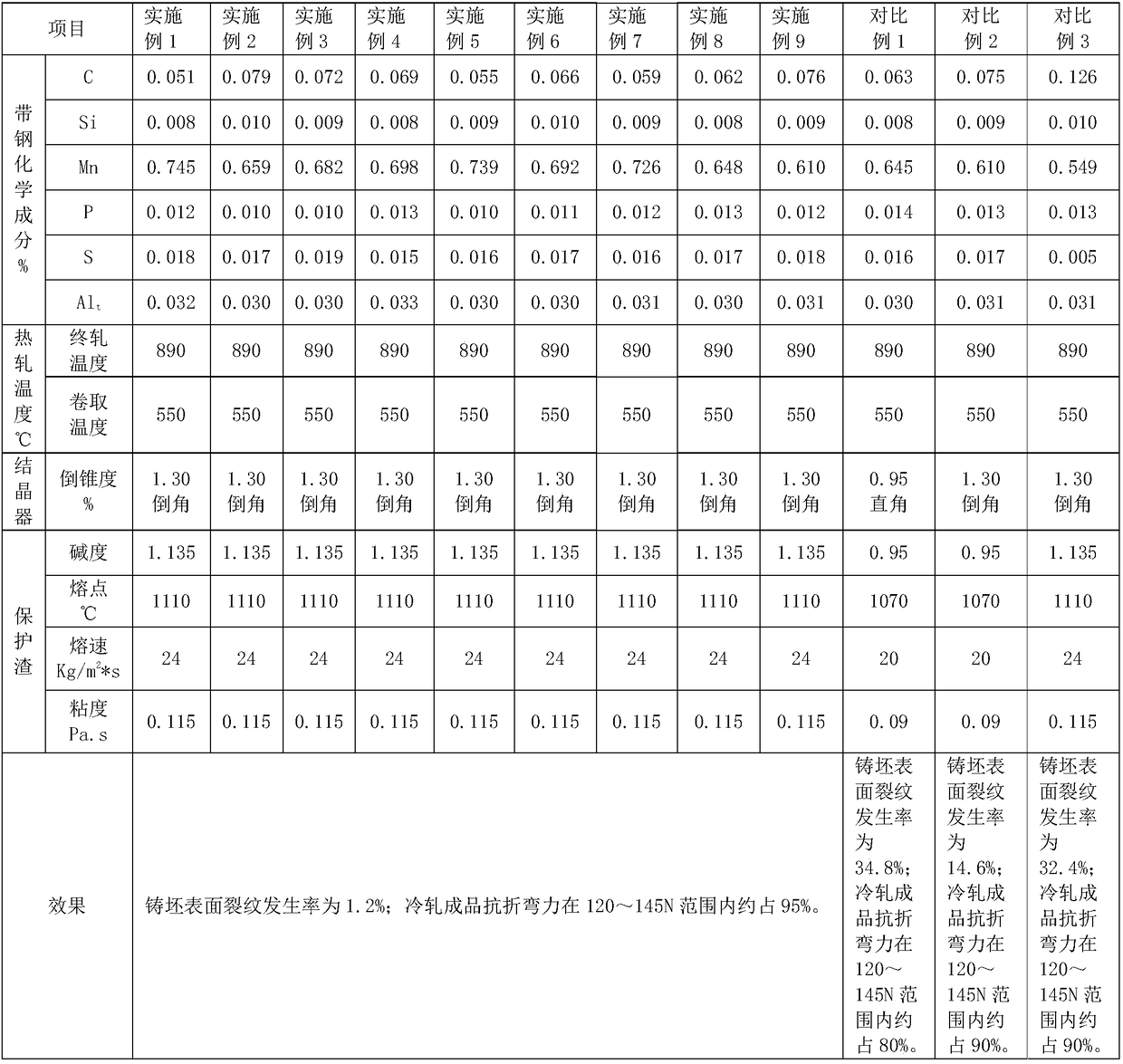

ActiveCN106868401AReduce the incidence of cracksAvoid peritectic transformationProcess efficiency improvementChemical compositionSlag

The invention discloses a tinplate base material used for a low-defect-rate bottle cap and a reduction production technology and belongs to the technical field of steel making and steel rolling. The control range of chemical components of the bottle cap steel base material include, by weight percent, 0.05%-0.08% of C, 0.60%-0.75% of Mn, smaller than or equal to 0.015% of Si, smaller than or equal to 0.020% of S, smaller than or equal to 0.020% of P, 0.025%-0.040% of Al, smaller than or equal to 0.008% of As, smaller than or equal to 0.003% of N, smaller than or equal to 0.003% of O and the balance iron and inevitable impurities. A continuous casting peritectic area is avoided by limiting the control range of the carbon chemical components, the defect of solution strengthening caused by carbon drop is overcome by improving the carbon control target, after-furnace slag washing and large-air-capacity argon blowing are used for replacing vacuum refining to ensure steel cleanliness, and a chamfer crystallizer and specific protection slag are adopted for ensuring the surface quality of a casting blank. An RH vacuum refining technology is omitted, and better finished product edge portion quality is improved.

Owner:德龙钢铁有限公司

Technology for producing peritectic steel by ultra-wide slab continuous casting machine

The invention discloses a technology for producing peritectic steel by an ultra-wide slab continuous casting machine, and relates to the technical field of metallurgy. Filling of argon is more favorable to inclusion removing, and protective casing argon seal protection and immersion protection further improve purity of molten steel; casting powder is high in alkalinity, so that heat transfer of the casting powder is more uniform, and non-uniformity of a solidification initial stage of a solidified shell is reduced; a cobalt 60 radiation method and a liquid level feedforward control technologygreatly reduce liquid level fluctuation on the basis of realizing automatic detection and control of a liquid level; and aerosol cooling of a secondary cooling zone and a drawing speed are set at a suitable level, fluctuation of the liquid level of a crystallizer can be reduced, and the bonding phenomenon is not prone to generate due to improper control over the drawing speed. By means of the above steps and parameter setting, an initial solidified shell can be more uniform, the grain size can be kept consistent everywhere, during a molten steel solidification process, the solidified shell canbe evenly solidified, and therefore the probability of occurrence of cracks on the surface of a cast blank is greatly reduced.

Owner:NANJING IRON & STEEL CO LTD

550 MPa-grade flux-cored wire with excellent moisture resistance

ActiveCN112917044AImprove moisture resistanceSimple welding processWelding/cutting media/materialsSoldering mediaShielding gasFerrosilicon

The invention belongs to the technical field of welding materials, and particularly relates to a 550 MPa-grade flux-cored wire with excellent moisture resistance. The flux-cored wire comprises a carbon steel sheath and a flux core. The flux core comprises the following components in percentage by mass: 34-42% of rutile, 2-6% of electrolytic manganese, 10-15% of silicon-manganese alloy, 14-18% of nickel powder, 2-6% of ferrotitanium, 1-5% of aluminum-magnesium alloy, 1-3% of sodium fluoride, 1-4% of zircon sand, 4-8% of ferroboron, 1-3% of potassium titanate, 2-6% of silicon iron, 1-6% of magnesium powder, 2-5% of feldspar, 1-5% of fluorinated ethylene propylene and the balance iron powder. According to the 550 MPa-grade flux-cored wire with the excellent moisture resistance, pure CO2 serves as shielding gas, the 550 MPa-grade flux-cored wire can be used in a maritime work construction working environment, the impact toughness requirement at -40 DEG C is met, the diffusible hydrogen content is lower than 5 ml / 100 g, the yield strength grade of the flux-cored wire is 460 MPa grade, the tensile strength grade reaches 550 MPa grade, and the flux-cored wire is good in cold crack resistance, extremely high in moisture absorption resistance and high in pore resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Rear glass cover plate for mobile phone

The invention belongs to the technical field of a glass cover plate for a mobile phone, and more particularly relates to a rear glass cover plate for mobile phone. The rear glass cover plate is made of the following raw materials: modified needle-shaped wollastonite powder, phosphogypsum, nano-micelle powder, nacre powder, sodium fluorosilicate, ammonium pentaborate, 2-ethylimidazole, melamine cyanurate, lanthanum hydroxide, vanadium pentoxide and thiourea dioxide. Compared with the prior art, the invention has the following advantages: a variety of modifiers are adopted to modify the needle-shaped wollastonite powder to improve the compatibility with other raw materials, reduce water absorption rate and oil absorption rate, have low crack generation rate, obviously improve the processability, and are matched with other raw materials to prepare the rear glass cover plate; the rear glass cover plate has strong chemical resistance, can effectively resist yellowing after use for long time, has hardness, toughness and anti-fouling properties capable of reaching corresponding standards, has strong impact resistance and elastic modulus so as to improve the breaking resistance performance to a certain extent, and is used for a rear shell cover of the mobile to maintain attractiveness for long period and prolong the service life.

Owner:枞阳县铭瑞电子科技有限公司

SCR (Selective Catalytic Reduction) honeycomb type denitration catalyst and preparation method thereof

InactiveCN109453761AGood effectReduce the incidence of cracksGas treatmentHeterogenous catalyst chemical elementsFiberGeneration rate

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

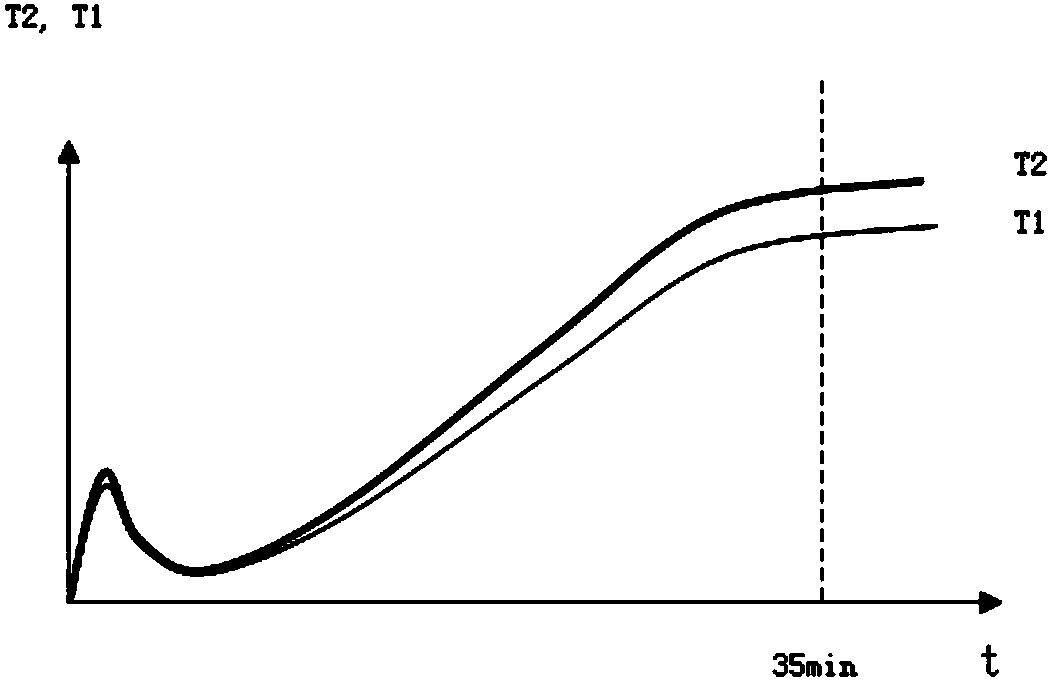

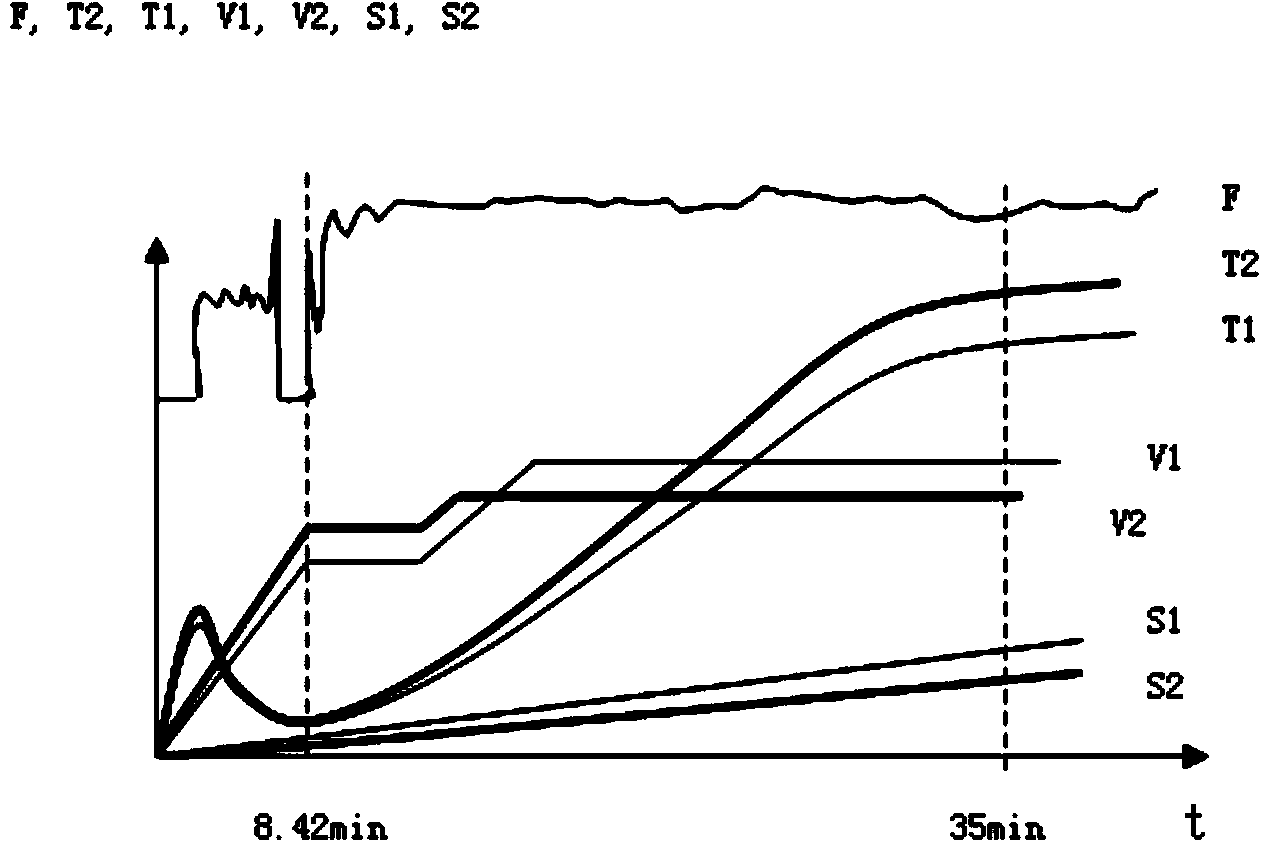

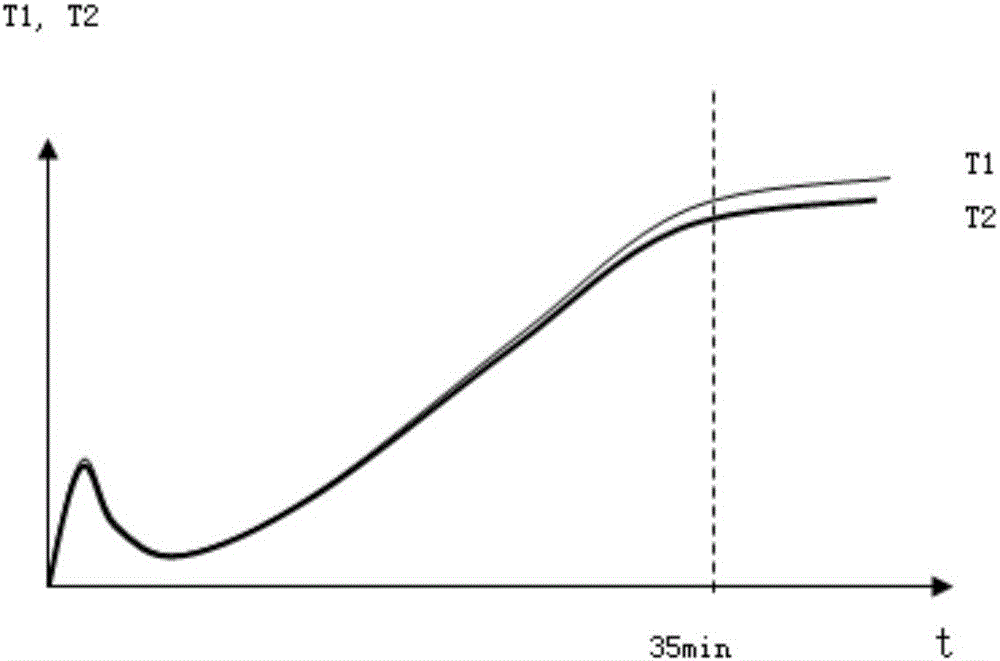

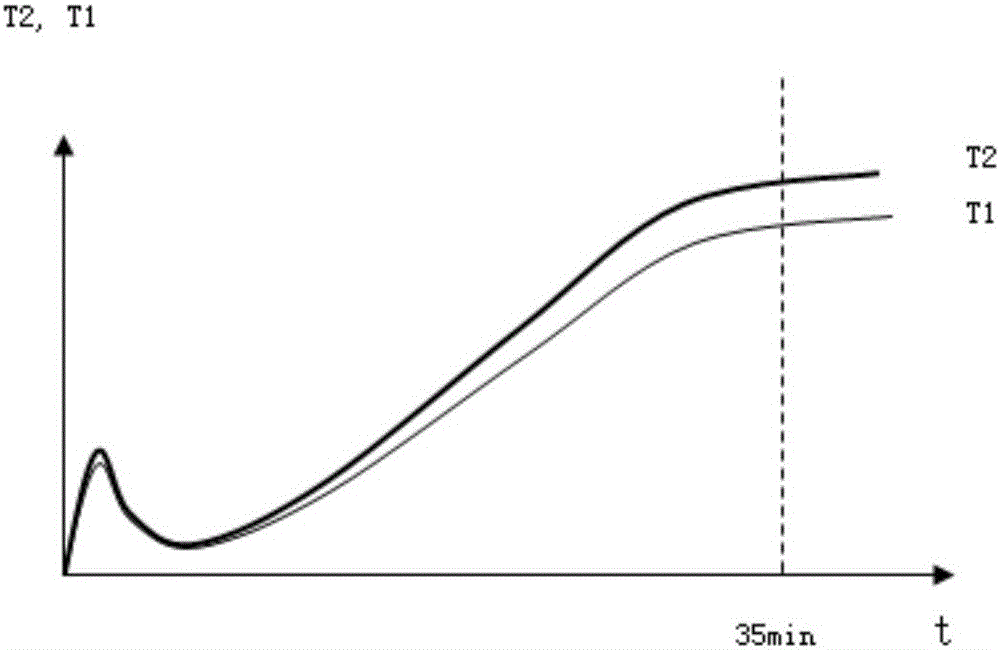

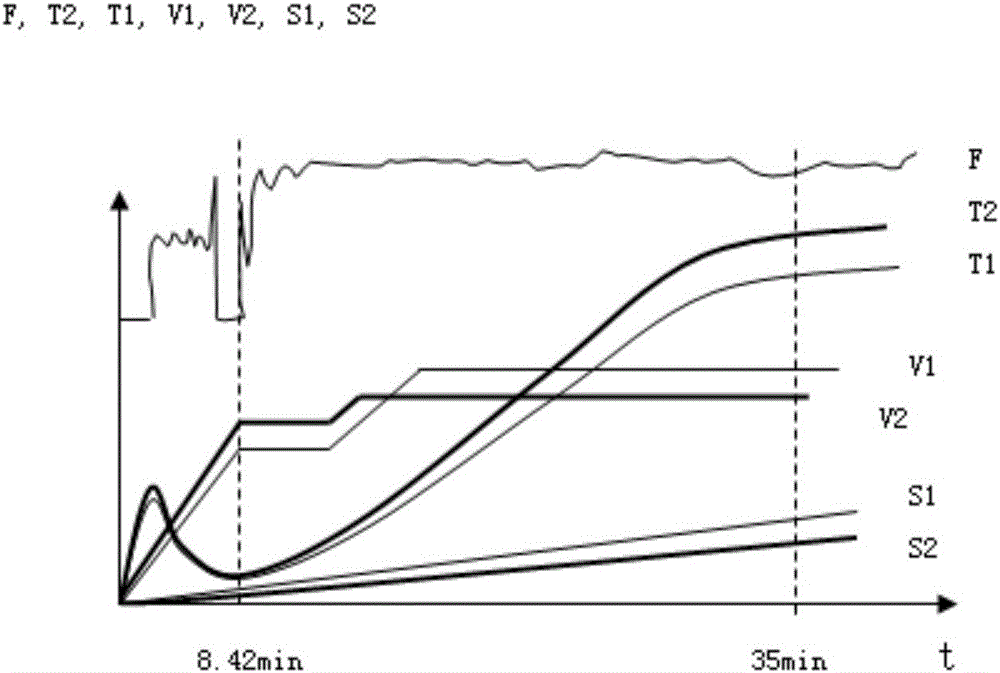

Withdrawal and straightening force fault diagnosis method of sector segment of continuous casting machine

InactiveCN103454109AImprove the stress condition of the billetImprove billet qualityStructural/machines measurementEngineeringEquipment state

The invention relates to a withdrawal and straightening force fault diagnosis method of a sector segment of a continuous casting machine. The withdrawal and straightening force fault diagnosis method includes the steps that an equipment state parameter database of a withdrawal and straightening machine is set up; a withdrawal speed curve, a total withdrawing and straightening curve, a flow casting tracing curve and a hidden danger segment withdrawing and straightening curve are drawn respectively according to measured data. If first total withdrawal and straightening force and second total withdrawal and straightening force do not exceed the range of the corresponding total withdrawal and straightening force in the database, hidden danger does not exist, and diagnosis is over; and otherwise, existence of the hidden danger is confirmed and the next step is executed; stressed abnormal points are determined, and the stressed abnormal points are verified. With the adoption of the withdrawal and straightening force fault diagnosis method of the sector segment of the continuous casting machine, under the same working rate of the casting machine, due to the fact that the hidden danger existing in the sector segment can be found in advance, the stressed condition of a casting blank is greatly improved, the quality of the casting blank is greatly improved, the crack occurrence rate of crack-sensitive steel is lowered to 3.5%, the commuted amount is effectively reduced, and the fault time is effectively shortened. The withdrawal and straightening force fault diagnosis method of the sector segment of the continuous casting machine is simple in operation, high in sensitivity, timely in detection and precise in positioning.

Owner:武汉钢铁有限公司

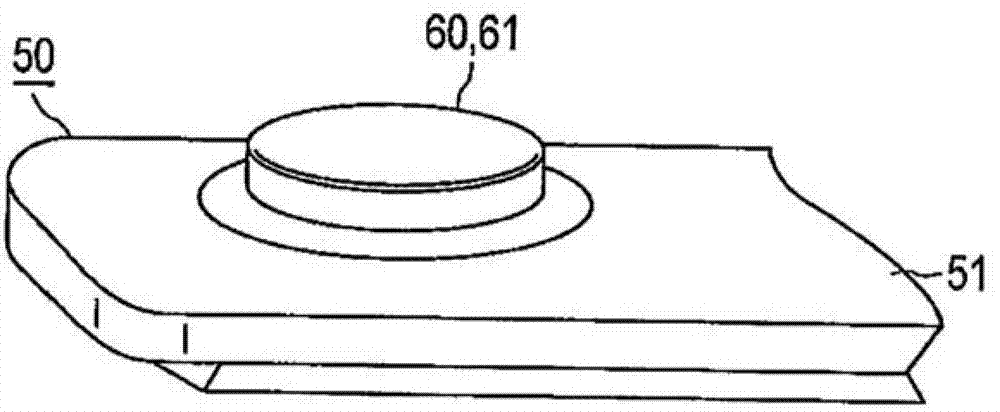

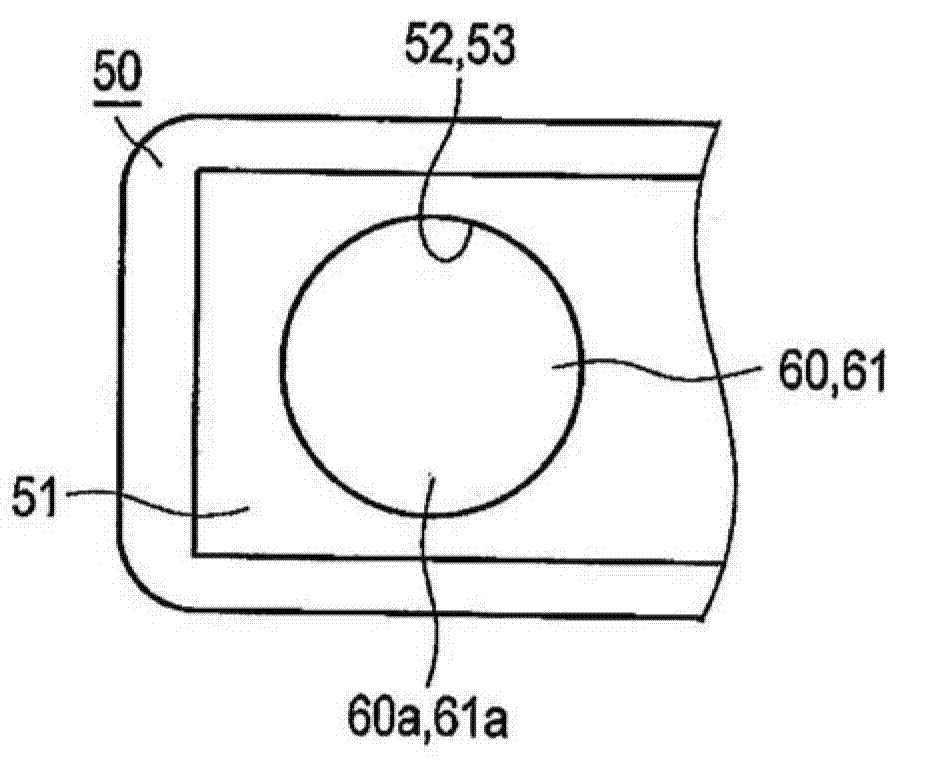

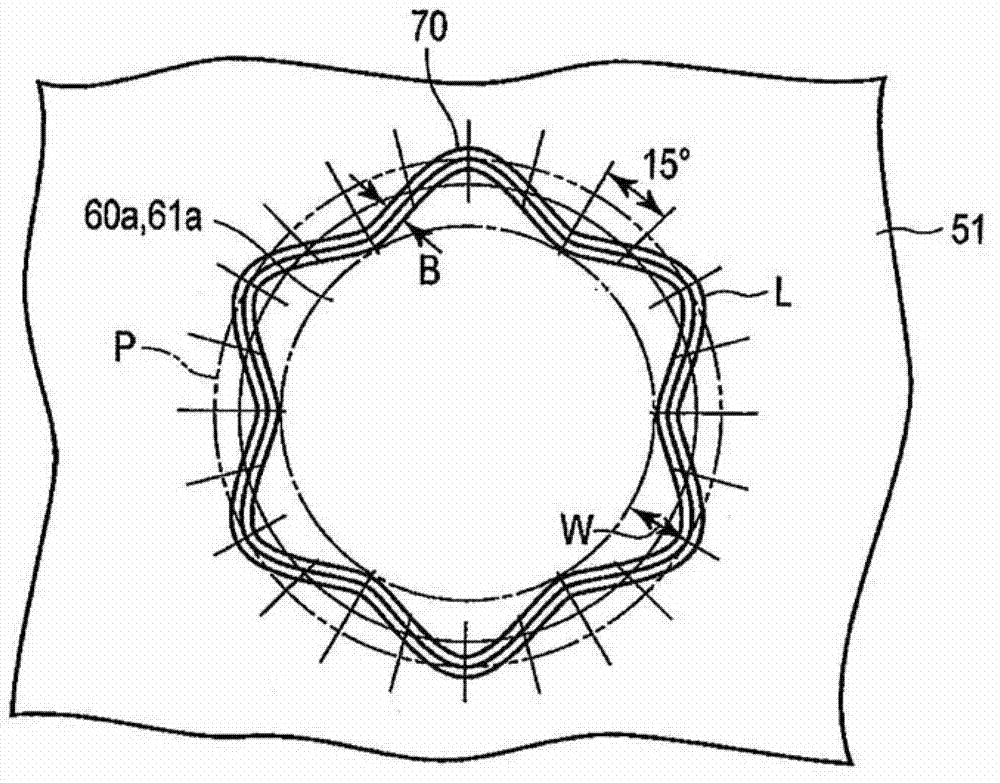

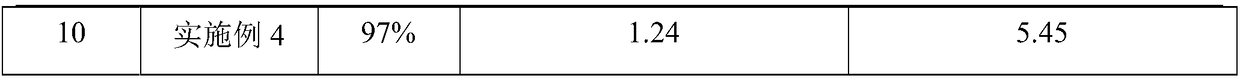

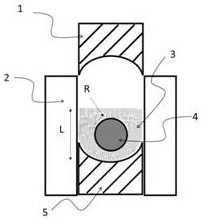

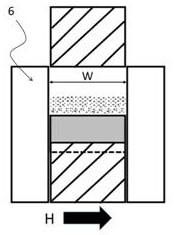

Preparation method and forming die of annular sintered neodymium-iron-boron magnet

PendingCN111916283AReduce intensitySmall temperature differenceTransportation and packagingMetal-working apparatusMetallurgyMaterials science

The invention provides a preparation method of an annular sintered neodymium-iron-boron magnet and a forming die of the annular sintered neodymium-iron-boron magnet. The forming die comprises a main body part, an upper pressing head, a lower pressing head and a die cavity; the main body part comprises two opposite non-magnetic-conductive side plates and two opposite magnetic-conductive side plates; in a space formed between the two non-magnetic-conductive side plates and the two magnetic-conductive side plates, the lower pressing head is located at the bottom of the space, and the upper pressing head is located at the top of the space. The die cavity is located between the upper pressing head and the lower pressing head, the flexible cylindrical core is placed in the die cavity, the flexible cylindrical core is placed in the die cavity after the neodymium iron boron magnetic powder in a loose state is placed in the die cavity during preparation, and a magnet finished product is obtained through pressing of a forming die. The method and the device with the mold core structure have the advantages that the material utilization rate and the product percent of pass can be greatly improved when the method and the device with the mold core structure are used for producing the annular sintered neodymium-iron-boron.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

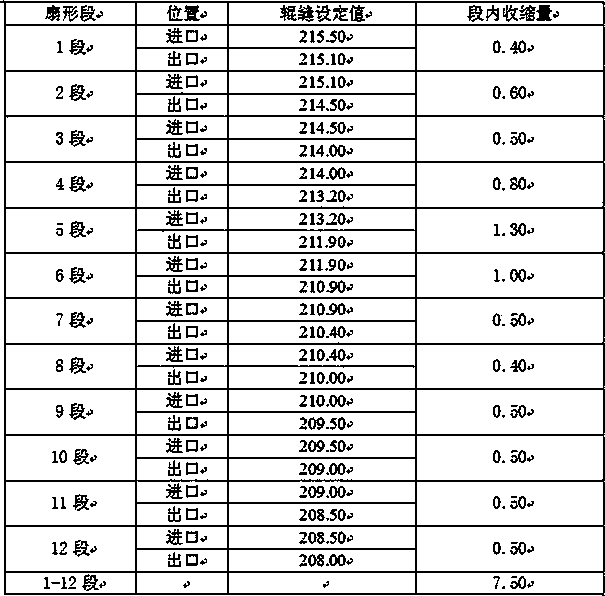

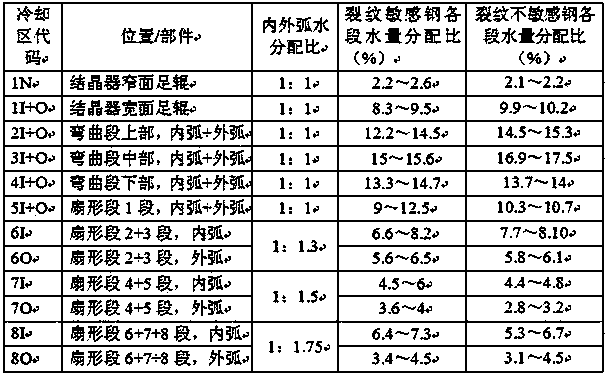

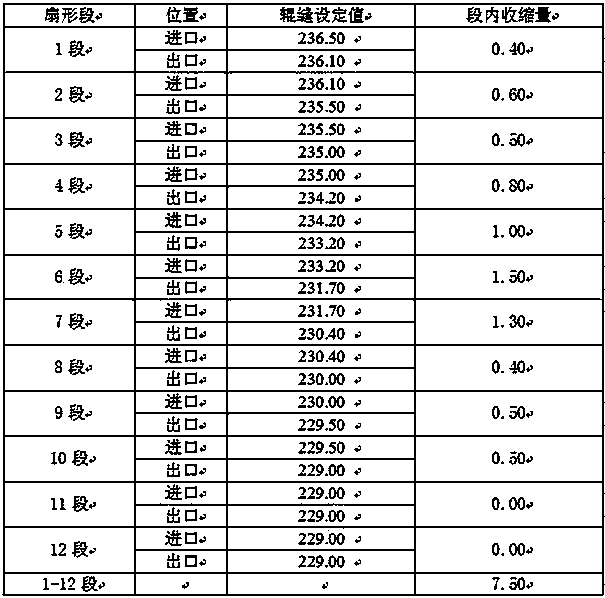

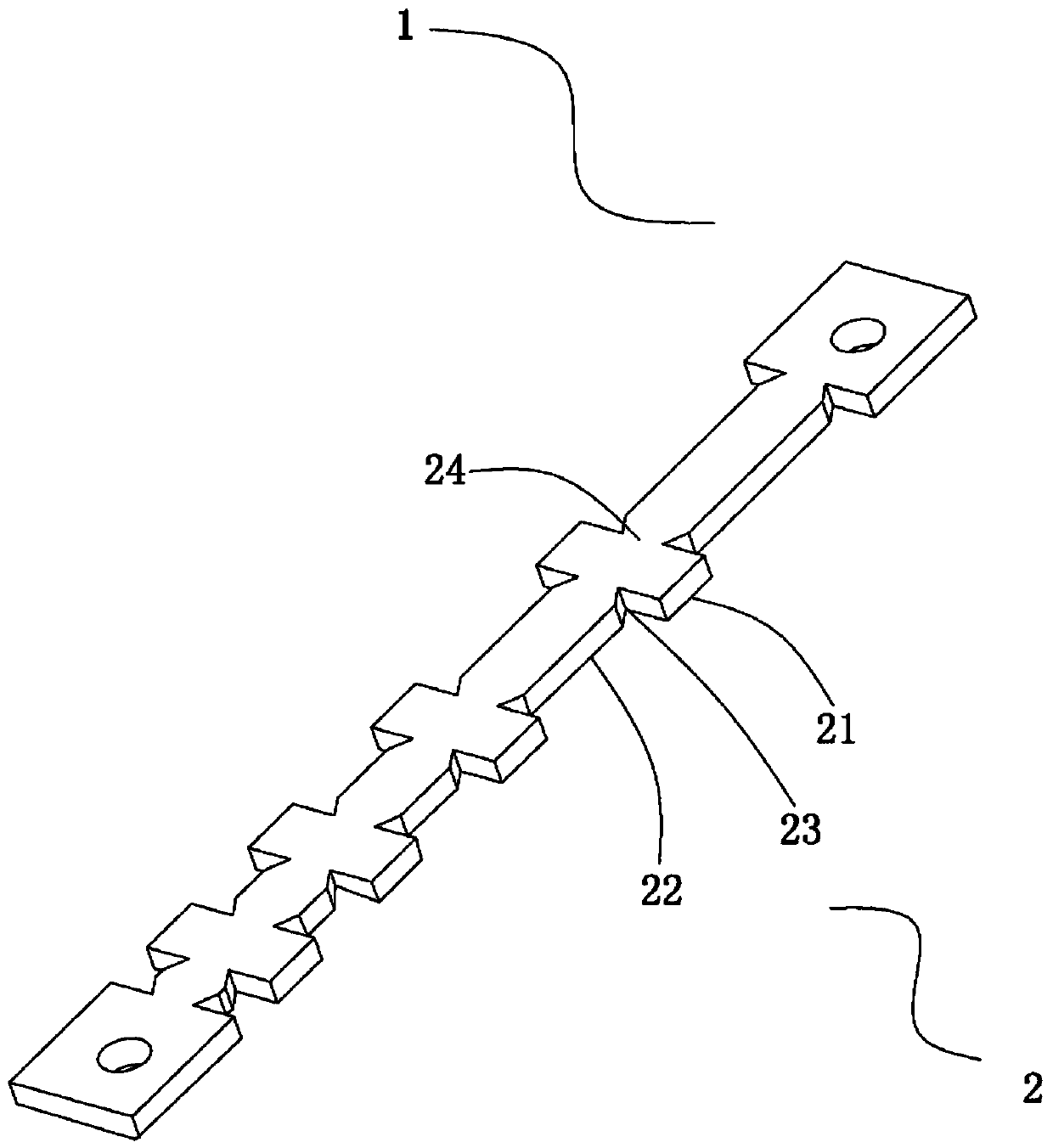

A Method for Adjusting Secondary Cooling Water Volume and Roll Gap Value of Two-strand Slab Continuous Casting Machine

The invention discloses a method for adjusting the secondary cooling water amount and the roll gap value of a double-flow slab casting machine. In the double-flow slab casting machine, 12 cooling regions are formed for secondary cooling; 10 cooling water meters are provided; five grades, i.e., strong cooling: the secondary cooling water amount is 1.0-1.1 L / kg, medium cooling: the secondary cooling water amount is 0.8-0.9 L / kg, weak cooling: the secondary cooling water amount is 0.7-0.8 L / kg, medium-weak cooling: the secondary cooling water amount is 0.45-0.6 L / kg, and slight cooling: the secondary cooling water amount is 0.4-0.45 L / kg are divided to adapt to the cooling requirements of different types of steel respectively; the roll gap of a secondary cooling region support roll is consistent with the linear shrinkage rule of a casting blank from top to bottom, and decrease continually; and the roll opening between the outlet of a previous fan-shaped section and the inlet of a next fan-shaped section is kept consistent. By adopting the method, the internal cracking rate is lowered, the macrostructure of the casting blank is optimized, and the performance yield of steel is increased.

Owner:ANYANG IRON & STEEL

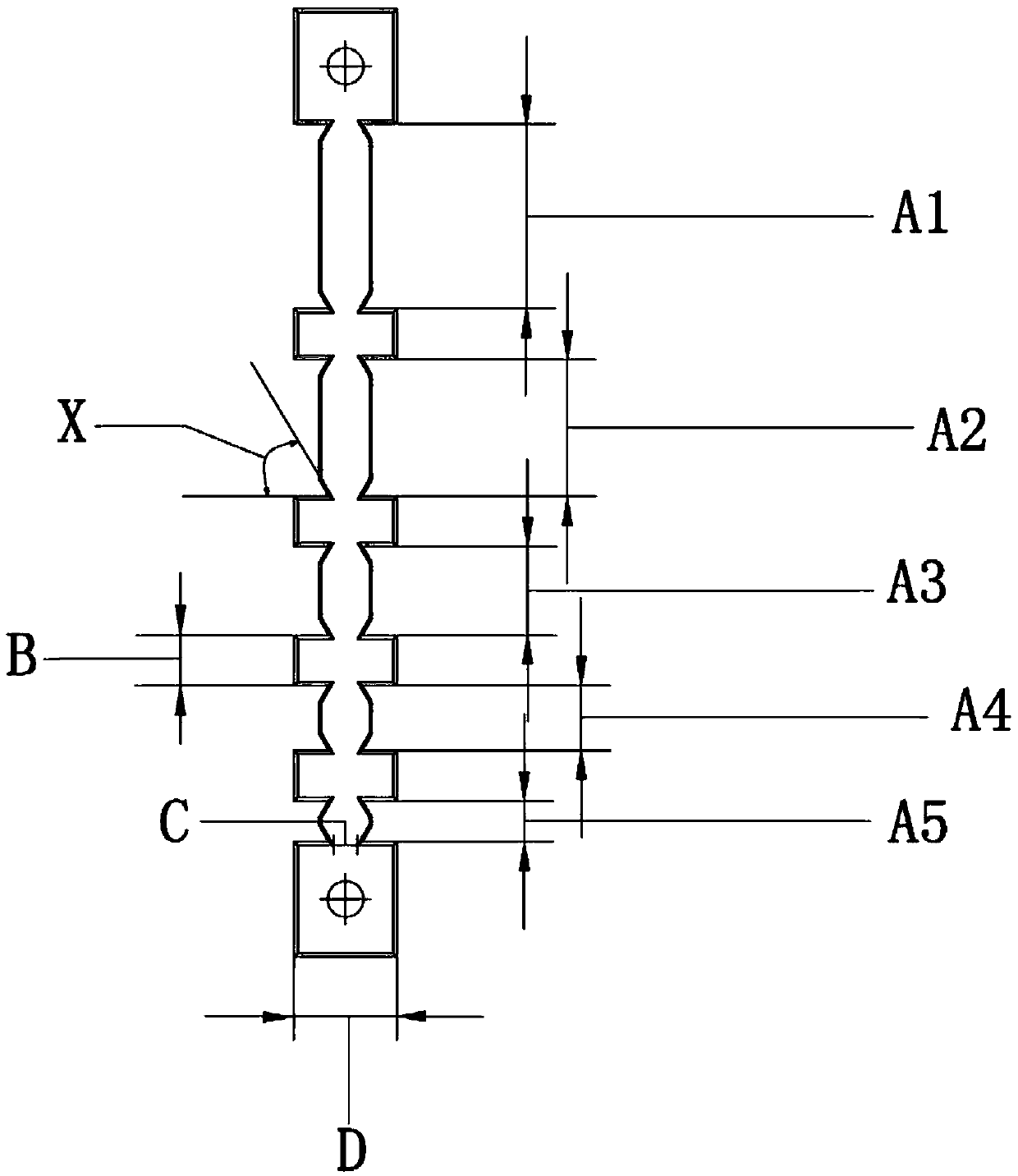

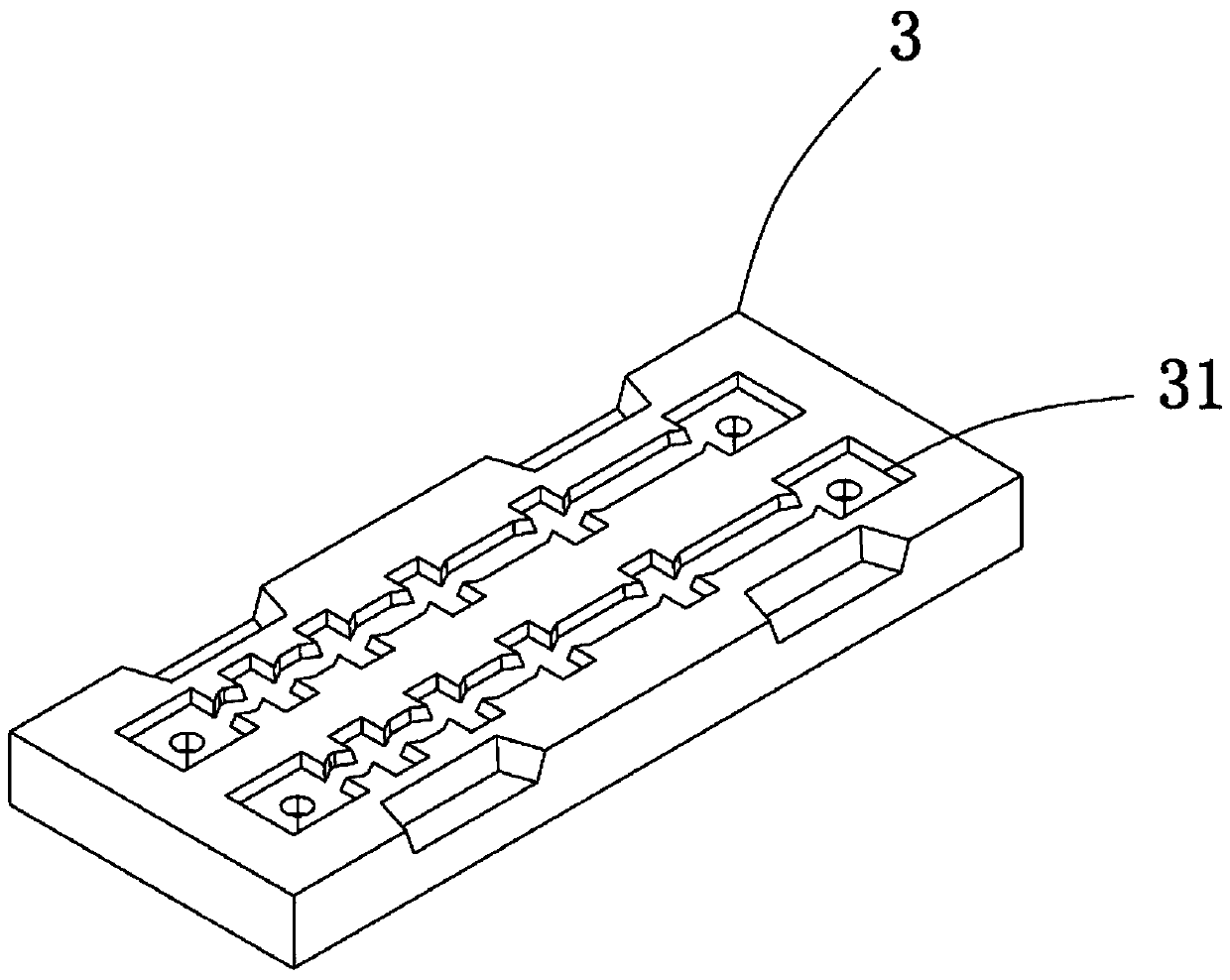

Green body for testing cracking performance of slurry wet blank, casting mold and method

ActiveCN109632440ATest crack performanceCracking performancePreparing sample for investigationMaterial strength using tensile/compressive forcesComputer moduleCasting mold

The invention discloses a green body for testing the cracking performance of a slurry wet blank, a casting mold and a method. The green body is provided with at least a detection module, each detection module comprises a connecting part and stretching parts arranged at the two ends of the connecting part, the connecting part and the stretching parts at the two ends of the connecting part for eachdetection module are connected into a whole, and an unfilled corner is arranged between the connecting part and the stretching part at the at least one end; and the unfilled corners are arranged in anacute angle mode and arranged towards the axis direction. According to the green body for testing the cracking performance of the slurry wet blank, the casting mold and the method, slurry is poured into the mold to form the green body, two or more detection modules with connecting parts with different lengths are included in each of all the green bodies, the mold is opened after time is manuallyset so that the cracking performance of the slurry wet blank can be tested, measured and evaluated more objectively according to the number of cracks of the green body and the situation that the detection module with the specific length in which the cracks occur is determined, and then the crack incidence rate of the green body is reduced.

Owner:JOMOO KITCHEN & BATHROOM

Continuous casting crystallizer casting powder for titanium-containing steel as well as preparation method and application of continuous casting crystallizer casting powder

ActiveCN114472824AHigh viscosityHigh melting pointProcess efficiency improvementTitaniumContinuous casting mold

The invention provides continuous casting crystallizer casting powder for titanium-containing steel as well as a preparation method and application of the continuous casting crystallizer casting powder, belongs to the field of continuous casting crystallizer casting powder for titanium-containing steel, and overcomes the defects that in the prior art, the crystallizer casting powder for titanium-containing steel continuous casting is poor in lubricating performance, and cracks are easily formed on the surface of a blank. The crystallizer casting powder comprises, by mass, 28%-33% of SiO2, 30%-35% of CaO, 2.5%-3.5% of MgO, 5%-8% of Al2O3, 9%-12% of Na2O + K2O, 3%-4% of F, 4%-8% of C, 1%-3% of B2O3, 1%-3% of MnO and the balance inevitable impurities. The binary alkalinity R is 1.0-1.1, R is CaO / SiO2, the melting point is 1000-1100 DEG C, and the viscosity at the temperature of 1300 DEG C is 0.46-0.86 Pa.s.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

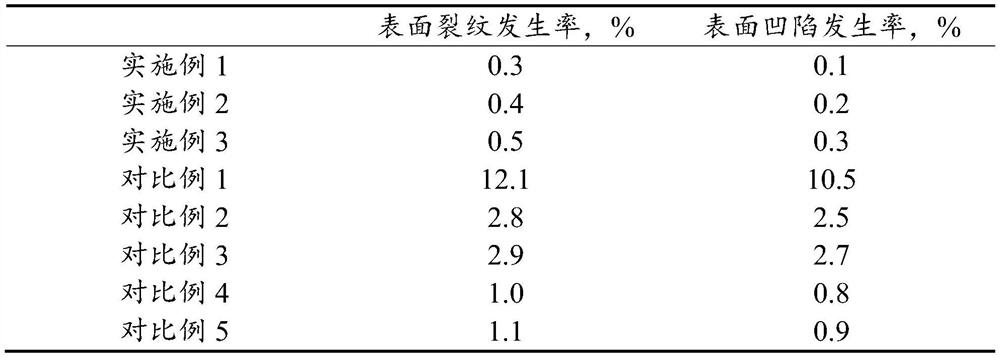

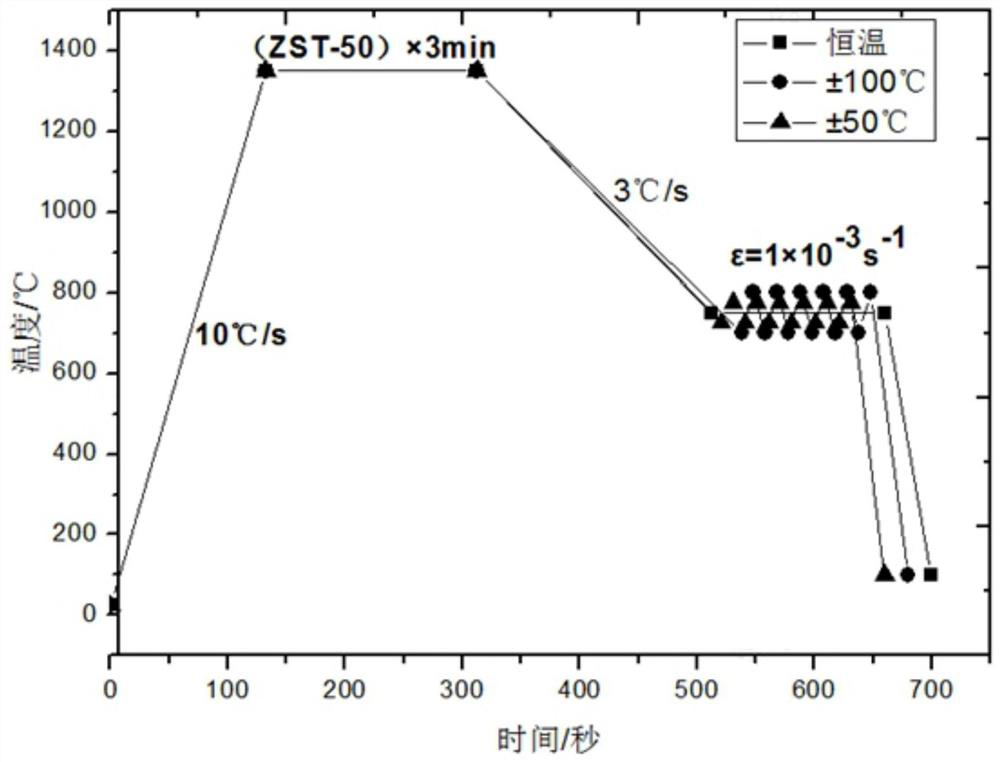

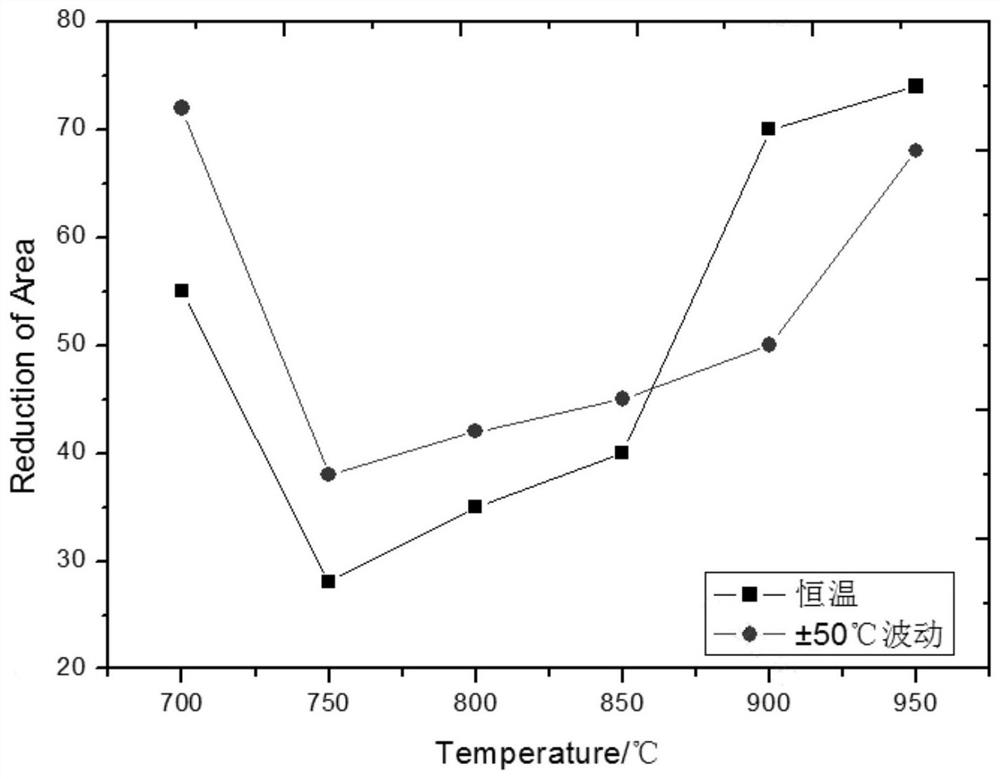

Test method for improving surface quality of microalloyed steel continuous casting slab

PendingCN113125253AReduce the incidence of cracksImprove surface qualityMaterial strength using tensile/compressive forcesProcess engineeringAlloy steel

The invention relates to a test method for improving the surface quality of a microalloyed steel continuous casting billet. The method comprises the following steps that an unconventional high-temperature tensile test is designed through a thermal simulation testing machine by mastering the temperature fluctuation of the continuous casting billet in a withdrawal and straightening process; and the continuous casting process is adjusted by simulating data of the casting blank in two states of temperature fluctuation and stretching in the withdrawal and straightening process, the obtained data better conforms to the actual rule, and the method has higher reference value for casting blank crack control. The temperature fluctuation period t is determined according to the casting blank pulling speed and the roller diameter, the temperature fluctuation T is determined according to a continuous casting tool, + / -T up-and-down fluctuation circulation is achieved within the time t at different stretching temperatures, and therefore data closer to the actual production technology is obtained to adjust the straightening temperature and the like. And finally, the continuous casting straightening temperature is formulated by analyzing and comparing high-temperature thermoplasticity under different parameters and according to the principle that the area shrinkage is higher than 60% and is a plastic area, and the area shrinkage is lower than 40% and is a brittle area.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Method for controlling triangular area cracks of continuous casting plain carbon steel slab

PendingCN114523081AReduce the incidence of cracksReduce incidenceCasting parameters measurement/indication devicesEngineeringMechanics

The invention discloses a method for controlling a triangular area crack of a continuous casting plain carbon steel slab, which belongs to the technical field of continuous casting slabs, and comprises the following steps: S1, keeping the wide surface water flow of a crystallizer at 3200L / min, controlling the narrow surface water flow of the crystallizer at 510L / min-600L / min, calculating the narrow side and wide surface heat flux according to a heat flux formula of the crystallizer in combination with the water inlet and outlet temperature difference of the crystallizer, meanwhile, the cooling water flow of the foot roller section of the crystallizer is increased by 10-30 L / min, a database is established, and data with the heat flux density ratio of the narrow side to the wide side being 0.8-1.0 MW / m < 2 > is selected; s2, measuring the surface temperature of an inlet and an outlet of the straightening section of the casting blank, firstly, establishing a database according to the measured temperature and the optimized secondary cooling water specific water flow, and selecting data of the straightening section at the temperature of 910-930 DEG C from the database; secondly, an arc-shaped section nozzle of the casting machine is changed into a backwashing nozzle, so that the temperature return amount is less than 20 DEG C;

Owner:天铁热轧板有限公司

Welding method of sealed battery, sealed battery and cover

ActiveCN103594723BReduce the incidence of cracksWeld firmlyFinal product manufactureSecondary cells manufactureEngineeringReference line

A welding method of a sealed storage battery provided with a case configured to encapsulate electrodes and electrolyte therein; a cover configured to cover the case; and two terminals inserted into into a hole provided in the cover body, connected to a pair of electrodes, and formed of a material of a composition different from the lead material, the soldering method comprising: squeezing and extending each of the two terminals along the cover body the distal end side of the terminal, and along the boundary line between the peripheral edge of the distal end side of the terminal and the cover body and alternately and repeatedly pass through the position on the terminal side of the boundary line regarded as the reference line and the cover body side of the boundary line continuous welding at the position on the

Owner:KK TOSHIBA

A kind of high carbon steel slab continuous casting method

ActiveCN105499528BEnhanced coagulation uniformityReduce the incidence of cracksAlkalinityGeneration rate

Owner:SHOUGANG CORPORATION

Fault Diagnosis Method of Tension and Correction Force in Segment of Continuous Casting Machine

InactiveCN103454109BImprove stress conditionReduce the incidence of cracksStructural/machines measurementStress conditionsEngineering

The invention relates to a withdrawal and straightening force fault diagnosis method of a sector segment of a continuous casting machine. The withdrawal and straightening force fault diagnosis method includes the steps that an equipment state parameter database of a withdrawal and straightening machine is set up; a withdrawal speed curve, a total withdrawing and straightening curve, a flow casting tracing curve and a hidden danger segment withdrawing and straightening curve are drawn respectively according to measured data. If first total withdrawal and straightening force and second total withdrawal and straightening force do not exceed the range of the corresponding total withdrawal and straightening force in the database, hidden danger does not exist, and diagnosis is over; and otherwise, existence of the hidden danger is confirmed and the next step is executed; stressed abnormal points are determined, and the stressed abnormal points are verified. With the adoption of the withdrawal and straightening force fault diagnosis method of the sector segment of the continuous casting machine, under the same working rate of the casting machine, due to the fact that the hidden danger existing in the sector segment can be found in advance, the stressed condition of a casting blank is greatly improved, the quality of the casting blank is greatly improved, the crack occurrence rate of crack-sensitive steel is lowered to 3.5%, the commuted amount is effectively reduced, and the fault time is effectively shortened. The withdrawal and straightening force fault diagnosis method of the sector segment of the continuous casting machine is simple in operation, high in sensitivity, timely in detection and precise in positioning.

Owner:武汉钢铁有限公司

A kind of tinplate base material for bottle cap with low defect rate and its production process of reduction

ActiveCN106868401BReduce the incidence of cracksAvoid peritectic transformationProcess efficiency improvementSteelmakingManganese

The invention discloses a tinplate base material used for a low-defect-rate bottle cap and a reduction production technology and belongs to the technical field of steel making and steel rolling. The control range of chemical components of the bottle cap steel base material include, by weight percent, 0.05%-0.08% of C, 0.60%-0.75% of Mn, smaller than or equal to 0.015% of Si, smaller than or equal to 0.020% of S, smaller than or equal to 0.020% of P, 0.025%-0.040% of Al, smaller than or equal to 0.008% of As, smaller than or equal to 0.003% of N, smaller than or equal to 0.003% of O and the balance iron and inevitable impurities. A continuous casting peritectic area is avoided by limiting the control range of the carbon chemical components, the defect of solution strengthening caused by carbon drop is overcome by improving the carbon control target, after-furnace slag washing and large-air-capacity argon blowing are used for replacing vacuum refining to ensure steel cleanliness, and a chamfer crystallizer and specific protection slag are adopted for ensuring the surface quality of a casting blank. An RH vacuum refining technology is omitted, and better finished product edge portion quality is improved.

Owner:德龙钢铁有限公司

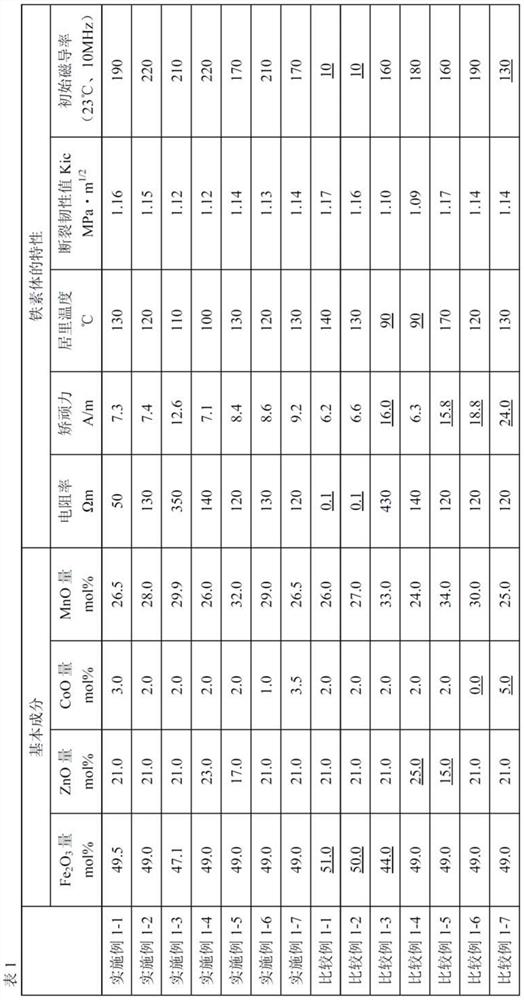

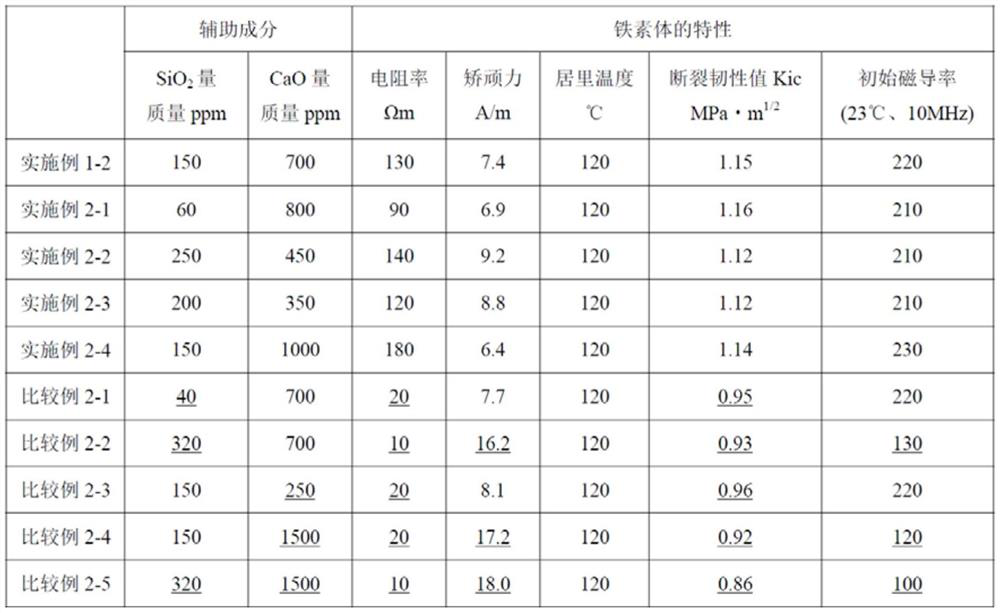

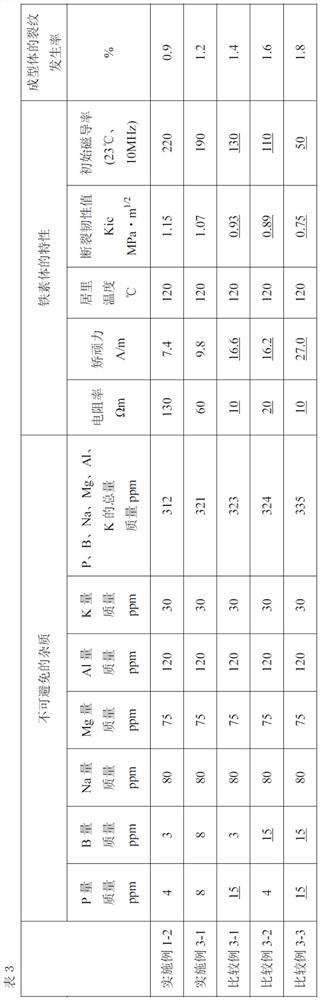

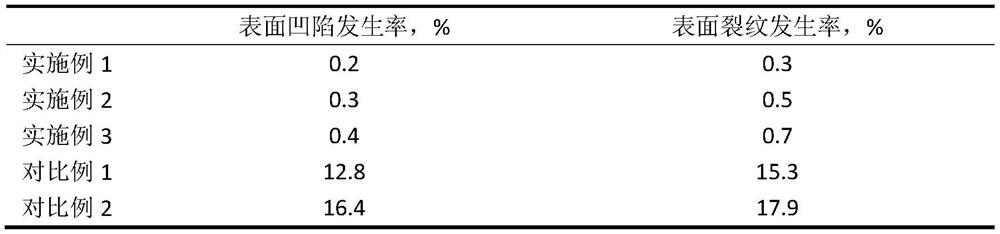

MnCoZn-based ferrite

ActiveCN114269709AReduce the incidence of cracksExcellent mechanical propertiesInorganic material magnetismIron compoundsInitial permeabilityCurie temperature

The invention provides a MnCoZn-based ferrite and a manufacturing method thereof. The MnCoZn-based ferrite has excellent mechanical properties in which a flat plate-shaped magnetic core has a fracture toughness value of 1.00 MPa.m1 / 2 or more as measured in accordance with JIS R1607, and excellent magnetic properties in which the resistivity is 30 [Omega] .m or more, the Curie temperature is 100 DEG C or more, the coercive force of a toroidal magnetic core produced under the same conditions is 15.0 A / m or less, and the initial permeability value at 23 DEG C and 10 MHz is 150 or more. The MnCoZn ferrite is composed of a basic component, an auxiliary component and unavoidable impurities, and the contents of P, B, Na, Mg, Al and K in the unavoidable impurities are respectively controlled to be as follows: P: less than 10 ppm by mass; b: less than 10 ppm by mass; less than 200 ppm by mass of Na; mg: less than 200 mass ppm; al: less than 250 ppm by mass, and K: less than 100 ppm by mass.

Owner:JFE CHEMICAL CORP +1

Continuous casting crystallizer casting powder for high-grade silicon steel as well as preparation method and application of continuous casting crystallizer casting powder

ActiveCN114012049AReduce saggingReduce the incidence of cracksProcess efficiency improvementChemical compositionSilicon

The invention relates to the technical field of metallurgy, in particular to continuous casting crystallizer casting powder for high-grade silicon steel as well as a preparation method and application of the continuous casting crystallizer casting powder. The continuous casting crystallizer casting powder provided by the invention comprises the following chemical components in percentage by mass: 40 to 45 percent of SiO2, 20 to 27 percent of CaO, 1.0 to 2.5 percent of MgO, 1 to 3 percent of Al2O3, 12 to 16 percent of Na2O, 10 to 13 percent of F, 1 to 3 percent of C and the balance of inevitable impurities. The binary alkalinity CaO / SiO2 of the casting powder ranges from 0.5 to 0.6, the melting point of the casting powder ranges from 950 DEG C to 1000 DEG C, and the viscosity of the casting powder at the temperature of 1300 DEG C ranges from 0.25 Pa.s to 0.35 Pa.s. According to the continuous casting crystallizer casting powder provided by the invention, through the low-alkalinity, low-melting-point and low-viscosity casting powder, the phenomenon that the surface of a casting blank is easy to sink and crack during continuous casting of a high-grade silicon steel material can be effectively inhibited.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

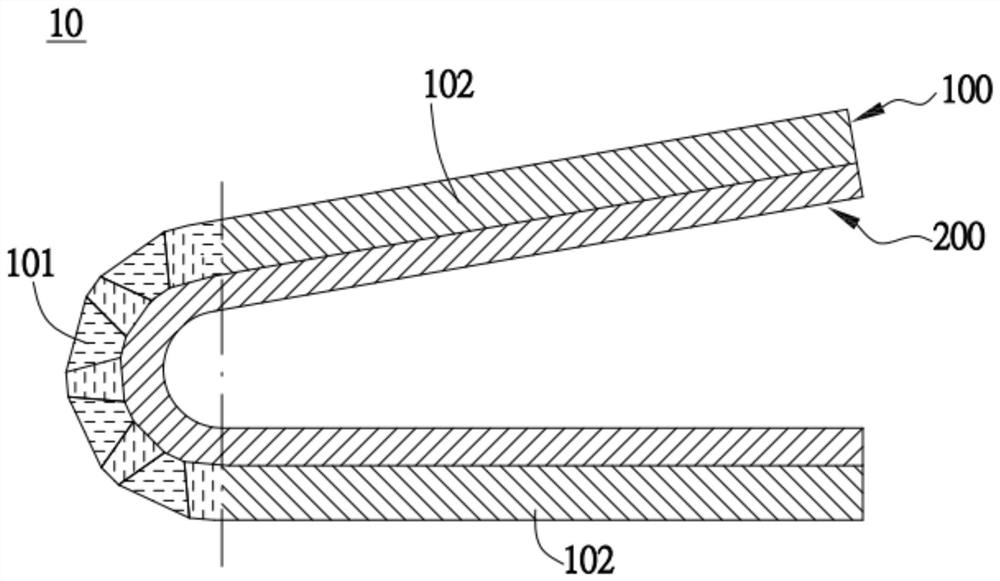

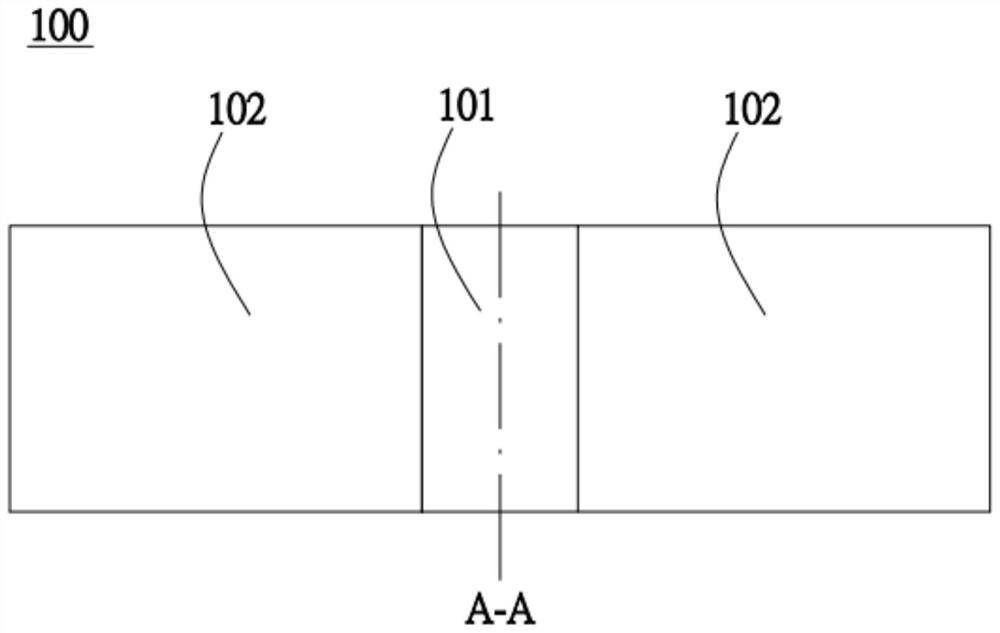

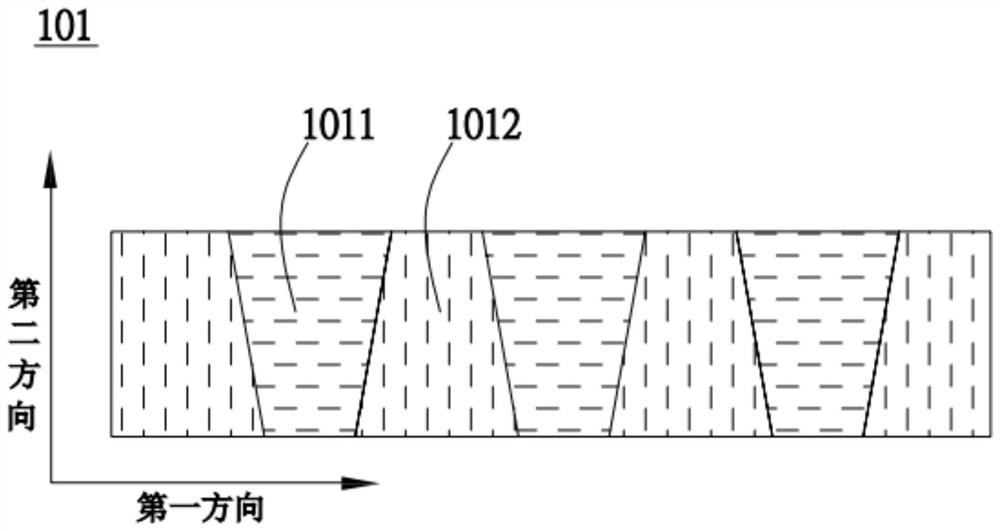

Flexible display panel and display device

ActiveCN110265438BReduce the incidence of cracksExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceStructural engineering

The present disclosure provides a flexible display panel and a display device. The flexible display panel includes a flexible substrate and a backplane disposed on the back of the flexible substrate. The backplane includes a bending area and a A non-bending area, wherein the bending area includes a plurality of first bending areas and a plurality of second bending areas, and a plurality of the first bending areas and a plurality of the second bending areas are alternately arranged, And the hardness of the first bending area is greater than the hardness of the second bending area, ensuring that the bending area of the back plate has a certain hardness to support the flexible display panel, while the second The material of the bending area is an elastic material, which effectively relieves the stress concentration, thereby reducing the occurrence rate of cracks on the flexible display panel, and improving the service life and performance of the flexible display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com