Test method for improving surface quality of microalloyed steel continuous casting slab

A surface quality, micro-alloyed steel technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of not considering temperature fluctuations, etc., to reduce the incidence of cracks and improve the surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further explained and described below in conjunction with the description of the drawings and specific embodiments, but the explanation and description do not constitute an improper limitation on the technical solution of the present invention.

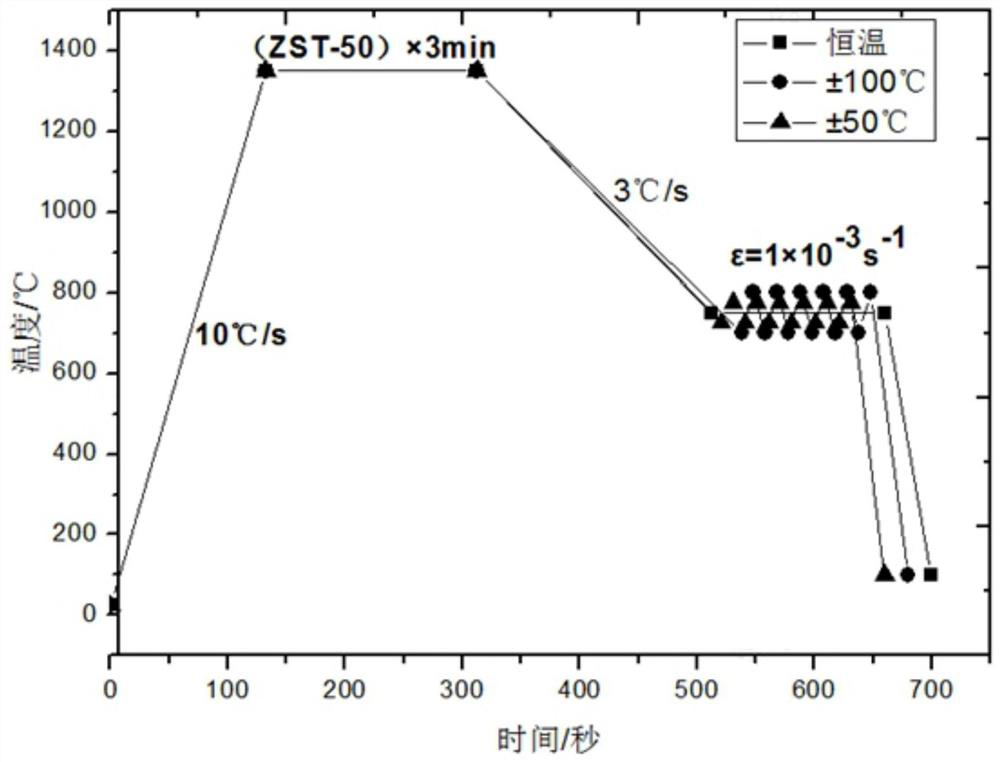

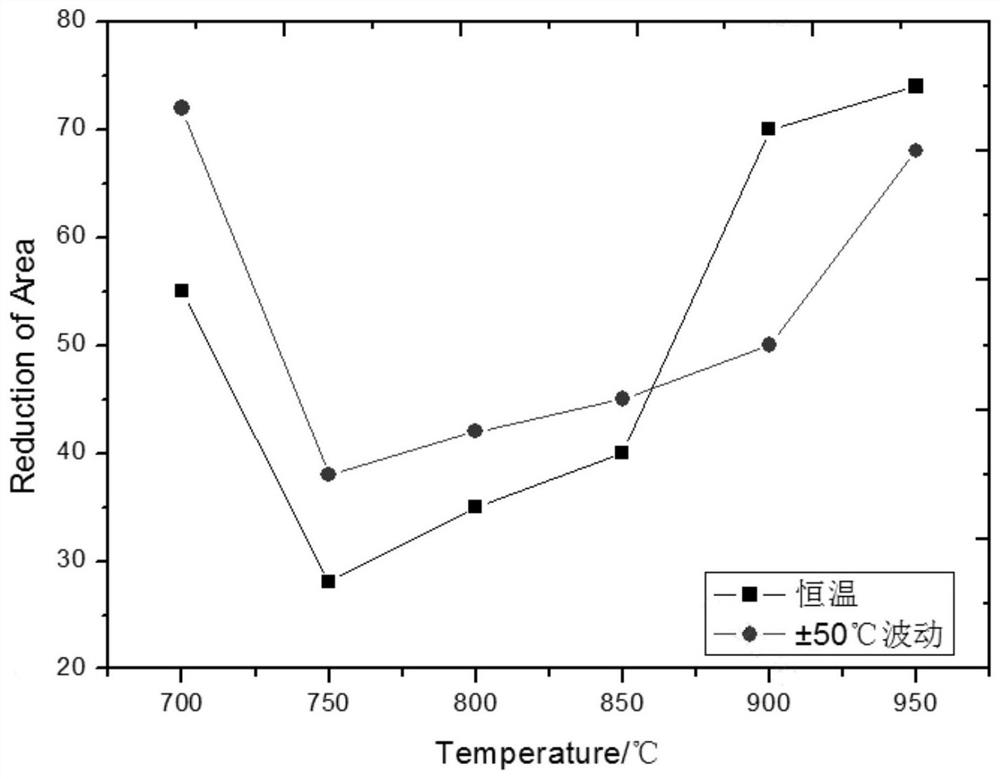

[0021] Select the micro-alloy steel plate A, process it into the size of high-temperature tensile sample, measure the high-temperature thermoplasticity under different processes by high-temperature tensile on the Gleeble-3800 thermal simulation testing machine, install the sample according to the steps, and put Ar protection after vacuuming. Run the program until the sample is broken, measure and calculate the reduction of area at the fracture of each broken sample.

[0022] Considering the temperature range of the actual continuous casting slab in the straightening area, the experimental temperature range is set at 700-1000°C, one point is taken every 50°C for the conventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com