Fault Diagnosis Method of Tension and Correction Force in Segment of Continuous Casting Machine

A continuous casting machine segment and fault diagnosis technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as difficult to find faults in the budding stage, blind spots in the field of view, and untimely fault detection, etc., to achieve Reduce the amount of change and failure time, improve the force condition of the slab, and improve the quality of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Diagnosis object:

[0032] The first and second strands simultaneously cast the slab with a section of 230×1900.

[0033] 2. Diagnostic method:

[0034] S1. Use the industrial control software wincc to establish a fault diagnosis system;

[0035] S1.1 Establish the state parameter database of tension leveling machine equipment;

[0036] Through the statistics of the total tension and straightening force of various cross-section cast slabs poured by the continuous casting machine, the database of the total tension and straightening force of the tension leveling machine is established as shown in the following table:

[0037]

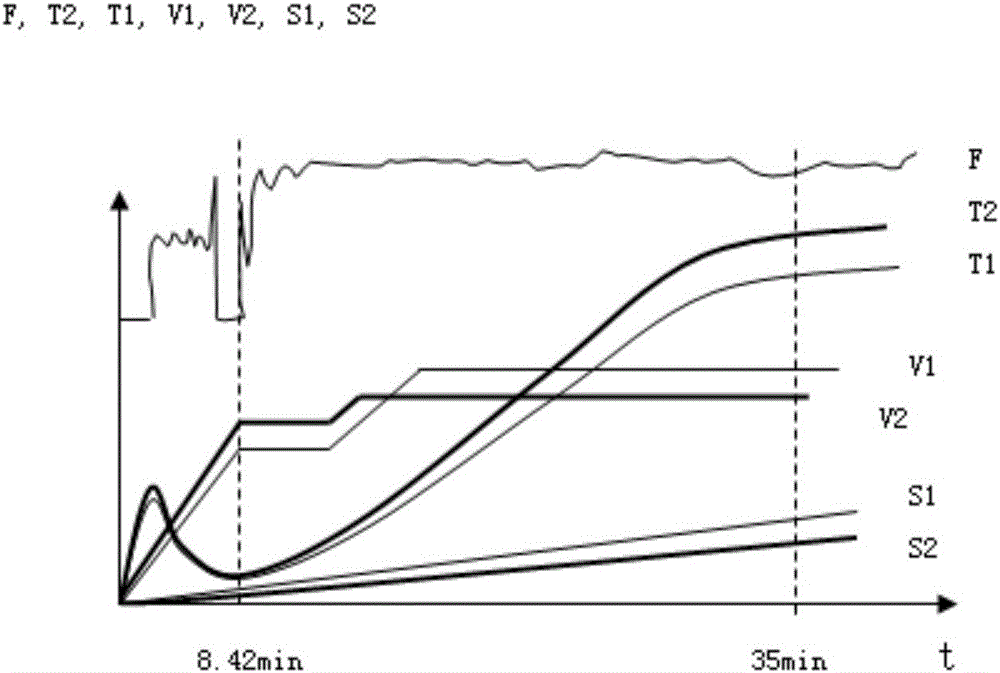

[0038] S1.2 Draw the pulling speed curve;

[0039] Taking 0-3m / min as the coordinate domain, according to the measured data, respectively draw the first-flow pulling speed curve V1 and the second-flow pulling speed curve V2;

[0040] S1.3 Draw the total tensile force curve;

[0041] Taking 0-1200kN as the coordinate domain, according to ...

Embodiment 2

[0049] 1. Diagnosis object:

[0050] The first and second strands simultaneously cast the slab with a section of 230×1800.

[0051] 2. Diagnostic method:

[0052] S1. is identical with embodiment one;

[0053] S2 checks whether there are hidden dangers;

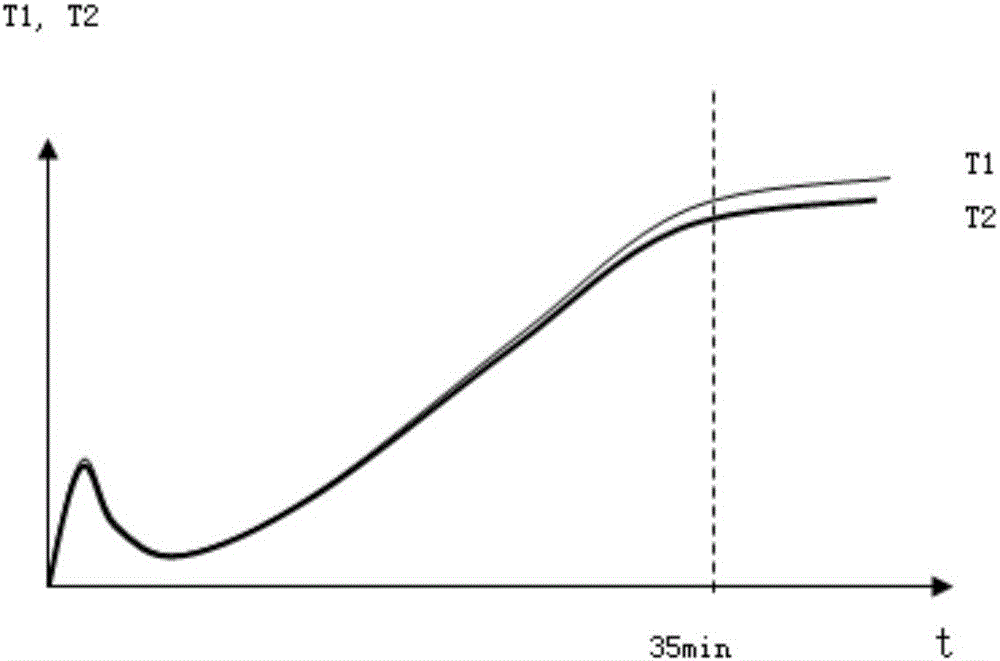

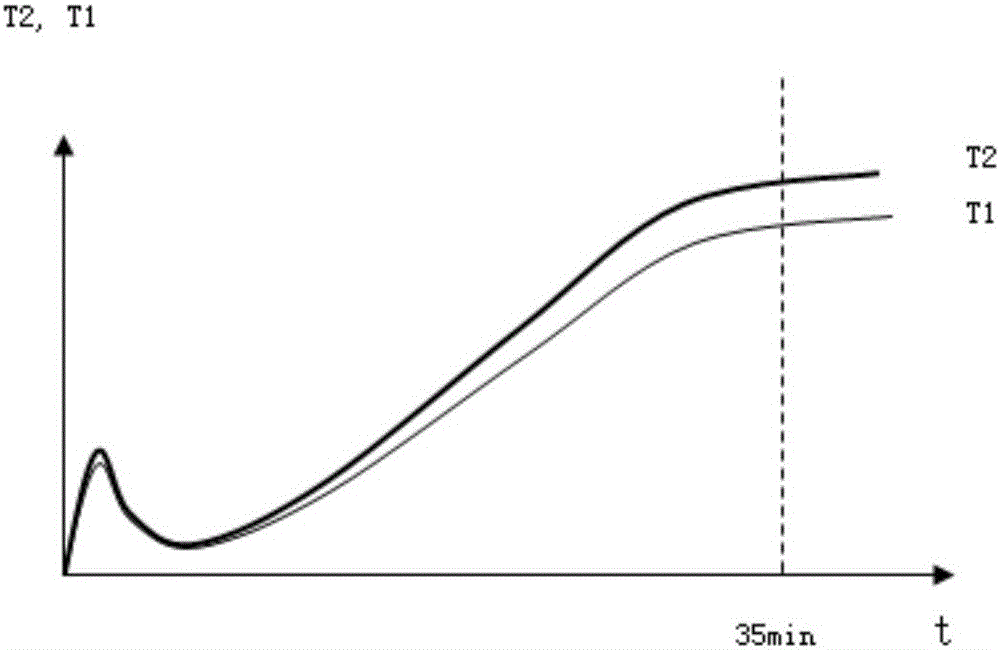

[0054] The total tensile force curve T1 of the first stream and the total tensile force curve T2 of the second stream drawn in step S1.3 are as follows figure 2 shown in figure 2 Find the time corresponding to the time when the total tensile force curve T1 of the first stream and the total tensile force curve T2 of the second stream both start to be stable is t 1 =35min, read t respectively 1 The total tensile force of the first stream and the total tensile force of the second stream at =35min, the total tensile force of the first stream is 845kN, and the total tensile force of the second stream is 910kN, of which the total tensile force of the second stream has exceeded the database The corresponding total tensile fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com