MnCoZn-based ferrite

A ferrite, fe2o3 technology, applied in the direction of magnetic objects, iron compounds, cobalt compounds, etc., can solve the problems of easy damage and achieve good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

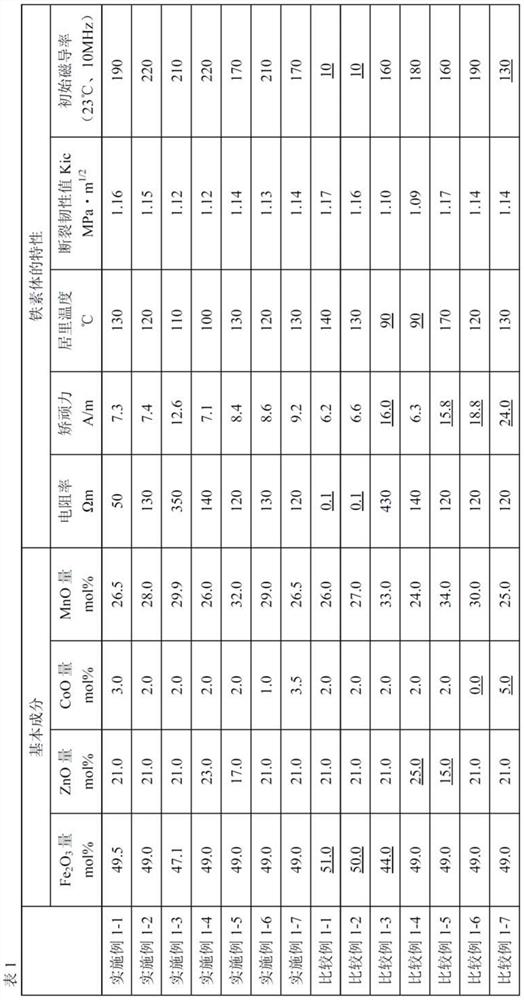

Embodiment 1

[0098] Fe, Zn, Co and Mn are all contained in Fe 2 o 3 , ZnO, CoO and MnO, weigh each raw material powder to make Fe 2 o 3 , ZnO, CoO and MnO ratios are shown in Table 1. Mix with a ball mill for 16 hours, then calcined in air at 900° C. for 3 hours, and cool in air for 1.5 hours to room temperature to obtain calcined powder. Next, SiO corresponding to 150 mass ppm and 700 mass ppm were weighed, respectively. 2 and CaO were added to the above-mentioned calcined powder, and pulverized using a ball mill for 12 hours to obtain a pulverized powder. Polyvinyl alcohol was added to the pulverized powder for spray-drying and granulation, and a pressure of 118 MPa was applied to form annular magnetic cores and flat magnetic cores. After that, it was visually confirmed that there were no cracks in these molded bodies, and the molded bodies were put into a firing furnace, and fired at a maximum temperature of 1320° C. for 2 hours in an air flow of a proper mixture of nitrogen and ai...

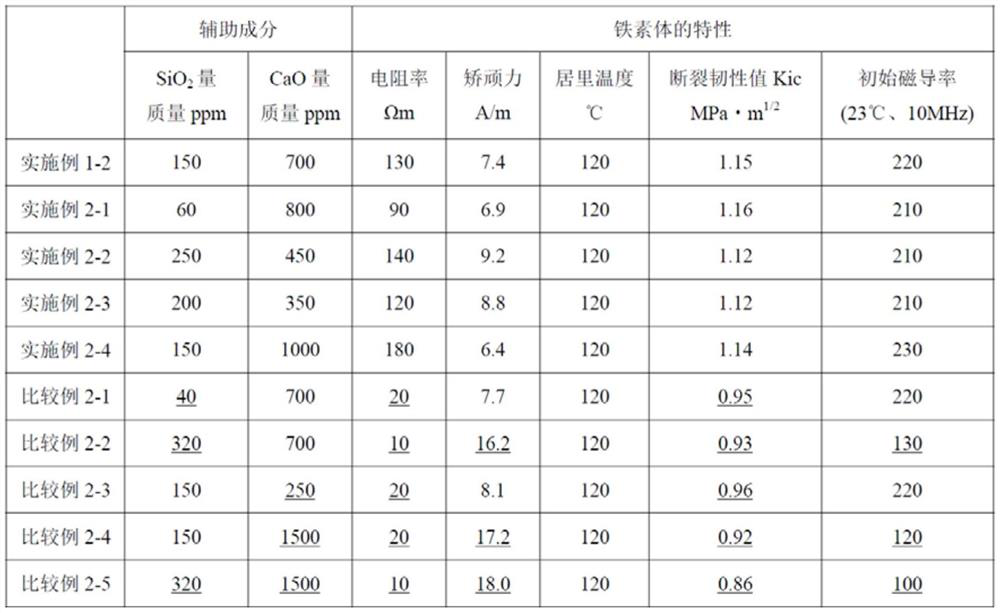

Embodiment 2

[0108] Convert all contained Fe, Zn, Co and Mn into Fe 2 o 3 , ZnO, CoO and MnO, weigh each raw material to make Fe 2 o 3: 49.0 mol%, CoO: 2.0 mol%, ZnO: 21.0 mol%, MnO: 28.0 mol%. Mix with a ball mill for 16 hours, then calcined in air at 900° C. for 3 hours, and cool in air for 1.5 hours to room temperature to obtain calcined powder. Next, the amount of SiO shown in Table 2 2 and CaO were added to the above-mentioned calcined powder, and pulverized using a ball mill for 12 hours to obtain a pulverized powder. Polyvinyl alcohol was added to the pulverized powder for spray-drying and granulation, and a pressure of 118 MPa was applied to form annular magnetic cores and flat magnetic cores. Thereafter, these compacts were visually confirmed to be free of cracks, inserted into a firing furnace, and fired at a maximum temperature of 1320° C. for 2 hours in an air stream of a proper mixture of nitrogen and air to obtain an outer diameter of 25 mm and an inner diameter of 15 mm...

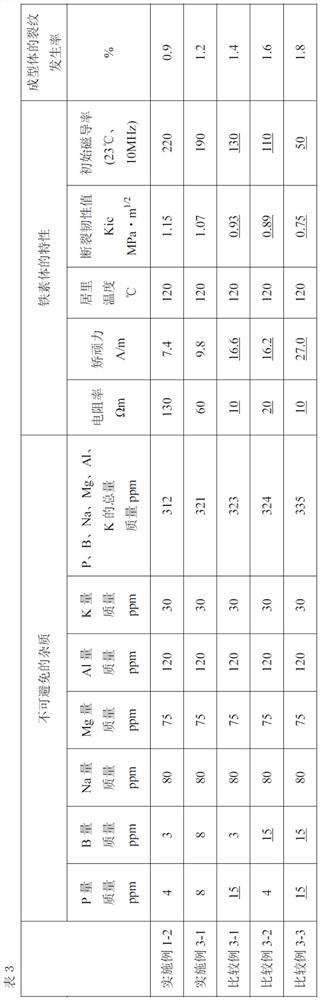

Embodiment 3

[0116] According to the method shown in Example 1, granulated powders were obtained by using raw materials having the same composition ratios of basic components and auxiliary components as in Example 1-2 but containing different amounts of P and B. A pressure of 118 MPa was applied to shape the granulated powder into ring-shaped magnetic cores and flat-shaped magnetic cores. Thereafter, these compacts were visually confirmed to be free of cracks, inserted into a firing furnace, and fired at a maximum temperature of 1320° C. for 2 hours in an air stream of a proper mixture of nitrogen and air to obtain an outer diameter of 25 mm and an inner diameter of 15 mm. , Height: 5mm sintered ring magnetic core and length: 4mm, width: 35mm, thickness: 3mm sintered flat magnetic core.

[0117] For each of the above samples, their characteristics were evaluated using the same method and equipment as in Example 1, respectively. The obtained results are shown in Table 3.

[0118] In addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com