Honeycomb-like SCR denitration catalyst and preparation method thereof

A technology of denitrification catalyst and honeycomb type, which is applied in the field of SCR honeycomb type denitrification catalyst and its preparation, can solve the problems of weak toughness of the green body, cracks, and influence on the mechanical strength of the finished product, and achieve the improvement of mechanical strength and the reduction of crack generation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

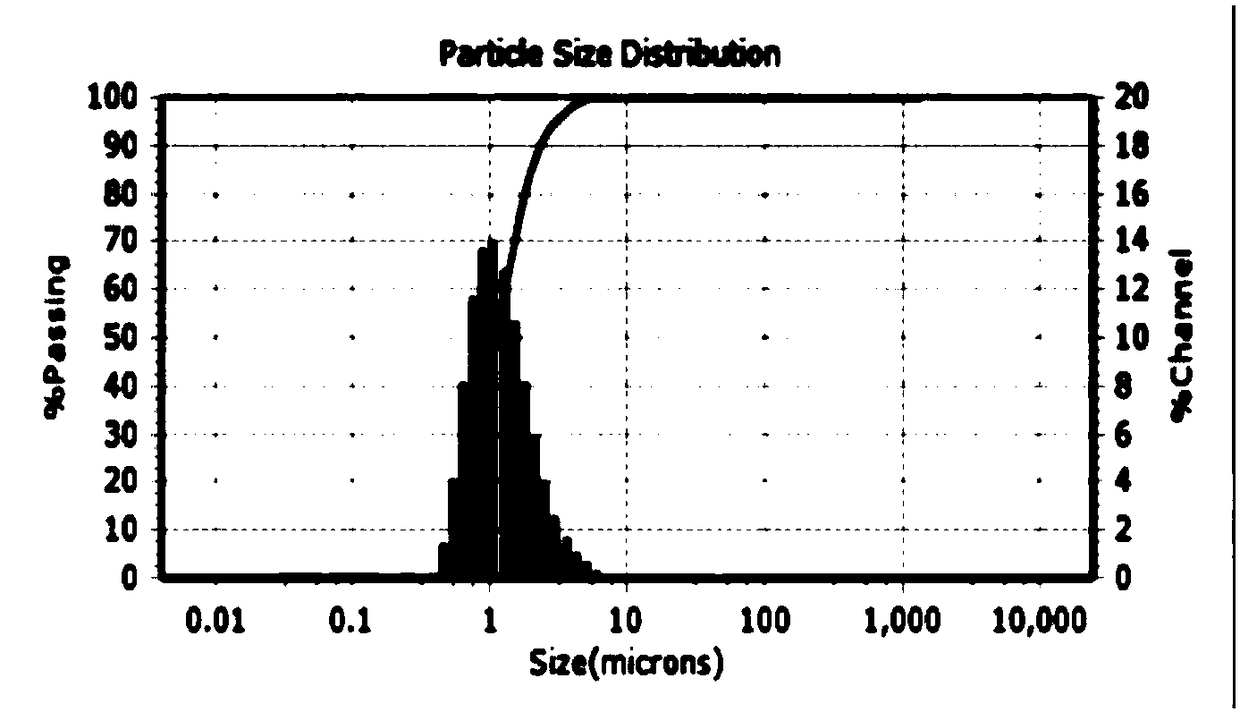

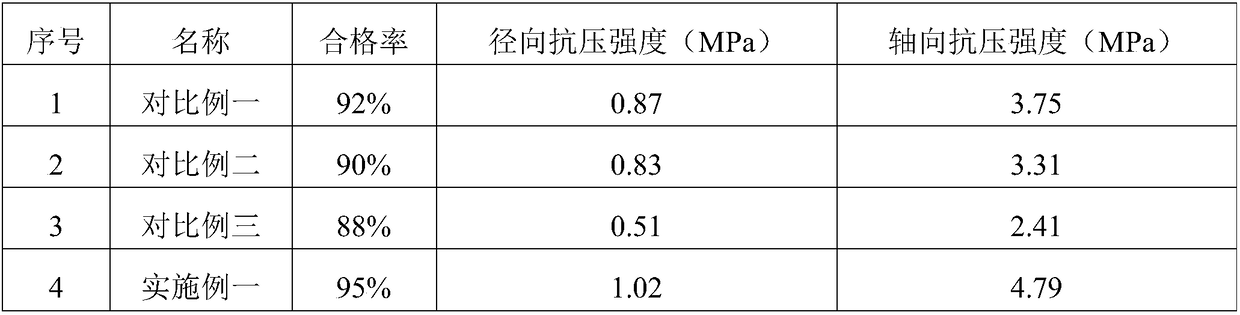

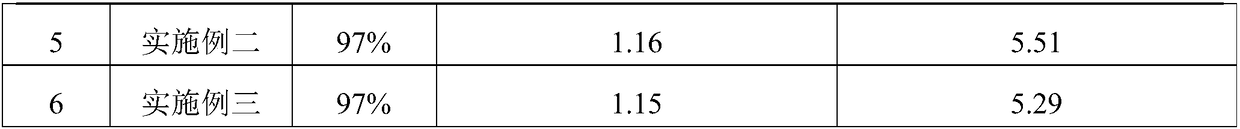

[0041] Put 1000kg titanium dioxide, 80kg carboxymethyl cellulose and 50kg polyoxyethylene into the mixer and mix thoroughly, add 80kg of Rp-chop and glass fiber in total, stir for 5min, the speed is 200r / min, and the particle size of titanium dioxide is d 10 = 0.56um, d 50 =1.27um, d 90 =3.64um, fiber diameter R=7um, distribution of fiber length L: 8kg for 3mm fiber, 64kg for 7mm fiber, and 8kg for 20mm fiber. Add 500kg deionized water, 50kg ammonium metavanadate, 100kg ammonium metatungstate, 300kg ammonia water, 100kg lactic acid, 10kg cerium nitrate hydrate, 1kg praseodymium nitrate hydrate, stir for 25min; turn on the dehumidifier, dehumidify for 35min, and finally get The material moisture content is 26.2%. The material is extruded through the filter plate with SCR porous catalyst wet embryo to filter, and the material whose particle size is smaller than the mesh of the filter plate is left, and the filtered material is subjected to mud treatment; the processed material...

Embodiment 2

[0043] In the present embodiment, the fiber selected to add is 90kg of wood pulp and glass fiber, wherein the particle size of titanium dioxide is d 10 =0.67um, d 50 =1.12um, d 90 =2.37um, the diameter R of the fiber=7um, the distribution of the fiber length L is: 3.5mm fiber 23kg, 6.5mm fiber 45kg, 12mm fiber 22kg, all the other are the same as embodiment one.

Embodiment 3

[0045]In the present embodiment, the fiber selected to add is a total of 80kg of Rp-chop, wood pulp and glass fiber, wherein the particle size of titanium dioxide is d 10 =0.64um, d 50 =1.08um, d 90 =2.21um, the diameter R of the fiber=7um, the distribution of the fiber length L is: 20kg of 3.5mm fiber, 40kg of 6mm fiber, 20kg of 12mm fiber, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com