Method for controlling triangular area cracks of continuous casting plain carbon steel slab

A common carbon steel, triangular area technology, applied in the configuration of manufacturing tools, casting equipment, indicating equipment/measuring equipment, etc., can solve problems such as triangular area cracks in continuous casting common carbon steel billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

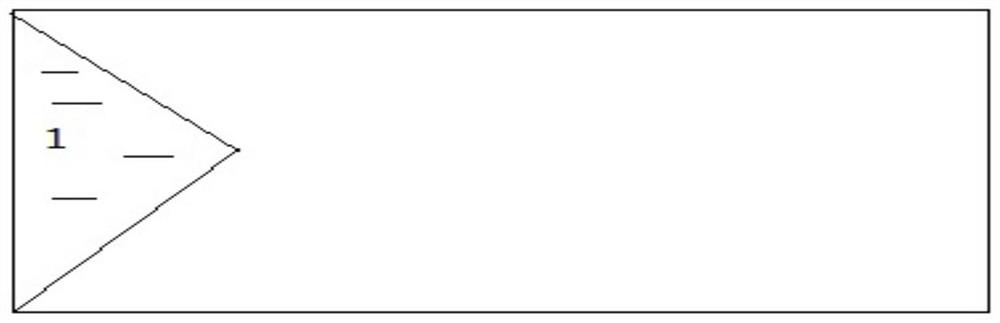

[0022] like figure 1 shown, figure 1 Schematic diagram of the triangular crack. Among them, the triangular crack 1 is in the triangular region of the slab cross-section, and the distance from the narrow surface is about 10-120 mm.

[0023] The technical scheme of the present invention is:

[0024] A method for controlling cracks in the triangle area of a continuous casting ordinary carbon steel slab, and the technical solution for controlling the cracks in the triangle area 1 is:

[0025] First, optimize the water volume on the narrow side of the mold and use strong cooling in the foot roller section. The specific method is: increase the water volume on the narrow side of the mold by 50-100L / min, and the heat flux ratio between the narrow side and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com