Welding method of sealed storage battery, sealed storage battery, and cap body

A welding method and battery technology, which can be applied to small-sized cells/battery packs, battery covers/end covers, welding equipment, etc., and can solve problems such as easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

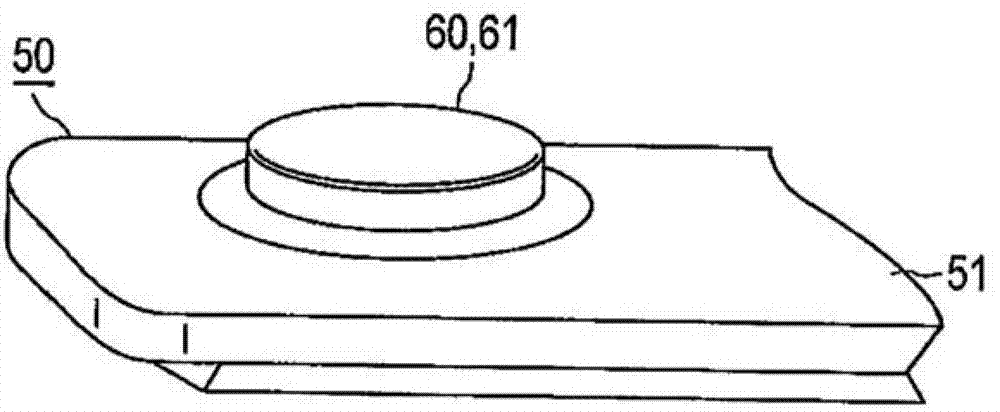

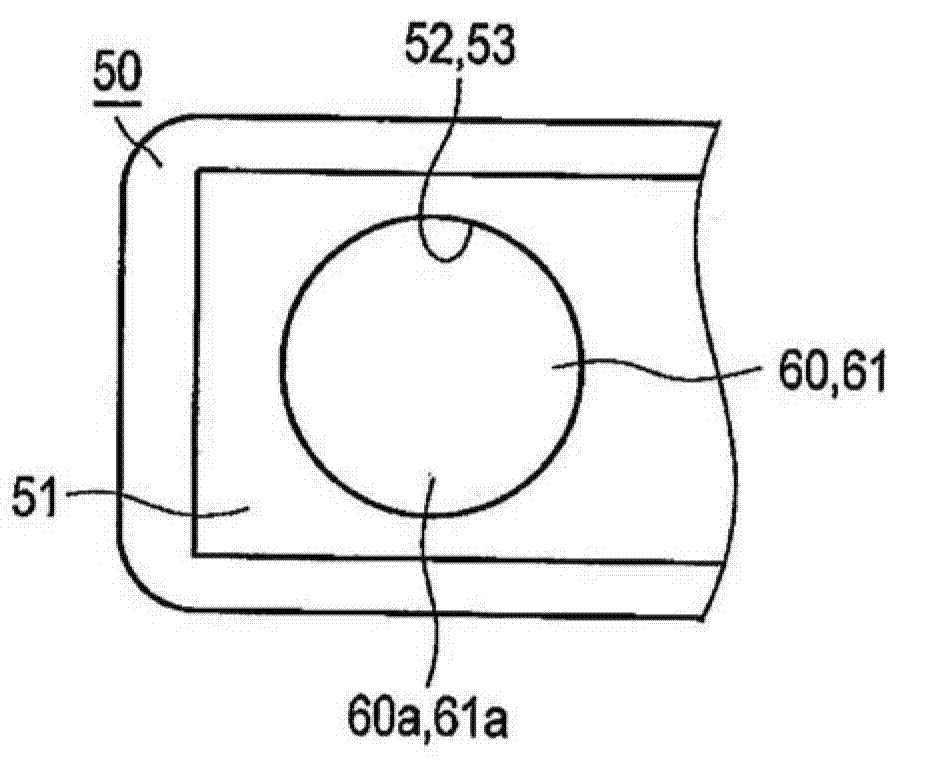

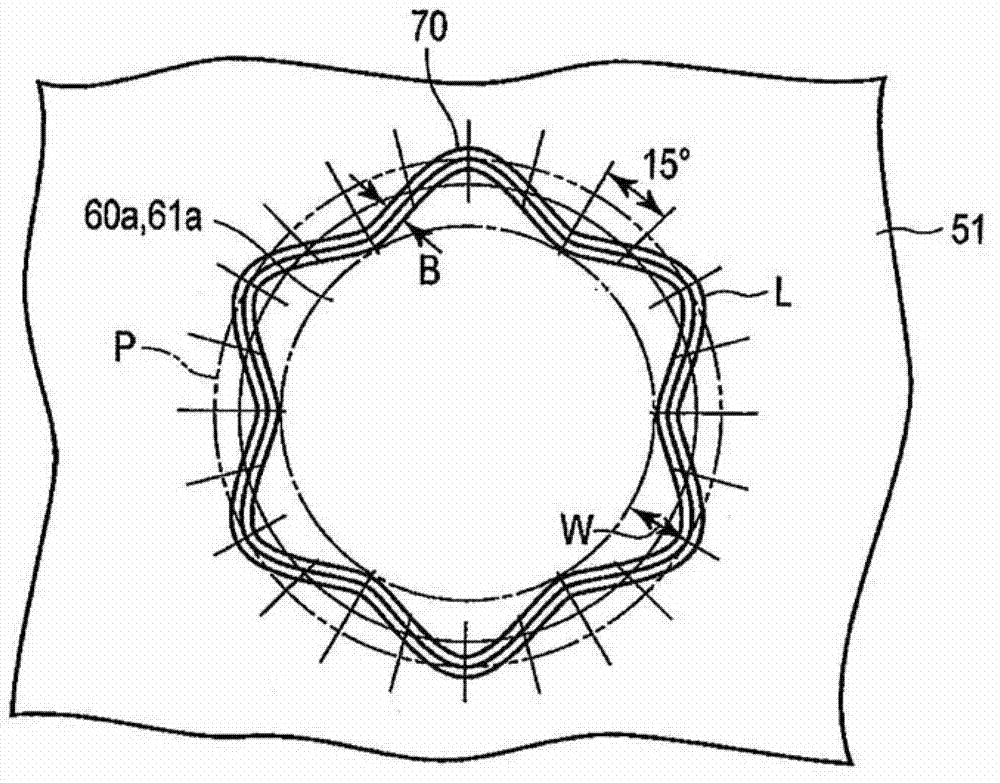

[0017] figure 1 is a perspective view showing the integration of the cover body 50 into the sealed secondary battery according to one embodiment. image 3 It is an explanatory diagram showing a terminal welding method for forming the cover body 50 . Figure 4 is an explanatory diagram showing the incident angle of the welding locus to the boundary line P and the crack length derived from the welding amplitude obtained from the experimental results.

[0018] The sealed type secondary battery is provided with a case having an opening portion on its upper portion and configured to enclose an electrolytic solution and a pair of electrodes therein; a cover body 50 configured to cover the case and a pair of terminals 60 and 61 connected to the pair of electrodes.

[0019] Such as figure 2 As shown, the cover body 50 is provided with a cover body 51 and terminals 60 , 61 made of an aluminum alloy material different from the material of the cover body 51 in terms of thermal diffus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com