Preparation method and forming die of annular sintered neodymium-iron-boron magnet

A molding die, NdFeB technology, applied in the direction of magnets, magnetic objects, inductors/transformers/magnets, etc., to achieve the effects of low density, improved utilization, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

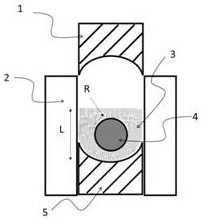

[0035] The preparation method of the ring-shaped sintered NdFeB magnet of the present invention, the preparation process of the magnet, comprises the preparation of the NdFeB flake alloy according to the quick-setting thin strip process, and the sintering of the NdFeB flake alloy through hydrogen treatment and jet milling process. For NdFeB powder, the powder is formed under the condition of pressure and parallel magnetic field for the first time, and the formed body is formed for the second time under the condition of liquid isostatic pressing, and then vacuum sintered and densified in a vacuum sintering furnace. Carry out heat treatment in a heat treatment furnace to obtain a rough blank.

[0036] The quick-setting thin strip process, the hydrogen treatment process, and the jet milling process of the aforementioned preparation process all adopt currently known or well-known technologies. The composition of the NdFeB powder refers to the commercially available general-purpose...

Embodiment 1

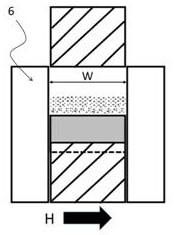

[0050] a) Prepare 20g of alumina powder and 40g of polyethylene glycol colloidal solution, mix and stir evenly, in a cylindrical rubber mold, isostatically press at 200Mpa, and dry at 120°C for 2h , prepare flexible cylindrical core, the diameter of this flexible cylindrical core is R1 is 4mm, and length W1 is 50mm;

[0051] b) In the loose state, pour 86g of powder into the forming mold, and the loose height L1 of the poured powder is 30mm;

[0052] c) Embed the flexible cylindrical core in the powder in a horizontal manner, so that its position in the height direction is at L1 / 2;

[0053] d) Close the indenter, and under the condition of a magnetic field of 1.5 Tesla, the powder and the core are integrally formed, and after demolding, a ring-shaped green body assembly is obtained;

[0054] e) After encapsulating the ring-shaped green body assembly, increase the density under 200Mpa hydroisostatic pressure;

[0055] f) Sintering and densifying the green body assembly in a v...

Embodiment 2

[0062] a) Prepare 36g of alumina powder and 40g of polyethylene glycol colloidal solution, mix and stir evenly, in a cylindrical rubber mold, isostatically press at 200Mpa, and dry at 120°C for 2h , preparing a flexible cylindrical core, the diameter of the flexible cylindrical core is R1 is 5mm, and the length W1 is 50mm;

[0063] b) In the loose state, pour 86g of powder into the forming mold, and the loose height L1 of the poured powder is 31mm;

[0064] c) Embed the flexible cylindrical core in the powder in a horizontal manner, so that its position in the height direction is at L1 / 2;

[0065] d) Close the indenter, and under the condition of a magnetic field of 1.5 Tesla, the powder and the core are integrally formed, and after demolding, a ring-shaped green body assembly is obtained;

[0066] e) After encapsulating the ring-shaped green body assembly, increase the density under 200Mpa hydroisostatic pressure;

[0067] f) Sintering and densifying the green body assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com