Chemically strengthened glass plate and preparation method thereof

A kind of glass plate, chemical technology, applied in the field of chemically strengthened glass plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

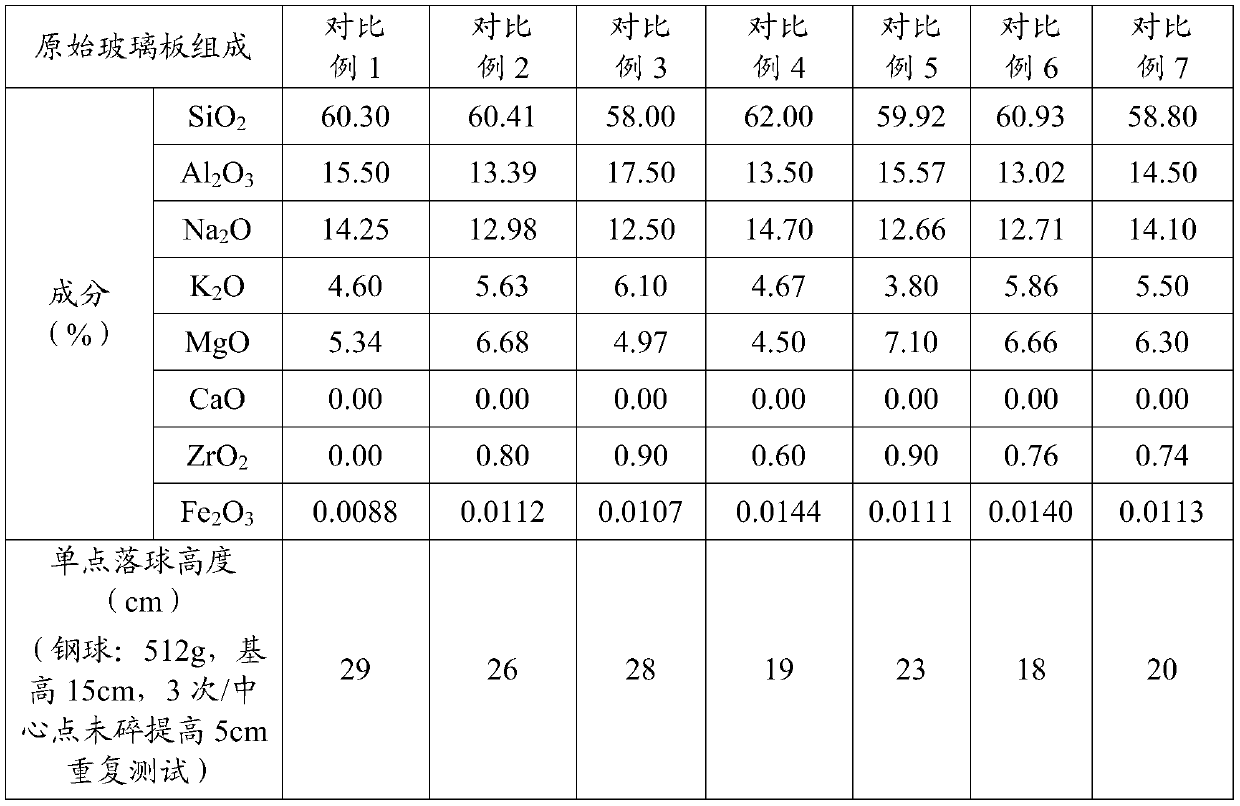

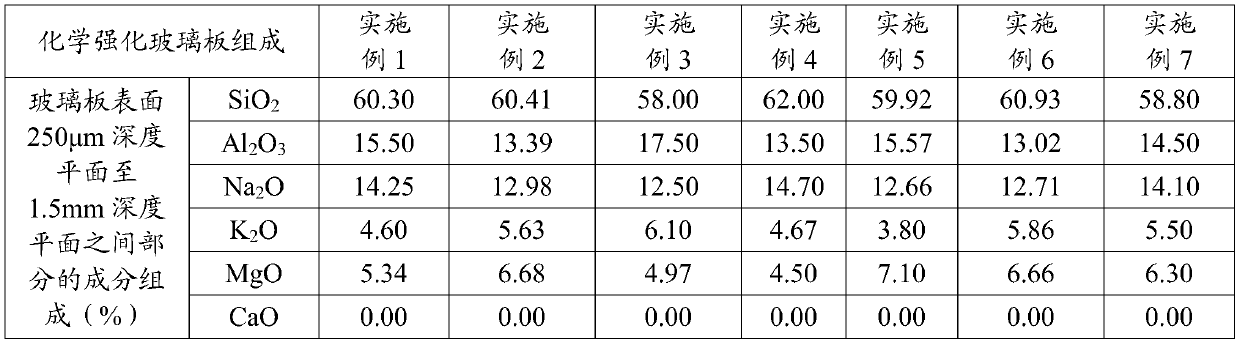

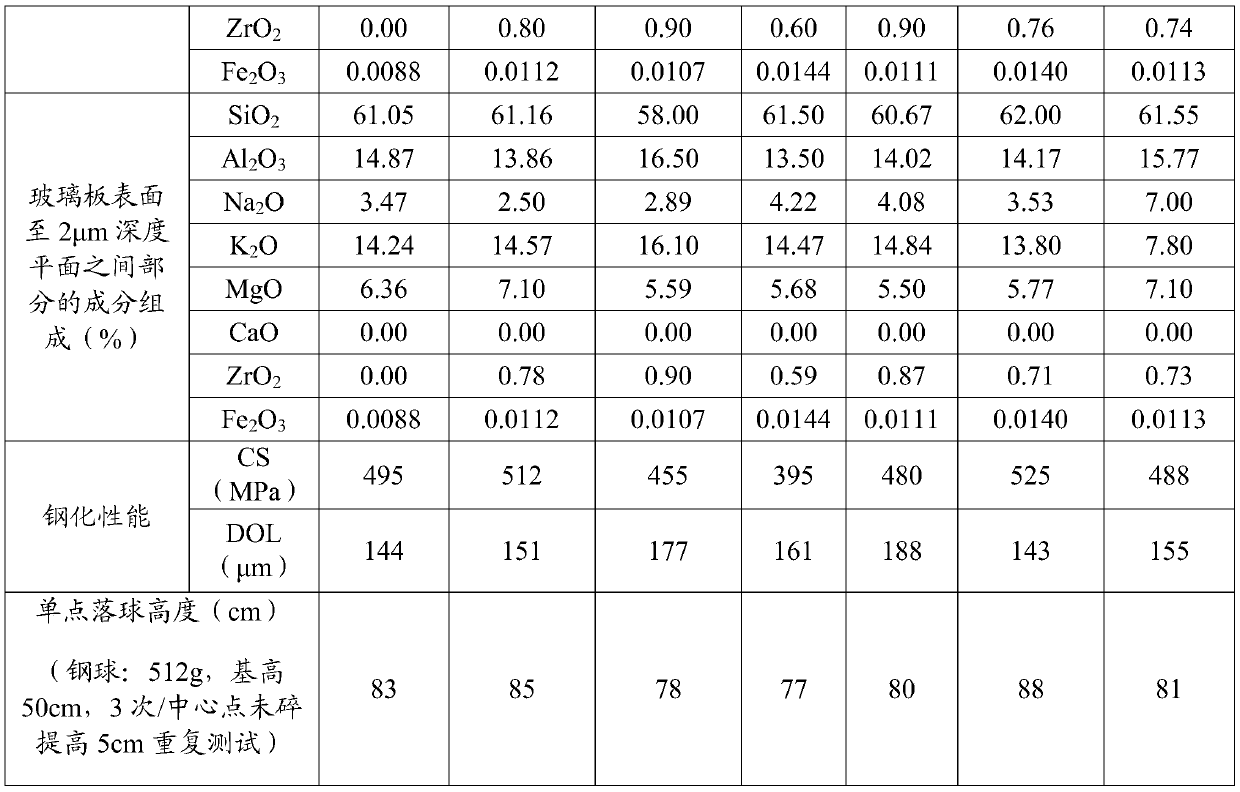

[0079] The following table 1 is the composition ratio combination of glass components involved in the following specific examples.

[0080] Table 1

[0081] Numbering

SiO 2

al 2 o 3

Na 2 o

K 2 o

MgO

CaO

ZrO 2

Fe 2 o 3

combination 1

60.30

15.50

14.25

4.60

5.34

0.00

0.00

0.0088

combination 2

60.41

13.39

12.98

5.63

6.68

0.00

0.80

0.0112

combination 3

58.00

17.50

12.50

6.10

4.97

0.00

0.90

0.0107

combination 4

62.00

13.50

14.70

4.67

4.50

0.00

0.60

0.0144

combination 5

59.92

15.57

12.66

3.80

7.10

0.00

0.90

0.0111

combination 6

60.93

13.02

12.71

5.86

6.66

0.00

0.76

0.0140...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com