Heat exchanger with corrugated pipe coil structure provided with internal duct and external duct

A technology of heat exchanger and bellows, which is applied in the field of heat exchangers, can solve the problems of no active air flow rate, large space occupation, and low heat exchange efficiency, and achieve integrated modularization, easy installation and portability, and heat exchange high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

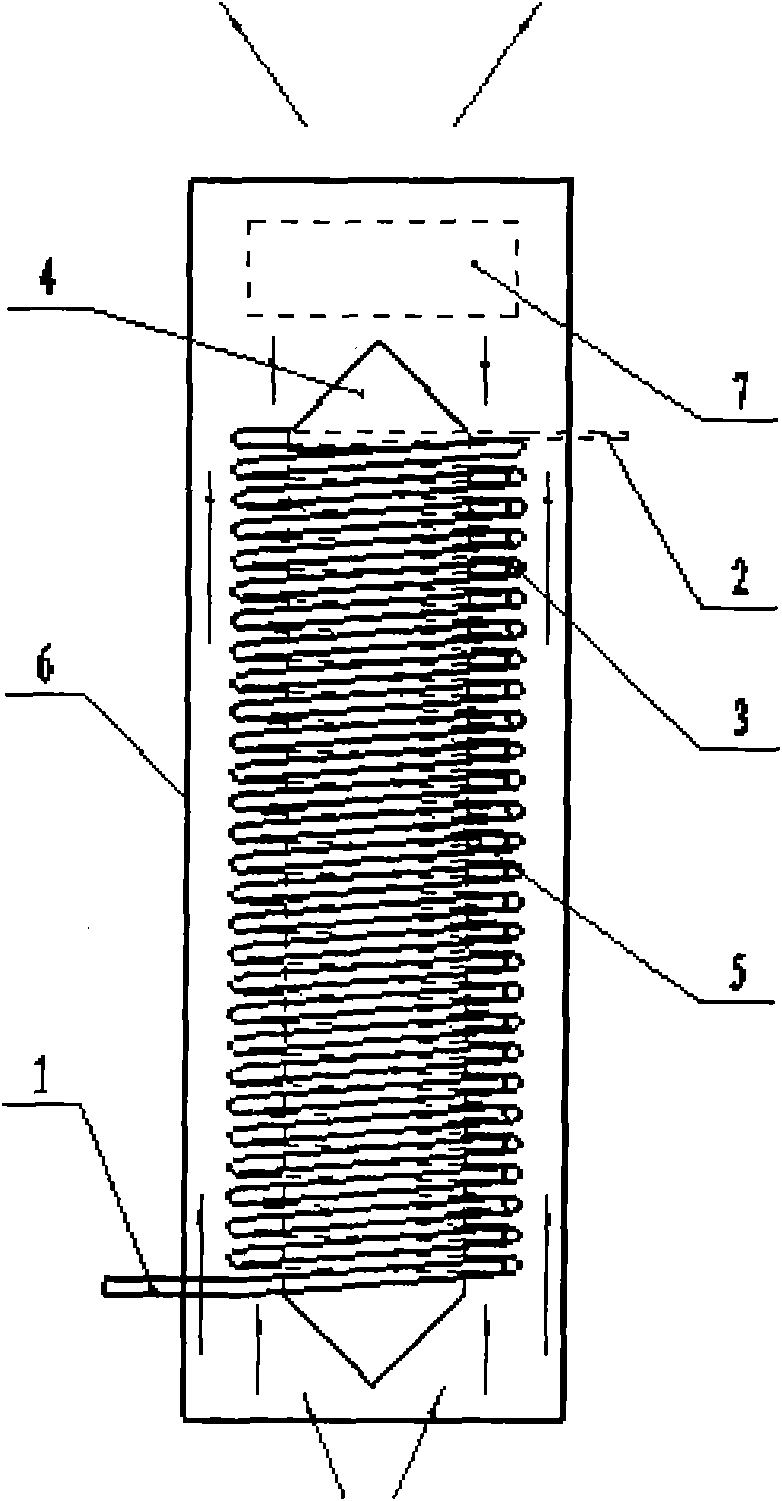

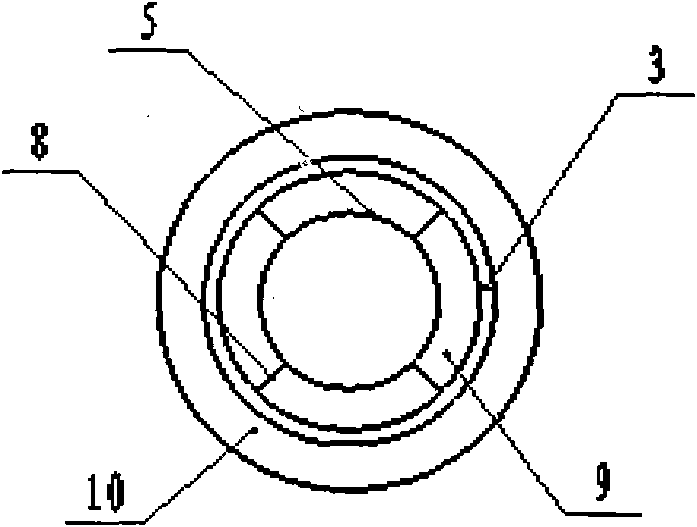

[0022] Embodiment 1: Taking the heat exchanger described in the present invention as an example for the heat dissipation of the electrolyte in the hydrogen-oxygen generator, the structure of the heat exchanger described in this embodiment is as attached figure 1 And attached figure 2 As shown, a heat exchanger with a corrugated coil structure with internal and external ducts consists of an inlet 1, an outlet 2, a bellows 3, a fairing 4, an inner ring sleeve 5, an outer ring sleeve 6, a fan 7, and a bracket 8 composition.

[0023] The bracket 8 is a group of raised brackets fixed on the outer wall of the inner ring sleeve 5 for fixing the bellows 3 to form a coil structure (see attached figure 2 ). The bellows 3 spirally surrounds the outer wall of the inner ring sleeve 5 through the bracket 8 (see attached figure 1 ), the inner ring duct 9 is formed between the outer wall of the inner ring sleeve 5 and the bellows 3, the bellows 3, the fairing 4, the inner ring sleeve 5, ...

Embodiment 2

[0034] Embodiment 2: Taking the heat exchanger of the present invention used in air-conditioning equipment as an example, the structure of the heat exchanger is the same as in Embodiment 1, the inner walls of the inlet 1 and outlet 2 are made of stainless steel, and the material of the bellows 3 is stainless steel. When the refrigerant (such as Freon, etc.) flows into the bellows 3 in the heat exchanger from the inlet 1, a turbulent flow is formed in the tube wall with a corrugated structure, and the air in the inner and outer ducts outside the bellows passes through the bellows wall and the bellows. For heat exchange, the fan 7 discharges the cooled air in the inner and outer ducts, and the refrigerant flows through the bellows 3 in a spiral manner and then is discharged from the outlet 2 to achieve the purpose of cooling the air. At this time, it flows through the outlet 2 The temperature of the refrigerant is higher than the temperature at the inlet 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com