Ultrafine EDM (Elctron Discharge Machining) machine tool

An electric discharge machining and ultra-fine technology, applied in the field of mechanical processing, can solve problems such as short circuit and arc discharge, processing stability and processing accuracy reduction, and difficulty in the flow of working fluid between electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

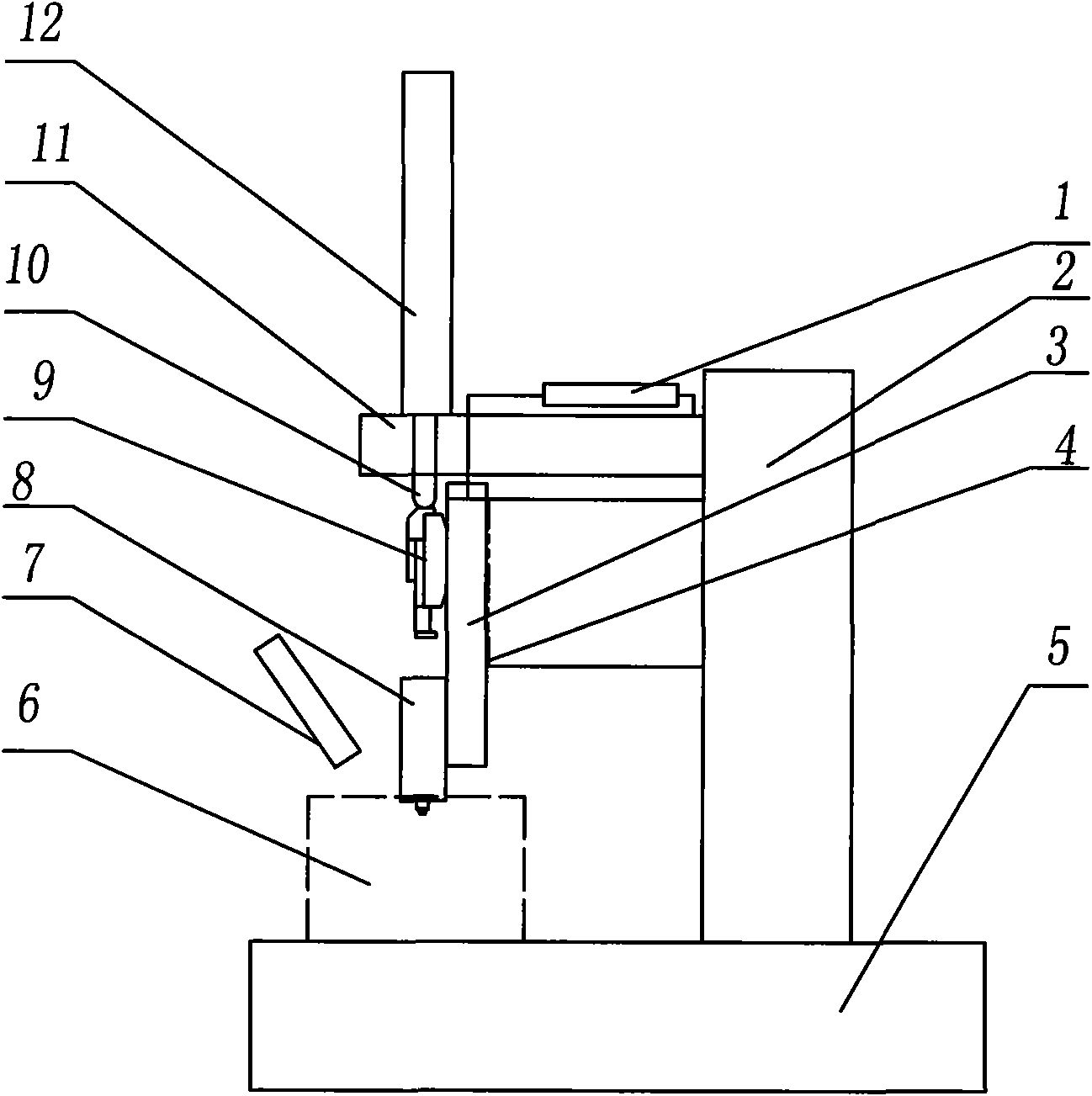

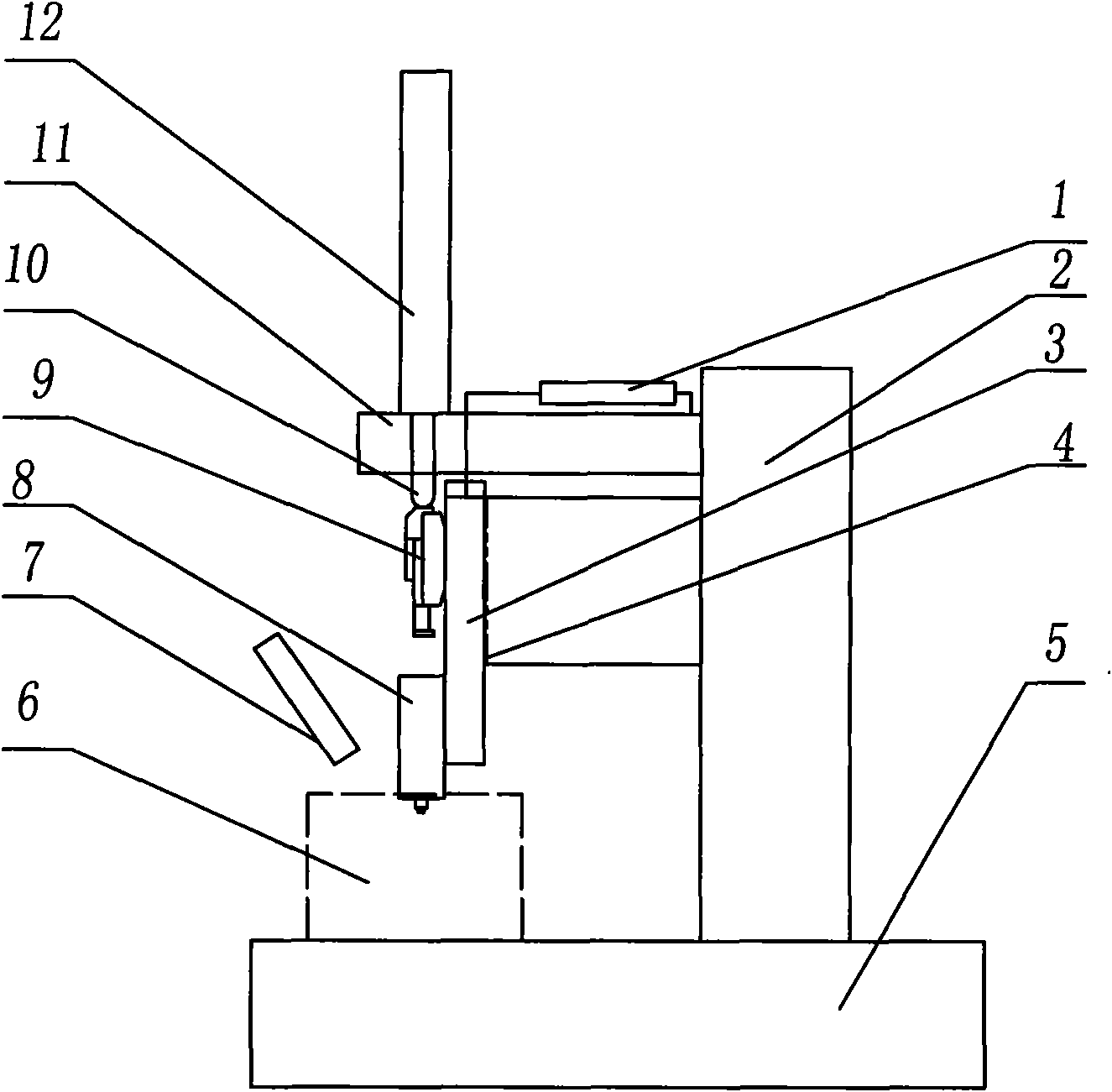

[0014] As shown in the figure: the ultra-fine EDM machine tool includes spring 1, machine body 2, connecting block 3, linear guide rail 4, machine base 5, working fluid tank 6, monitoring camera 7, rotating spindle 8, slide table 9, servo motor drive Shaft 10, top connecting plate 11, servo motor 12, fixing plate 13, etc.

[0015] The present invention comprises the machine tool main body 2 that is installed on the machine tool base 5, on the machine tool main body 2, a top connecting plate 11 and a fixed plate 13 are installed, and the fixed plate 13 is installed under the connecting plate 11, on the fixed plate 13 A linear guide rail 4 is provided; a servo motor 12 is installed on the upper end surface of the top connection plate 11, the servo motor 12 is connected with the servo motor transmission shaft 10, and the servo motor transmission shaft 10 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com