Nano manufacturing system

A manufacturing system and nanotechnology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of atomic particle alignment and control difficulties, difficulty in obtaining breakthroughs, and reduced resolution, etc., to achieve convenient structure graphics , small damage, and small processing scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

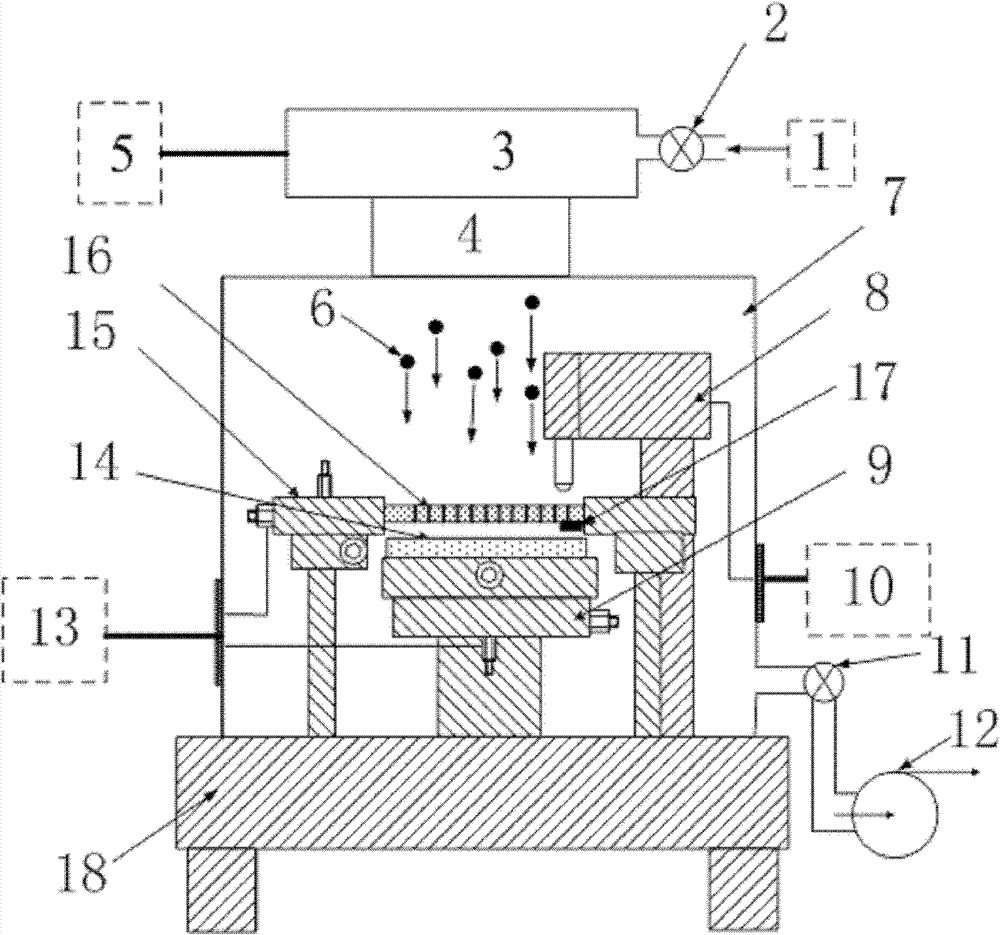

[0014] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] Referring to the accompanying drawings, a nano-manufacturing system includes an atomic particle generation system 3, the atomic particle generation system 3 communicates with the gas source 1 through a valve 2, and forms an atomic particle generation part; the atomic particle generation system 3 communicates with the atomic transport system 4 , the atom transport system 4 communicates with the vacuum studio 7, the vacuum studio 7 is placed on a stable workbench 18, the vacuum studio 7 is provided with a lifting and two-dimensional graphics scanning support 15, and a lifting and two-dimensional graphics scanning support 15 The upper end is provided with a nanohole array mask 16, a distance above the edge of the nanohole array mask 16 is an optical alignment system 8, and below the nanohole array mask 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com