Exhaust gas heat exchanger, in particular an exhaust gas cooler for exhaust gas recirculation in a motor vehicle

A technology of exhaust gas recirculation and exhaust gas cooler, which can be used in exhaust gas recirculation, heat exchange equipment, heat exchanger shells, etc., and can solve problems such as high space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

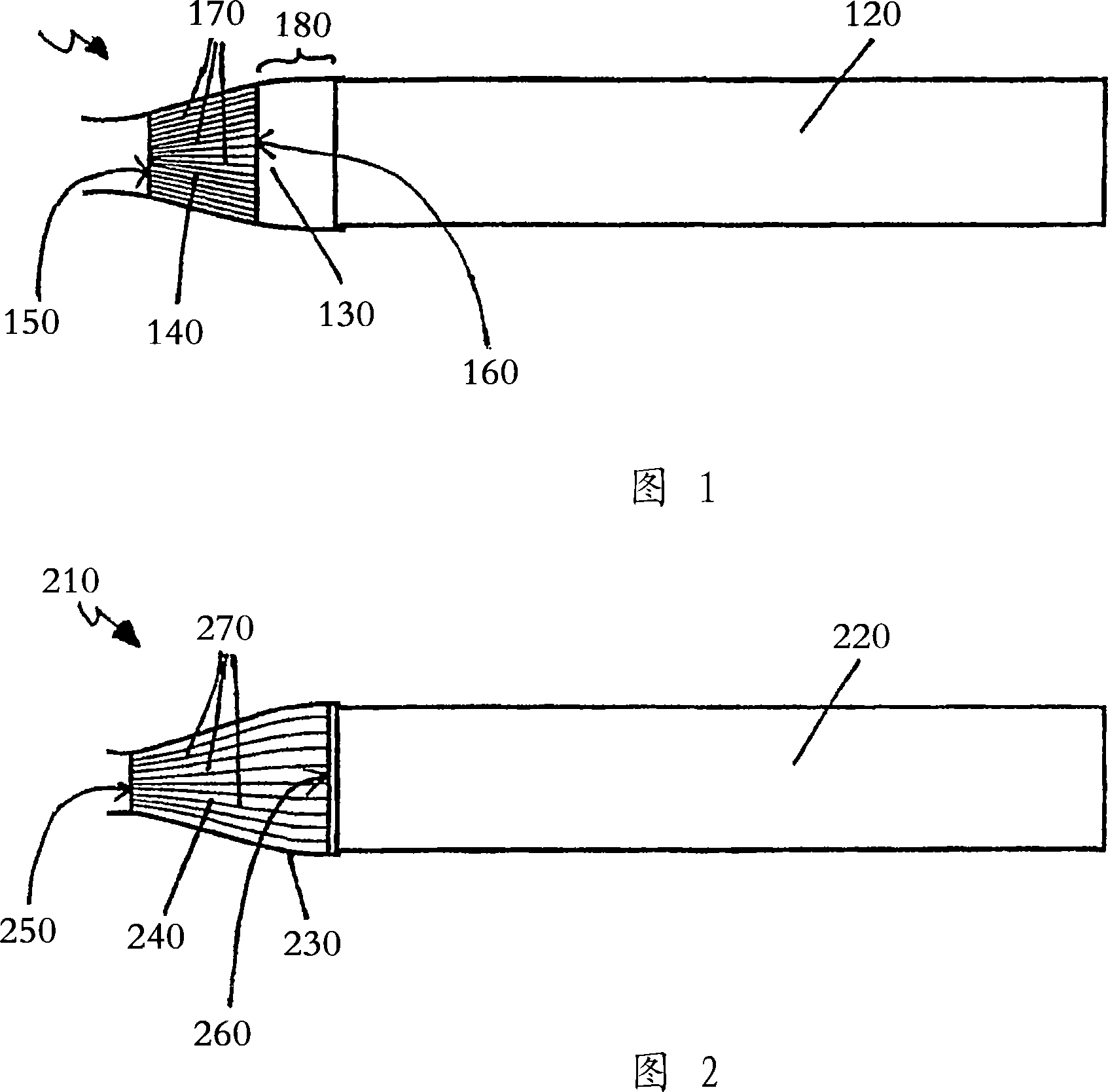

[0027] FIG. 1 shows a heat exchanger 110 with heat exchanger channels, not specifically shown, which are combined to form a heat exchanger assembly 120 , for example a tube bundle. The inflow side channel distribution chamber 130 of the heat exchanger channel is arranged in the distribution chamber with a flow guiding device 140 having a flat exhaust gas inlet surface 150 and a flat exhaust gas inlet surface 150 . Parallel exhaust gas outlet surfaces 160 . The distribution chamber 130 is welded or soldered to the heat exchanger assembly 120, for example.

[0028] A plurality of flow passages 170 extend from the exhaust gas intake face 150 to the exhaust gas discharge face 160 . The flow channels 170 are inclined relative to one another, so that the cross-section of the exhaust gas flow entering the exhaust gas heat exchanger 110 from the left in FIG. 1 is enlarged by means of the flow guiding device, wherein the exhaust gas flow is preferably additionally homogenized here.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com