Connection between cyclone separators and hearth of large-scale circulating fluidized bed boiler

A technology of cyclone separator and circulating fluidized bed, which is applied in the directions of fluidized bed combustion equipment, fuel burned in a molten state, combustion type, etc., can solve problems such as complexity, damage to furnace flue gas mixing, and performance degradation of cyclone separators. , to achieve the effect of reasonable particle concentration distribution, uniform flue gas flow distribution, and uniform flow distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

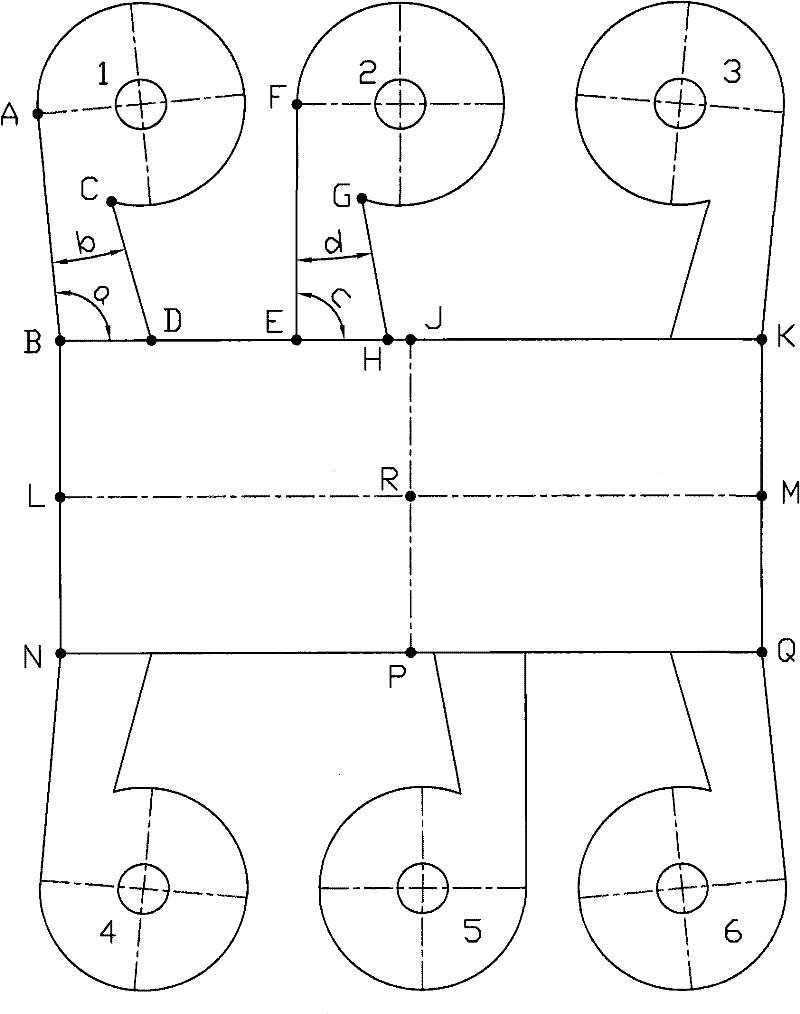

[0030] figure 1It is the top plan view of the large-scale circulating fluidized bed boiler furnace and six cyclone separators in Example 1 of the present invention. In the figure, the basic outline of the furnace and cyclone separators on the top view is indicated by a single line, which is the inner wall surface of the flue gas circulation. Parameters such as concrete structure and thickness of these wall surfaces have nothing to do with the task of the present invention, do not represent among the figure. The rectangle BKQN represents the cross-section of the furnace surrounded by four side walls. Sometimes the four corners of the furnace may have cut corners, and the cross-section can still be approximately considered as a rectangle.

[0031] The six cyclone separators are all composed of a cylinder body and an inlet flue, and the six cyclone separators are connected to the flue gas outlet of the furnace through their respective inlet flues. The cylinder structures and dim...

Embodiment 2

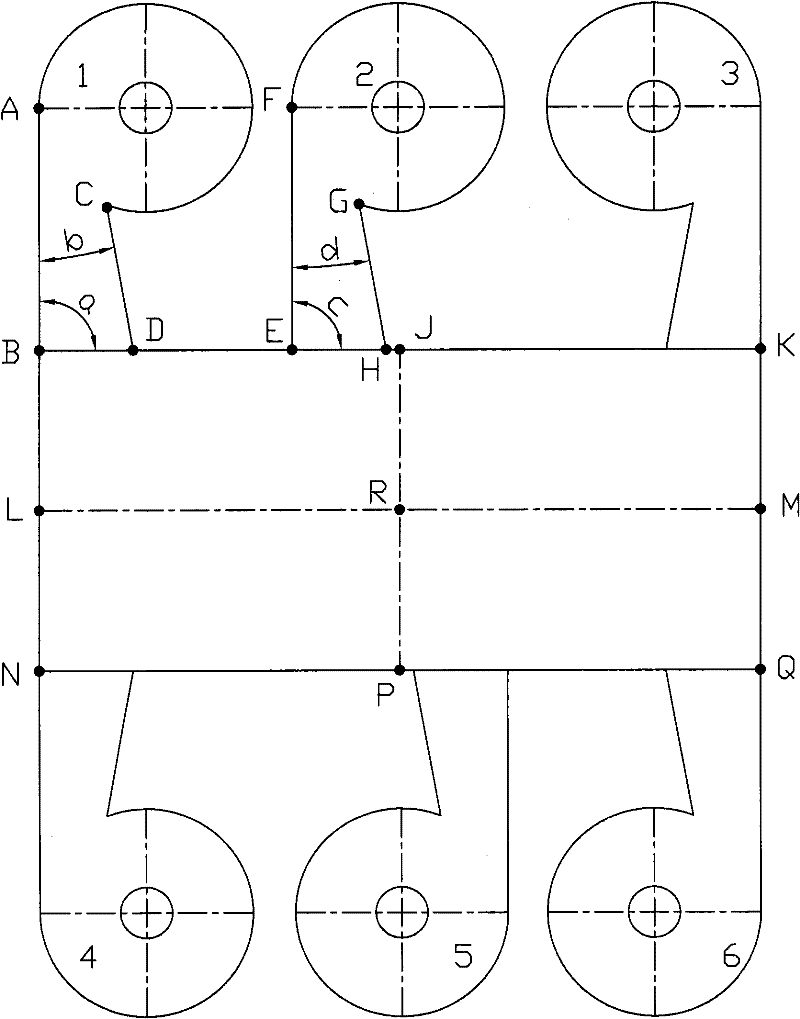

[0043] figure 2 It is the top plan view of the large-scale circulating fluidized bed boiler furnace and six cyclone separators in Example 2 of the present invention. The rectangle BKQN represents the cross-section of the furnace enclosed by four side walls.

[0044] The six cyclone separators are all composed of a cylinder body and an inlet flue, and the six cyclone separators are connected to the flue gas outlet of the furnace through their respective inlet flues. The cylinder structures and dimensions of the six separators are the same.

[0045] Cyclone separators 1, 2, and 3 are arranged side by side on the BK side of the furnace in sequence, and cyclone separators 4, 5, and 6 are arranged side by side on the NQ side of the furnace in sequence, and the BK side and the NG side are the long sides of the furnace cross section; the cyclone separator On the cross-section of the inlet flue of 1, there are the outer side AB and the inner side CD of the inlet flue, and BD is the...

Embodiment 3

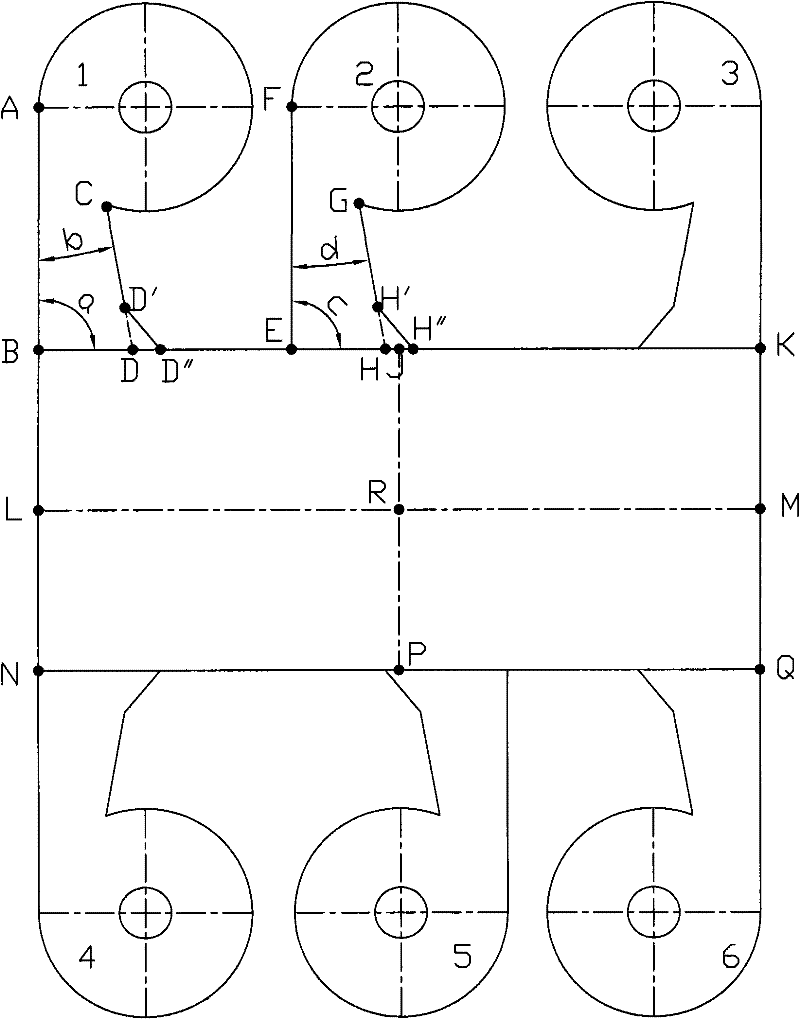

[0052] Such as image 3 As shown, the connection method between the furnace and the cyclone separator is exactly the same as that in Embodiment 2, the only difference is that the openings of the inlet flues of the cyclone separators 1 to 6 on the furnace are in the form of flaring, and the inner side of the cross section A polyline segment formed by two straight line segments.

[0053] The cross-section of the inlet flue of cyclone separator 1 is ABD”D’C, the outer side is AB, and the inner side is the broken line segment CD’D”, which is the extension line of the straight line segment CD’ close to the separator cylinder to the direction of the furnace It intersects with the furnace side wall BK at point D, and BD is the opening width of the inlet flue connecting the furnace 10 with the cyclone separator 1 .

[0054] The cross-section of the inlet flue of the cyclone separator 2 is FEH”H’G, the outer side is FE, the inner side is the broken line segment GH’H”, and the extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com