Patents

Literature

132 results about "Fluidic oscillator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

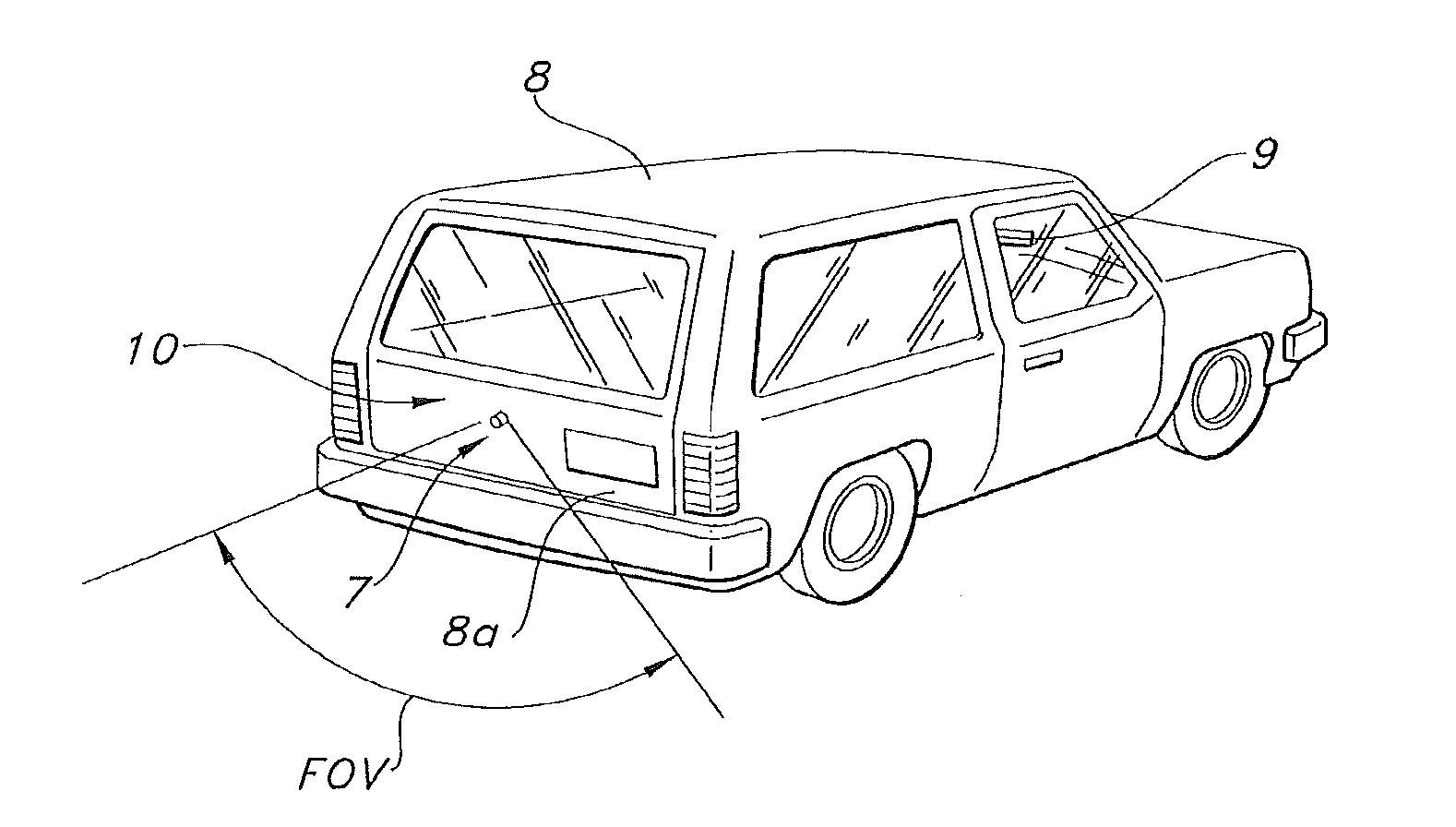

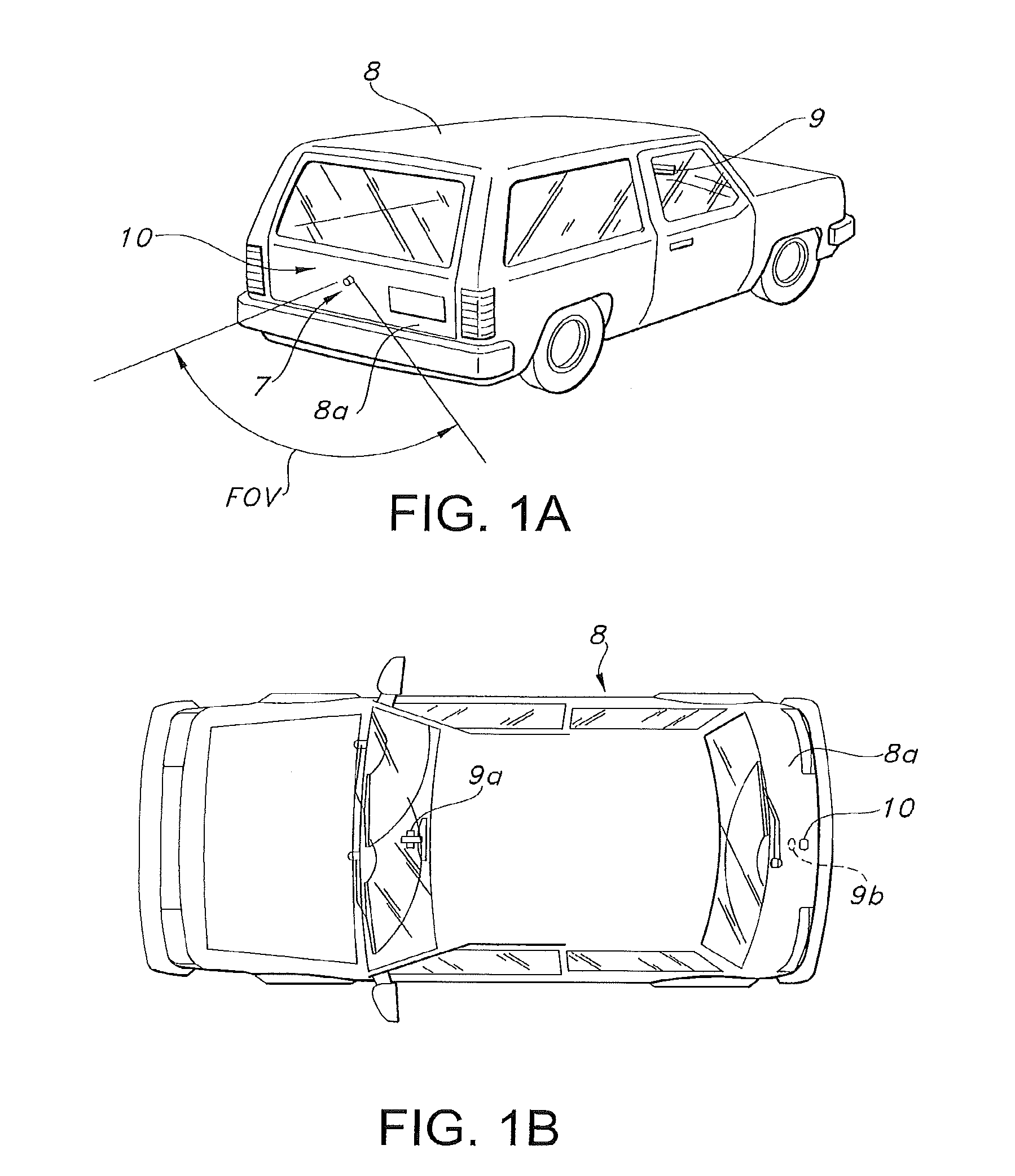

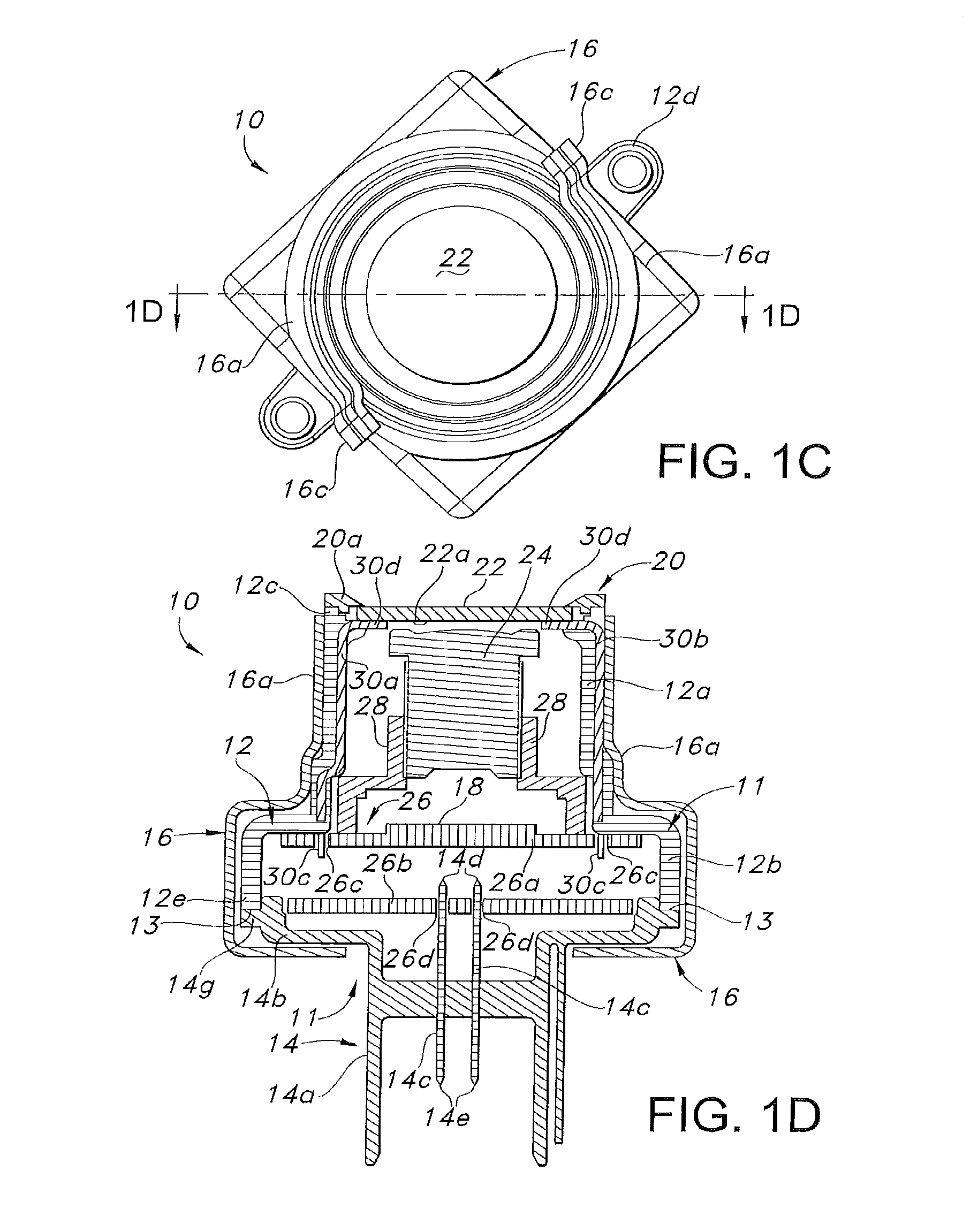

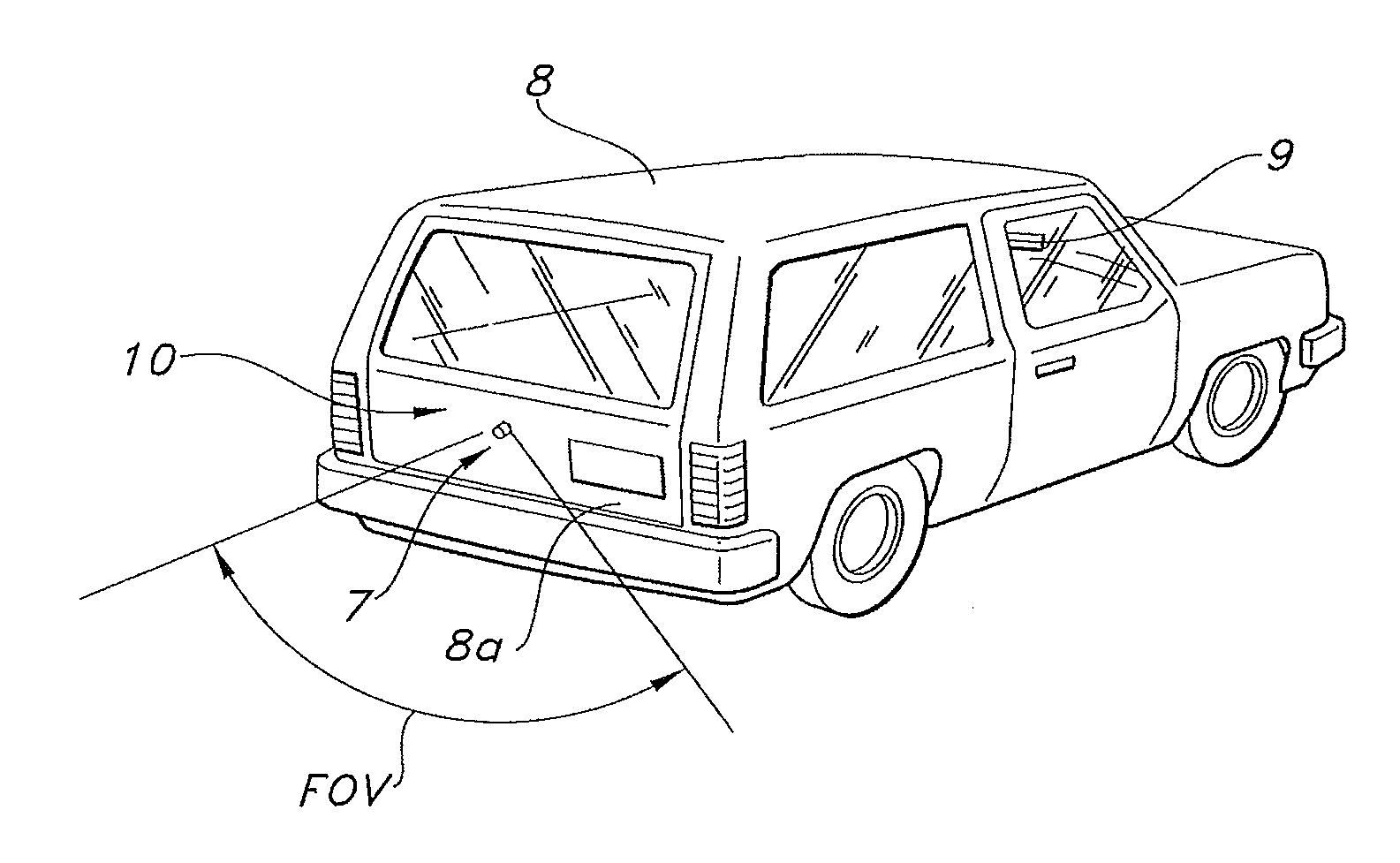

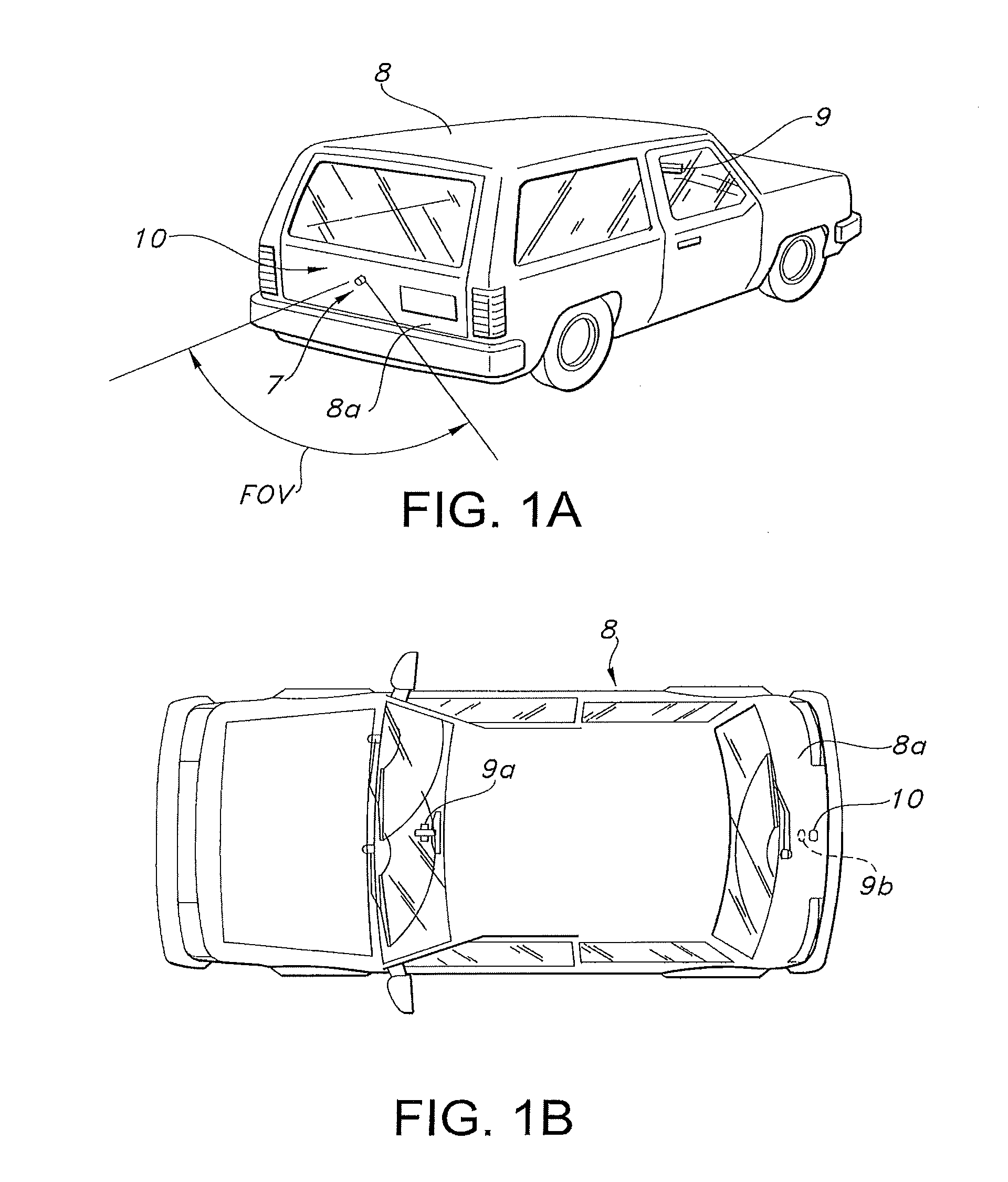

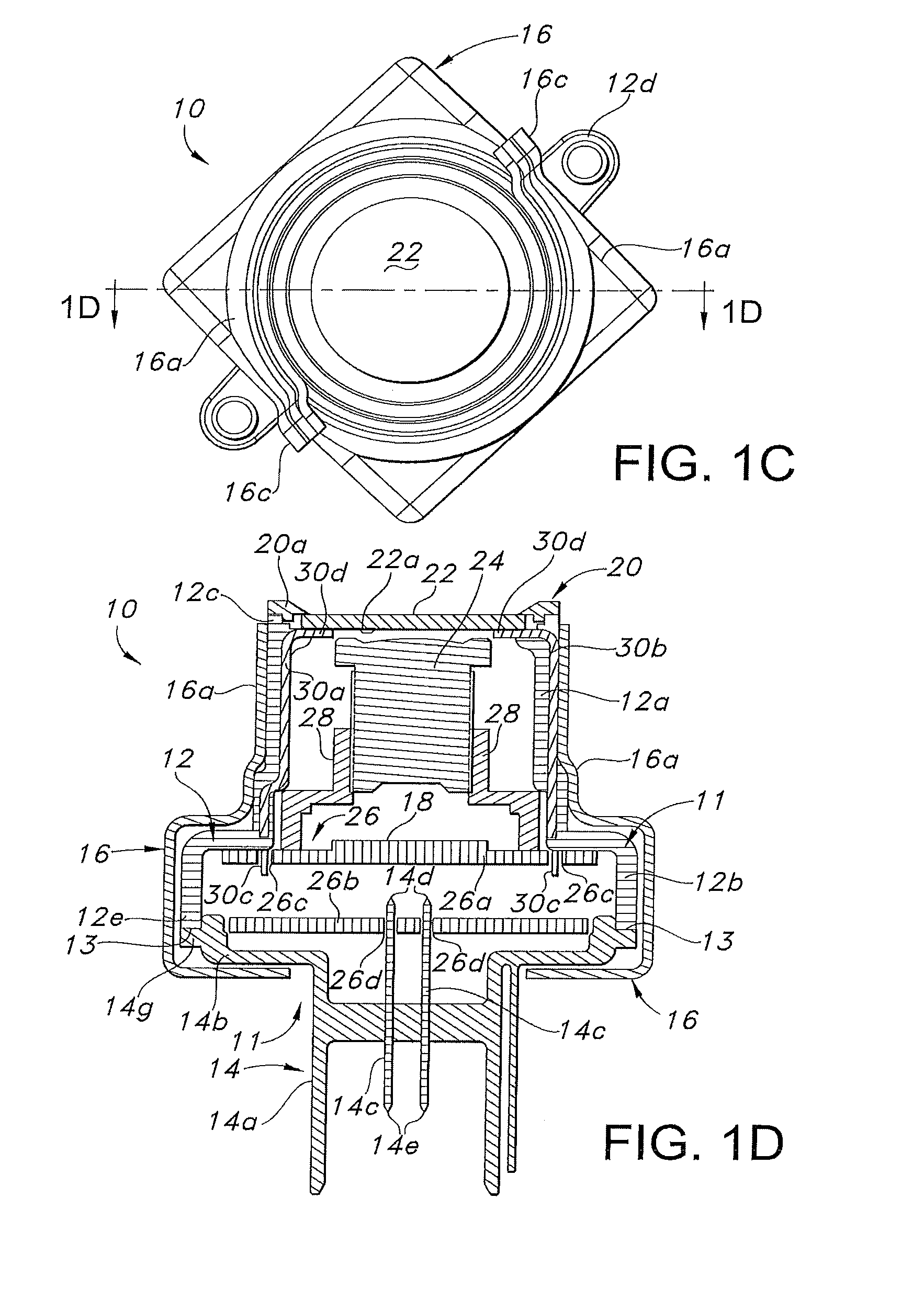

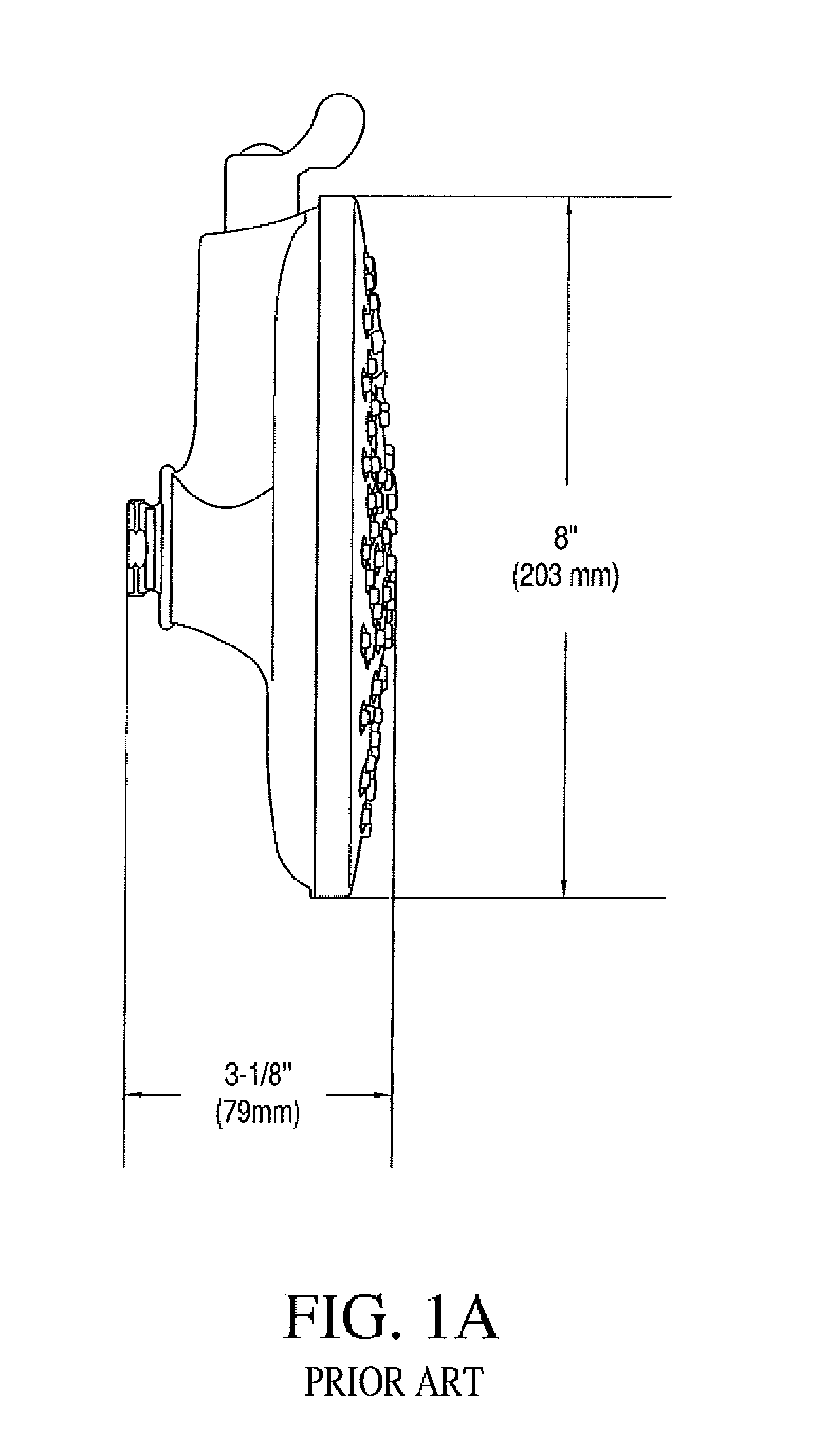

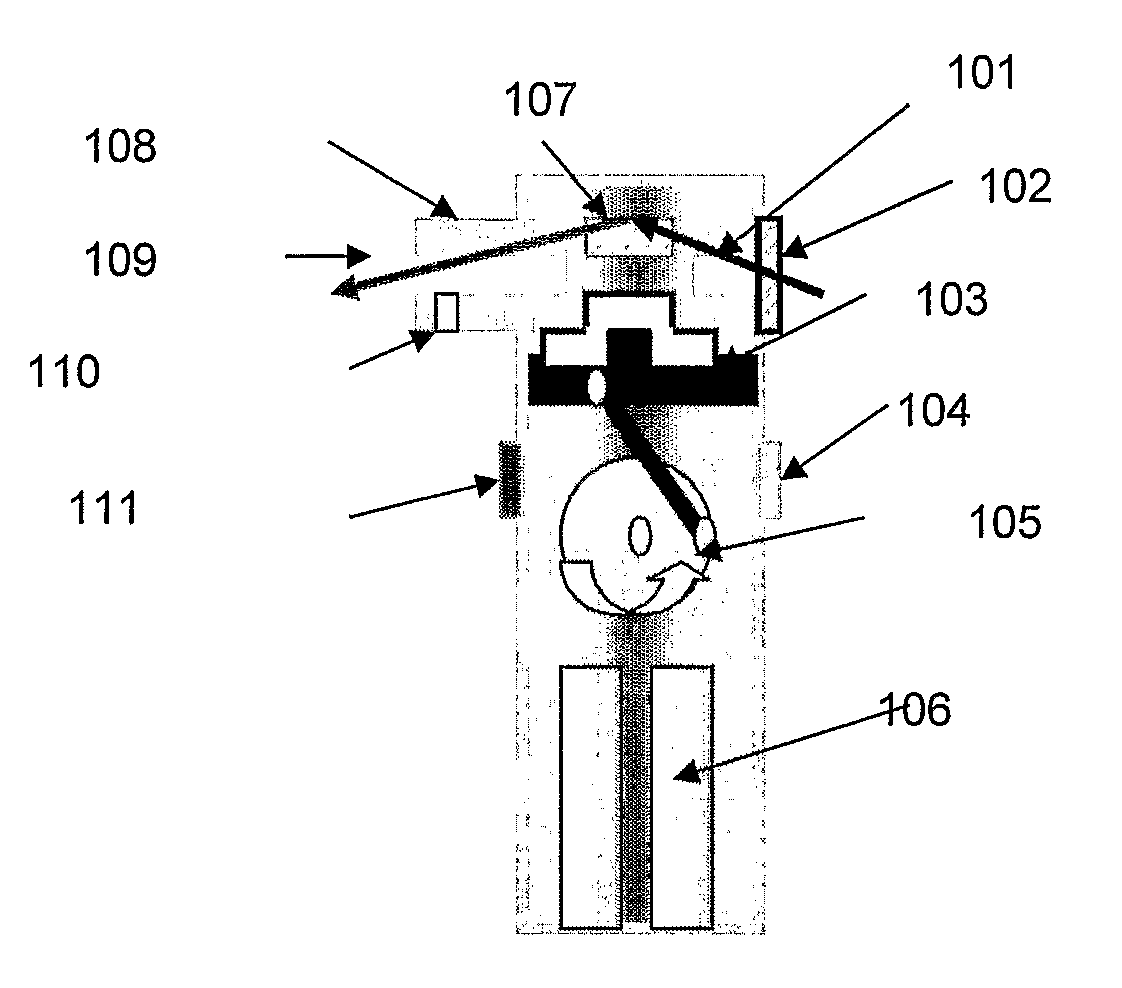

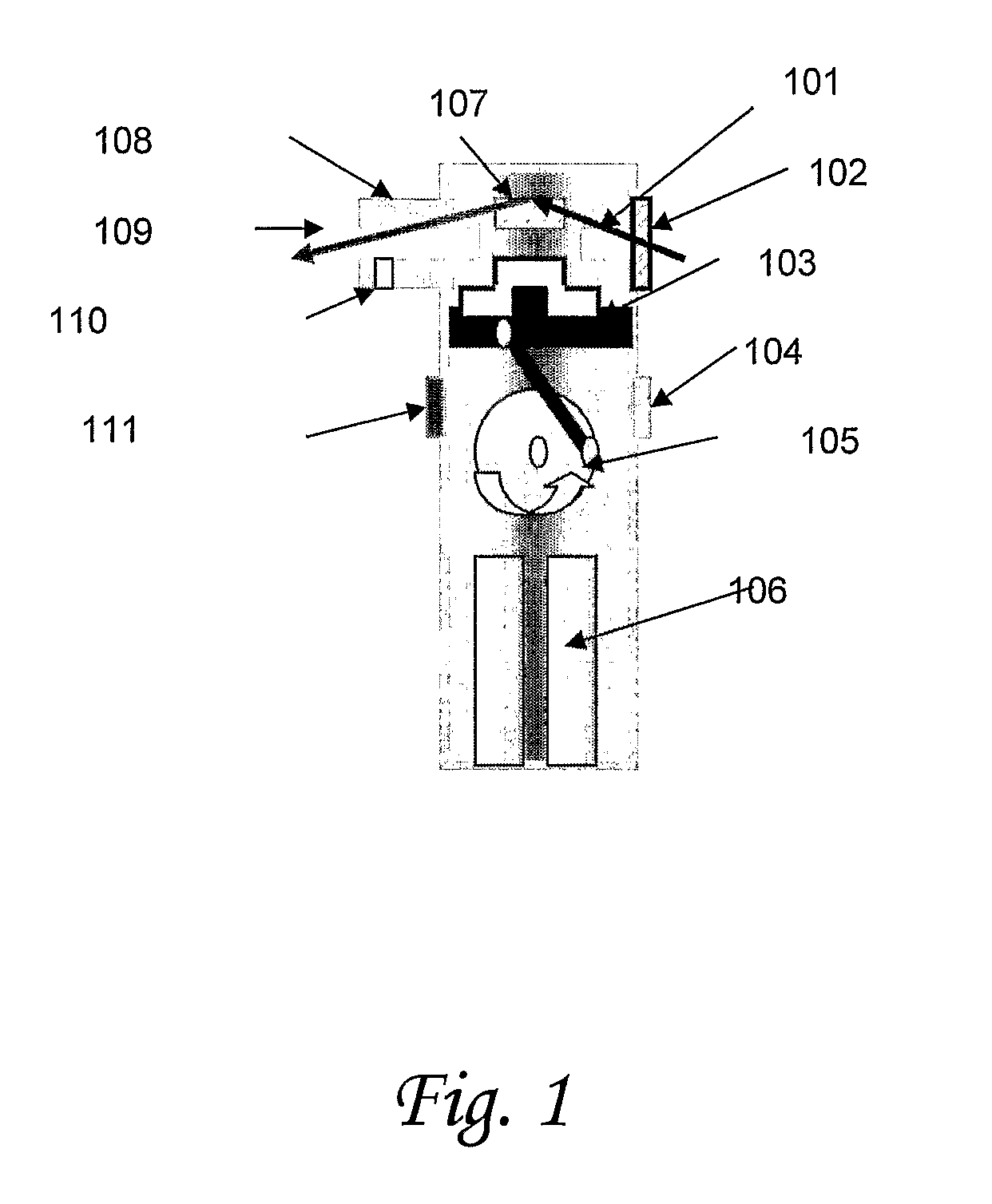

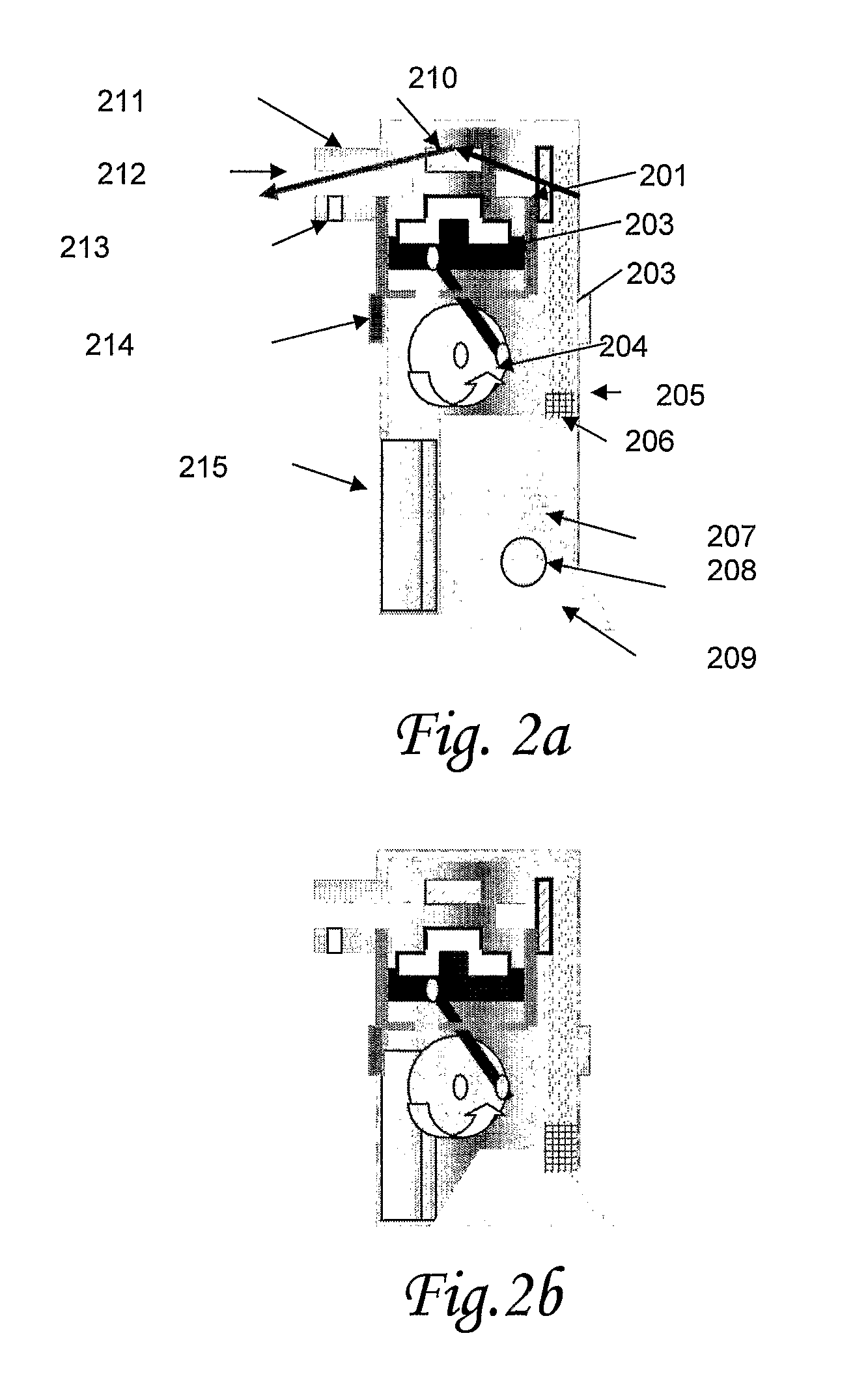

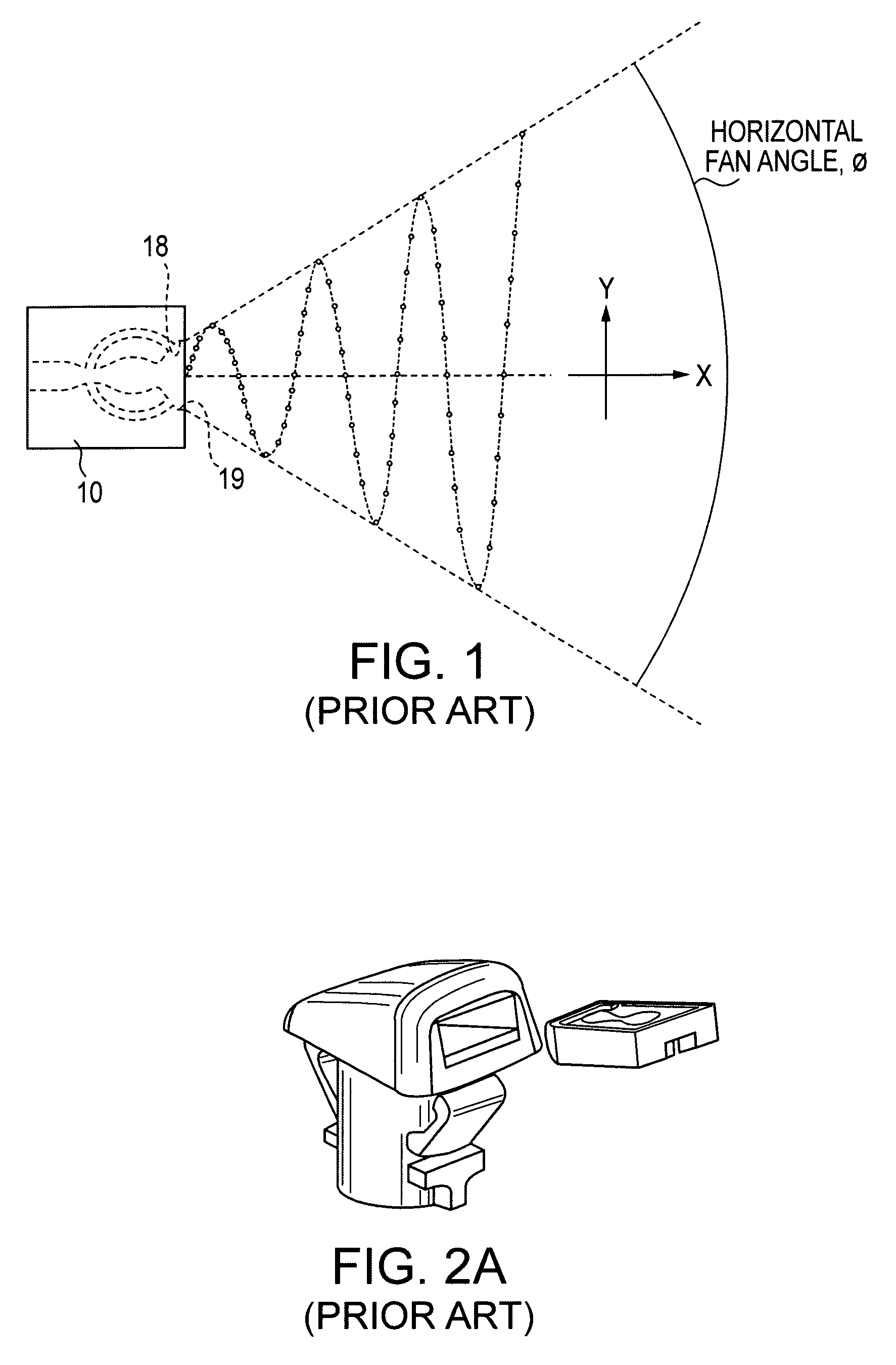

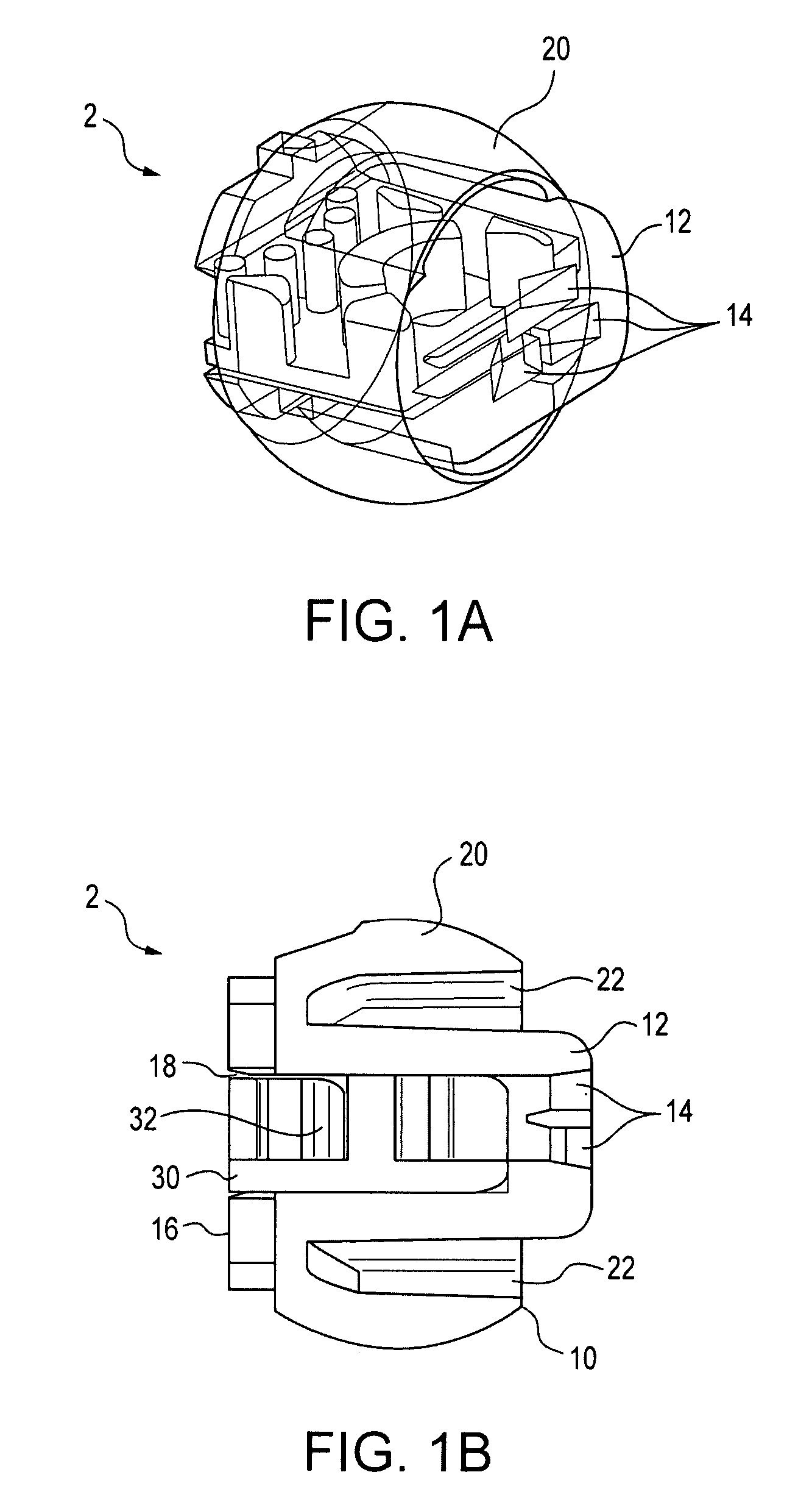

Integrated automotive system, nozzle assembly and remote control method for cleaning an image sensor's exterior or objective lens surface

ActiveUS20140060582A1Easy to cleanPromote effectiveElectrostatic cleaningSpray nozzlesCamera lensRemote control

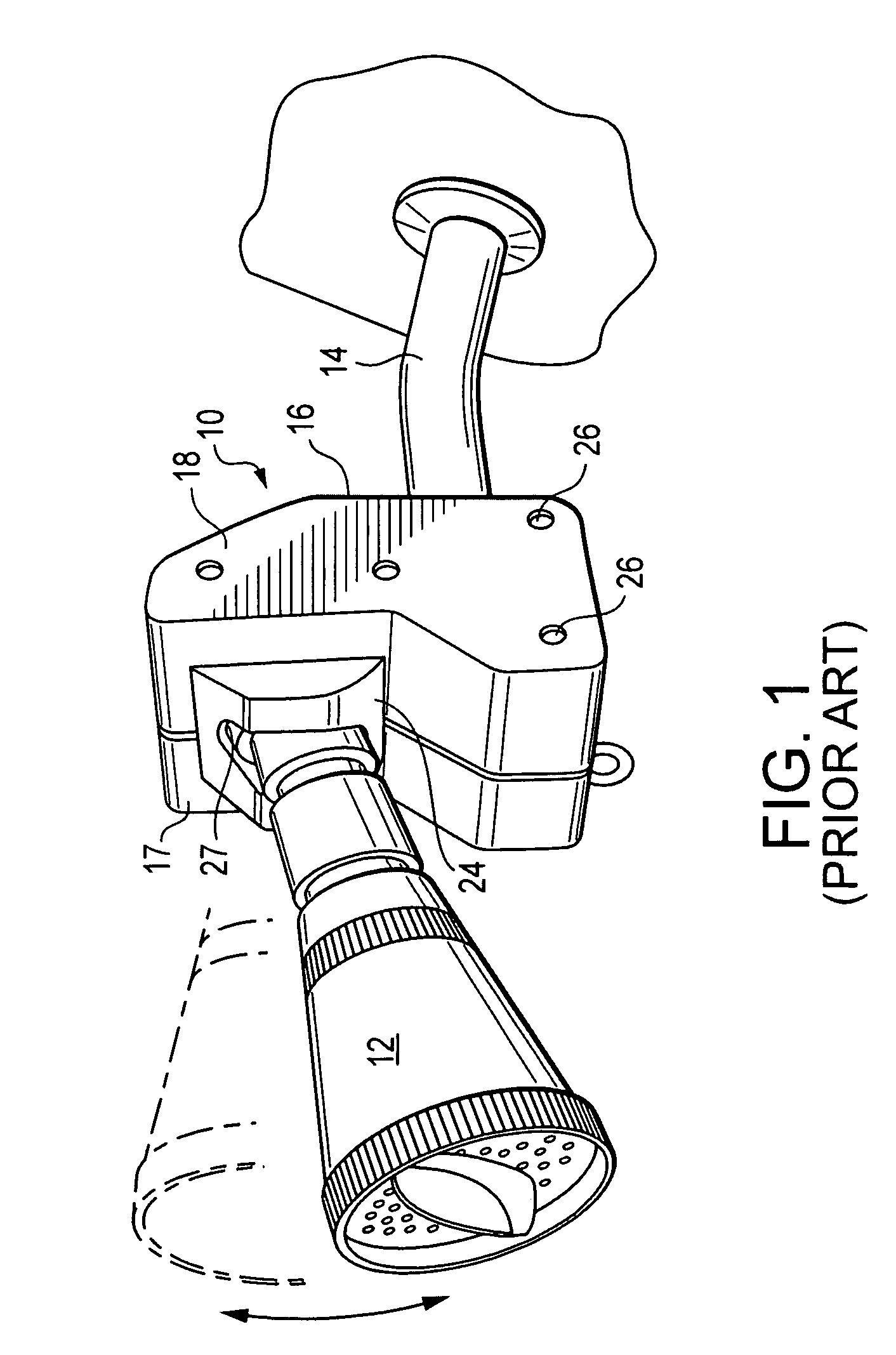

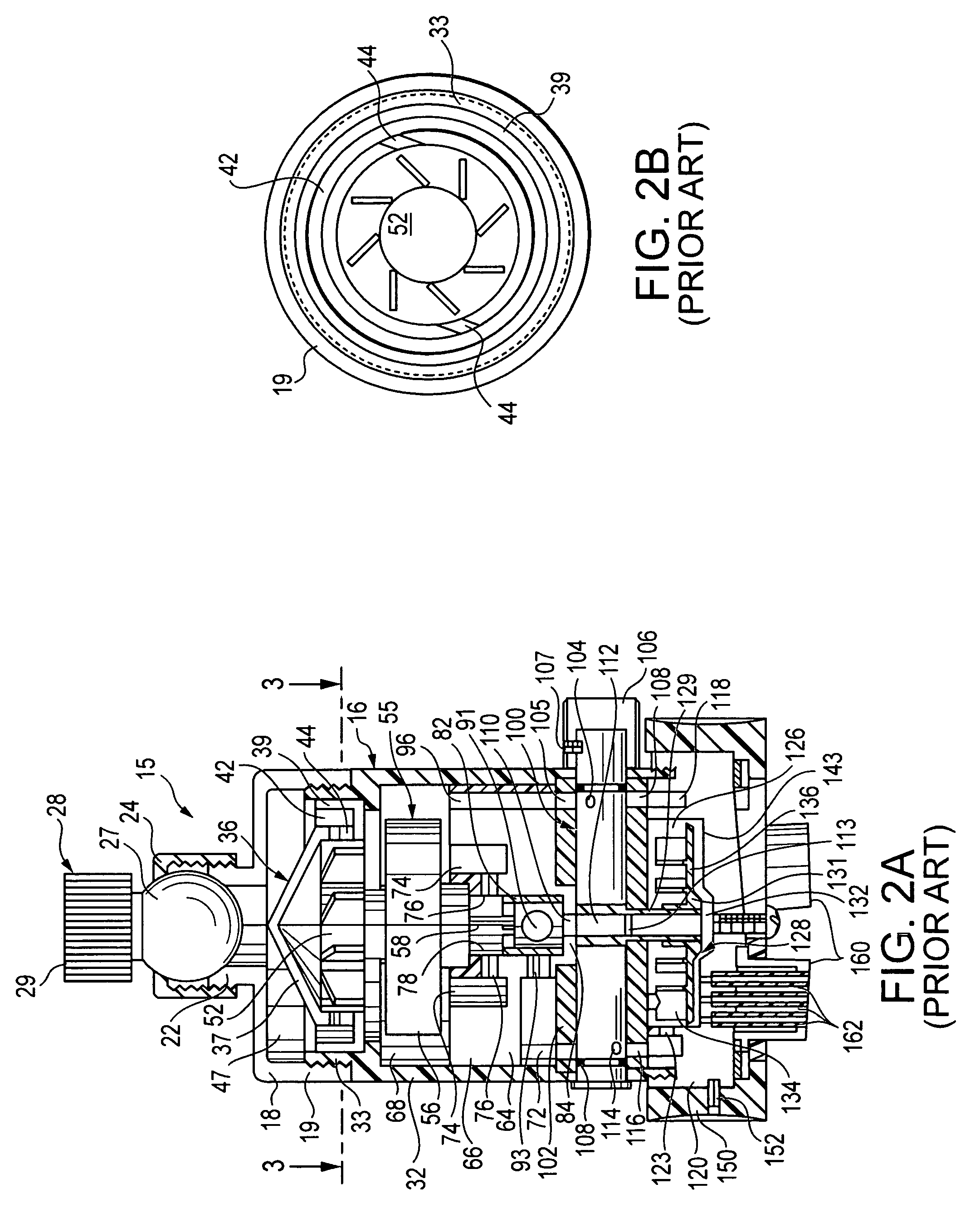

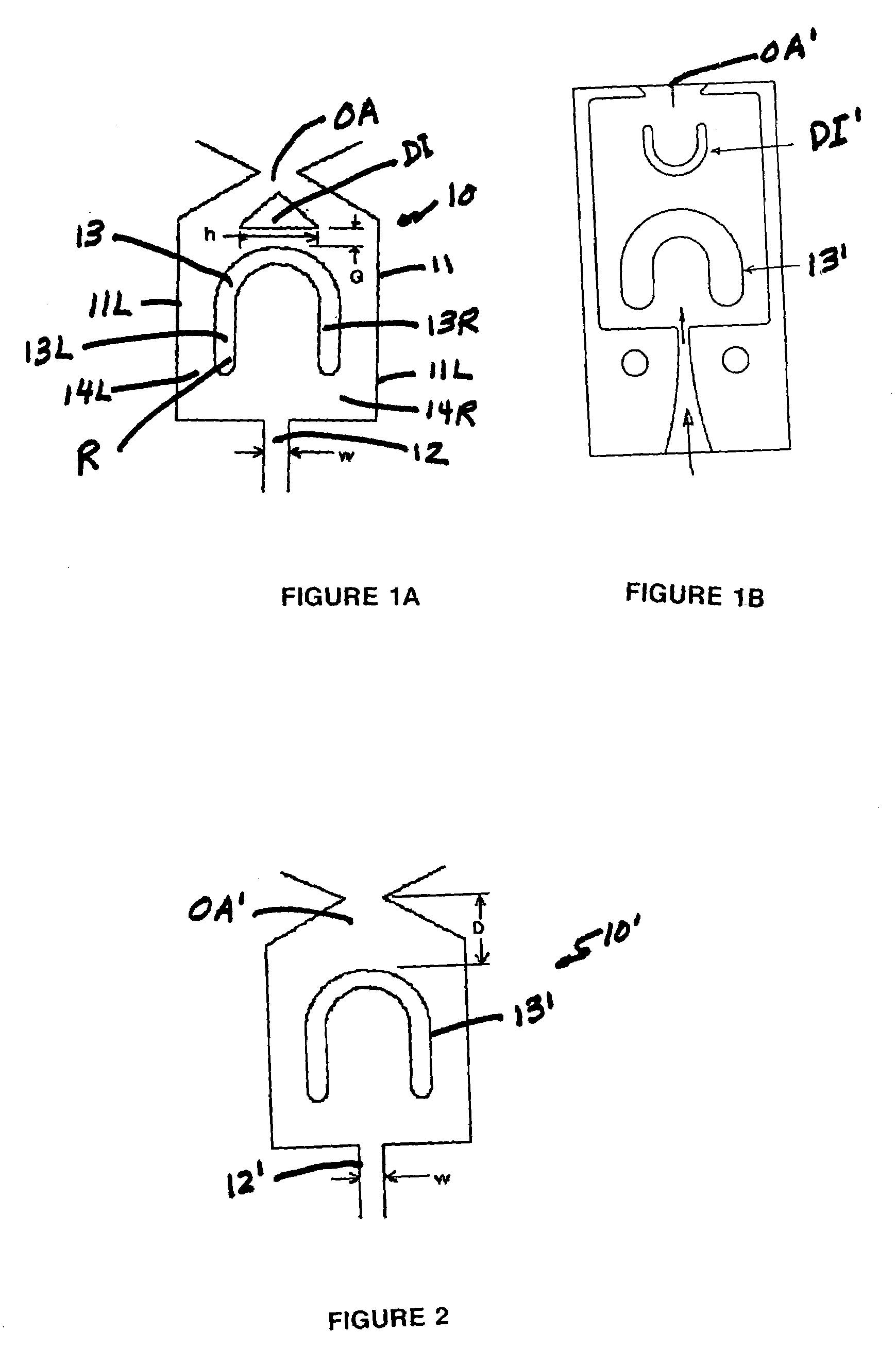

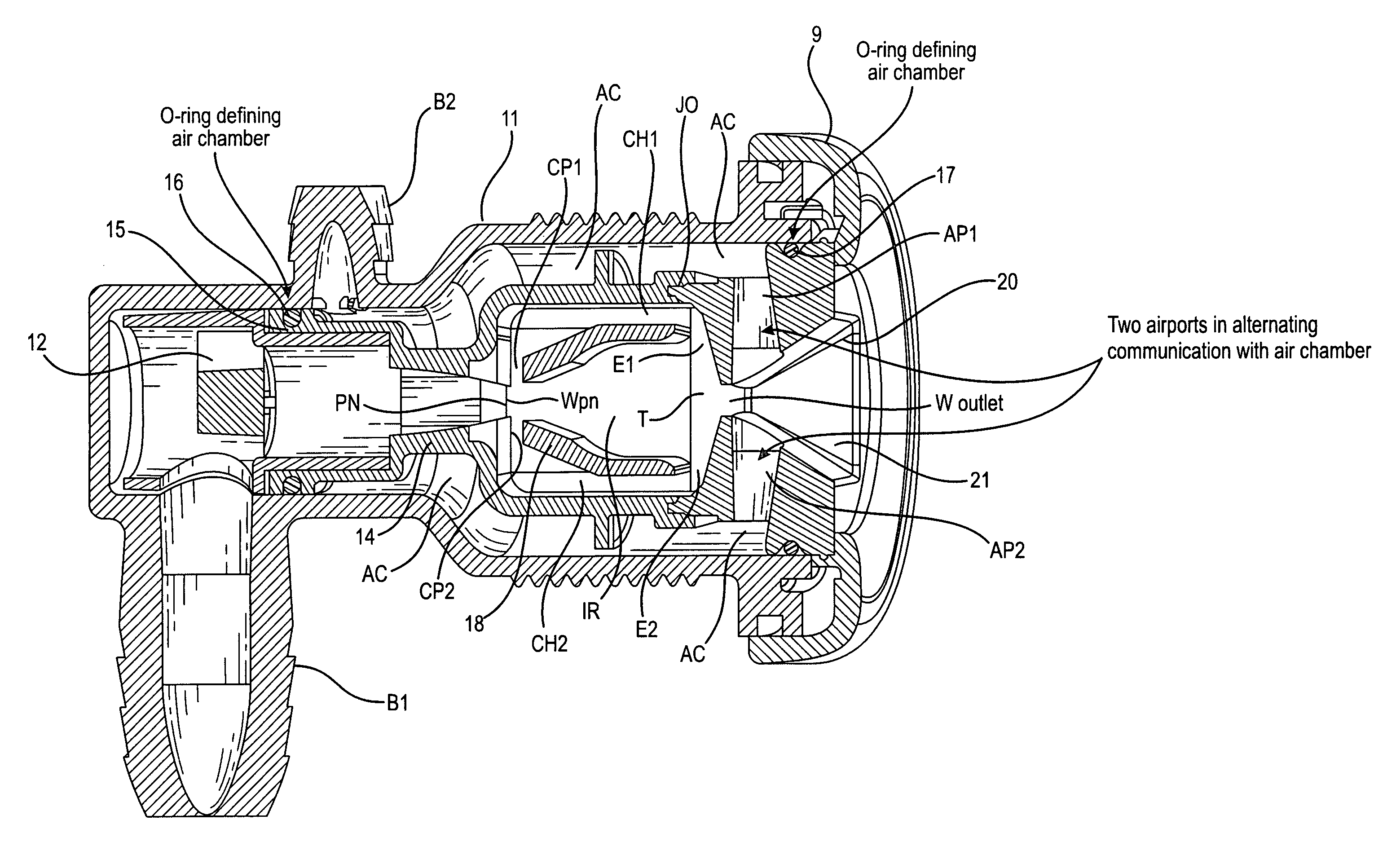

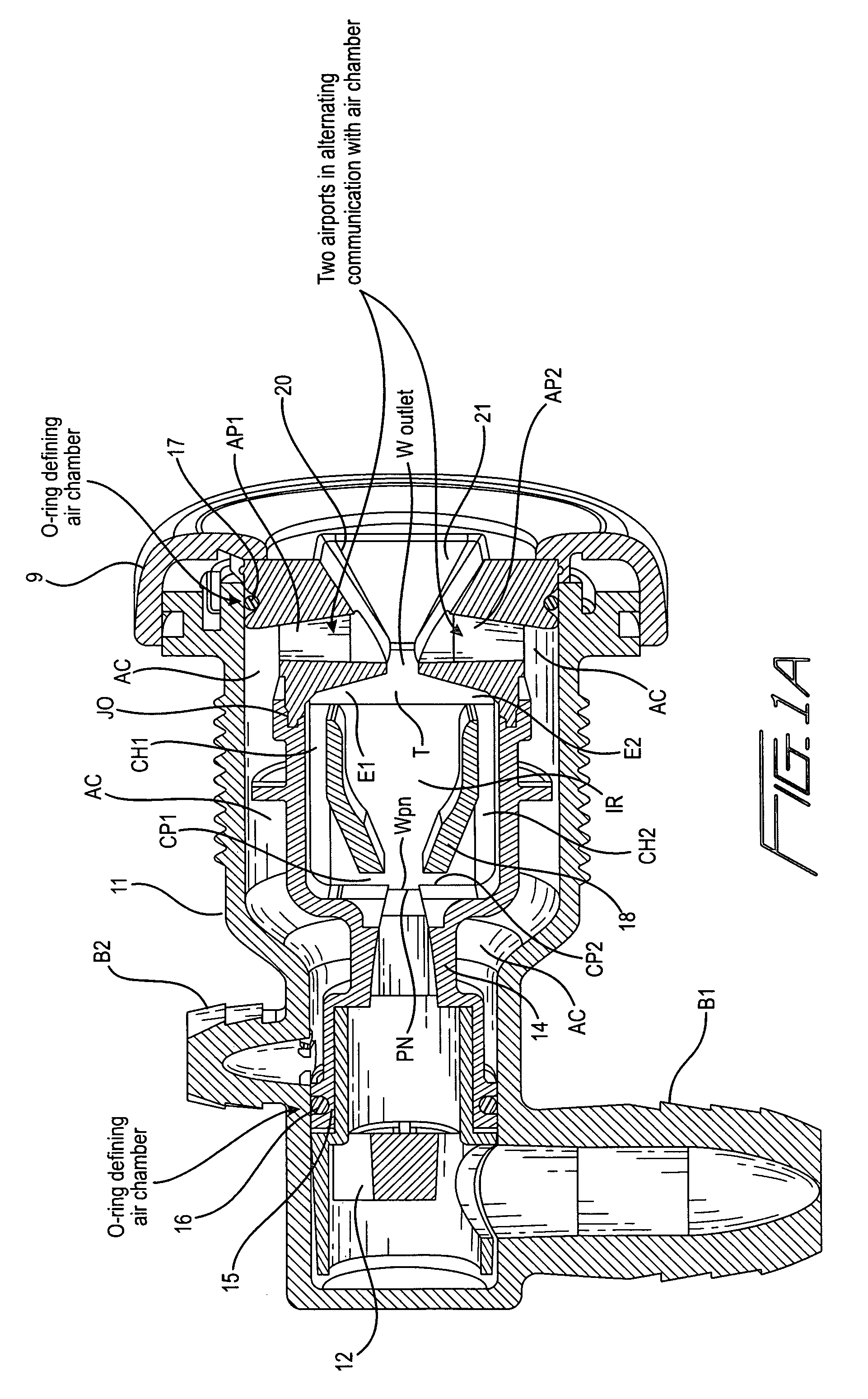

An external lens washing system has an aiming fixture configured to support and constrain an external lens which is exposed to the elements and apt to become soiled with debris. A nozzle assembly is configured to be supported and aimed toward the external lens by the aiming fixture and has at least one laterally offset washing nozzle projecting from the aiming fixture to a spray washing fluid toward the external lens surface, spraying at a shallow, glancing spray aiming angle to impinge upon and wash the lens external surface. Optionally, an integrated image sensor and lens washing assembly is configured for use with a remote control method for cleaning an exterior objective lens surface and includes a sealed image sensor housing assembly including an integral, remotely controllable lens cleaning system with an optimized configuration for aiming one or more cleansing sprays from one or more laterally offset fluidic oscillators.

Owner:DLHBOWLES INC

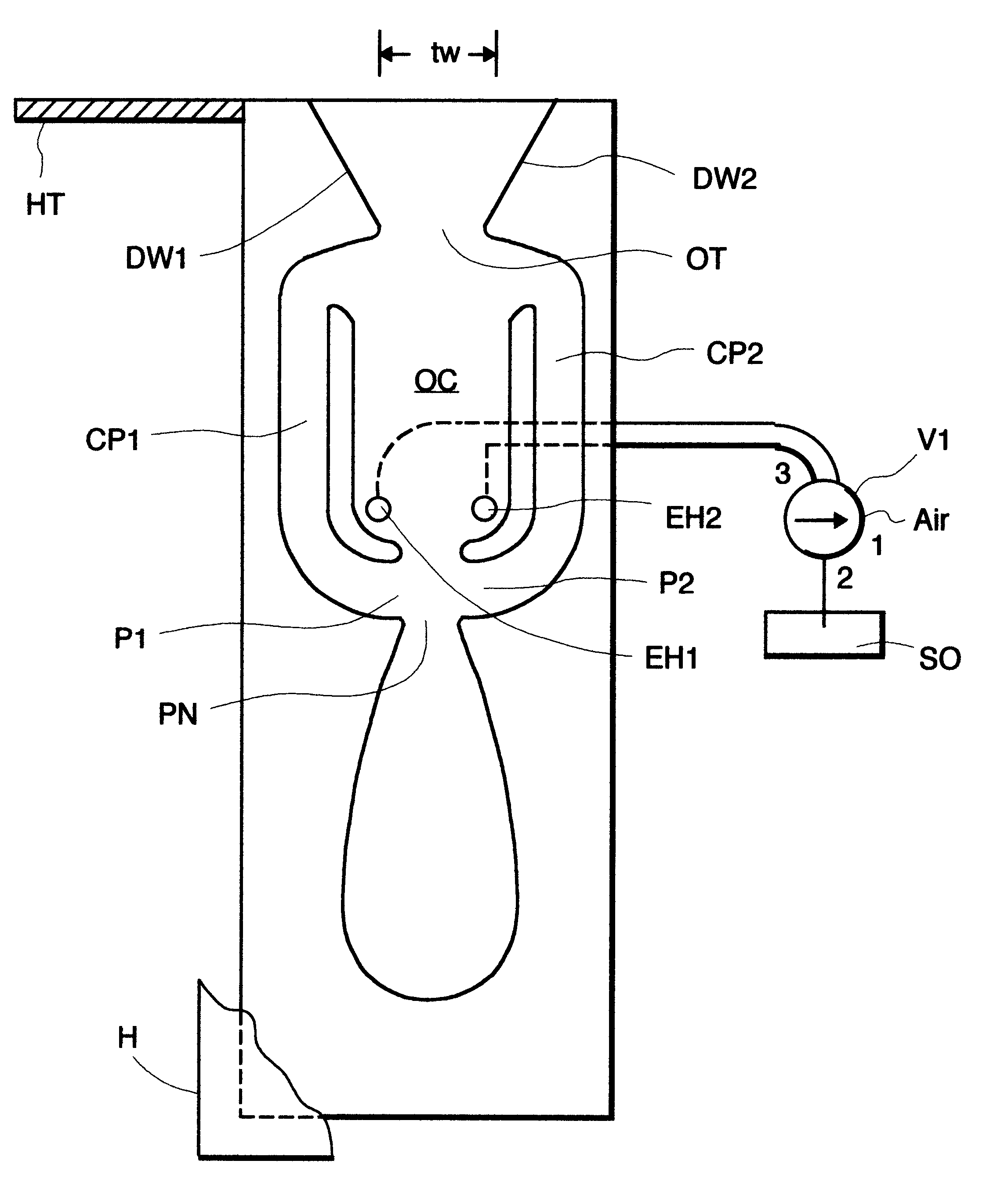

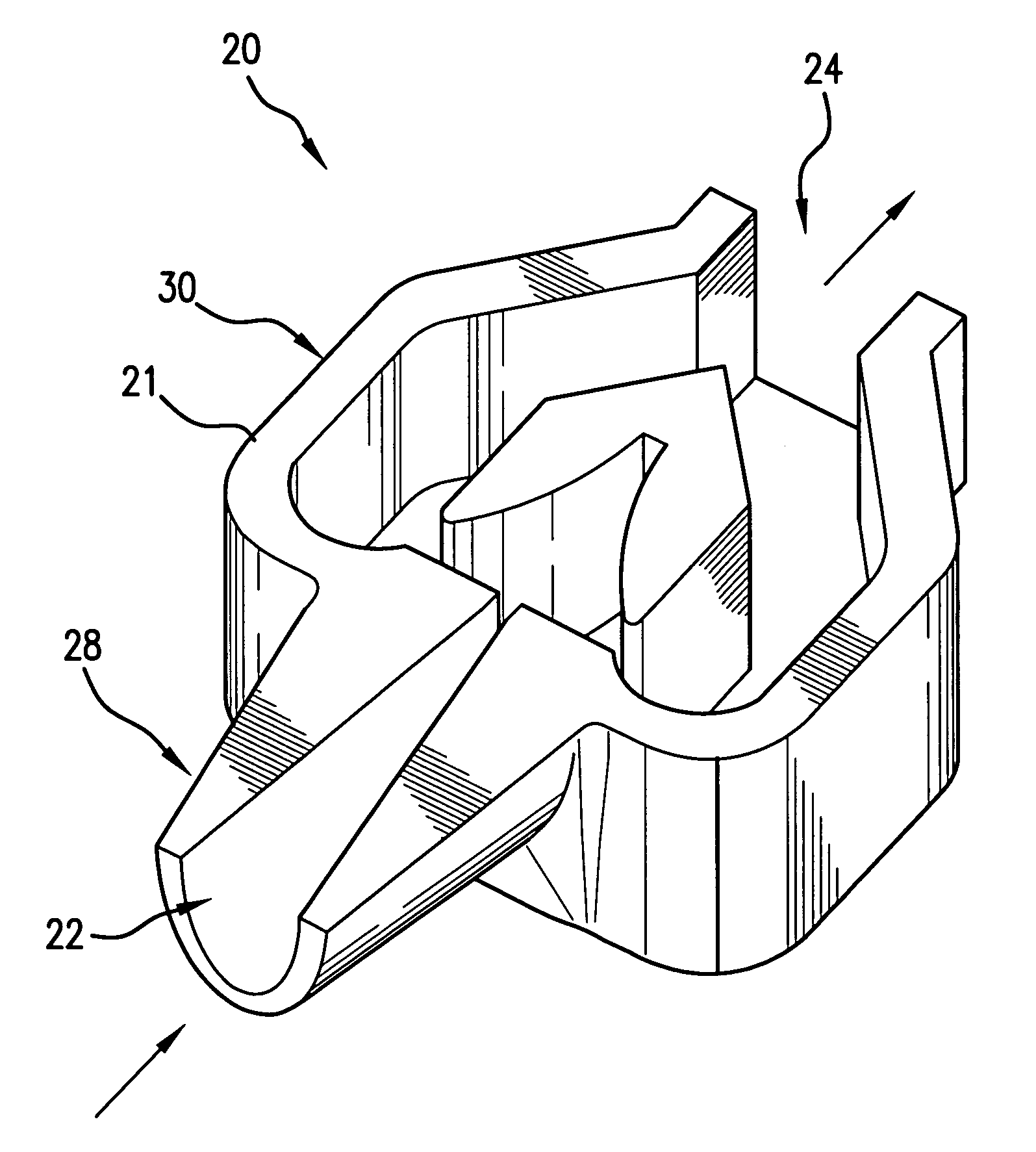

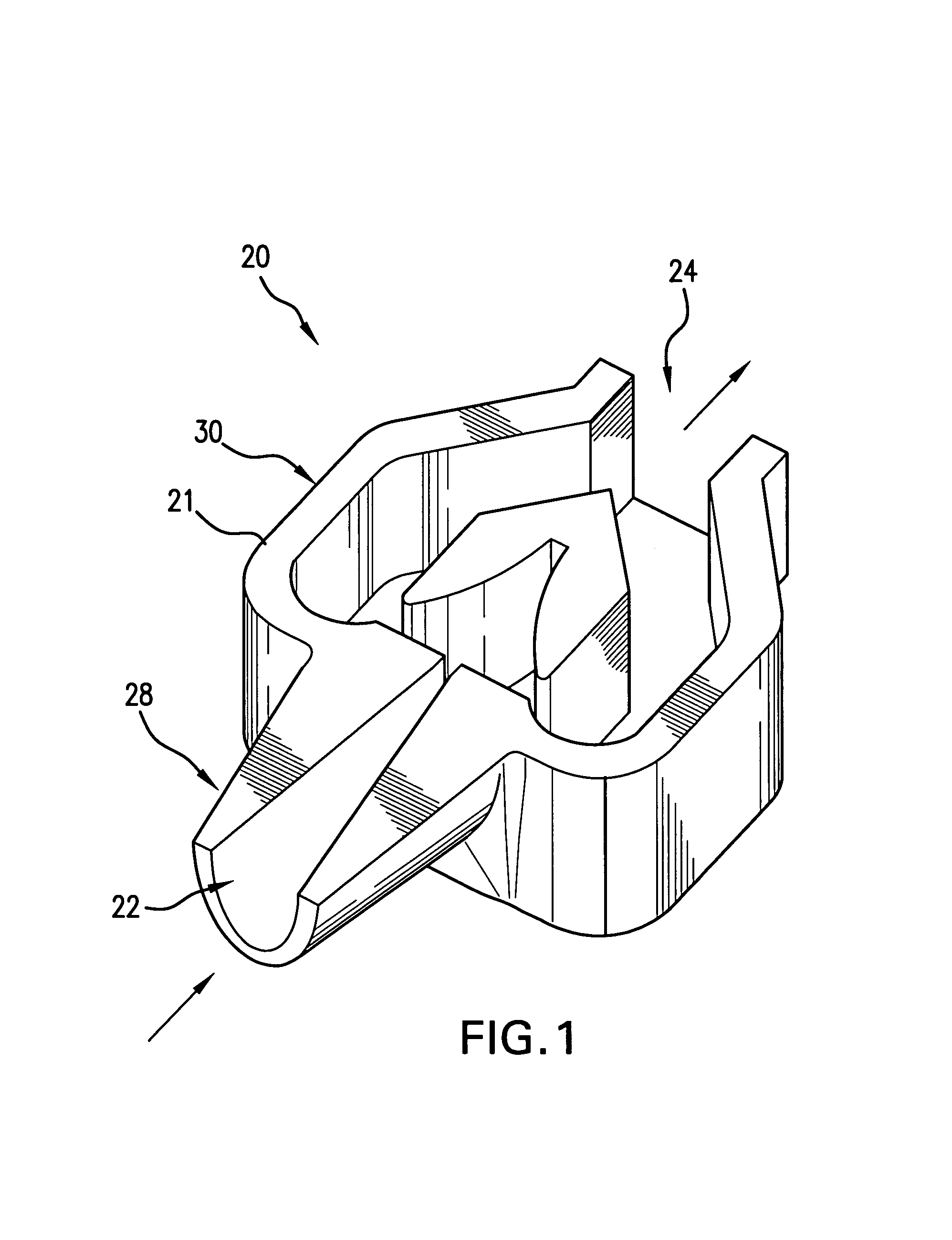

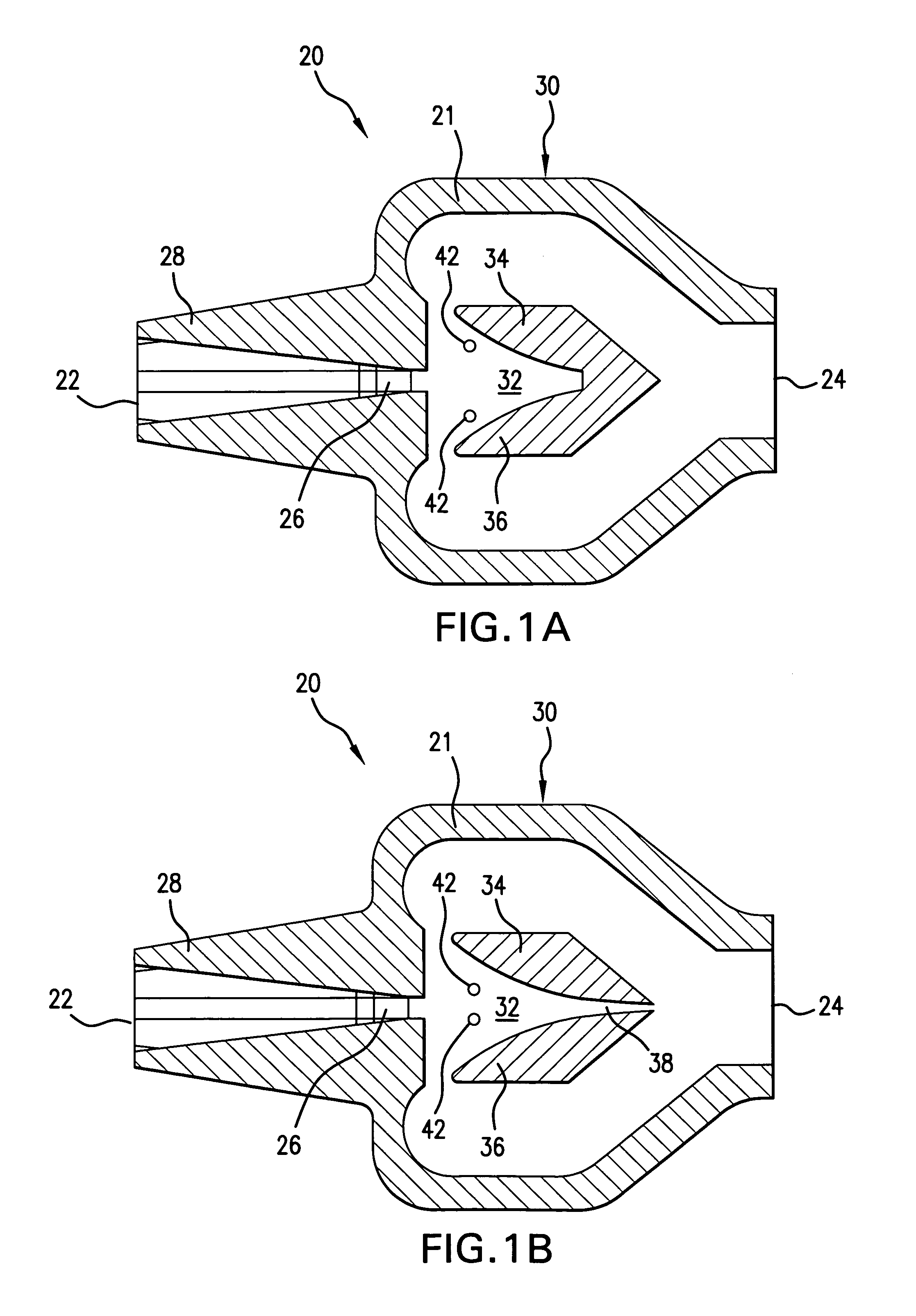

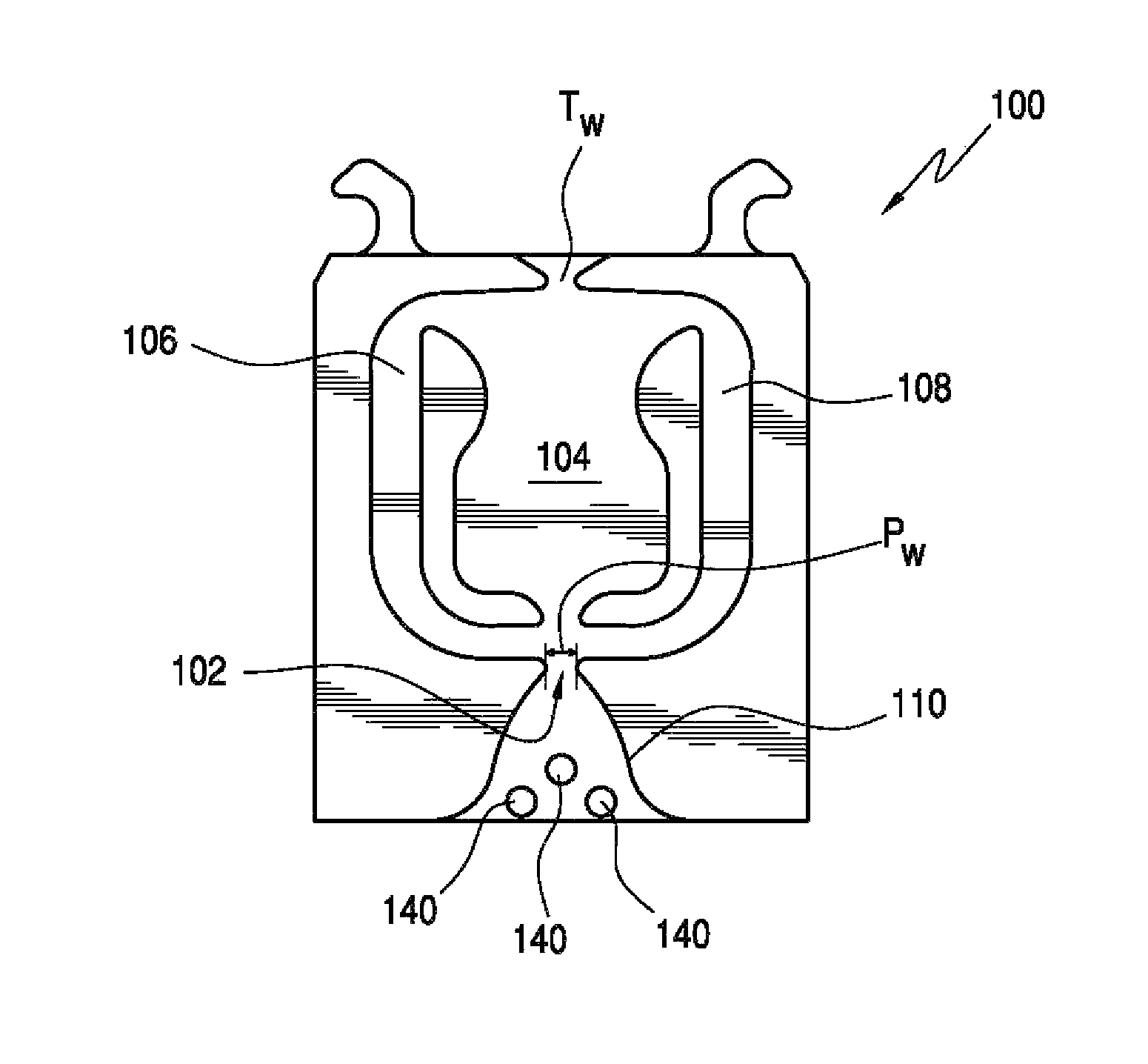

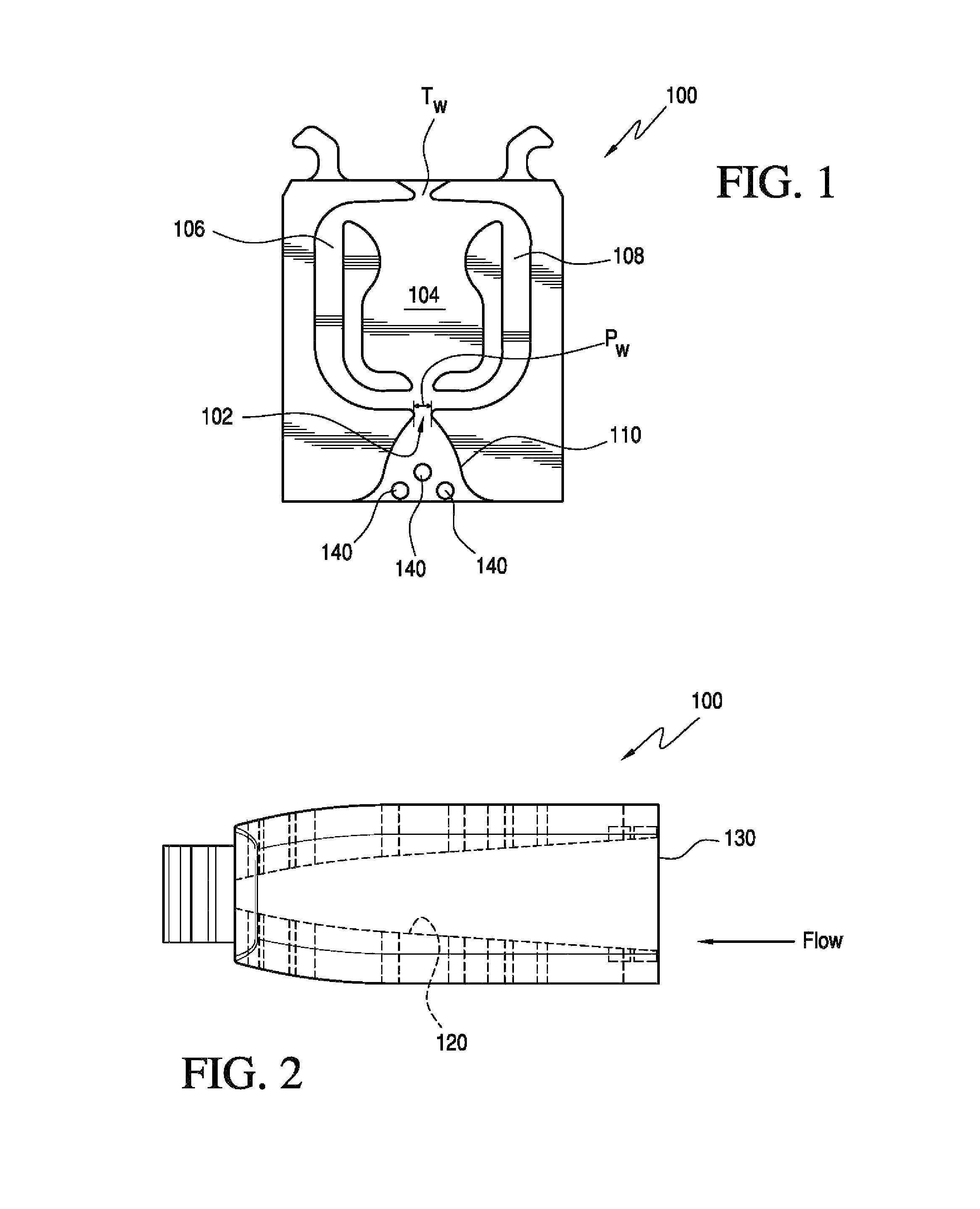

Fluidic nozzle with multiple operating modes

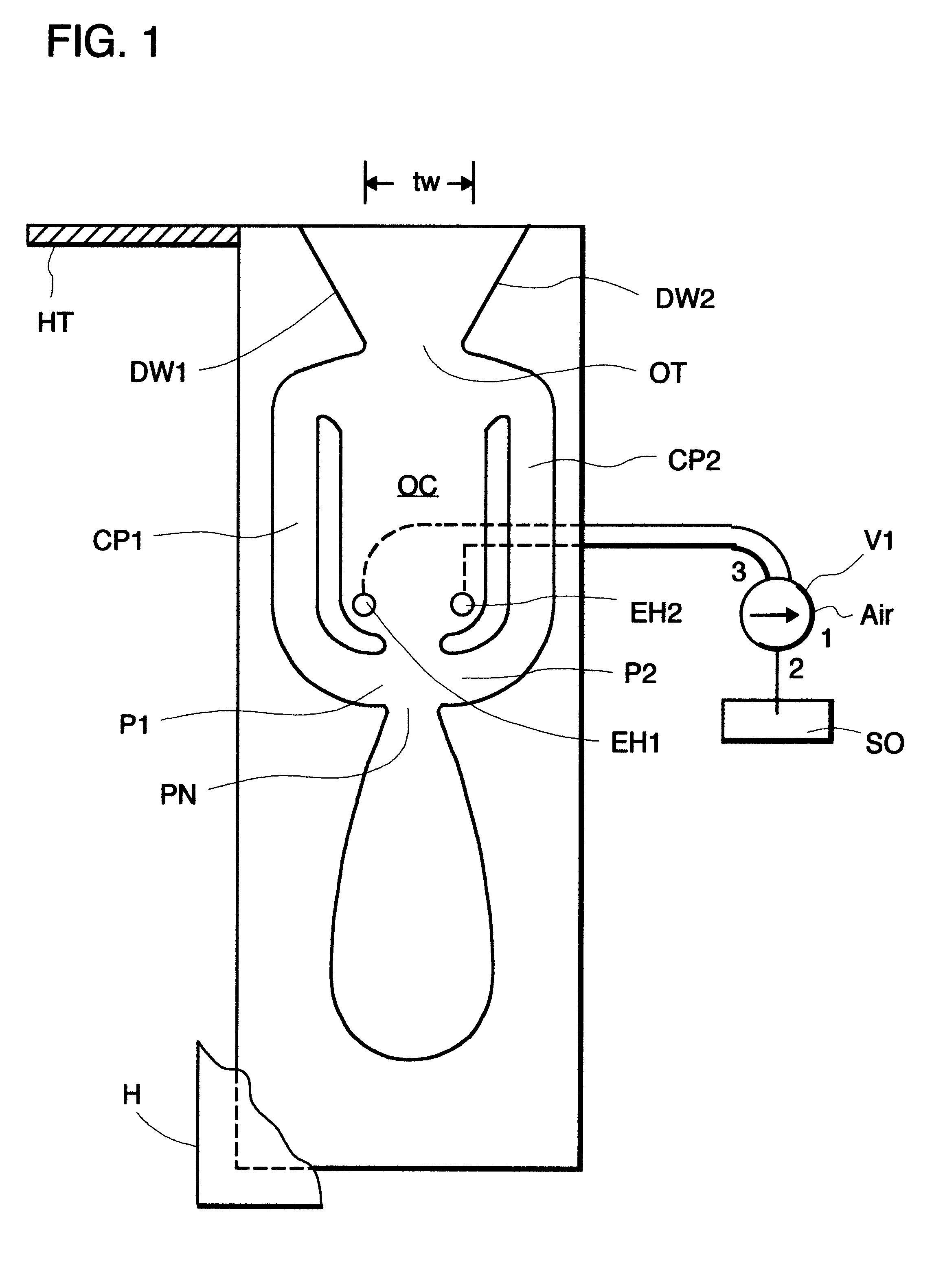

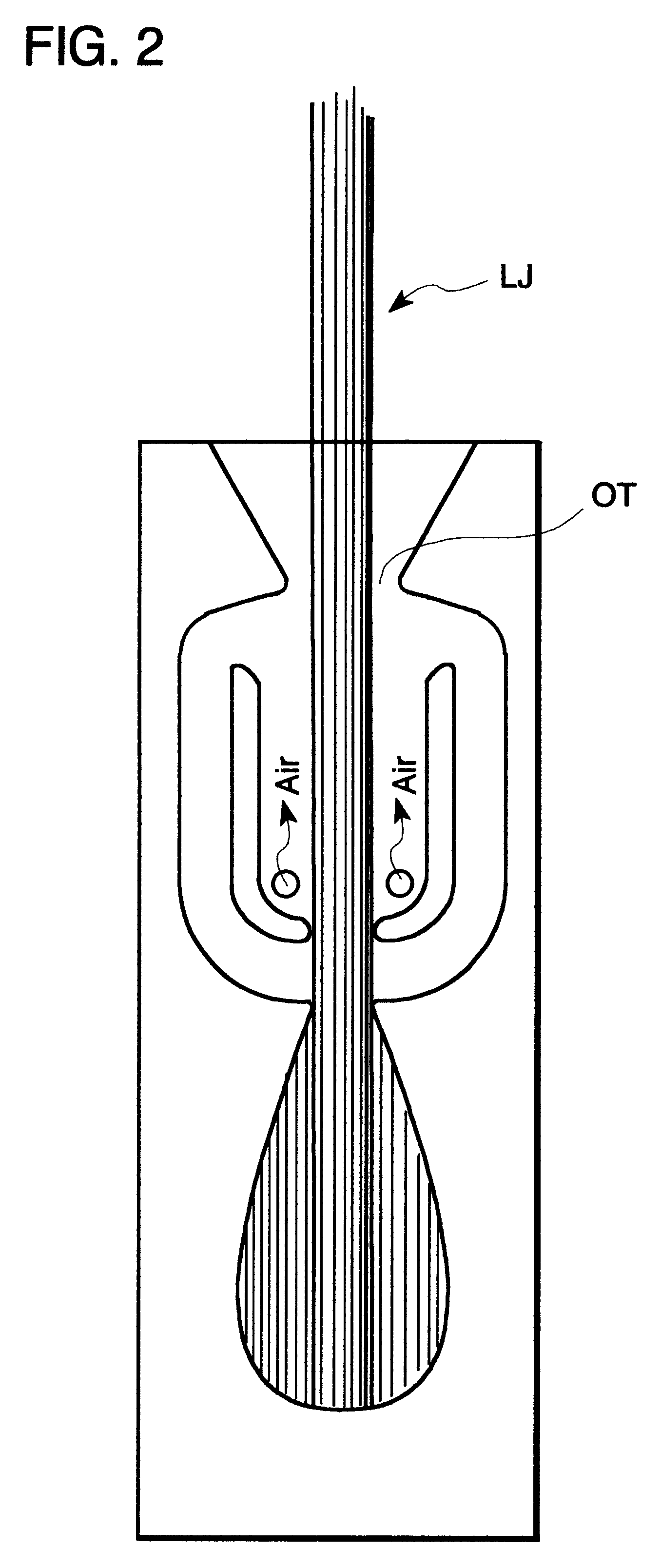

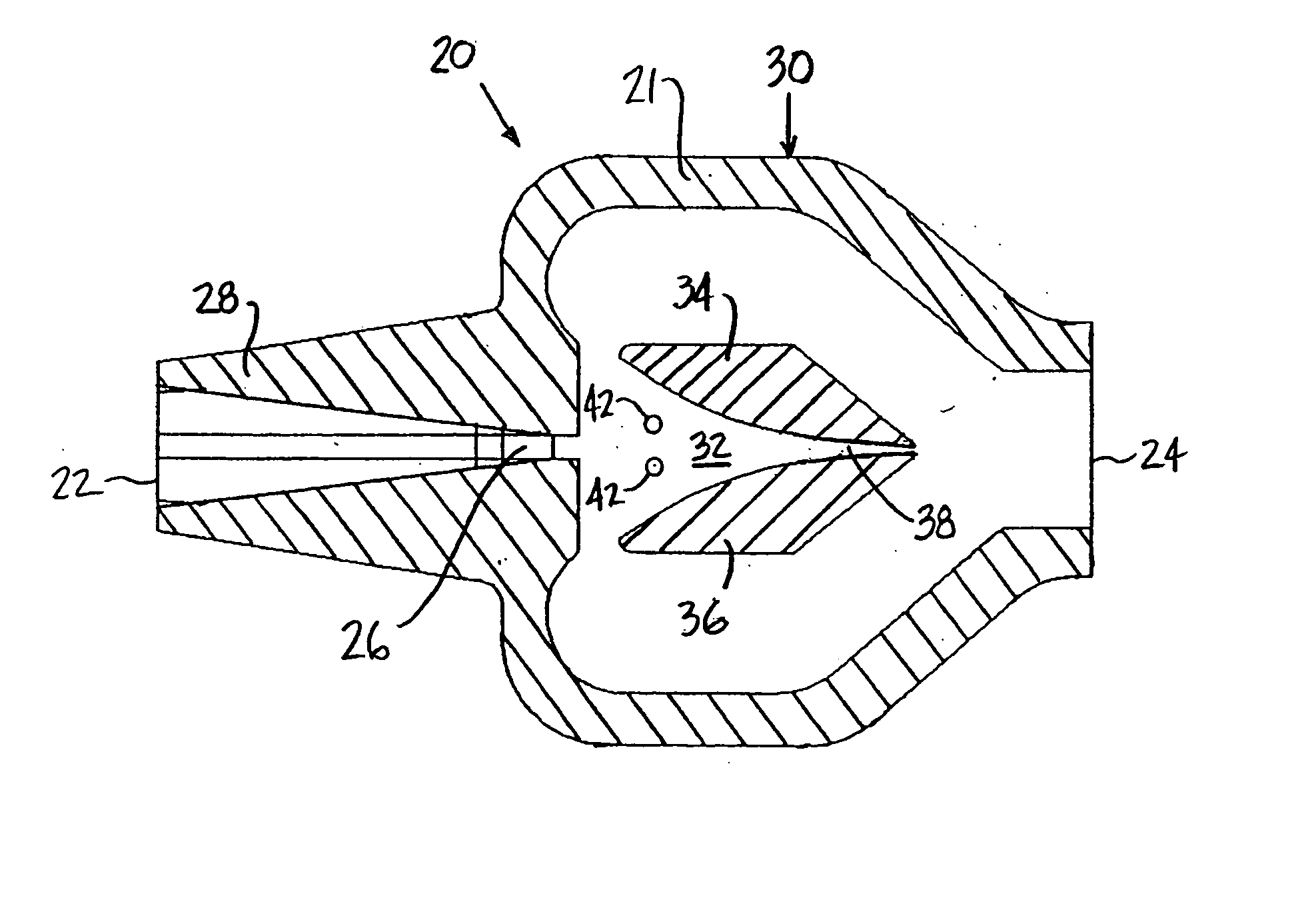

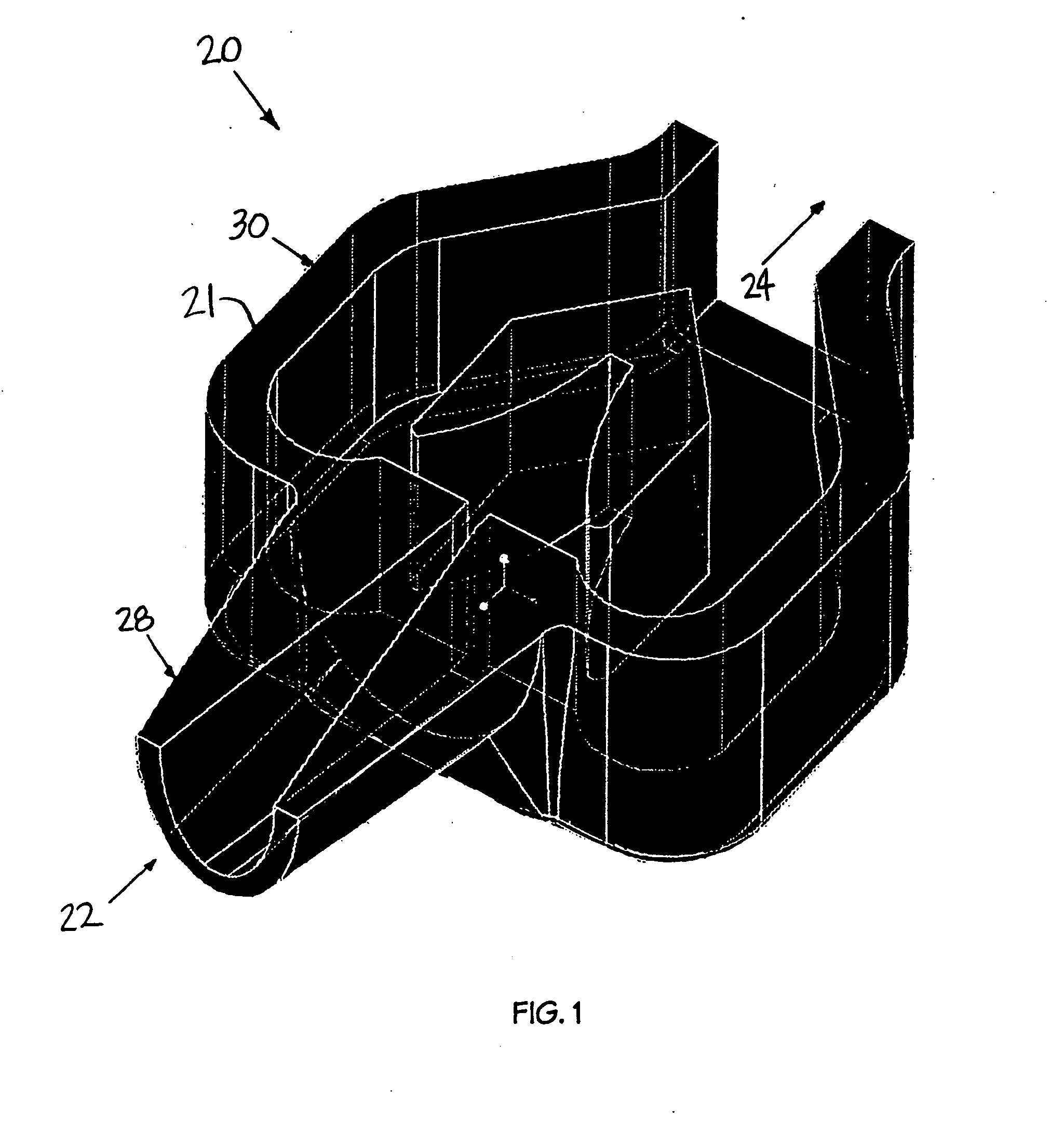

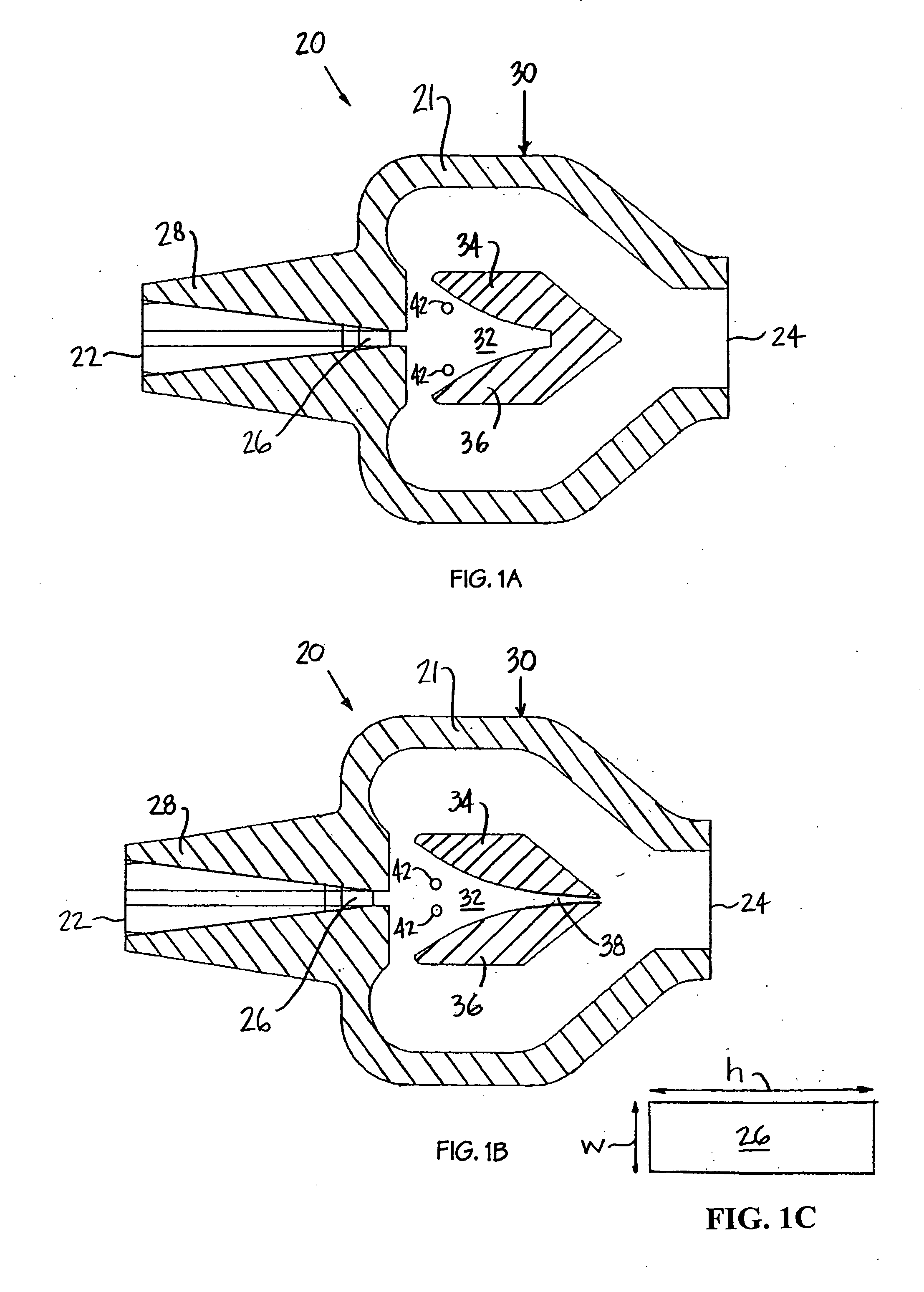

A fluidic nozzle having multiple operating modes comprising a fluidic oscillator circuit having an oscillation chamber having an upstream end and a downstream end and a power nozzle at the upstream end for introducing a jet of a liquid (water) into the oscillation chamber. An outlet throat at the downstream end has a width, which does not allow the oscillation circuit to fill up and start to oscillate without entrained liquid. A pair of control ports are at the upstream end of the oscillation chamber and a pair of feedback passages connect said control ports to downstream ends of said oscillation chamber adjacent said outlet throat. A pair of controllable entrainment holes are provided in the oscillation chamber at the upstream end and a valve opens and closes the entrainment holes, such that when the entrainment holes are open to air, air is entrained and the oscillator does not oscillate. Closing the air entrainment holes initiates oscillation and the issuance of a sweeping liquid jet through the outlet throat.

Owner:DLHBOWLES INC

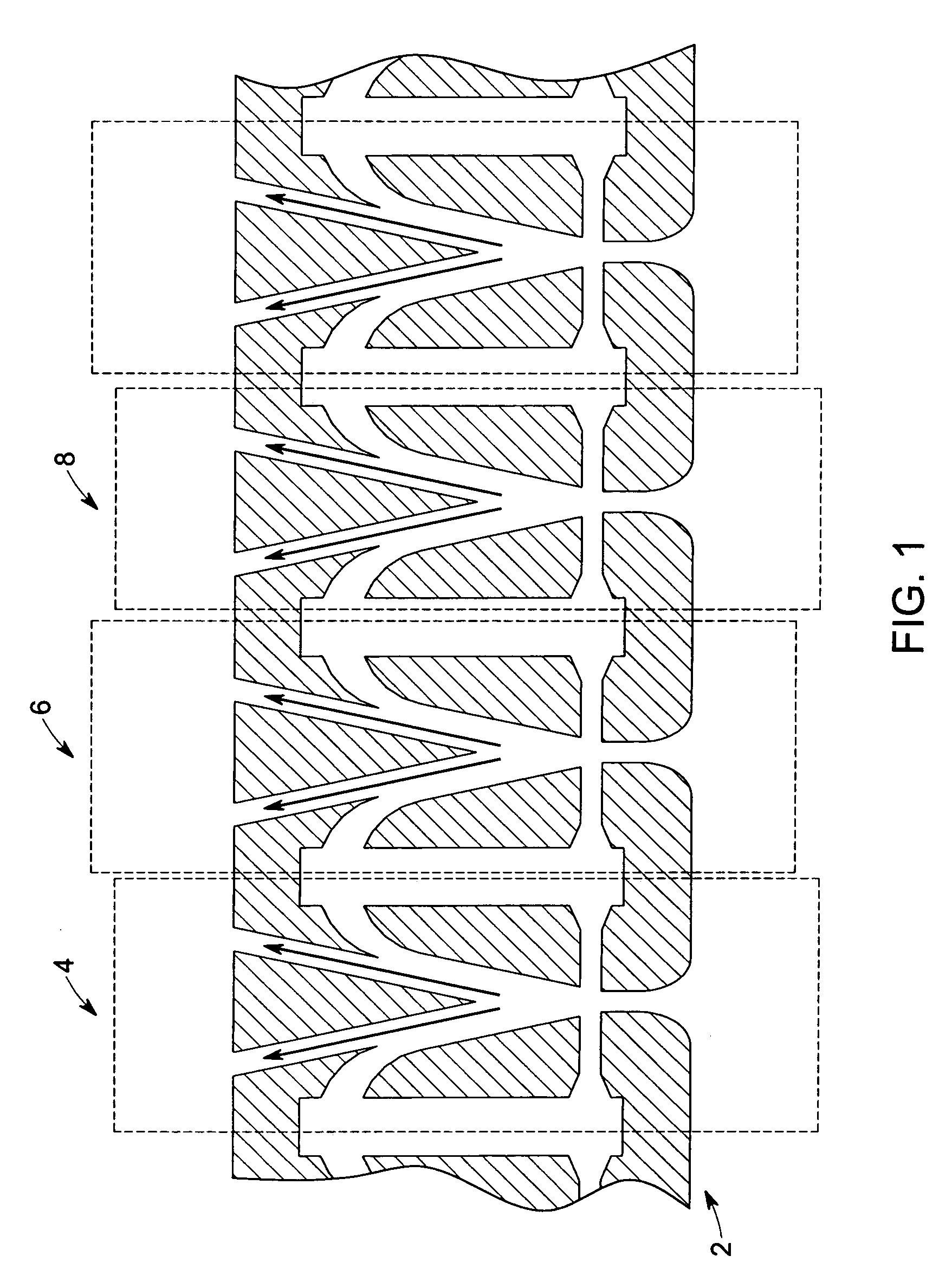

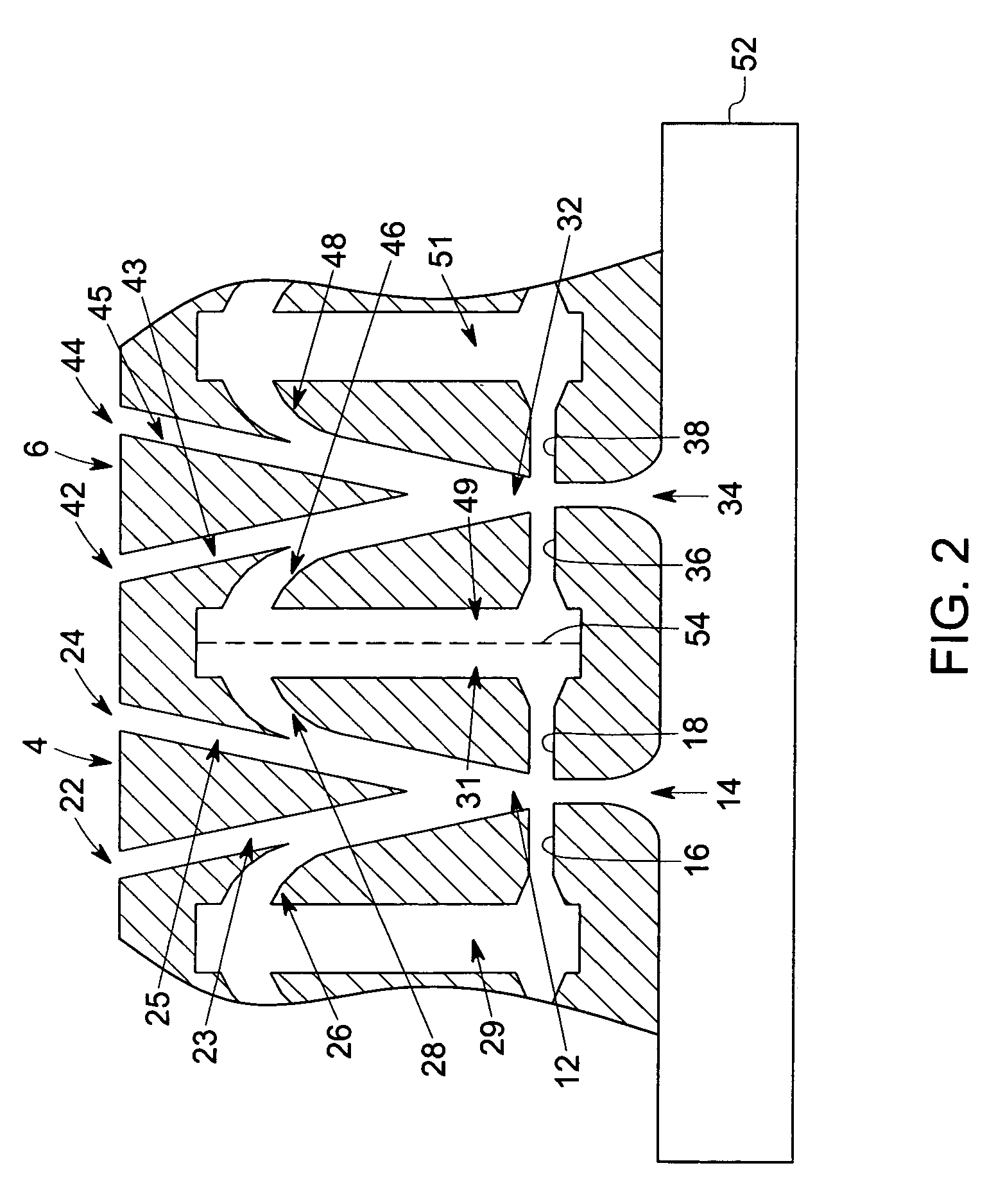

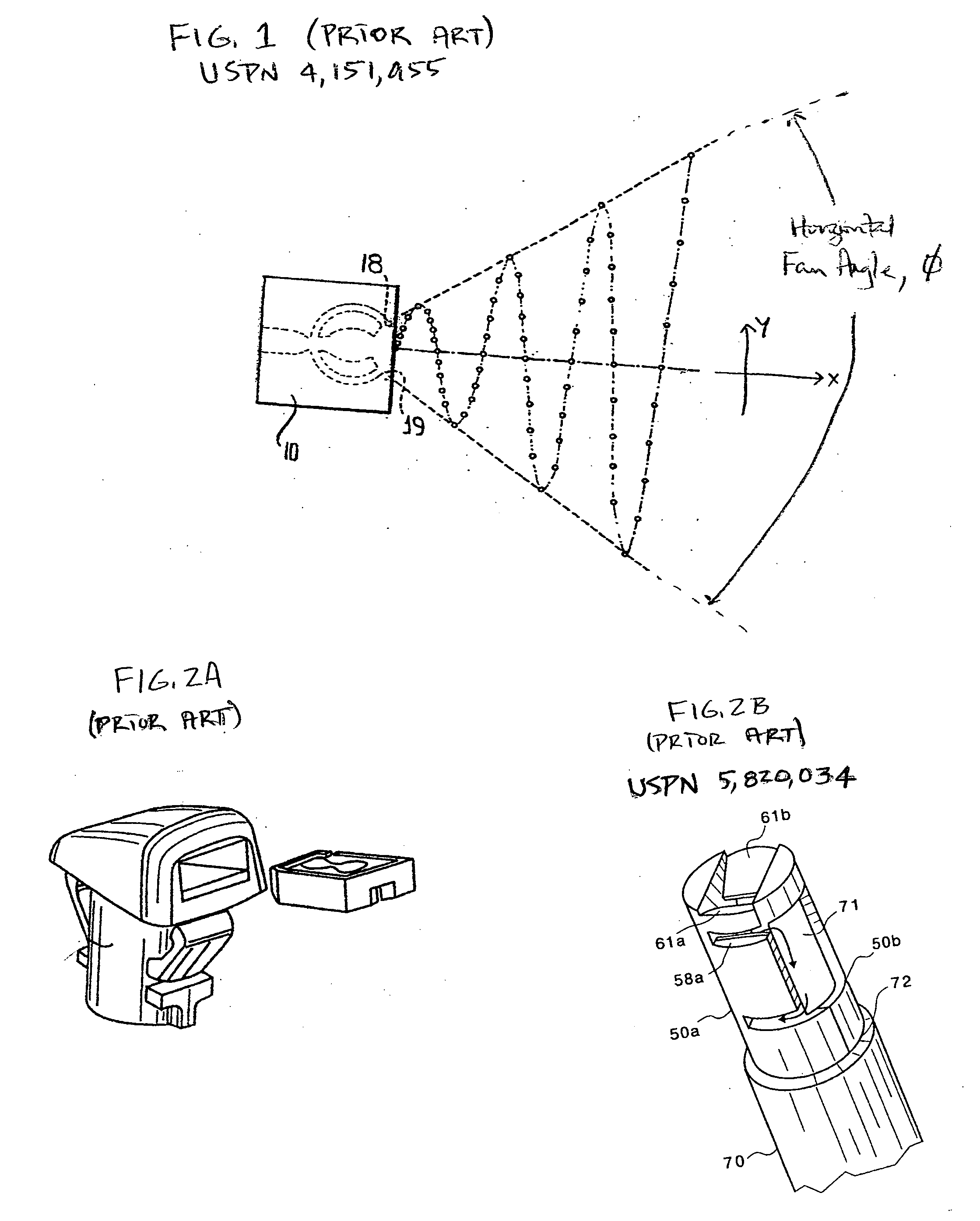

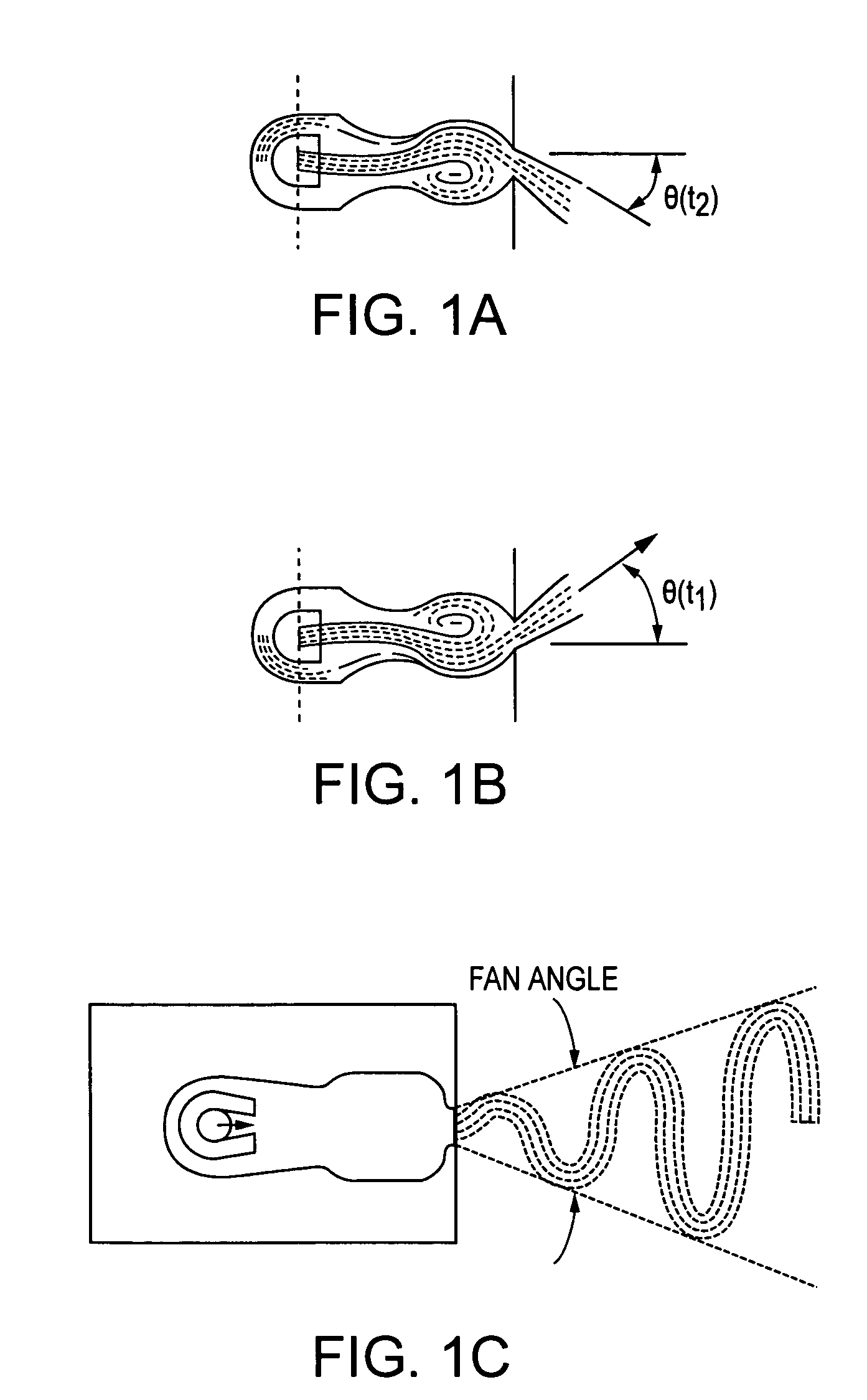

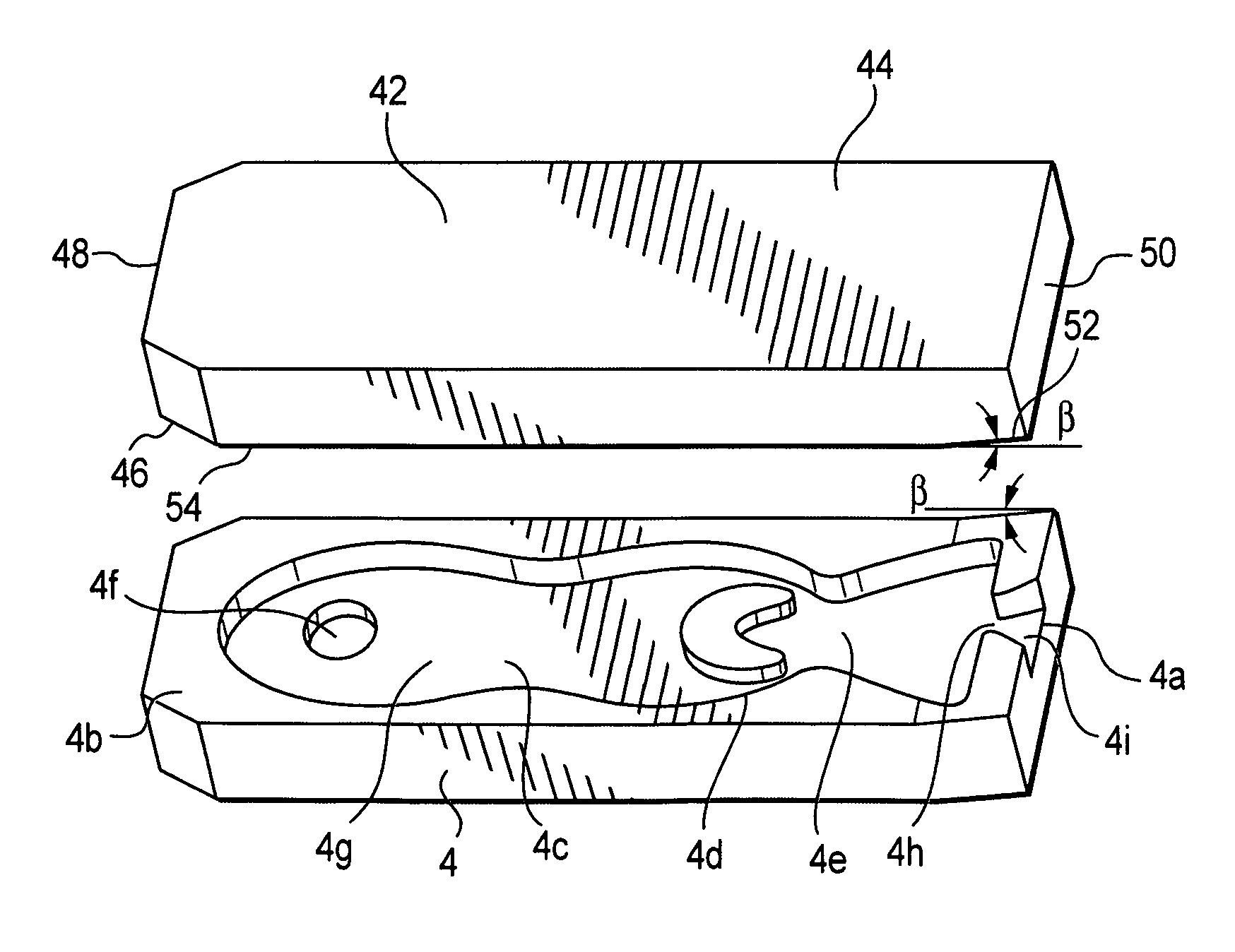

Method and system for flow control with fluidic oscillators

A system for control of a fluid flow. The system includes an array of fluidic oscillators. Each fluidic oscillator carries an oscillating flow of the fluid and includes a throat, an input port connected to the throat, two control ports connected to the throat and two output ports extending from the throat. A feedback line is connected to each of the two output ports and each of the two control ports. The system further includes a plenum connected to the input ports of the fluidic oscillators to supply the fluid to the fluidic oscillators and a feedback chamber disposed along each feedback line of each fluidic oscillator to provide a feedback path for the control fluid to cause oscillatory fluid motion between the first output port and the second output port, the frequency of which may be modulated by adjusting the volume of the feedback chamber.

Owner:GENERAL ELECTRIC CO

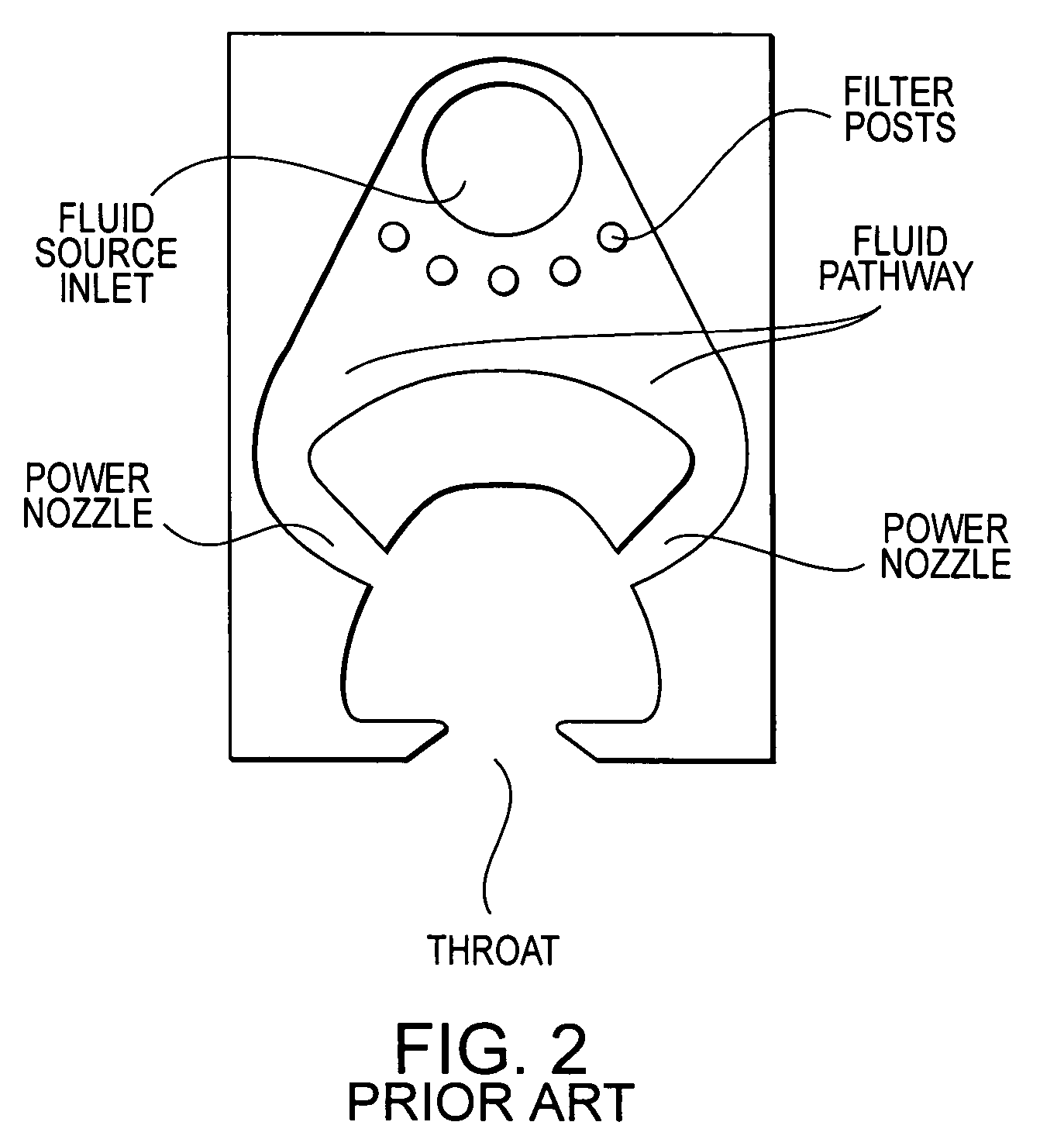

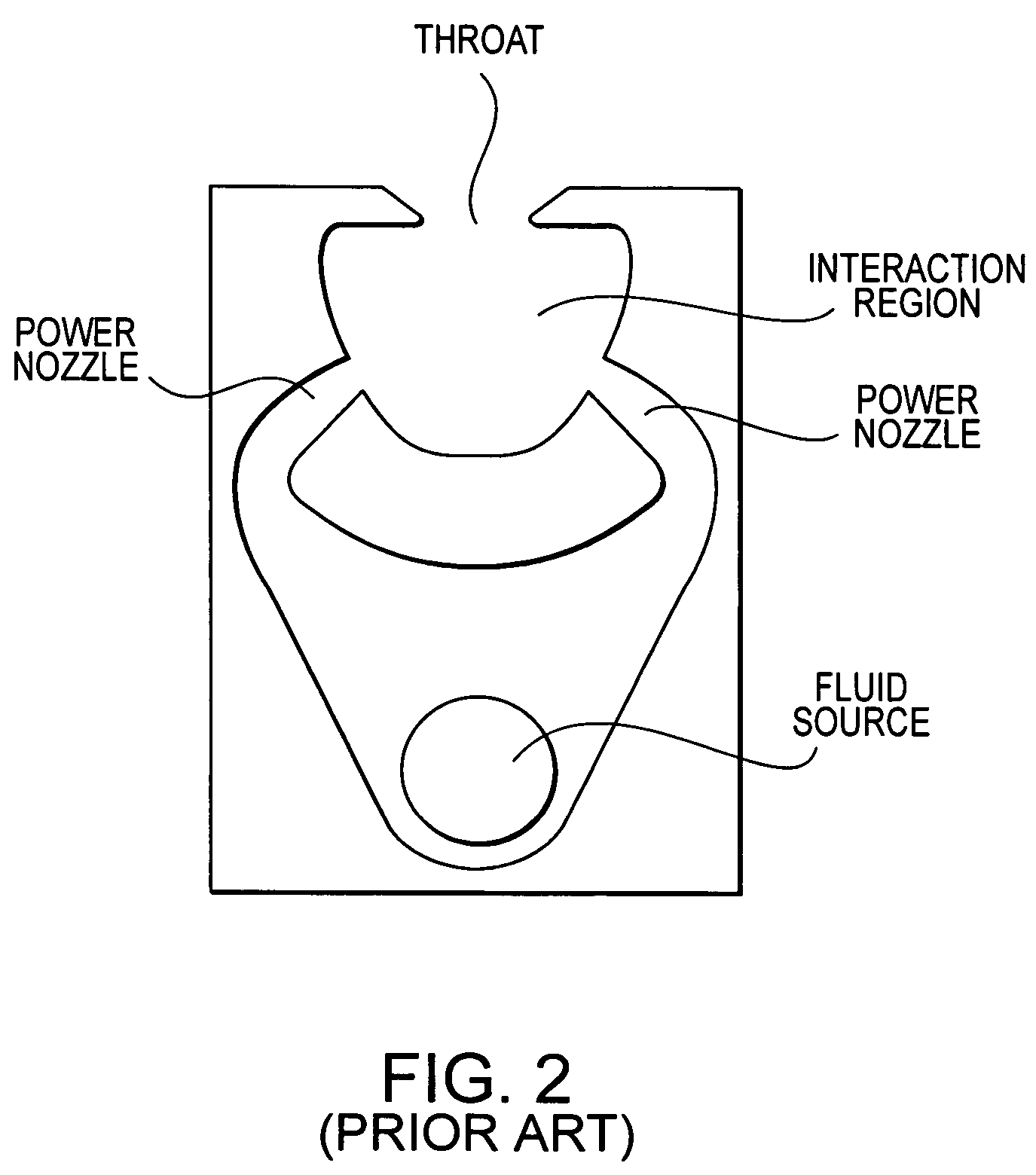

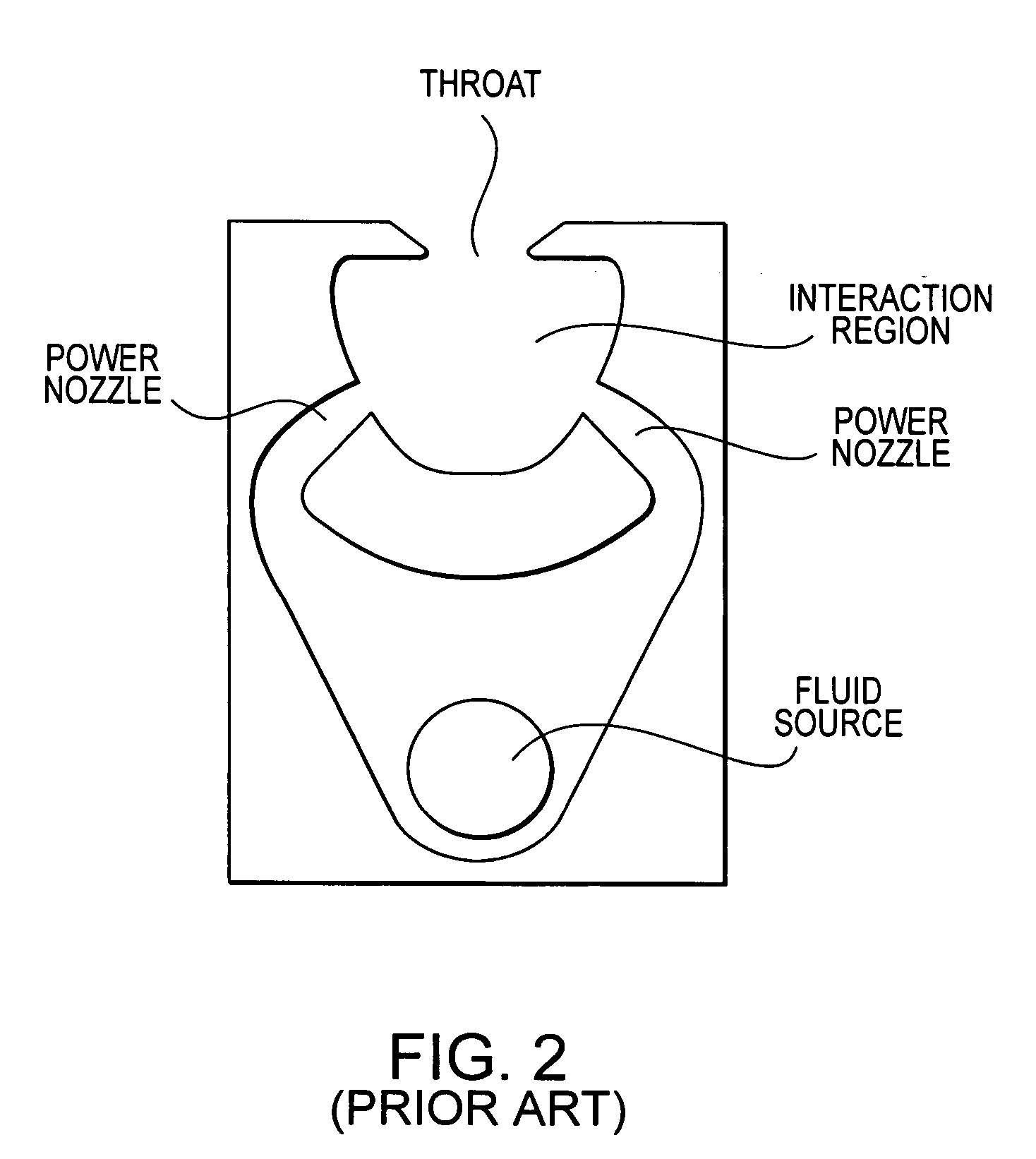

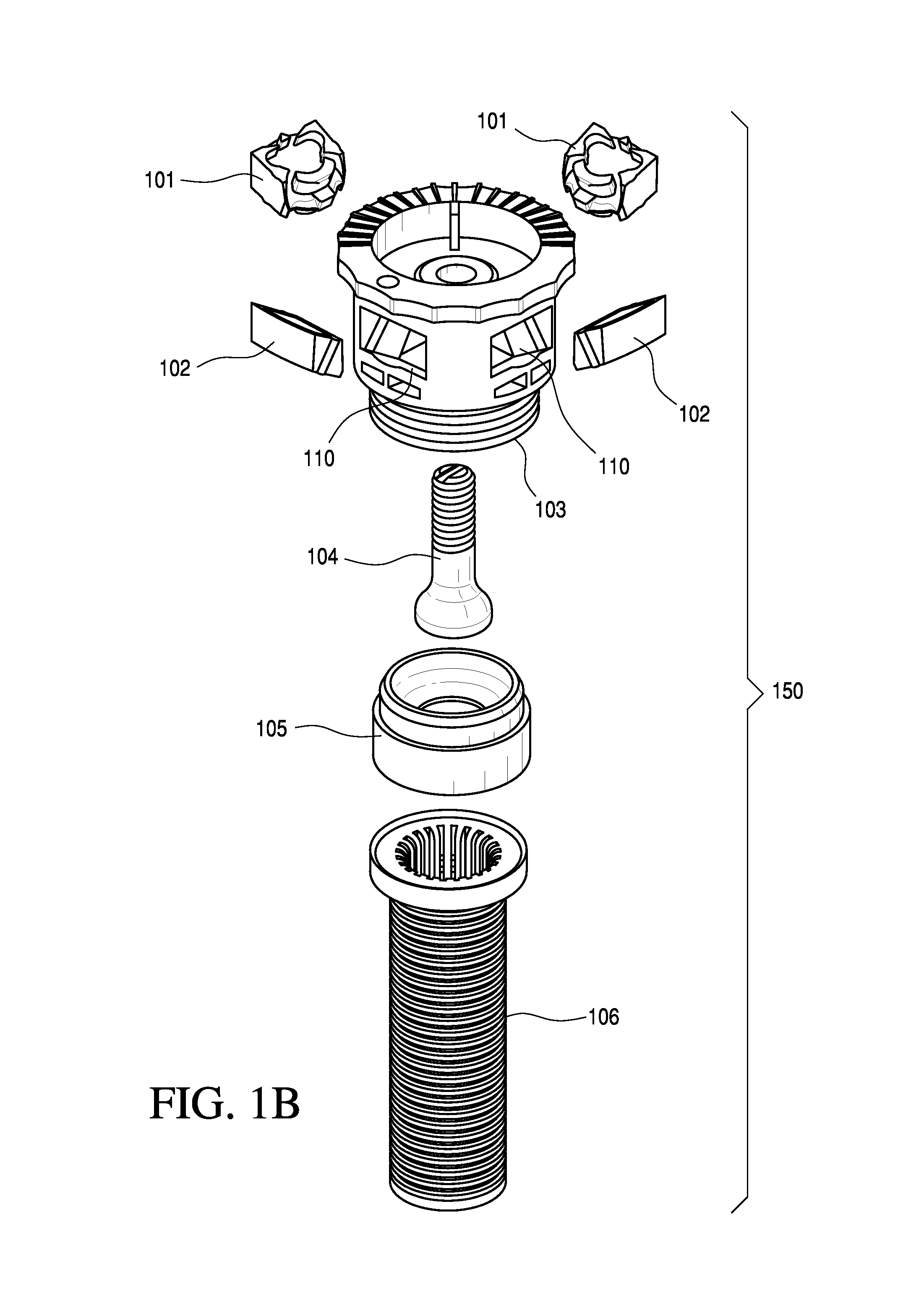

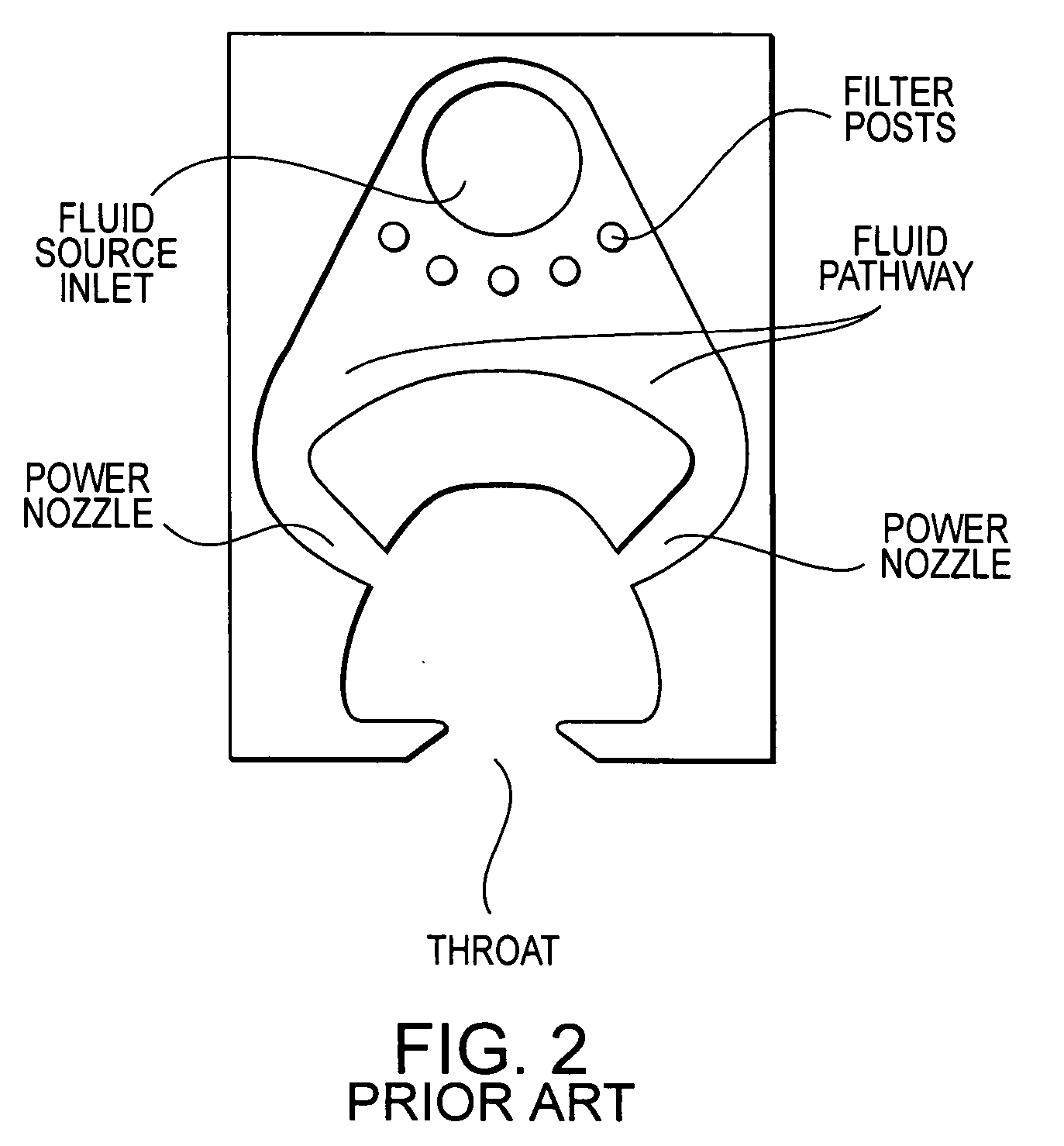

Cold-performance fluidic oscillator

A fluidic oscillator suitable for use at colder temperatures for generating an exhaust flow in the form of an oscillating spray of fluid droplets has an inlet for pressurized fluid, a pair of power nozzles configured to accelerate the movement of the pressurized fluid, a fluid pathway that connects and allows for the flow of pressurized fluid between its inlet and the power nozzles, an interaction chamber which is attached to the nozzles and receives the flow from the nozzles, a fluid outlet from which the spray exhausts from the interaction chamber, and a means for increasing the instability of the flow from the power nozzles, with this means being situated in a location chosen from the group consisting of a location within the fluid pathway or proximate the power nozzles. In a first preferred embodiment, the flow instability generating means comprises a protrusion that extends inward from each side of the fluid pathway so as to cause a flow separation region downstream of the protrusions. In a second preferred embodiment, the flow instability generating means comprises a step in the height elevation of the floor of the power nozzles with respect to that of the interaction chamber.

Owner:DLHBOWLES INC

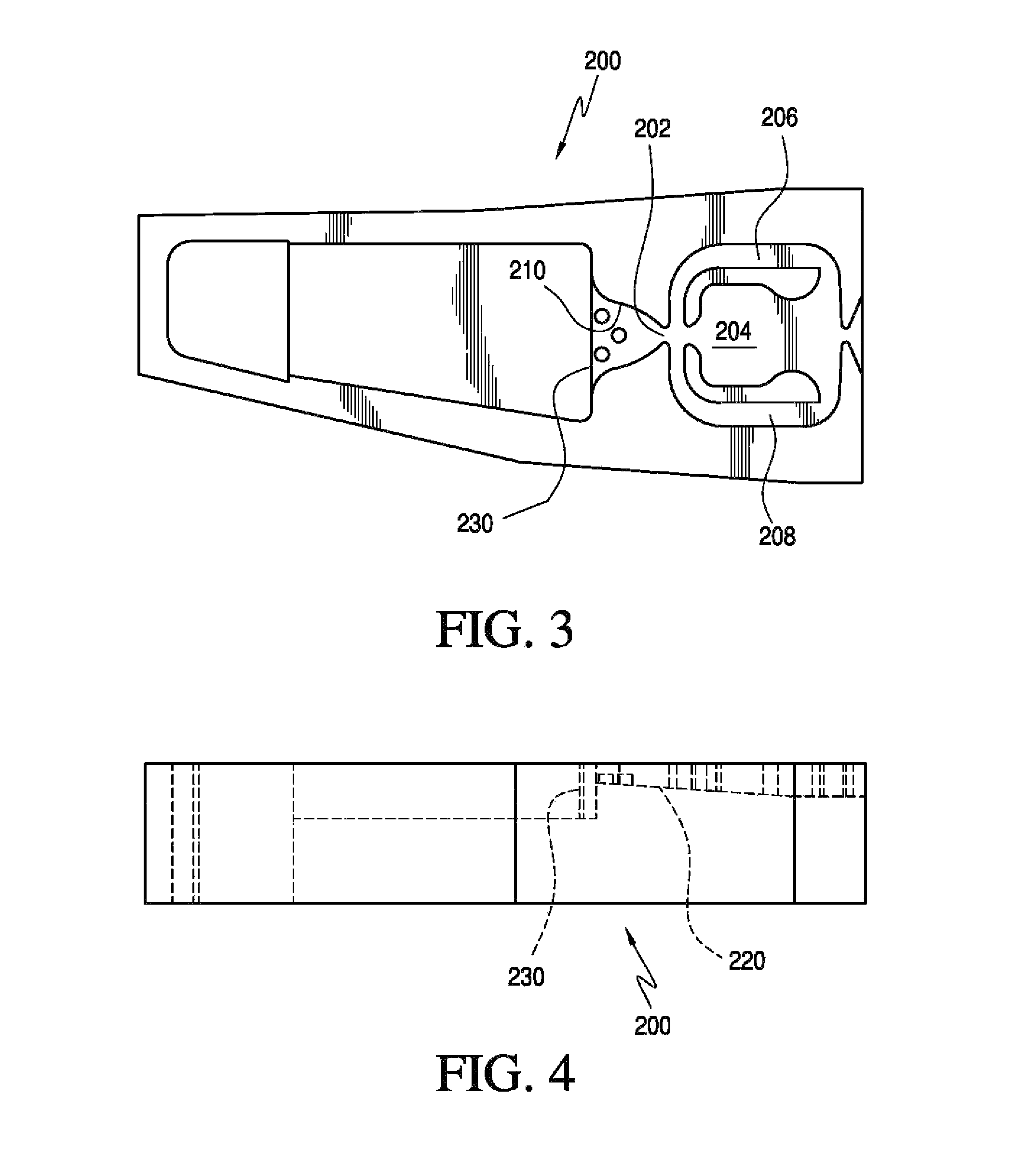

Integrated automotive system, nozzle assembly and remote control method for cleaning an image sensor's exterior or objective lens surface

ActiveUS20160001330A1Easy to cleanPromote effectiveSpray nozzlesColor television detailsCamera lensRemote control

An external lens washing system has an aiming fixture configured to support and constrain an external lens which is exposed to the elements and apt to become soiled with debris. A nozzle assembly is configured to be supported and aimed toward the external lens by the aiming fixture and has at least one laterally offset washing nozzle projecting from the aiming fixture to a spray washing fluid toward the external lens surface, spraying at a shallow, glancing spray aiming angle to impinge upon and wash the lens external surface. Optionally, an integrated image sensor and lens washing assembly is configured for use with a remote control method for cleaning an exterior objective lens surface and includes a sealed image sensor housing assembly including an integral, remotely controllable lens cleaning system with an optimized configuration for aiming one or more cleansing sprays from one or more laterally offset fluidic oscillators.

Owner:DLHBOWLES INC

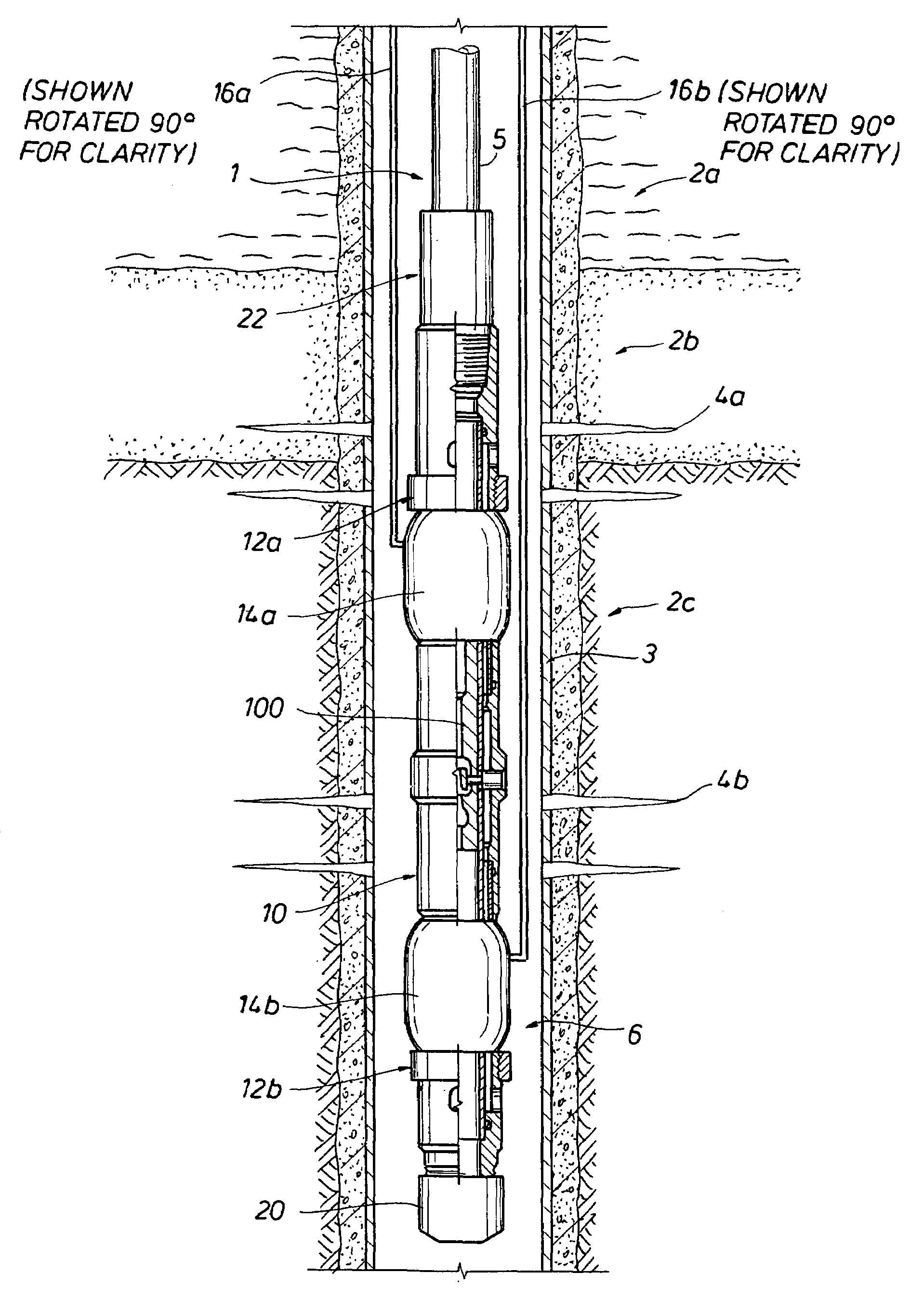

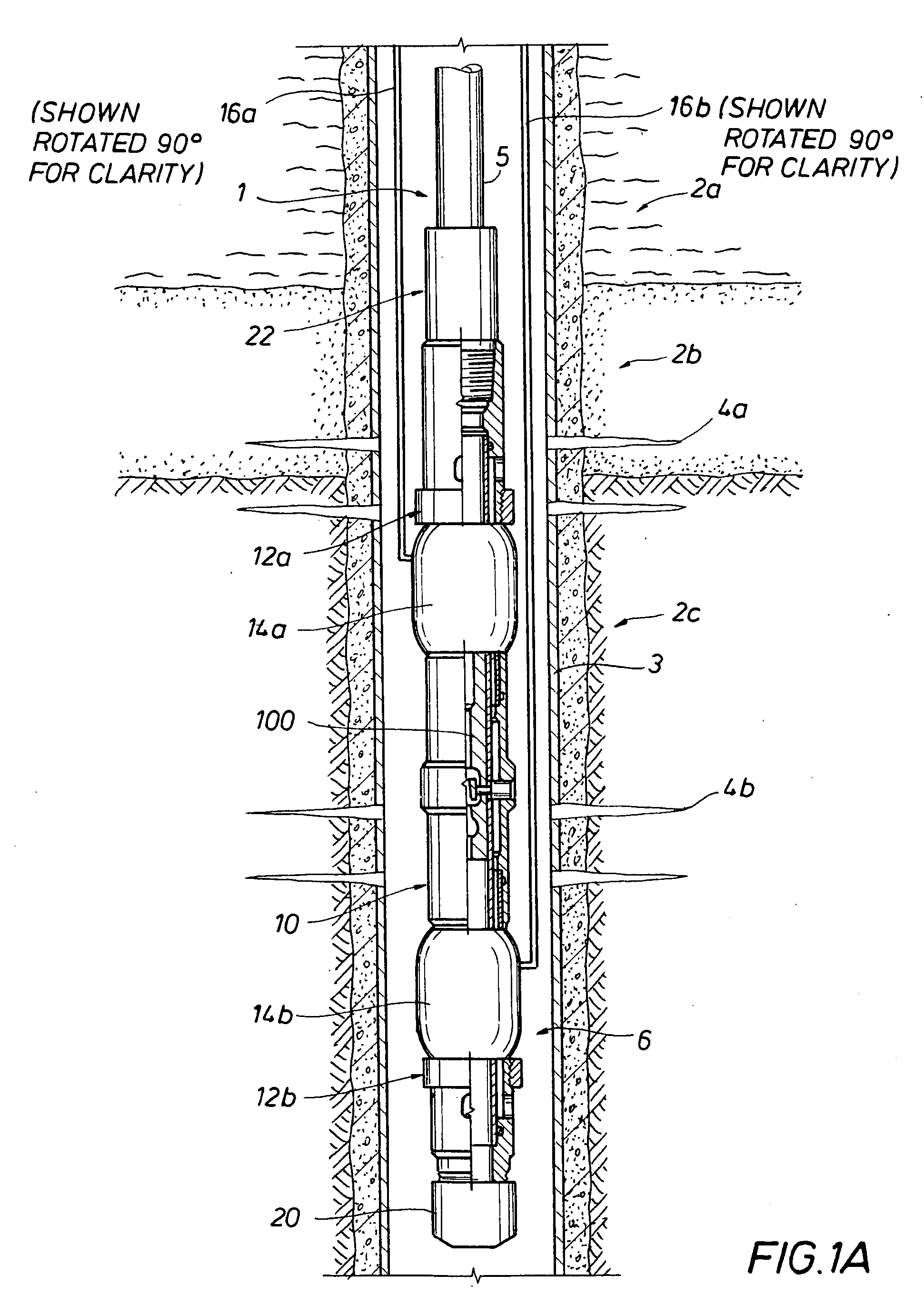

Methods for injecting a consolidation fluid into a wellbore at a subterranian location

Disclosed are apparatuses and methods for stabilizing portions of a subterranean formation and controlling the production of water from those subterranean formations. In one aspect, a method of treating a plurality of discrete portions of a subterranean formation penetrated by a wellbore, the method comprising the steps of: (a) moving a treatment tool through the wellbore on work tubing to a desired subterranean location, wherein the treatment tool comprises: (i) a fluidic oscillator; and (ii) a lower packer positioned below the fluidic oscillator; (b) expanding the cross-section of the lower packer to engage the wellbore, thereby isolating a portion of the wellbore from another portion below the lower packer; (c) injecting a consolidation fluid through the tubing and through the fluidic oscillator into the isolated portion of the wellbore; (d) reducing the cross-section of the lower packer, thereby disengaging the tool from the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

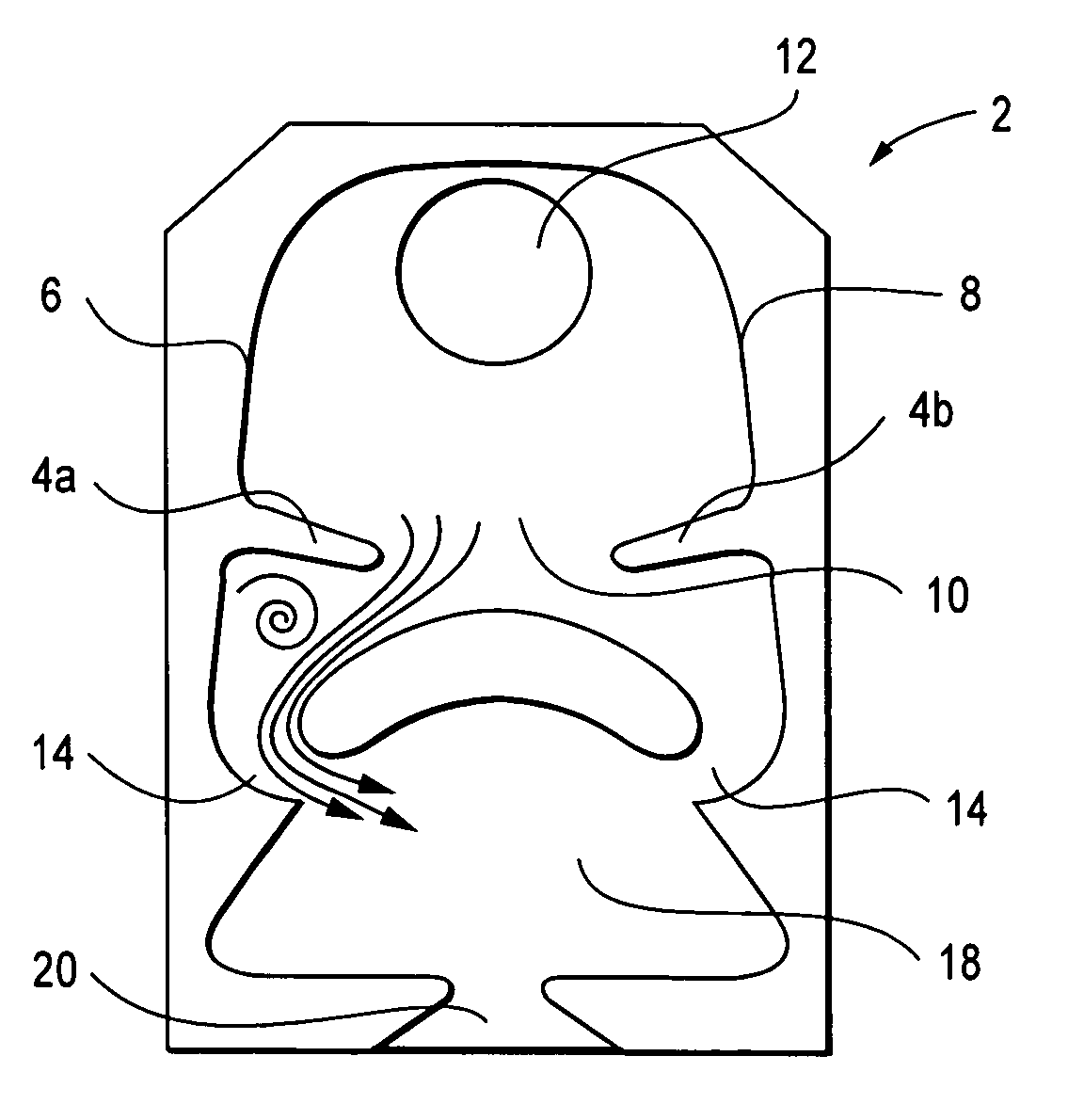

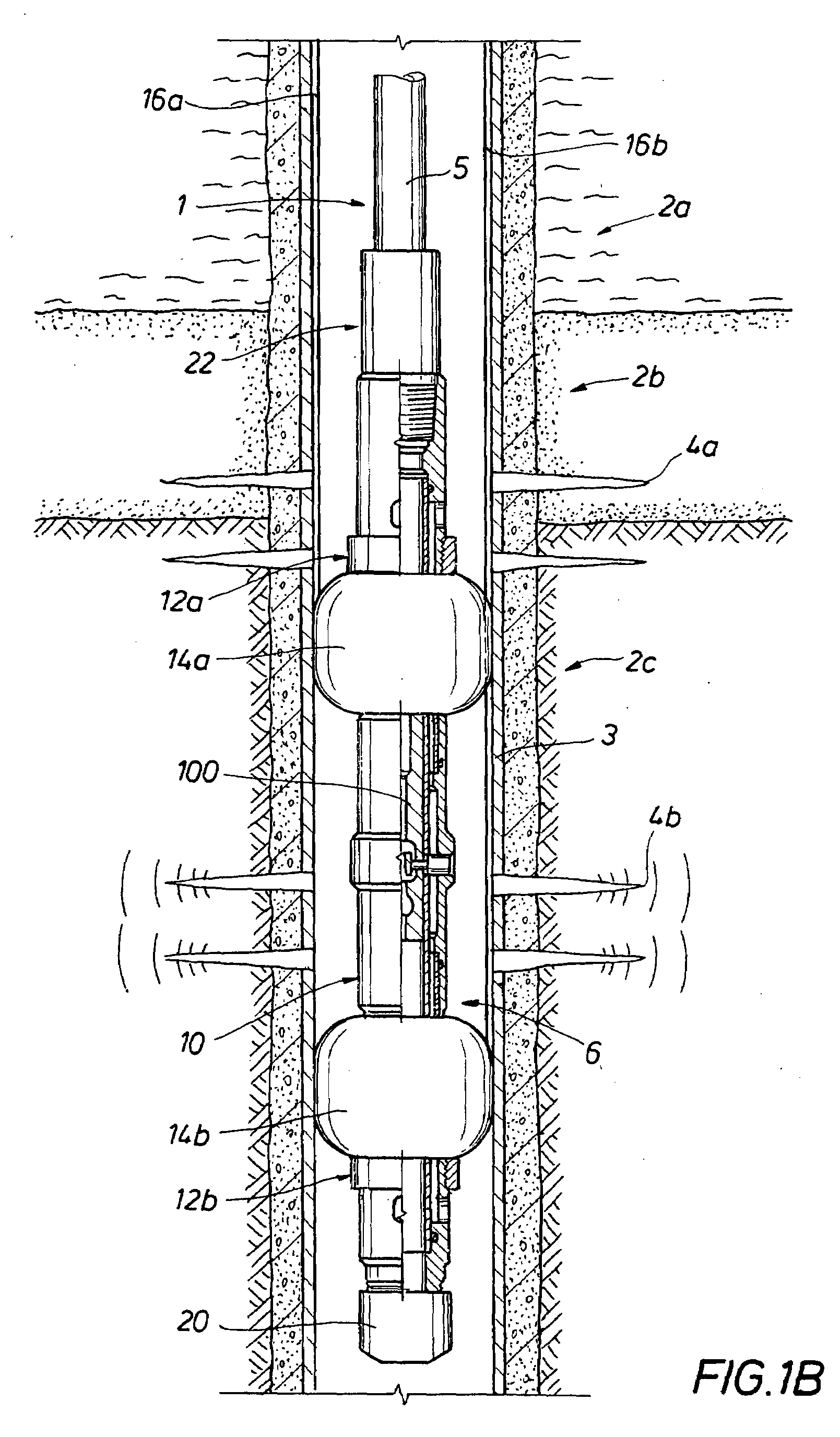

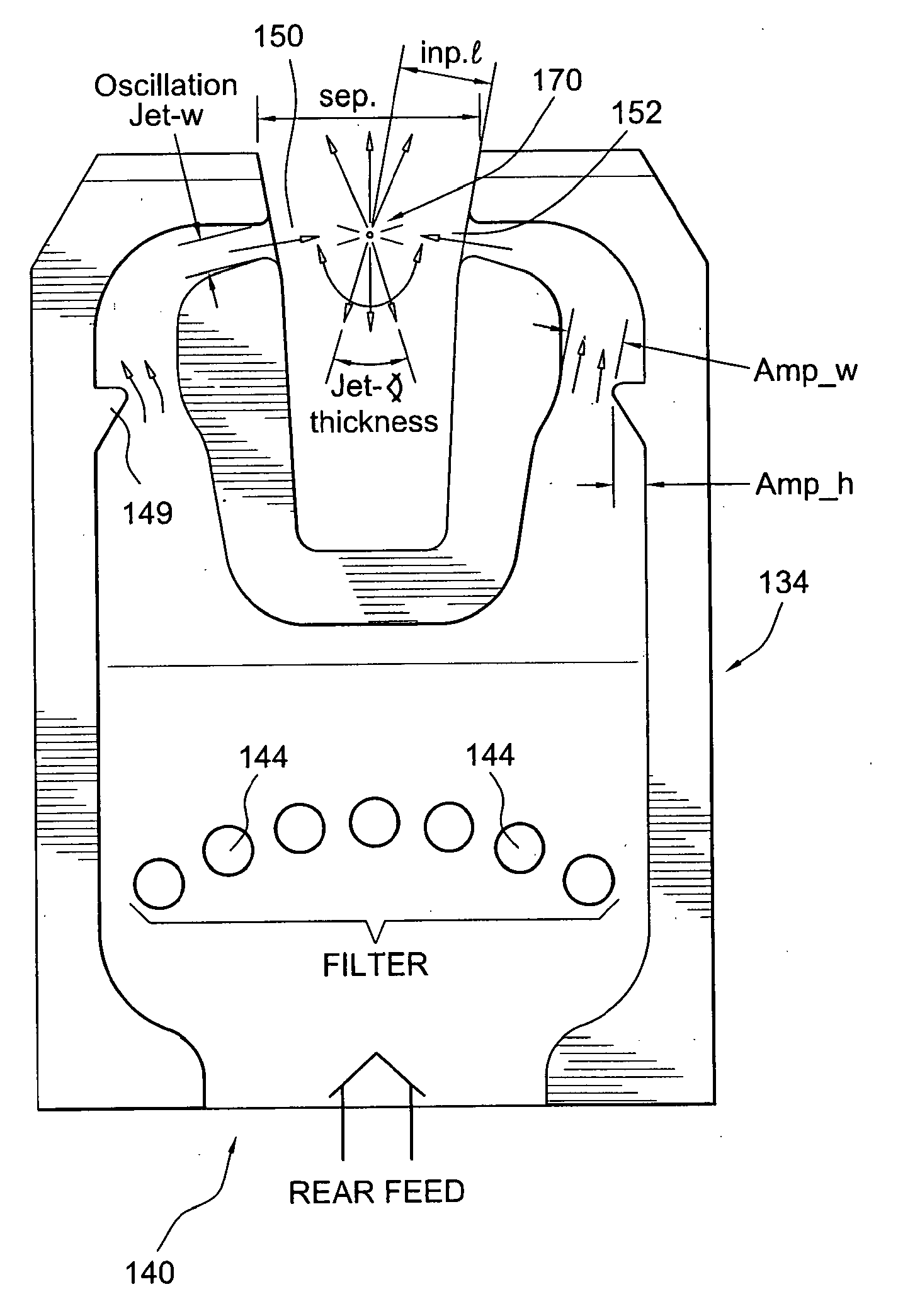

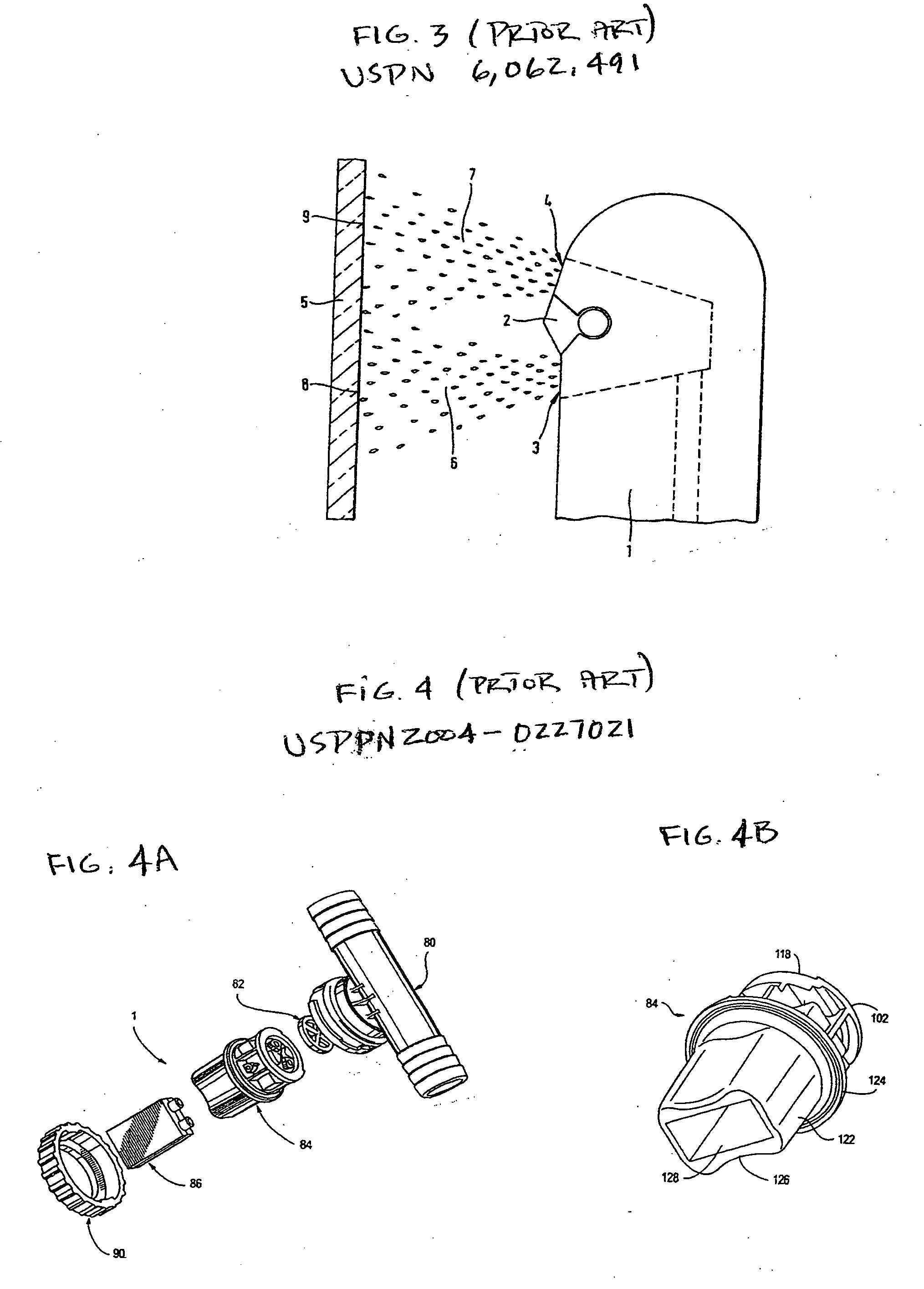

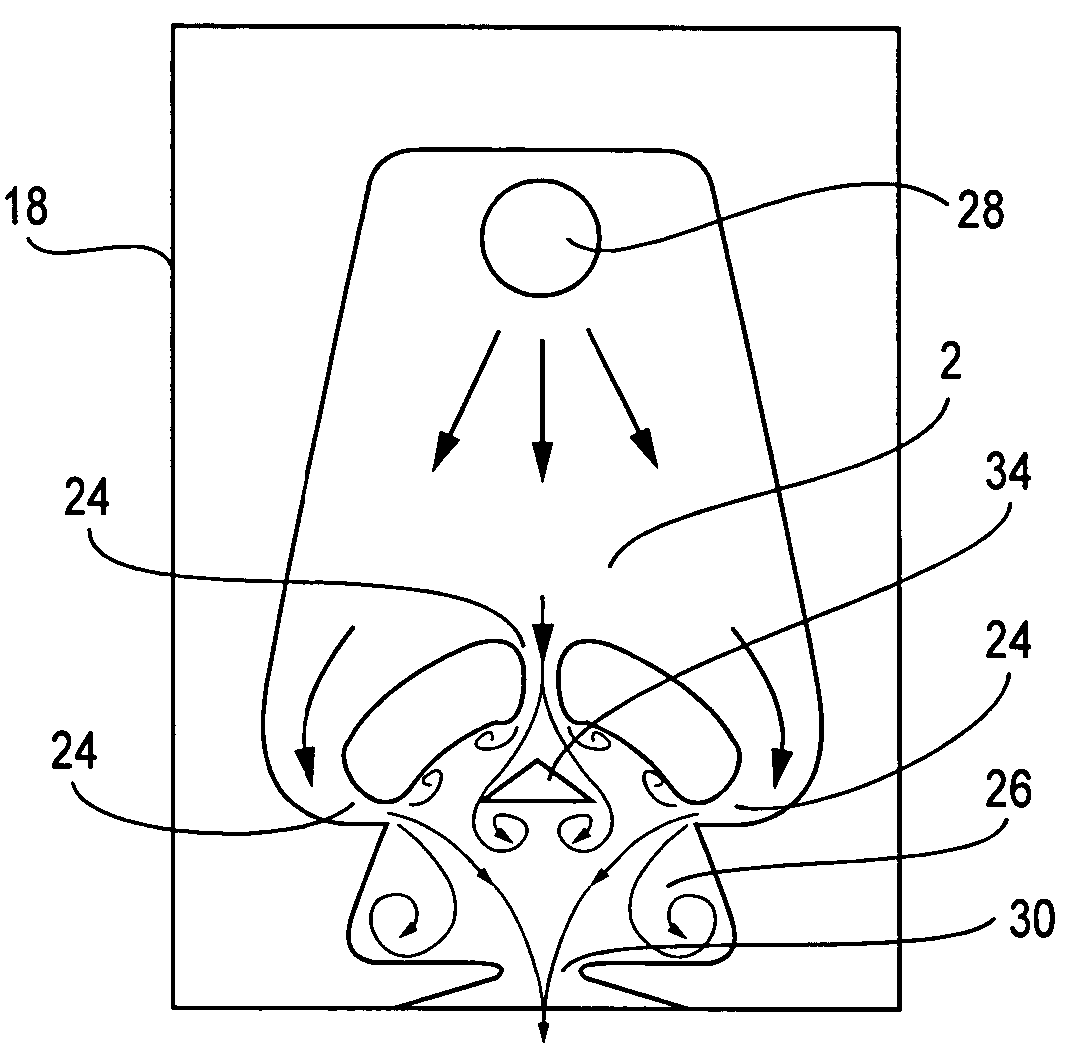

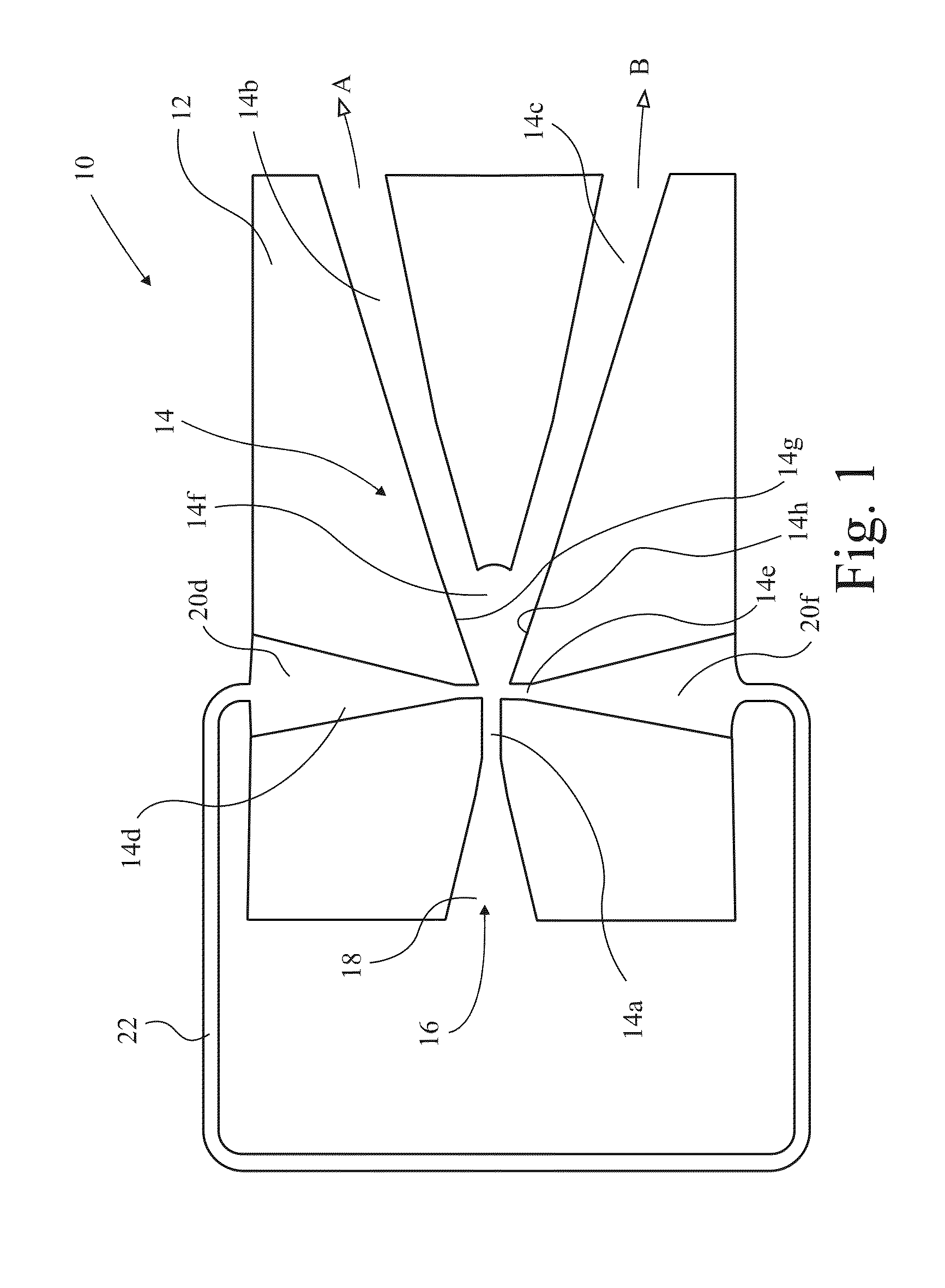

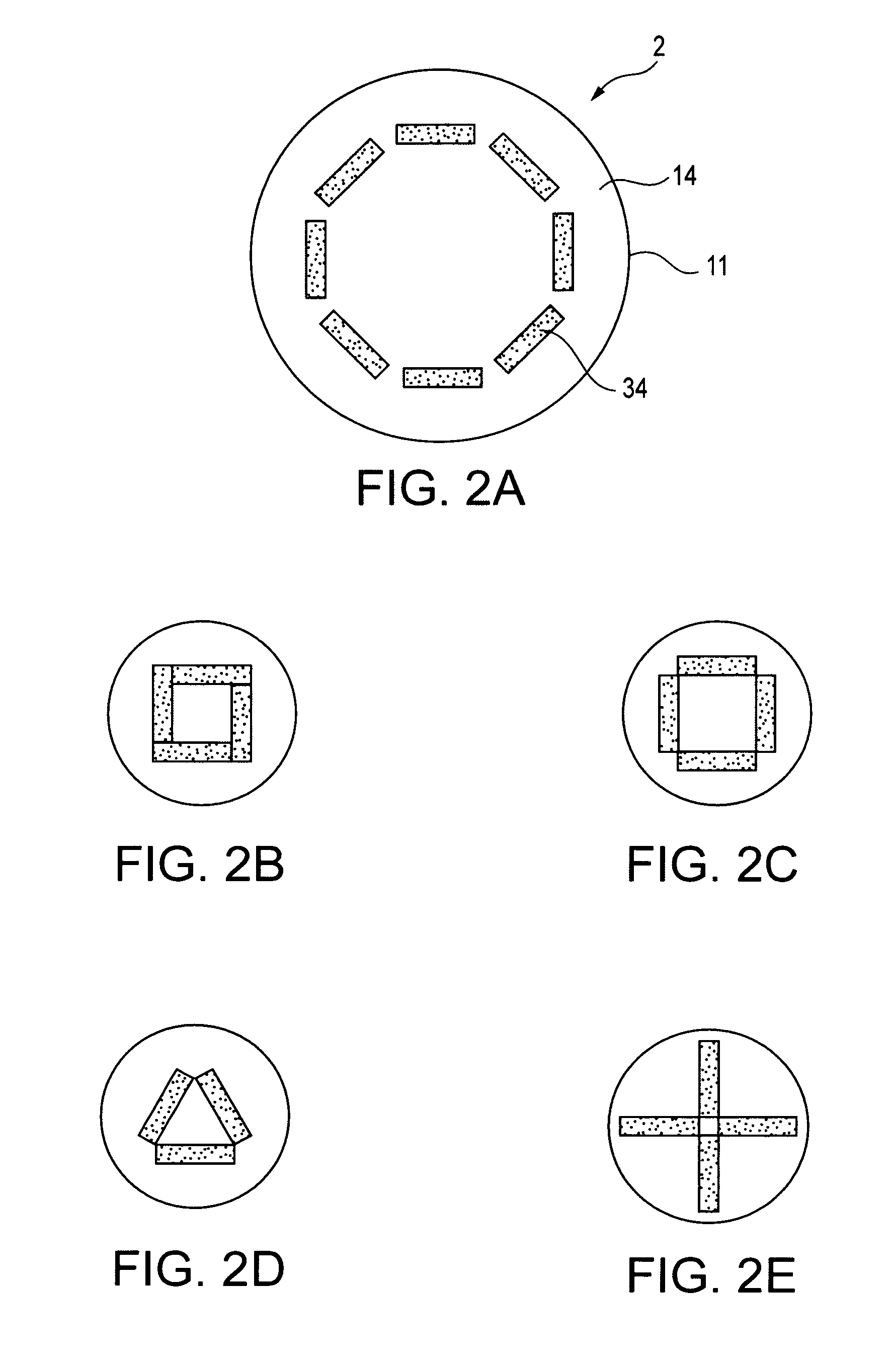

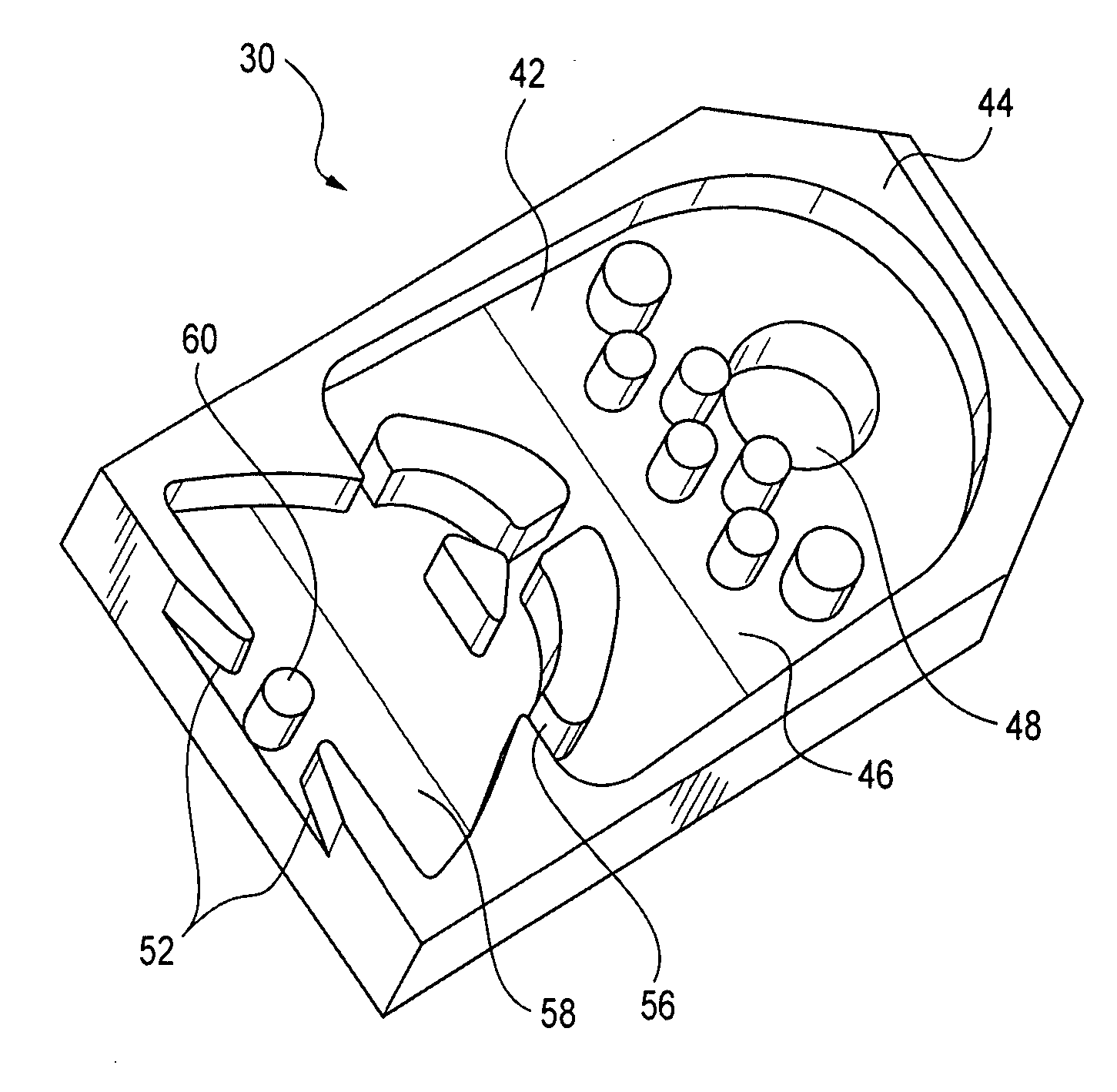

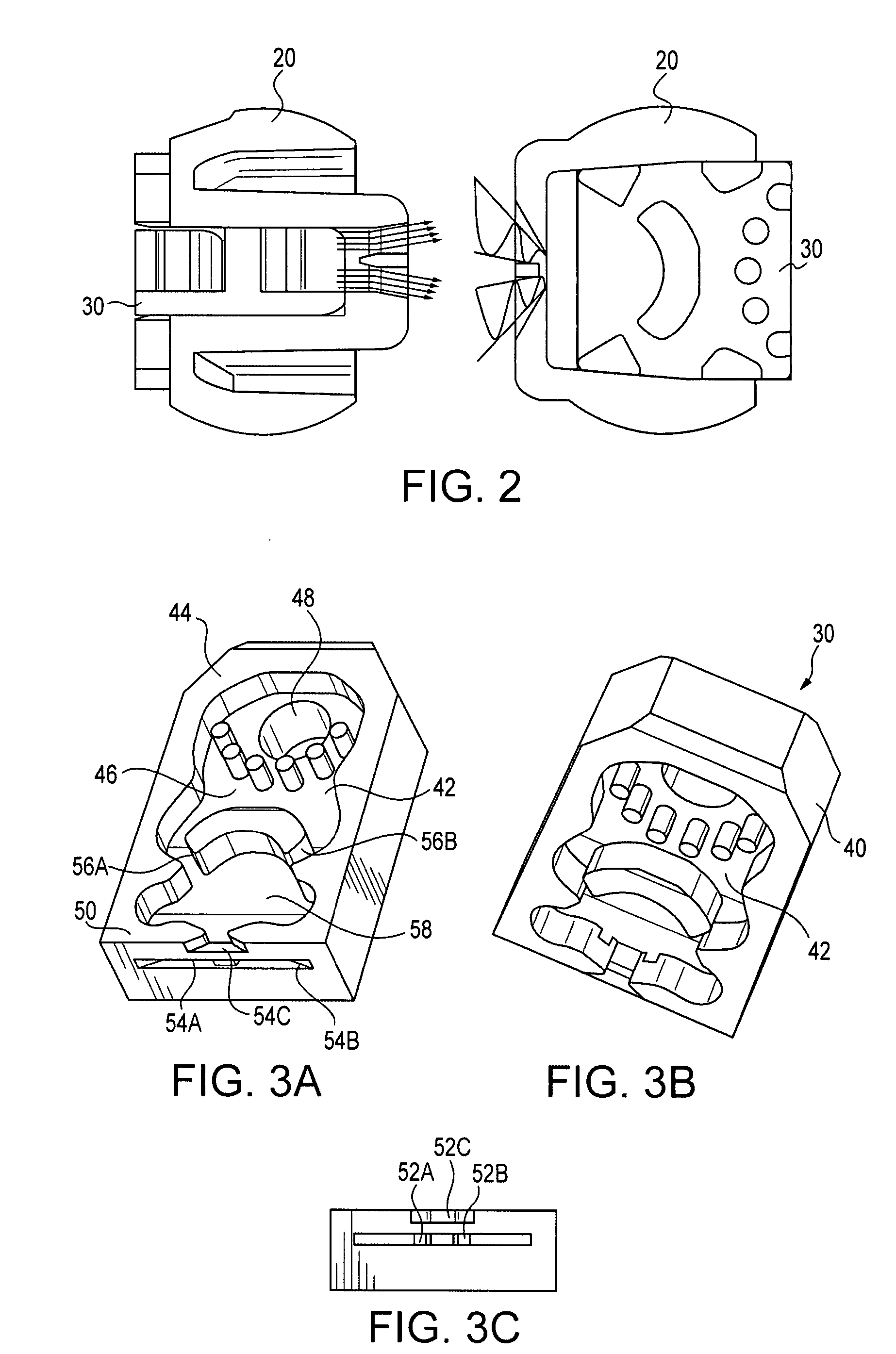

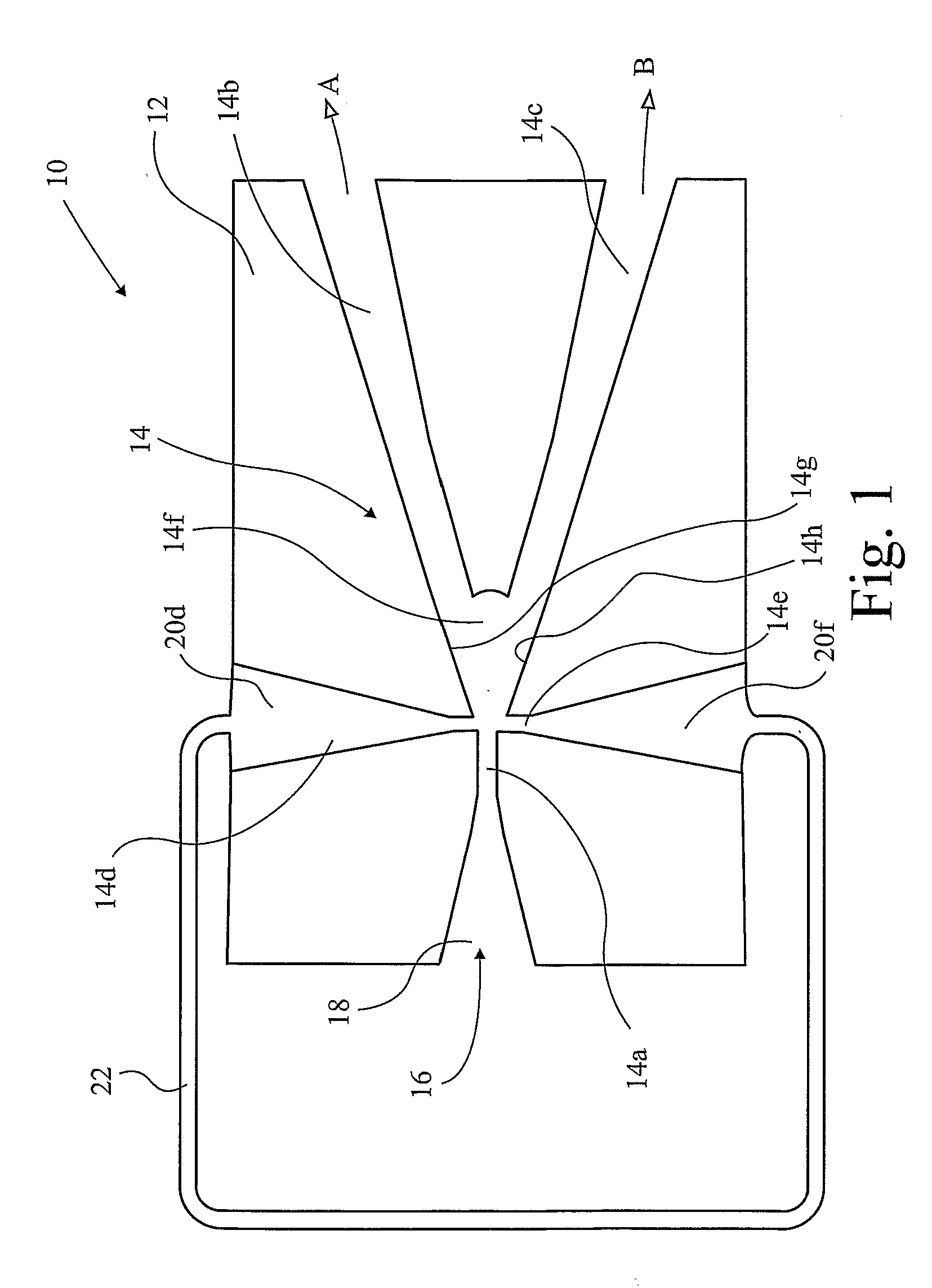

Full coverage fluidic oscillator with automated cleaning system and method

InactiveUS20110061692A1Increase heightImprove spraying effectUrinalsWater closetsAudio power amplifierFluidic oscillator

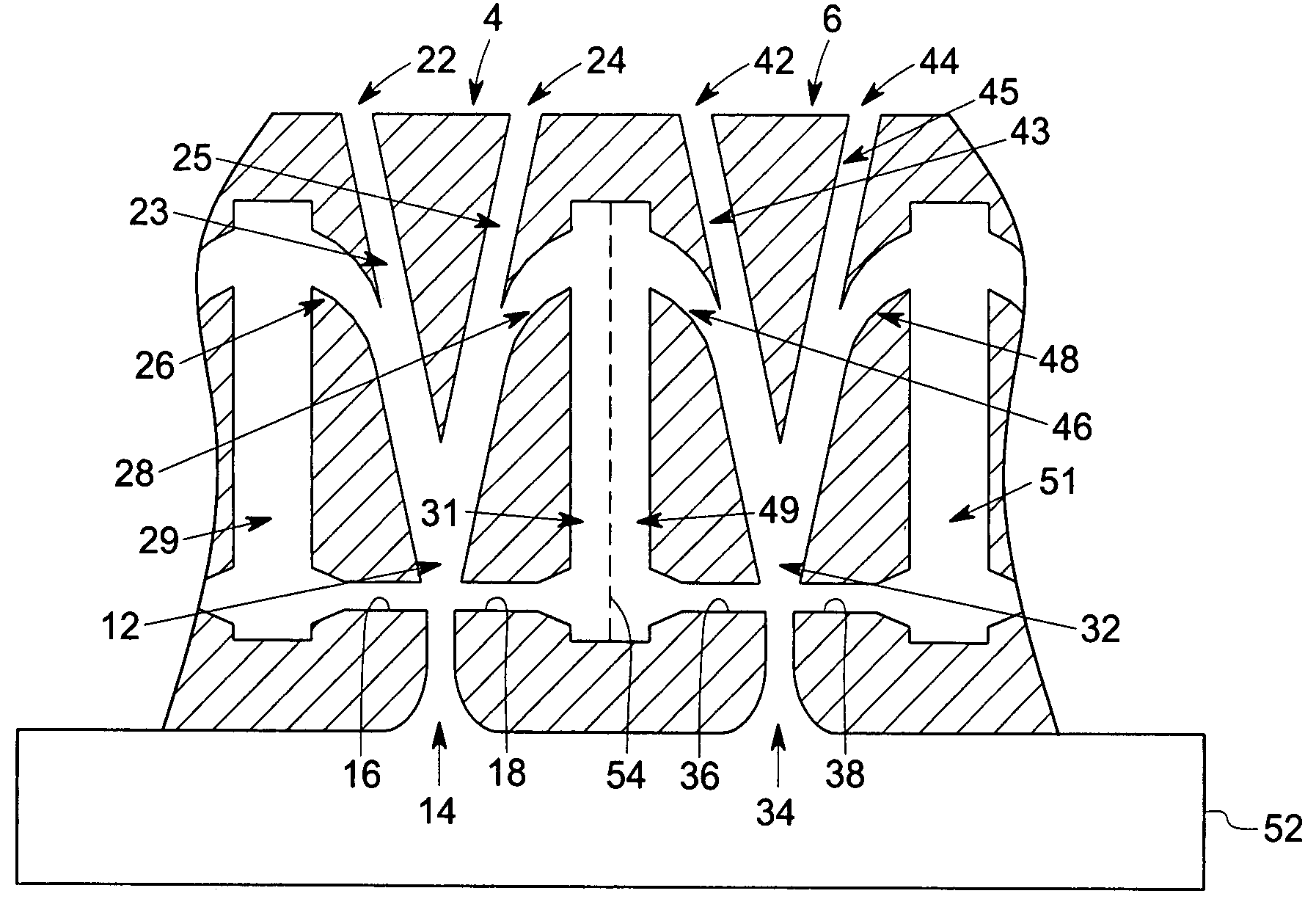

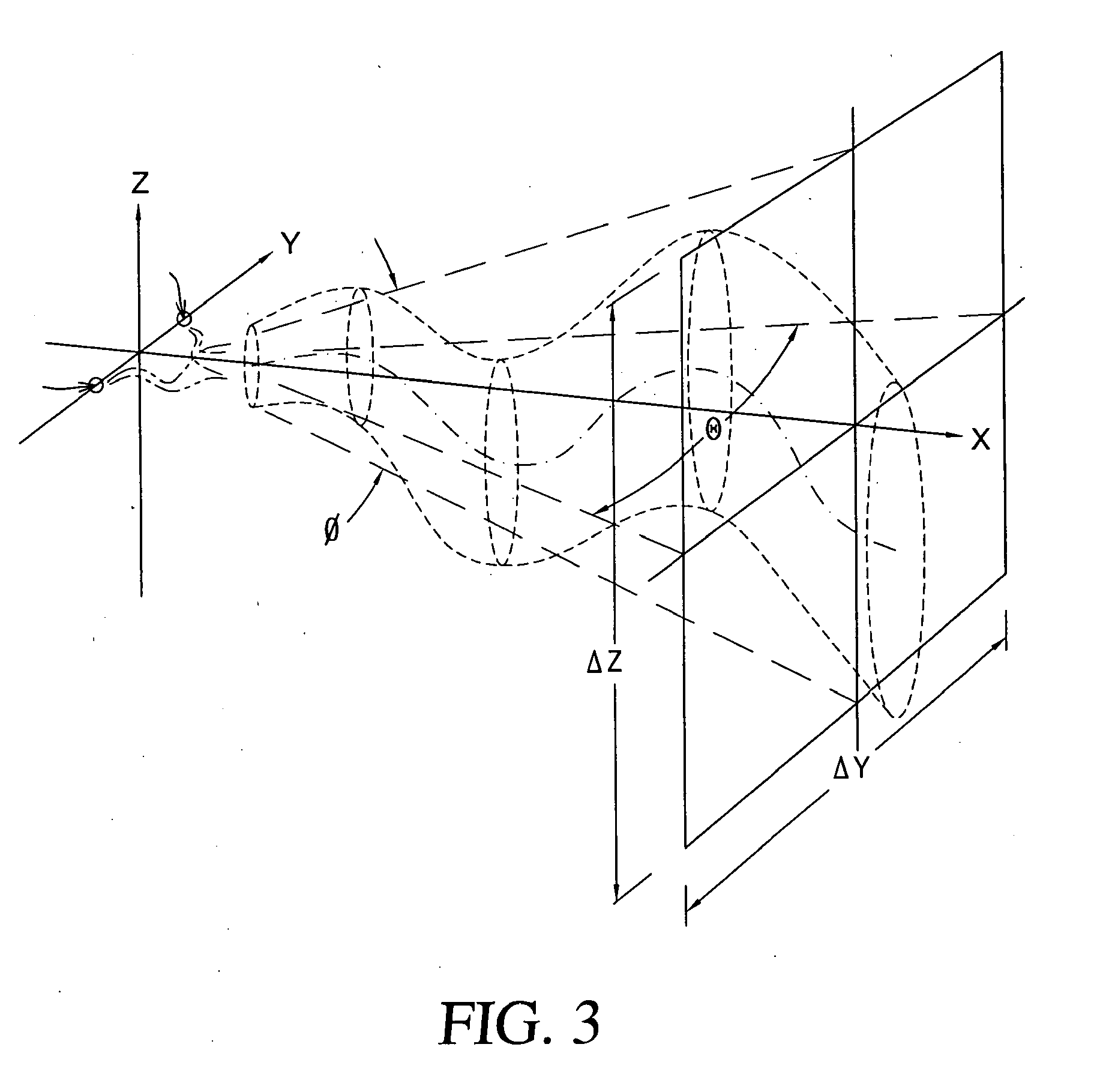

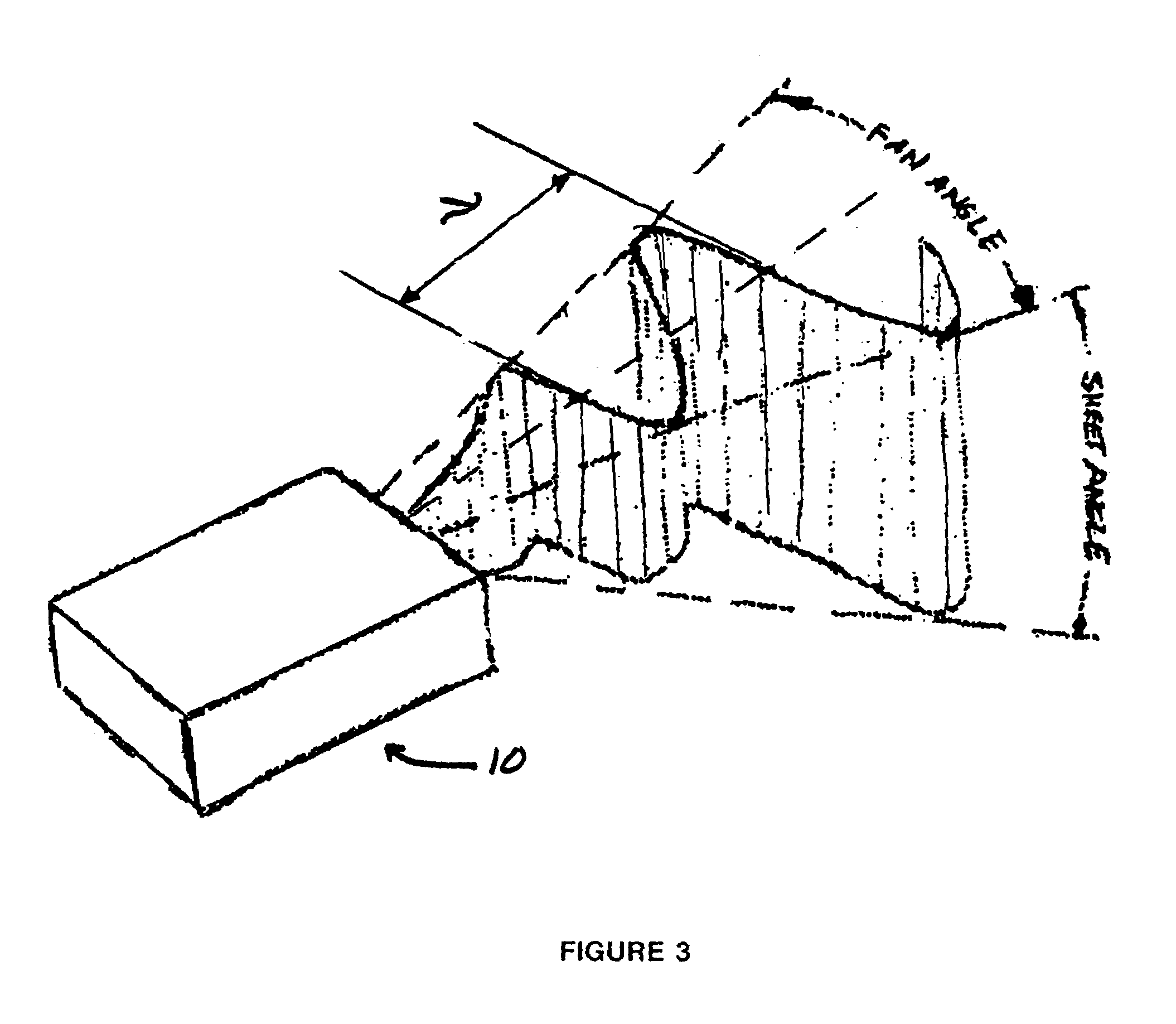

A full coverage fluidic oscillator (2) includes a fluidic circuit member preferably having an oscillation inducing internal chamber, at least one inlet (8) or source of fluid under pressure, at least a pair of output nozzles (14, 16) connected to the source of fluid for projecting at least first and second impinging fluid jets into free space, where the first and second impinging jets collide or impinge upon one another at a selected jet angle to generate a substantially omni-directional sheet jet having selected thickness. The first and second jets are aimed at a pre-selected intersection point in free space where impingement is to occur. The sheet jet's thickness Δy is determined by the time-varying path or oscillation of each of the first and second impinging jets. The first and second impinging jets can be made to oscillate or pulsate by use of vortex generating amplifier structures (68, 70, 72, 149) within the internal chamber's fluid flow paths.

Owner:DLHBOWLES INC

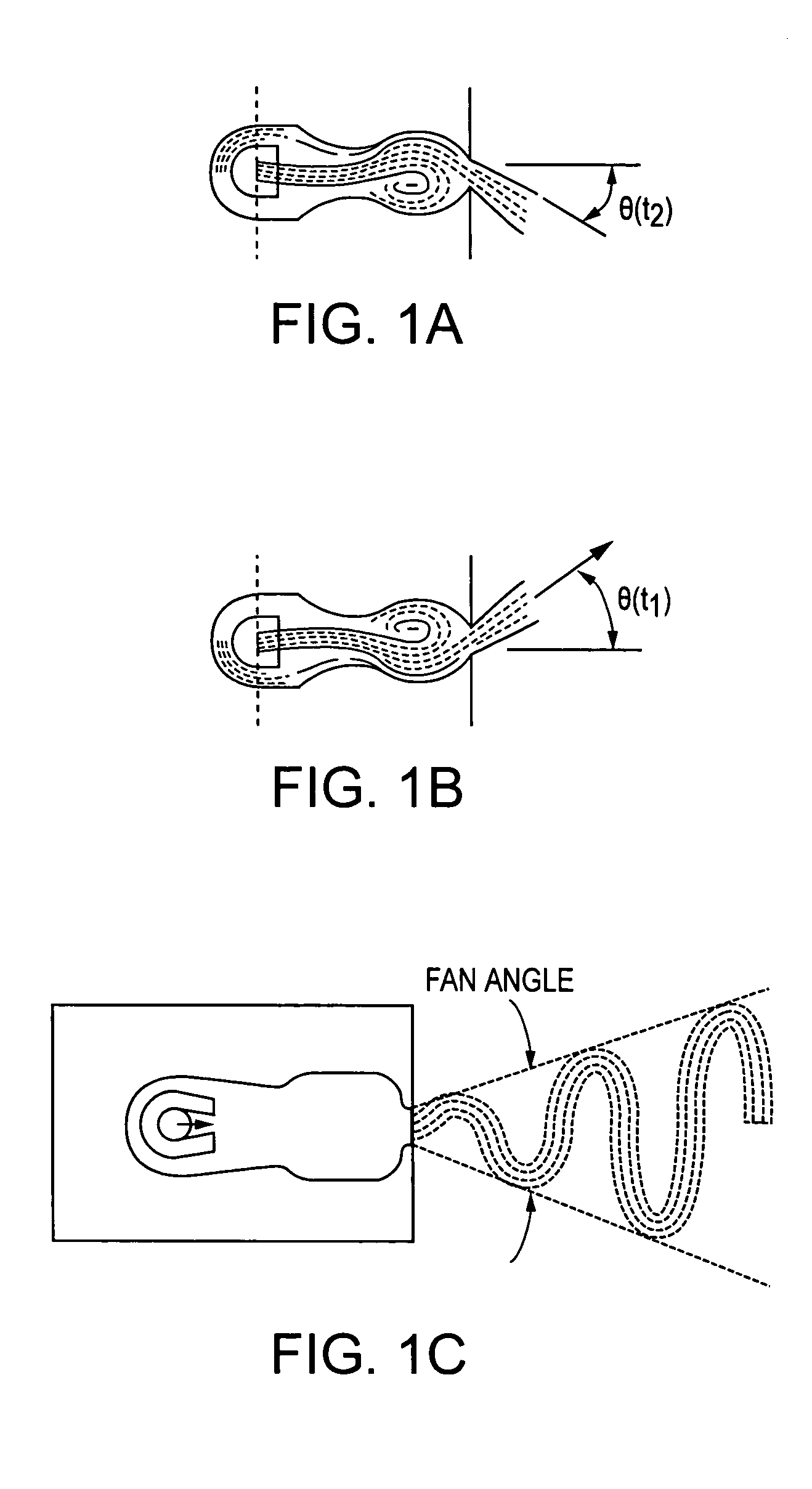

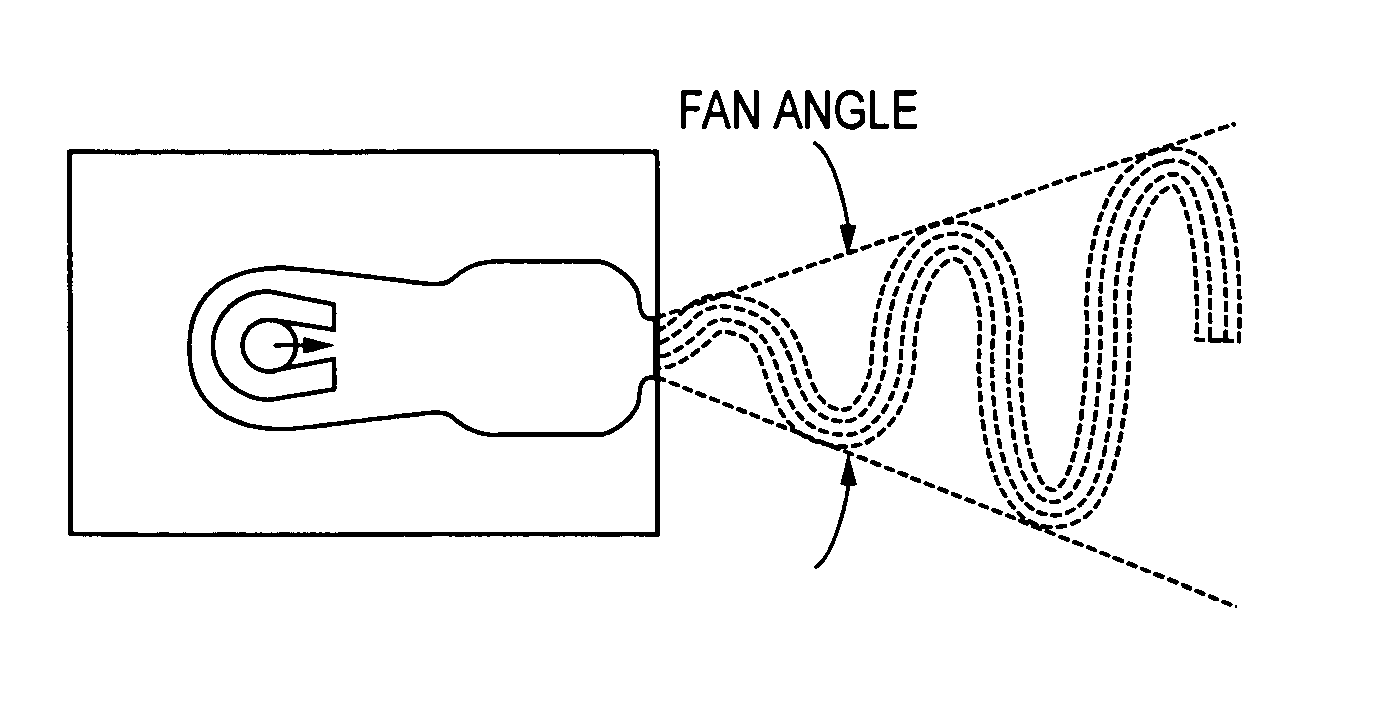

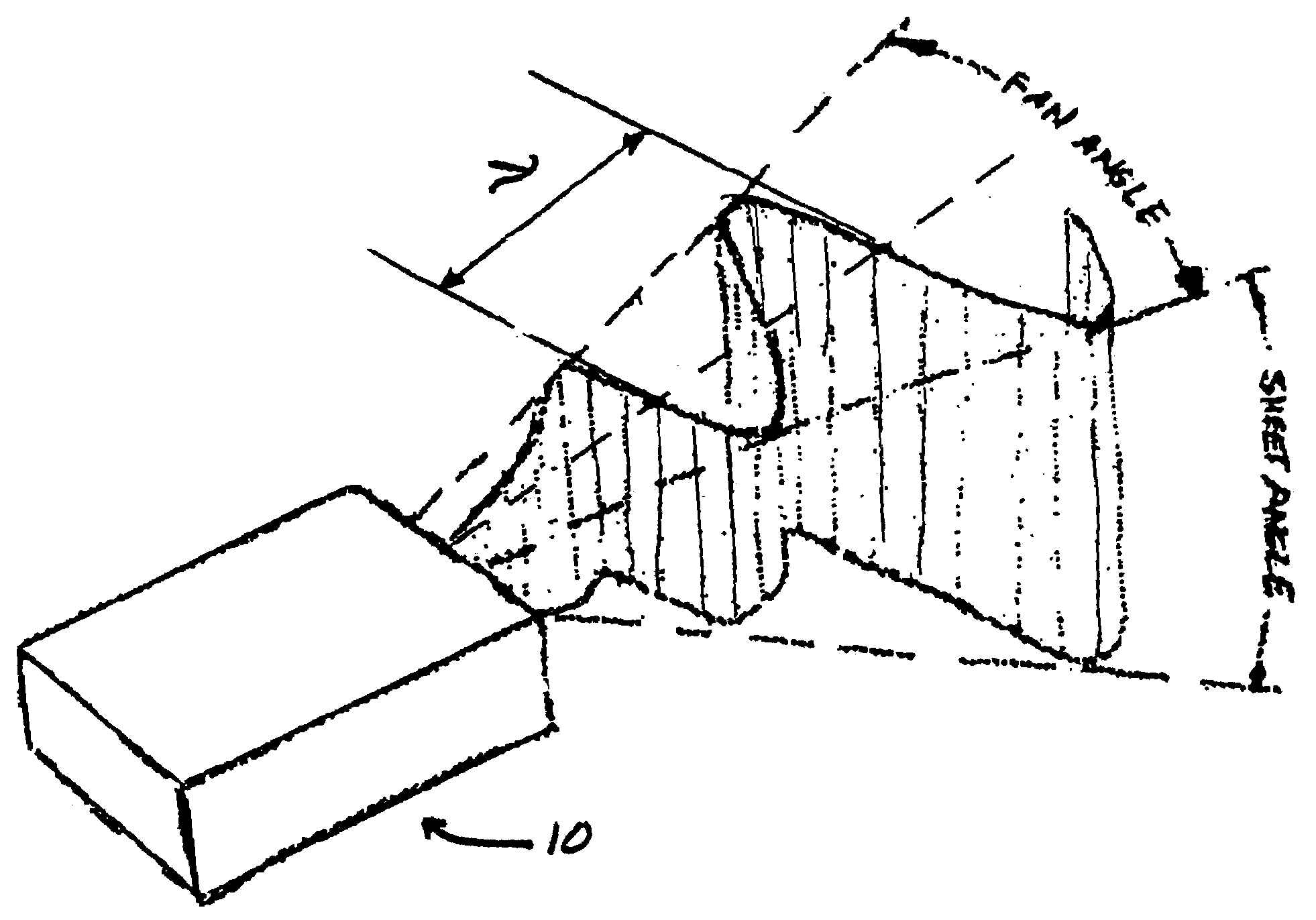

Fluid spray apparatus

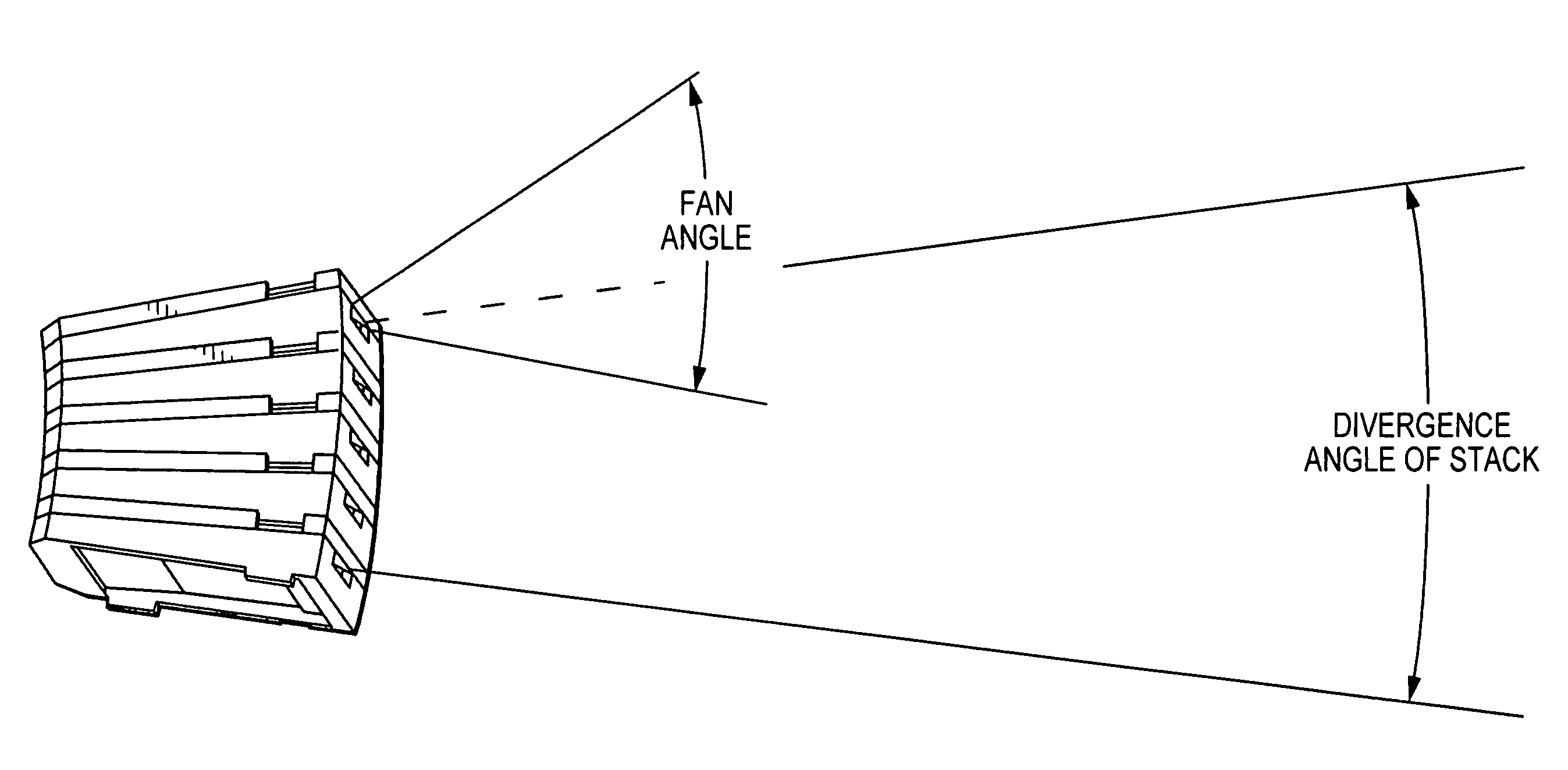

An improved spray head that is more effective and efficient at providing a wider range of desired spray distributions includes the following elements: (a) a plurality of fluidic oscillators, each oscillator having a fluidic circuit embedded in its top surface, with this circuit forming a path in which a fluid may flow through the oscillator, wherein these oscillators are stacked one on top of the other, with the sides of the oscillators being configured so that they stack such that the flow of fluid from adjoining oscillators in the stack have an angle of divergence between the centerlines of the planes defined by the flows from the outlets of the adjoining oscillators that is in the range of 2–5 degrees, (b) a plurality of cover plates, with each cover plate being proximate the top surface of one of the fluidic oscillators and attached to the oscillator so as to provide a seal against the flow of fluid from the oscillator's fluidic circuit, (c) a carrier assembly having a front and a rear surface and a cavity extending between these surfaces, with this cavity being configured so to receive and hold the stack of fluidic oscillators in the spray head, and (d) a stopper unit that attaches to the assembly's rear surface and seals it against leakage from the assembly's rear surface.

Owner:DLHBOWLES INC

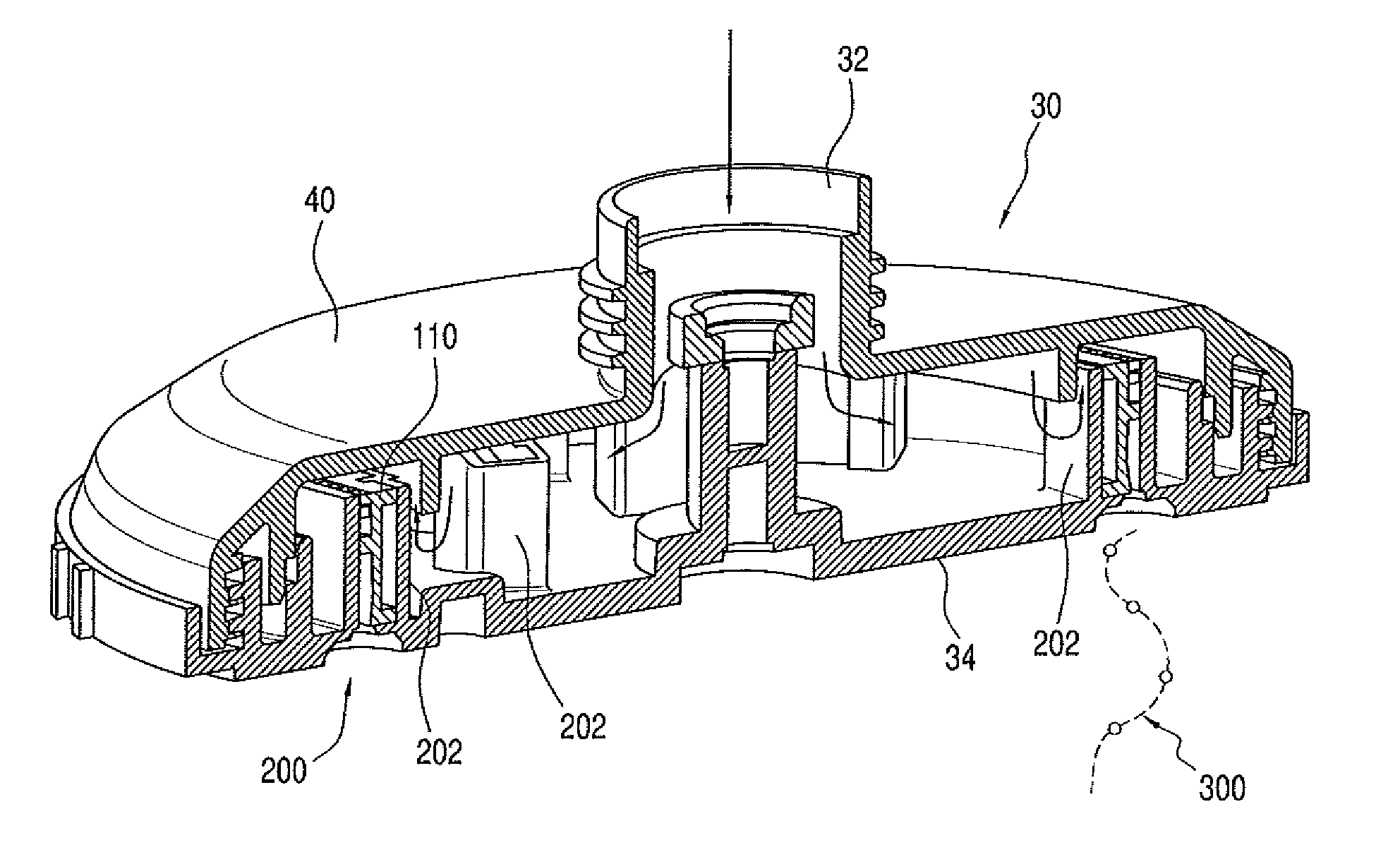

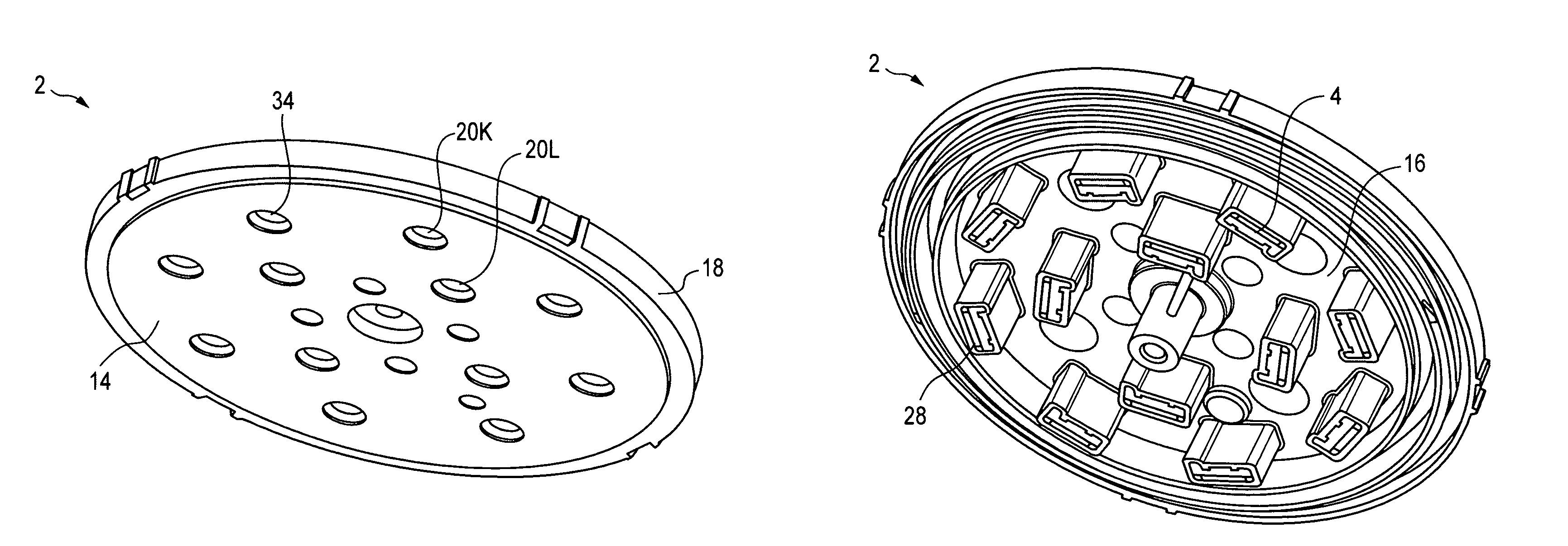

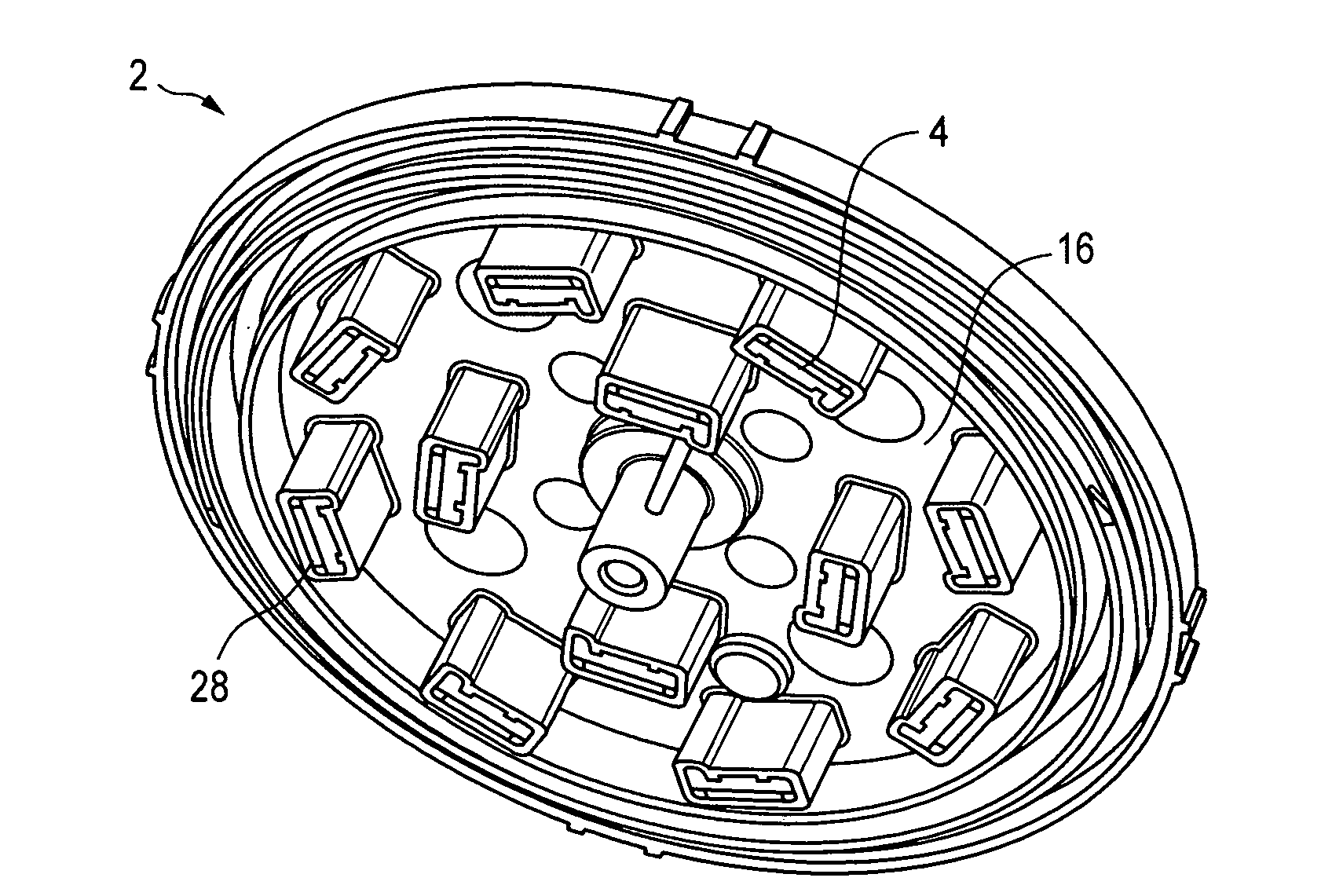

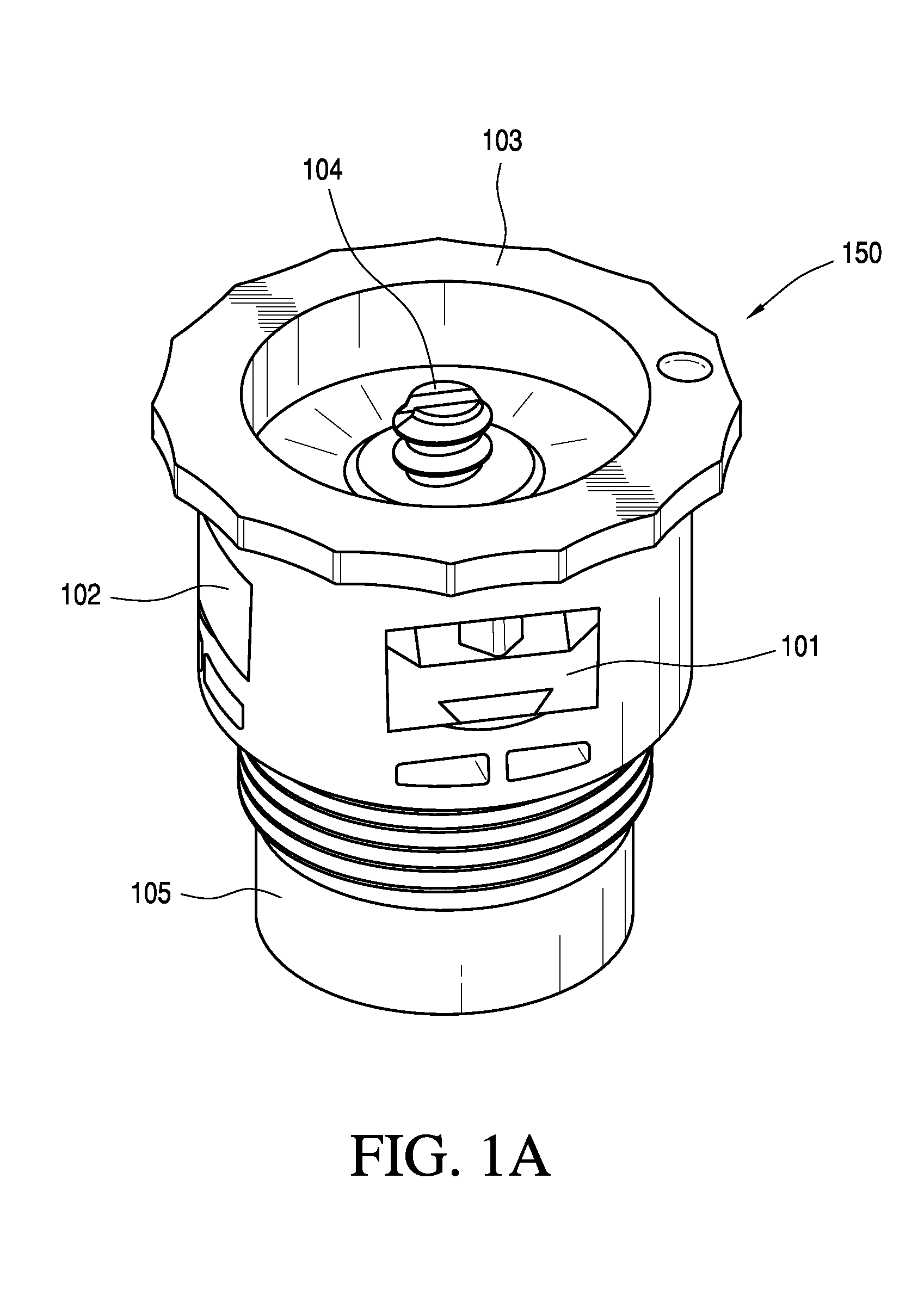

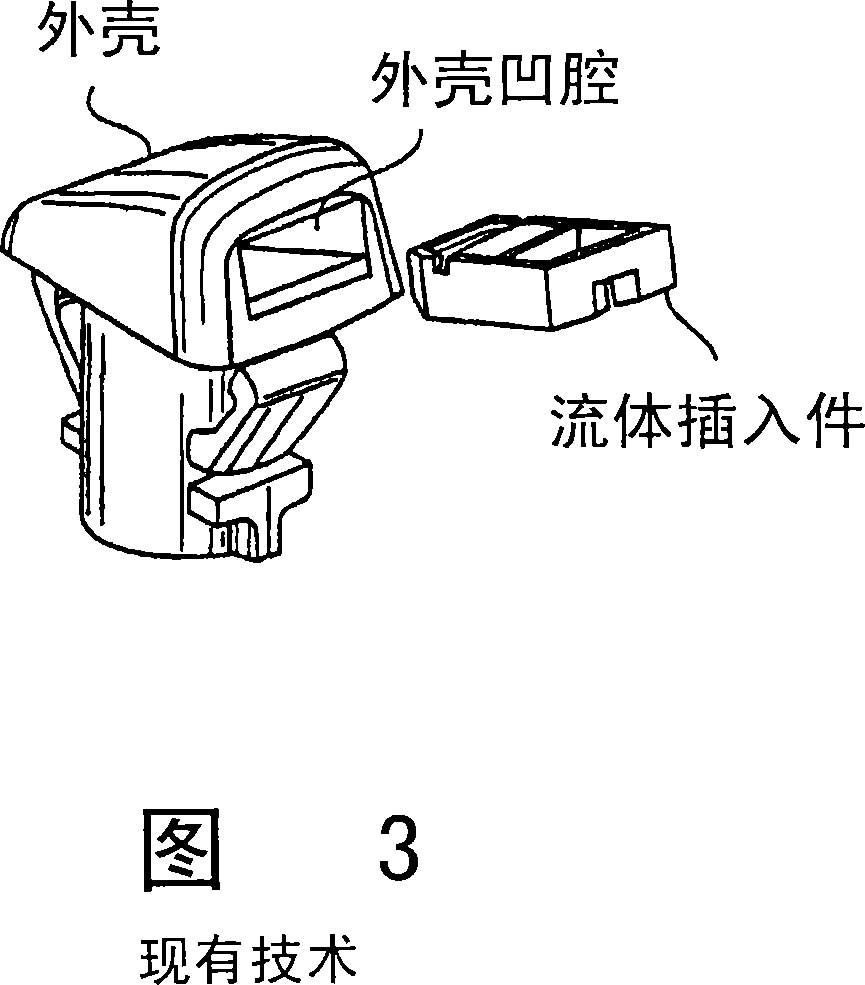

Rain can style showerhead assembly incorporating eddy filter for flow conditioning in fluidic circuits

InactiveUS20110233301A1Reduce adverse effectsImprove operating characteristicsDust removalFire preventionFluidic oscillatorEngineering

A fluidic oscillator adapted for use in a showerhead or nozzle assembly includes an eddy filter structure which reduces the adverse effects of fluid supply turbulence on the fluidic oscillator's spraying performance. A nozzle or rain can style showerhead assembly includes a water chamber or manifold which receives water via a central inlet fitting. Water entering the water chamber or manifold flows turbulently into and through the manifold and is expelled under pressure through a plurality of nozzles which are configured as specially adapted fluidic inserts.

Owner:DLHBOWLES INC

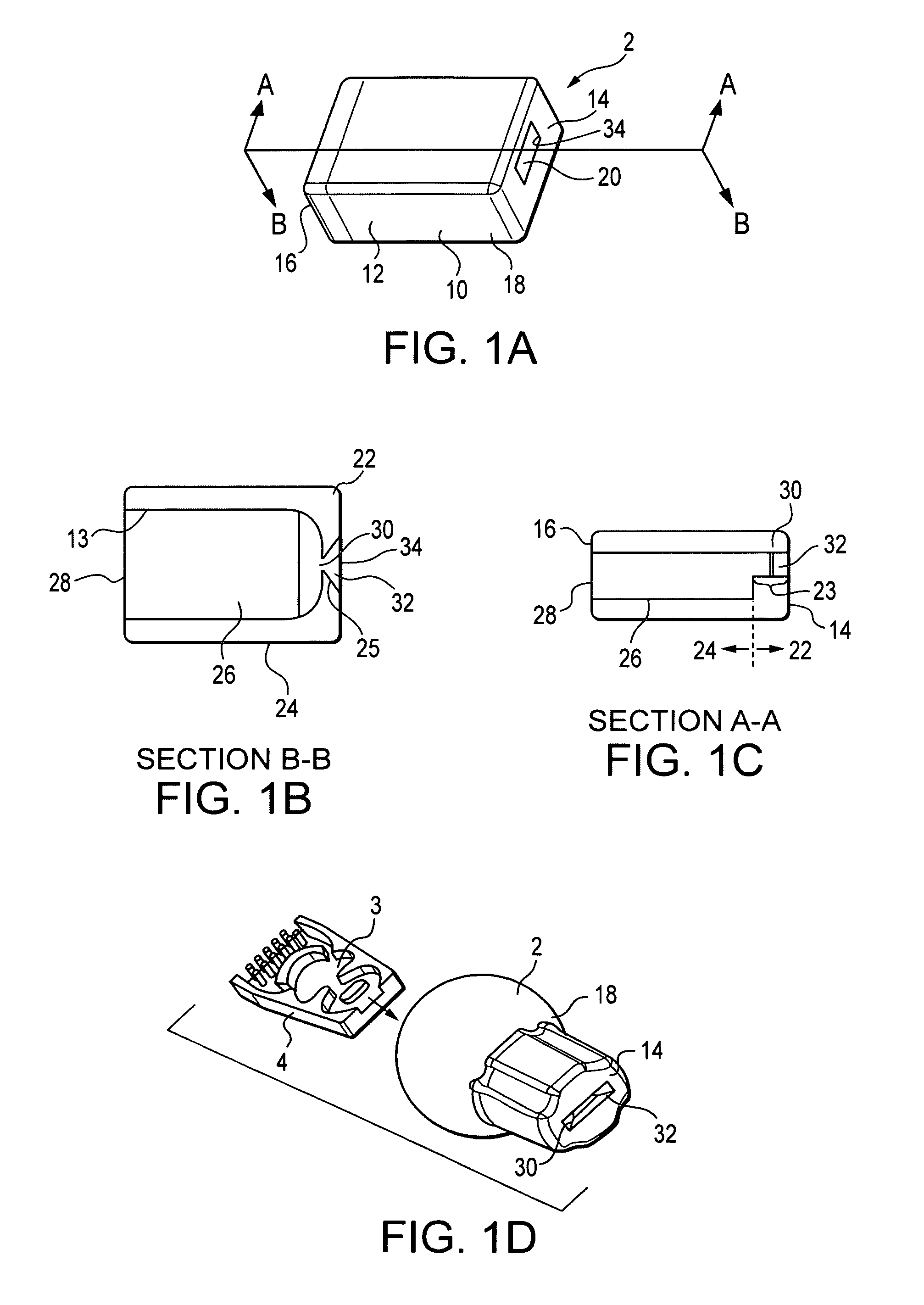

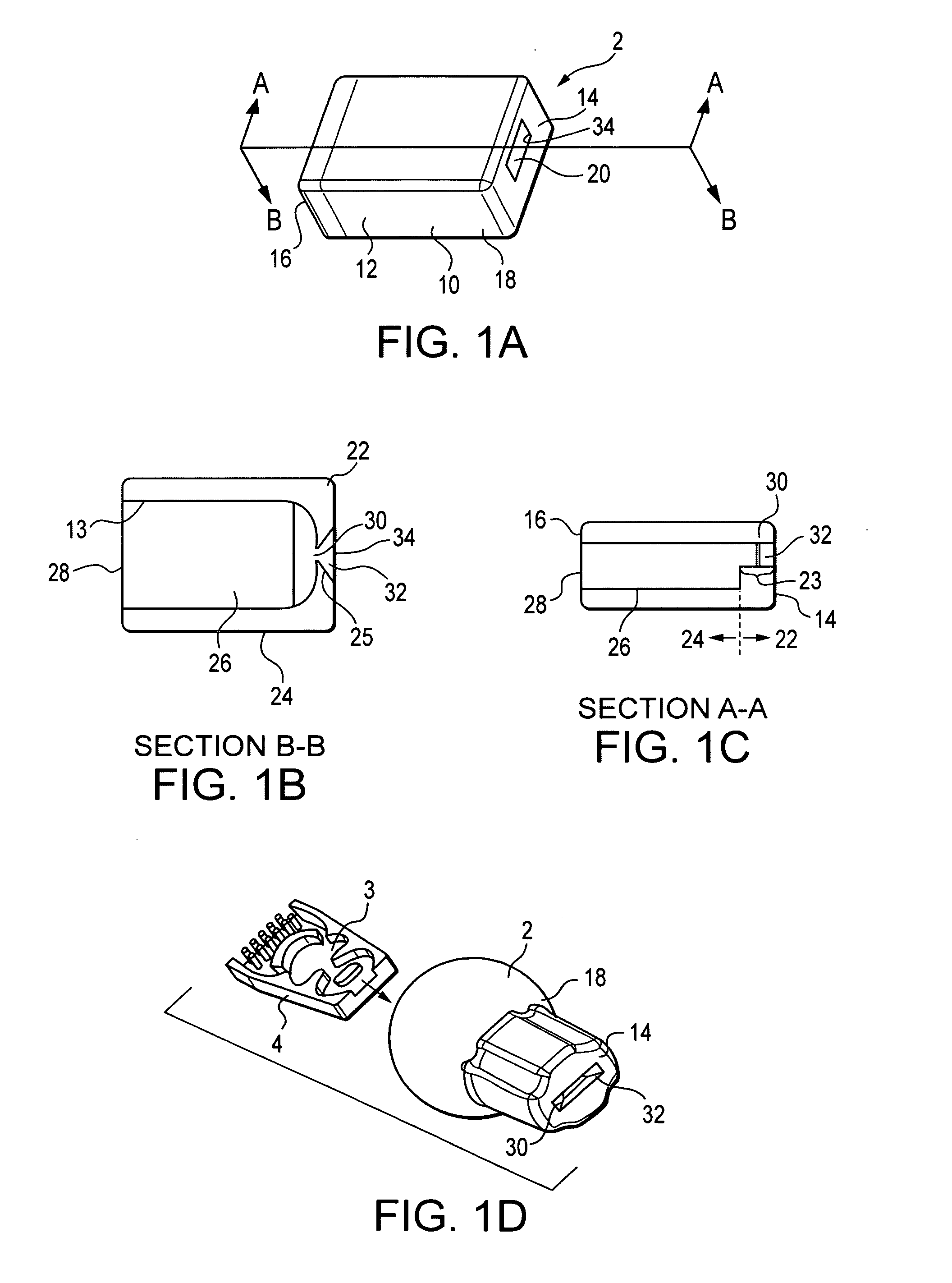

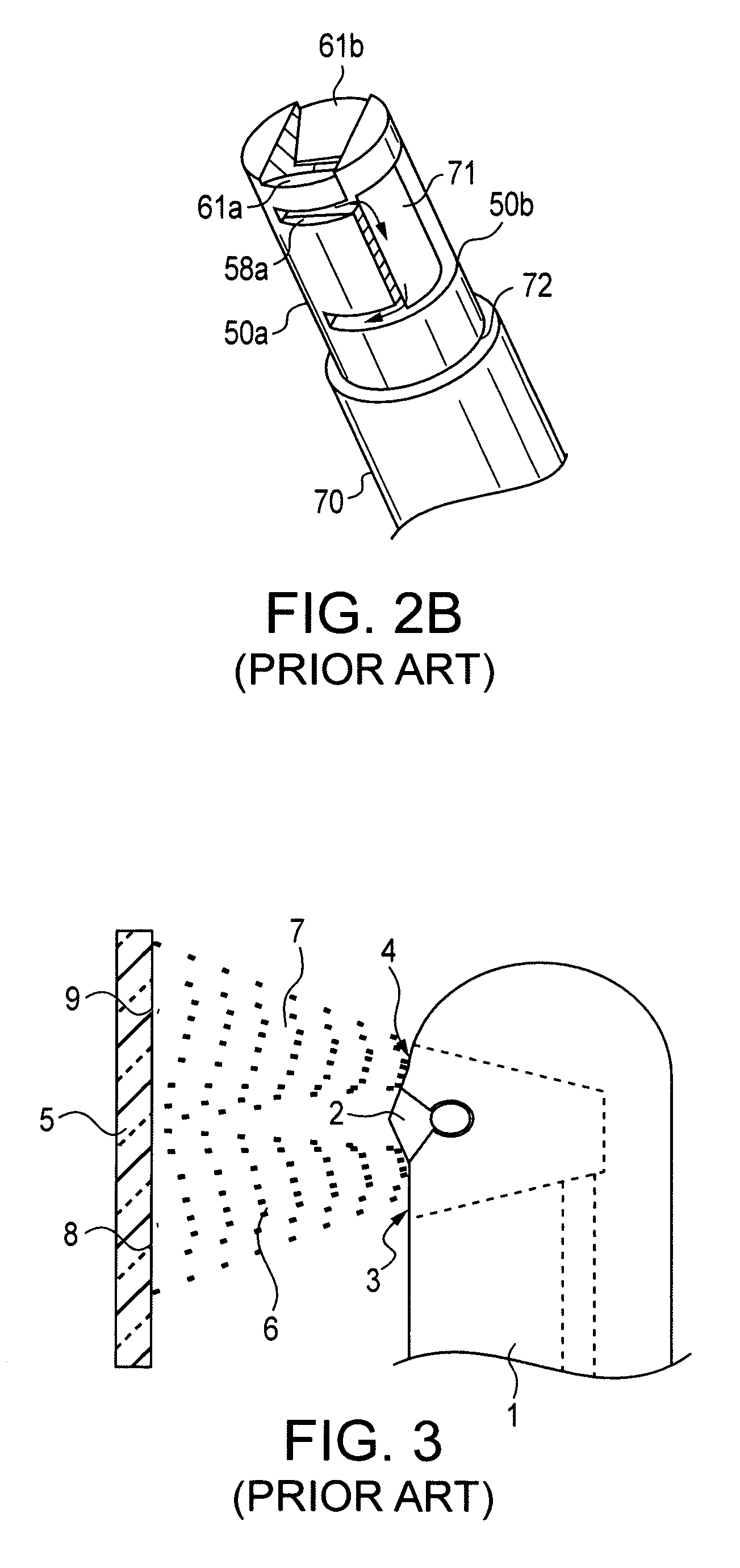

Enclosures for fluidic oscillators

ActiveUS20060108442A1Improve spraying effectIncrease surface areaCircuit elementsMovable spraying apparatusFluidic oscillatorEngineering

For those spray applications that use a fluidic oscillator of the type that generates a spray by having a pressurized liquid flow through the oscillator and exhaust into a surrounding environment, and where such an oscillator has a boundary surface which has fabricated into it a channel in the form of what is referred to herein as fluidic circuit, an improved enclosure for this oscillator includes: a body having an interior and an exterior surface, wherein a portion of this interior surface is configured to attach to the oscillator boundary surface so as to form with the oscillator's channel an enclosed pathway through which the to-be-sprayed liquid may flow, and wherein a segment of this interior surface is configured so as to yield specified properties of the resulting spray.

Owner:DLHBOWLES INC

Pulsating Inhaler and a Method of Treating Upper Respiratory Disorders

InactiveUS20080156319A1Facilitates medicament dispensingReduce edemaRespiratorsLiquid surface applicatorsDiseaseMedication Dispenser

The present invention discloses a pulsating inhaler, comprising a fluid oscillator providing a focused fluid column with a series of alternating high and low pressures zones; a medicament dispenser adapted for releasing small and constant measures of at least one medicament via said fluid column; and, at least one outlet orifice adapted to direct said focused fluid column towards the respiratory tract of a patient, wherein said small and constant measures of medicament are subjected to the patients while its respiratory tracts are gently and continuously vibrated The present invention also discloses a method of inhaling small and constant measures of medicament while gently and continuously vibrating the patient's respiratory tracks by a means of a fluid column characterized by a series of alternating high and low pressures zones.

Owner:RESPINOVA

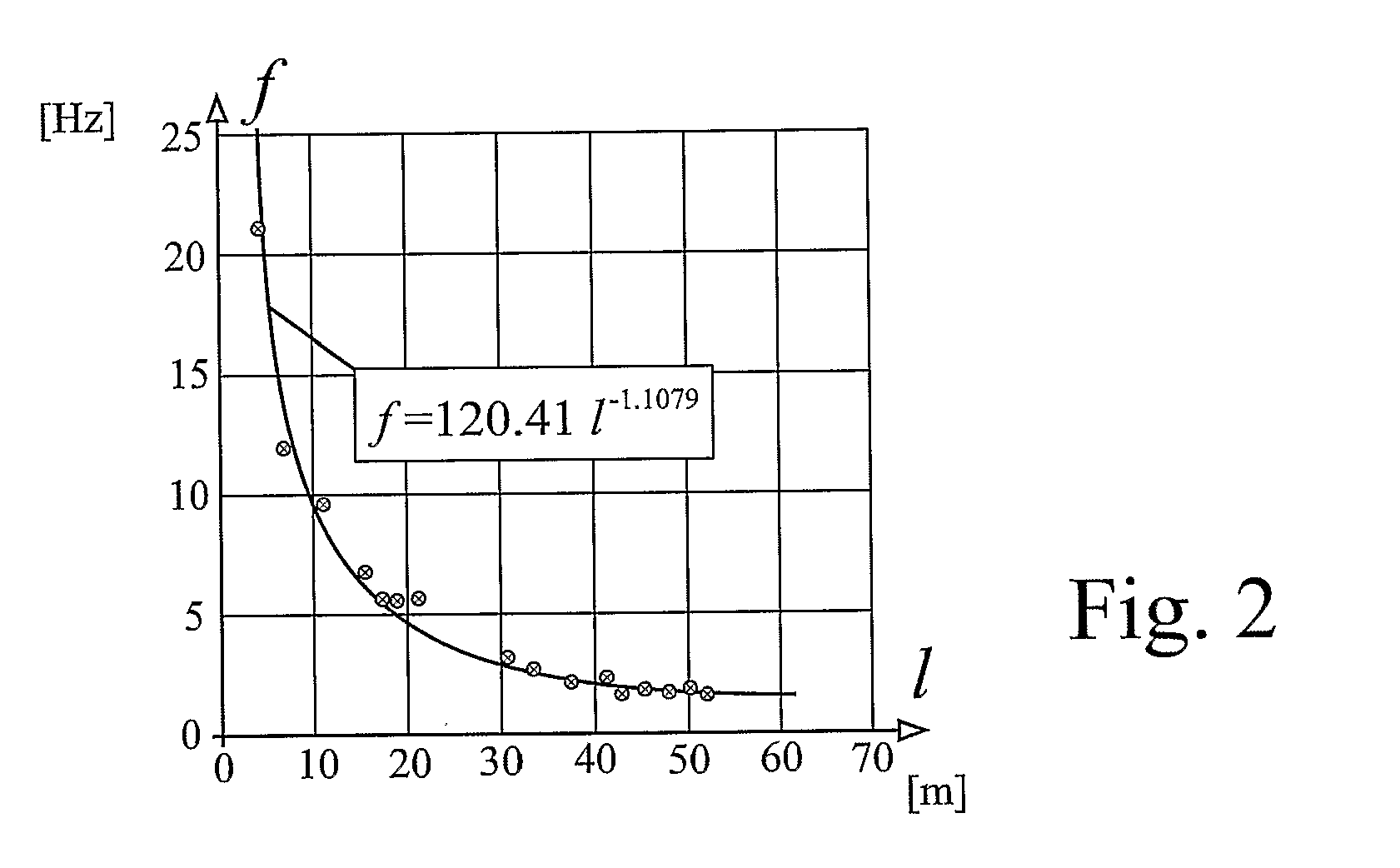

Spirometer

InactiveUS7094208B2Easily and accurately used in a home environmentSmall and portableRespiratory organ evaluationSensorsMedicineFluidic oscillator

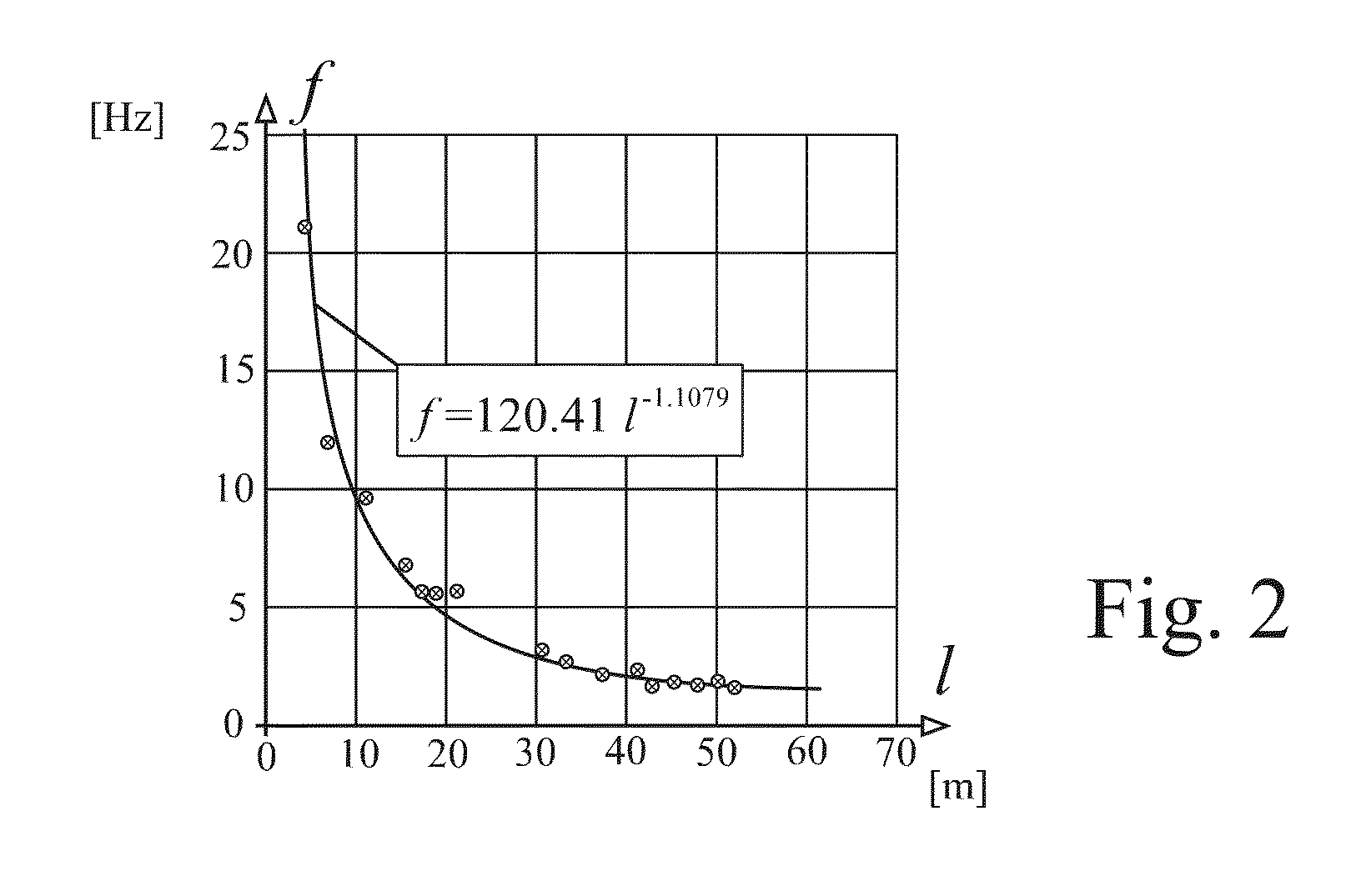

A spirometer for measuring fluid flow, particularly associated with exhalation of respiratory patients. The spirometer of this invention preferably has a fluidic oscillator wherein the fluid oscillates within a chamber of the fluidic oscillator. An oscillation frequency of the fluid flow within the chamber is correlated to a flow rate. A computer is used to process input data, such as data representing frequency of the oscillatory flow within the chamber, to a flow rate passing through the spirometer. The spirometer of this invention may have no moving parts, which results in the need for only a design calibration and no periodic calibrations throughout use of the spirometer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Three jet island fluidic oscillator

A fluidic oscillator suitable for use at colder temperatures for utilizing a pressurized liquid to generate a uniform spatial distribution of droplets has (a) an inlet for the pressurized liquid, (b) a set of three power nozzles that are fed by the pressurized liquid, (c) an interaction chamber attached to the nozzles and which receives the flow from the nozzles, wherein this chamber has an upstream and a downstream portion, with the upstream portion having a pair of boundary edges and a longitudinal centerline that is approximately equally spaced between the edges, and wherein one of the power nozzles is directed along the chamber's longitudinal centerline, (d) a throat from which the liquid exhausts from the interaction chamber, and (e) an island located in the interaction chamber, with this island being situated downstream of the power nozzle that is directed along the chamber's longitudinal centerline. In a preferred embodiment, this oscillator is further configured such that: (i) one of the power nozzles is located proximate each of the chamber's boundary edges, (ii) its nozzles are configured to accelerate the movement of the liquid that flows through the nozzles, (iii) its throat has right and left sidewalls that diverge downstream, and (iv) the power nozzles and island are oriented and scaled such as to generate flow vortices behind the island that are swept out of the throat in a manner such that these vortices flow alternately proximate the throat's right sidewall and then its left sidewall.

Owner:DLHBOWLES INC

Three jet island fluidic oscillator

ActiveUS20050087633A1High viscosityReadily apparentCircuit elementsSpray nozzlesFluidic oscillatorEngineering

A fluidic oscillator suitable for use at colder temperatures for utilizing a pressurized liquid to generate a uniform spatial distribution of droplets has (a) an inlet for the pressurized liquid, (b) a set of three power nozzles that are fed by the pressurized liquid, (c) an interaction chamber attached to the nozzles and which receives the flow from the nozzles, wherein this chamber has an upstream and a downstream portion, with the upstream portion having a pair of boundary edges and a longitudinal centerline that is approximately equally spaced between the edges, and wherein one of the power nozzles is directed along the chamber's longitudinal centerline, (d) a throat from which the liquid exhausts from the interaction chamber, and (e) an island located in the interaction chamber, with this island being situated downstream of the power nozzle that is directed along the chamber's longitudinal centerline. In a preferred embodiment, this oscillator is further configured such that: (i) one of the power nozzles is located proximate each of the chamber's boundary edges, (ii) its nozzles are configured to accelerate the movement of the liquid that flows through the nozzles, (iii) its throat has right and left sidewalls that diverge downstream, and (iv) the power nozzles and island are oriented and scaled such as to generate flow vortices behind the island that are swept out of the throat in a manner such that these vortices flow alternately proximate the throat's right sidewall and then its left sidewall.

Owner:DLHBOWLES INC

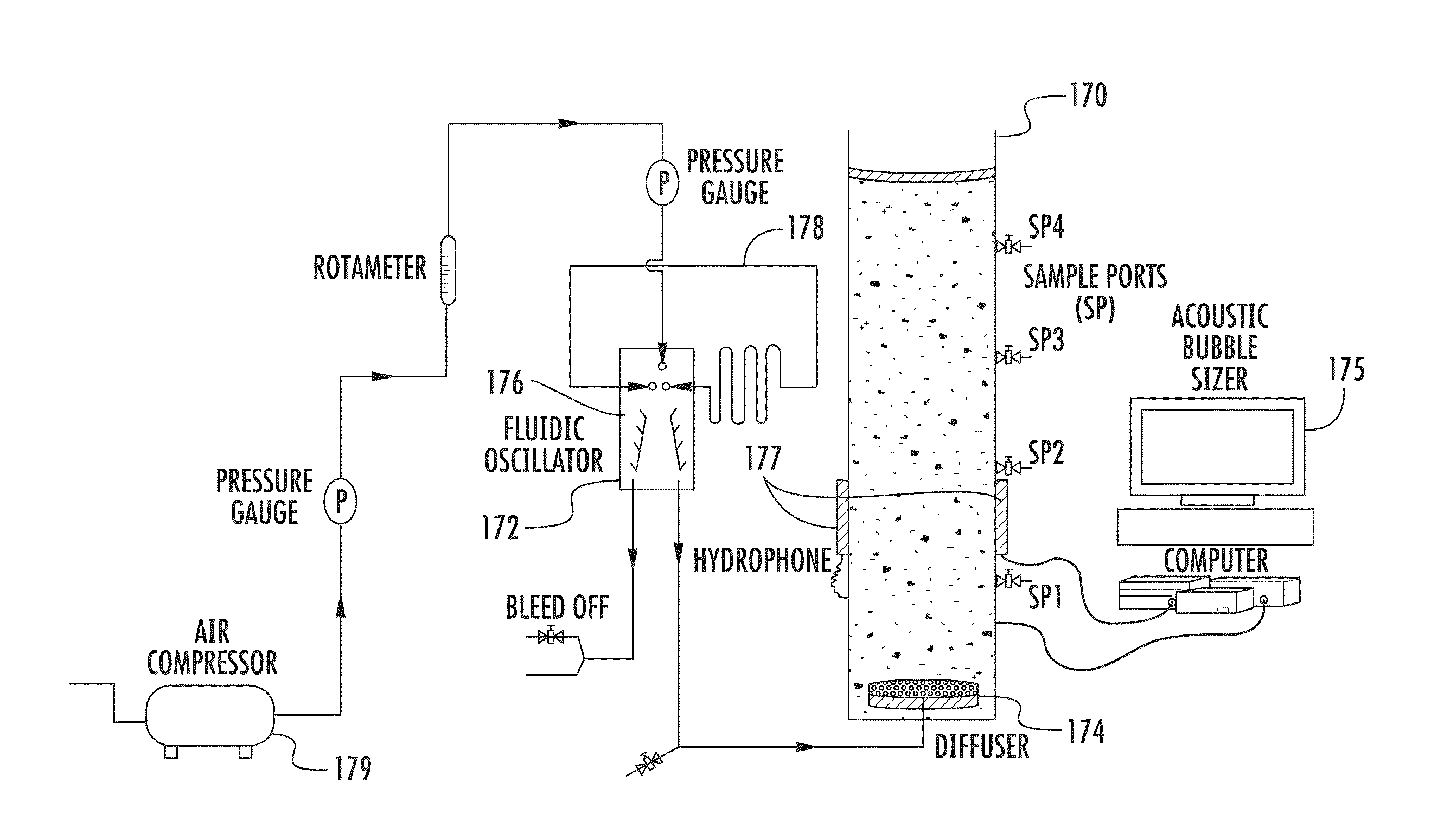

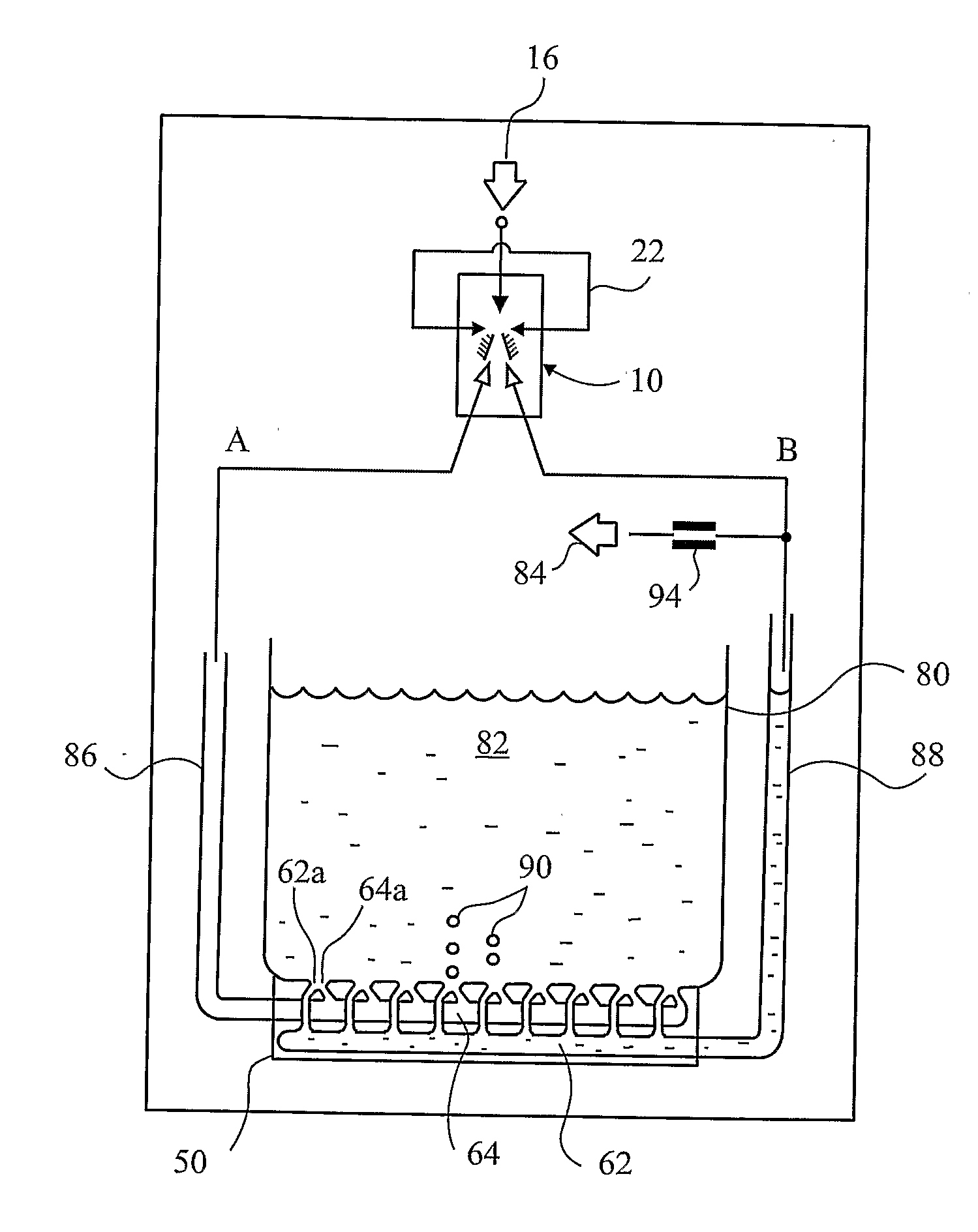

Bubble generation for aeration and other purposes

ActiveUS20130092626A1Reduce energy consumptionSmall sizeTransportation and packagingMixing methodsMicrobubblesFluidic oscillator

Uses of a method of producing small bubbles of gas in a liquid include gas transfer in airlift bioreactors and anaerobic digesters, and particle separation. The method uses a source of the gas under pressure, a conduit opening into a liquid and oscillating the gas passing along the conduit. The oscillation is effected by fluidic oscillator, comprising a diverter that divides the supply into respect outputs, each output being controlled by a control port, wherein the control ports are interconnected by a closed loop. Separation of algae from water involves delivering a laminar flow of microbubbles in the range 10 to 100 μm diameter. Such bubbles also deliver a laminar flow in bioreactors that delivers enhanced liquid flow despite the small bubbles, which improves mixing and also enhances efficiency of gas exchange and retention of the bubbles in the reactor.

Owner:PERLEMAX LTD

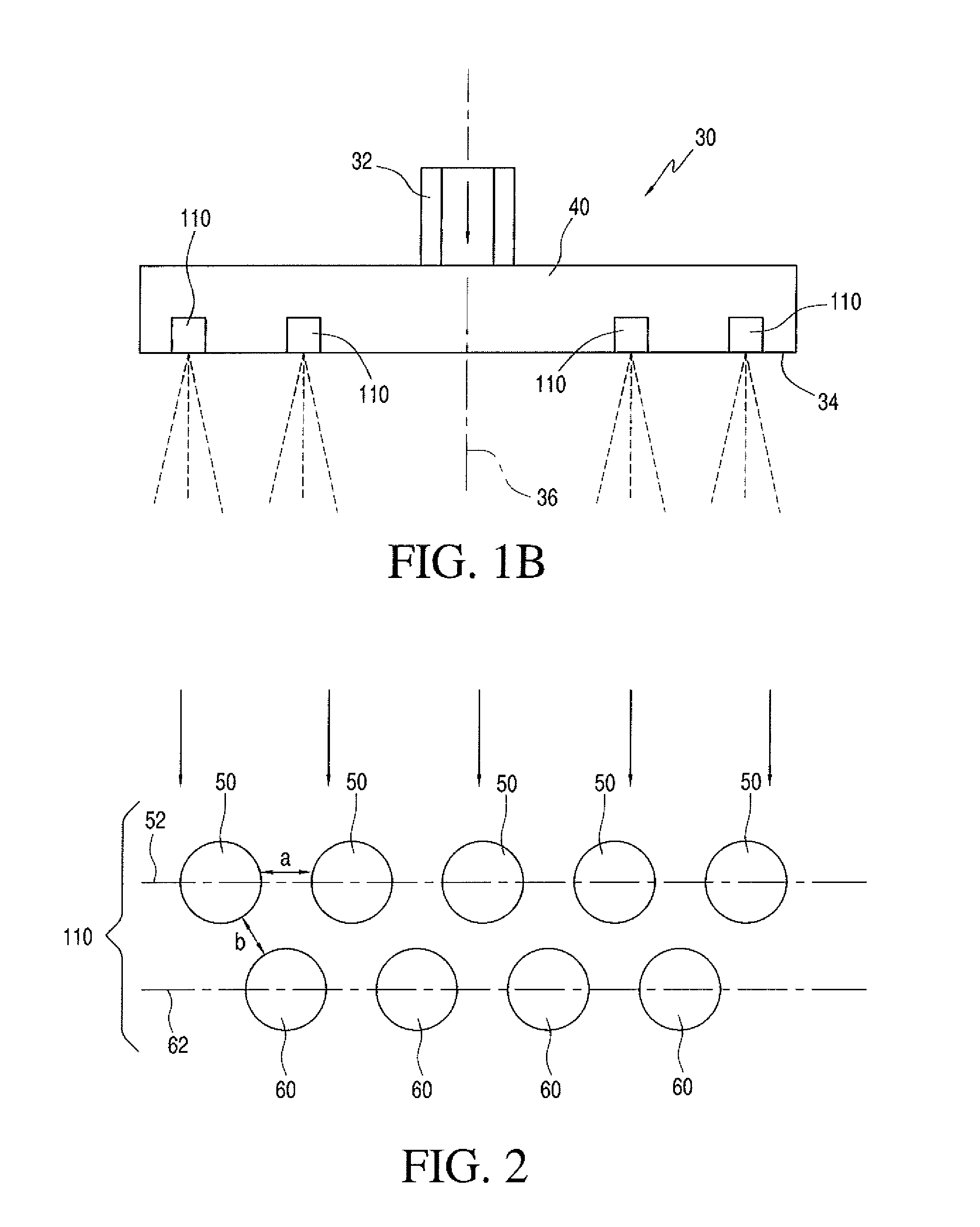

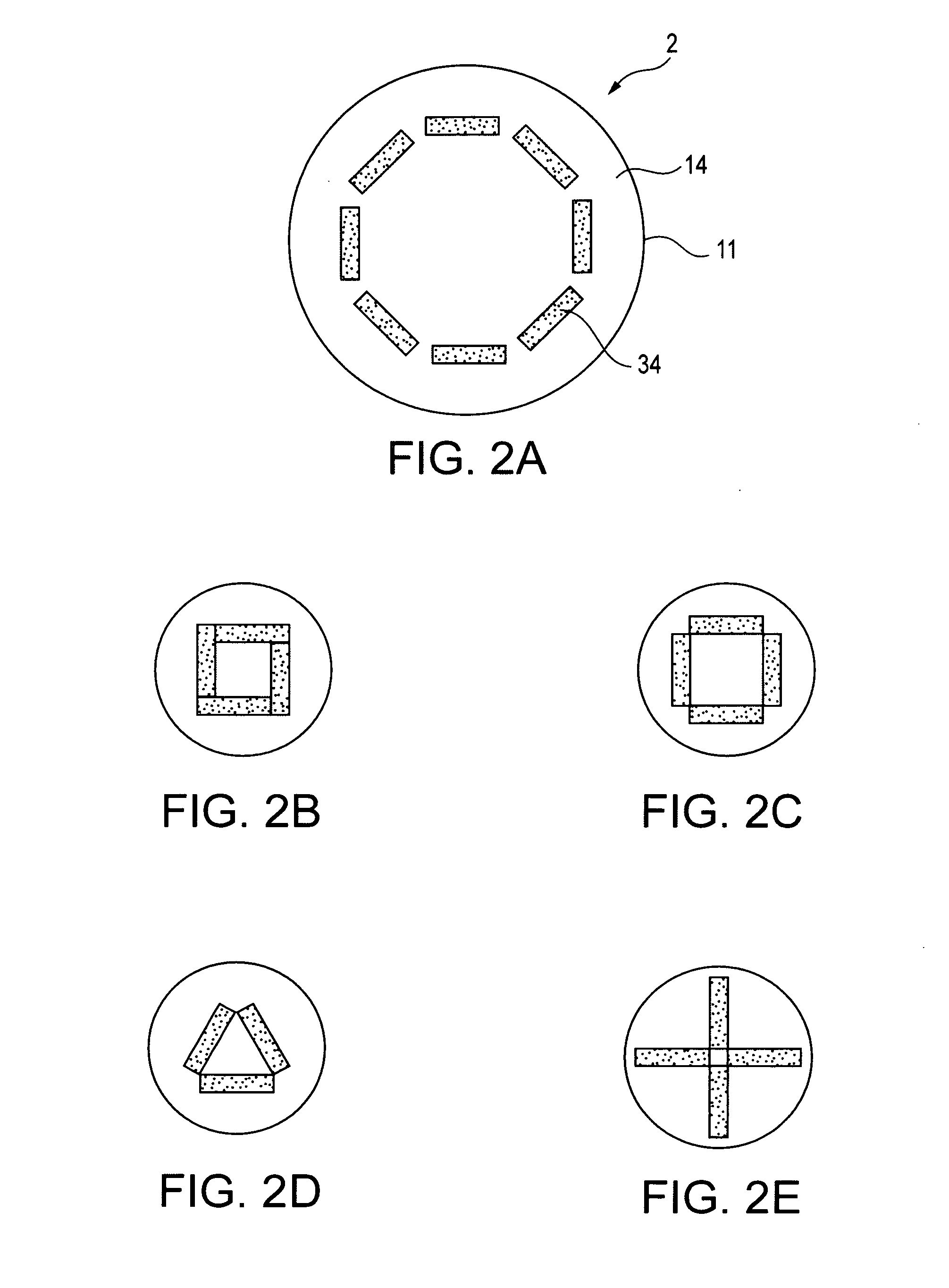

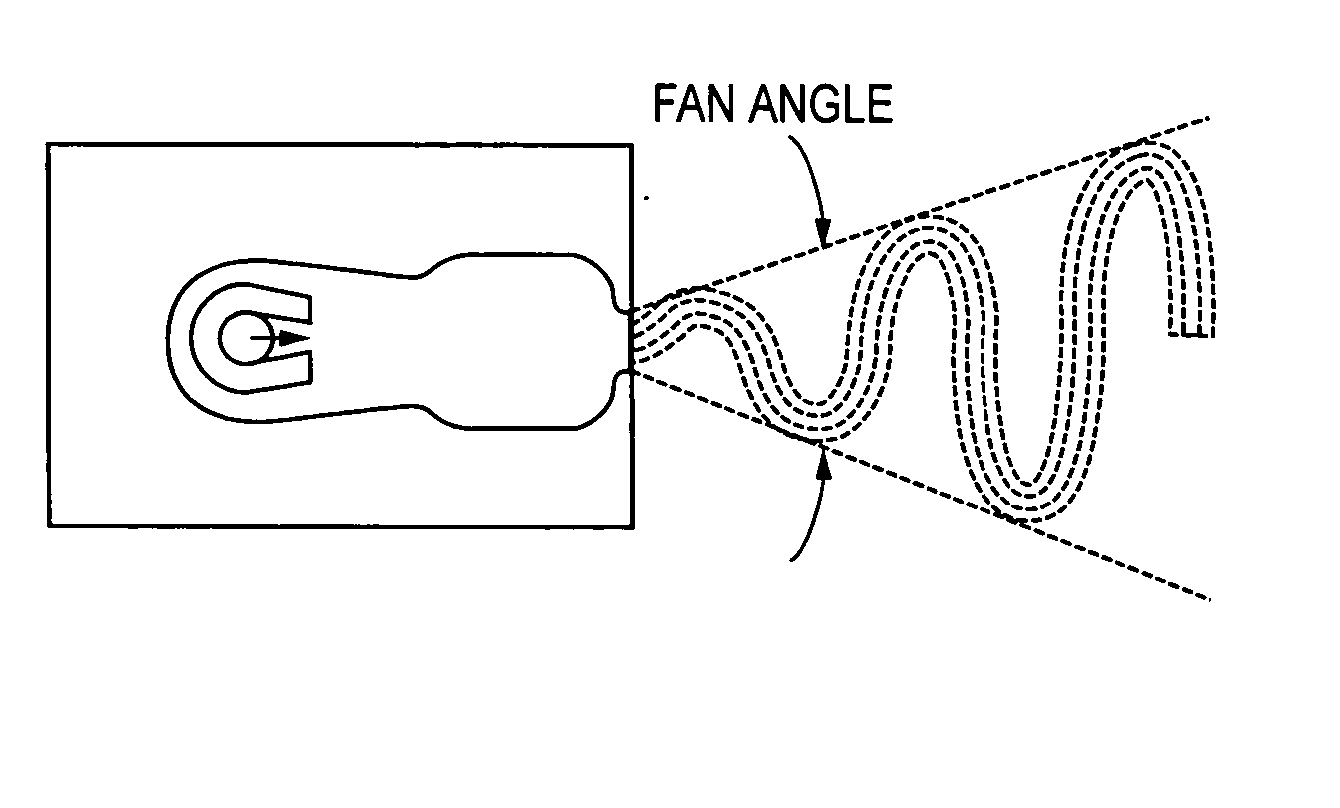

Enclosures for multiple fluidic oscillators

Owner:DLHBOWLES INC

Enclosures for multiple fluidic oscillators

ActiveUS20100072307A1Improve spraying effectIncrease surface areaCircuit elementsSpray nozzlesFluidic oscillatorEngineering

An improved fluidic device that operates on a pressurized liquid flowing through it at a specified flow rate to generate an oscillating spray of liquid droplets having desired properties (e.g., average spatial distribution, size, velocity, frequency and wavelength of liquid droplets at a defined distance in front of the device) includes: (a) a plurality of fluidic oscillators, each having a channel that is part of a fluidic circuit for inducing oscillations in the pressurized liquid that flows through the oscillator, (b) a housing having an exterior surface that includes a front face with a center-point and a rear face, (c) a plurality of passages, each of which extends through the housing and intersects with its front face to define an outlet, with each passages configured to allow for the insertion of one of the plurality of fluidic oscillators into each of the plurality of passages, and (d) a geometrical arrangement of these outlets in the housing front face that is chosen so as to achieve the desired properties of the oscillating spray when the device is operating at its specified flow rate.

Owner:DLHBOWLES INC

Fluidic circuit with bump features for improving uniform distribution of fluidic sprays

InactiveUS20100090036A1Improve performanceEvenly distributedWriting implementsMetal-working apparatusLiquid jetFluidic oscillator

A fluidic circuit or oscillator is provided with one or more small raised bumps or protrusions near the outlet or exhaust of a fluidic circuit to alter the spray pattern by re-distributing heavy areas of flow, resulting in a more uniform spray. The fluidic oscillator enclosure operates on a pressurized liquid flowing through the oscillator to generate a liquid jet that flows from said oscillator and into a surrounding environment to form an oscillating spray of liquid droplets, where the oscillator generates a stream of liquid droplets. The outlet or throat structure includes at least one bump or protuberance configured to project into the oscillating spray.

Owner:ALLEN KERRIE +2

Enclosures for fluidic oscillators

For those spray applications that use a fluidic oscillator of the type that generates a spray by having a pressurized liquid flow through the oscillator and exhaust into a surrounding environment, and where such an oscillator has a boundary surface which has fabricated into it a channel in the form of what is referred to herein as fluidic circuit, an improved enclosure for this oscillator includes: a body having an interior and an exterior surface, wherein a portion of this interior surface is configured to attach to the oscillator boundary surface so as to form with the oscillator's channel an enclosed pathway through which the to-be-sprayed liquid may flow, and wherein a segment of this interior surface is configured so as to yield specified properties of the resulting spray.

Owner:DLHBOWLES INC

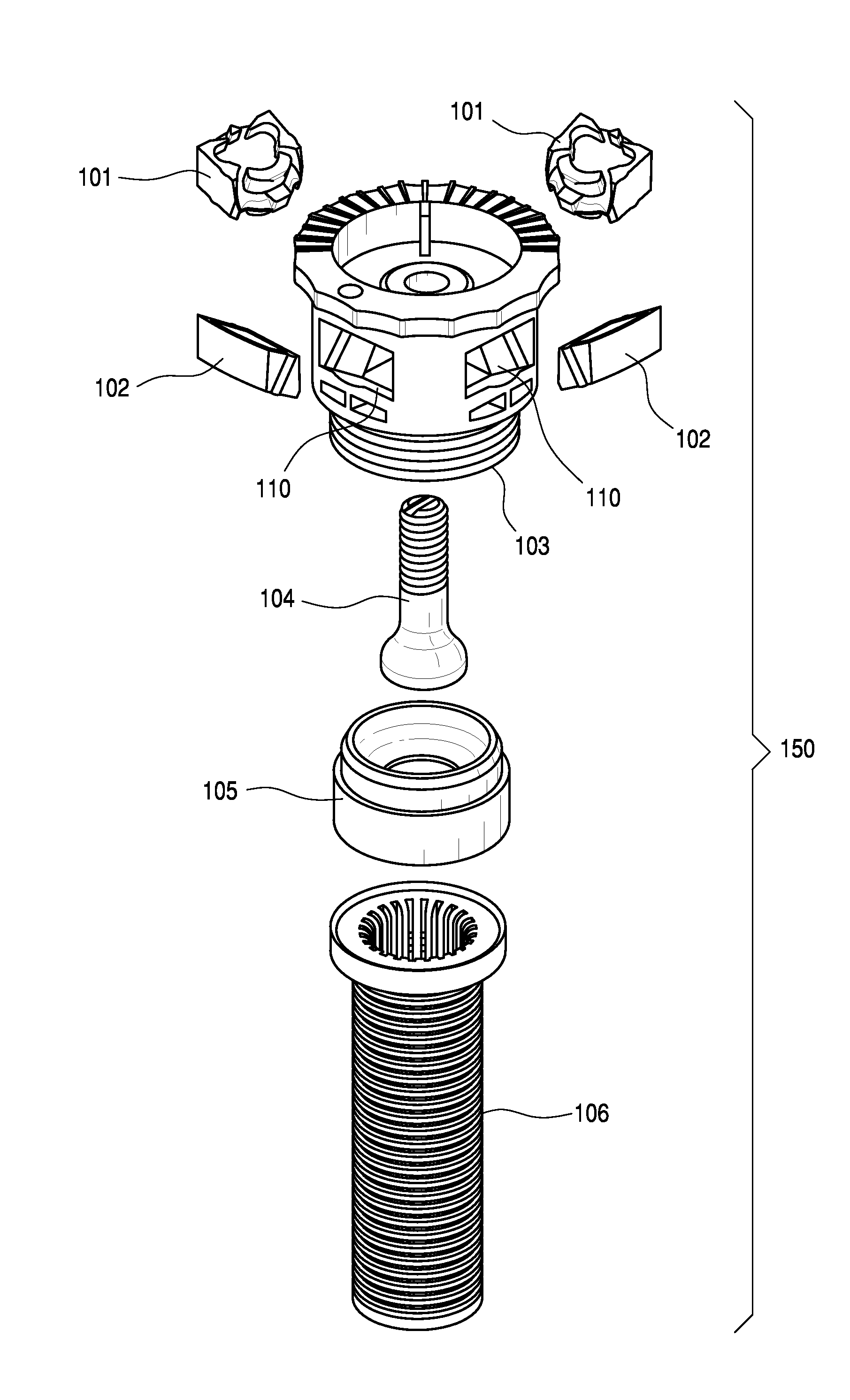

Nozzle and fluidic circuit adapted for use with cold fluids, viscous fluids or fluids under light pressure

Owner:DLHBOWLES INC

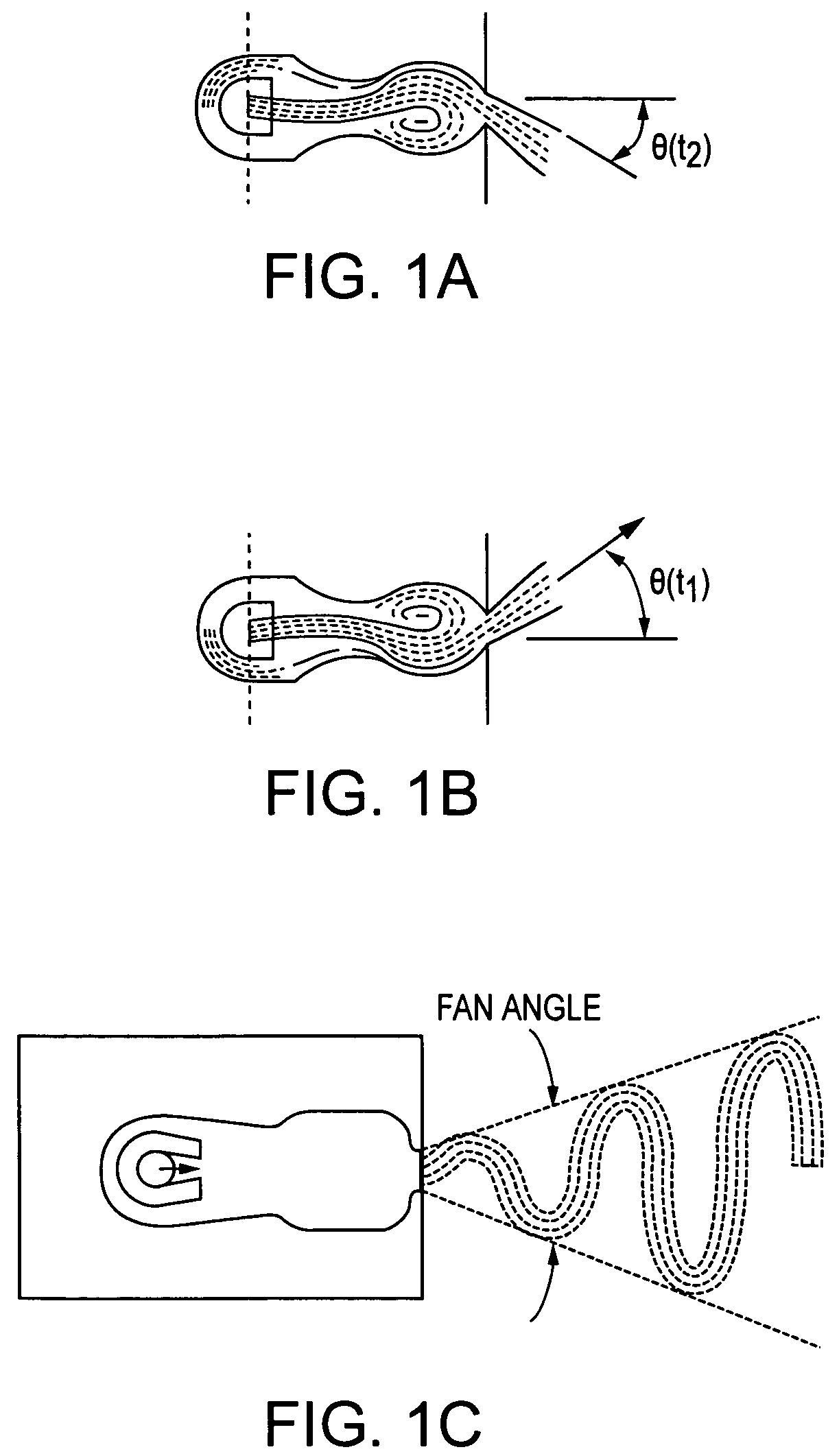

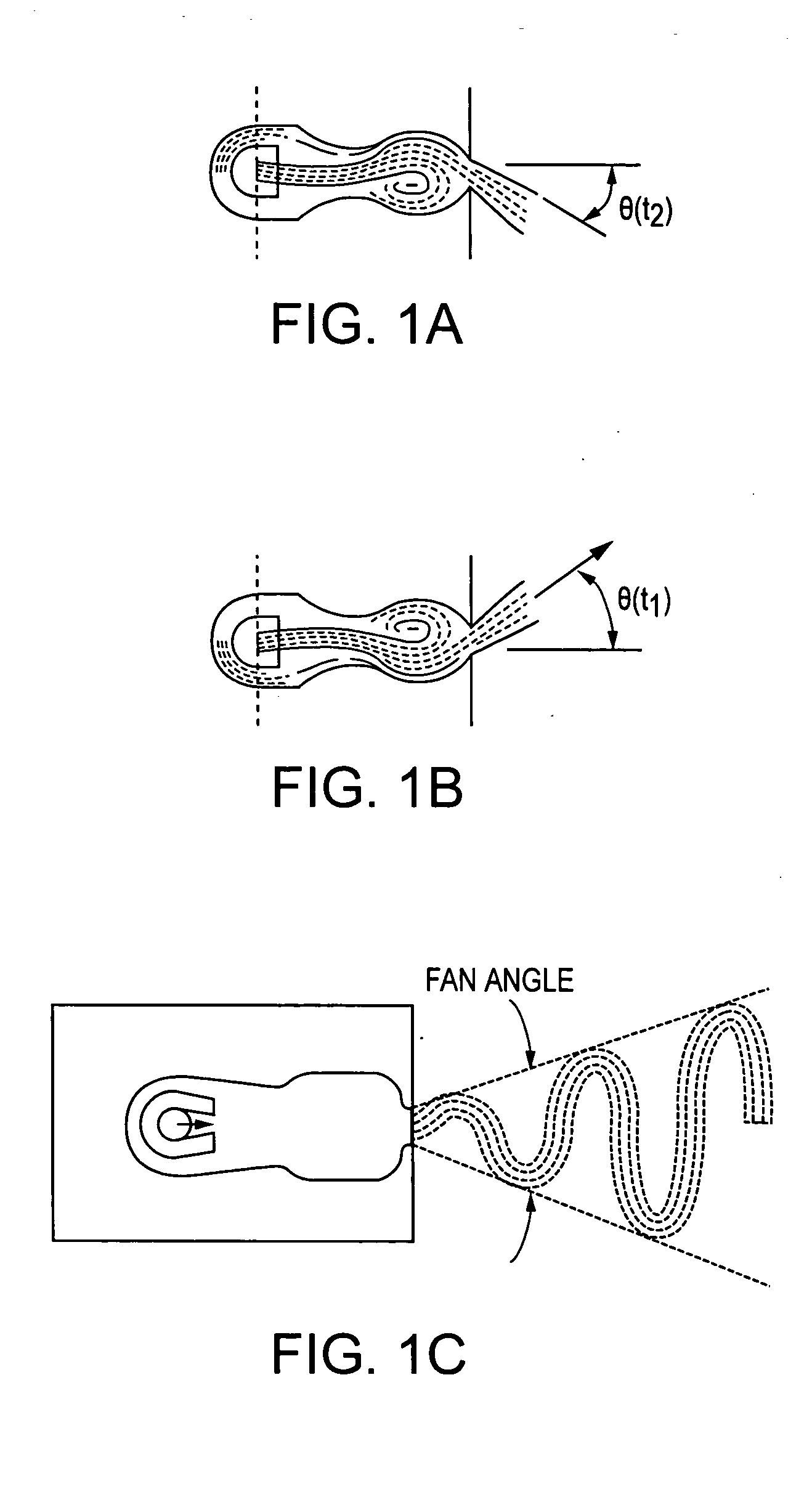

Fluidic oscillators and enclosures with split throats

An improved fluidic oscillator, that operates on a pressurized liquid flowing through the oscillator to generate a liquid jet that flows into the surrounding environment to form of an oscillating spray of liquid droplets, includes: a member into which is fabricated a two-portion, flow channel, with this first portion configured so as to create the flow phenomena in the member that yields the spray's oscillating nature, and wherein its second portion is configured so as to provide a plurality of throats by which the pressurized liquid exhausts into the surrounding environment.

Owner:BOWLES FLUIDICS

Fluidic oscillator and method

An oscillating spray device comprising an oscillation chamber. A power nozzle for projecting a jet of liquid under pressure into the oscillation chamber in a given direction. A reversing member in the chamber has a reversing wall for reversing the direction of flow of the fluid jet in a direction 180° opposite the given direction. A system of vortices is formed thereby for alternately passing fluid to one side or the other of the reversing member. A pair of passages, one on each side of the reversing member, convey alternate pulses of fluid through the passageways in the given direction past the reversing member to an outlet to ambient, and an island barrier positioned in the outlet to ambient and forming two separate passageways to the outlet and a third passageway between the reversing member and the island barrier. The spray characteristics can be adjusted by changing the spacing between the reversing member and island barrier.

Owner:DLHBOWLES INC

Improved cold-performance fluidic oscillator

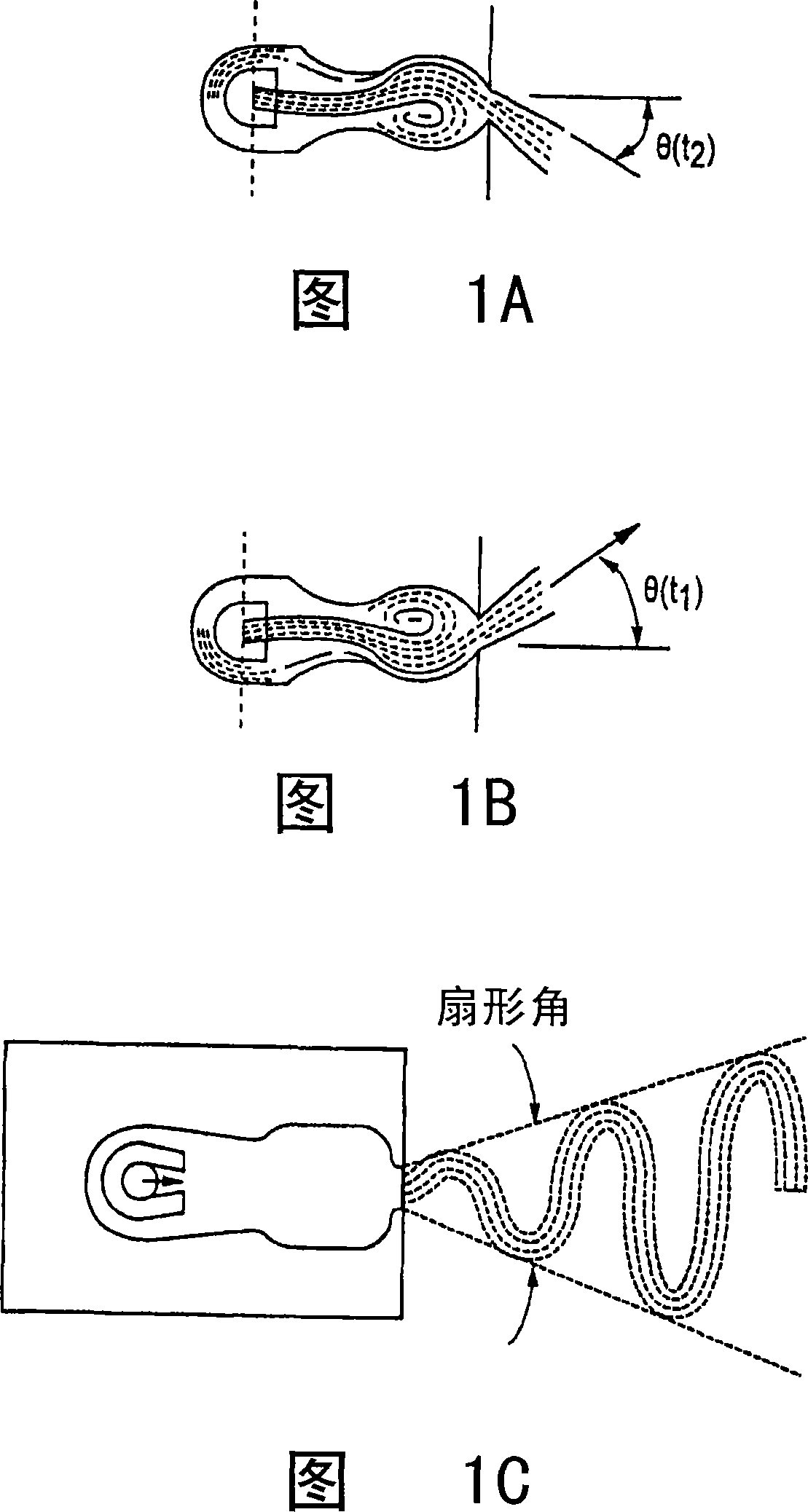

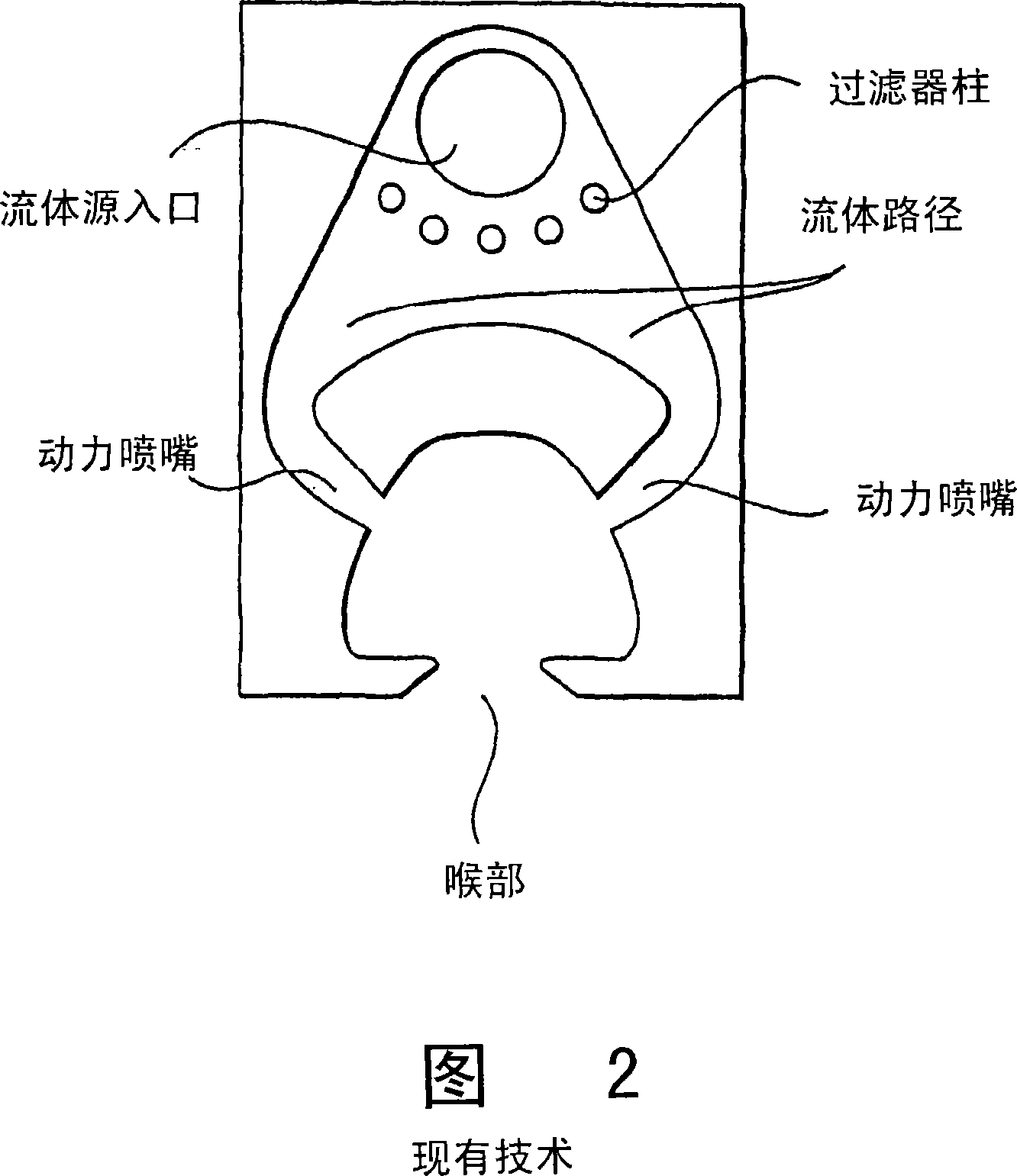

An ejecting flowing fluid oscillator (2) suitable for generating a fluid drop oscillating ejecting form has: an entrance (12) for pressing fluid, a dynamic nozzle (14) for constructing accelerate pressurization fluid motion, a fluid path (10) allow pressed fluid flowing between the entrance (12) and the dynamic nozzle (14), an interaction chamber (18) attached to the dynamic nozzle (14) and receiving the flowing from the nozzle, an outlet (20) ejecting fluid discharged during through the interaction chamber (18), and a device for increasing flowing instability flowing from the dynamic nozzle (14). In one first optimization embody, the device comprises a projection (4) internal extending from each side of the fluid path (10). In a second optimization embody, the device comprises a step (24), its height is the height of the dynamic nozzle (14) hoisting relative to bottom plate of the interaction chamber (18).

Owner:BOWLES FLUIDICS

Cold-performance fluidic oscillator

ActiveUS20060091242A1High viscosityReadily apparentCircuit elementsSpray nozzlesFluidic oscillatorStreaming instability

A fluidic oscillator suitable for use at colder temperatures for generating an exhaust flow in the form of an oscillating spray of fluid droplets has an inlet for pressurized fluid, a pair of power nozzles configured to accelerate the movement of the pressurized fluid, a fluid pathway that connects and allows for the flow of pressurized fluid between its inlet and the power nozzles, an interaction chamber which is attached to the nozzles and receives the flow from the nozzles, a fluid outlet from which the spray exhausts from the interaction chamber, and a means for increasing the instability of the flow from the power nozzles, with this means being situated in a location chosen from the group consisting of a location within the fluid pathway or proximate the power nozzles. In a first preferred embodiment, the flow instability generating means comprises a protrusion that extends inward from each side of the fluid pathway so as to cause a flow separation region downstream of the protrusions. In a second preferred embodiment, the flow instability generating means comprises a step in the height elevation of the floor of the power nozzles with respect to that of the interaction chamber.

Owner:DLHBOWLES INC

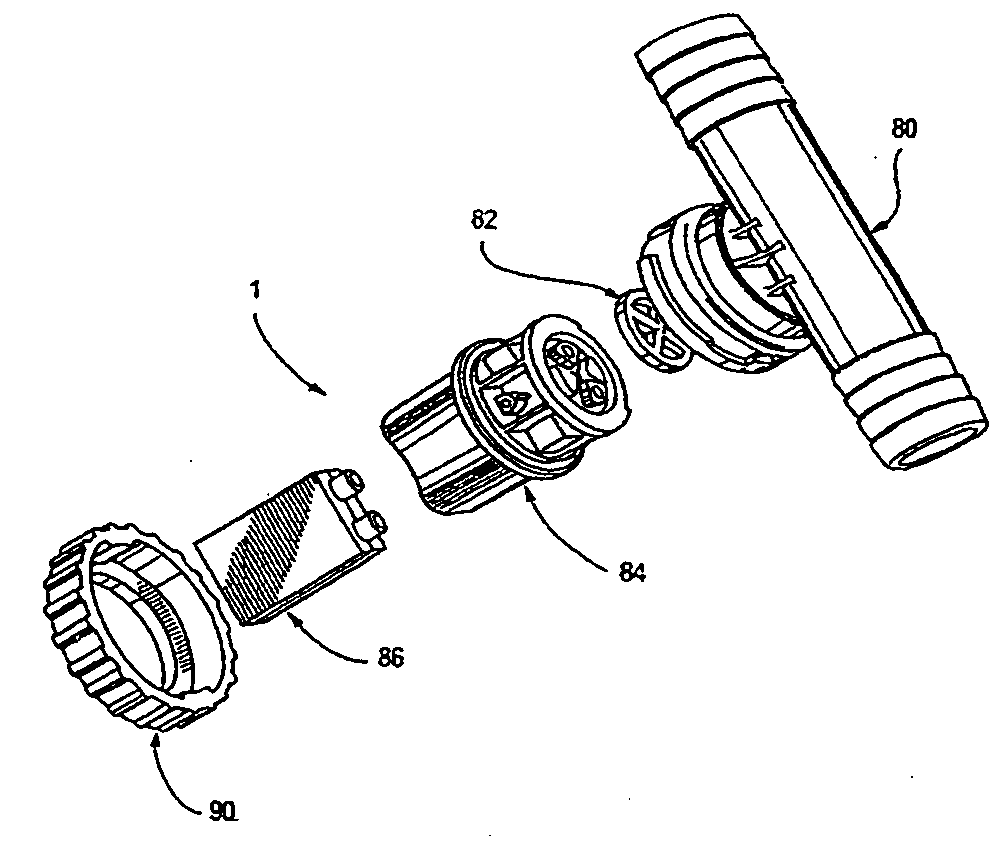

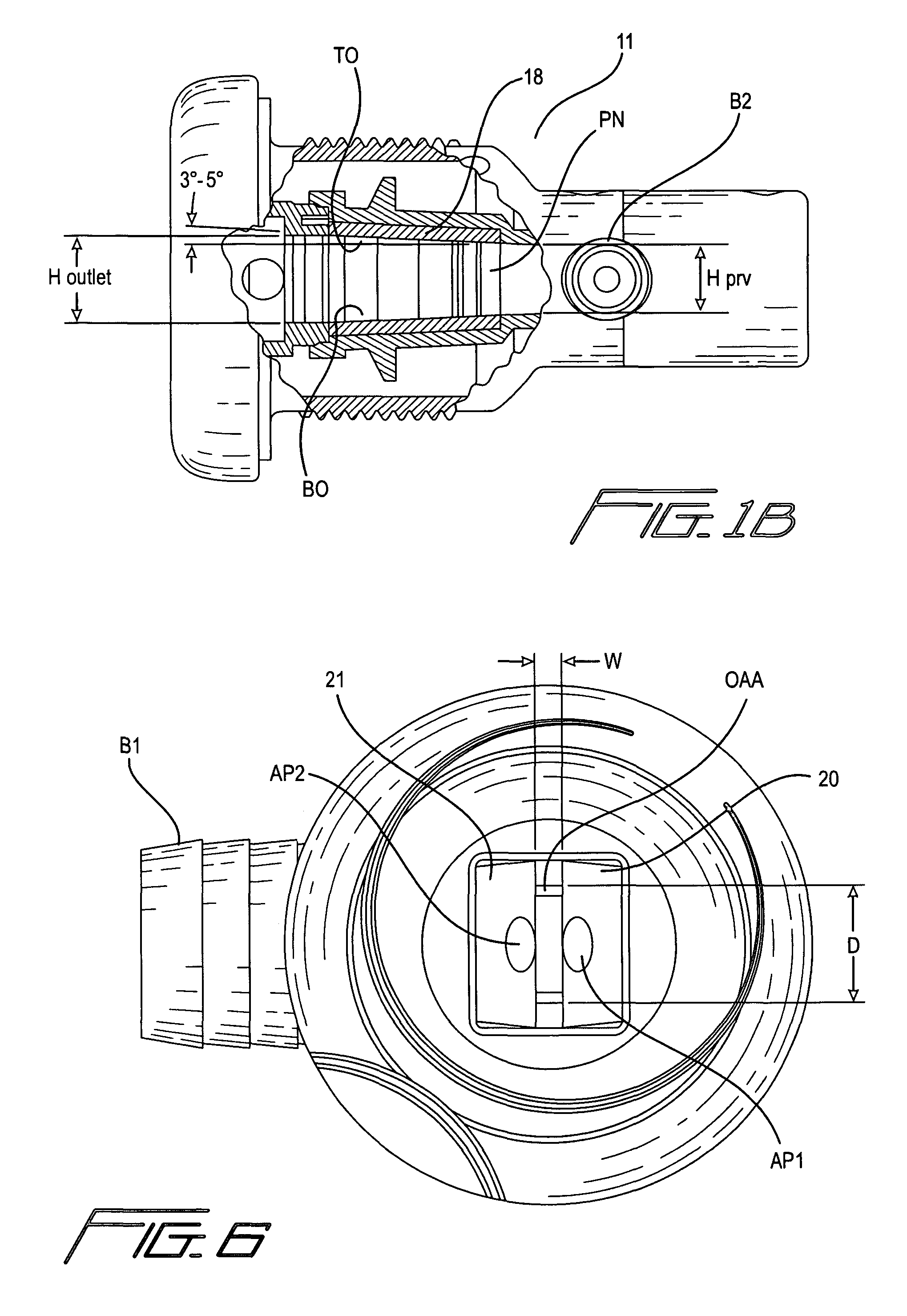

Compact spa jet with enhanced air effects

ActiveUS8869320B1More water flow rateImprove visual effectsDomestic plumbingSpray nozzlesFluidic oscillatorAir entrainment

A spa nozzle has a fluidic oscillator for oscillating a jet of water back and forth through an outlet aperture and a pair of diverging sidewalls extending downstream of the outlet aperture for issuing a sweeping jet of water into the spa. An air entrainment port is formed in each diverging sidewall downstream of the outlet aperture. The top and bottom walls in the oscillator interaction region diverge sufficiently so as to provide a relatively large outlet aperture area but not so large as to cause the jet to roll as it exits the outlet aperture, and wherein the ratio of the depth D of the power nozzle to the width W thereof is from about 2.9 to about 3.1 and the ratio of the depth D of the outlet throat to the width W thereof is from about 4.4 to about 4.6.

Owner:DLHBOWLES INC

Spirometer

InactiveUS20060100537A1Small and portableEliminate needRespiratory organ evaluationSensorsFluidic oscillatorSpirometer

A spirometer for measuring fluid flow, particularly associated with exhalation of respiratory patients. The spirometer of this invention preferably has a fluidic oscillator wherein the fluid oscillates within a chamber of the fluidic oscillator. An oscillation frequency of the fluid flow within the chamber is correlated to a flow rate. A computer is used to process input data, such as data representing frequency of the oscillatory flow within the chamber, to a flow rate passing through the spirometer. The spirometer of this invention may have no moving parts, which results in the need for only a design calibration and no periodic calibrations throughout use of the spirometer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Bubble generation for aeration and other purposes

A method of producing small bubbles (90) of gas in a liquid comprises a source (16) of the gas under pressure, a conduit (64a) opening into a liquid and oscillating the gas passing along the conduit at a frequency between 1 and 100 Hz. The oscillation is effected by fluidic oscillator (10) comprising a diverter that divides the supply into respect outputs (A, B), each output being controlled by a control port, wherein the control ports are interconnected by a closed loop (22). There may be at least two of said conduits (62a, 64a), each output port being connected to one or the other of said conduits, in which one phase of the oscillating gas is employed to drive liquid across the conduit (64a) after formation of a bubble in the other phase of oscillation, whereby the bubble is detached by the force of said driven liquid.

Owner:PERLEMAX LTD

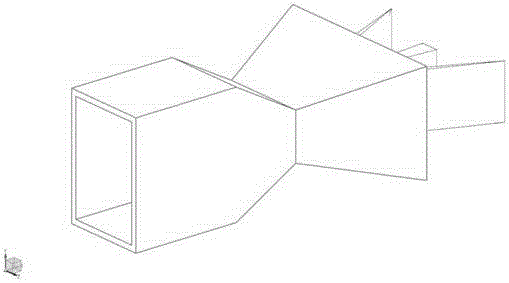

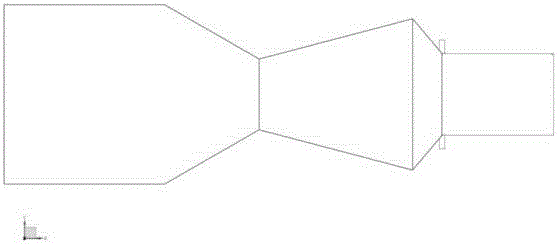

Throat deviated pneumatic vectoring nozzle based on fluid oscillator principle

ActiveCN106837600AEasy to controlImprove mobilityJet propulsion plantsAxis of symmetryFluidic oscillator

The invention discloses a throat deviated pneumatic vectoring nozzle based on a fluid oscillator principle. The throat deviated pneumatic vectoring nozzle comprises an inner runner of the nozzle. The inner runner of the nozzle is of a fluid oscillator structure for adjusting an off-course vector angle direction; the fluid oscillator structure comprises an oscillating cavity and a spoiler, the oscillating cavity is arranged close to a throat I, the spoiler is mounted in the central position at the outlet of the throat II in a deviated manner and the head of the spoiler is located in the oscillating cavity, and the tail end of the spoiler arranged extending out of the throat II; when the spoiler deviates relative to axis of symmetry of the inner runner of the nozzle, an air flow flowing through the inner runner of the nozzle generates asymmetrical air flow extrusion in the oscillating cavity under the influence of the spoiler deviated downstream to form asymmetrical eddies. At the moment, an off-course direction vector is generated by virtue of the spoiler, so that the off-course vector angle direction of the nozzle is adjusted; therefore, the nozzle can generate the off-course vector angle and adjust the off-course vector angle.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

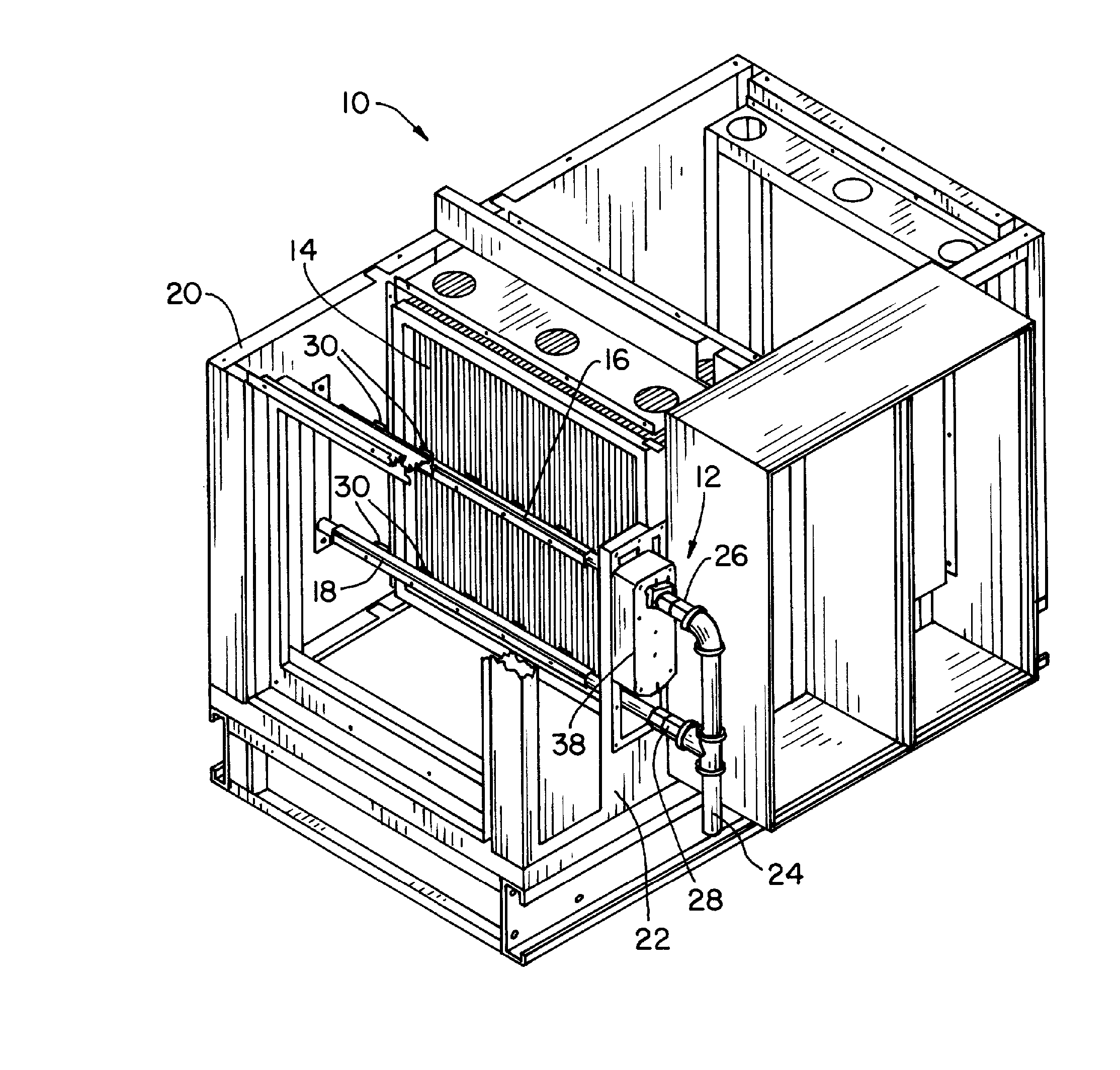

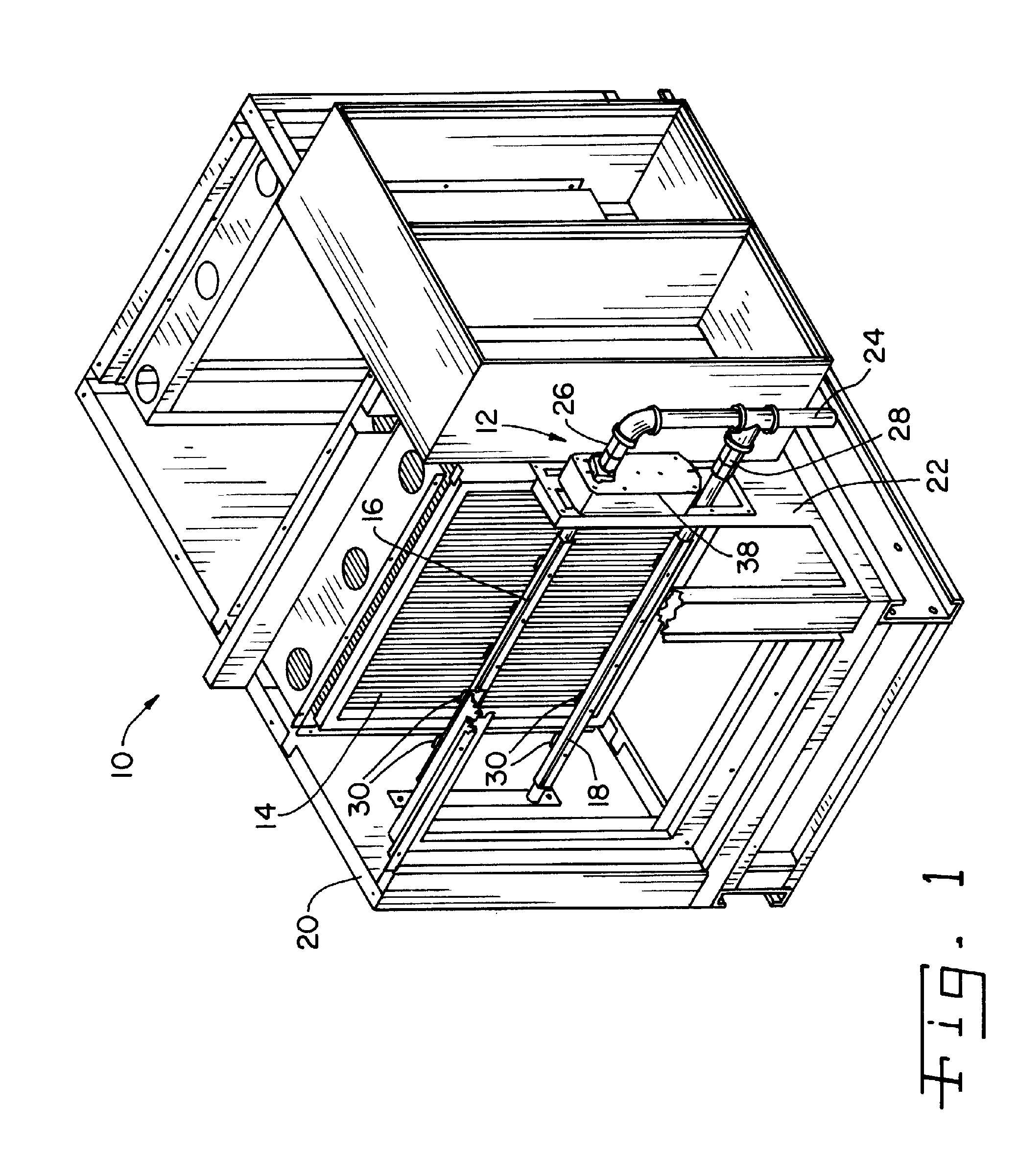

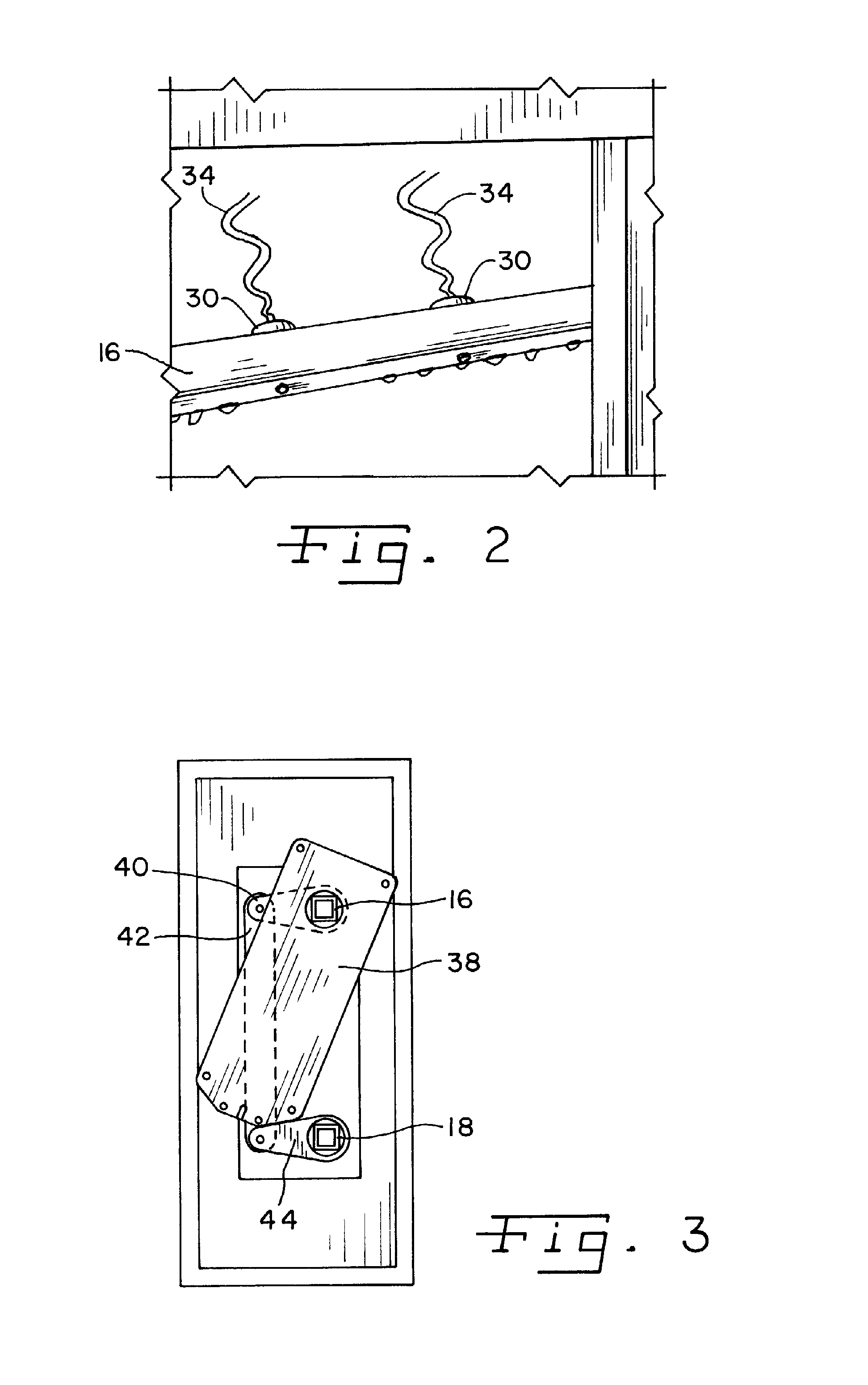

Electrostatic precipitator wash system

InactiveUS20070240742A1Easy to operateIncrease kinetic energyExternal electric electrostatic seperatorCleaning using liquidsFluidic oscillatorSpray nozzle

An electrostatic precipitator wash system includes a plurality of fluidic oscillator nozzles through which wash solution is directed at the electrostatic cell of the electrostatic precipitator. The nozzles are provided in a manifold rotatable about an axis of the manifold. The manifold is rotated through an arc of about 90° while emitting wash solution toward the cell in an oscillating stream of drops.

Owner:ILLINOIS TOOL WORKS INC

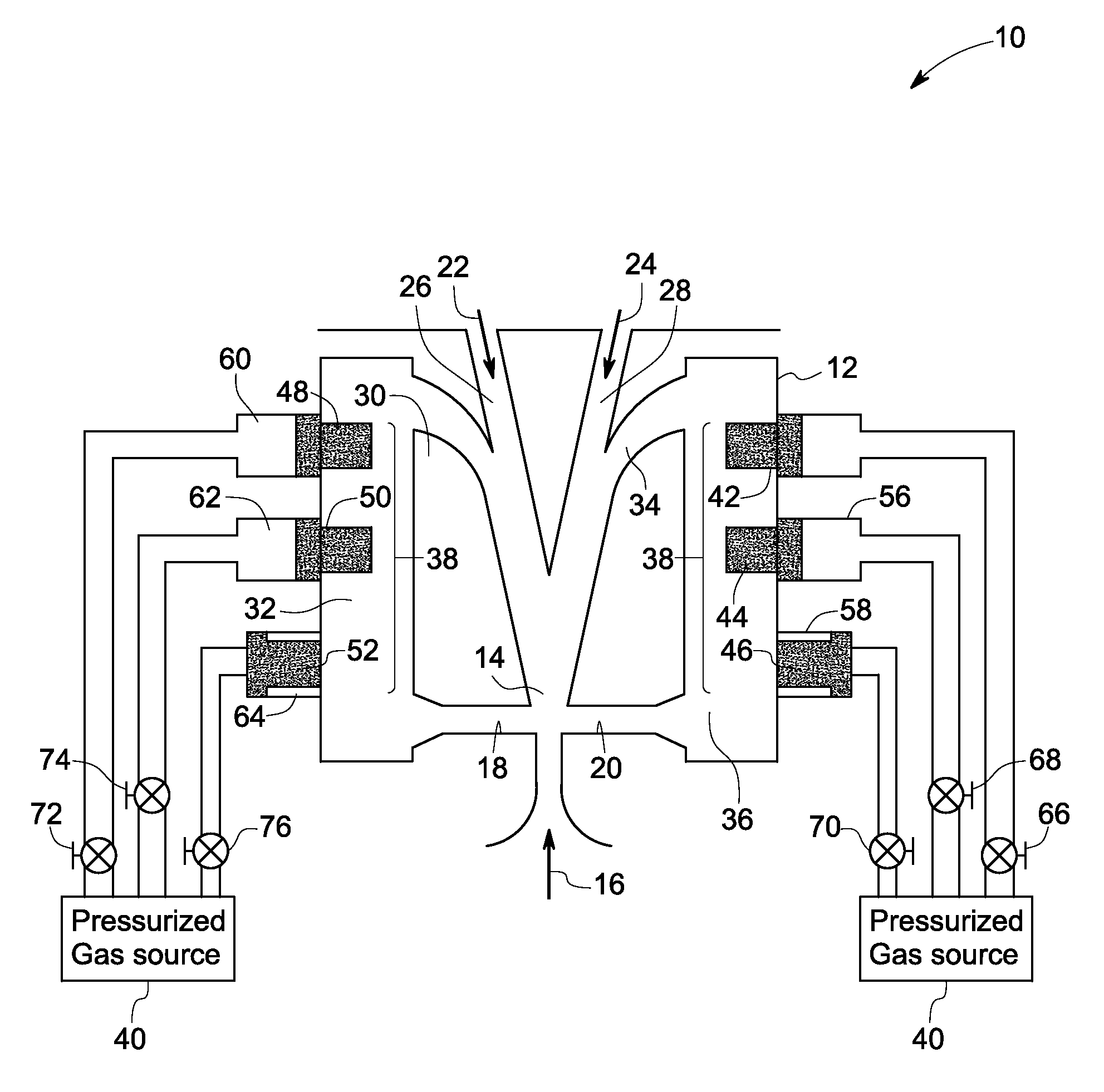

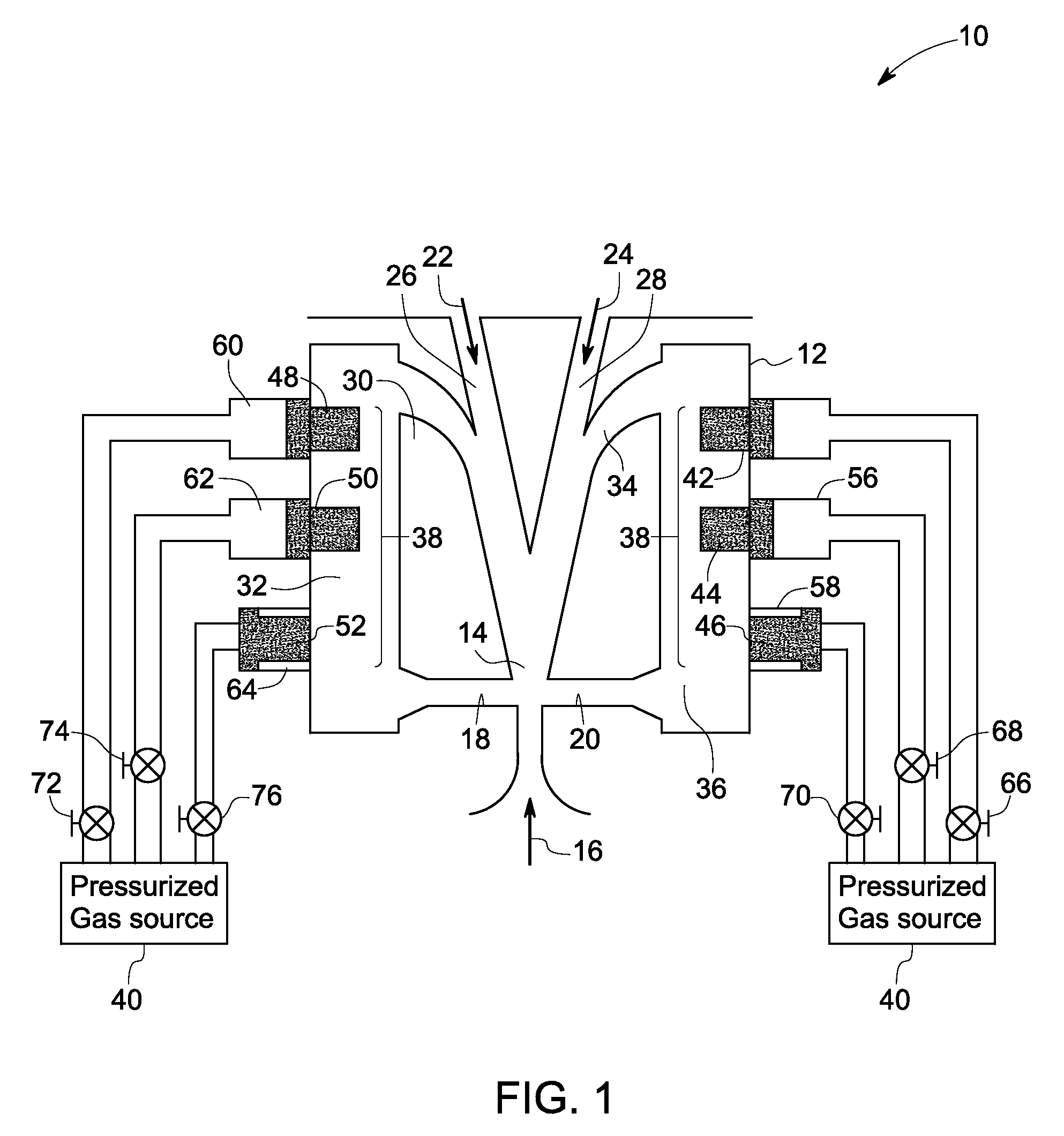

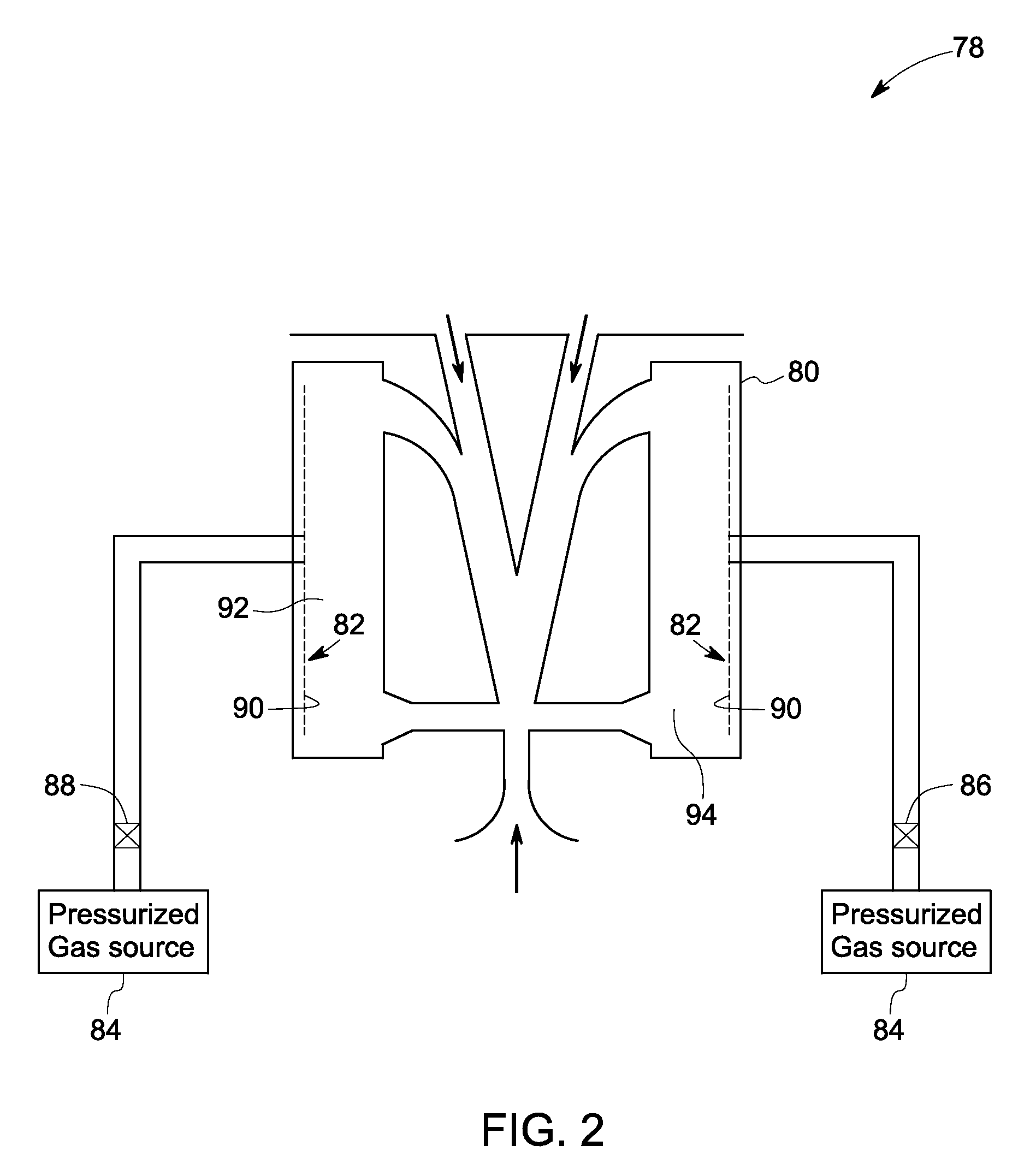

Tunable fluid flow control system

InactiveUS20110005334A1Frequency controlControl flowBurnersFuel supply regulationControl systemFluidic oscillator

A tunable fluid flow control system includes a fluidic oscillator having a movable boundary wall. A pressurized gas source is coupled to the movable boundary wall and configured to supply a stream of pressurized gas to the movable boundary wall to actuate the boundary wall. The boundary wall is actuatable to vary a cavity volume in the fluidic oscillator so as to control frequency of flow of a pulsating fluid generated by the fluidic oscillator. A portion of a fluid is bypassed the fluidic oscillator so as to control amplitude of flow of a pulsating fluid generated by the fluidic oscillator.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com