Flue-gas swirl strong mixing split filter board

A filter plate and vortex technology, applied in the field of flue gas vortex strong mixing split filter plate, can solve the problems of increasing the volume of the SCR device, inconvenient design, installation and operation, reducing escape and air leakage, convenient installation and operation. The effect of running, reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described as follows in conjunction with accompanying drawing:

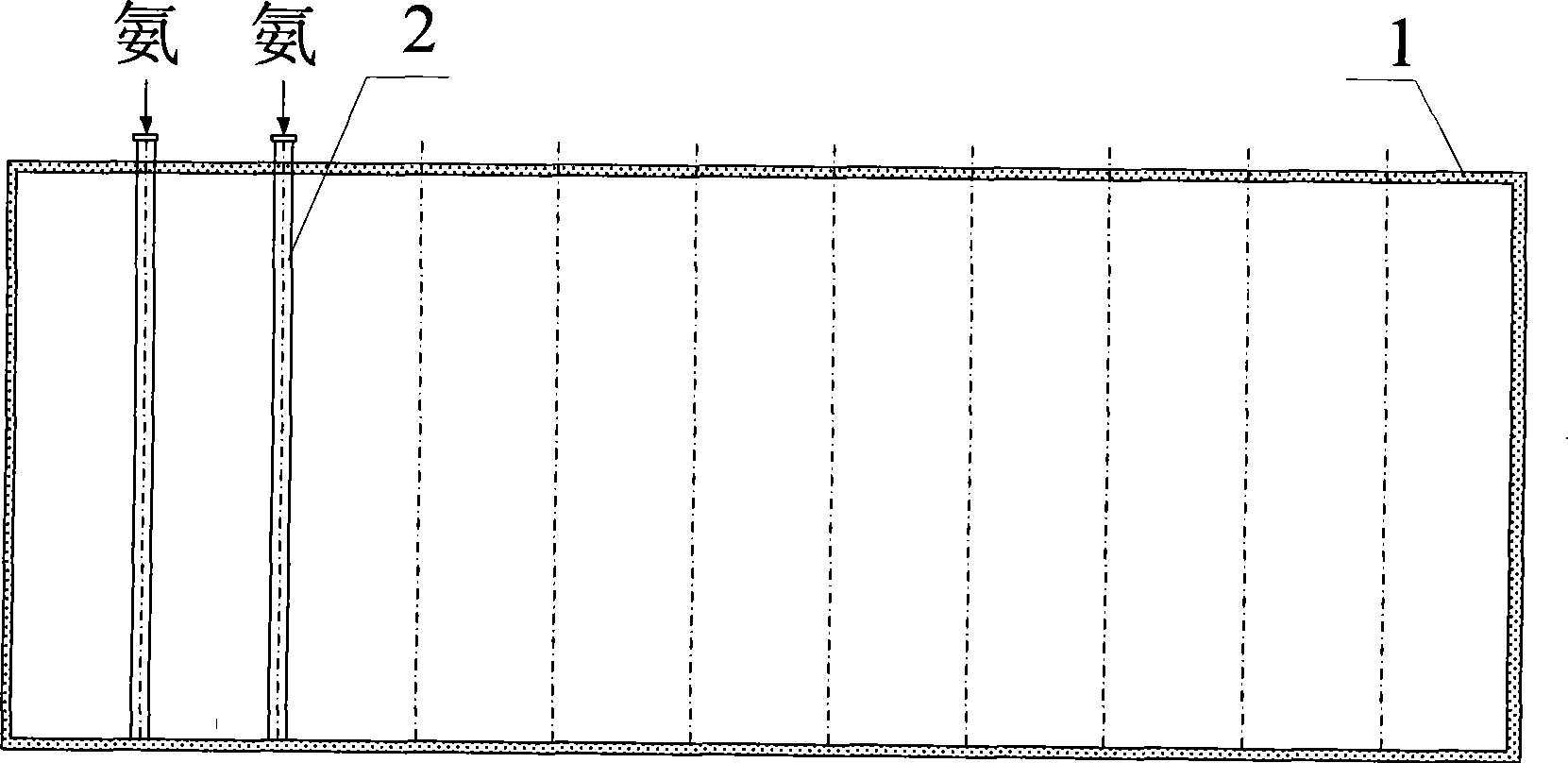

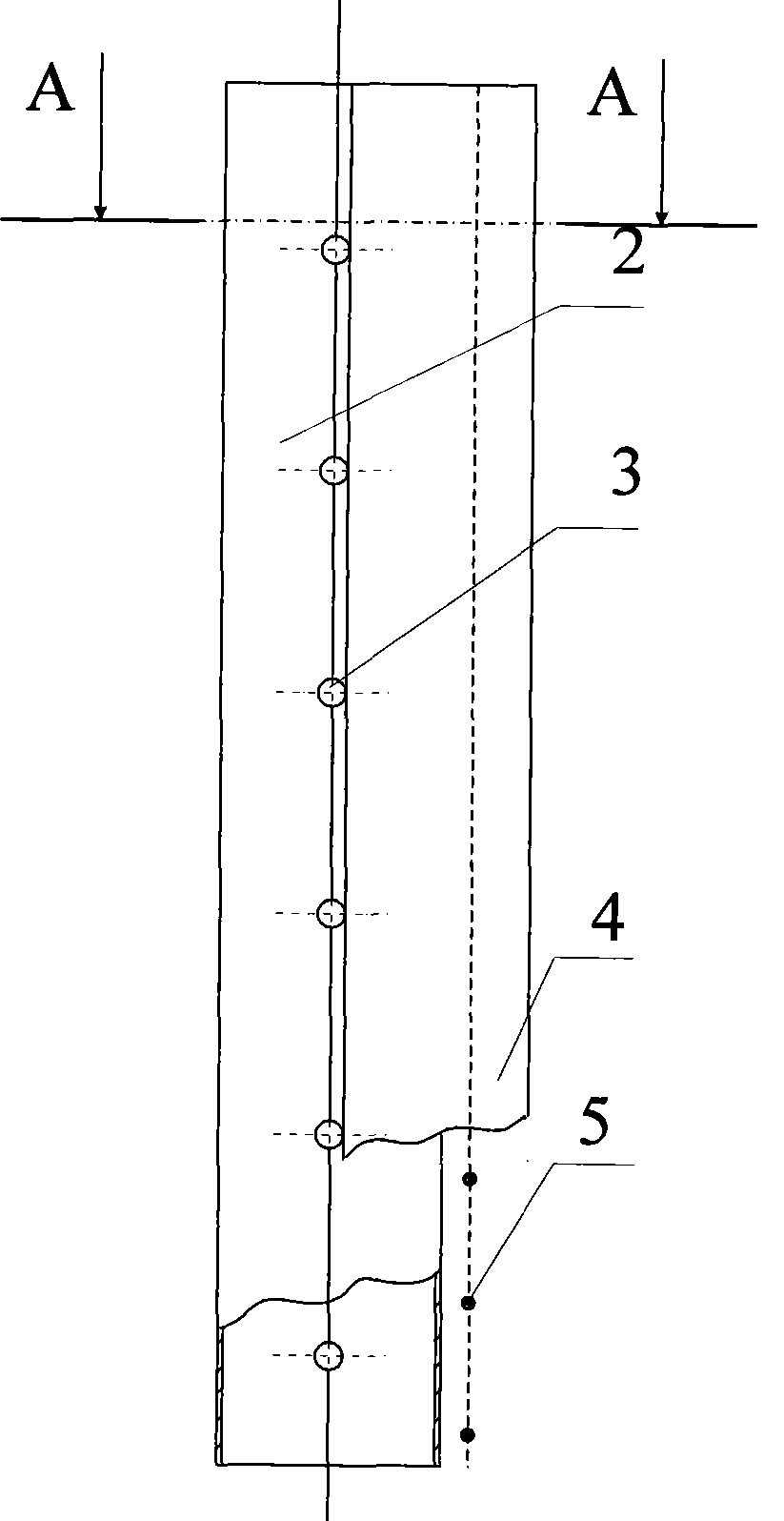

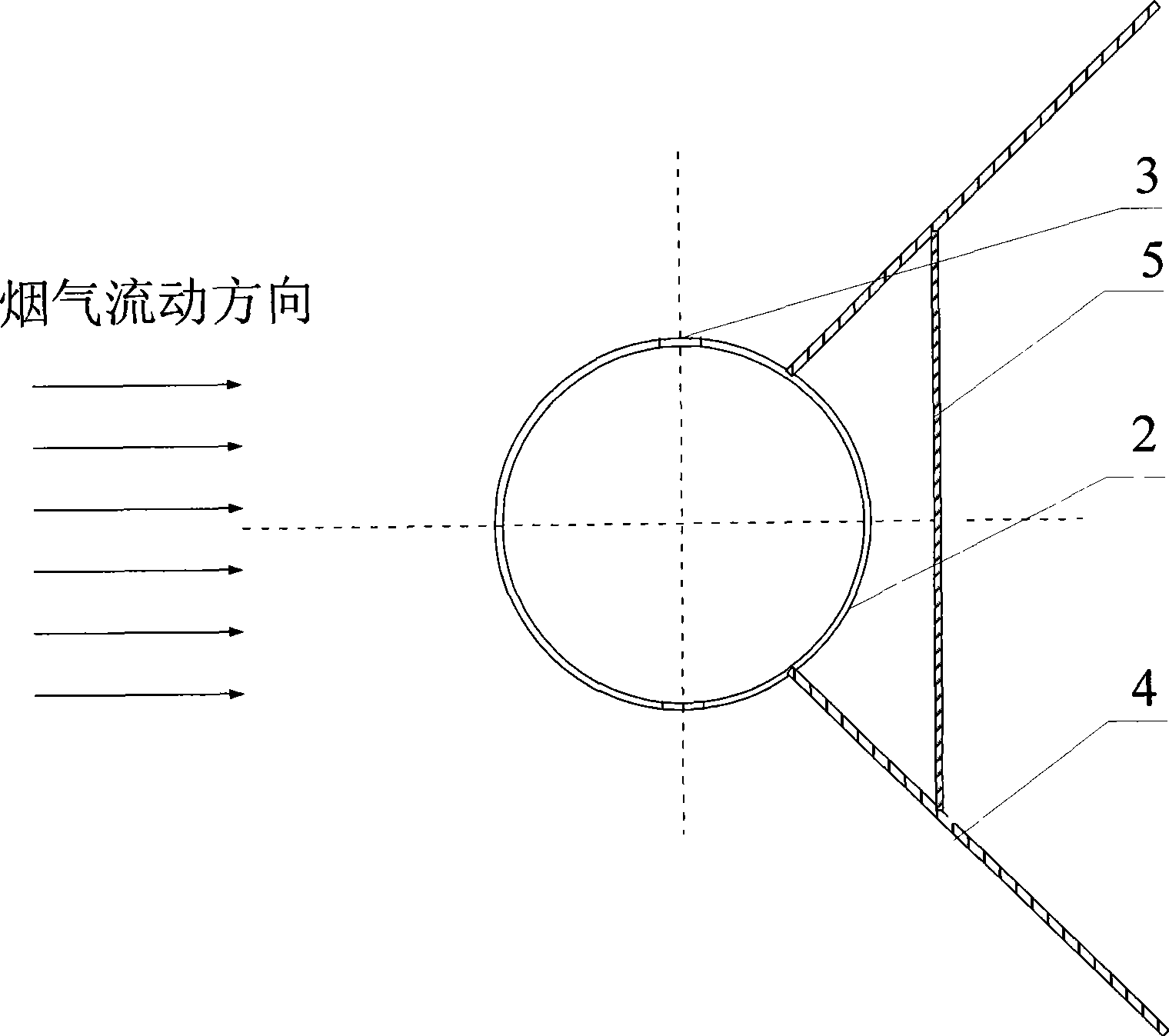

[0022] A number of ammonia injection pipes 2 of ammonia injection grids are arranged on the cross section of the flue 1, and two vortex strong mixing and split flow filter plates 4 are arranged on each ammonia injection pipe. The structure of the filter plate 4 is an angle steel with small holes of different apertures, and the length is equal to the length of the nozzle or slightly longer. Near the ammonia gas outlet, that is, the pore size at the root of the filter plate is small and the number is small; the pore size near the edge of the filter plate is large and the number is large. The edge of the filter plate is semicircular and serrated. The filter plate 4 is installed on the ammonia injection grid pipe, close to the ammonia gas nozzle, and forms an included angle of 40° to 60° with the direction of the flue gas. The upper and lower filter plates are symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com