Patents

Literature

720 results about "Pulverized coal-fired boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox.

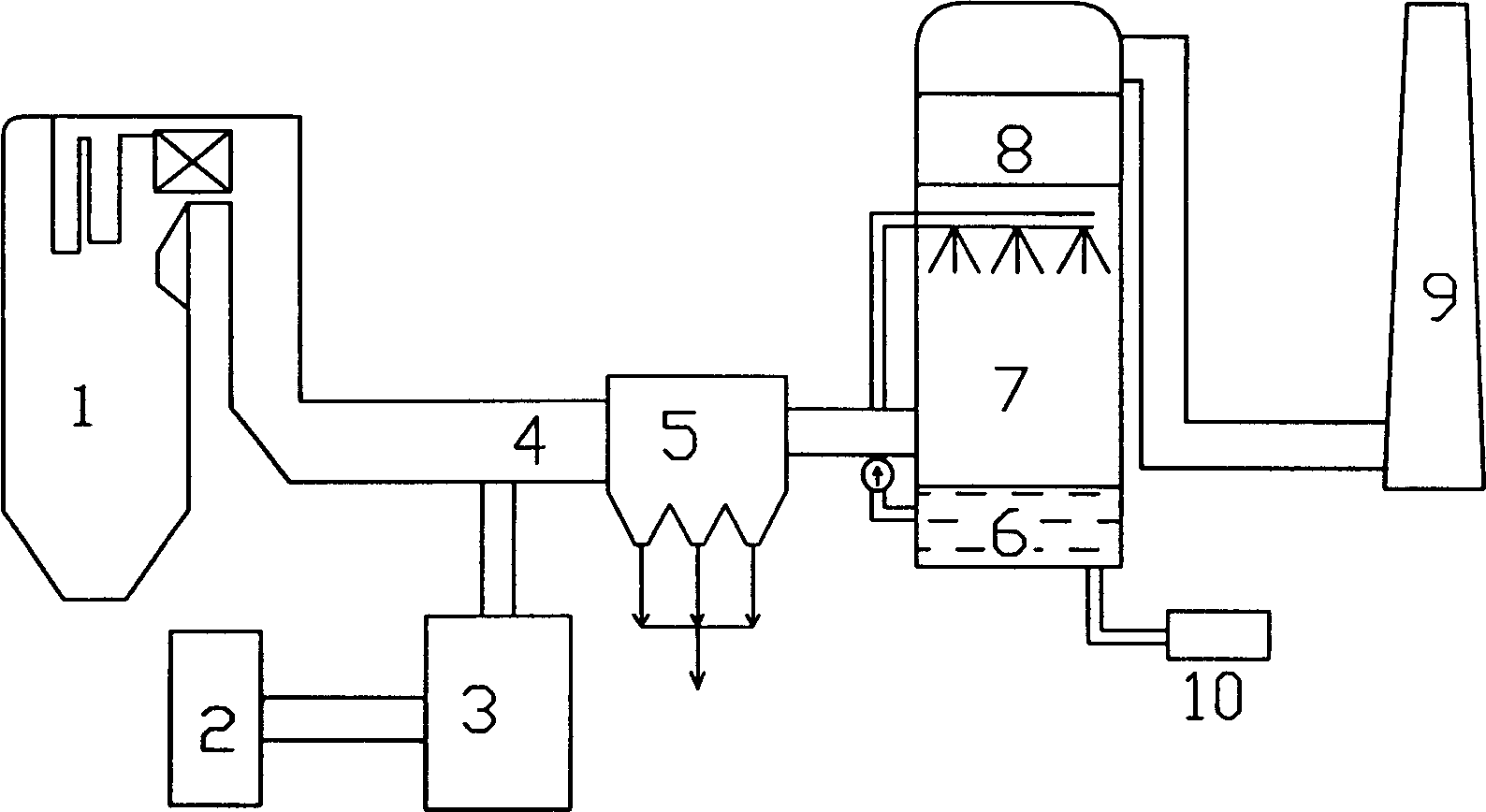

Ozone oxidation and denitration method of boiler flue gas

The invention provides a method for processing de-nitration on the boiler smoke, belonging to the environmental protective technique. The method comprises: ejecting ozone O3 into the low-temperature section of smoke channel of boiler whose temperature ranges from 110-150Deg. C; oxygenizing the nitric oxide NO into high-state nitrogen oxide as NO2, NO3 or N2O5; washing the smoke with alkali liquor to remove the nitrogen oxide in the smoke. Compared to other de-nitration method, said invention has higher efficiency, lower cost, and non-secondary pollution, while the absorption effect combined with alkali liquor can reach more than 80%. In addition, the invention can apply variable boiler devices, which is not relative to the burning condition of boiler.

Owner:ZHEJIANG UNIV

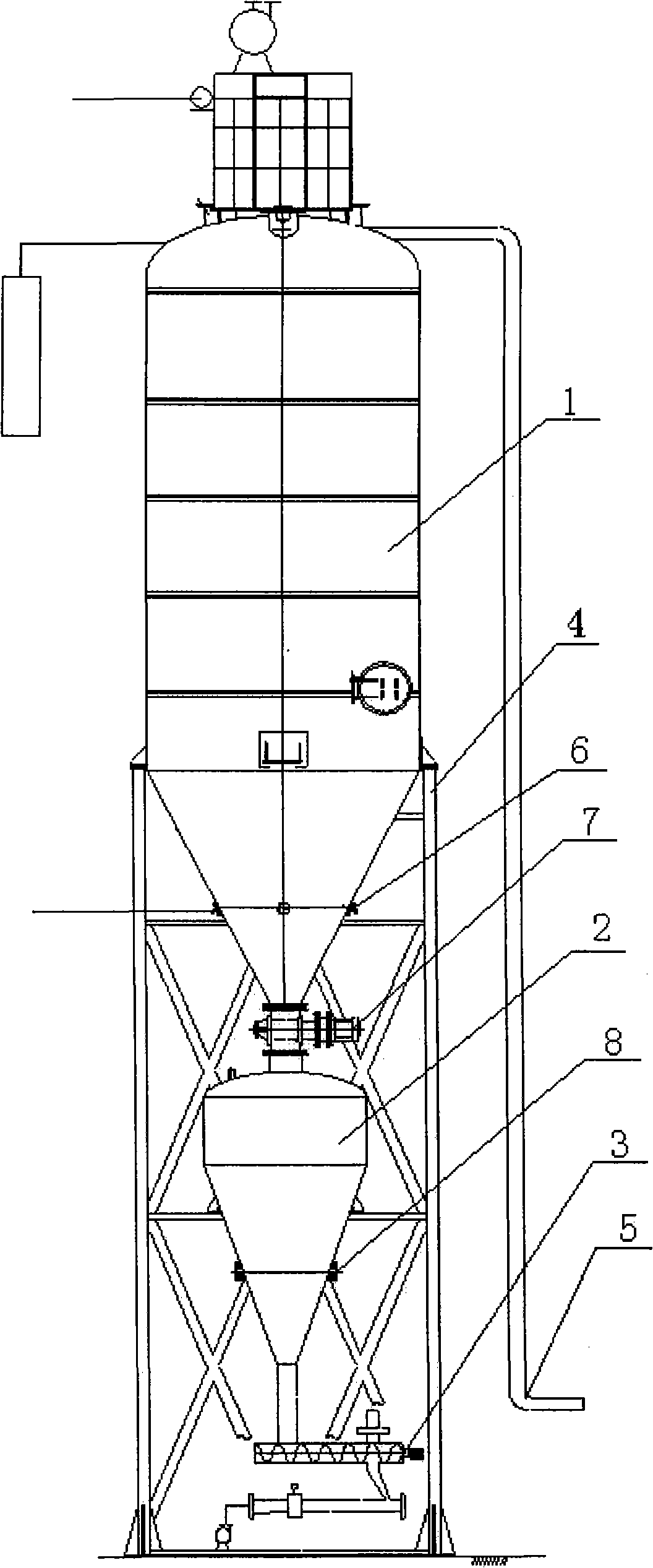

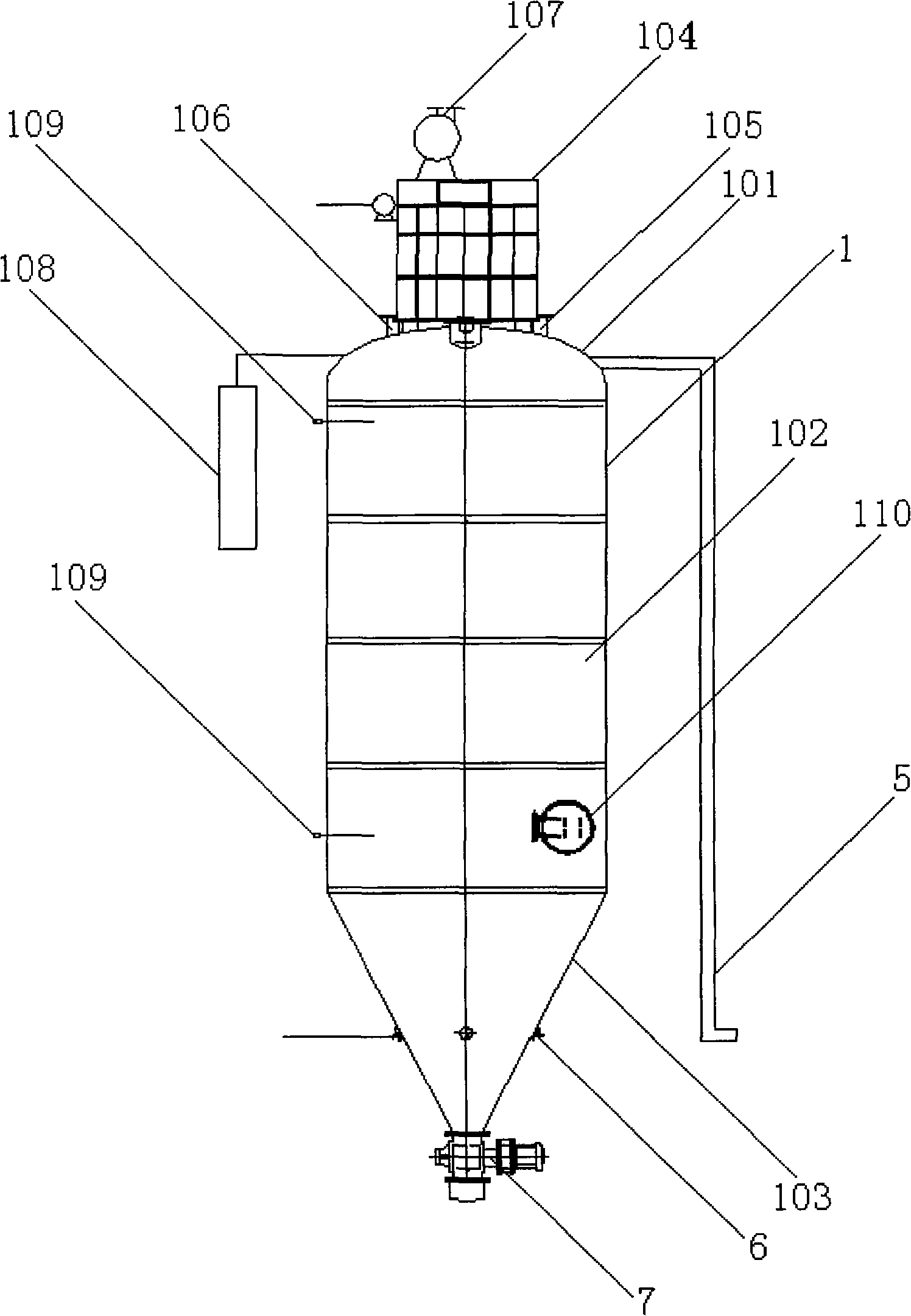

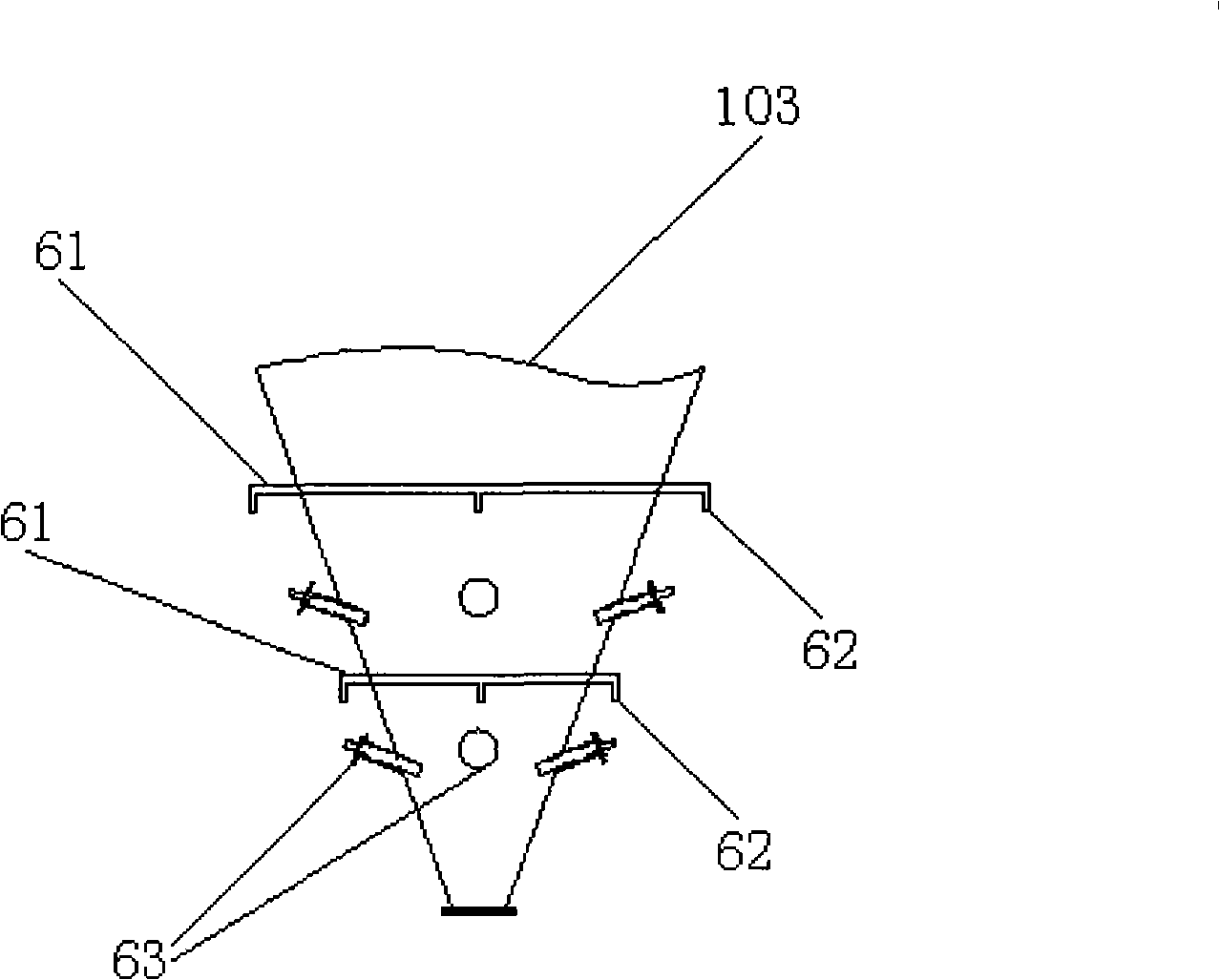

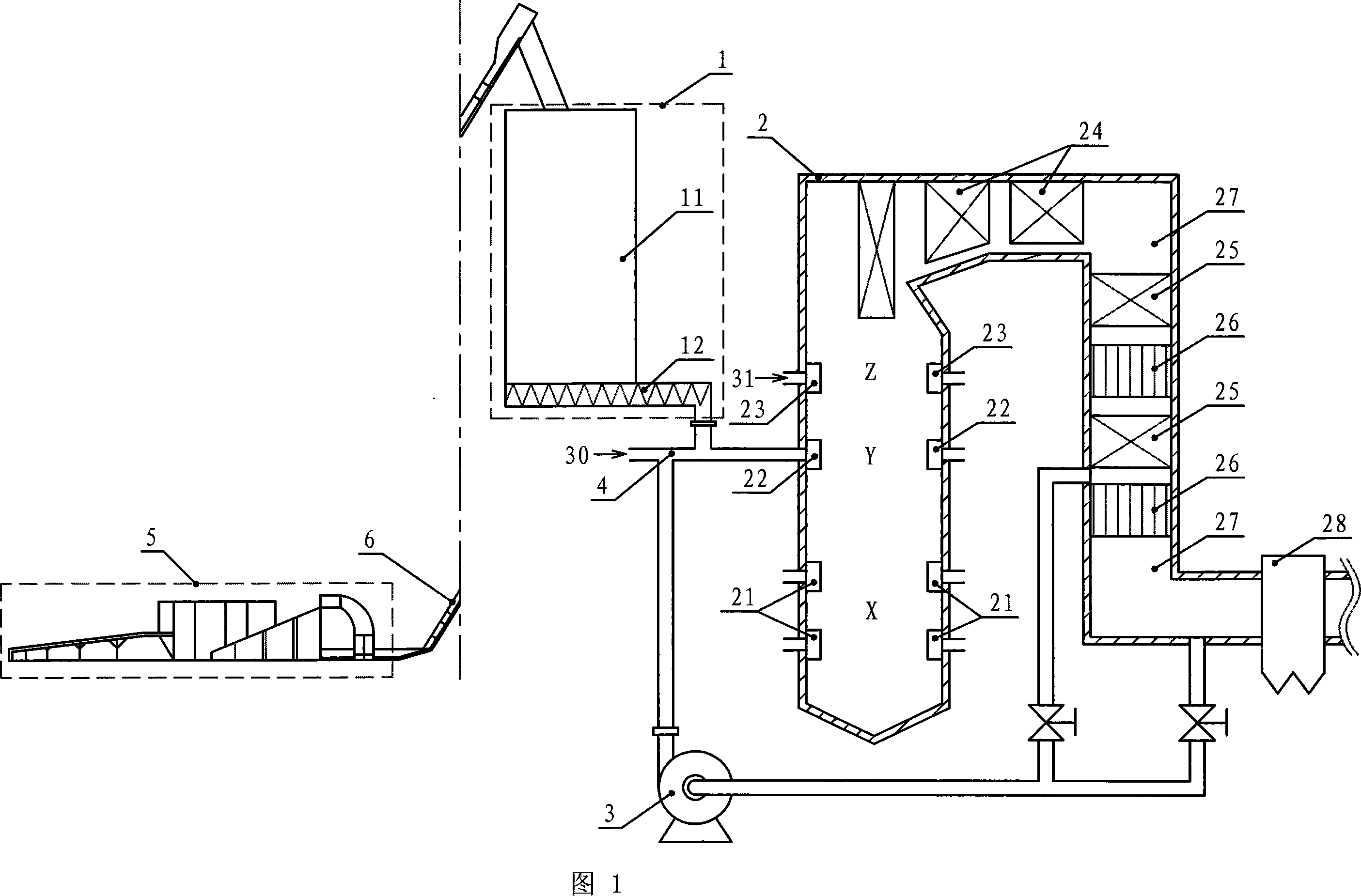

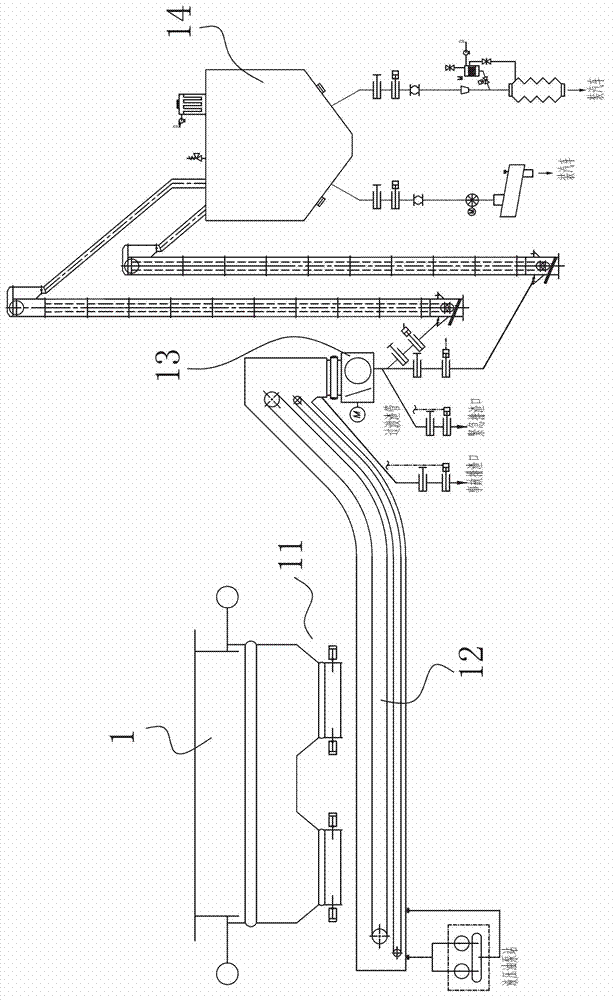

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

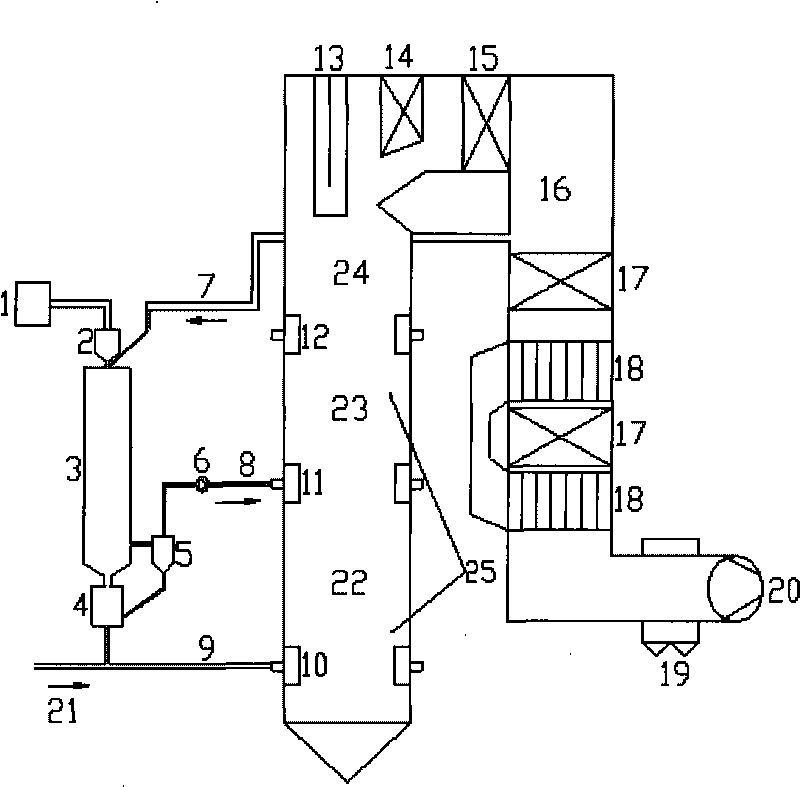

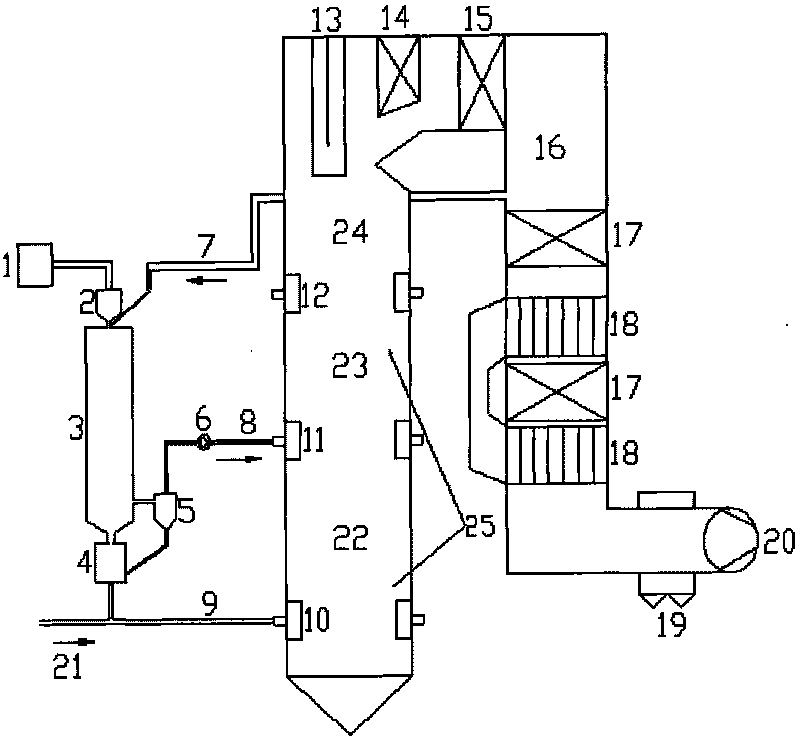

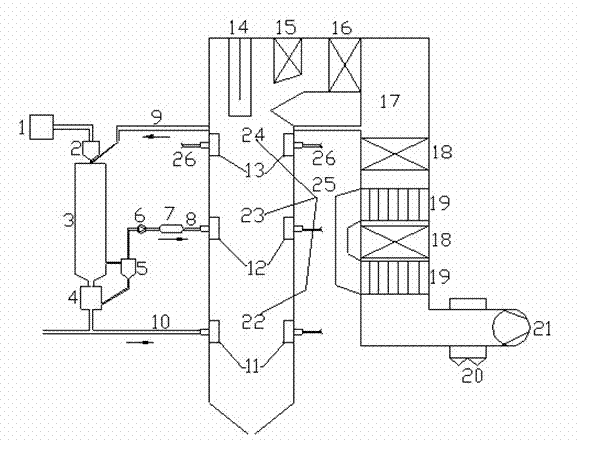

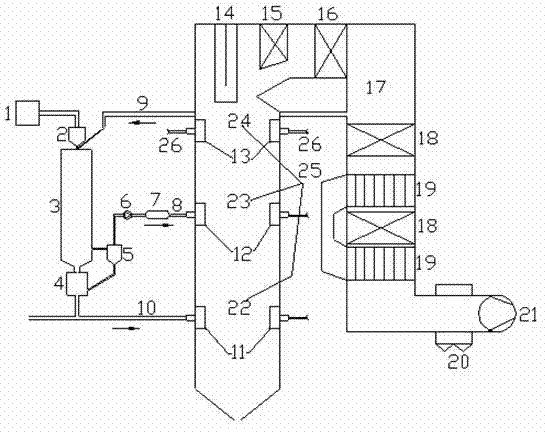

Method and device for burning low NOx by utilizing reburning of pulverized coal pyrolysis gas

InactiveCN101761920AEasy to transformEfficient reductionCombustion apparatusFlue gasProcess engineering

The invention discloses a method and device for burning low NOx by utilizing reburning of pulverized coal pyrolysis gas. The method comprises the following steps: quickly pyrolizing the pulverized coal by utilizing partial hot smoke gas of a tail flue of a pulverized coal boiler entering a pyrolysis reactor; delivering the pulverized coal pyrolysis gas serving as the gas reburning fuel into a reburning area of the pulverized coal boiler to perform high-efficiency NOx reduction, and completely burning the gas reburning fuel subjected to NOx reduction in a burning-out area of the pulverized coal boiler to discharge the low NOx of the pulverized coal boiler; and allowing semicoke which is produced through the pulverized coal pyrolysis to enter a main burning area of the pulverized coal boiler which is carried by primary air to finish burning. The device of the technique mainly comprises a pulverized coal quick pyrolysis device, a pulverized coal flue gas circulating system, a boiler low NOx burning system and a pipeline which is connected with the boiler low NOx burning system. The method and the device have the advantages of simple structure, low investment, high denitration efficiency, and wide application prospect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

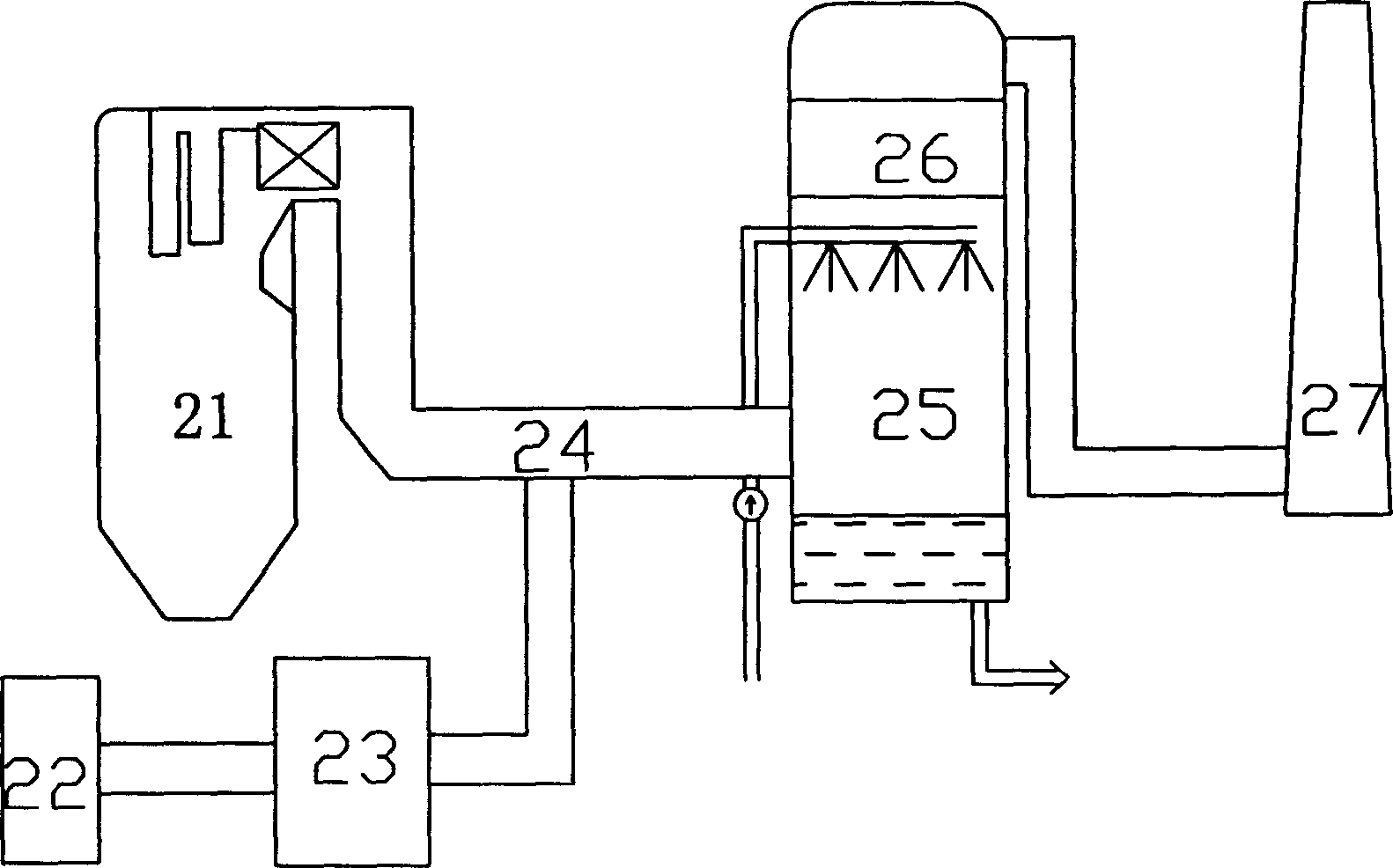

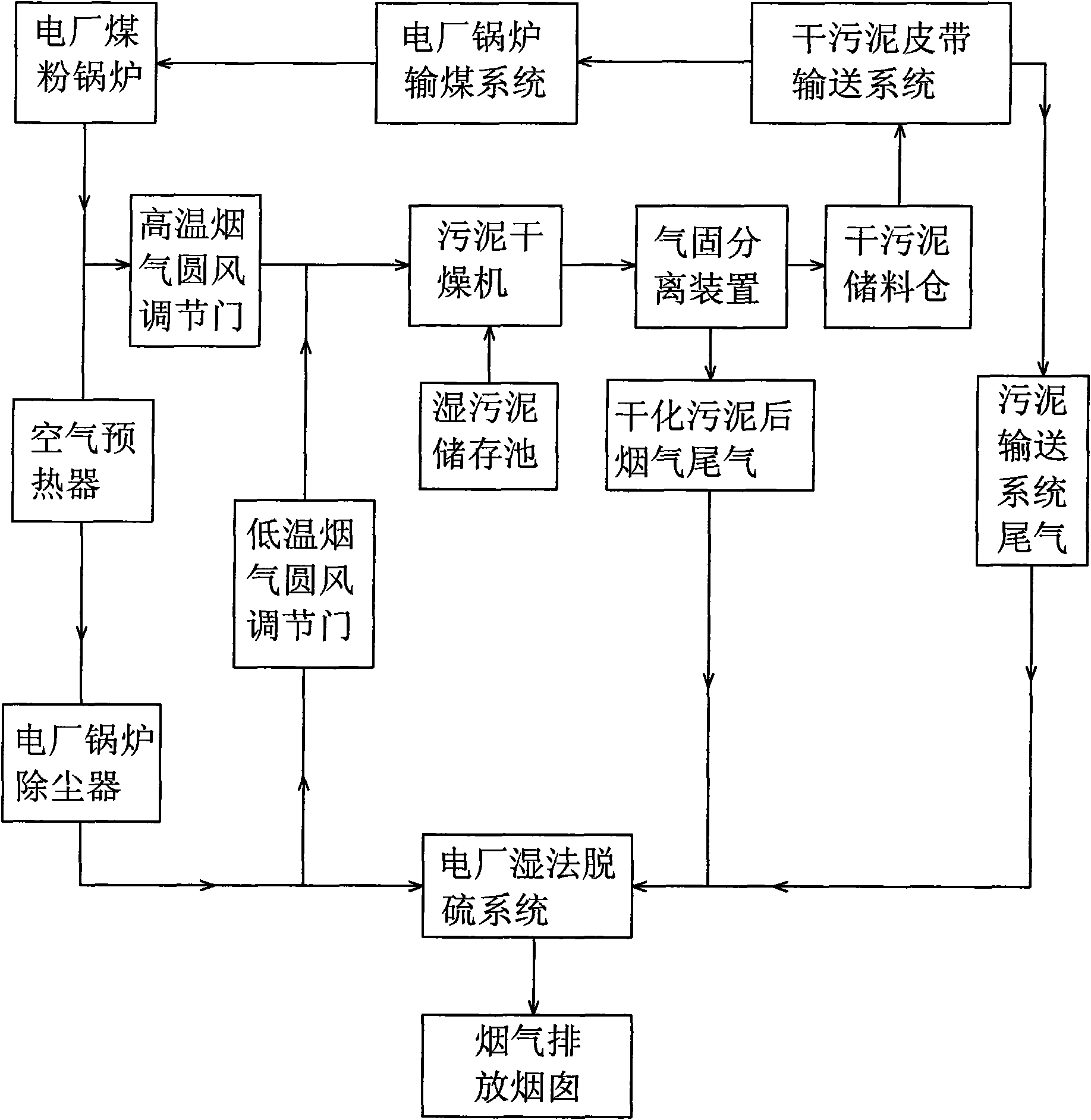

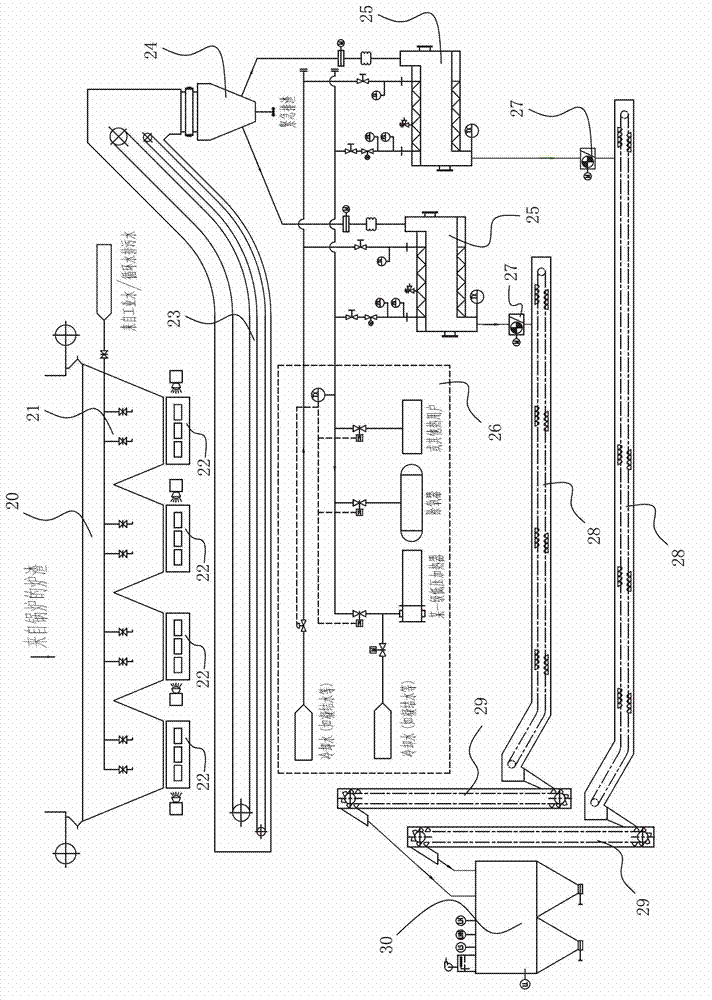

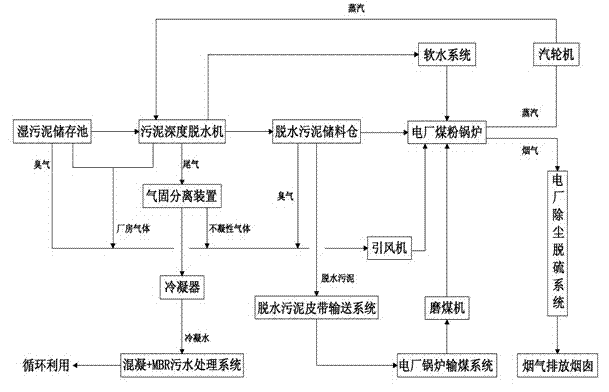

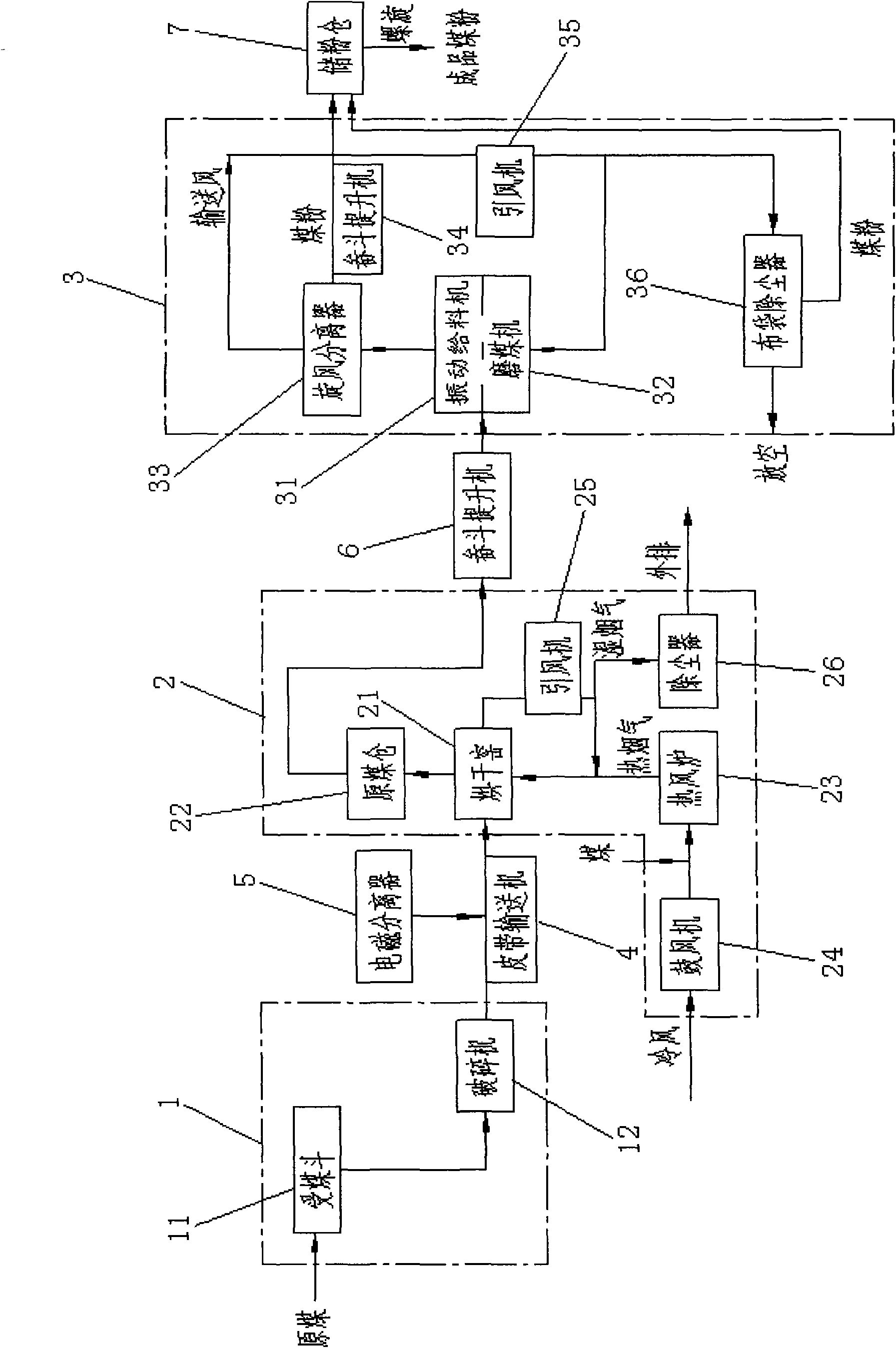

Harmless recycling treatment process for urban sludge

ActiveCN101570388ASimple processLess investmentSludge treatment by de-watering/drying/thickeningDispersed particle separationAir preheaterFlue gas

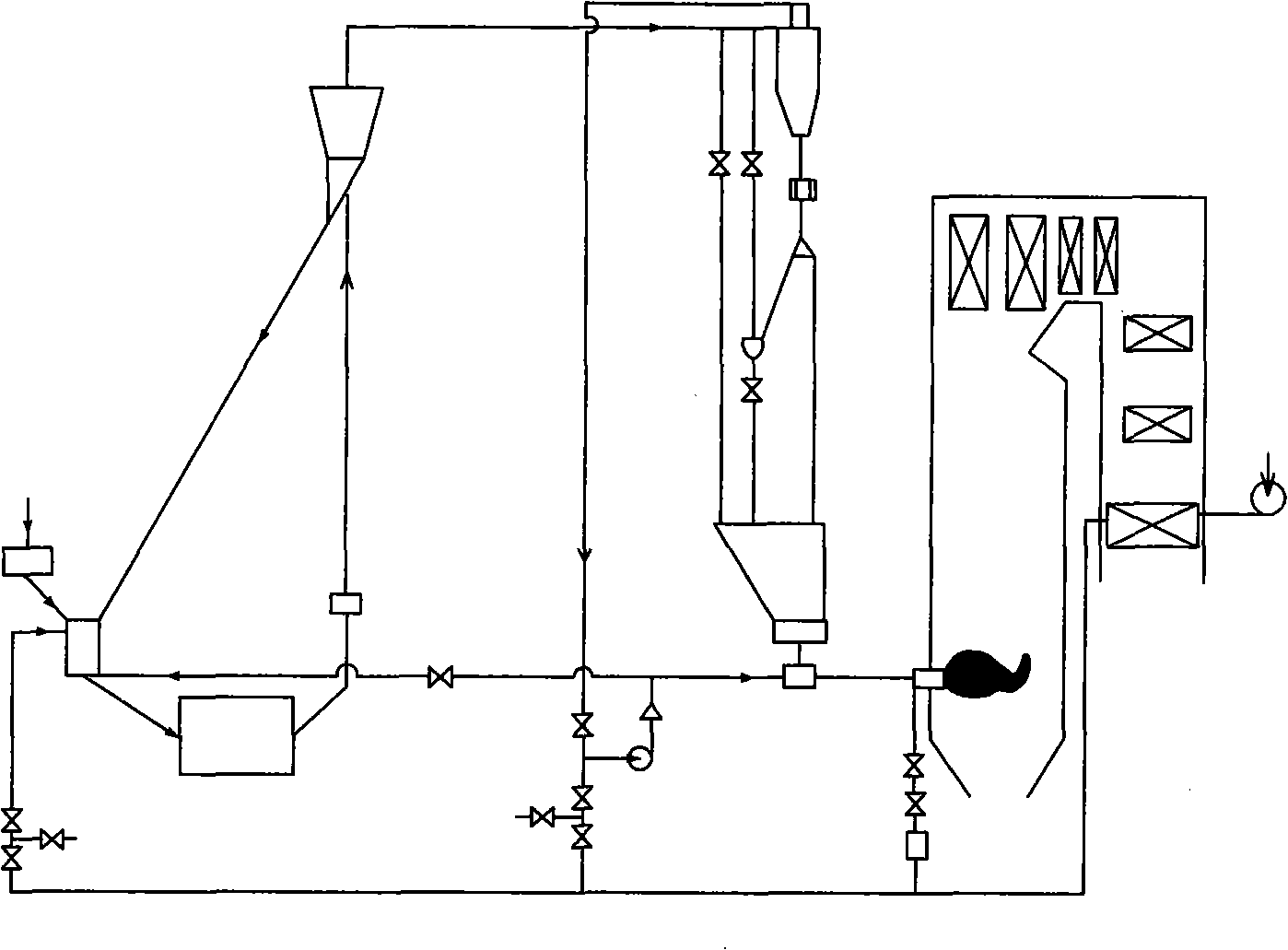

A harmless recycling treatment process for urban sludge carries out urban sludge treatment through the prior pulverized coal boiler and coal conveying and tail exhaust treatment systems in a power plant. In the treatment process, flue gas extracted from the front part of an air preheater of a power plant pulverized coal boiler is mixed with flue gas extracted from the back part of a power plant boiler dust remover into flue gas with the temperature ranging between 140 and 180 DEG C; the flue gas is conveyed to a sludge drier to carry out sludge drying; and the dried sludge is fed into a power plant coal conveying system, mixed with coal, and then fed into a furnace to carry out incineration for power generation so as to realize the recycling utilization of the sludge. The coal and dry sludge are burnt in a boiler and discharged flue gas is fed into the power plant boiler dust remover and a wet desulphurization system for treatment; and the flue gas after the drying and tail gas generated by storing and conveying the dry sludge are discharged into a power plant desulphurization system for treatment, so that the standard discharge of pollutants is realized and secondary environmental pollution is eliminated. The harmless recycling treatment process makes effective use of the prior power plant boiler and coal conveying, burning, dust removal and desulphurization facilities, and has the advantages of simple equipment, less investment, short construction cycle and low operating cost.

Owner:华电滕州新源热电有限公司

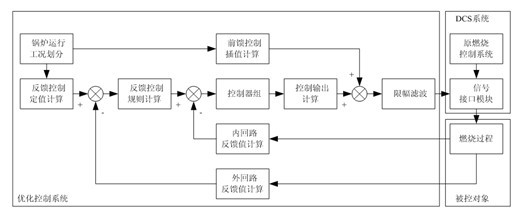

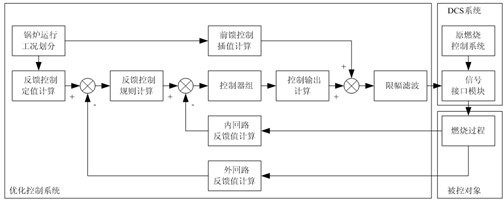

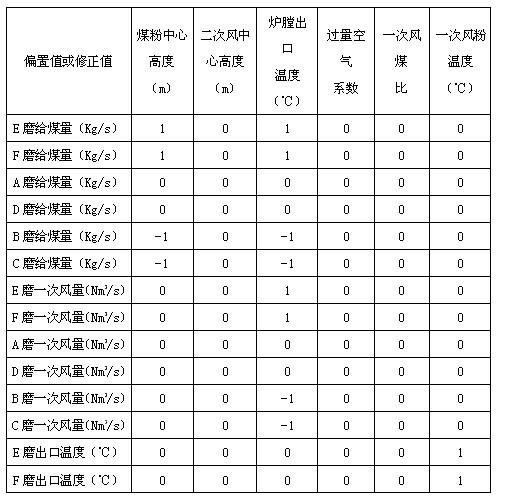

Combustion feedforward and feedback composite optimization controlling method for pulverized coal fired boiler

InactiveCN102425807AImprove combustion efficiencyEmission reductionCombustion regulationCombustorComposite optimization

The invention discloses a combustion feedforward and feedback composite optimization controlling method for a pulverized coal fired boiler. The method is used for realizing dynamic accurate proportioning of wind and coal under a full working condition and in the full combustion process. According to the technical scheme, the method comprises the following steps of: determining feedforward signals according to combustion adjusting experiment data or operation personnel experience, determining feedback signals according to the thermodynamic properties and laws of the boiler, and automatically and accurately adjusting the coal quantity proportion of each burner, the primary air quantity proportion of each coal mill, the outlet temperature of each coal mill and the secondary air quantity and burning-out air quantity proportion of each burner under different working conditions to keep the burning efficiency and the NOX discharge of the boiler in an optimal state. By the method, the advantage of coexistence of a plurality of independent adjusting means of the large pulverized coal fired boiler and the advantages of high dynamic response speed of feedforward control and high static precision of feedback correction control are fully exerted, the pulverized coal fired boiler is close to the optimal state under various working conditions, the burning efficiency of the boiler is improved, and the discharge of NOX is reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

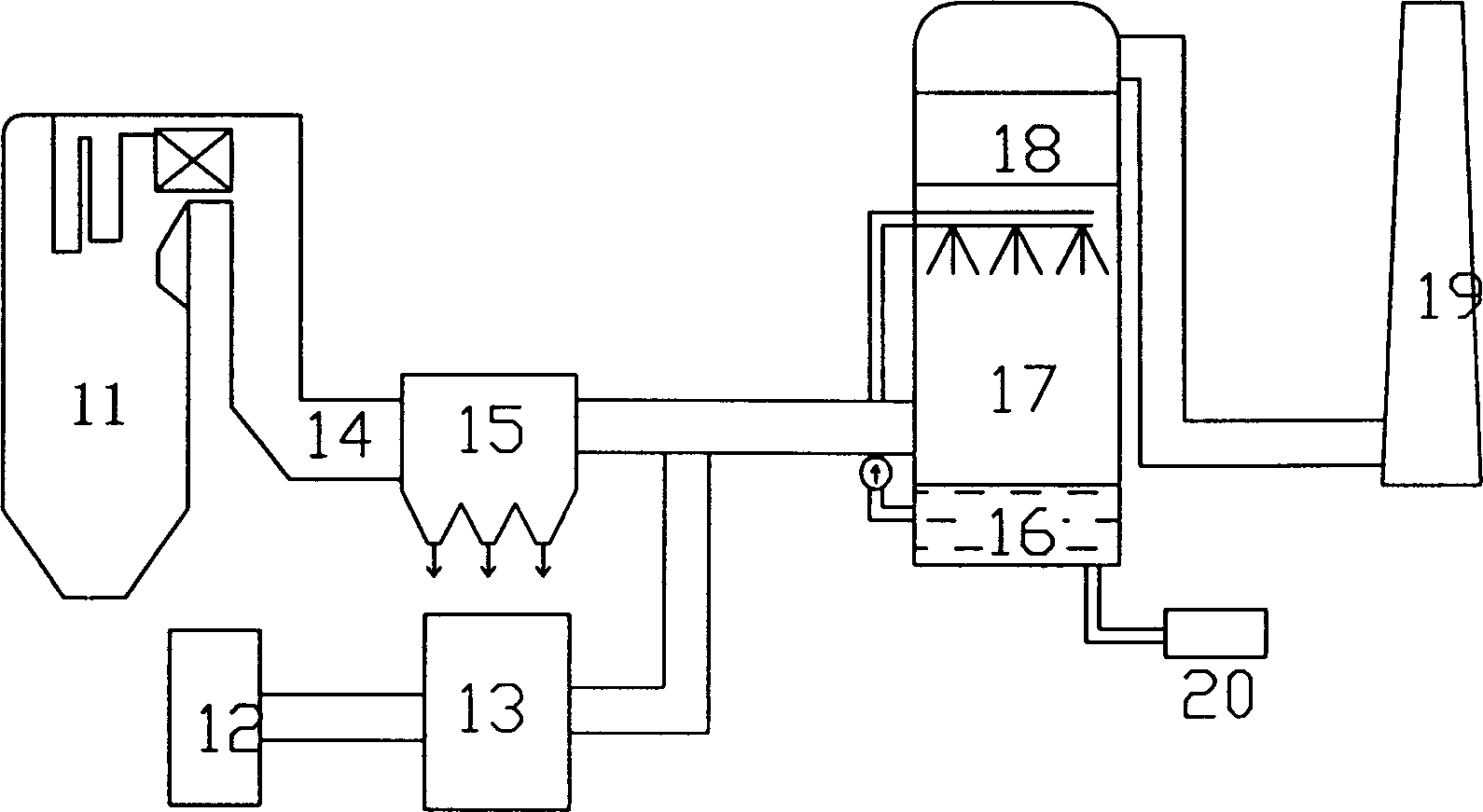

Method and device of denitration utilizing biomass direct burning and re-burning as well as smoke gas recirculating technology

InactiveCN101021316AReduce technical riskLow technical costCombustion apparatusCombustorDirect combustion

The present invention belongs to a denitration method by utilizing biomass direct combustion and secondary combustion and flue gas recirculating process and its equipment, and relates to a coal powder boiler low NOx combustion process and its equipment. The invented method includes the following steps: making coal powder be passed through the combustor of coal powder boiler and fed into main combustion zone to make combustion and form the flue gas containing NOx; utilizing the mixture of once air and recirculating tail portion flue gas to spray biomass particles into secondary combustion reduction zone and make NOx formed in the main combustion zone be reacted and formed into N2; at the same time make the biomass coke ad NOx produce isophase reduction reaction to form Nz; spraying burning air from upper portion of secondary combustion reduction zone to make non-burnt combustible material be burnt up.

Owner:HARBIN INST OF TECH

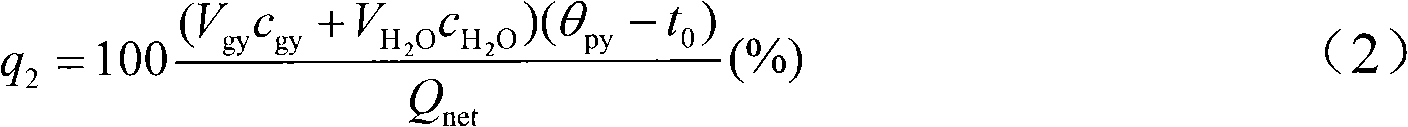

Method for monitoring thermal efficiency and coal quality data of pulverized coal fired boiler in real time

InactiveCN102012968AThe real-time monitoring method is scientific and reasonableAccurate real-time monitoringSpecial data processing applicationsAir preheaterAir volume

The invention relates to a method for monitoring thermal efficiency and coal quality data of a pulverized coal fired boiler in real time. A digital model for monitoring the thermal efficiency of a pulverized coal fired boiler system in real time is established to obtain an excess air coefficient, theoretical air volume of a fuel, theoretical nitrogen volume of a combustion product, flue gas carbon dioxide, carbon monoxide, sulfur dioxide, dry flue gas volume, volume difference between theoretical oxygen demand of full coal combustion and practical combustion oxygen consumption, mass percentage of coal as received basis machinery unburned carbon, mass percentage of coal generated carbon dioxide as received basis carbon, mass percentage of coal generated carbon monoxide as received basis carbon, mass percentage of coal as received basis; densities of carbon, hydrogen, oxygen, nitrogen, sulfur, ash, water and flue gas, flow speed of flue gas in air preheater, lower heating value of coal,heat loss due to exhaust smoke, heat loss due to chemical incomplete combustion, heat loss due to mechanical incomplete combustion, radiating heat loss, ash residue physic heat loss, boiler thermal efficiency, mass percentage of carbon in fly ash and coal combustion. The method has the characteristics that: the method is scientific and reasonable, monitors data correctly, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY +1

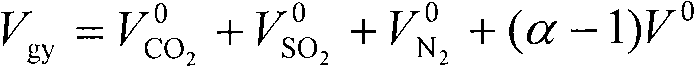

Method for re-circulating combustion of flue gas of pulverized coal fired boiler

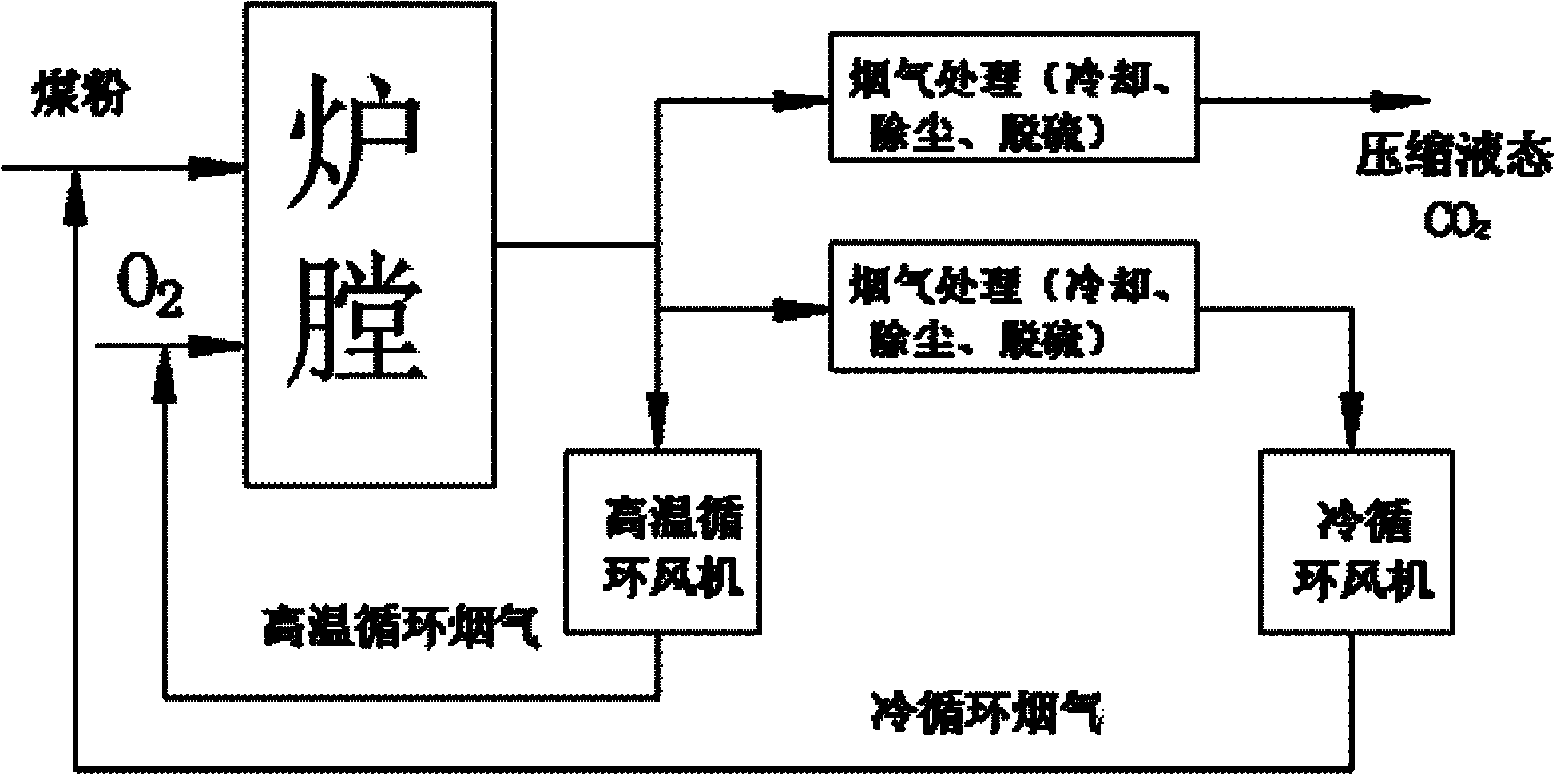

InactiveCN101839474ASteam temperature increasedHigh thermal efficiencyFluidized bed combustionCarbon compoundsCO2 contentHearth

The invention provides a method for re-circulating combustion of flue gas of a pulverized coal fired boiler, belongs to a method for circulating combustion of oxygen gas (O2) and carbon dioxide (CO2) of pulverized coal, and aims to solve the problems of low heat efficiency and poor burn-out property existing in the conventional combustion method. The method comprises the steps of: 1,igniting and combusting: conveying the pulverized coal to a furnace hearth by using the circulation flue gas, and simultaneously conveying O2 to the furnace hearth for ignition; 2, circulating the flue gas: dividing the high-temperature flue gas generated by combustion into two parts, and performing cooling, dust removal and desulfurization compression on the first part to obtain liquid CO2; dividing the second part into two paths, conveying the first path to an entrance of the furnace hearth by using a high-temperature circulation fan, and mixing the first path of the flue gas and O2; and performing cooling, dust removal and desulfurization on the second path, and conveying the second path carrying the pulverized coal to the furnace hearth by using a cold circulation fan. The method has the advantages of adjusting the steam temperature of the boiler by using the high-temperature flue gas, enhancing convective heat transfer, increasing the steam temperature of the boiler, improving the heat efficiency of the boiler and the denitration rate, increasing the CO2 content after the high-temperature flue gas is cooled, reducing emission load of NOx, lowering CO2 capturing and collecting cost, and meeting the national energy conservation and environmental protection standard.

Owner:HUAZHONG UNIV OF SCI & TECH

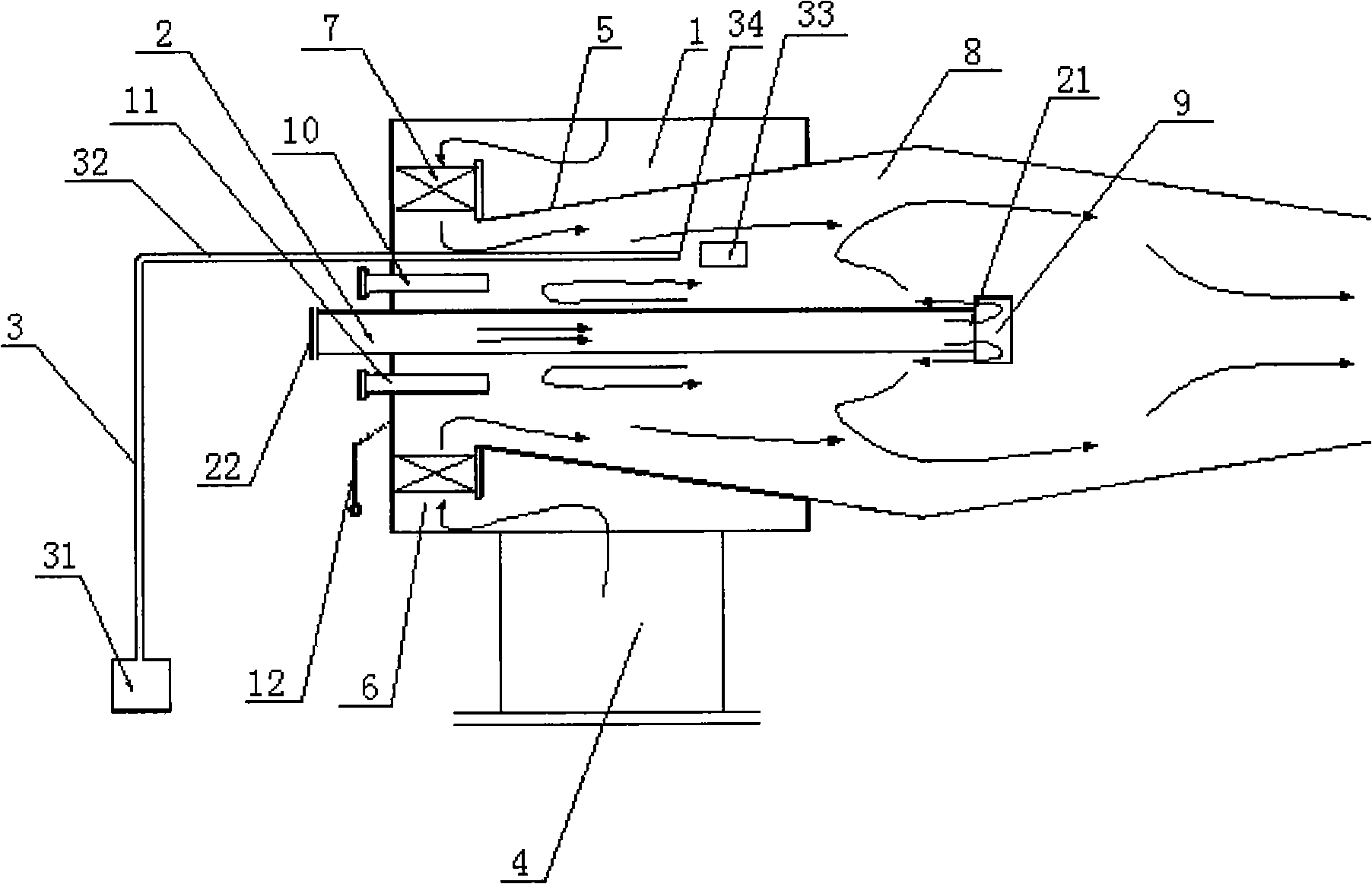

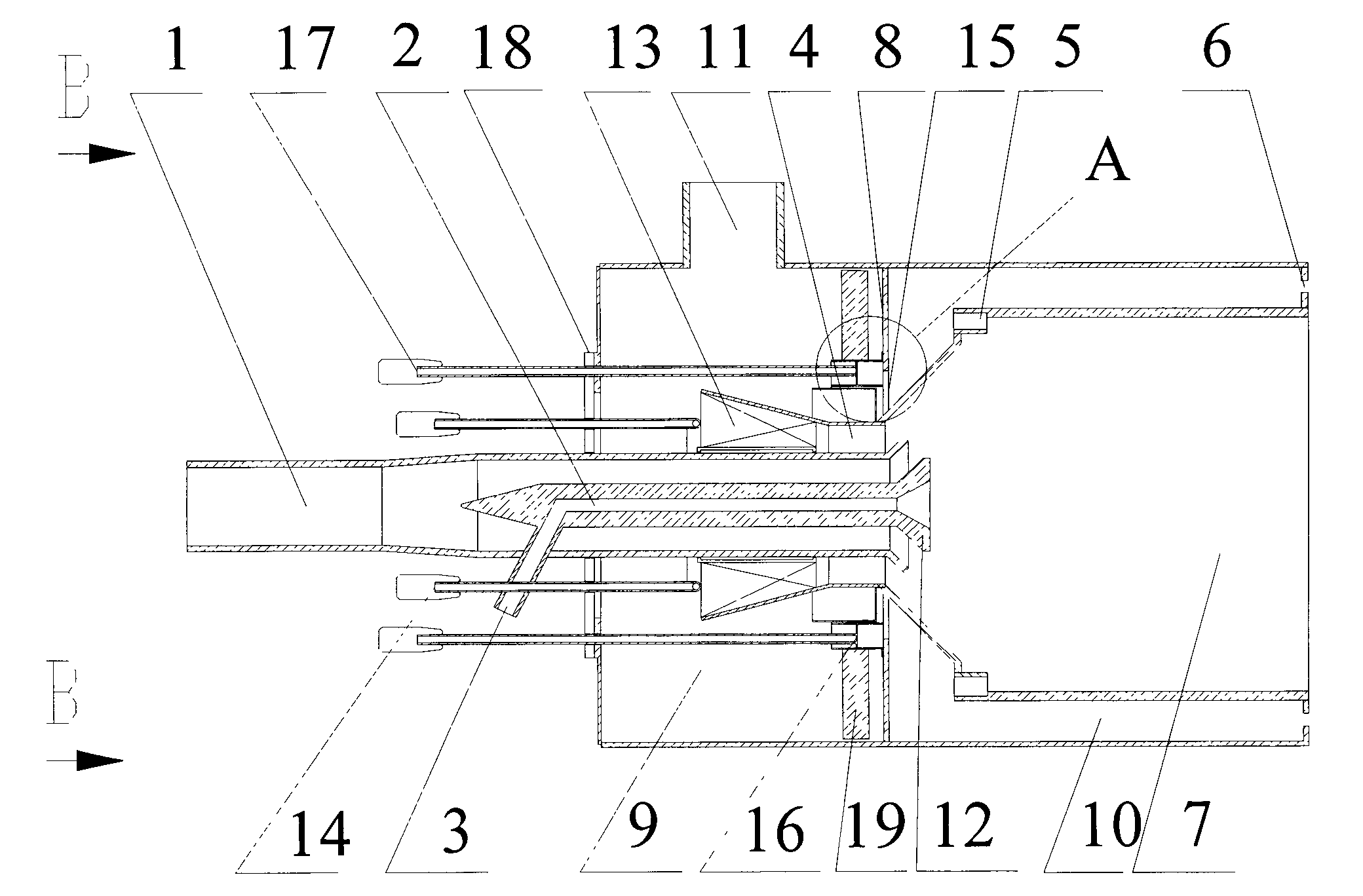

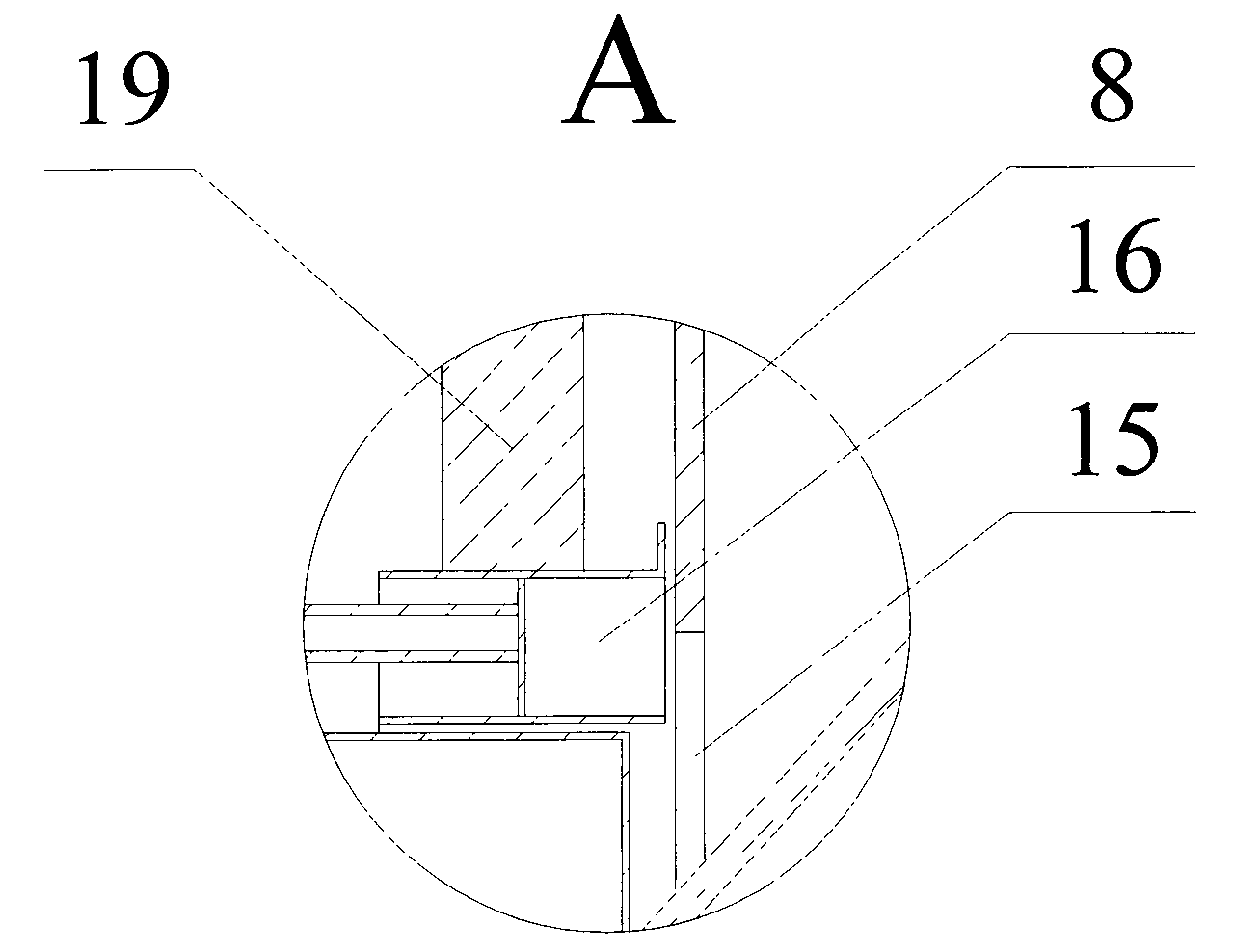

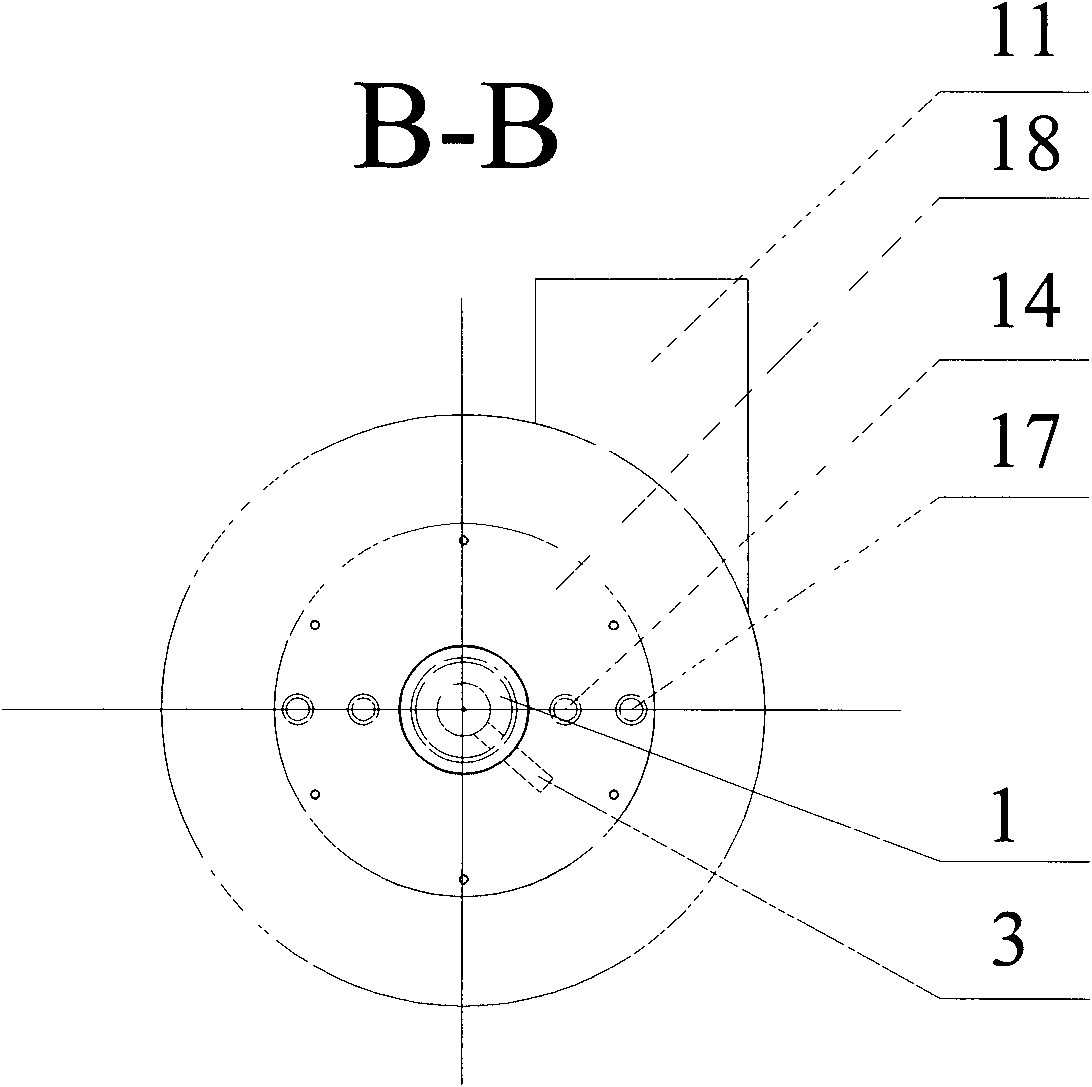

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

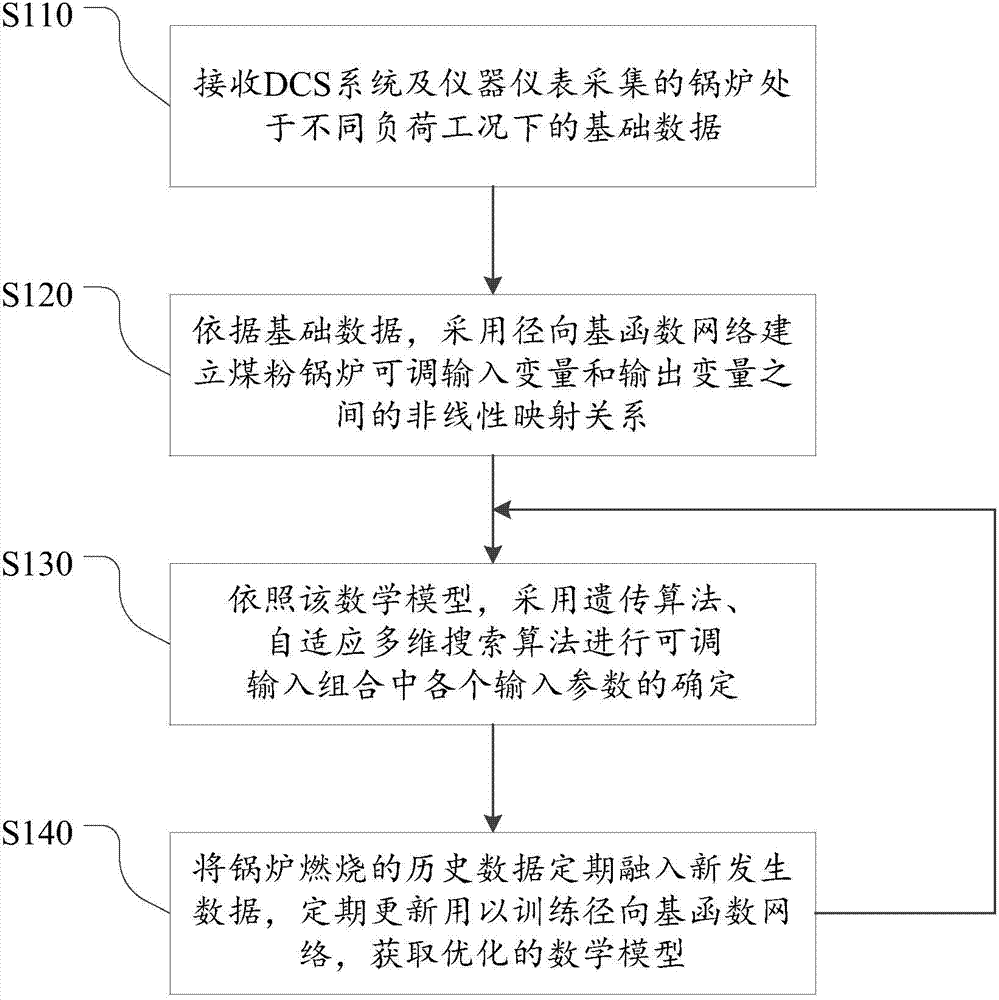

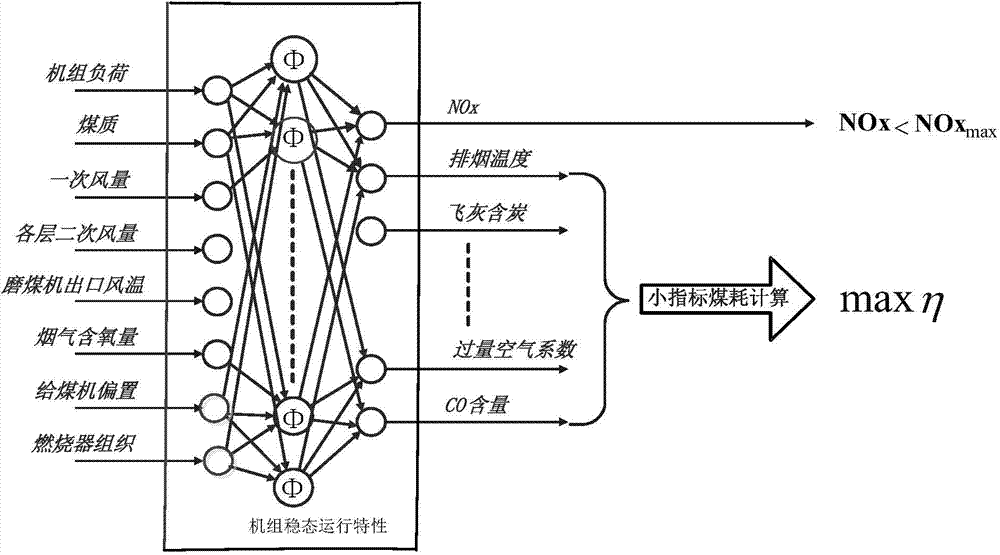

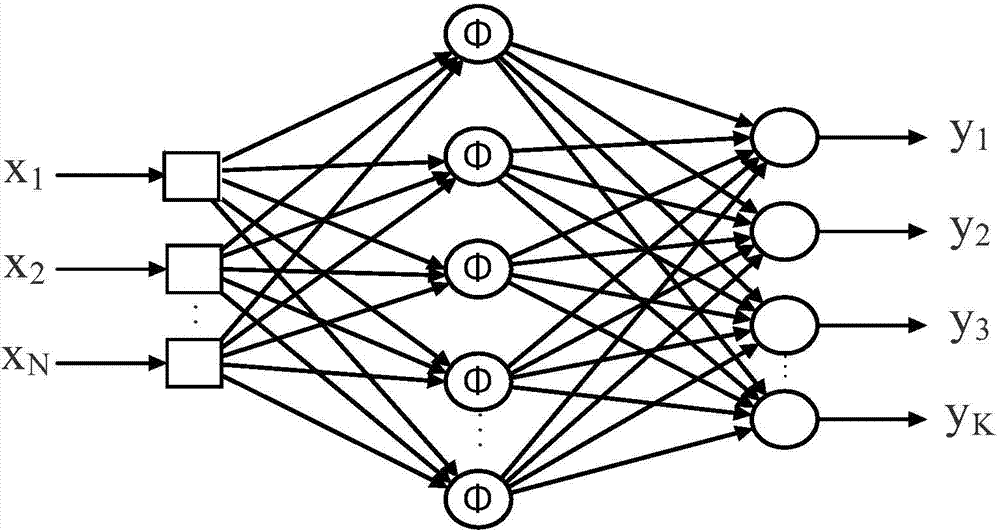

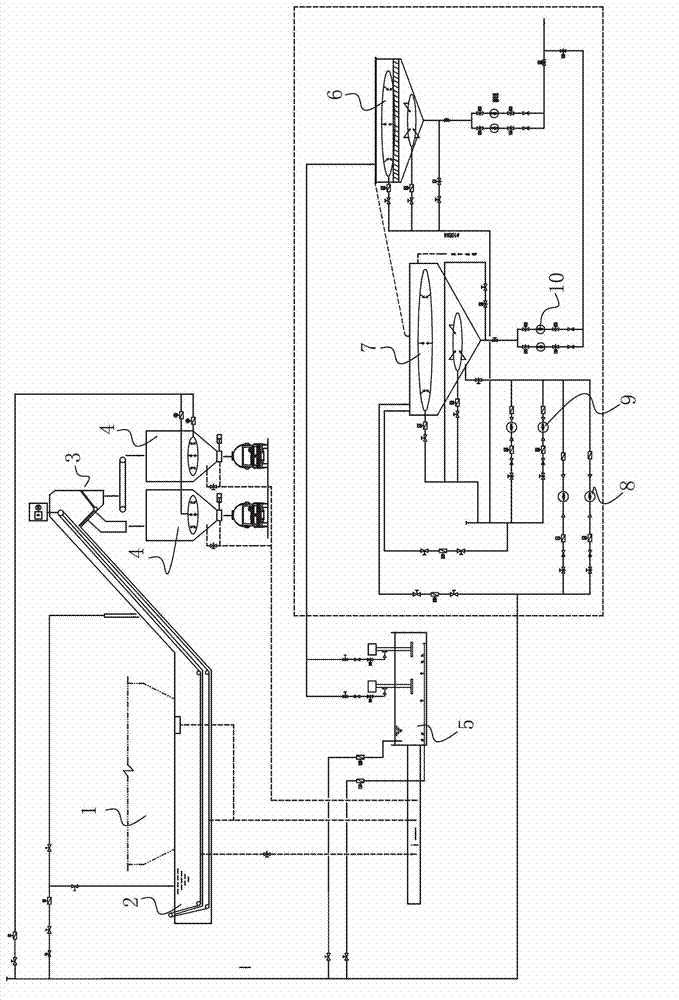

Power plant pulverized coal boiler combustion performance online optimizing method and system

InactiveCN104763999AImprove performanceSimplify complexityBoiler controlCombustion systemMathematical model

The invention provides a power plant pulverized coal boiler combustion performance online optimizing method and system. The method comprises the steps of receiving basic data of boilers in different load work conditions, which are acquired by a Distributed Control System (DCS) and an instrument, wherein the basic data is used for establishing non-linear mapping relationship between pulverized coal boiler adjustable input variables and output variables through a radial basis function network, and the non-linear mapping relationship is used as a boiler combustion mathematic model; obtaining an optimal input combination and value of boiler combustion system adjustable variables under the corresponding expectation coal consumption and NOX emission level. By the aid of the method and the system, optimal control can be performed on boiler operation engineering, relationships among all operation parameters of the boiler are coordinated, the safety, the economy and the reliability of the system are further improved, and the boiler combustion system comprehensive performance is improved comprehensively.

Owner:INNER MONGOLIA RUITE TECH

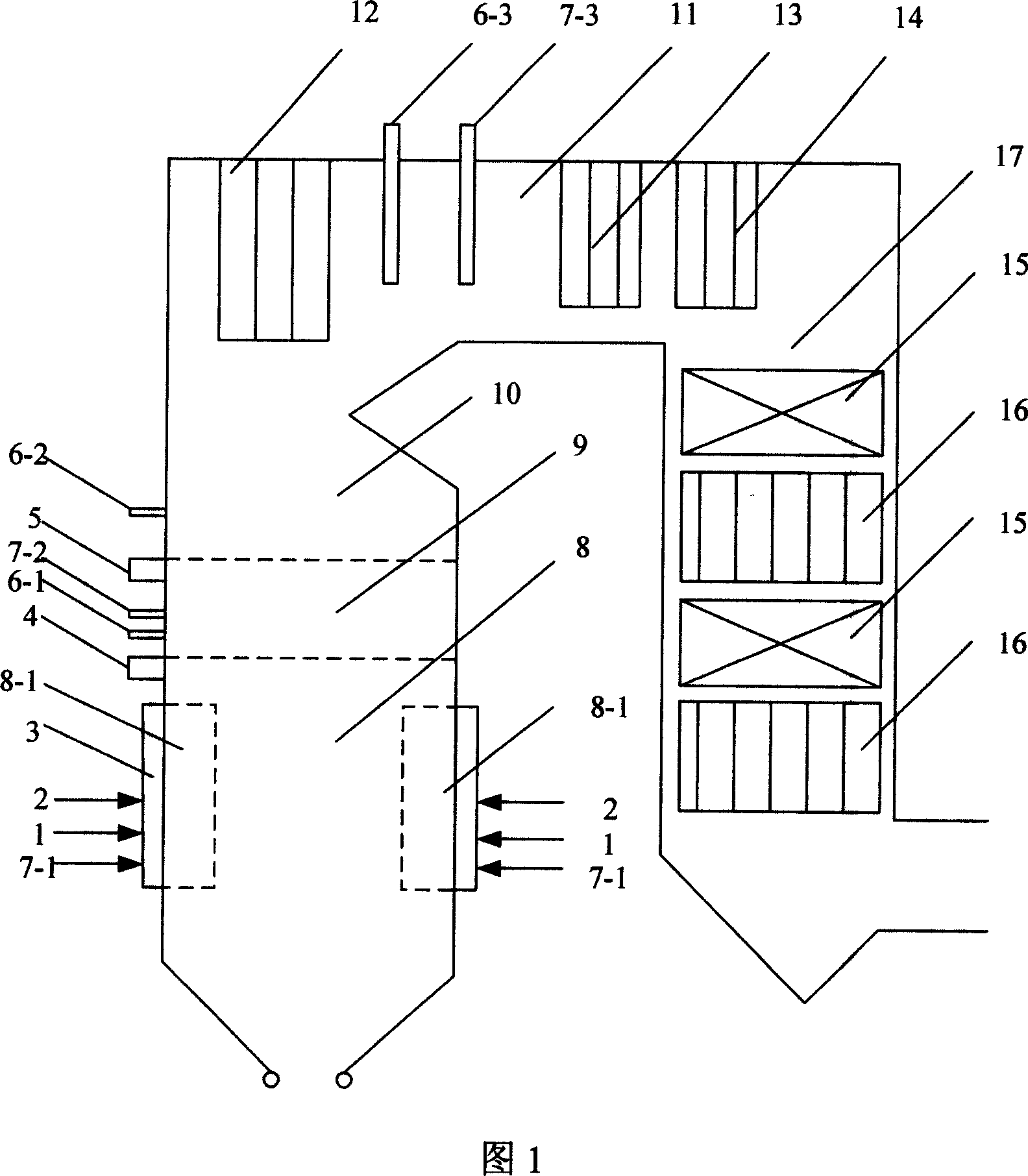

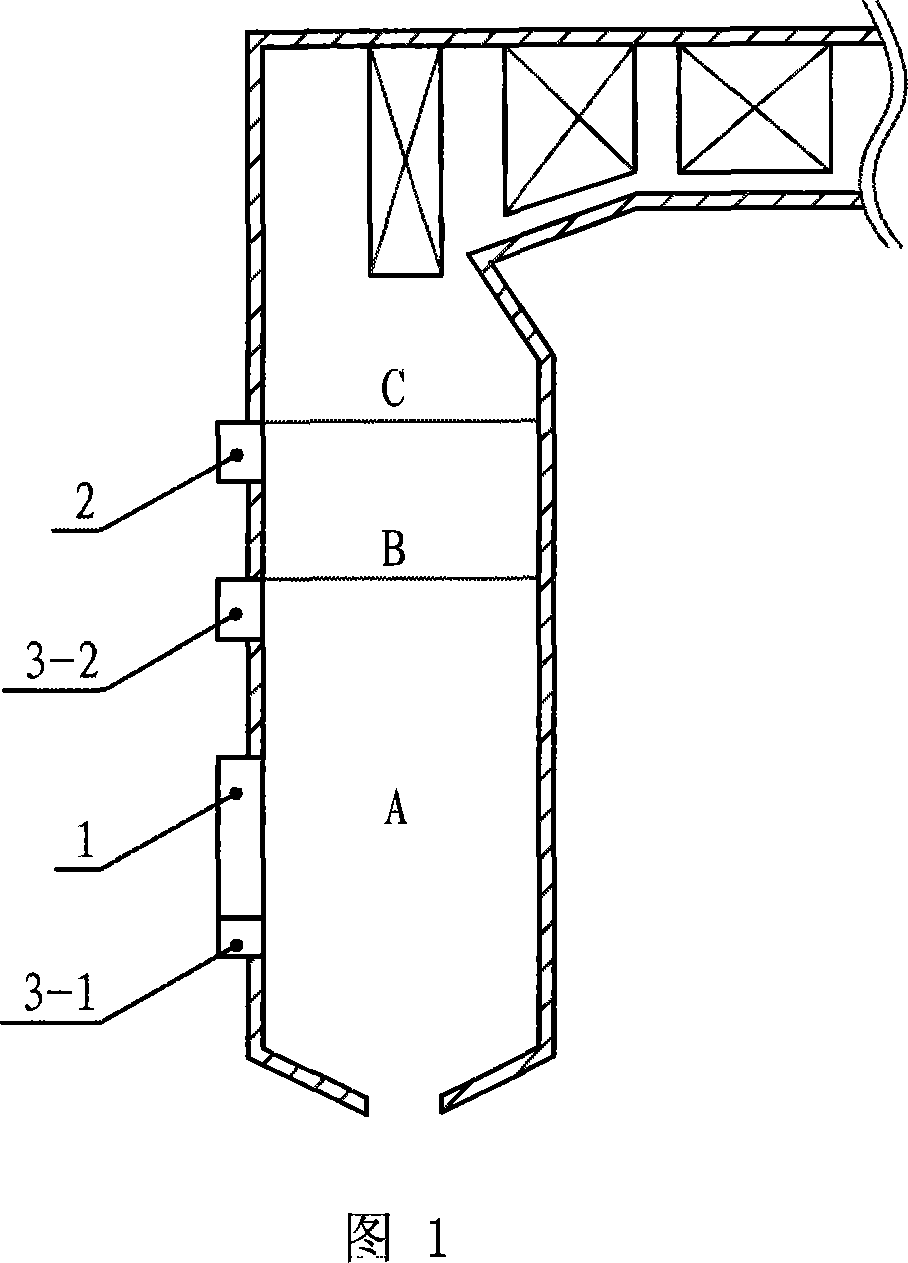

Method of decreasing release of nitrogen oxide in the pulverized-coal fired boiler and its used boiler

InactiveCN101021327AEmission reductionIncrease burn rateLighting and heating apparatusBoiler furnaceCombustor

The present invention relates to a method capable of reducing nitrogen oxide discharge for coal powder boiler and boiler using said method. Said invention is characterized by that said boiler is composed of boiler furnace cavity, horizontal flue and tail flue, and the furnace cavity interior is divided into main combustion zone, reduction zone and burning zone. The method for reducing discharge adopts the coal powder boiler with main combustion zone, reduction zone, burning zone, near combustor zone, horizontal flue and tail flue, makes the amino reducing agent be sprayed into reduction zone, burning zone and horizontal flue and make the hydrocarbyl reducing agent be sprayed into main combustion zone and reduction zone or main combustion zone, reduction zone and horizontal flue. Said method can effectively reduce NOx discharge by 60%-80%.

Owner:HARBIN INST OF TECH

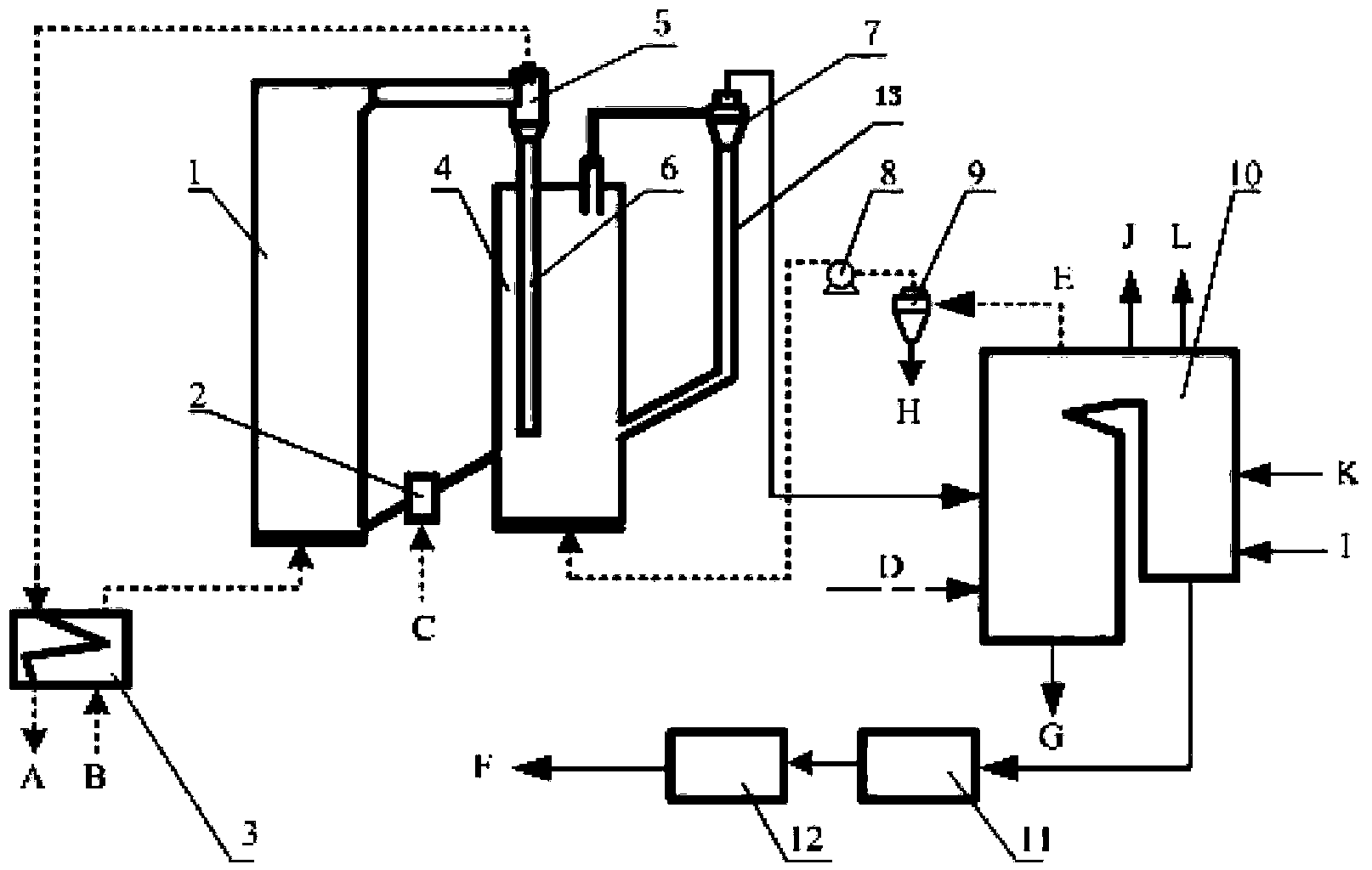

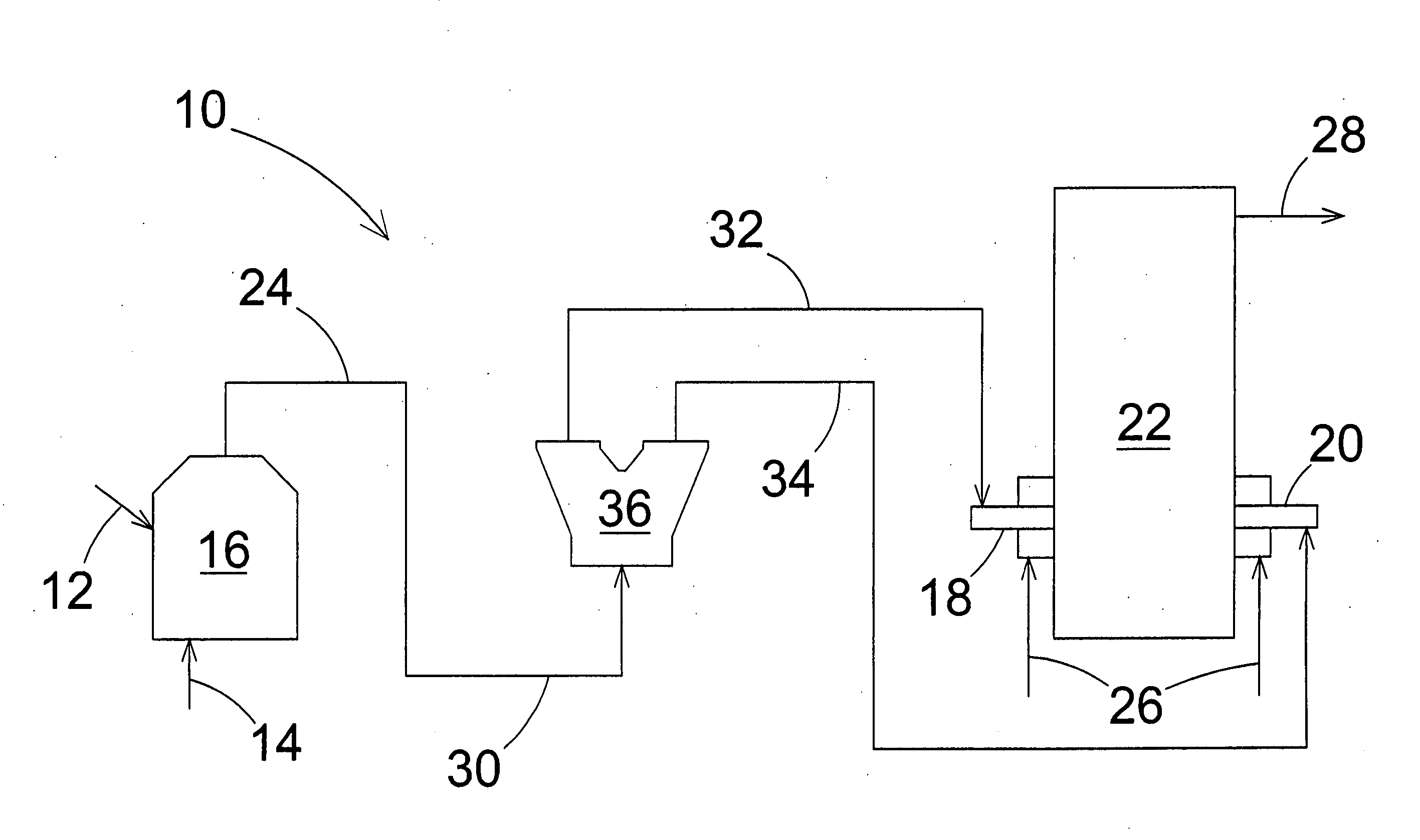

Oxygen-enriched combustion pulverized coal boiler integrating chemical-looping high-temperature air separation oxygen production and CO2 gathering method

InactiveCN104033890AReduce oxygen consumptionImprove power generation efficiencyCarbon compoundsEnergy inputAir preheaterCyclone

The invention discloses an oxygen-enriched combustion pulverized coal boiler integrating chemical-looping high-temperature air separation oxygen production. The pulverized coal boiler comprises an air preheater, an oxidation reactor, a first cyclone separator, an overflow box with a loose tuyere, a reduction reactor, a second cyclone separator, a high-temperature flue gas draft fan, a high-temperature dust catcher, a coal-fired boiler, a low-temperature dust catcher and a flue gas cooling compression and purification device. The invention also provides a CO2 gathering method using the boiler. According to the invention, the oxygen-enriched combustion pulverized coal boiler is integrated with chemical-looping high-temperature air separation oxygen production, and can effectively reduce the oxygen production power consumption of oxygen-enriched combustion, improve the power generation efficiency of an oxygen-enriched combustion set and realizes gathering of CO2 as compared with an existing boiler.

Owner:SOUTHEAST UNIV

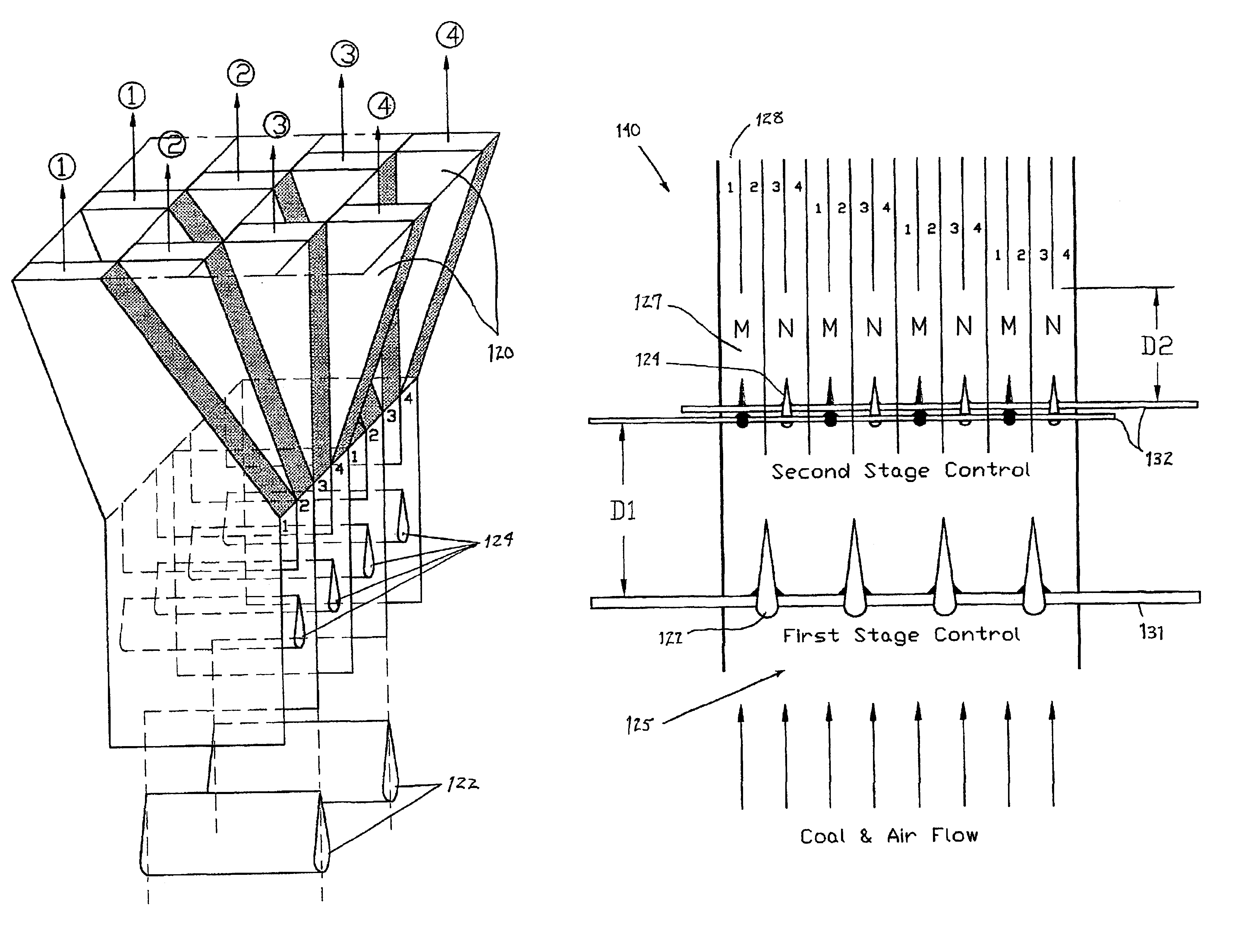

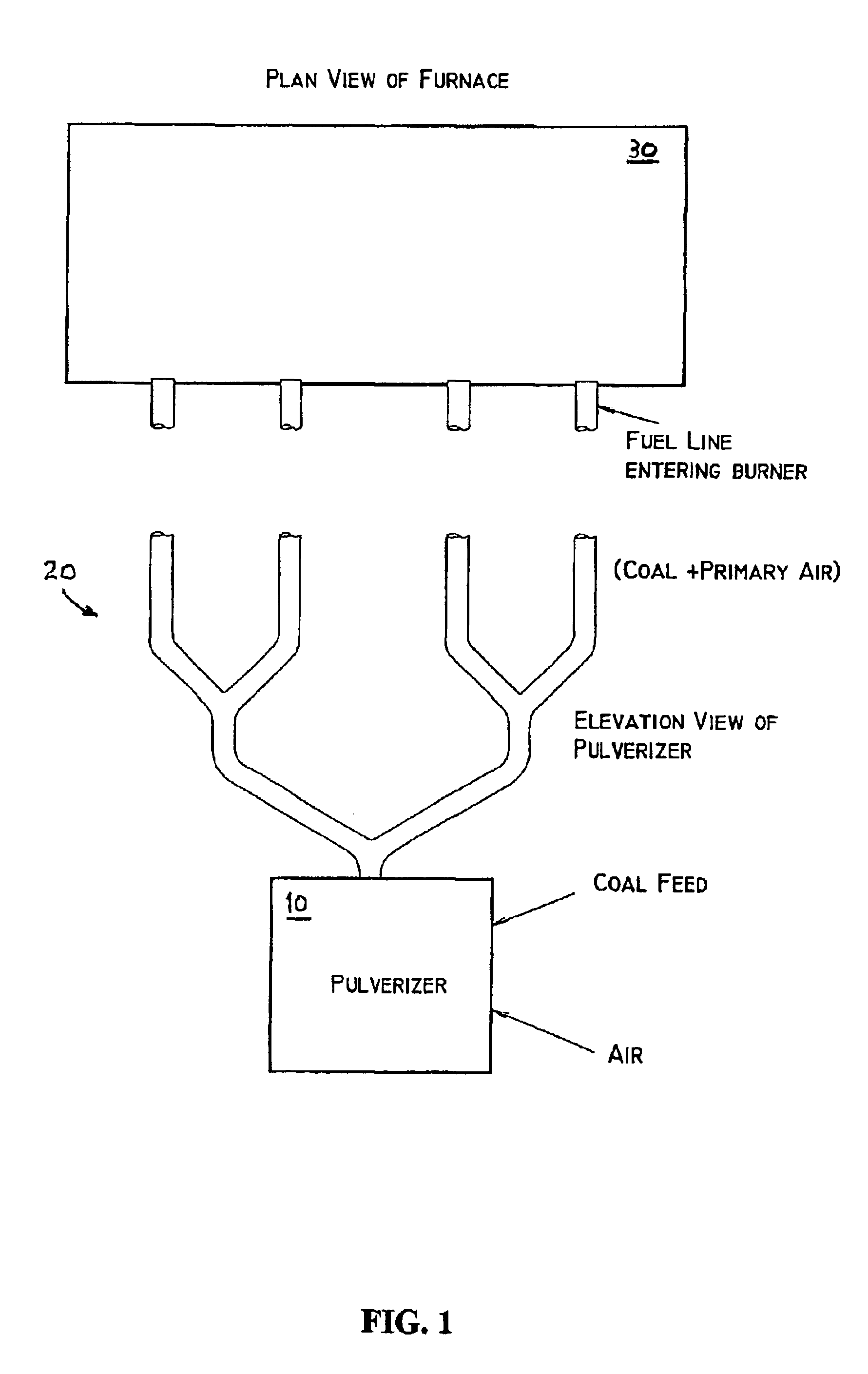

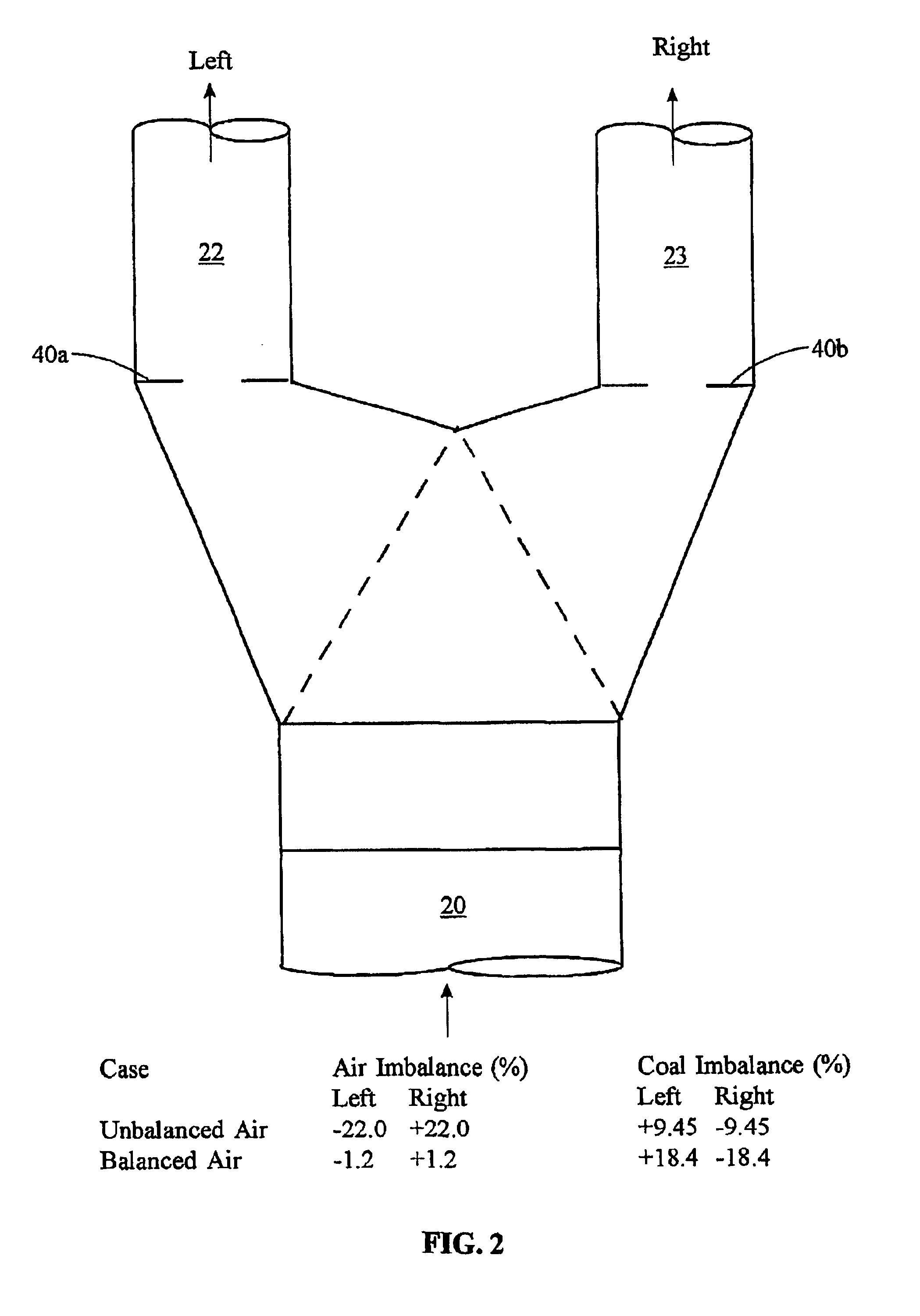

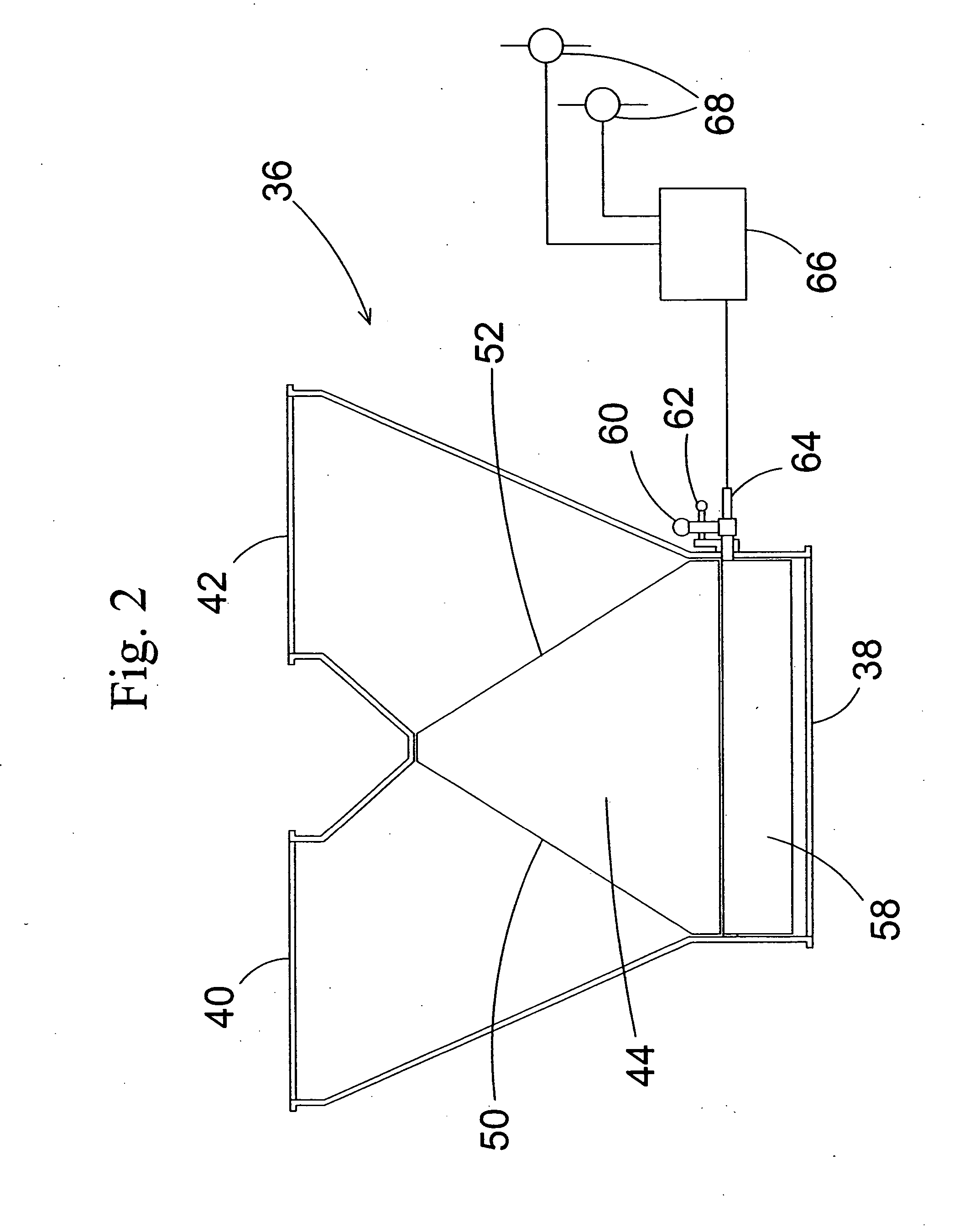

Adjustable flow control elements for balancing pulverized coal flow at coal pipe splitter junctions

InactiveUS6789488B2Lower Level RequirementsImprove combustion efficiencyFuel feeding arrangementsPulverulent fuel combustion burnersCombined usePollutant emissions

An adjustable device installed at the inlet of conventional junctions / splitters (116) for on-line control of the distribution of coal among the outlet pipes is herein disclosed. The device includes a plurality of flow control elements (60) each positioned upstream of a plurality of flow channels in the riffler (50) for directing coal flow to the outlet pipes. Each flow control element preferably comprises a rounded convex edge leading to straight tapered sides (FIG. 9). The surfaces of the sides may be roughened or textured (63) for promoting turbulent boundary layers (FIG. 9). In addition, conventional fixed or variable orifices may be used in combination with the flow control elements for balancing primary air flow rates. The device allows fine-adjustment control of coal flow rates when used in combination with the slotted riffler, yet it has negligible effect on the distribution of primary air. The combination of the riffler assembly and the coal flow control elements (60) results in closely balanced coal flow. Balanced coal flow is imperative to the optimization of the operation of pulverized coal boiler systems (i.e. reduced pollutant emissions, improved combustion efficiency).

Owner:LEVY EDWARD KENNETH +2

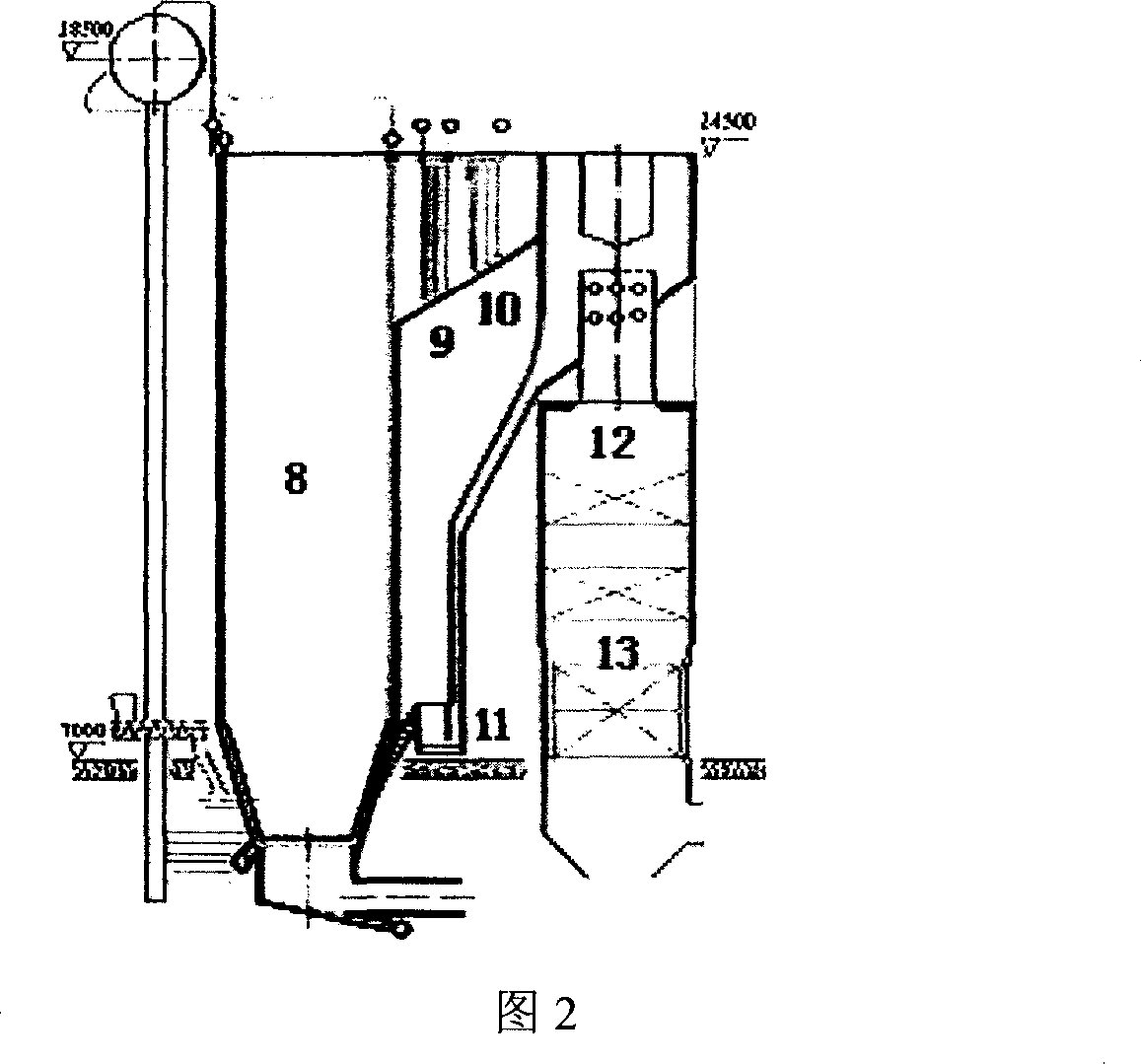

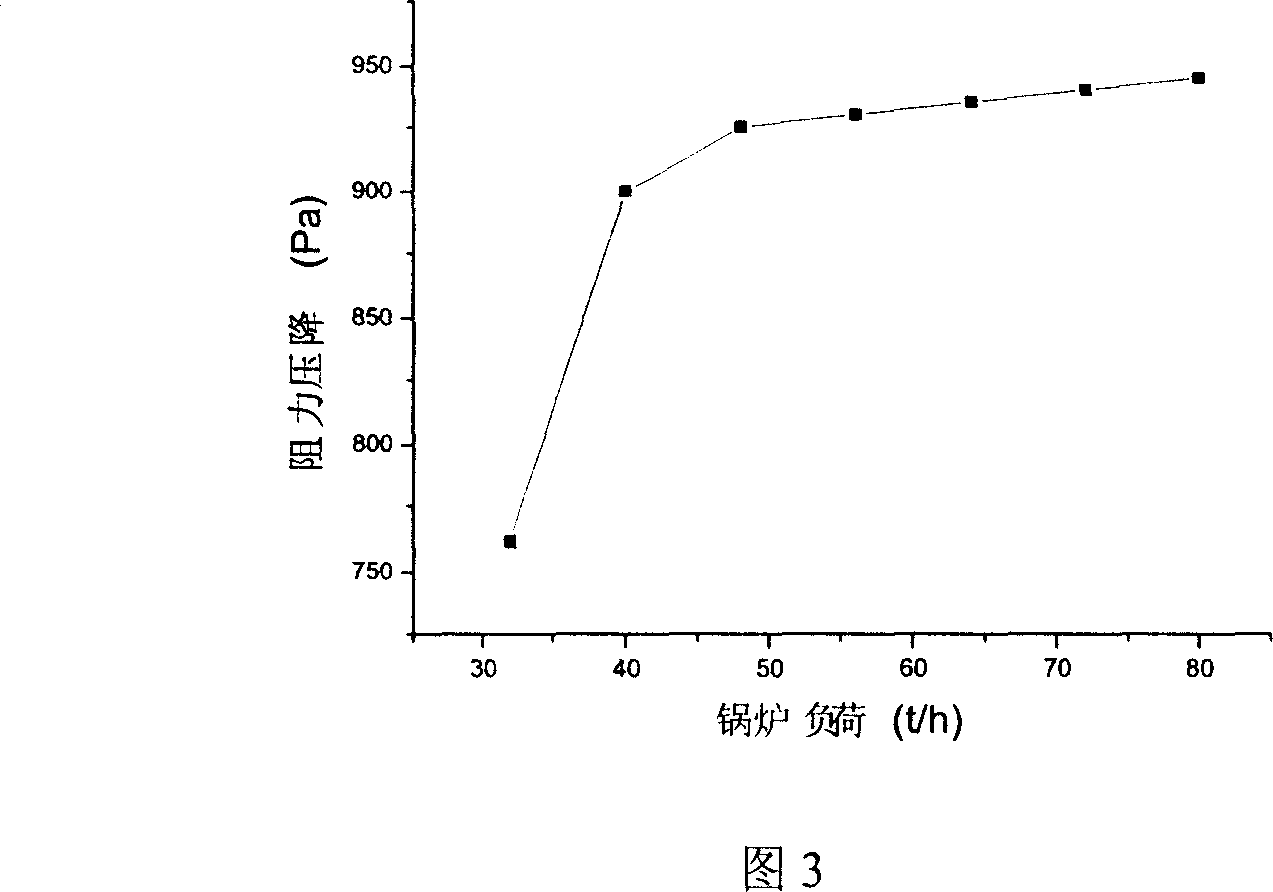

Air-water combined cooling dry slagging method and system of pulverized coal boiler

ActiveCN102954478AReduce incomplete combustion lossesImprove efficiencyLighting and heating apparatusAir volumePower station

The invention relates to an air-water combined cooling dry slagging method and a system of a pulverized coal boiler. The method comprises the following steps of primarily adopting an air-cooling steel-strip (chain plate) slag cooling machine to pre-cool and withdraw the slag of the boiler; adopting a roller-type slag cooler to further cool the slag after precooling; and finally directly transporting or conveying the slag after being cooled through the roller-type slag cooler to a slag cabin. The slag from the boiler is conveyed to a transitional slag bucket through the air-cooling steel-strip slag cooling machine, then the slag enters the roller-type slag cooler, and finally the hot air being heated by the slag enters a boiler hearth to be burned. The cooling water of the rotary-type slag cooler is from a condensed water (or other cooling medium) system in a power plant, and the cooling water is returned to a heat power system of the power plant after being heated by the slag. Due to the adoption of the method and the system, the problems that the air volume of a dry slagging system is difficult to control and side effect is produced on the burning of the boiler can be solved, the waste heat of the slag can be recycled, the unit efficiency can be improved, and the power generation coal consumption can be reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

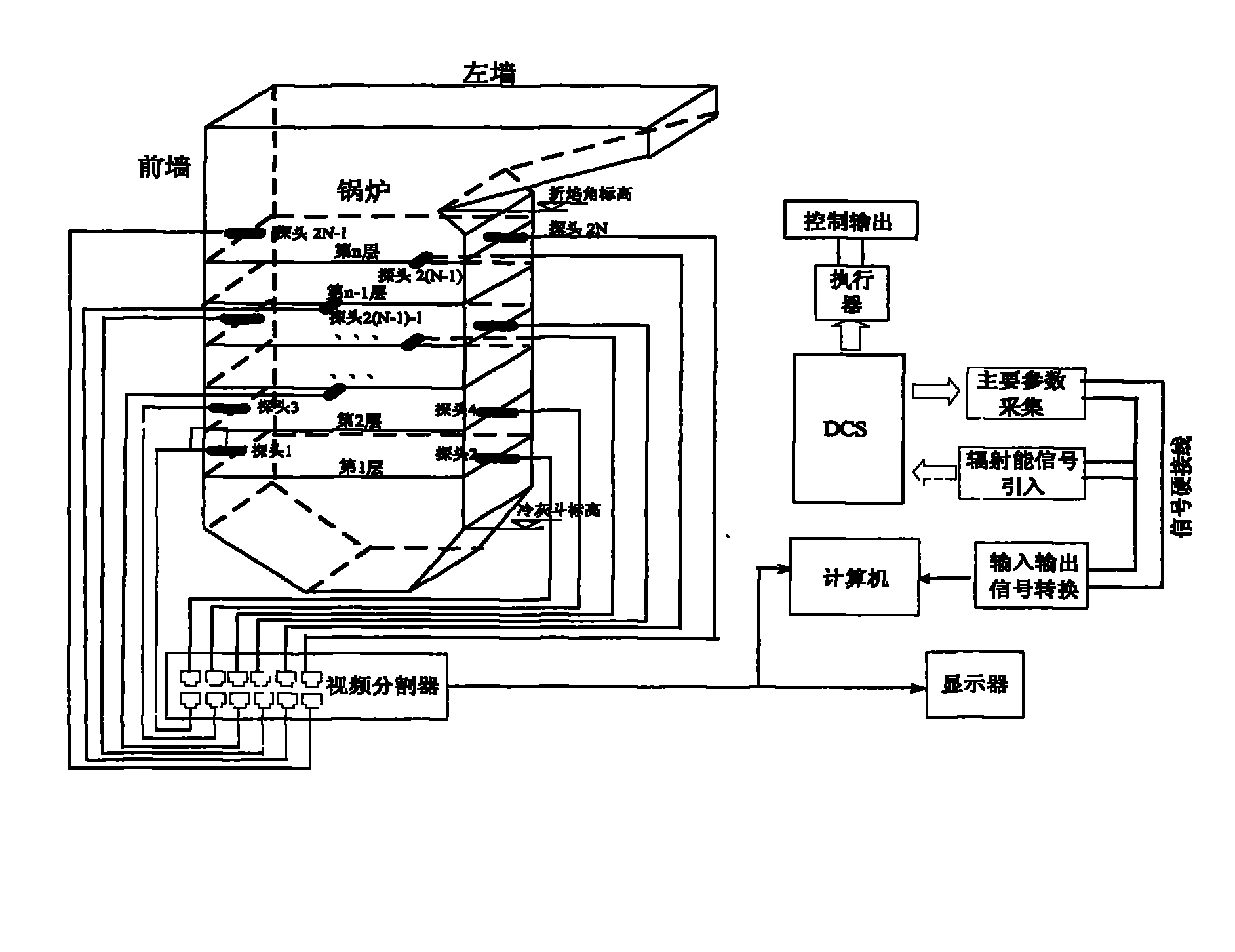

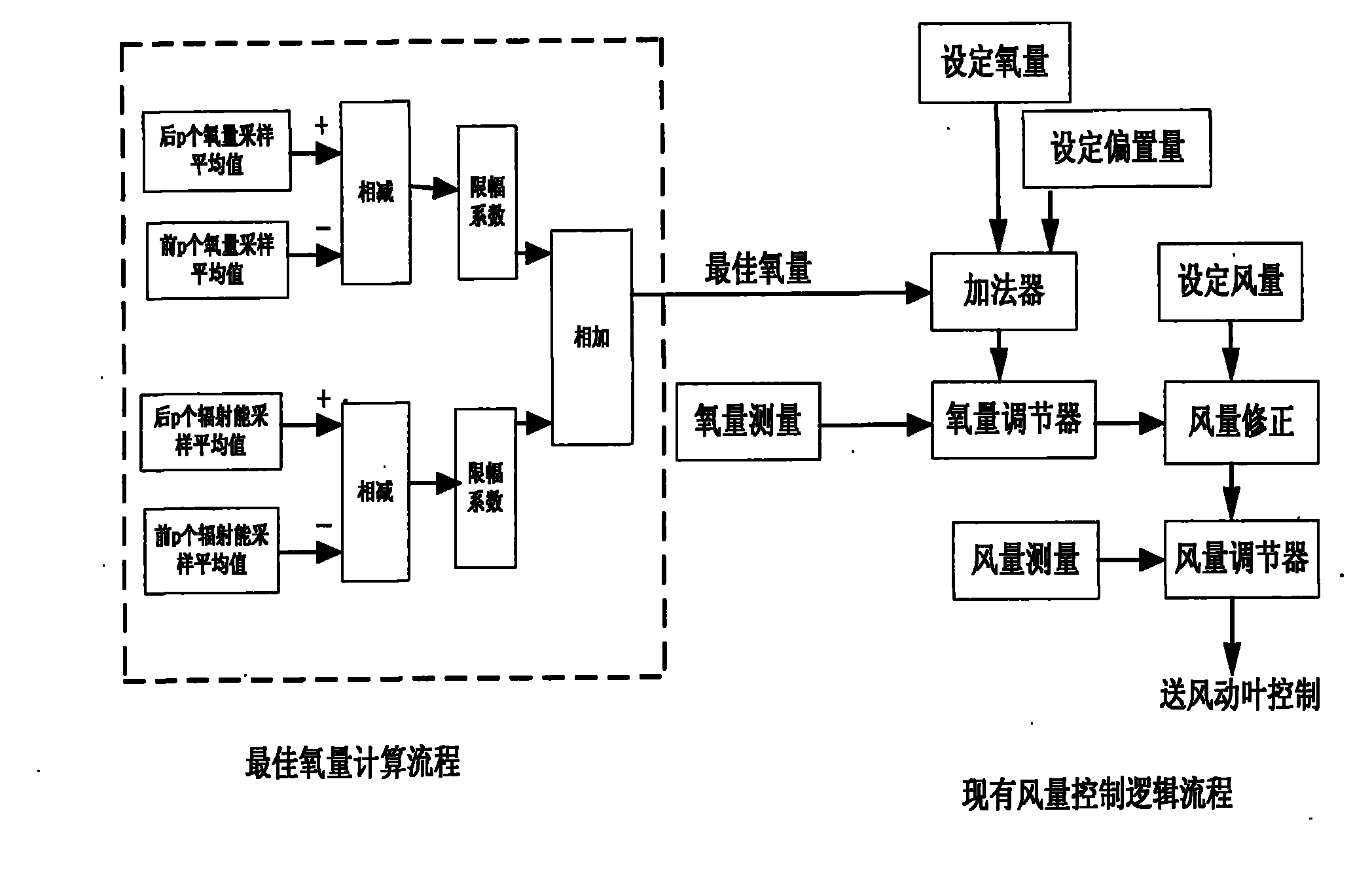

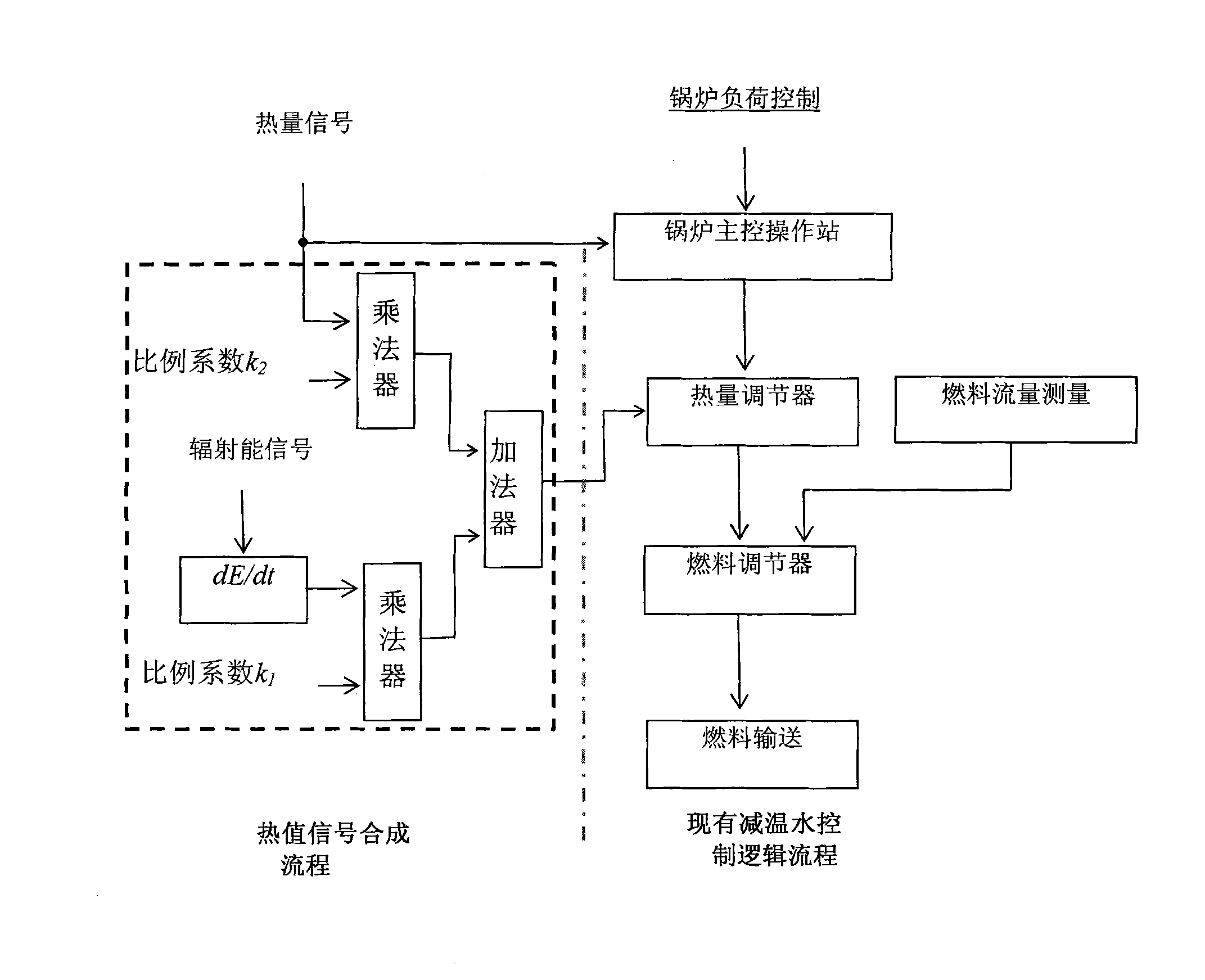

Method for detecting hearth radiation energy signal and method for controlling boiler combustion by using same

InactiveCN101788343ARealize combustion monitoringImprove temperature control qualitySuperheating controlRadiation pyrometryUnit operationSuperheater

The invention provides a method for detecting a hearth radiation energy signal and a method for controlling boiler combustion by using the same, and belongs to the field of combustion monitoring and controlling. The method for detecting the hearth radiation energy signal comprises steps of analog-to-digital conversion, color value extraction and hearth radiation energy signal calculation. In the method for controlling air quantity of hearth combustion, the optimum oxygen quantity calculated by using the hearth radiation energy signal, set oxygen quantity and set offset are added, and the sum is sent to an oxygen quantity regulator to control the air quantity of the hearth combustion. The method for controlling superheater attemperating water comprises the steps of combining the hearth radiation energy signal with a heat signal to form a heat value signal; and introducing the heat value signal to a heat regulator to control the superheater attemperating water. The radiation energy signal detected by the method has the advantages of stability, reliability, capability of accurately reflecting the combustion situation in the hearth space in real time, and strong correlation with unit operation parameters; and when the new heat value signal constructed by the radiation energy signal is introduced to air supply and attemperating water control loops of the unit, the control effect of the unit can be optimized, and the efficiency of the unit can be improved. Therefore, the method for controlling the boiler combustion is suitable for combustion optimization control of a pulverized coal fired boiler of a thermal power generating unit.

Owner:HUAZHONG UNIV OF SCI & TECH

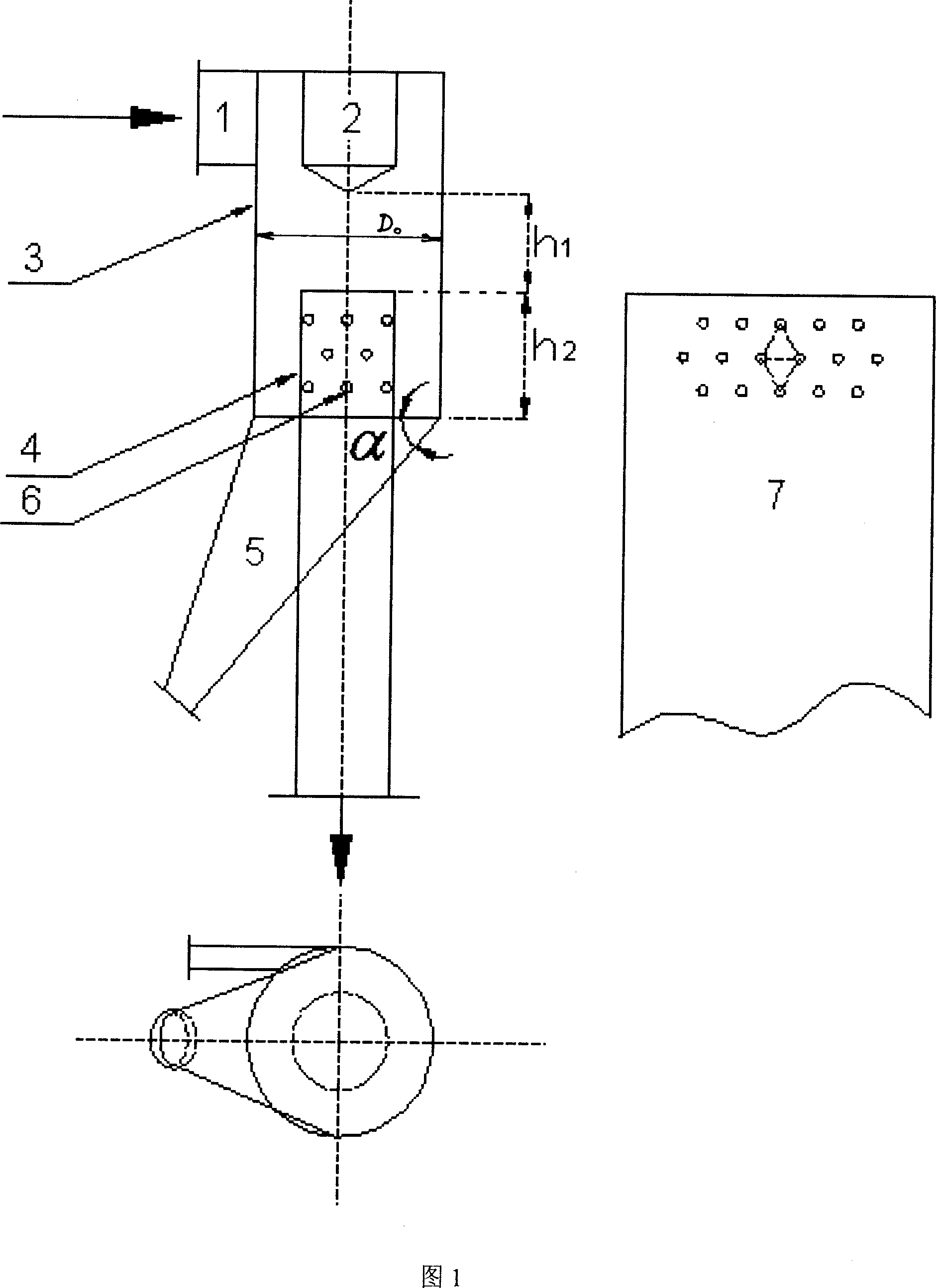

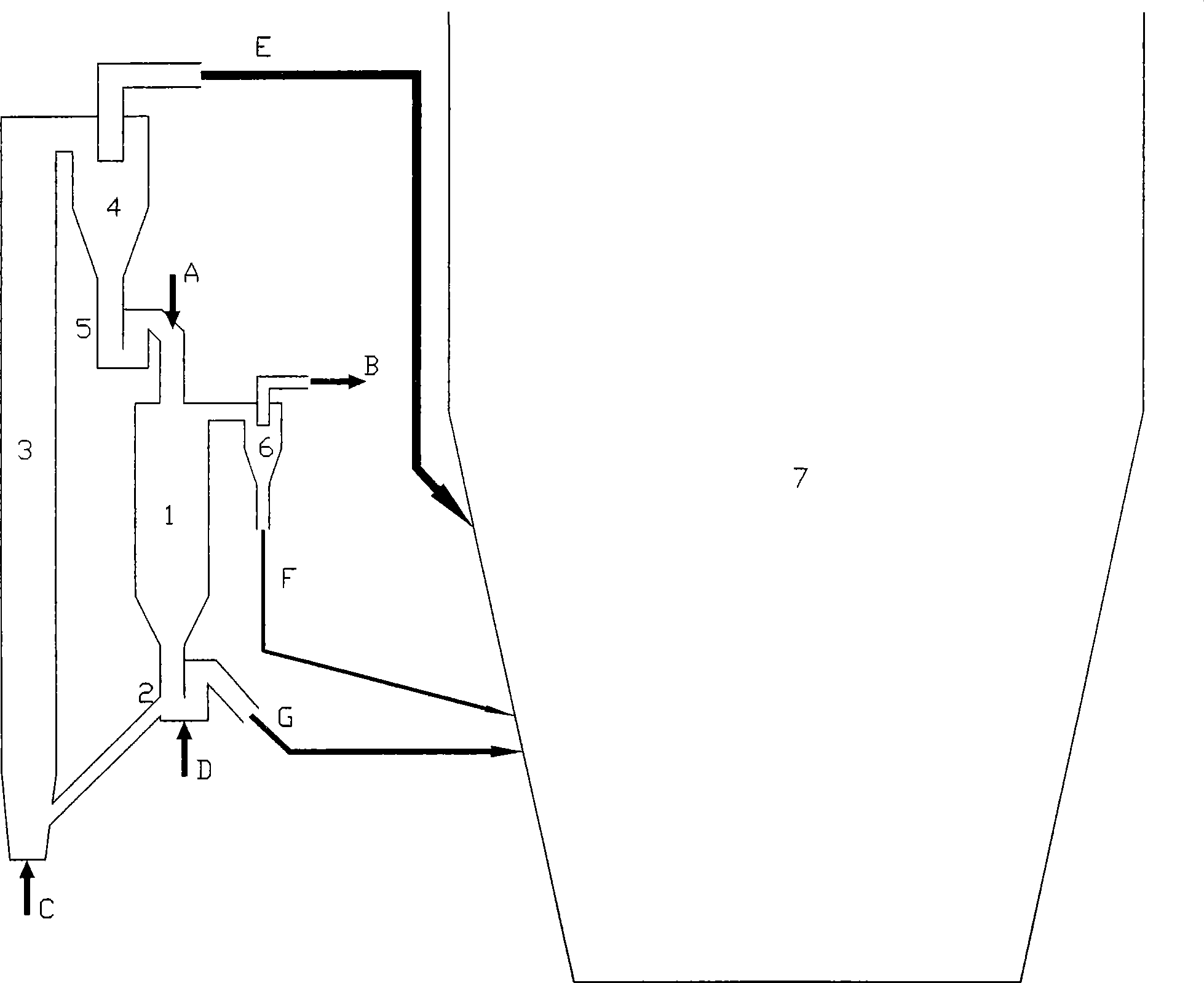

Gas lower exhaustion type whirlwind air-solid separator

InactiveCN1927469AReduced external dimensionsReasonable structureReversed direction vortexLighting and heating apparatusEngineeringWhirlwind

The invention relates to a down-discharge cyclone gas-solid separator, which comprises inlet tube (1), divert rod (2), cylinder (3), discharge tube (4) and incline ash hopper (5). Wherein, said discharge tube is inserted into the cylinder for D0 length, while the inserted section has small hole (6) that distributed in triangle and at 5-10mm diameter; the area sum of all small holes are equal to the inlet area of discharge tube; the inner diameter of cylinder is D0, while the width of inlet is 0.22D0-0.35D0 and the height is 0.44D0-0.75D0; the diameters of divert rod and the discharge tube both are 0.5D0, while the distance between their tops is 0.5-1D0; the incline angle of incline ash hopper is 50-75degree; therefore, the flow file of diverter is more reasonable, to reduce the secondary transmission of fly ash, improve the separating efficiency and reduce the resistance. The invention can be used to separate the fly ash in the tail smoke of boiler, etc.

Owner:HUAZHONG NORMAL UNIV

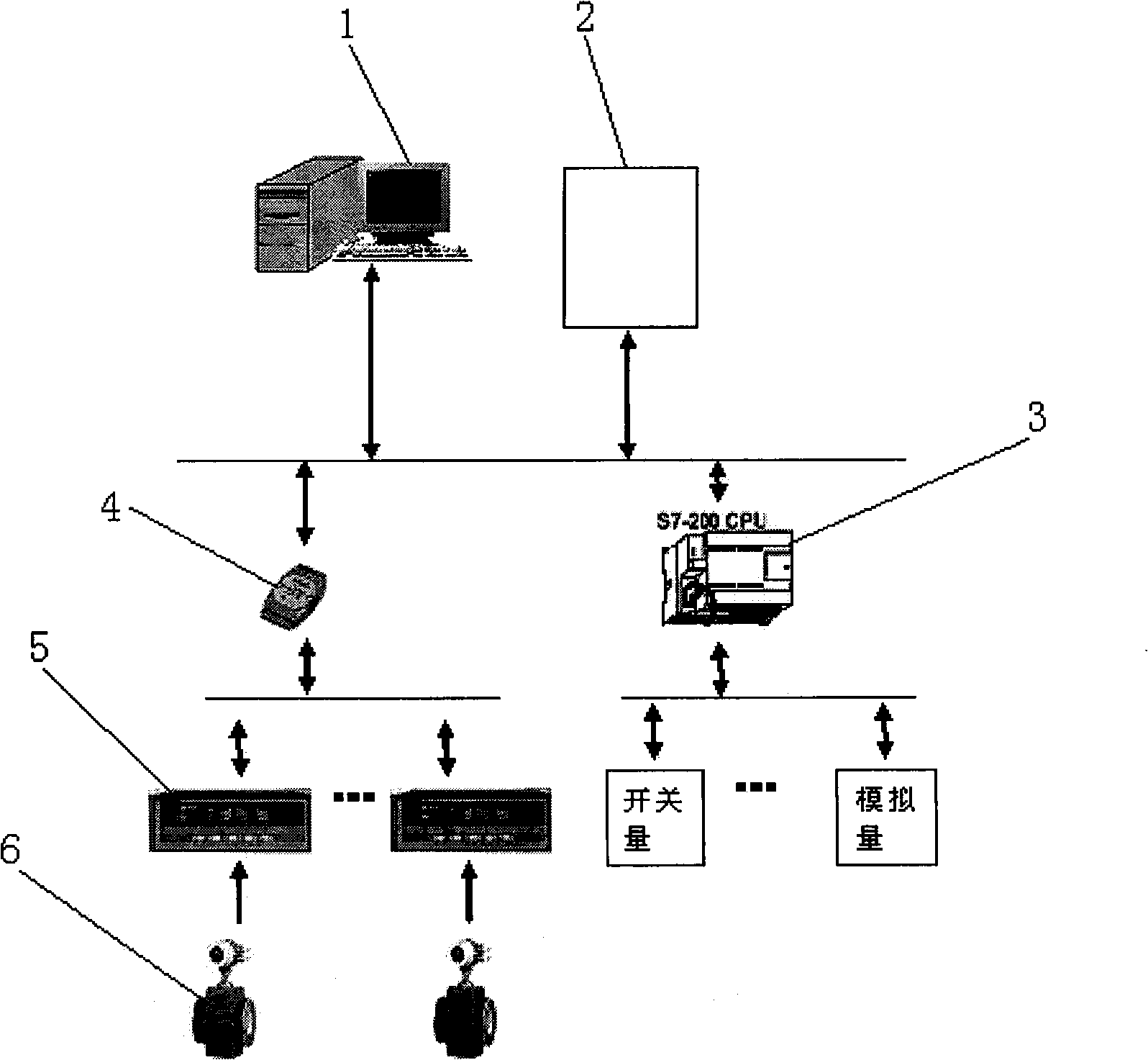

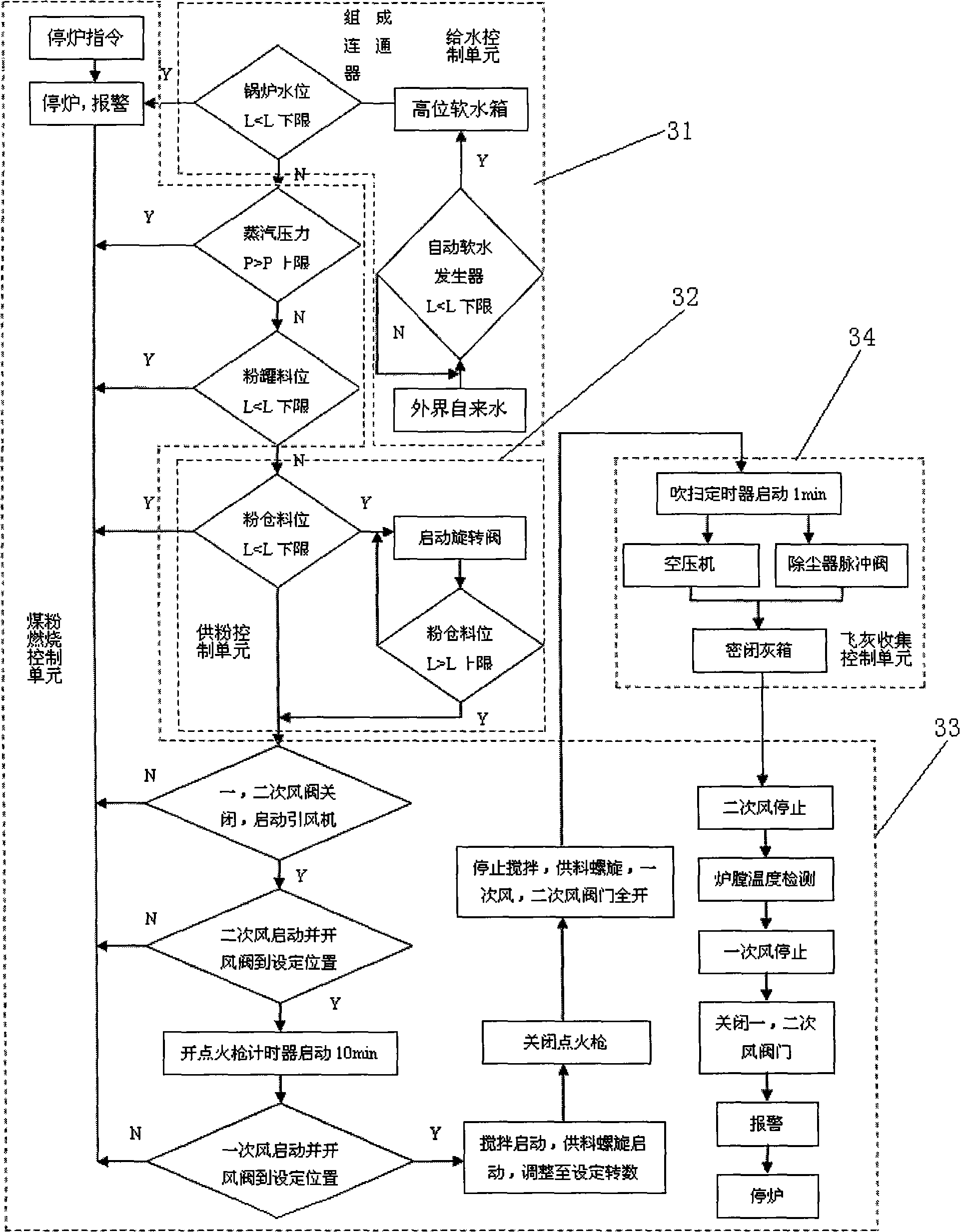

Automatic control system for industrial coal powder boiler

ActiveCN101576247AGuaranteed uptimeWith self-diagnosis functionBoiler controlWater feed controlAuto regulationAutomatic train control

The invention relates to an automatic control system for an industrial coal powder boiler, which is characterized by comprising an industrial computer, a control cabinet, a core controller, an RS signal converter, an intelligent display instrument and a plurality of sensors; the output terminals of the sensors are connected with the input terminal of the intelligent display instrument, the output terminal of the intelligent display instrument is connected with the input terminal of the RS signal converter, and the output terminal of the RS signal converter is connected with the industrial computer and the control cabinet; the core controller is directly connected with the industrial computer and the control cabinet; and the core controller comprises a water supply controlling unit, a powder supply controlling unit, a pulverized-coal combustion controlling unit and a fly ash collection controlling unit. The invention not only can finish the acquisition of the related technical parameters of the boiler, ensure the normal running of the boiler, and achieve the optimum burning effect, but also can realize the automatic regulation and control of water supply, powder supply, starting and stopping and dust removal and ensure the normal running of the boiler under the condition without being monitored by a person.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

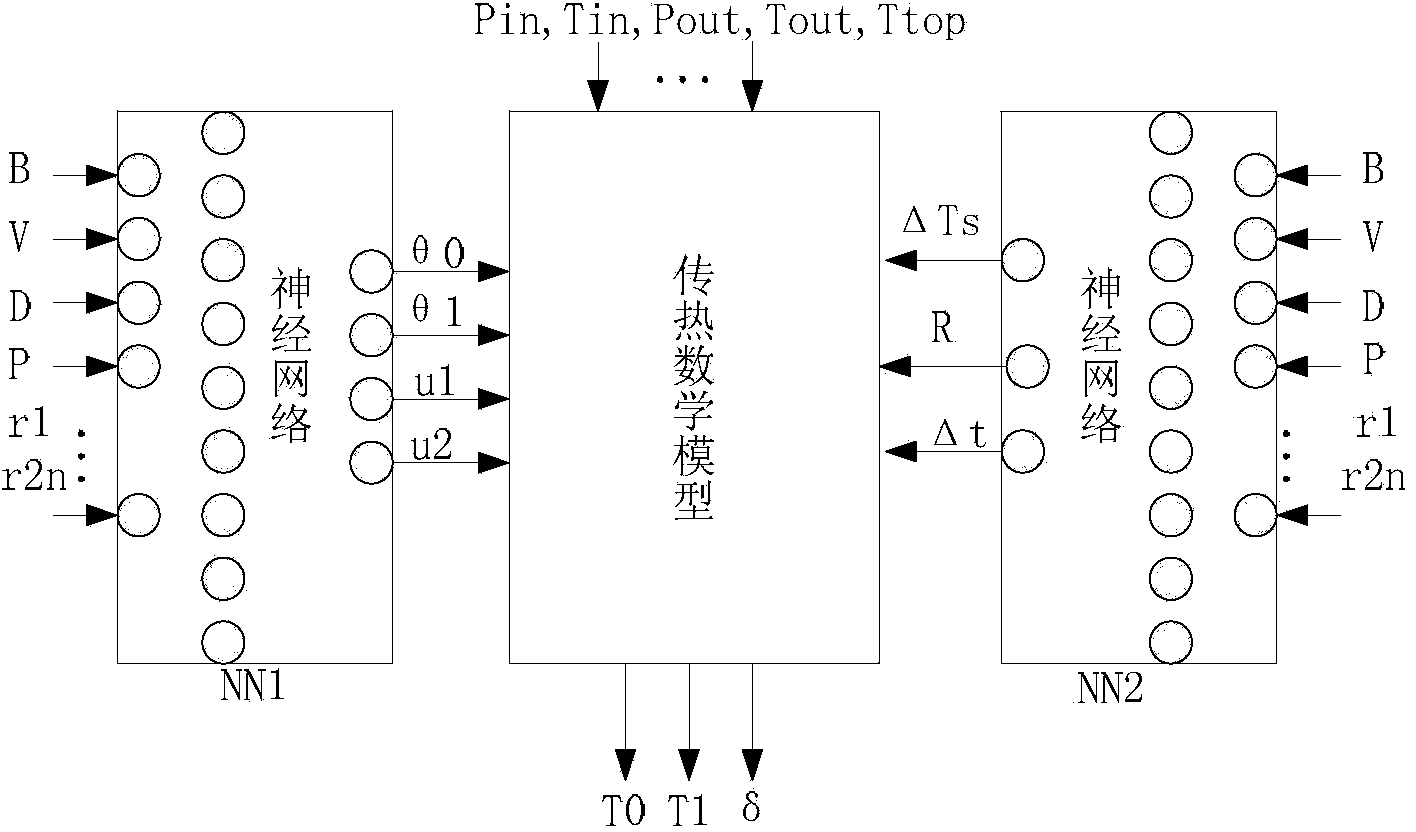

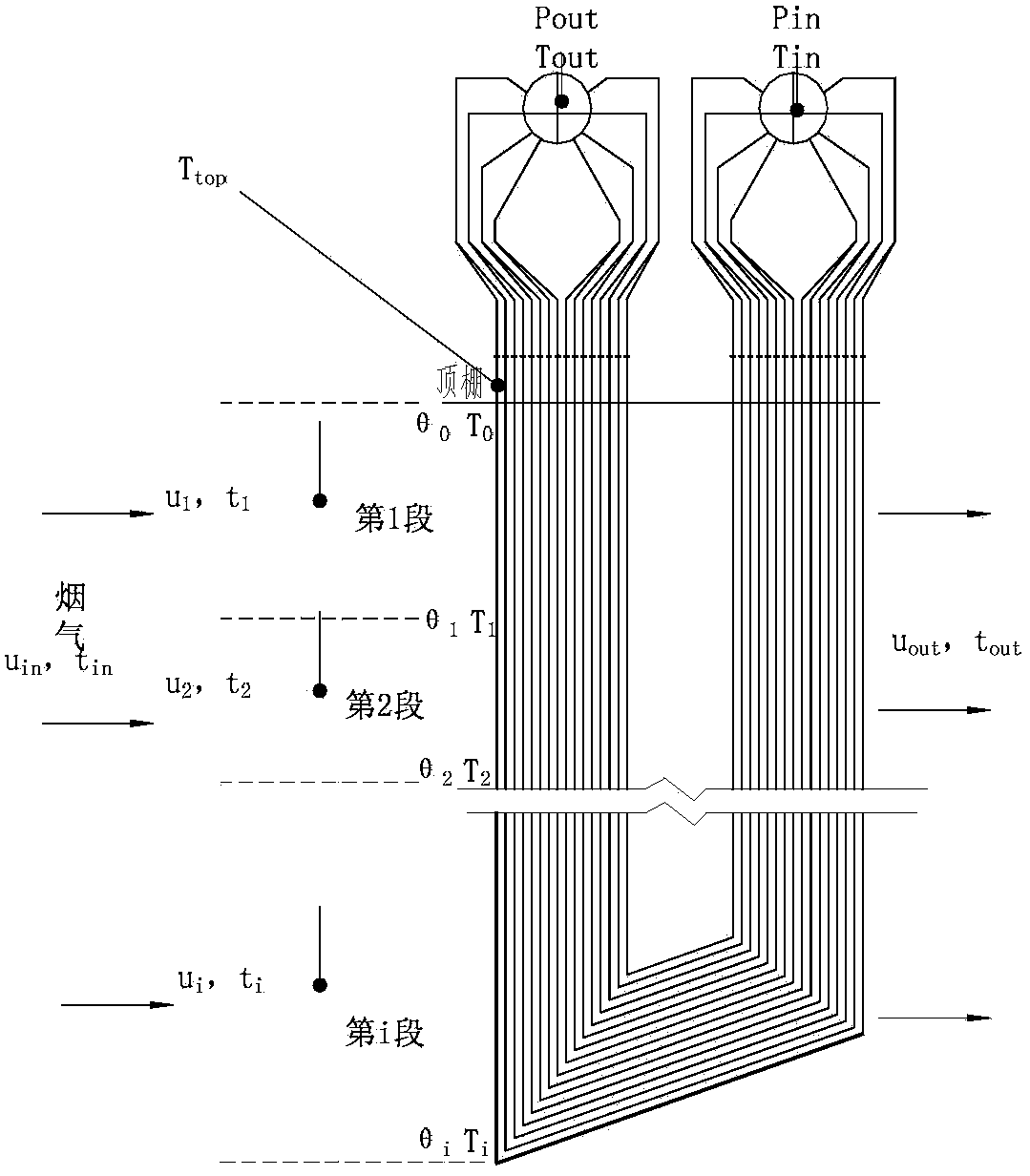

Method for monitoring wall temperature of heating surface and thickness of scale cinder of boiler superheater or reheater

The invention discloses a method for quantitatively and online monitoring the metal wall temperature of a heating surface and the thickness of a scale cinder (scale layer) of a boiler superheater or a reheater. The method includes the steps that according to operating parameters of a boiler, flue-gas temperature and speed of partition sections in the front of a pipe are predicted and monitored through a neutral network, and based on the flue-gas temperature and the speed, the distribution of the wall temperature of the heating surface and the thickness of the scale cinder (scale layer) of the superheater or the reheater are acquired according to a heat transfer mathematical model of the heating surface. The method has the advantages that the method is simple, rapid and capable of being continuously conducted, regular automatic learning can be achieved, the method can be used for quantitatively monitoring the wall temperature of the heating surface and the thickness of the scale cinder in the actual operating process of the pulverized coal boiler, and a quantitative basis is provided for preventing pipe explosion through optimizing, adjusting and controlling thermal deviation and for managing the service life of the heating surface of the boiler.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

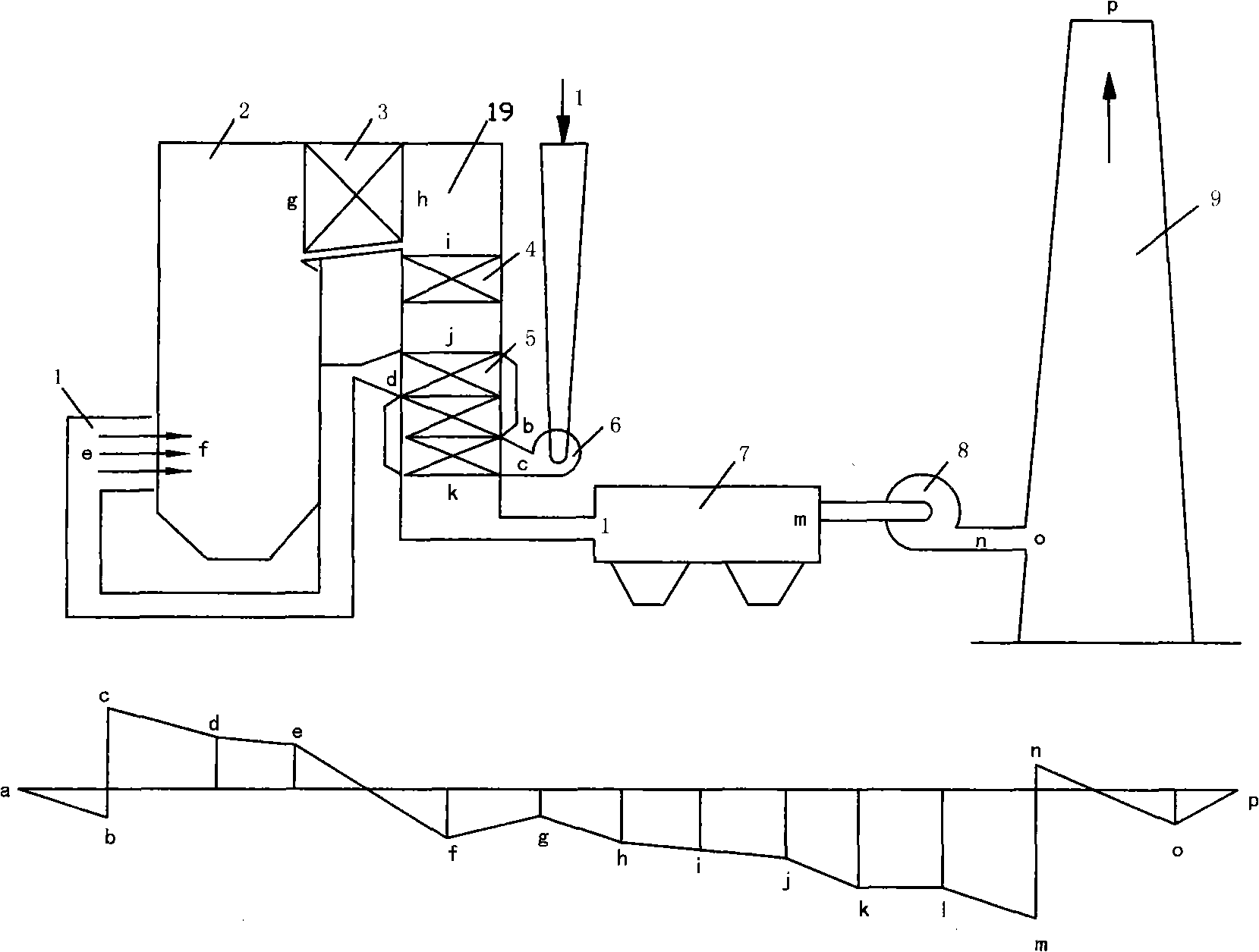

Treatment process of in-depth dehydration and resource utilization for sludge

ActiveCN102730916ASimple processLess investmentCombination devicesSludge treatment by de-watering/drying/thickeningResource utilizationSludge

The invention provides a treatment process of in-depth dehydration and resource utilization for sludge. The process comprises the following steps that: afterheat steam with a temperature of 250 DEG C is extracted from a steam turbine of a pulverized coal boiler in a power plant and then delivered to a sludge in-depth dehydrator through a pipeline after the afterheat steam is adjusted to a temperature of 210 + / - 15 DEG C and a pressure of 0.4 + / - 0.1 MPa by a temperature-pressure reducer; wet municipal sludge with water content of 80 to 85% is delivered to a wet sludge storage tank, and in-depth dehydration is carried out so as to obtain sludge particles with water content of 40 + / - 4% and a particle size of 1 to 6 mm; the sludge particles obtained after in-depth dehydration is collected and stored in a dehydrated sludge storage bin; and the deeply dehydrated sludge particles in the dehydrated sludge storage bin is delivered to a coal conveying system of the boiler in the power plant by a dehydrated sludge belt conveying system through a gate valve at the bottom of the bin and mixed with fire coal, and an obtained mixture enters into the pulverized coal boiler in the power plant through a coal pulverizer and burnt at a temperature of 1200 DEG C so as to generate power. According to the invention, original pulverized coal boilers and coal conveying, burning and desulphurization facilities in the power plant are effectively utilized; equipment used in the whole process is simple; and the advantages of small investment, stable operation and no generation of secondary pollution are achieved.

Owner:南京国能环保有限公司

Explosion-proof processing method of medium-storage type bituminous coal boiler and special system thereof

ActiveCN101358735ASolve explosion-proofKeep dryDrying solid materials with heatHearth type furnacesBrown coalProcess engineering

Owner:NORTHEAST POWER SCI RES INSTITUTION +2

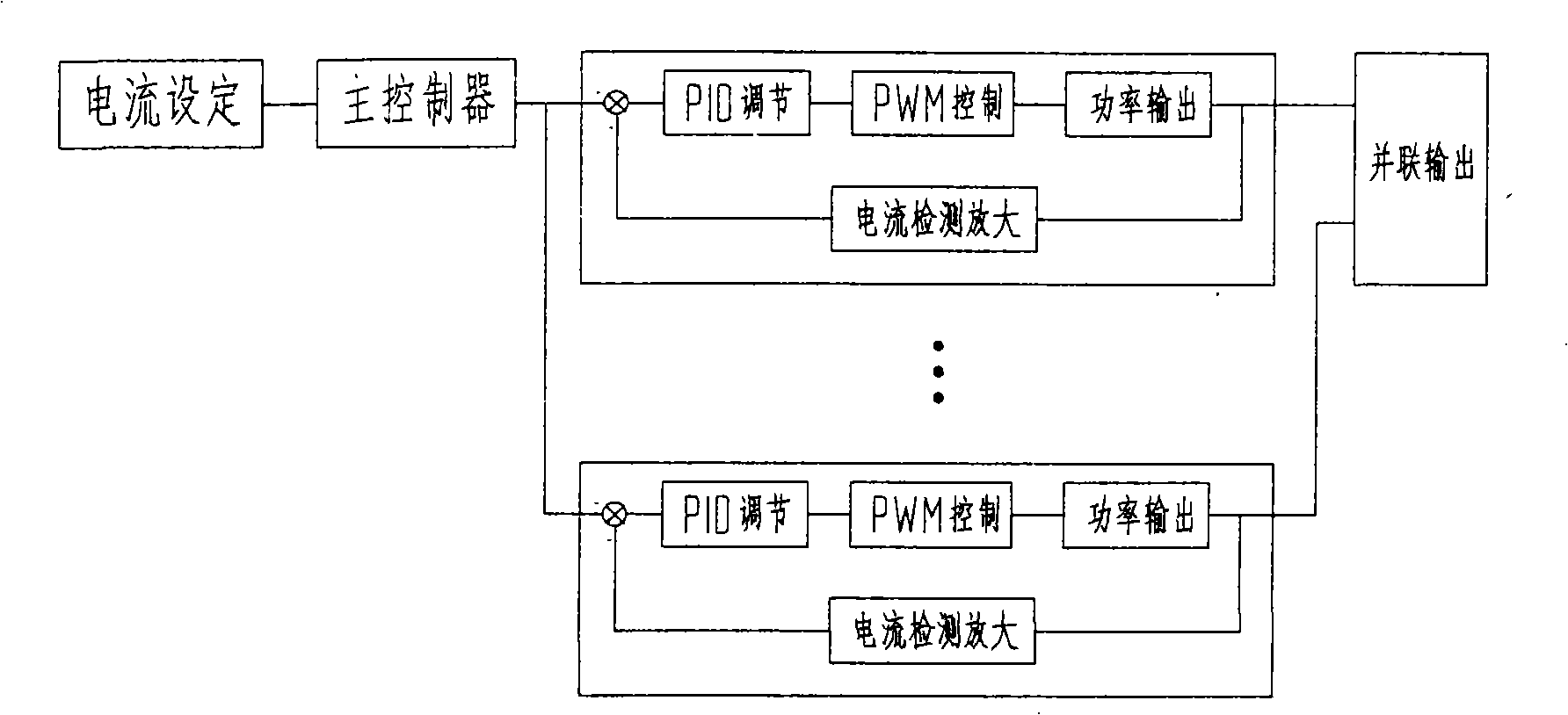

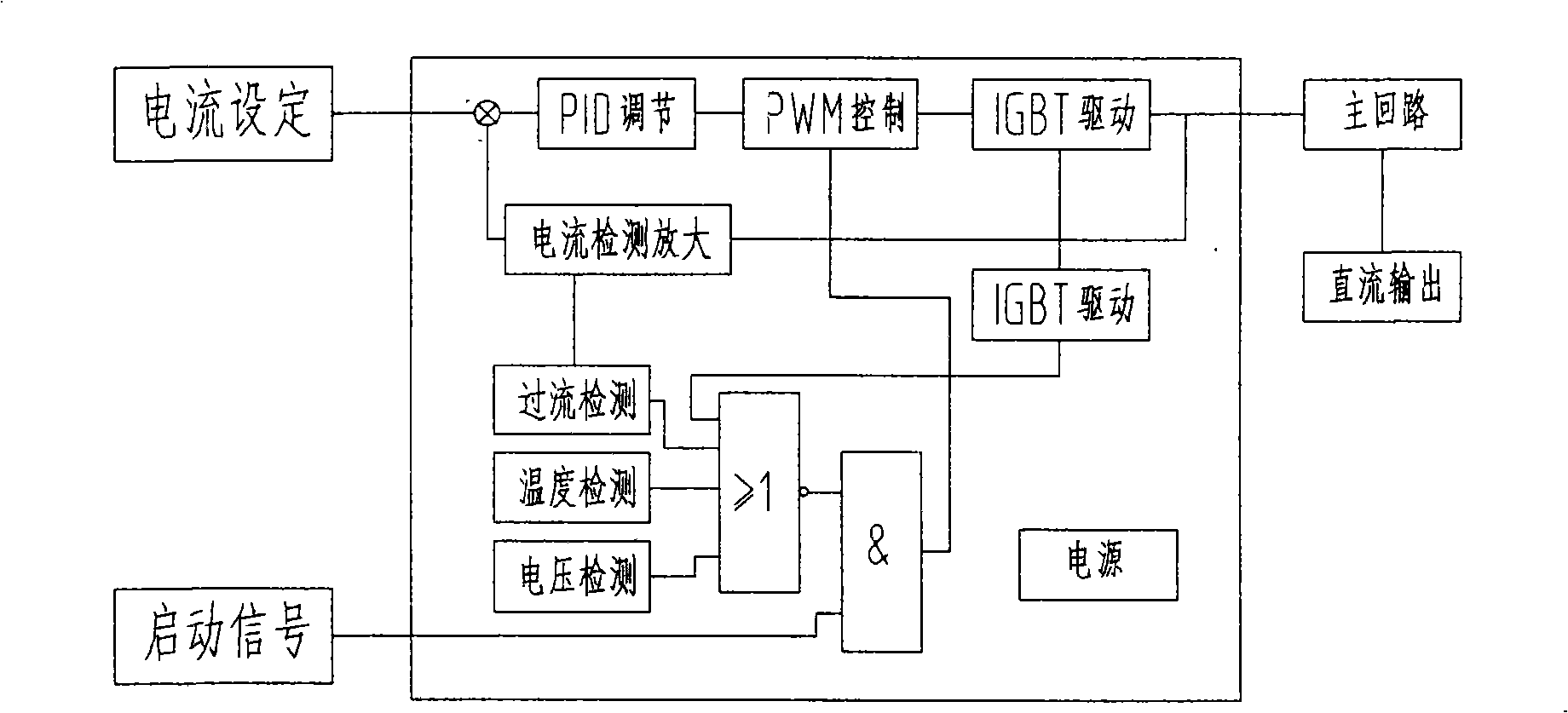

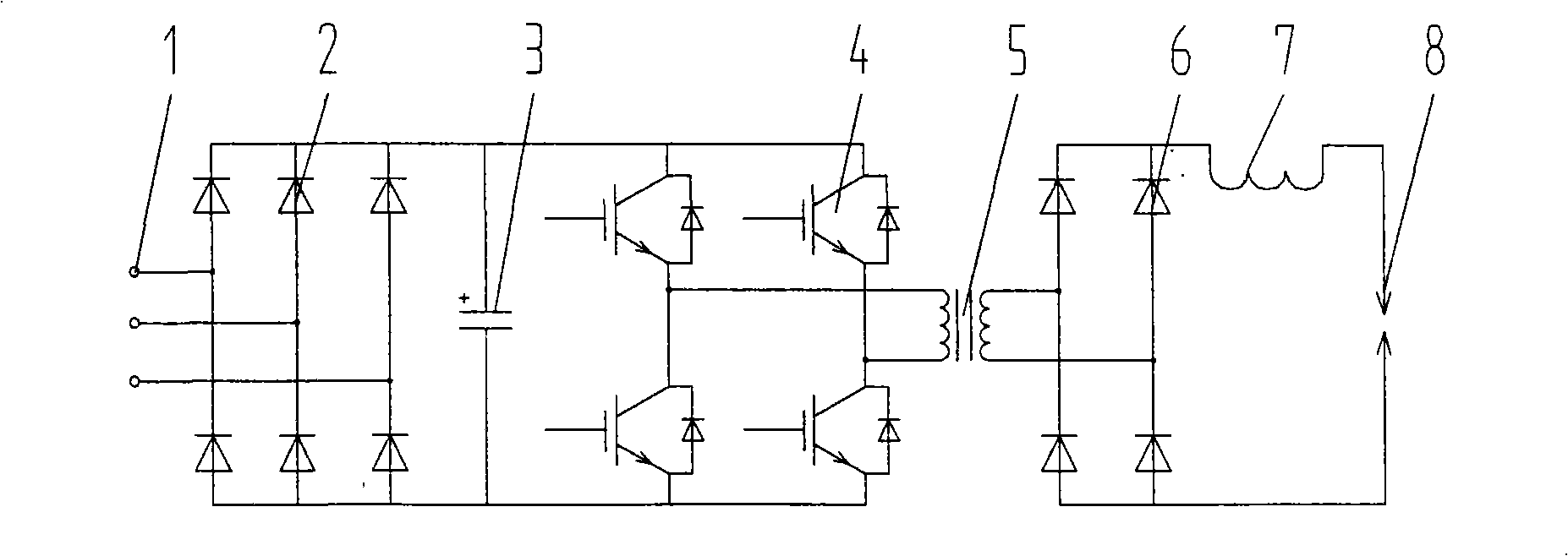

Plasma ignition high power switch power source

InactiveCN101271345AEasy Power ExpansionImprove reliabilityDc-dc conversionElectric variable regulationAverage currentPlasma generator

A plasma ignition large-power switch power supply belongs to a switch power supply. Working current is set by a plasma switch power supply. A given current signal passes through a main controller and controls multiple groups of power supply modules which are connected in parallel at the same time. Each group of independent power supply module outputs current according to the current signal distributed by the main controller and finally outputs normal working current in parallel. The invention provides single-group power supply modularization, the working form of the multiple groups of power supply modules in parallel connection, the flow equalization form of the multiple groups of power supply modules in parallel connection as a master-slave mode, the control mode of the single-group power supply module as an average current mode and a power redundancy technology. The switch power supply is used in a plasma generator which ignites coal powder directly in a pulverized coal fired boiler to provide large-power direct current power supply and the switch power supply is multiple groups of switch power supplies in parallel connection and outputs high voltage and large current. The flow equalization form of the multiple groups of power supply modules in parallel connection is as the master-slave mode. The control mode of the single-group power supply module is as the average current mode. The power redundancy technology is used so as to improve the reliability. The plasma ignition large-power switch power supply has the characteristic of constant current, smaller volume, weight saving, high working frequency, fast response speed, very little loss and high working efficiency. Modularization design is adopted by the single-group power supply, so as to expand easily.

Owner:徐州燃烧控制研究院有限公司

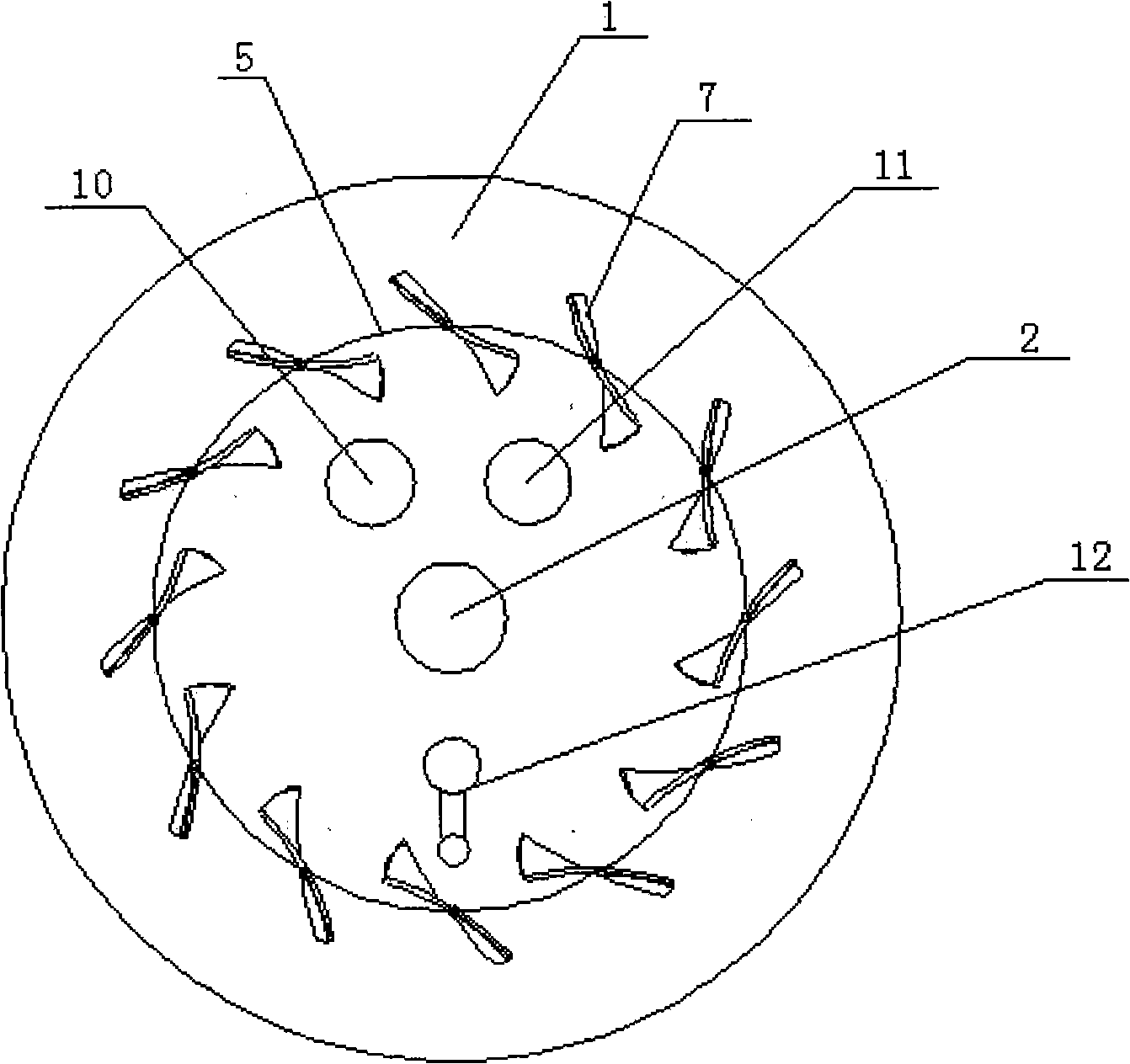

Self-stabilizing three-stage air-distribution low-NOx pulverized coal burner

InactiveCN101644431AEasy to igniteEasy to adjust the swirl intensityPulverulent fuel combustion burnersCycloneImpeller

The invention discloses a self-stabilizing three-stage air-distribution low-NOx pulverized coal burner. A pre-burning chamber and a conical barrel formed by the cone expansion and extension of an internal secondary air duct are arranged in an external secondary bellows. A large end of the conical barrel is sheathed in an external secondary air passage formed by an opening at one end of the pre-burning chamber. A wall surface at the other end of the pre-burning chamber, which is closed with an external end face of the external secondary bellows, is provided with an annular tertiary air passage.A central air duct is coaxially arranged in a primary air duct. The primary air duct and a cone expanding end of the central air duct are both arranged in the conical barrel. The internal secondary air duct sheaths the outside of the primary air duct. An axial movable cyclone impeller is arranged in the internal secondary air duct. The outer end of the axial movable cyclone impeller is provided with an internal secondary air impeller pull rod. An annular passage of a separating plate is provided with an air regulator. The outer end of the air regulator is provided with an air regulating pullrod. The circumference at the inner end of the air regulating pull rod is equally divided to arrange sliding fins cooperating with an internal secondary bellows in a sliding manner. The burner has strong self-stabilization capability, can adjust a flame position, prevent slag formation in the pre-burning chamber and realize low NOx emission, and is capable of wide application in various industrialpulverized coal boilers.

Owner:CHINA JILIANG UNIV +2

Coal firing method with low discharged nitrous oxides

ActiveCN101097060AReduce generationSuppress generationFluidized bed combustionAir supply regulationBack burnsCombustion chamber

The invention discloses a fire coal method to discharge low nitrogen oxide, which is characterized by the following: adopting high temperature oxygen-enriched smoke gas from circulating fluidized bed burner as high temperature low oxygen twice wind of pulverized coal fired boiler; burning coal dust in high temperature low oxygen coordinating wind with temperature at 800-950 deg. c; decreasing generated quantity of nitrogen oxide (NOx)greatly; controlling circulating fluidized bed burner and main combustion area of coal dust burner fire box at reducing atmosphere; controlling burning temperature; inhibiting the generation of NOx; keeping stability and complete burning property of burning; realizing low NOx discharge of boiler; decreasing the discharging quantity of NOx below 130mg / Nm3.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Combustion device for dewatering upgradation of lignite and reduction of nitrogen oxide emission and method thereof

InactiveCN102200275AEmission reductionEfficient reductionDrying gas arrangementsSteam boilersAir preheaterNitrogen oxides

The invention discloses a combustion device for dewatering upgradation of lignite and reduction of nitrogen oxide emission. The combustion device comprises a pulverized coal drying device and a lignite combustion boiler, wherein the pulverized coal drying device consists of a pulverized coal cabin, a coal hopper, a drying furnace, a coke collection tank, a separator, a fan, a chilling machine, a first gas circulating pipeline, a second gas circulating pipeline and a primary air pipeline; and the lignite combustion boiler consists of a boiler hearth, an over fire air pipeline, a primary air and pulverized coal nozzle, a re-combustion fuel nozzle, an over fire air nozzle, a reheater, a high temperature convection superheater, a low temperature convection superheater, a coal economizer, an air preheater, a dust remover, an induced draught fan and a tail flue. The invention also discloses a combustion method for dewatering upgradation of lignite and reduction of nitrogen oxide emission. A fuel staged combustion technology is organically combined with a high temperature gas lignite drying technology, so that dewatering upgradation of lignite and reduction of nitrogen oxide NOx emission are guaranteed. The combustion device and the combustion method are simple and reliable, are convenient to manage, are suitable for pulverized coal boilers for combusting the lignite, particularly large and medium-sized power station boilers, and have broad application prospect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

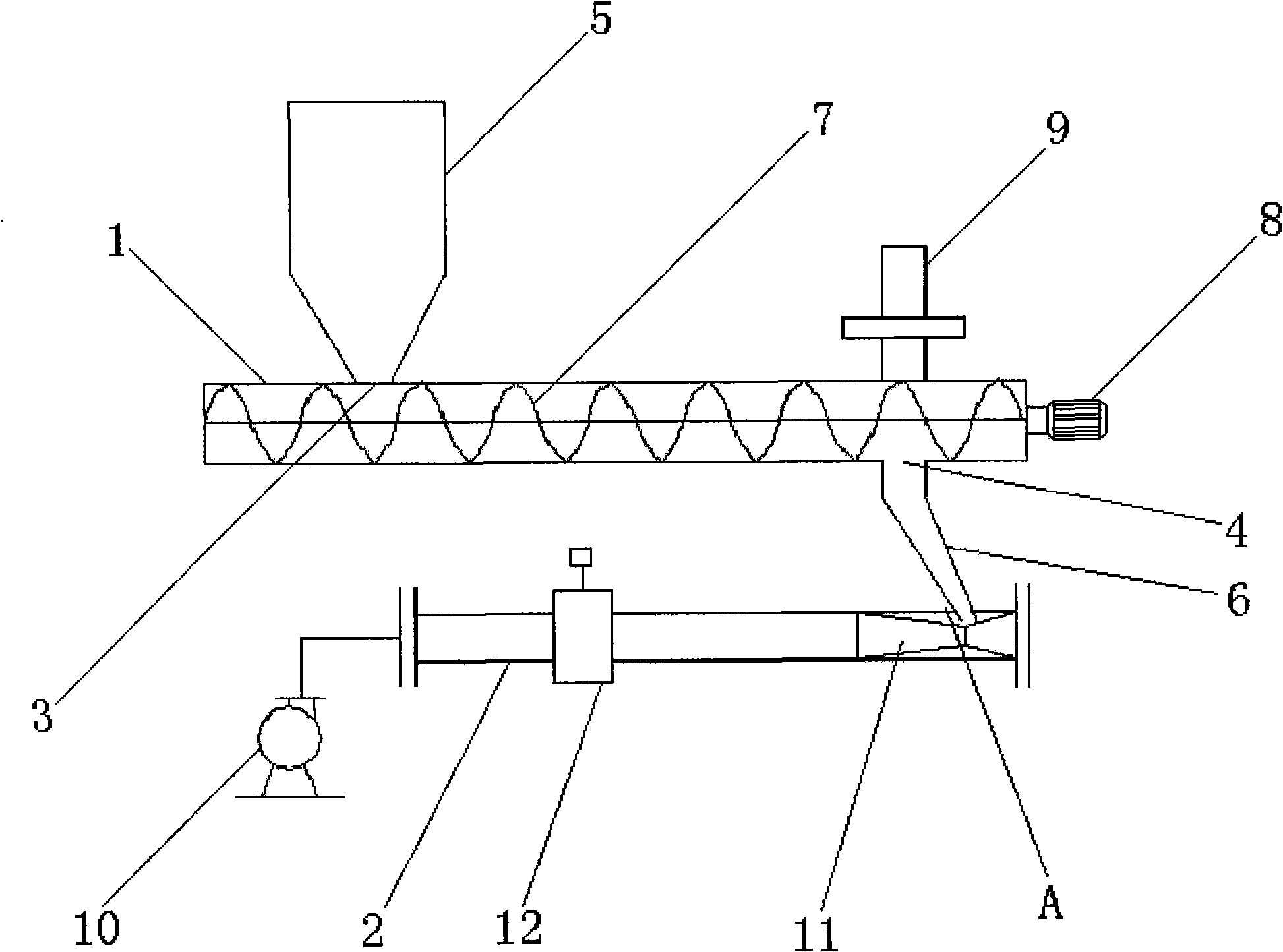

Pulse-free coal powder supply device

The invention relates to a pulse-free coal powder supply device which is characterized by comprising a delivery pipe and an air pipe arranged below the delivery pipe; the two ends of the delivery pipe are sealed, a feeding opening is arranged at the upper side adjacent to one end of the delivery pipe, and a discharging opening is arranged at the lower side adjacent to the other end of the delivery pipe; the feeding opening is radially connected with a storage silo and the discharging opening is radially connected with a blanking pipe; the upper half part of the blanking pipe is vertical and the lower half part of the blanking pipe is inclined towards the outer side of the delivery pipe; a feed screw is arranged in the delivery pipe, and one end of the feed screw, adjacent to the discharging opening, is connected with the output end of a motor; a voltage stabilizer is radially connected on the delivery pipe and adjacent to one end of the motor; the blanking pipe is radially connected at one end of the air pipe and an air blower is connected at the other port of the air pipe; the lower half part of the blanking pipe is obliquely connected in the air pipe and an included angle is formed between the lower half part of the blanking pipe and the air pipe; a Venturi structure is arranged at the joint between the air pipe and the blanking pipe; and a regulating valve is also arranged on the air pipe. The invention can effectively avoid the phenomenon that the coal powder is accumulated and blocked and is not delivered smoothly in the coal delivery pipeline, has the advantages of rapid, uniform and pulse-free continuous coal powder feeding and is suitable for the small and medium-sized industrial coal powder boiler systems.

Owner:CHINA COAL RES INST

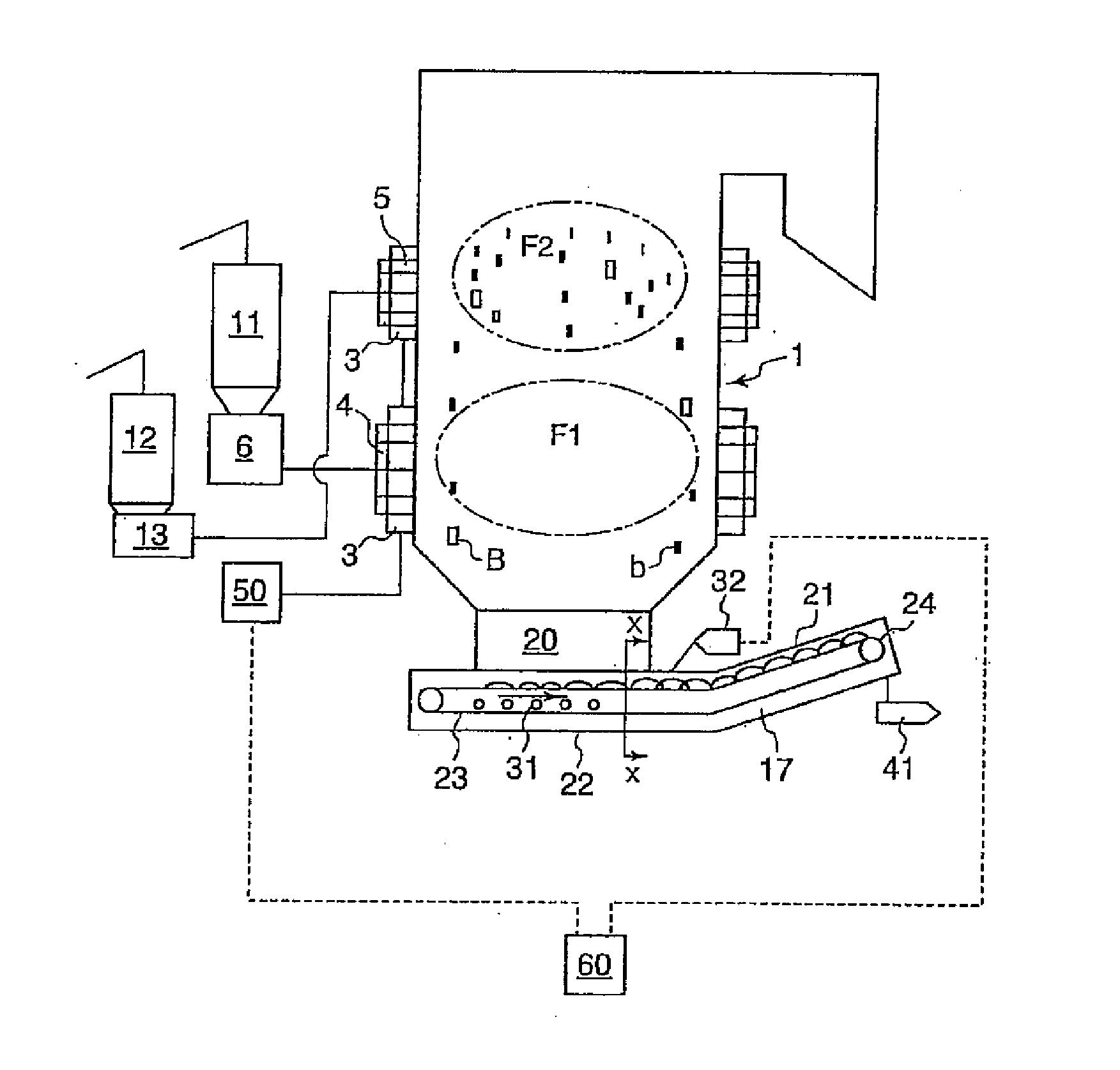

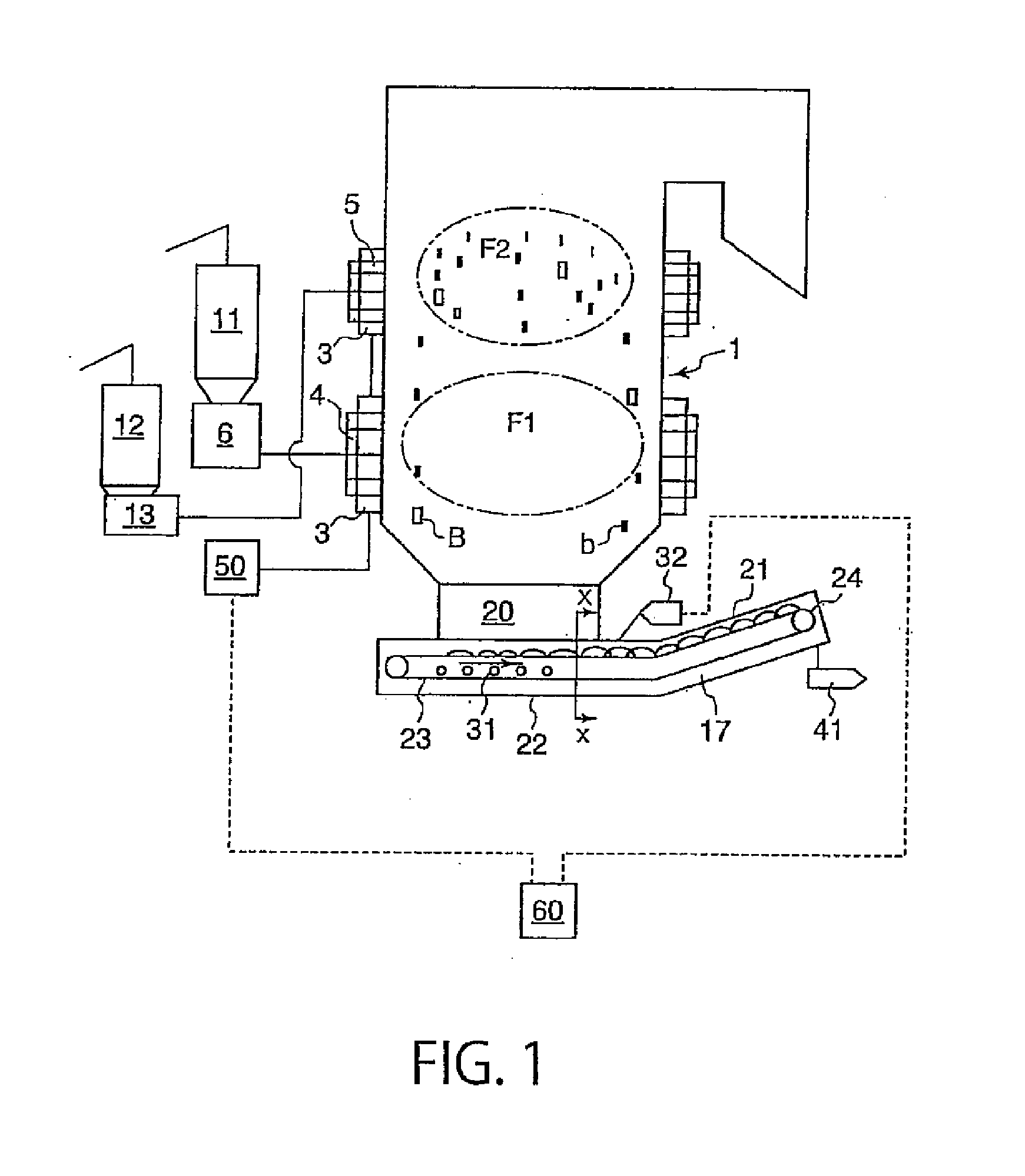

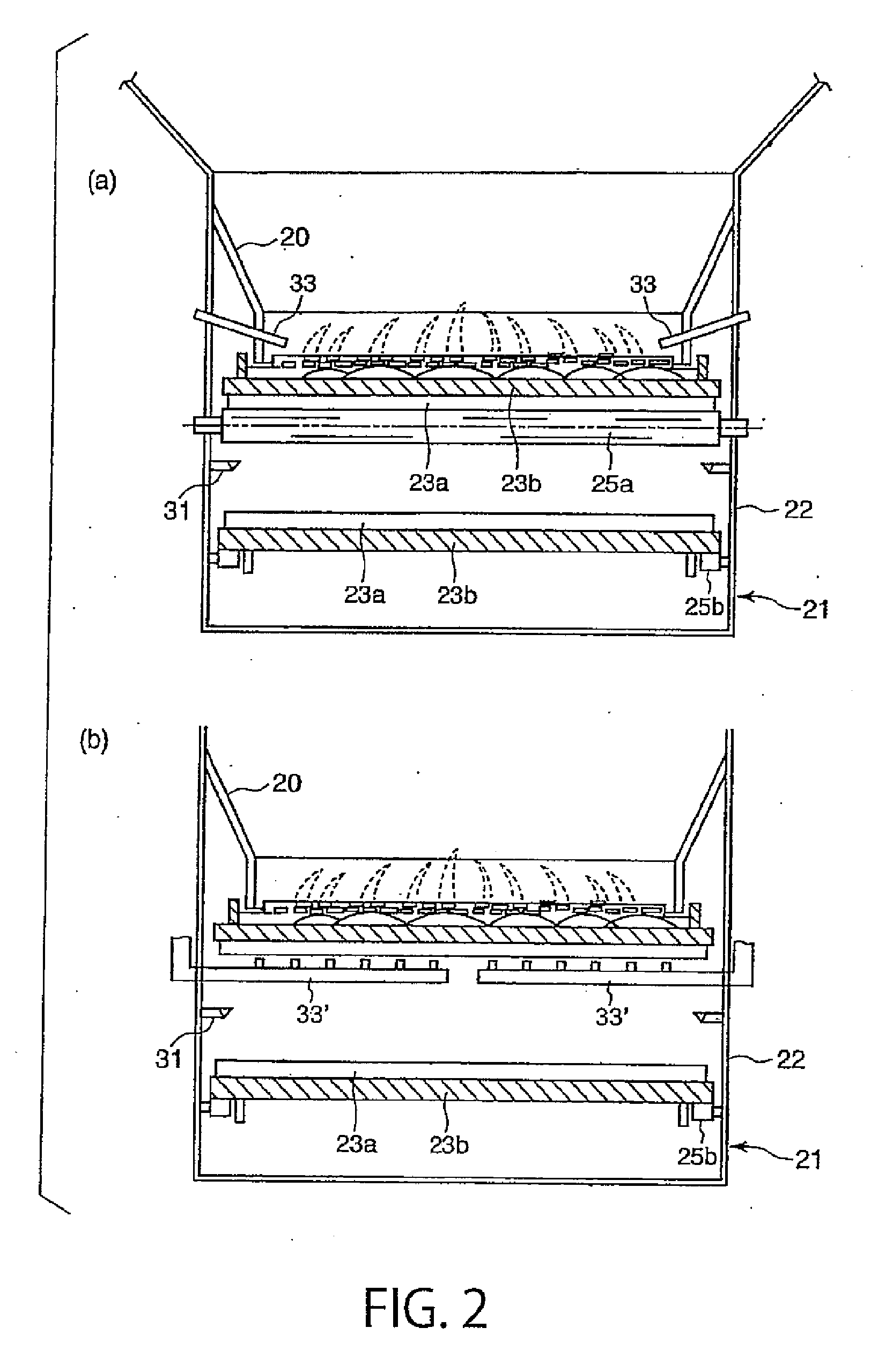

Biomass-mixed-firing pulverized coal fired boiler and operation method of the boiler

InactiveUS20110107948A1Reduced Power RequirementsEfficient use ofSolid fuel pretreatmentPilot flame ignitersProcess engineeringBiomass fuels

A biomass-mixed-firing pulverized coal fired boiler includes: a furnace for burning biomass fuel together with pulverized coal in a mixed state; a pulverized coal burner for supplying the pulverized coal into the furnace; a biomass burner for supplying the biomass fuel into the furnace; a biomass mill for milling the biomass fuel to be supplied to the biomass burner; a dry clinker processing unit provided below the furnace and including a clinker conveyor for carrying ashes discharged from the furnace at a furnace bottom; and a combustion-air supply unit for supplying combustion air toward the ashes discharged at the furnace bottom on the clinker conveyor, thereby to burn an unburned component of the biomass fuel contained in the ashes discharged at the furnace bottom on the clinker conveyor.

Owner:KAWASAKI HEAVY IND LTD +1

Method for reducing nitrogen oxide of powder coal boiler mixed burning gas fuel

InactiveCN101050853AGuaranteed combustion efficiencyEmission reductionCombustion using gaseous and pulverulent fuelBurnersOxygenMixed gas

A method for decreasing nitrogen oxide of mixed gas fuel used on pulverized-coal boiler includes dividing gas fuel to be two grades then leading them into pulverized-coal furnace tank, leading in primary gas fuel as combustion-assistant fuel at bottom of master burner at master combustion region to burn it by utilizing gradation air-combustion technique with low air overdose parameter, leading in secondary gas fuel at top of master combustion region to form reducing atmosphere of re-combustion region and leading in burn out air at top of re-combustion region.

Owner:HARBIN INST OF TECH

On-line adjustable coal flow distributing device

InactiveUS20070095260A1The method is simple and reliableEffective controlFuel feeding arrangementsSolid fuel combustionCombustorProcess engineering

A method of and an apparatus for operating a pulverized coal-fired boiler system, which includes at least one coal pulverizer in flow connection with at least two burners disposed on a boiler enclosure by a coal feed system having a coal pipe junction with a riffle enclosure including a plurality of parallel partition walls forming multiple flow channels from an upstream coal pipe to each of at least two downstream coal pipes and a plurality of individually pivotable vanes upstream of the plurality of partition walls, and controlling the distribution of coal between the downstream pipes by pivoting at least one of the vanes. Preferably a coal flow rate is monitored in the downstream coal pipes and at least one of the vanes is pivoted in response to a measured distribution of the coal flow rate.

Owner:FOSTER WHEELER ENERGY CORP

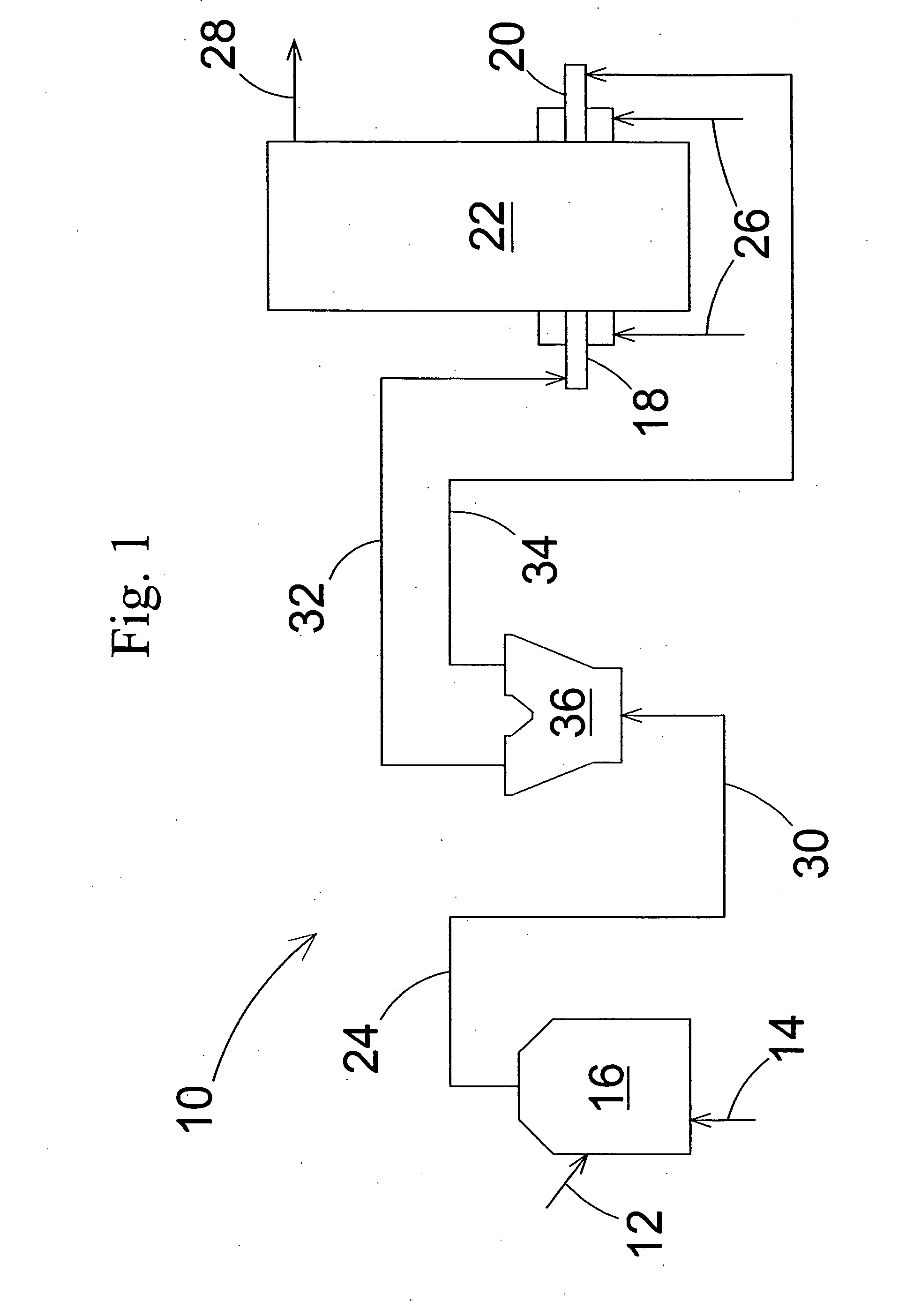

System and process for coal powder preparation

The invention relates to a system and a process for coal powder preparation, which is characterized in that the system for coal powder preparation comprises a crushing system, a drying system and a grinding system; the crushing system comprises a coal receiving hopper and a crushing machine connected with the coal receiving hopper; the drying system comprises a drying kiln, and the drying kiln is communicated with the crushing machine through a belt conveyer; the drying kiln is connected with a raw coal silo; an air inlet opening at the charging side of the drying kiln is connected with a hot blast furnace and the hot blast furnace is connected with an air blower; an air outlet opening at the top of the drying kiln is connected with a first induced draft fan and an air outlet opening of the first induced draft fan is respectively connected with a hot air pipeline and a dust collector between the drying kiln and the hot blast furnace; the grinding system comprises a vibration feeder and a coal grinding mill connected with the vibration feeder, wherein the vibration feeder is communicated with the raw coal silo through a first bucket elevator; the coal grinding mill is connected with a cyclone separator, an ascension pipe of the cyclone separator is connected to the storage silo through a second bucket elevator; and the cyclone separator is connected with a second induced draft fan and connected to the coal grinding mill. The invention not only can be applied to establish the independent coal powder preparation plant, but also can be applied in front of an industrial coal powder boiler as the stokehole powder-making unit.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Furnace front coal head-drawing method for circulating fluid bed boiler

ActiveCN101435574ADoes not affect operationTake advantage ofFluidized bed combustionCombined combustion mitigationCombustion chamberHeat carrier

The invention discloses a method for topping boiler-front coal for a circulating fluidized bed boiler, and relates to pyrolysis technology of coal. The method comprises the following steps: arranging a pyrolysis gasification device for a solid heat carrier in the front of the circulating fluidized bed boiler, feeding partial or full coal supplied to the circulating fluidized bed boiler into the device, and topping the coal to generate pyrolysis gas and tar; and feeding part of semi-coke into a hearth of the circulating fluidized bed boiler to combust, and feeding the other part of the semi-coke into a coal topping combustion chamber to combust; and introducing smoke gas in the coal topping combustion chamber into the hearth of the circulating fluidized bed boiler to combust. The method extracts high-value components from the fed coal to supply outwards, utilizes residual components for combustion in the boiler, does not influence running of a pulverized coal fired boiler, and can make full use the high-value components in the coal, so as to make full use of energy.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com