Plasma ignition high power switch power source

A high-power switch, plasma ignition technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, electrical components, etc., can solve the problem of large volume, slow response speed and low operating frequency of isolation transformers and reactors and other problems, to achieve the effect of fast dynamic response, fast response speed and high working frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

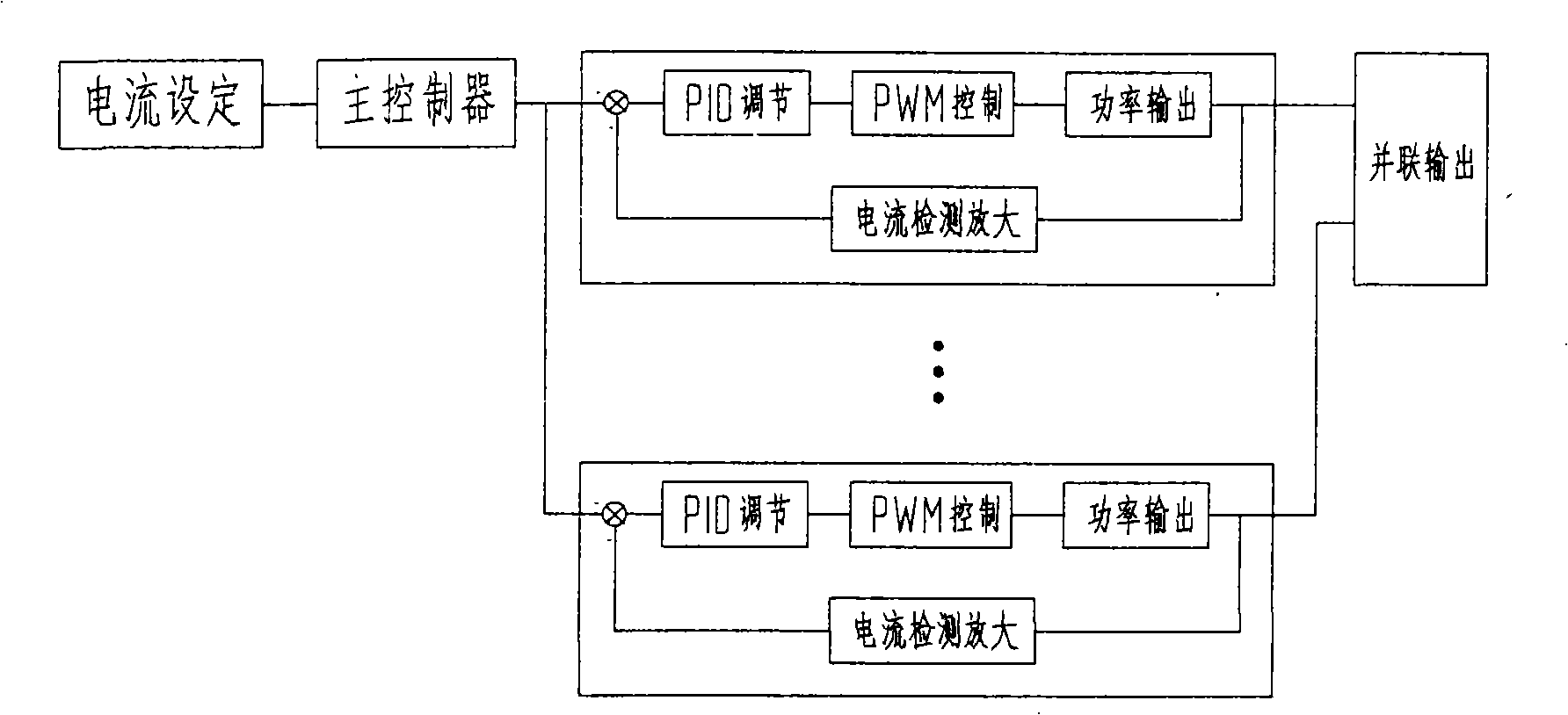

[0027] Embodiment 1: The plasma power supply sets the working current, and the set current signal passes through the main controller to simultaneously control multiple sets of parallel power supply modules, and each set of independent power supply modules outputs current according to the current signal distributed by the main controller, and finally Parallel output normal working current;

[0028] The high-power switching power supply adopts multiple sets of parallel connection; single set of power supply adopts modular design, which is easy to expand; multiple sets of parallel current sharing mode is master-slave mode; the control mode of single set of power supply is average current mode; power redundancy technology to improve reliability.

[0029] The way of multiple groups of parallel connection is not simply to connect the output terminals of multiple power supplies together. When several power supplies with the same structure are operated in parallel, the output terminal...

Embodiment 2

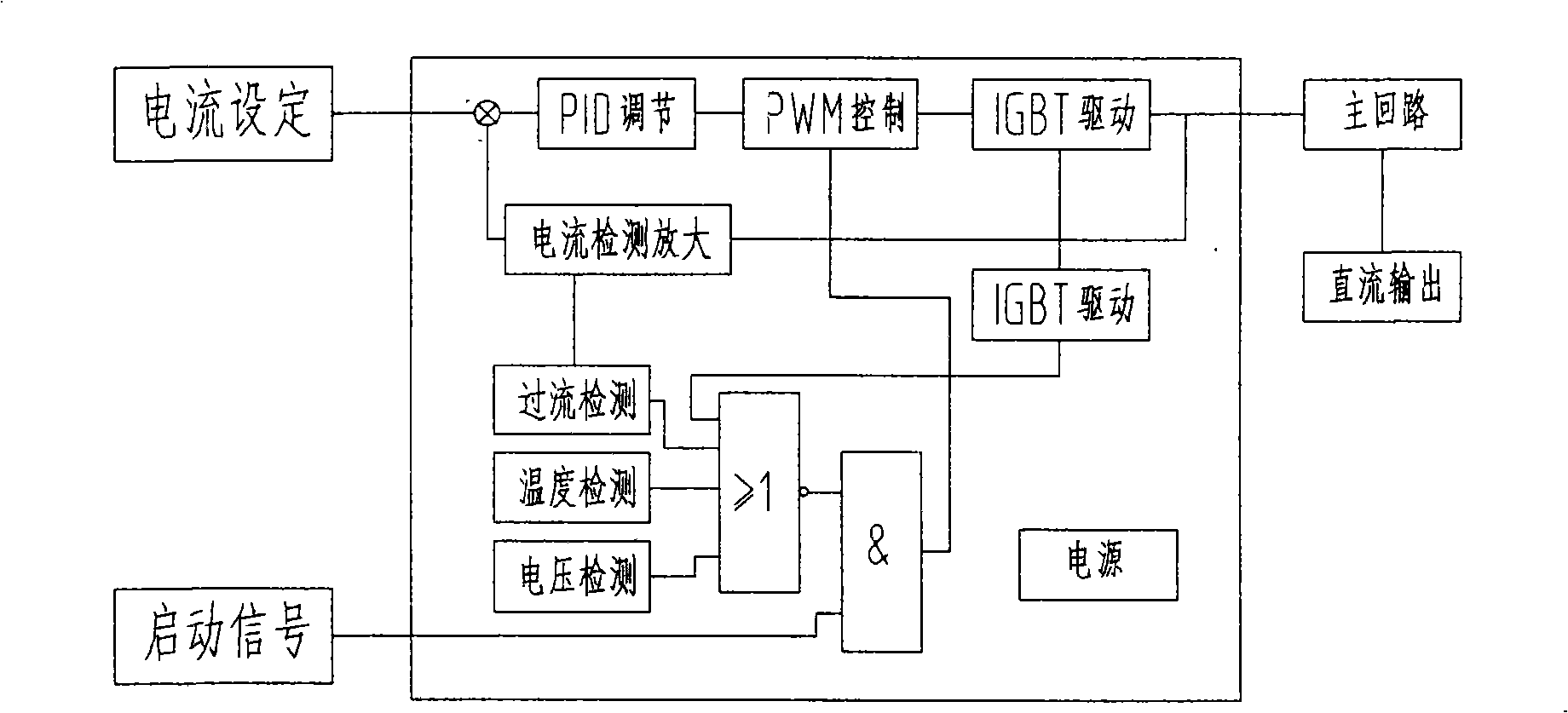

[0036] Example 2: In figure 2 Among them, the working process of the single-group power supply module of the plasma ignition high-power switching power supply of the present invention is as follows: the main controller outputs the flow signal as the setting signal, compares it with the output current signal of the single group, and outputs an error signal to indicate The difference between the actual output current of this group and the current assigned to this group enters the PID regulator for calculation, outputs a control signal, and sends it to the PWM circuit. The PWM circuit generates a corresponding pulse width according to the control signal to adjust the IGBT output, so that the output current of this group equal to the assigned current.

[0037]The single-group power supply module is equipped with a detection circuit and a protection circuit to detect the voltage signal, temperature signal, and current signal, and generate a fault signal together with the IGBT erro...

Embodiment 3

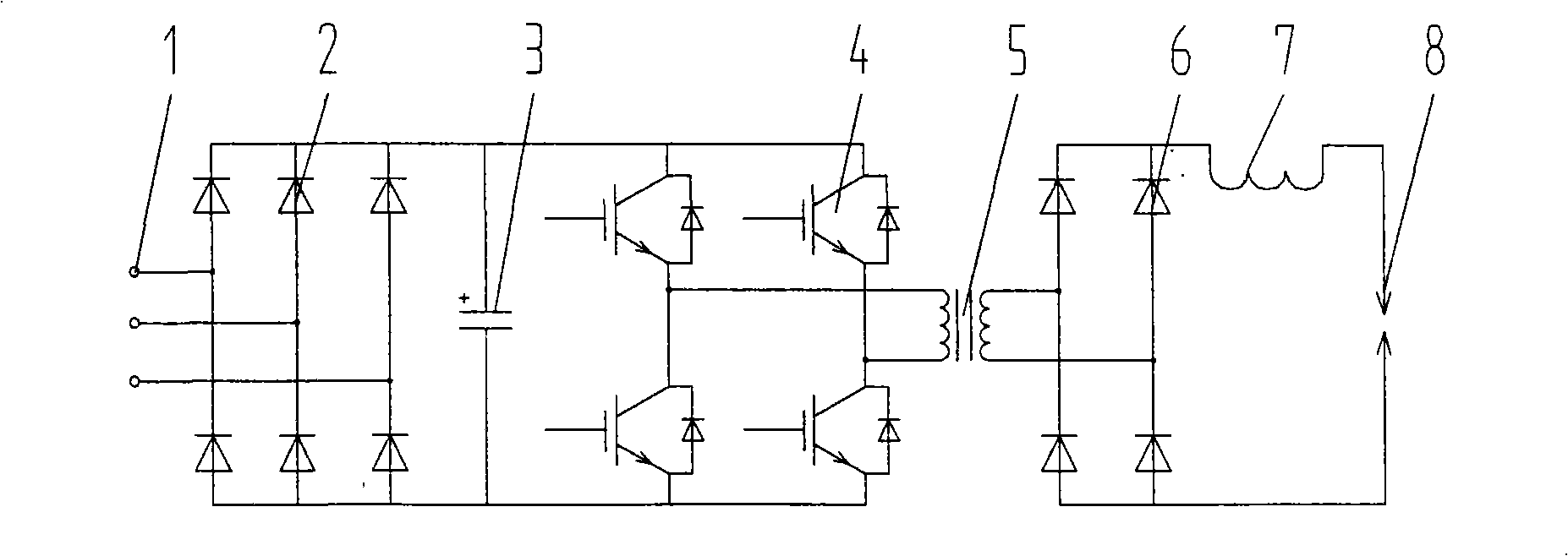

[0039] Example 3: In image 3 Among them, the main circuit principle of the single-group power supply module dedicated to the plasma ignition high-power switching power supply of the present invention is as follows:

[0040] Three-phase AC input 1 is rectified by six rectifier diodes 2 and filtered by capacitor 3 to become DC, and then the full-bridge circuit inverter composed of four IGBT4 is inverted into high-frequency AC square wave pulse voltage, and the full-bridge circuit is inverted The inverter is driven by the control drive protection circuit. The output of the inverter is isolated by the high-frequency transformer 5 and converted into a suitable AC voltage. After being rectified by four high-frequency rectifier diodes 6 and filtered by the reactor 7, it becomes the required DC output voltage to provide Give the plasma arc 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com