A permanent magnet single-phase switched reluctance motor and its control method

A switched reluctance motor, permanent magnet technology, applied in electromechanical devices, electrical components, electronic commutators, etc., can solve the problems of unable to generate continuous torque output, reduce motor power factor, unable to achieve bidirectional operation, etc. Achieve the effect of eliminating torque ripple, improving conversion efficiency, and good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

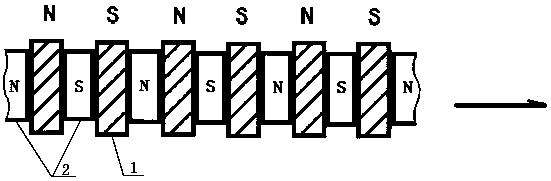

[0047] Embodiment 1: as figure 2 and 3 As shown, a permanent magnet single-phase switched reluctance motor includes a motor output shaft, a control system and at least one set of armature devices. In this embodiment, the armature devices are one group, and the armature devices It includes a stator 1 and a rotor 2. There is an air gap between the salient poles of the stator 1 and the rotor 2. The rotor 2 is fixedly sleeved on the outer periphery of the motor output shaft 5. The number of salient poles on the stator 1 is the same as that on the rotor 2. The number of salient poles is the same, the stator electromagnetic winding 4 is installed at the salient pole part of the stator 1, and the winding directions of the adjacent stator electromagnetic windings 4 are different, that is, the stator electromagnetic windings installed at the salient pole part of the stator They can be connected in series, in parallel, or combined in series and parallel. The head of the first stator e...

Embodiment 2

[0051] Embodiment 2: as Figure 4 , 5 As shown in and 6, in this embodiment, the armature devices are two groups, that is, the stator 1 of the permanent magnet type single-phase switched reluctance motor is composed of a front stator core and a rear stator core, and the The rotor 2 is composed of a front rotor core and a rear rotor core. The stators and rotor cores included in the front and rear segments respectively form independent and self-closing magnetic field circuits.

[0052] Wherein, the number of salient poles of the front stator core and the rear stator core is equal, and there is a gap between the two stator cores, and the salient pole positions in the front stator core and the rear stator core are as follows: Cross positioning arrangement, that is, the salient pole centerline of the front stator core corresponds to the concave center line of the rear stator core, and the stator electromagnetic winding on the front stator core is the same as the stator electromagn...

Embodiment 3

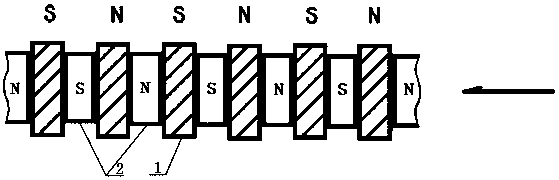

[0056] Embodiment 3: as Figure 7 and 8 As shown, in this embodiment, the armature devices are two groups, that is, the stator 1 of the permanent magnet single-phase switched reluctance motor is composed of a front stator core and a rear stator core, and the rotor 2 It is composed of the front rotor core and the rear rotor core. The stator and rotor core contained in the front and rear segments respectively form an independent and self-closing magnetic field circuit.

[0057] Wherein, the number of salient poles of the front stator core and the rear stator core is equal, and there is a gap between the two stator cores, and the salient pole positions in the front stator core and the rear stator core are as follows: Cross positioning arrangement, that is, the salient pole centerline of the front stator core corresponds to the concave center line of the rear stator core, and the stator electromagnetic winding on the front stator core is the same as the stator electromagnetic win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com