Patents

Literature

146results about How to "Guaranteed installation reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

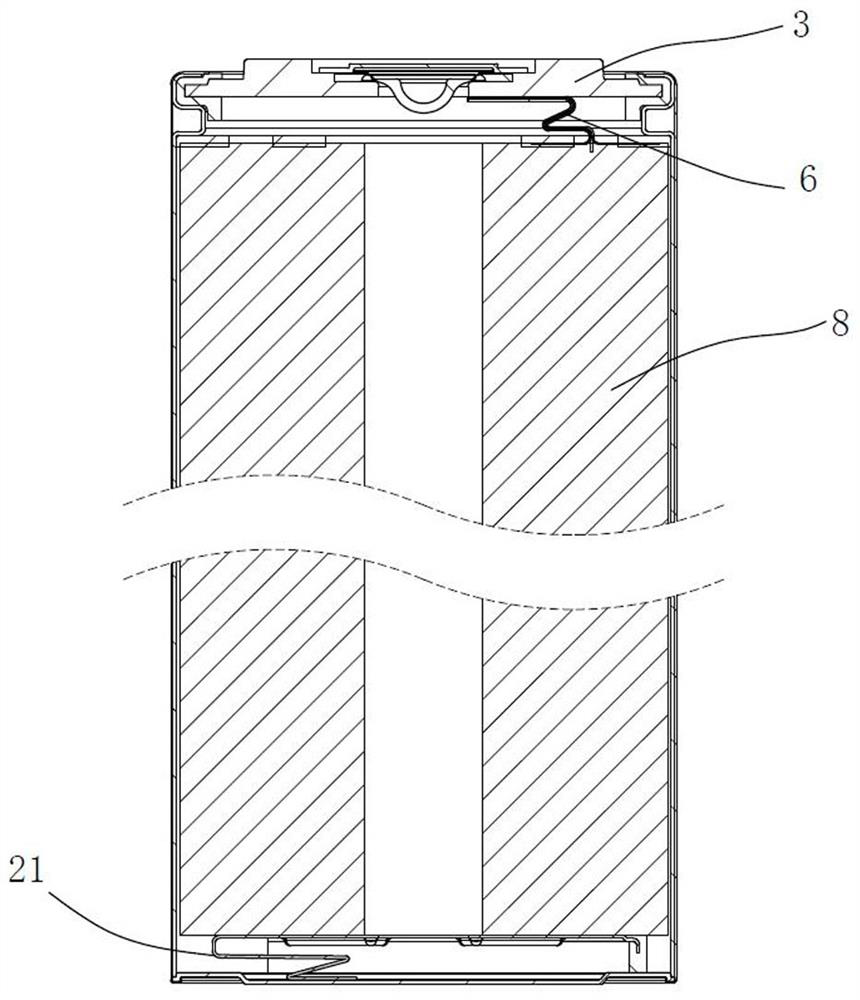

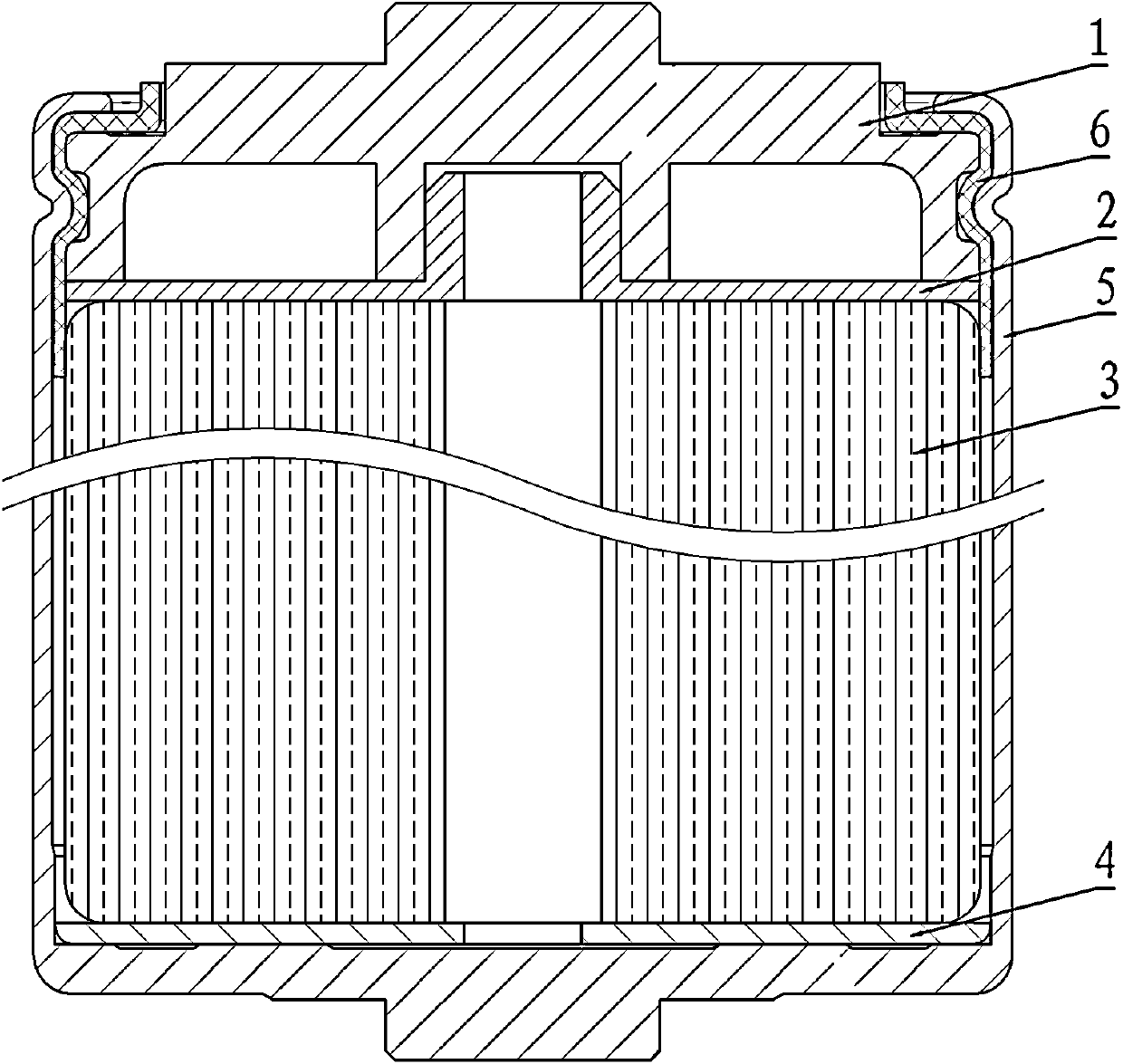

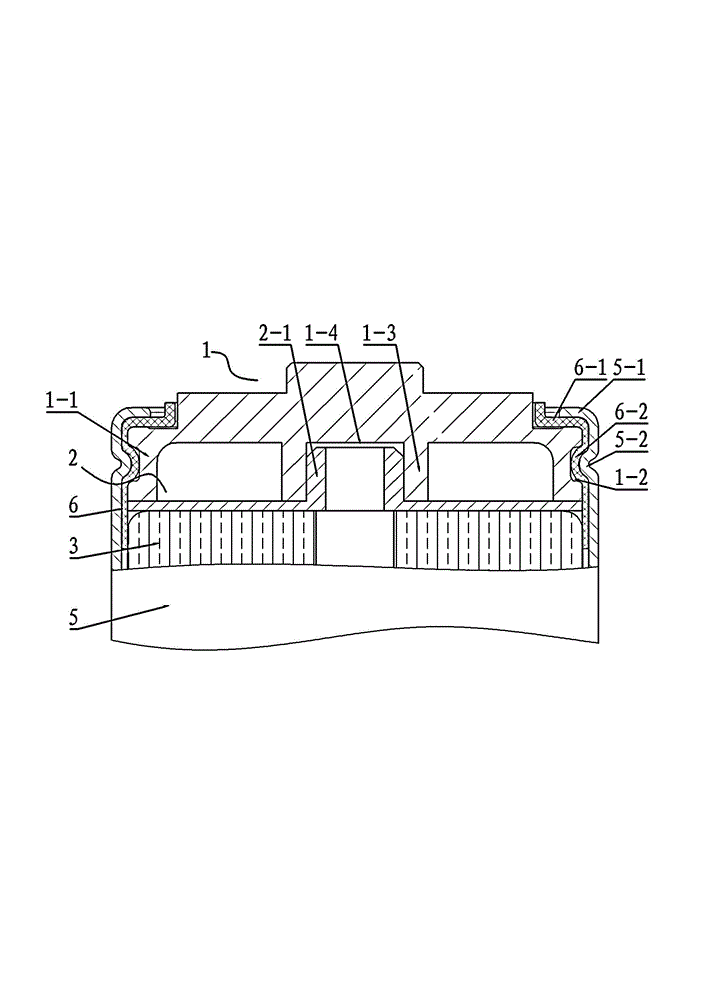

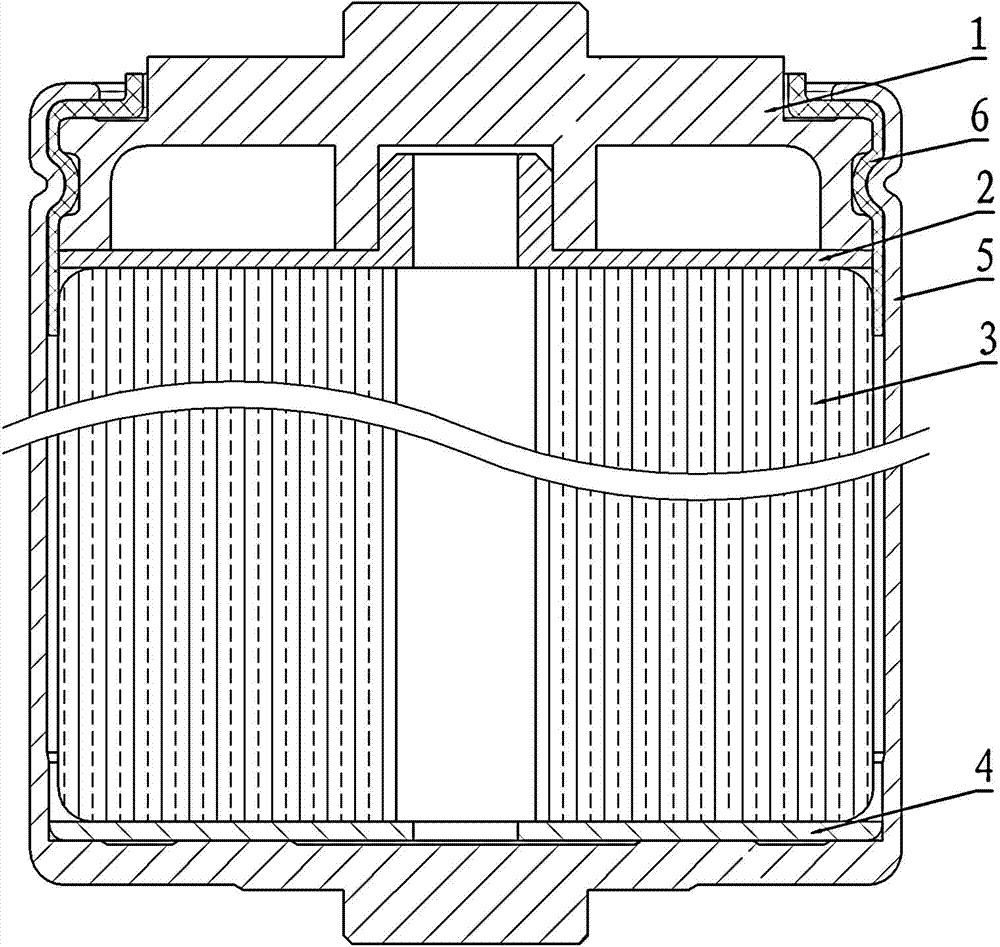

Circular lithium battery and production method thereof

PendingCN112151732AGuaranteed overcurrent capabilityEasy injectionFinal product manufactureSmall-sized cells cases/jacketsMechanical engineeringBattery cell

The invention discloses a circular lithium battery and a production method thereof. The lithium battery comprises a shell, a battery cell, a positive electrode battery cover plate assembly and a negative electrode battery cover plate assembly. A positive electrode foil and a negative electrode foil are separated by a diaphragm and then wound into a cylindrical battery cell. A positive electrode isa multi-tab structure, and a negative electrode is a full-tab structure. A sealing body is fixed on the anode battery cover plate in surrounding manner, and a safety valve is arranged in the middle.The negative electrode battery cover plate assembly comprises a current collector, a negative electrode battery cover plate and a current collector bracket; and the current collector body is fixedly connected to the upper part of the current collector bracket and is electrically connected with the negative electrode battery cover plate through a current collector connecting part. According to theinvention, an over-current capability of the battery is ensured, liquid injection and formation of the battery are facilitated, and installation is convenient and reliable.

Owner:星恒电源(滁州)有限公司

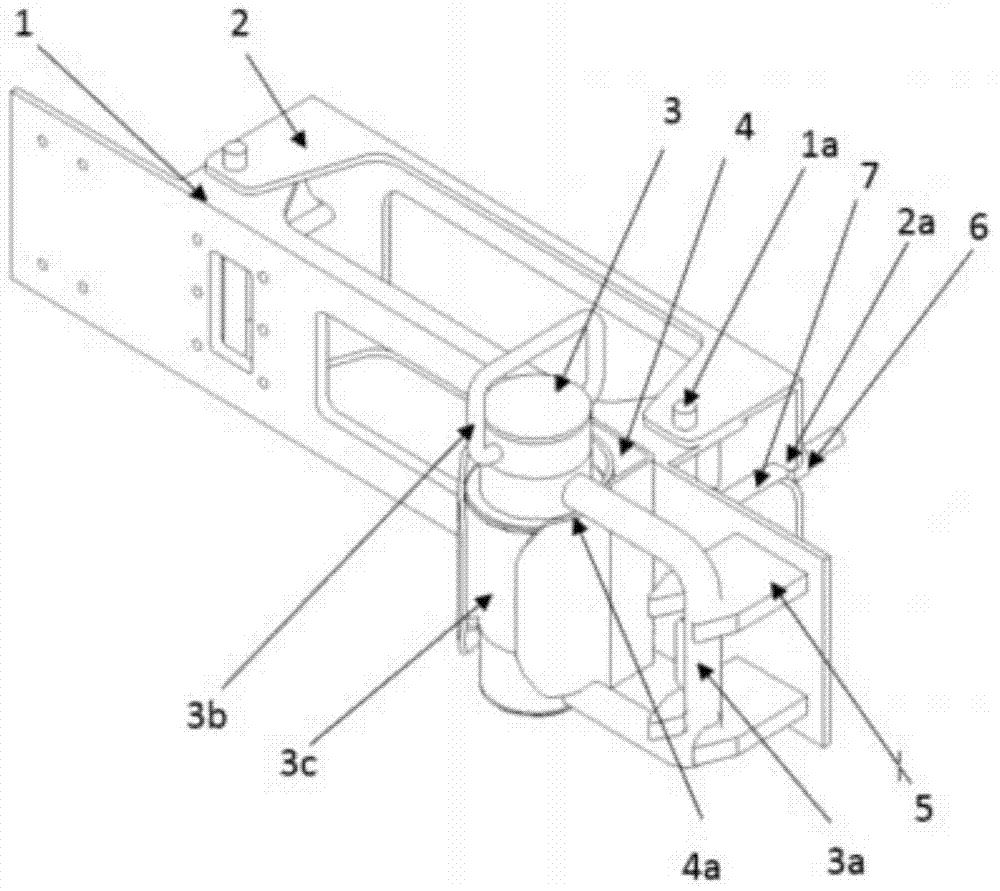

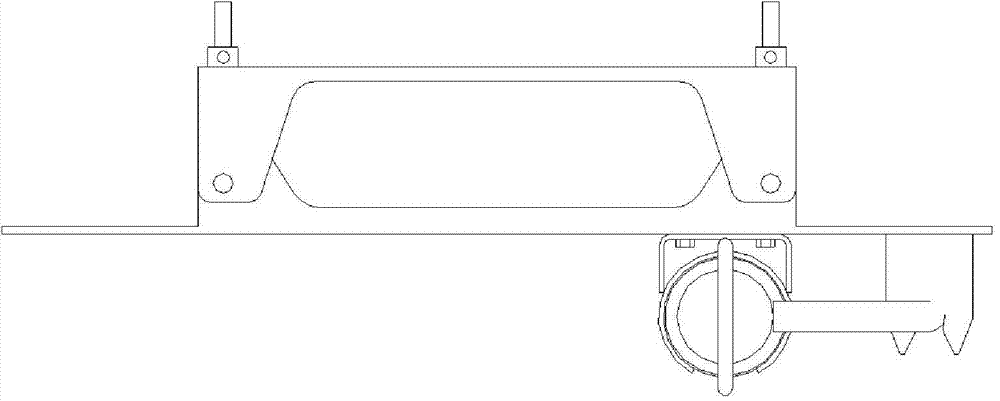

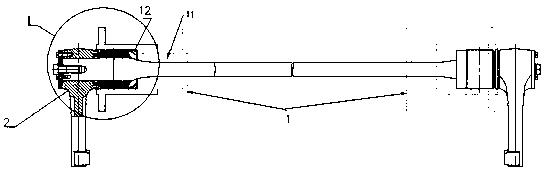

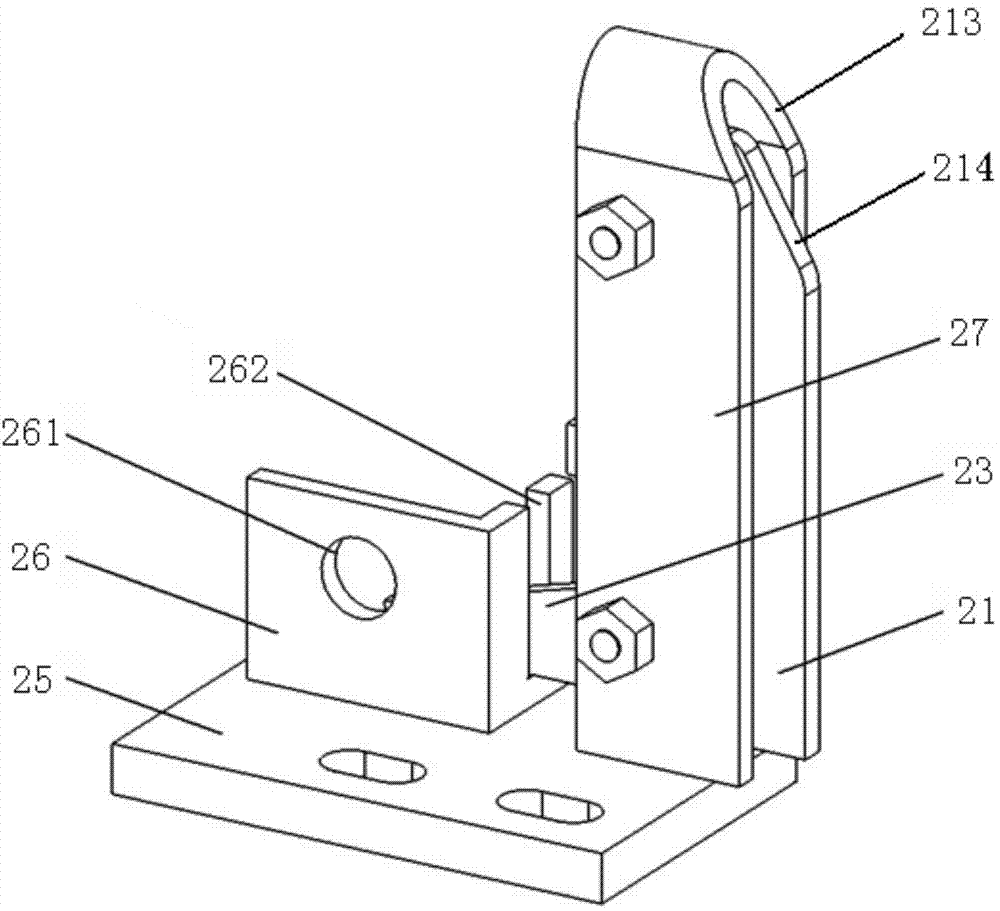

Device for remotely-operated vehicle (ROV) to quickly mount and replace sensor on deepwater platform anchor chain underwater

InactiveCN104729555ASimple structureEasy to installMeasurement apparatus componentsMarine engineeringLocking mechanism

The invention provides a device for a remotely-operated vehicle (ROV) to quickly mount and replace a sensor on a deepwater platform anchor chain underwater and belongs to ocean platform equipment. By adopting the device, unmanned mounting and replacing of the sensor on the deepwater platform anchor chain can be achieved through the ROV. The device comprises an upper frame, a lower frame, a sensor bearing and positioning cylinder and a locking mechanism, wherein the upper frame and the lower frame are fixed to the anchor chain through the locking mechanism; the sensor bearing and positioning cylinder is matched with the upper frame in a clamped mode and fixed to the upper frame; the lower frame is of a hollow structure with a rectangular cross section; the upper frame is of a structure formed by welding a bent steel plate and a cylinder together; the sensor bearing and positioning cylinder is of a cylinder structure provided with a handle matched with an underwater robot arm, and the cylinder seals up the sensor and can resist external pressure. The sensor fixing device is simple in structure and brings convenience to the ROV to quickly mount and replace the self-contained sensor underwater, and the mounting accuracy and reliability are guaranteed.

Owner:DALIAN UNIV OF TECH

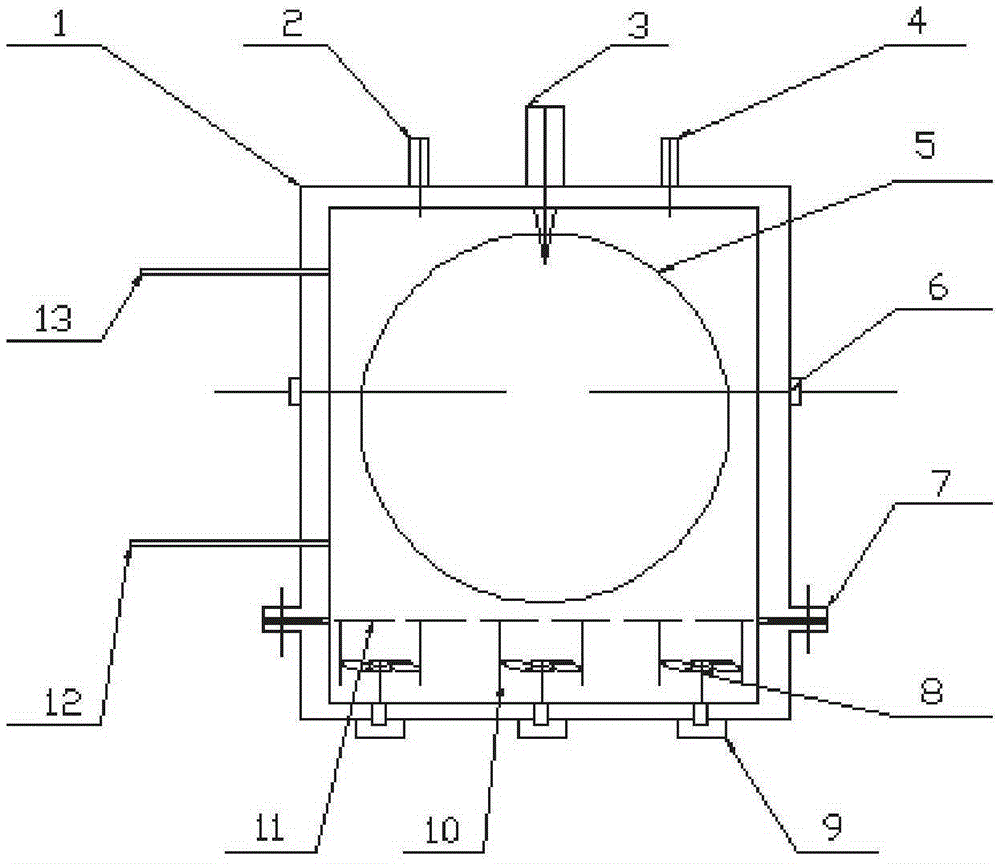

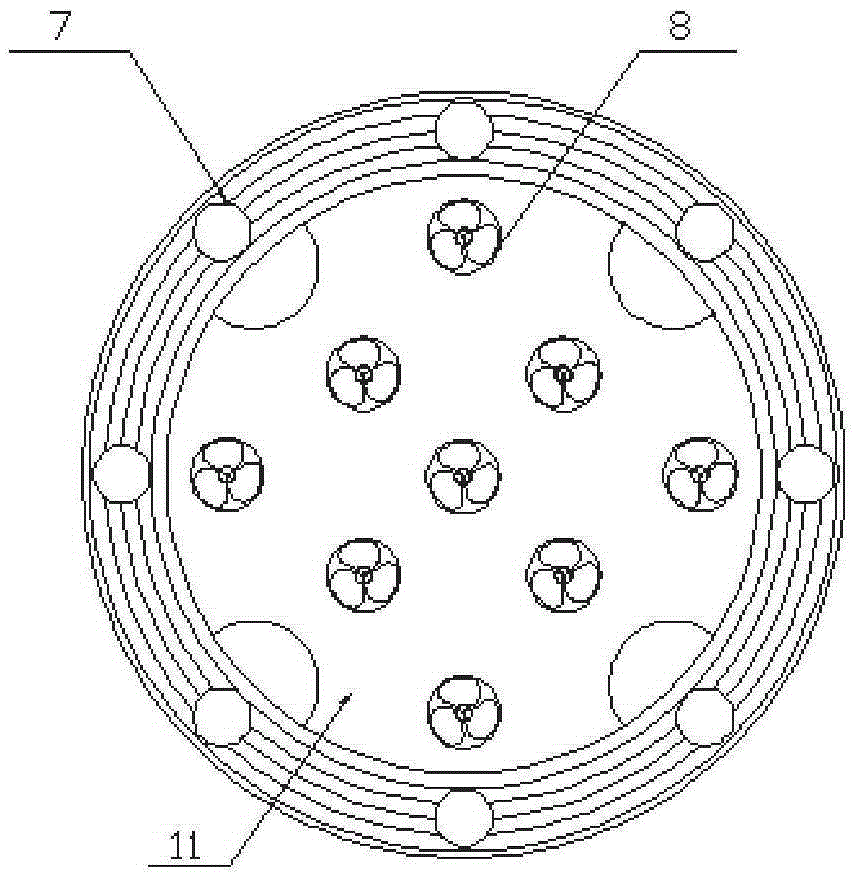

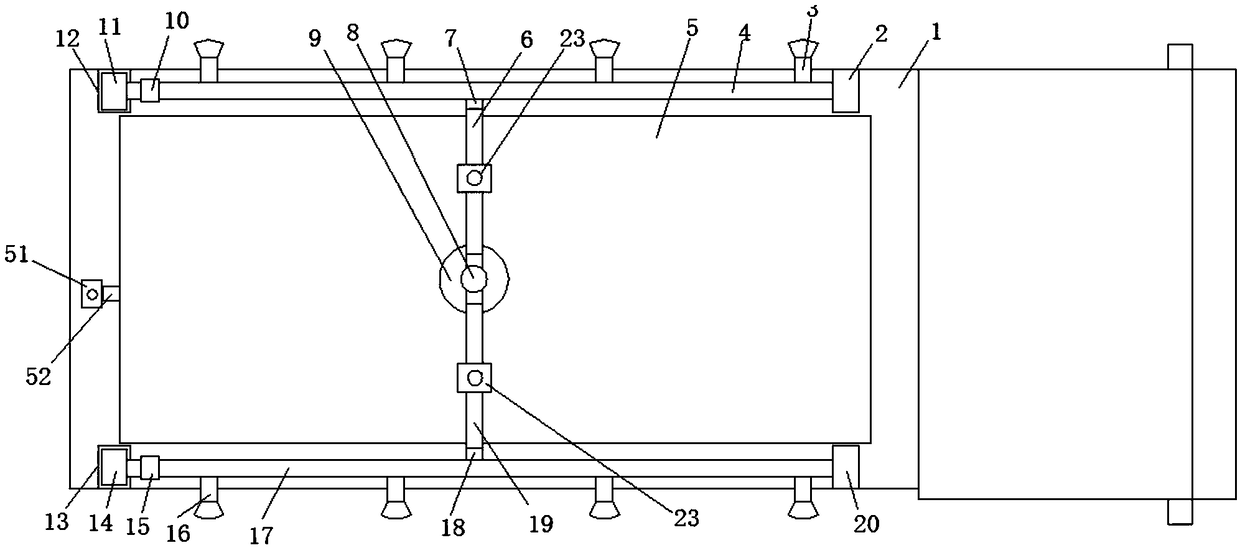

Test constant volume bomb controllable in turbulent flow intensity and position, and control method

ActiveCN105352736AAvoid mutual interferenceAccurately achieve target turbulenceEngine testingEngineeringUltimate tensile strength

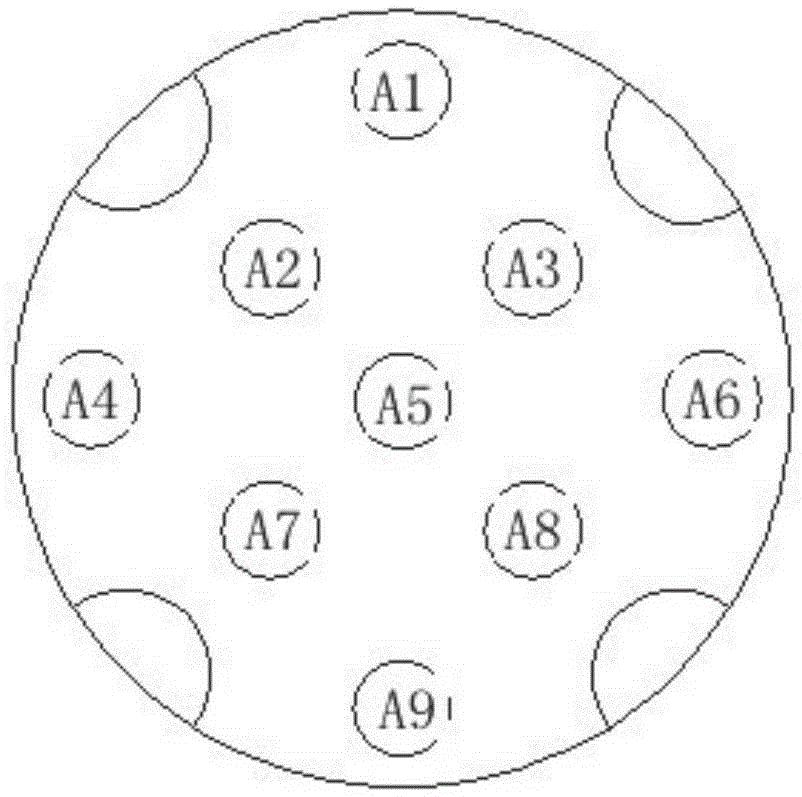

The invention discloses a test constant volume bomb controllable in turbulent flow intensity and position, and a control method. The constant volume bomb apparatus comprises a temperature sensor, a pressure sensor, a fuel injector, air inlet and air outlet pipes, turbulent flow generation modules, a PLC control module, etc. The turbulent flow generation modules are nine miniature axial-flow fans that are arranged evenly, and the nine miniature axial-flow fans are connected to the bottom end of the constant volume bomb through bolts. On the basis of human setting, a host computer test system and a PLC are adopted to control the starting scheme and the rotating speed of axial-flow fans, so turbulent flows with required intensity and position are achieved. The test constant volume bomb has a simple structure. Target turbulent flows with required accurate intensity and position can be automatically achieved as long as bolts are utilized to fix turbulent flow generation devices in an initial stage of a test and parameters are adjusted externally. The process of mounting and dismounting the test constant volume bomb is simplified, and the test constant volume bomb plays a significant role in researching the combustion process and the characteristics of fuels in conditions of different turbulent flow intensities and different generation positions.

Owner:JIANGSU UNIV

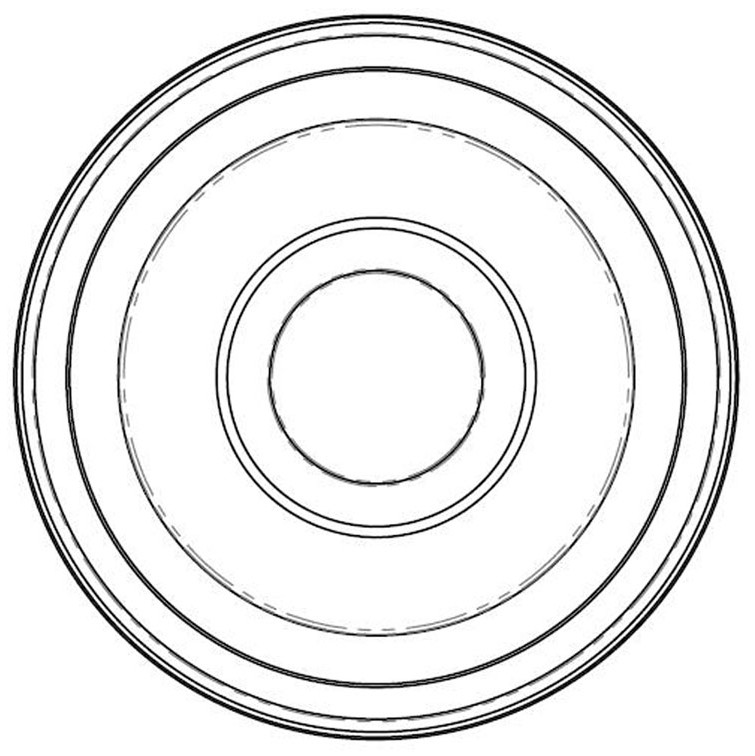

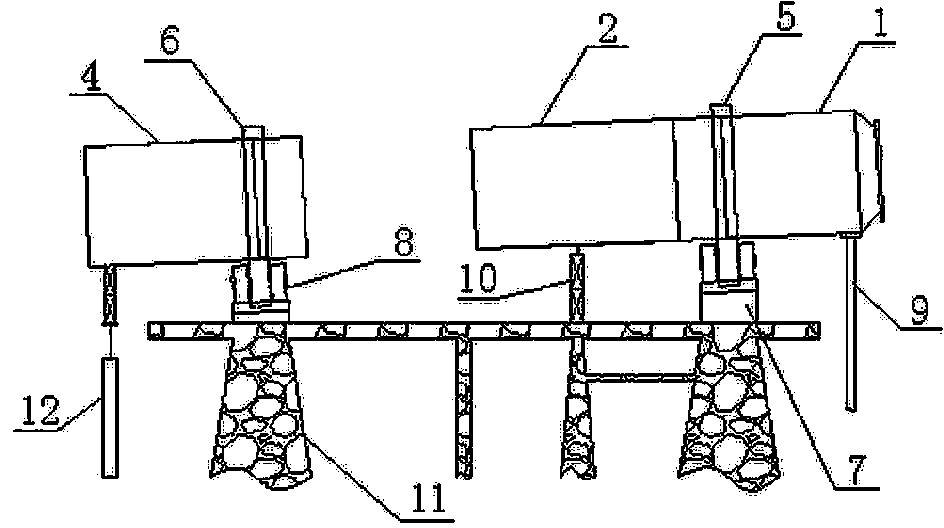

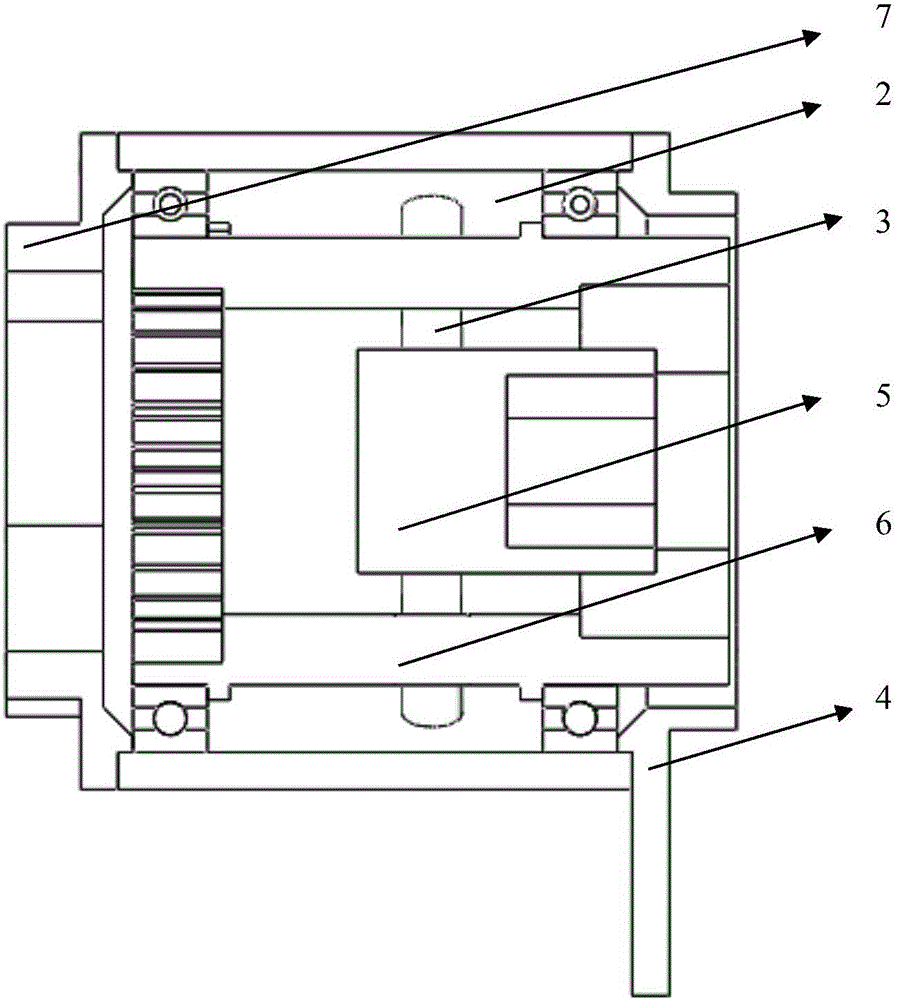

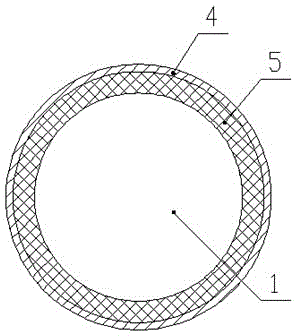

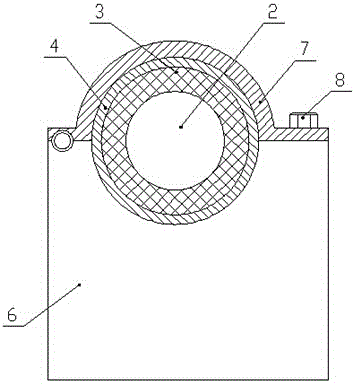

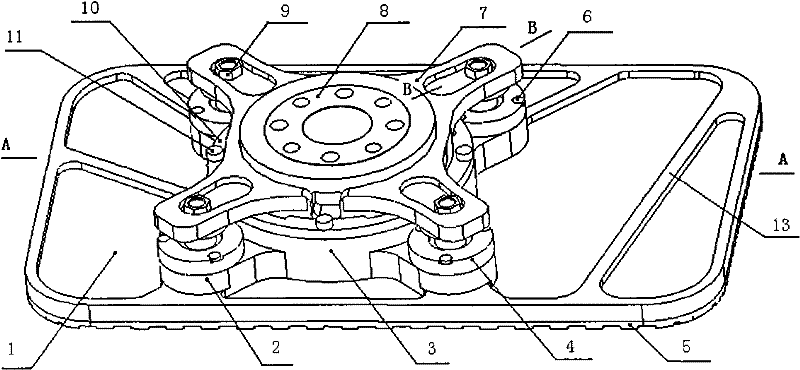

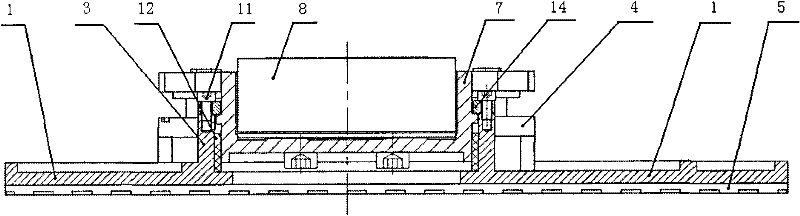

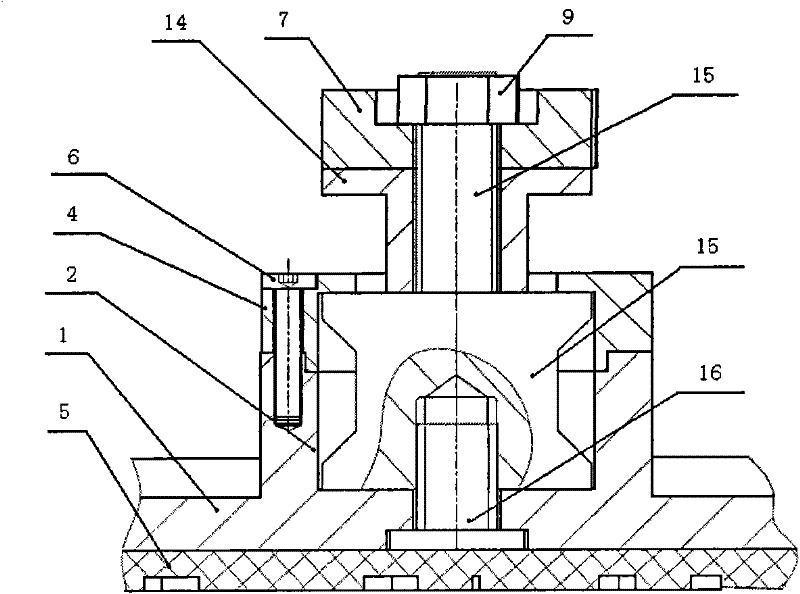

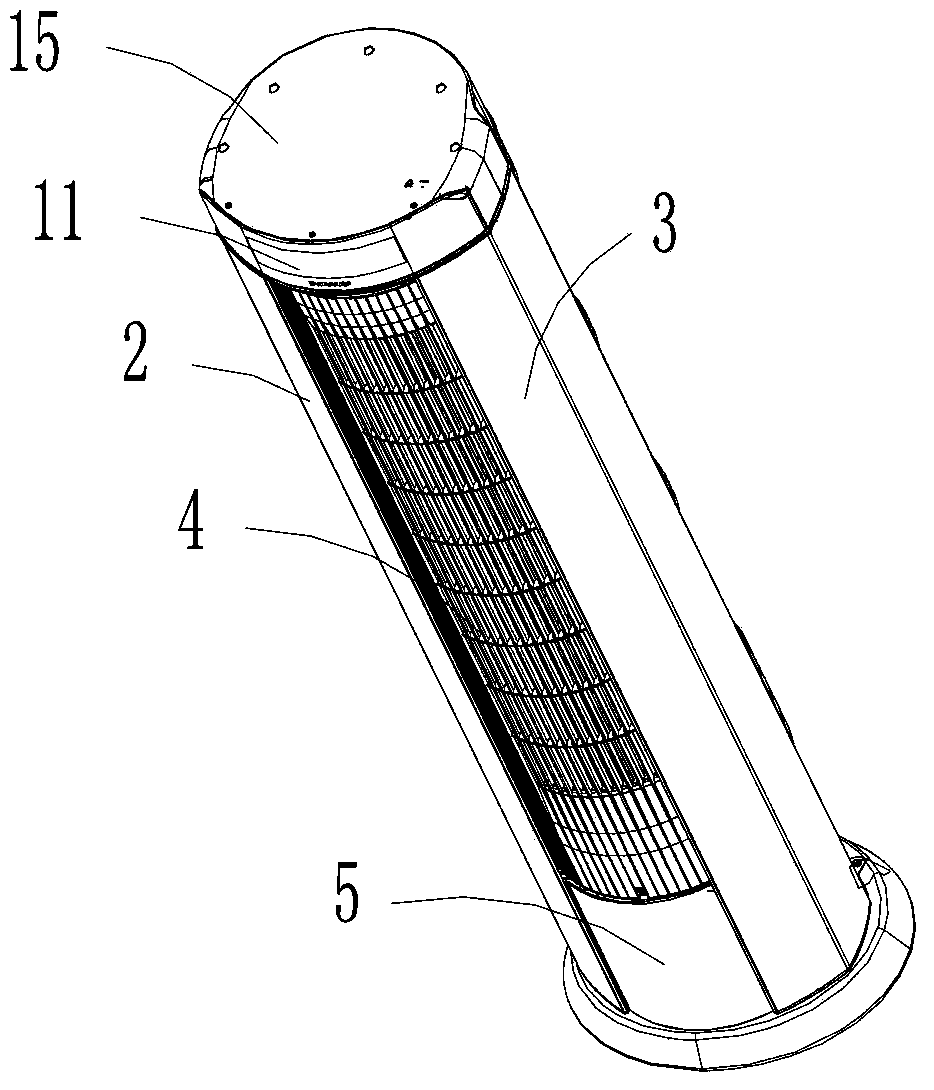

Solar photovoltaic tracking system angle position feedback module

ActiveCN102289232AHigh concentricityGuaranteed concentricityControl using feedbackCouplingEngineering

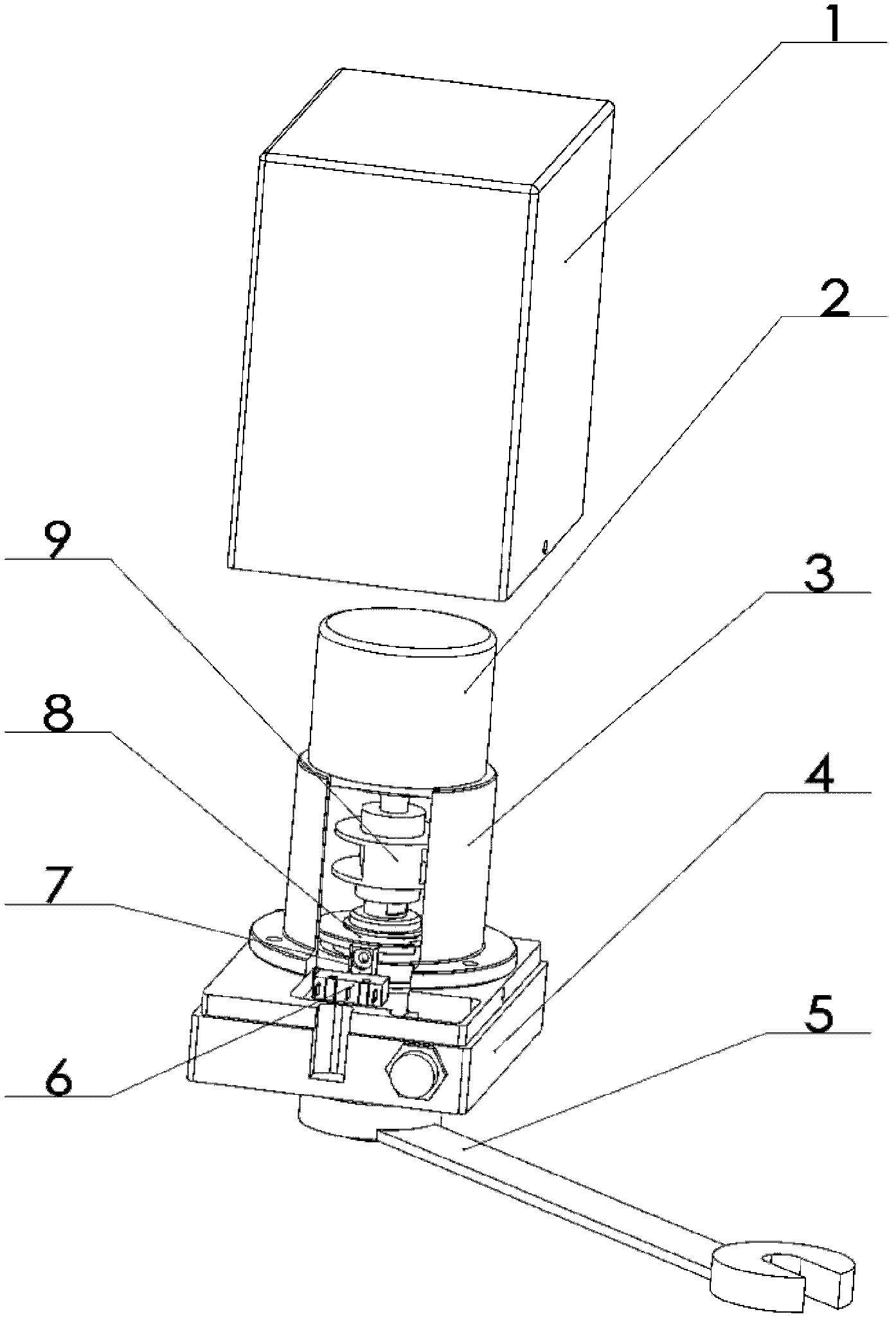

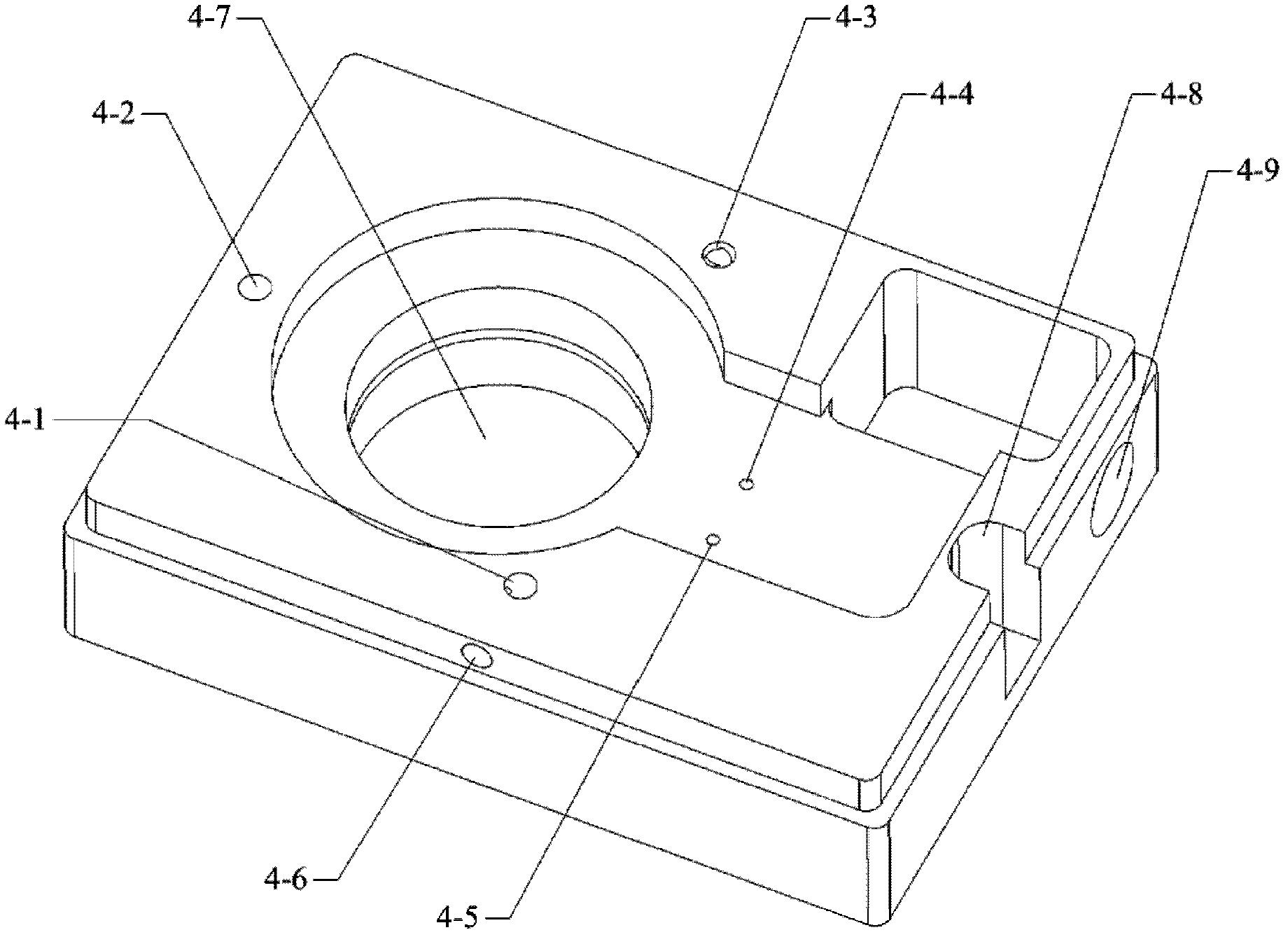

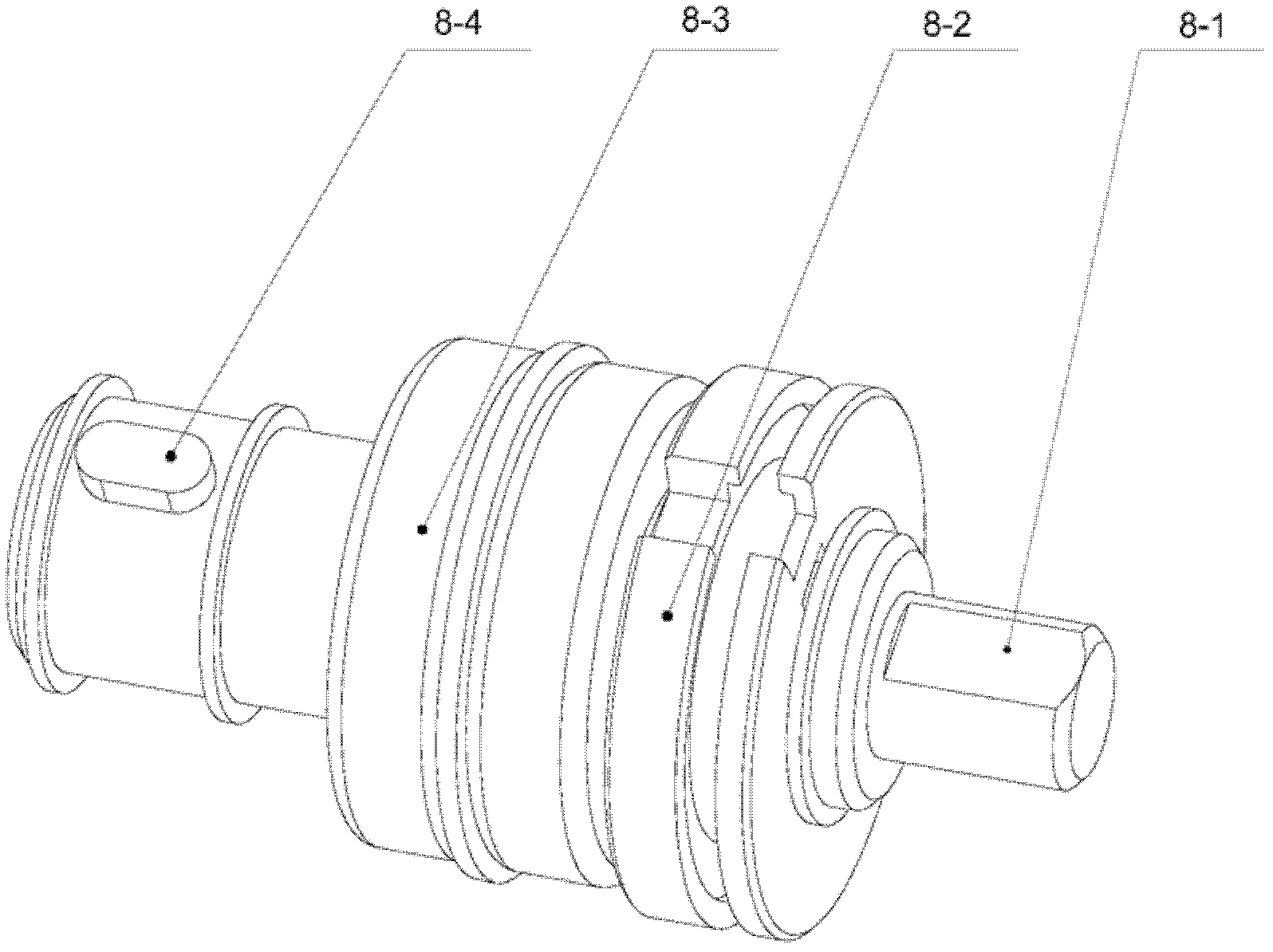

The invention discloses an angular position feedback module of a sun photovoltaic tracking system. The angular position feedback module is composed of a shell (1), a rotary encoder (2), a coded disc installation rack (3), a module base (4), a connecting rod (5), a limiting switch (6), a sliding block, a central shaft combination (8) and a flexible coupling (9). The shell (1) covers the module base (4), the rotary encoder (2), the coded disc installation rack (3), the limiting switch (6), the sliding block (7), the upper half part of the central shaft combination (8) and the flexible coupling (9) are sealed in a seal cavity consisting of the shell (1) and the module base (4). By integrating two functions of angular size feedback and extreme position alarming, the angular position feedback module provided by the invention has high integral protection level in comparison with the way of using independent components; meanwhile, the protection design for a sensor is added, a limiting angleis convenient for adjusting, the transport and installation are convenient; therefore, the angular position feedback is more stable and reliable.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

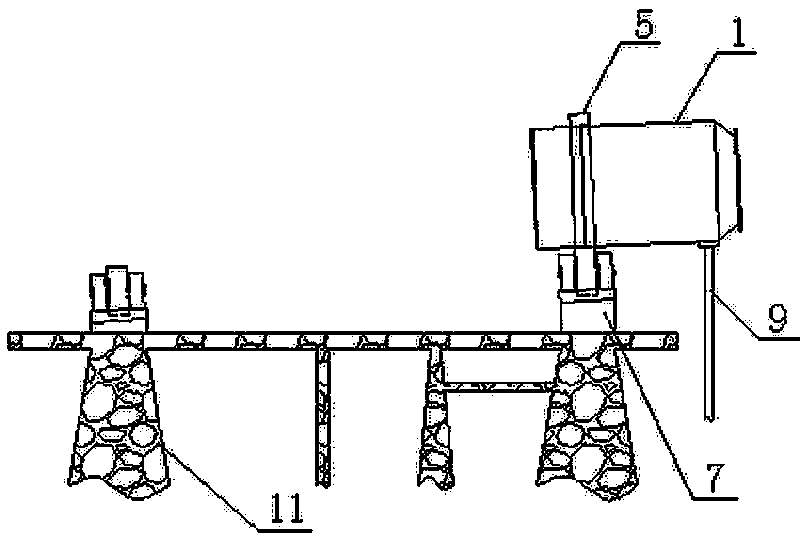

Rotary kiln barrel mounting method

ActiveCN103557693AGuaranteed installation reliabilityGuaranteed stabilityRotary drum furnacesEngineeringMechanical engineering

The invention discloses a rotary kiln barrel mounting method which includes the steps: (a) mounting a kiln tail barrel; (b) mounting a first rolling ring; (c) mounting a second barrel; (d) mounting a kiln head barrel; (e) mounting a second rolling ring; (f) mounting a third barrel. By the aid of the steps, when the third barrel is mounted, a support device does not need to be set up, so that cost input is reduced, and construction period is shortened.

Owner:CHINA MCC5 GROUP CORP

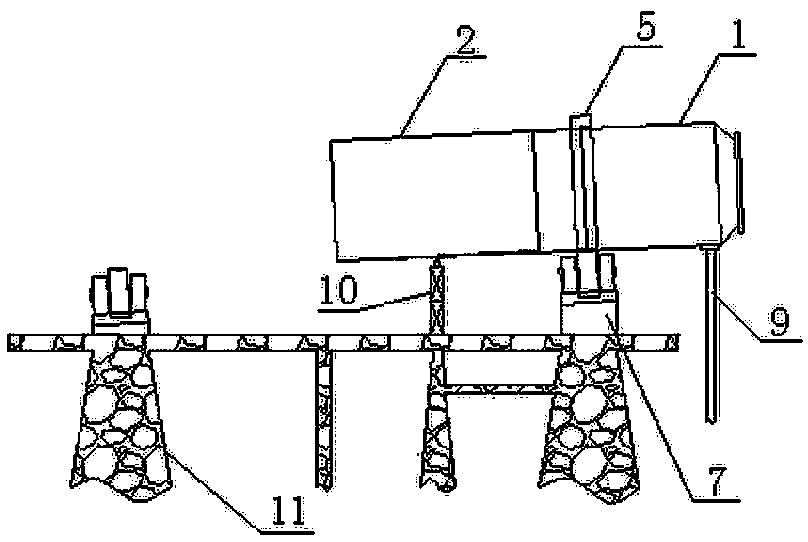

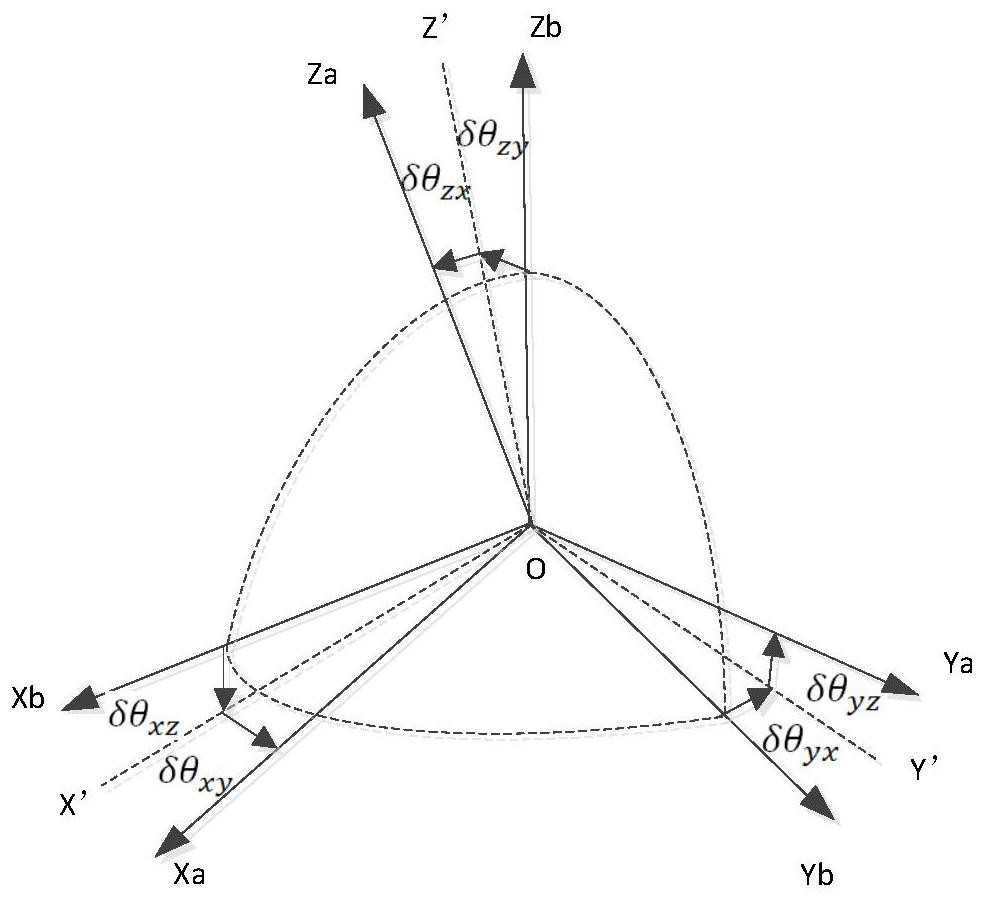

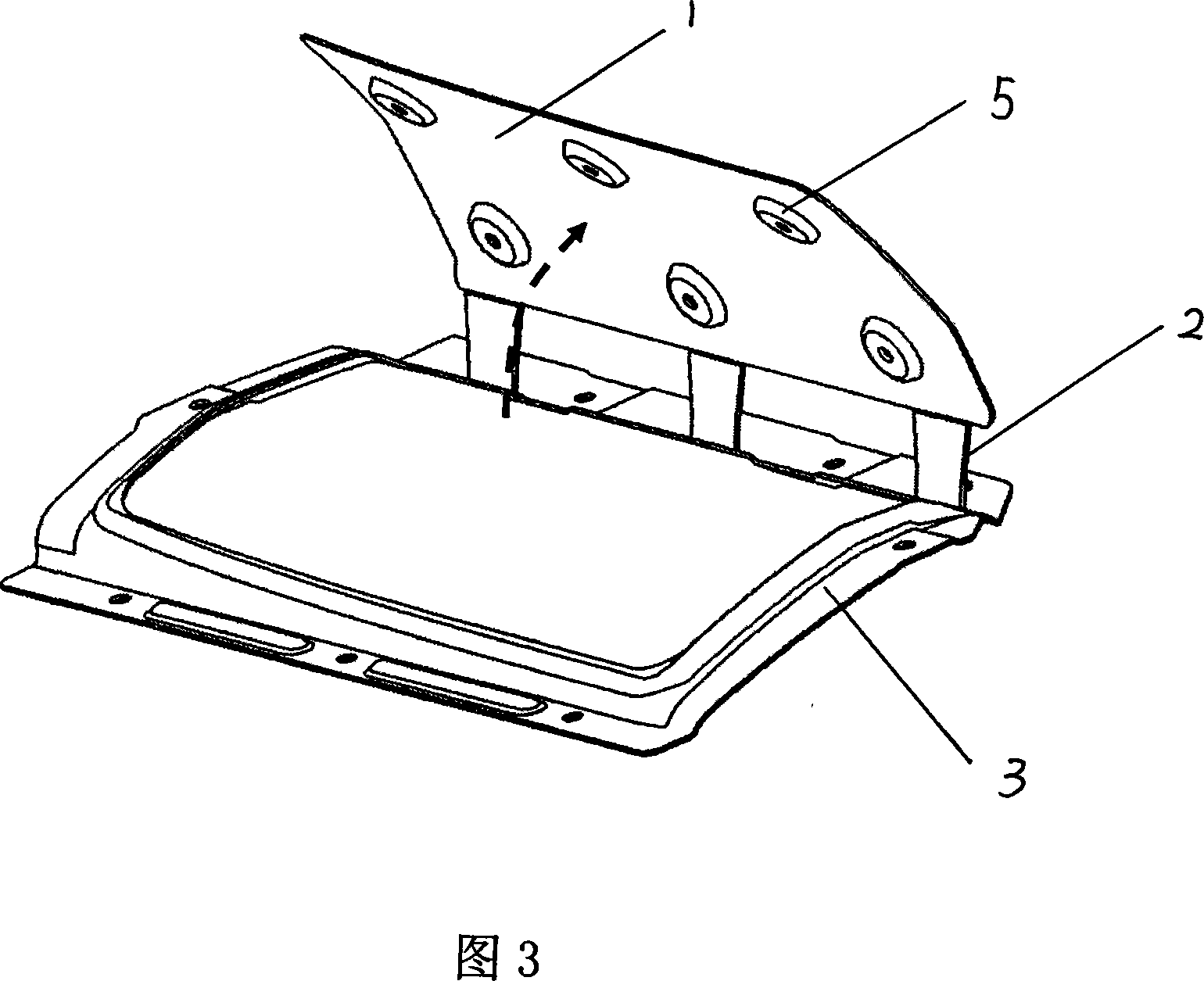

Method for calibrating and compensating installation errors of single-axis gyroscope

InactiveCN111664868AReduced measurement accuracyGuaranteed measurement accuracyMeasurement devicesGyroscopeEngineering

The invention discloses a method for calibrating and compensating installation errors of a single-axis gyroscope, belongs to the technical field of installation errors of fiber-optic gyroscopes and inertial measurement devices of the fiber-optic gyroscopes, particularly relates to a method for calibrating and compensating the installation errors of a fiber-optic gyroscope in an inertial measurement device of the single-axis gyroscope, and can be applied to the technical field of assembly of the inertial measurement devices. According to the method, the installation error angles relative to allthe axial directions are measured through projection of the angular velocity caused by installation errors on a sensitive shaft, then, the height needing to be compensated is calculated according tothe size of the gyroscope, the gasket meeting the compensation requirements is machined through a feeler gauge, and the effects of reducing the installation errors and improving the measurement precision of the gyroscope are achieved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

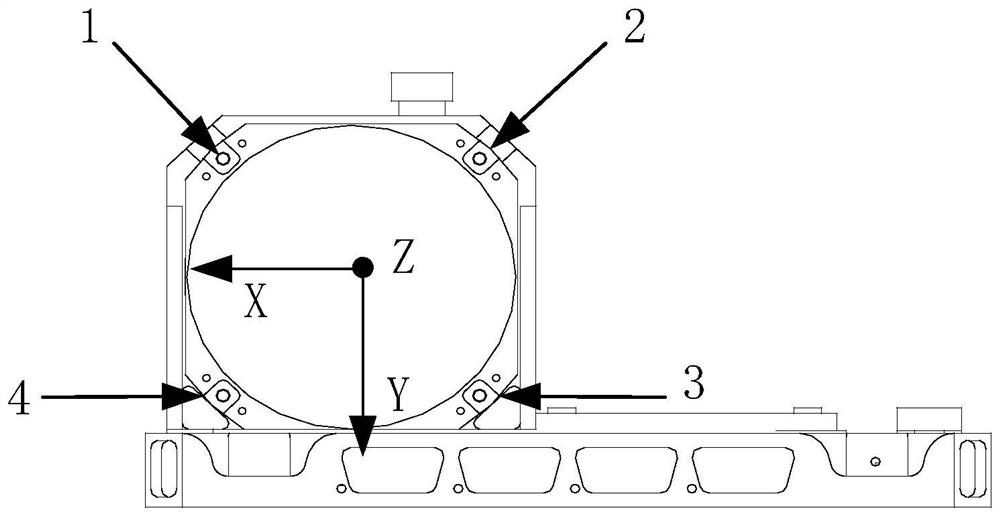

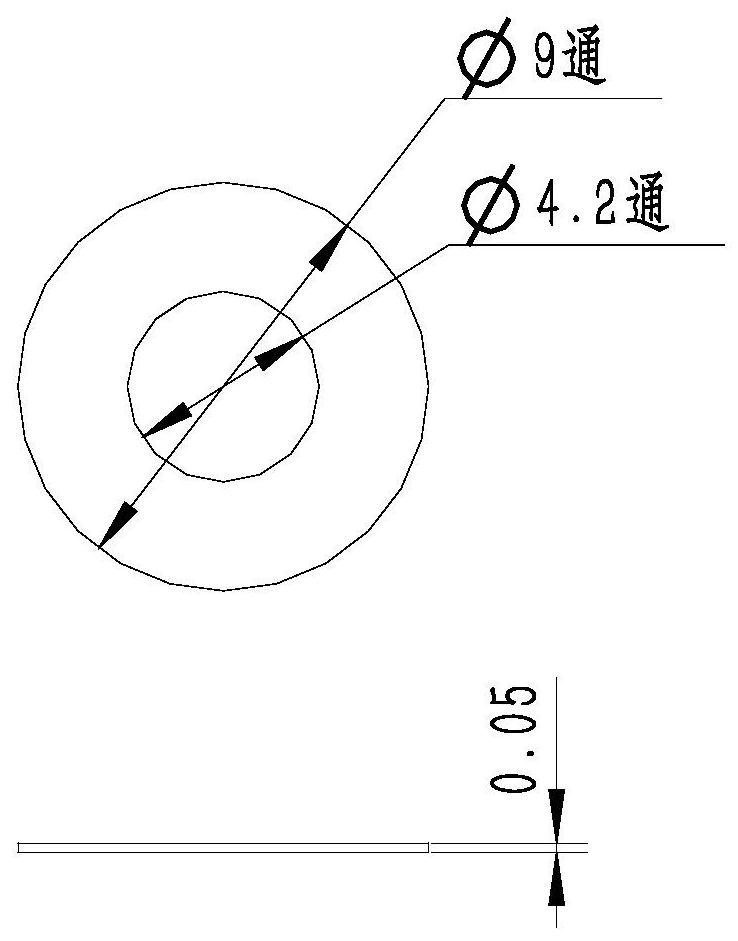

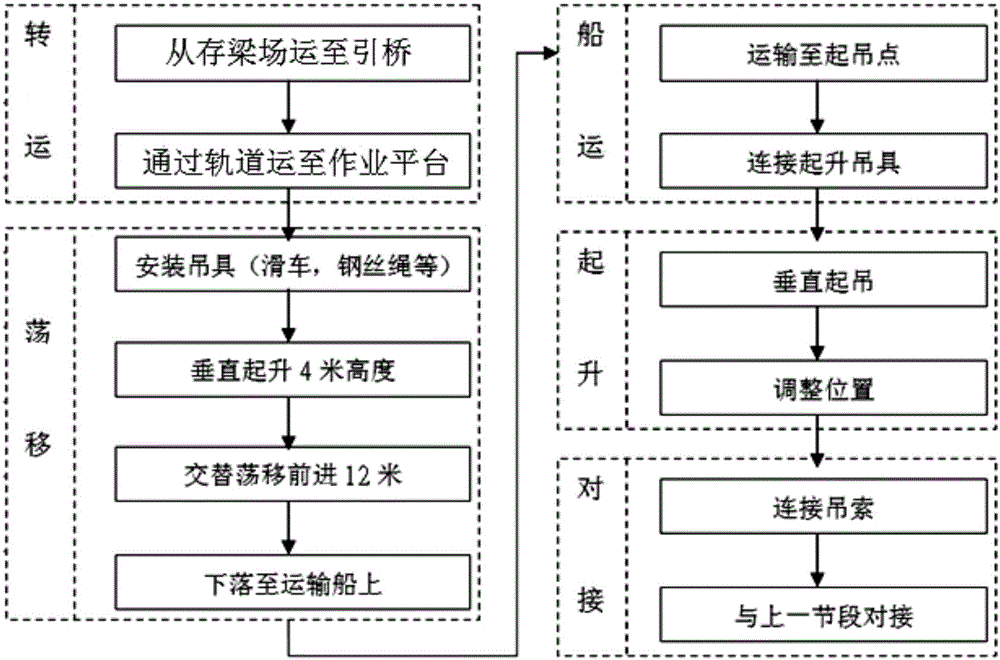

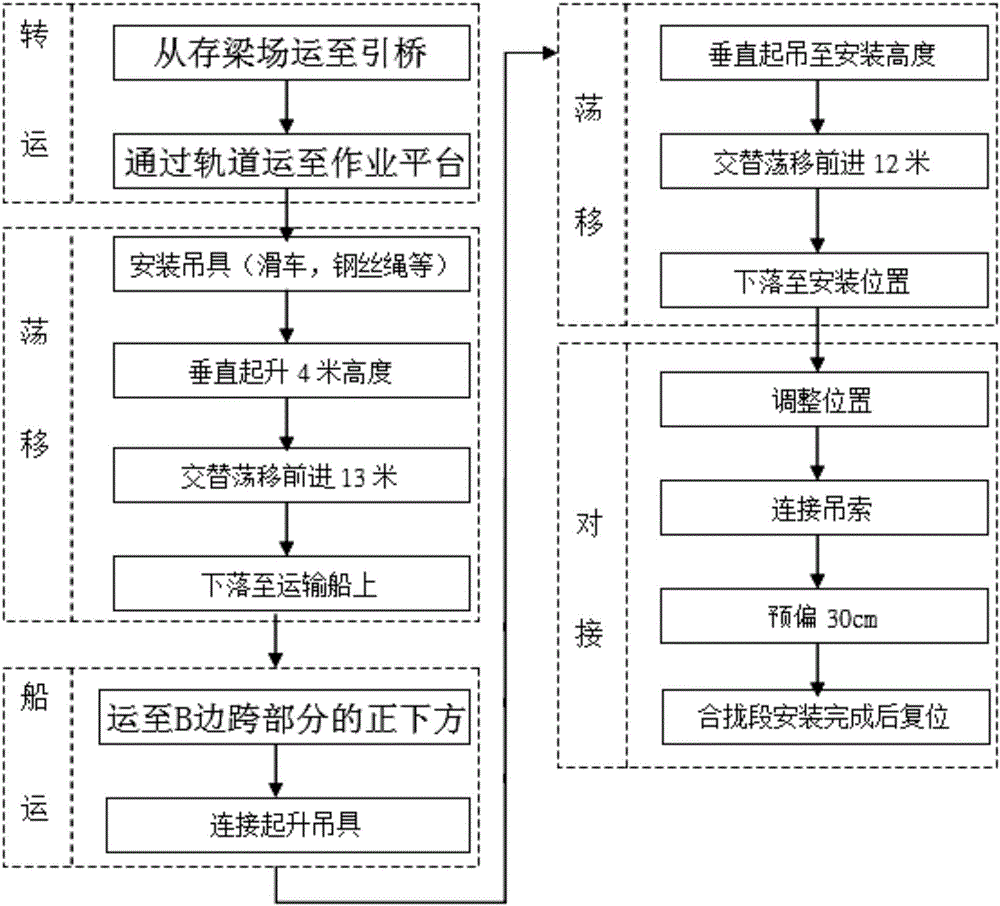

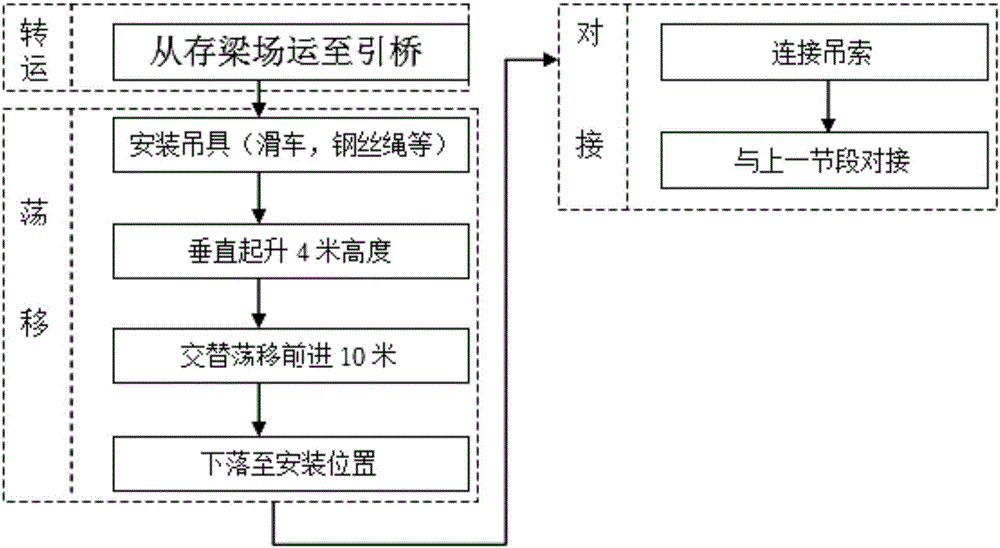

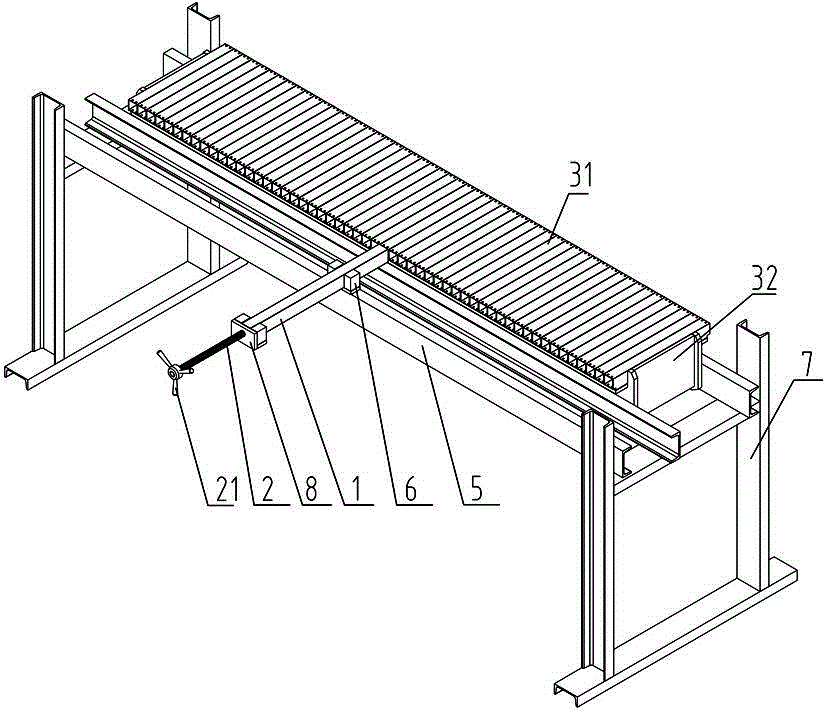

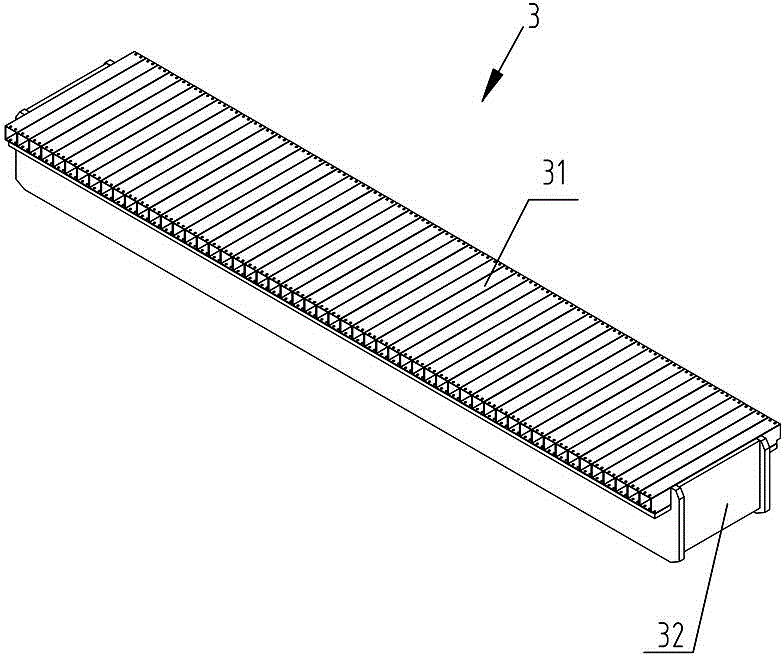

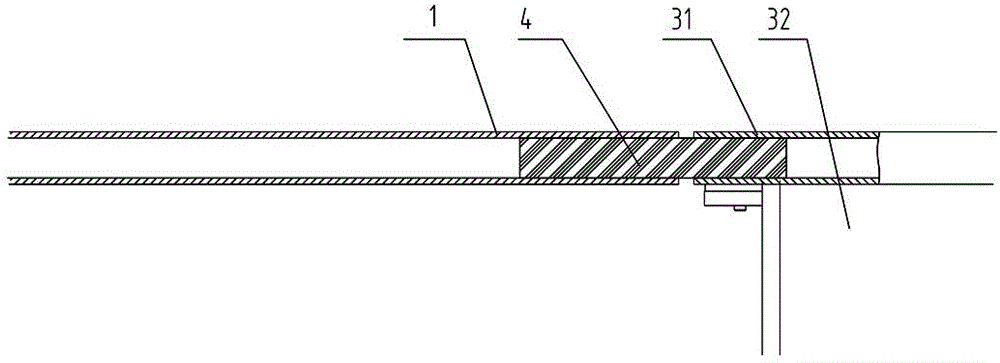

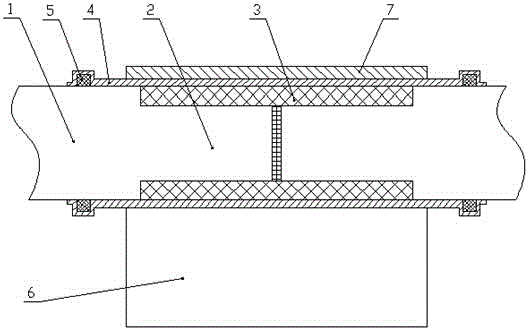

Method for installing stiffening beam of suspension bridge over navigable river and swing shift system used in method

ActiveCN106049293AGuaranteed installation reliabilityReduce investmentSuspension bridgeBridge erection/assemblyEngineeringYard

The invention discloses a method for installing a stiffening beam of a suspension bridge over a navigable river and a swing shift system used in the method. The suspension bridge is an earth-anchored suspension bridge of a two-tower three-span structure and comprises a main tower A, a main tower B, a side span part A, a side span part B and a middle span part, and a beam storage yard is arranged at the position, on one side of the main tower A, of a shore base. The installation method includes the following steps that a plurality of winches are arranged at the top of the main tower A and the top of the main tower B respectively, an approach bridge is erected between the beam storage yard and the main tower A, a work platform communicated with the approach bridge is erected on the surface, back on to the approach bridge, of the main tower A, and a transport ship is prepared on the river; the middle span part, the side span part B and the side span part A are installed in sequence, wherein the middle span part is installed in the sequence of approach bridge transport, swing shift lowering, ship transport and lifting connection, the side span part B is installed in the sequence of approach bridge transport, swing shift lowering, ship transport, lifting swing shift and combination connection, and the side span part A is installed in the sequence of approach bridge transport, swing shift positioning and combination connection.

Owner:DEYANG TIANYUAN HEAVY IND

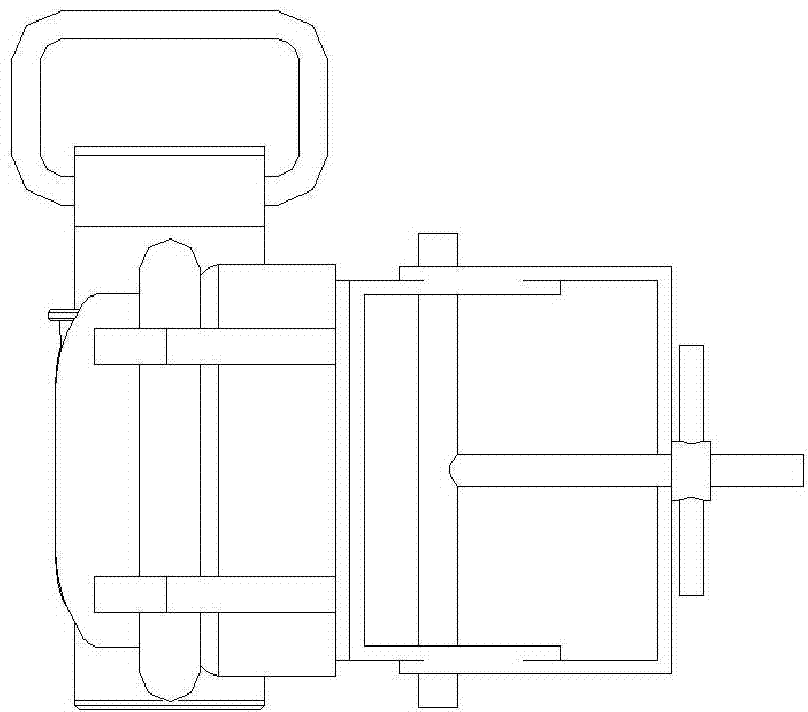

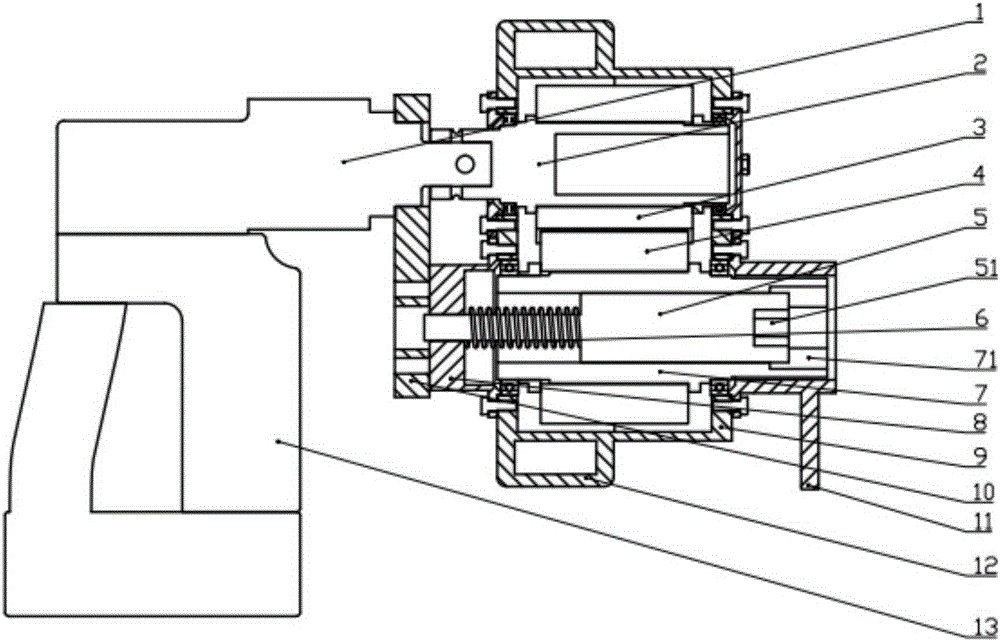

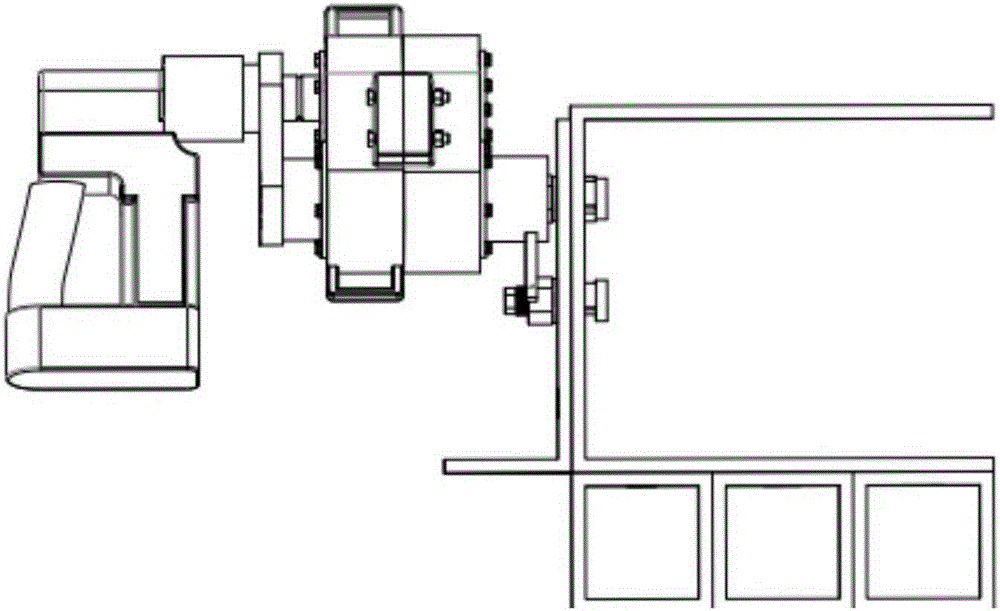

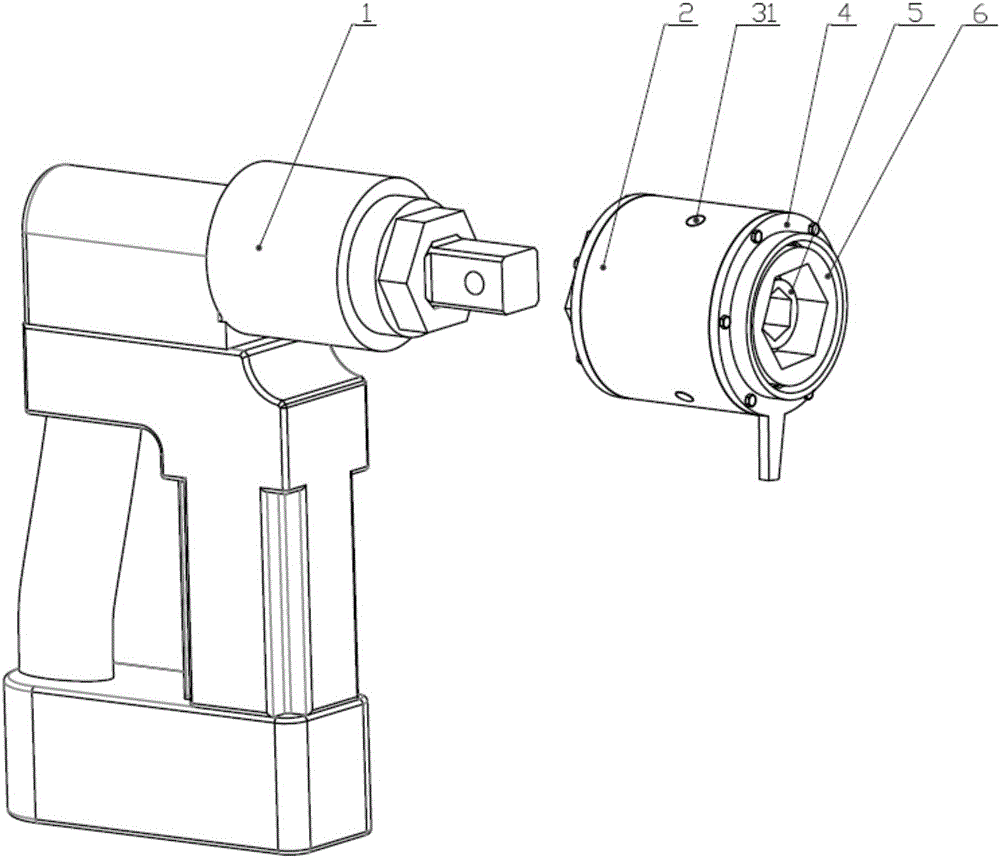

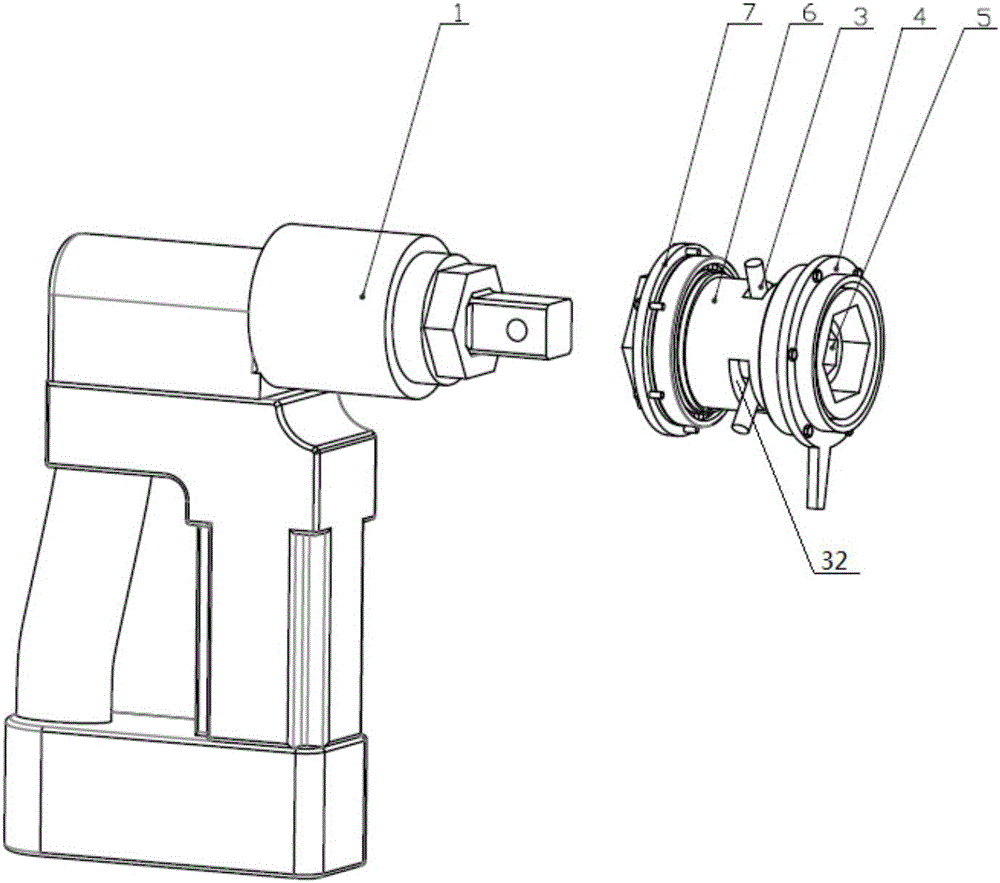

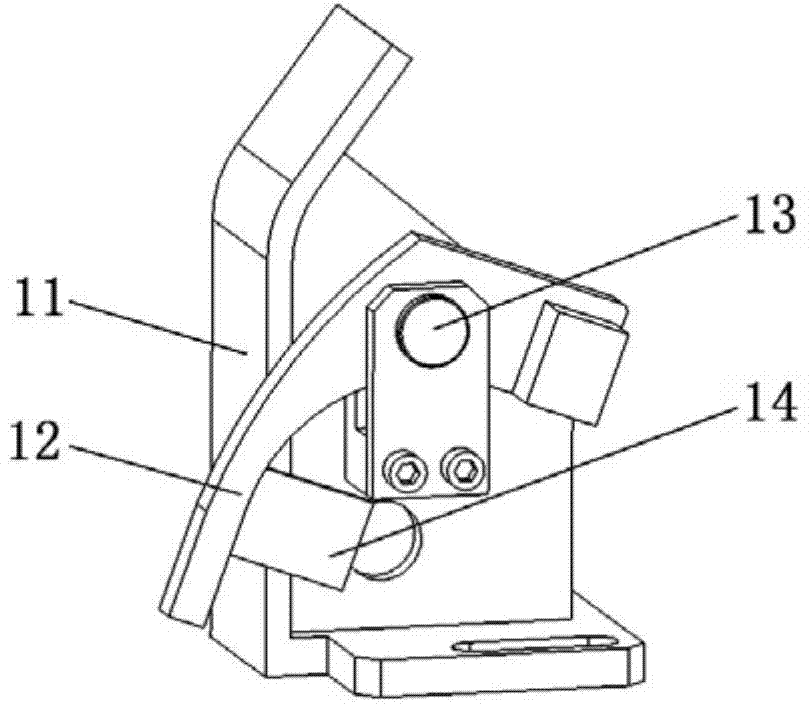

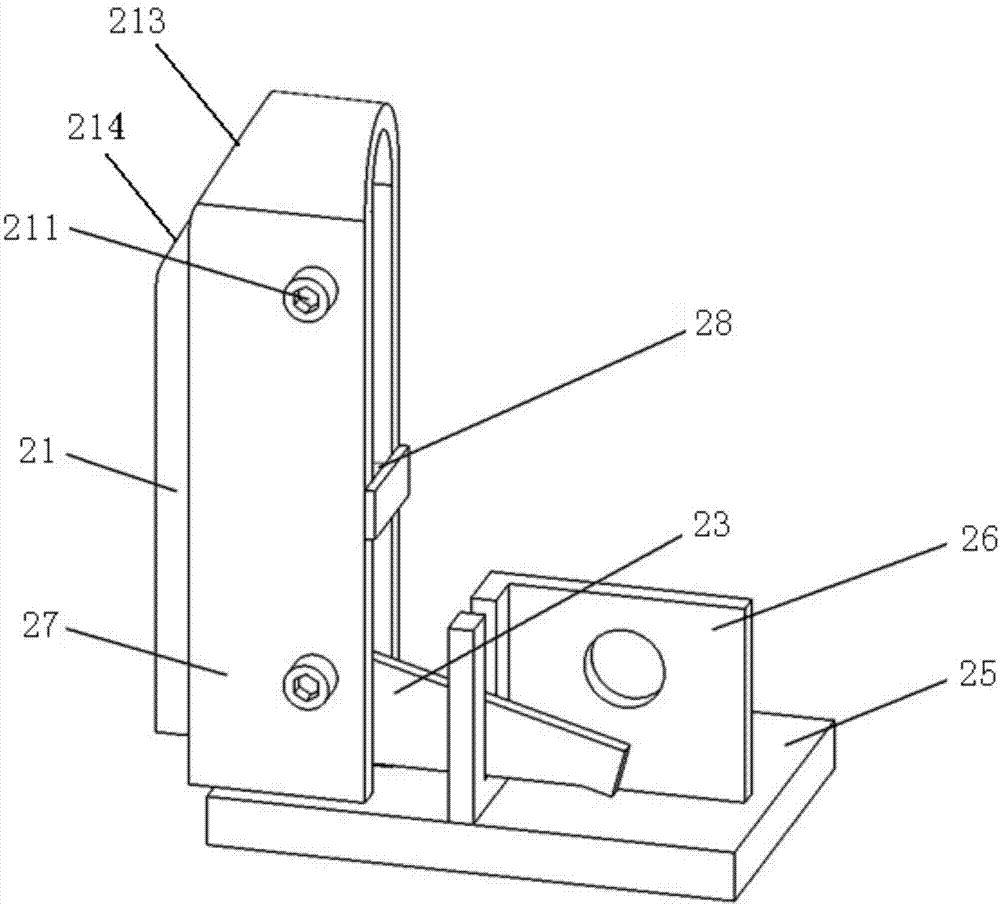

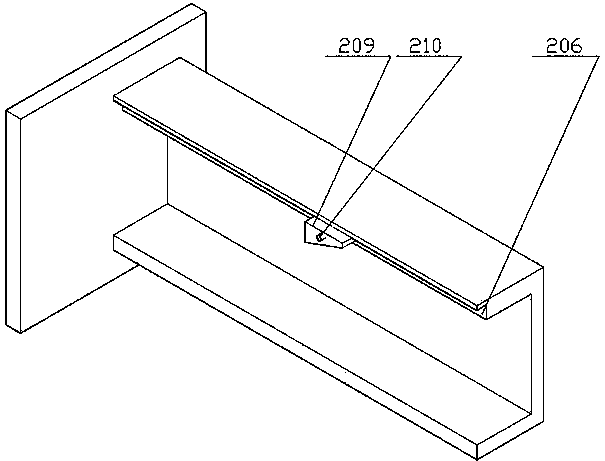

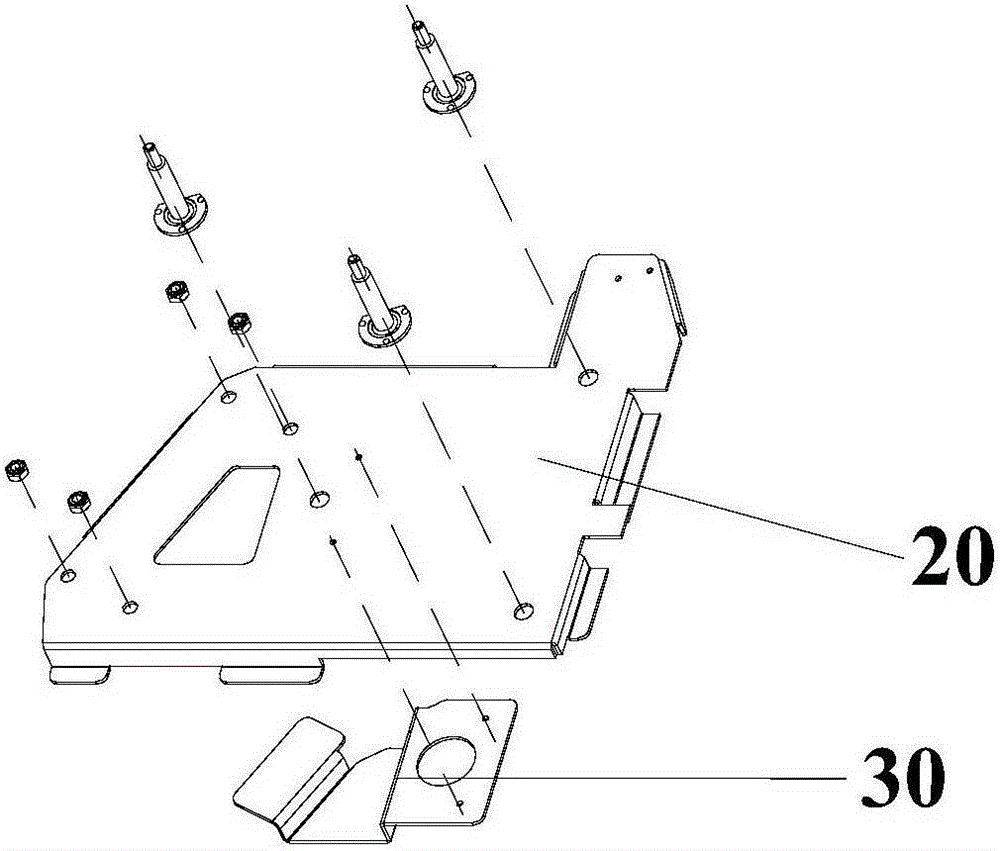

Electric mounting tool for split nested one-sided bolt fastener

ActiveCN105328650AGuaranteed installation reliabilityGood mechanical propertiesPortable power-driven toolsPower driven toolsFastenerGasket

The invention relates to an electric mounting tool for a split nested one-sided bolt fastener, which is used for mounting the split nested one-sided bolt fastener. The bolt fastener comprises a bolt (14), a nut (16) and a split gasket (15); the tool comprises a main body, an input mechanism and an output mechanism; the input mechanism and the output mechanism are arranged on the main body; the output mechanism comprises an inner output shaft sleeve (5) and an outer output shaft sleeve (7) sleeving the inner output shaft sleeve (5); a first gear (4) which is connected with the input mechanism in a meshing way is arranged on the outer wall of the outer output shaft sleeve (7); the inner output shaft sleeve (5) is fixed on the main body; the outer output shaft sleeve (7) is connected with the nut (16); the inner output shaft sleeve (5) is connected with the bolt (14); and the input mechanism rotates and drives the outer output shaft sleeve (7) to rotate via the first gear (4), so that the bolt (14) and the nut (16) rotate relatively to finish mounting. Compared with the prior art, the electric mounting tool has the advantages of high reliability, high adaptability and simple structure.

Owner:TONGJI UNIV

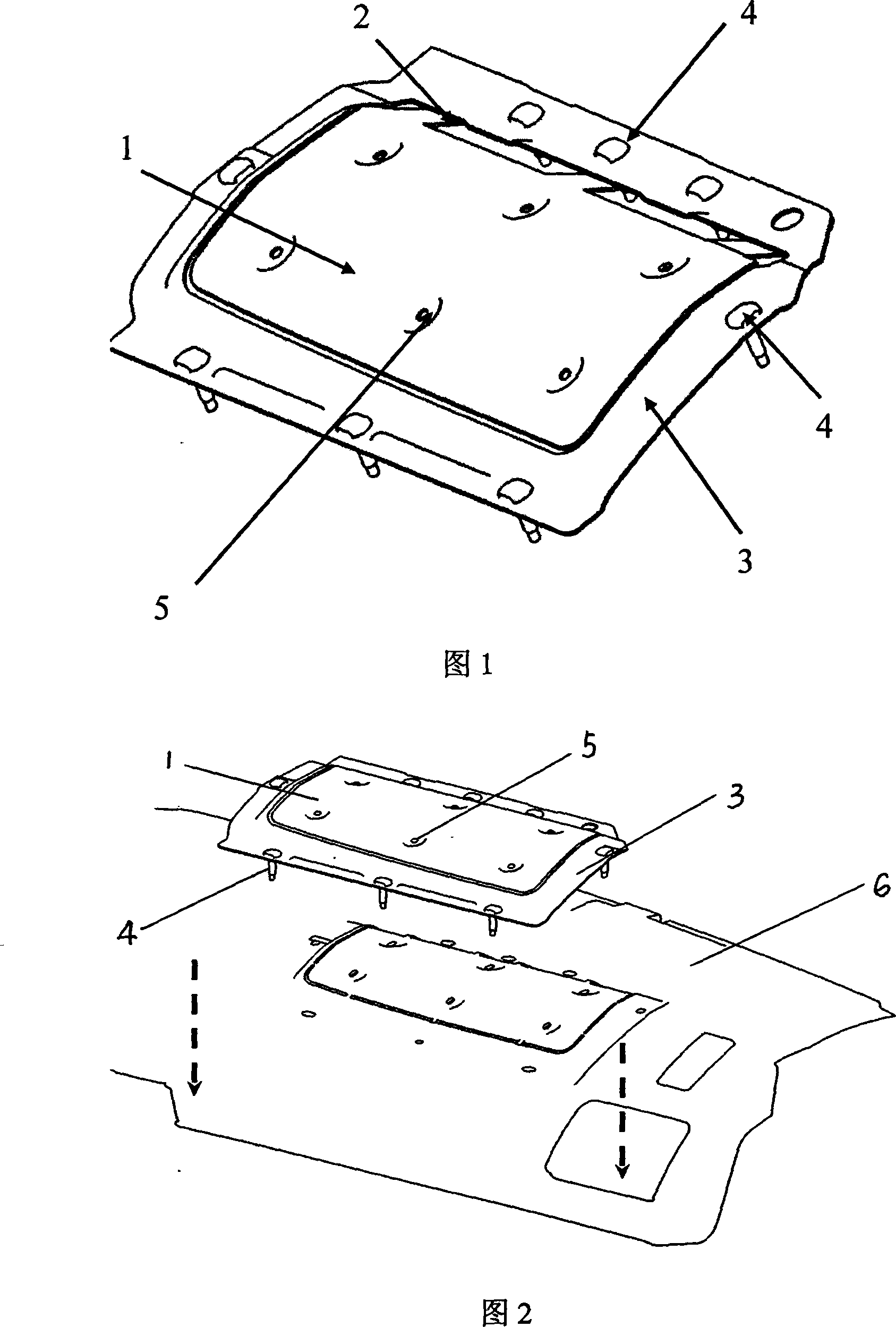

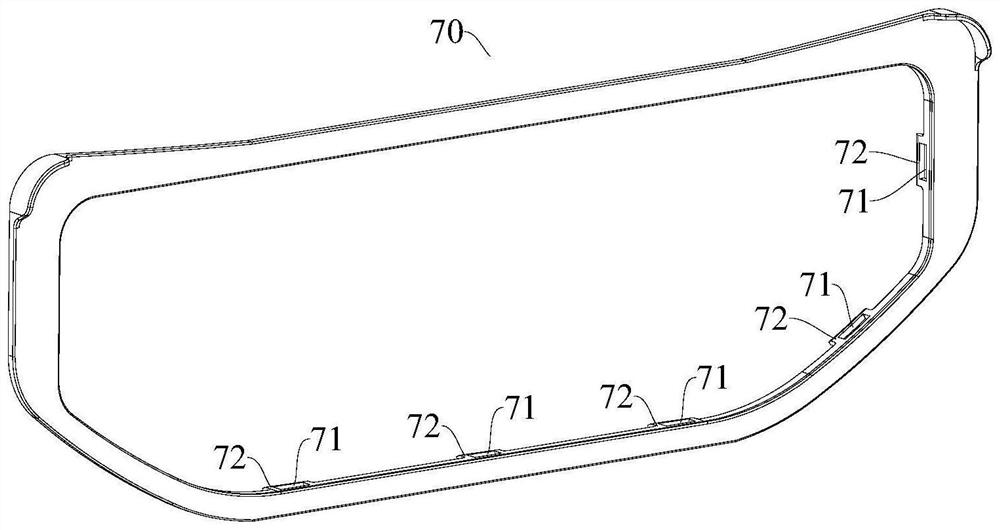

A mixed mode expansion plate of automobile safety air bag

InactiveCN101161510AGuaranteed positional stabilityGuaranteed installation reliabilityPedestrian/occupant safety arrangementComplex typeEngineering

The invention relates to a complex type unfolding plate of vehicle safety air chamber comprising a main body of unfolding plate and a frame of unfolding plate. The main body of the unfolding plate is connected with the frame of the unfolding plate by hinge. The frame of the unfolding plate is permanently connected to the position of mounting air chamber module corresponding with the main body of fascia. A counter bore is in the main body of the unfolding plate and the main body is connected with the body of the fascia by the counter bore. The counter bores are evenly dispersed on the main body of the unfolding plate to make the unfolding plate and skeleton of the fascia completely jointed with each other. The frame of the unfolding plate is permanently connected with the main body of the fascia by projection weld nut. The unfolding plate and the frame are produced by steel material. The invention uses composite plate structure of overturning hinge cooperation frame structure. The unfolding plate and the frame thereof are produced by steel material. The unfolding plate and the fascia use design of rivet joint. The structure can ensure the stability of position of the unfolding plate and the mounting reliability and strength the guiding function of the air chamber and increase the stability of guiding by the hinge.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

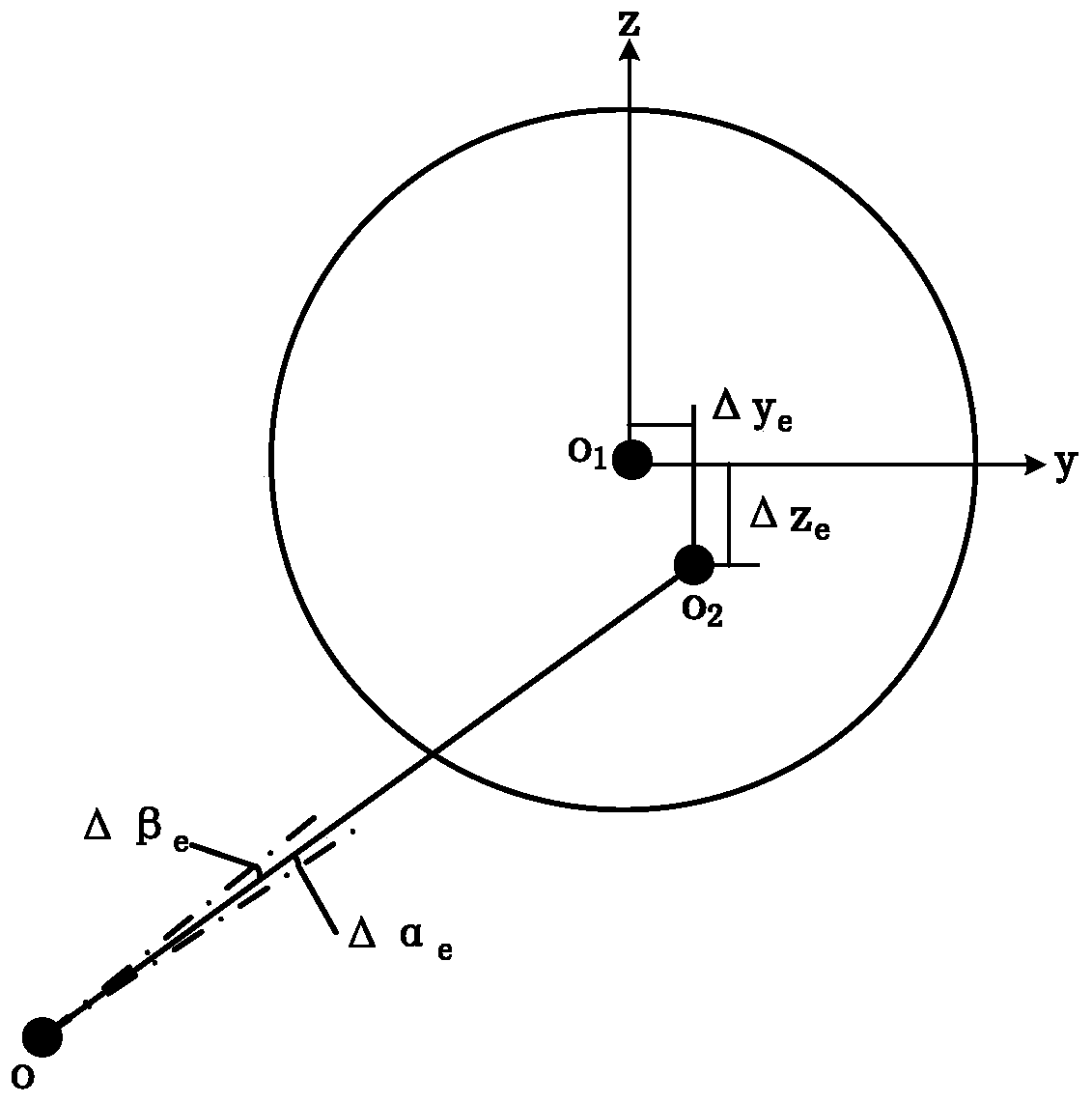

Drilling position positioning system and method of drilling machine

ActiveCN111536954AHigh positioning accuracyLow coordination requirementActive open surveying meansDirectional drillingLight spotLight beam

The invention discloses a drilling position positioning system and method of a drilling machine. The system comprises a positioning laser unit, a centering laser unit, a first laser position detectionunit, a second laser position detection unit, an inclination angle detection unit and a display unit. The positioning laser unit is used for determining the position of a tapping point on a working surface and emitting a positioning laser beam to the rear end surface of a big arm; the first laser position detection unit is installed on the rear end face and used for detecting the position of a light spot of a positioning laser beam on the rear end face. The centering laser unit is arranged on the big arm and is used for emitting a centering laser beam to a tapping point; the second laser position detection unit is installed on the working face and used for detecting the position of a light spot of the centering laser beam on the working face. The inclination angle detection unit is mounted on the big arm and used for detecting an inclination angle value of the big arm; the display unit is connected with each unit and is used for displaying the positioning information. The drilling position positioning system and method have the advantages of simple structure, high positioning precision, high automation level, high positioning efficiency and the like.

Owner:63653 FORCES PLA

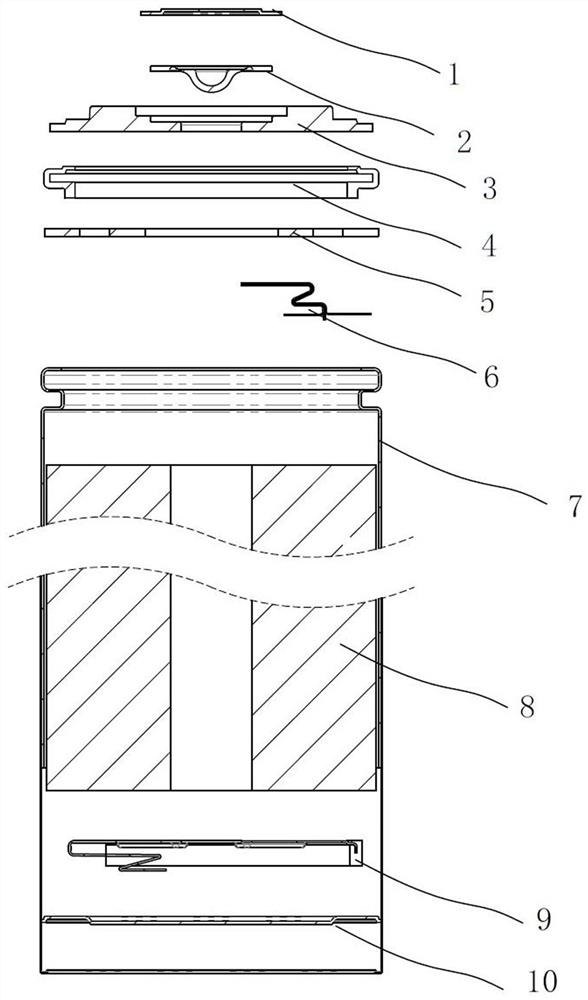

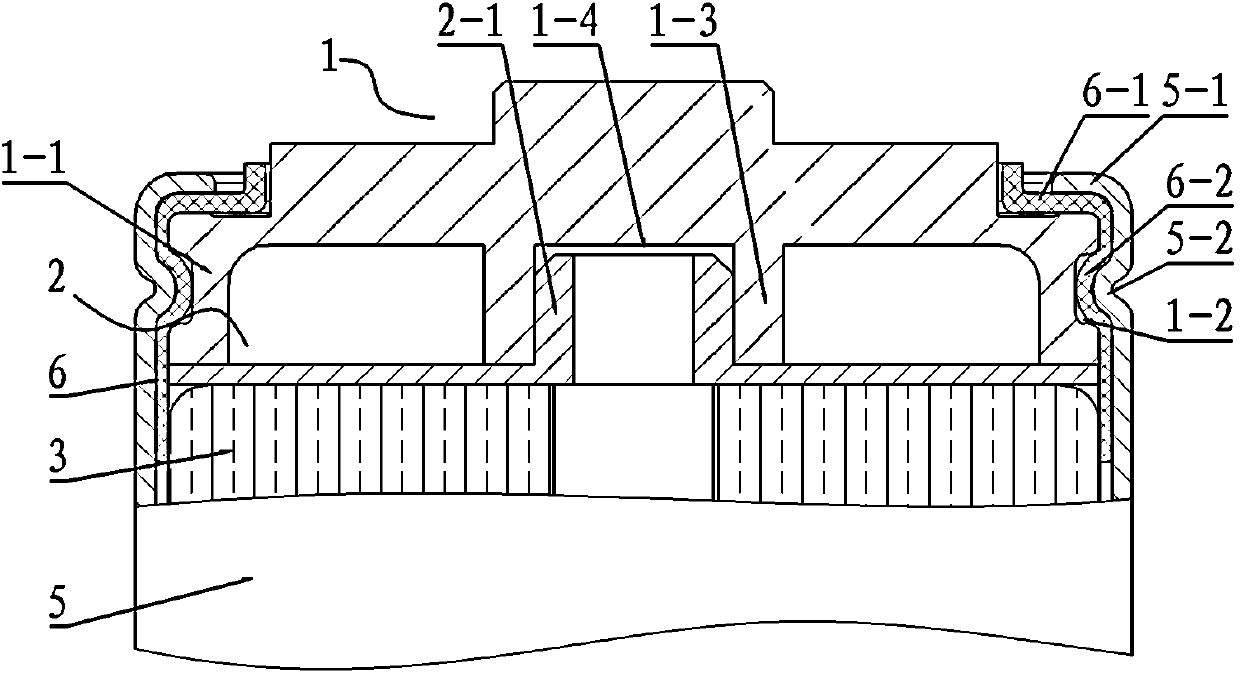

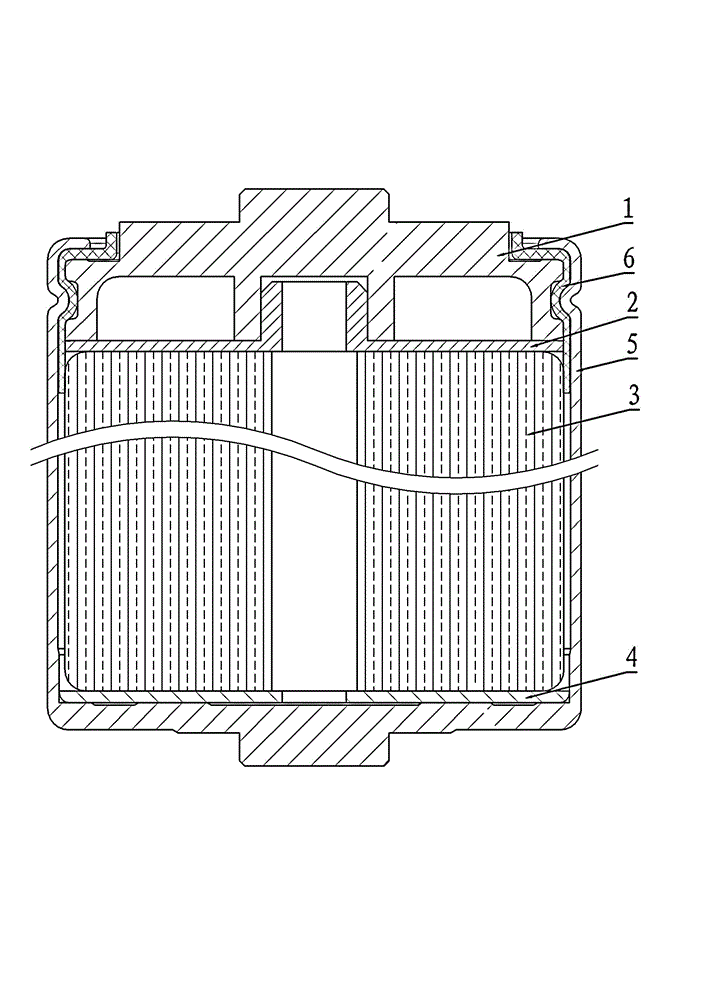

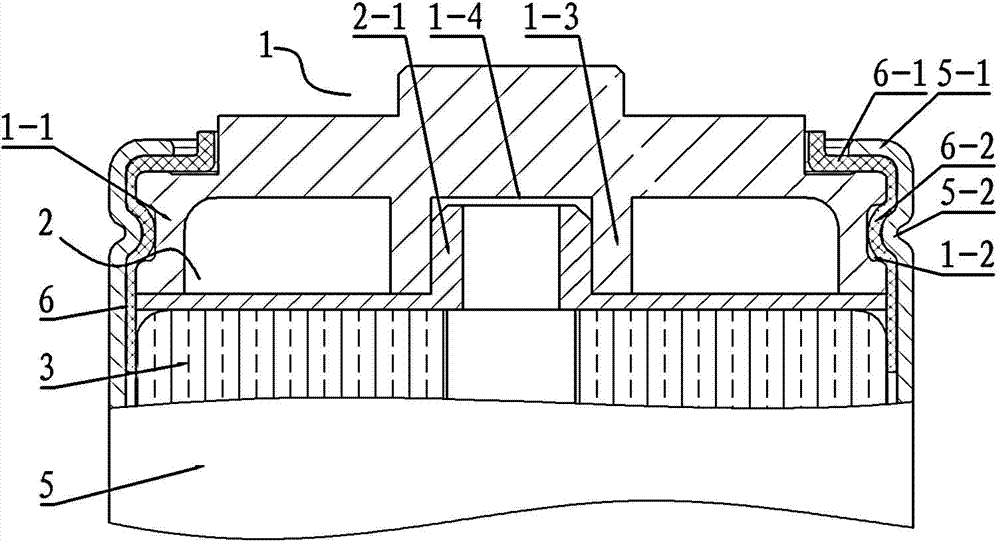

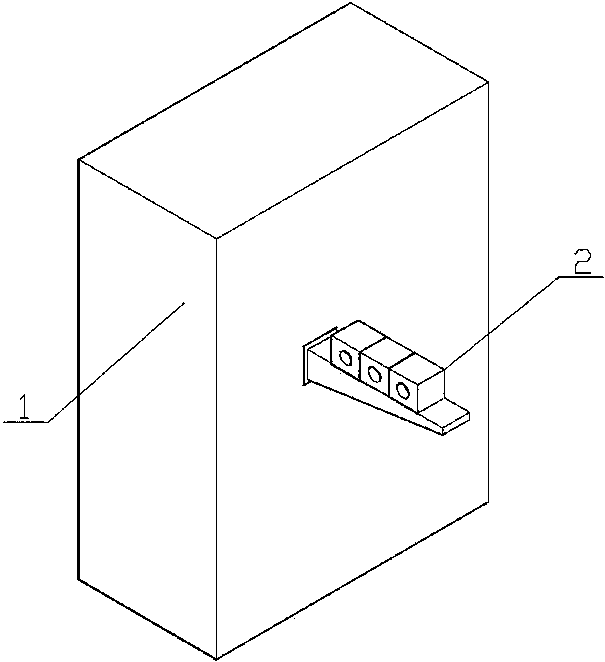

Electric energy storing device

ActiveCN103219489AGuaranteed installation reliabilityReduce lossHybrid capacitor separatorsCell component detailsElectricityFlange

The invention discloses an electric energy storing device, wherein an insulating seal body of the electric energy storing device is an insulating seal cover covered on the periphery of an electrode leading-out structure, one end of the insulating seal cover is erected on the end face of the electrode leading-out structure, which is back to an electric core, the other end of the insulating seal cover is covered on the periphery of the electric core, and a positioning drape which is complementarily fit with a deformed drape and embedded into a groove is arranged on the periphery in the middle of the insulating seal cover. Therefore, the electrode leading-out structure and a housing can be separated from each other by the integrated insulating seal cover, the insulating seal cover can be conveniently and quickly sleeved on the periphery of the electrode leading-out structure, and the insulating seal cover can be tightly compressed on the electrode leading-out structure by a sealed flange and the deformed drape on the housing, so that the assembly technology can be simplified, the assembly period can be shortened, the assembly efficiency can be improved, the loss of the material in the electric energy storing device can be reduced, and the manufacture cost can be reduced.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

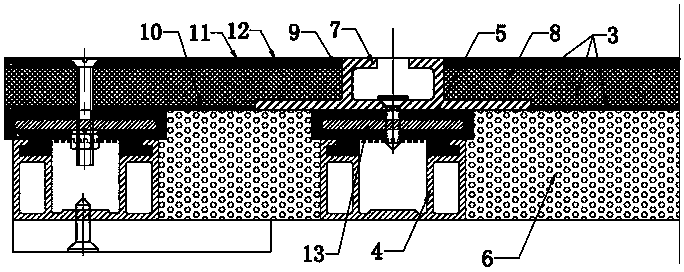

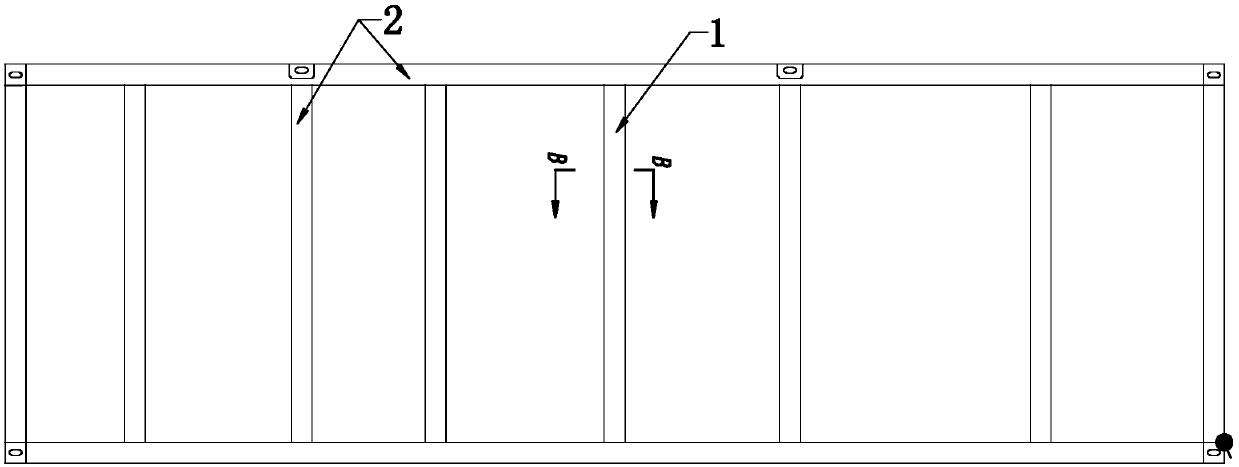

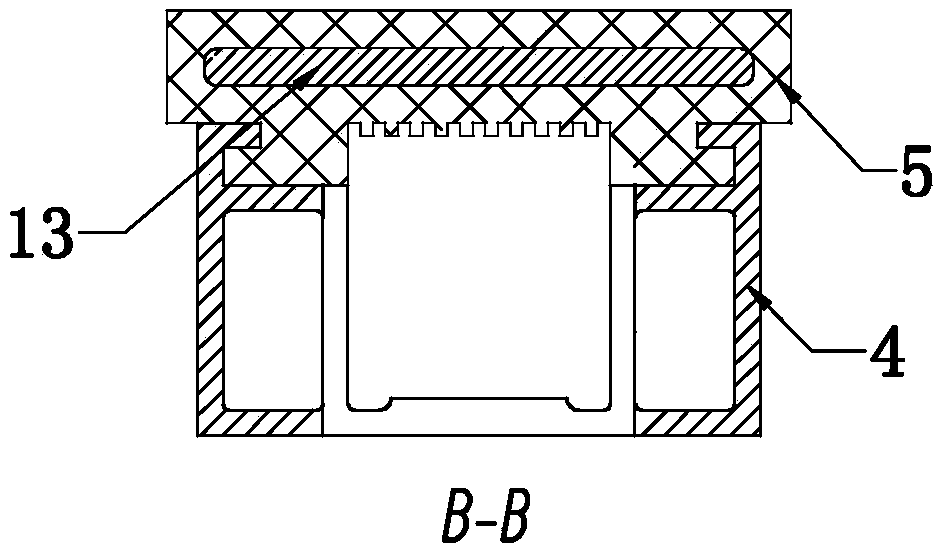

Floor installing structure for compartment

PendingCN109664949AGuaranteed installation reliabilityImprove comfortSuperstructure subunitsAxle-box lubricationEngineeringComfort levels

The invention discloses a floor installing structure for a compartment. The floor installing structure for the compartment comprises a support base body formed by mutually connecting vertically and horizontally arranged support frames and a floor structure layer arranged above the support base body; each support frame comprises an aluminum alloy frame and a faceplate installing groove arranged atthe upper part of the aluminum alloy frame; a faceplate made of an elastic material is arranged inside each faceplate installing groove; the floor structure layer passes through each faceplate througha fastener and is fixedly arranged at the upper part of the support base body; a space between the adjacent support frames in the support base body is filled with heat-preserving cotton; and the bottoms of the support frames are fixedly connected with a compartment bottom plate through fasteners. After the above structure is adopted, not only is a comfort level increased through utilizing the faceplates of the elastic material, but also connection reliability is improved; Upper and lower distributed installation is adopted, so that convenience of installation is greatly improved and stabilityand reliability after installation are improved, and the service life of the structure is greatly improved; and in addition, the comfort level is further improved through rational design of the floorstructure layer.

Owner:JIANGSU TIEKE NEW MATERIAL CO LTD

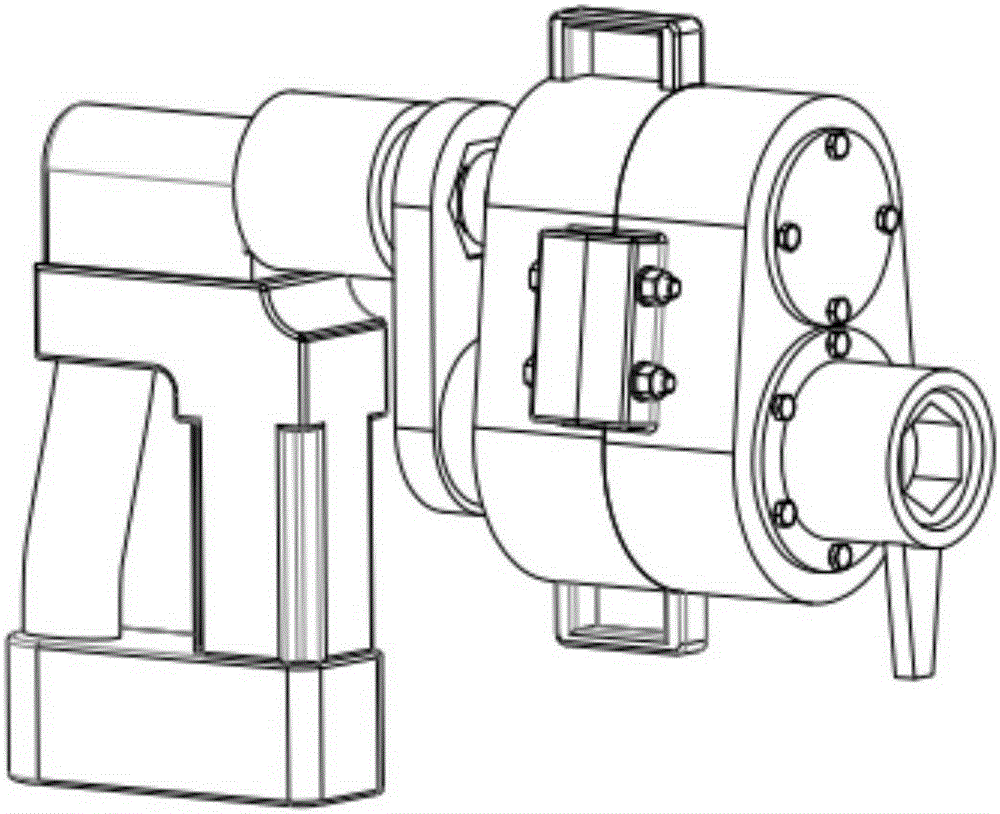

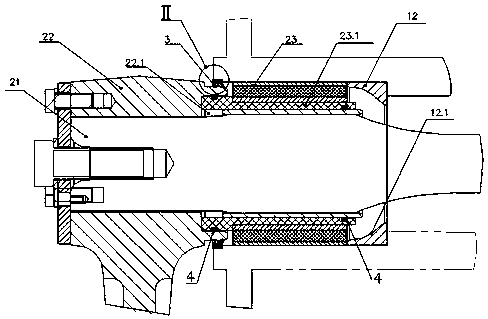

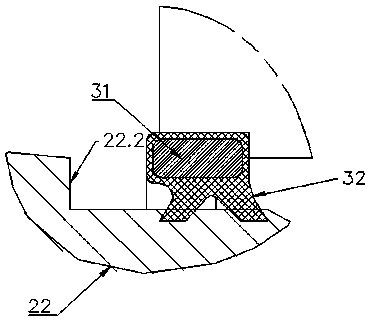

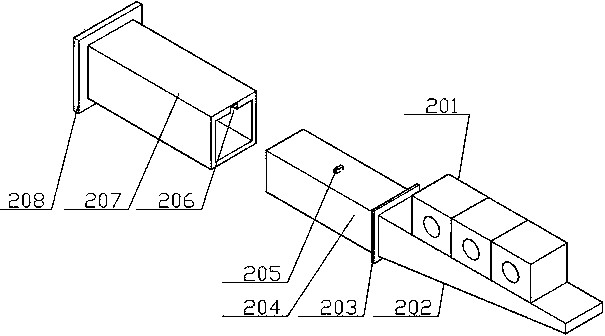

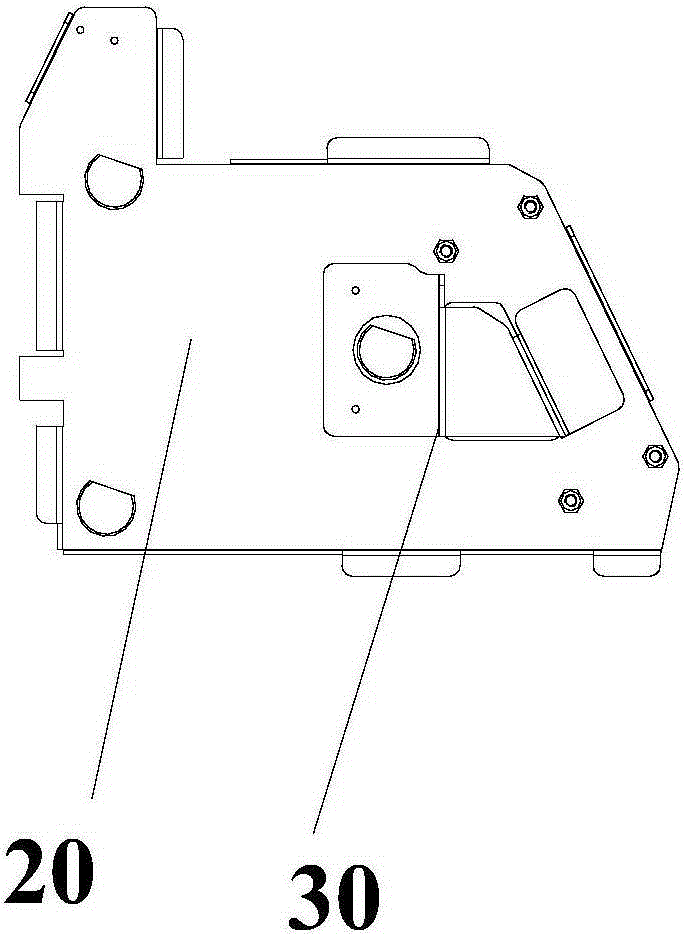

Mounting adapter for split nested unilateral bolt fastener

InactiveCN105952742ARealize one-sided installationAvoid unbalanced forceRod connectionsEngineeringFastener

The invention relates to a mounting adapter for a split nested unilateral bolt fastener. The mounting adapter comprises a main body, an inner sleeve (5) fixed on the main body and an outer sleeve (6) arranged outside the inner sleeve (5) in a sleeving manner, wherein the inner sleeve (5) is used for accommodating and fixing a bolt (9); the outer sleeve (6) is connected with a rotation output shaft of a driving mechanism and used for accommodating and driving a nut (11) to rotate; an inner gear is arranged on the inner wall of the outer sleeve (6) and used for being meshed with an outer gear (8) on the rotation output shaft of the driving mechanism; the main body comprises a cylindrical housing (2) arranged outside the outer sleeve (6) in a sleeving manner; hinge pin holes (31) are formed in the cylinder body of the housing (2); circular-arc-shaped holes (32) are formed in the cylinder body of the outer sleeve (6); and hinge pins (3) are fixedly mounted on the outer wall of the inner sleeve (5) and penetrate the corresponding circular-arc-shaped holes (32) and hinge pin holes (31). Compared with the prior art, the mounting adapter has the advantages of small space occupation and high reliability.

Owner:TONGJI UNIV

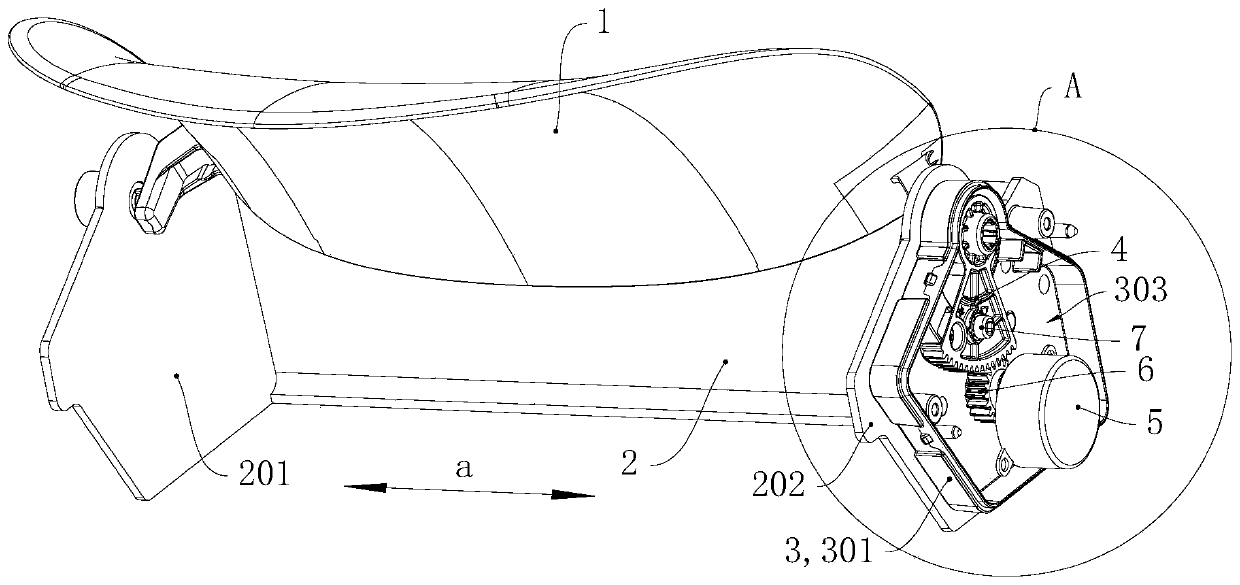

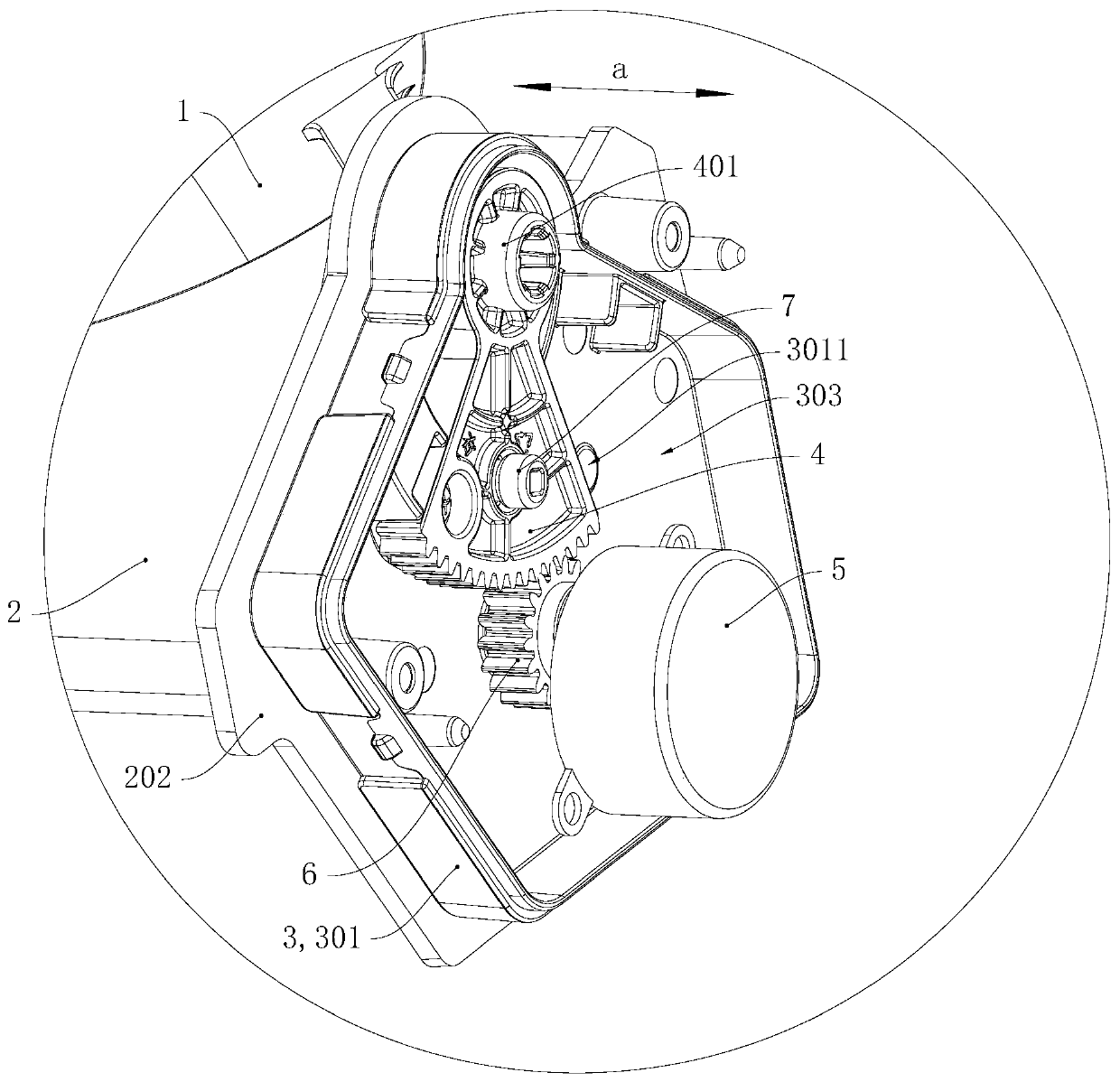

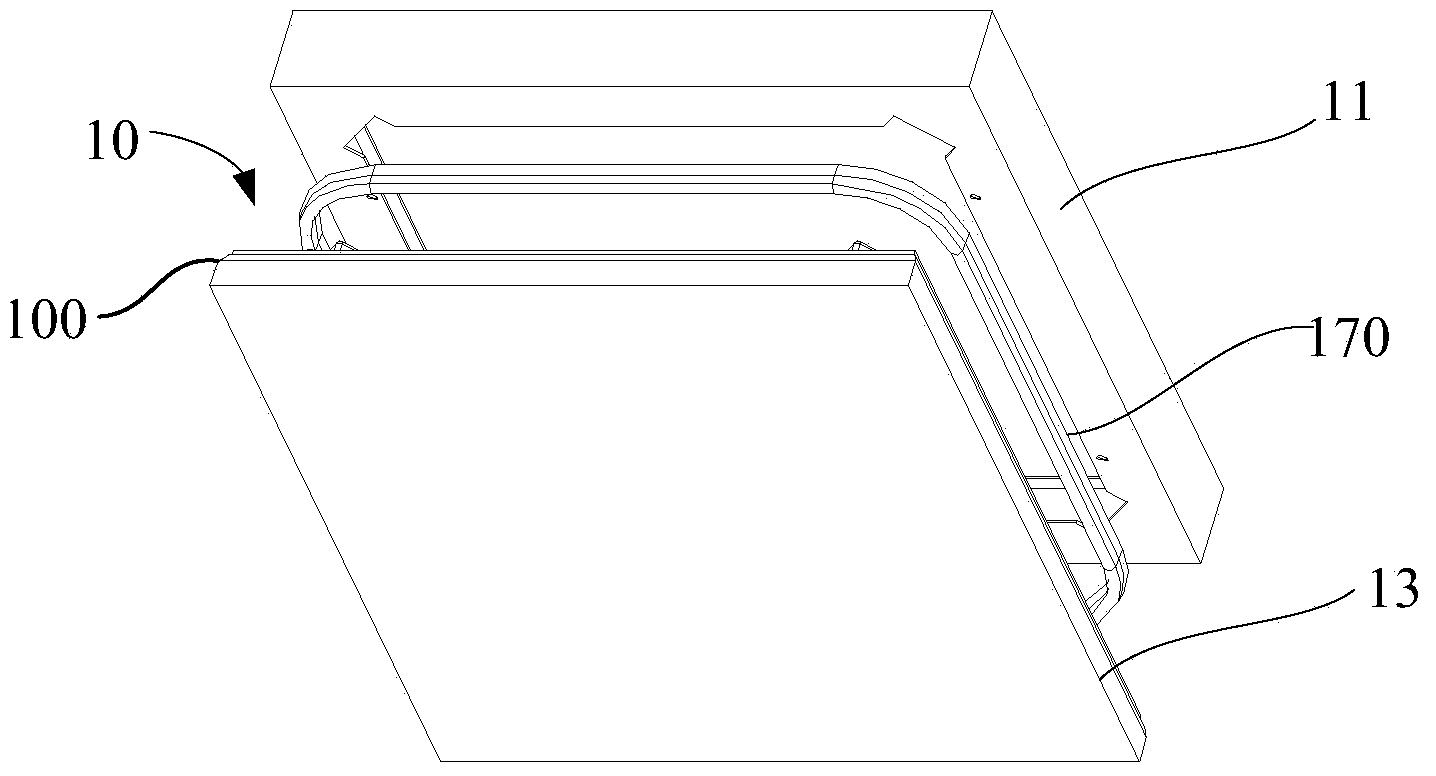

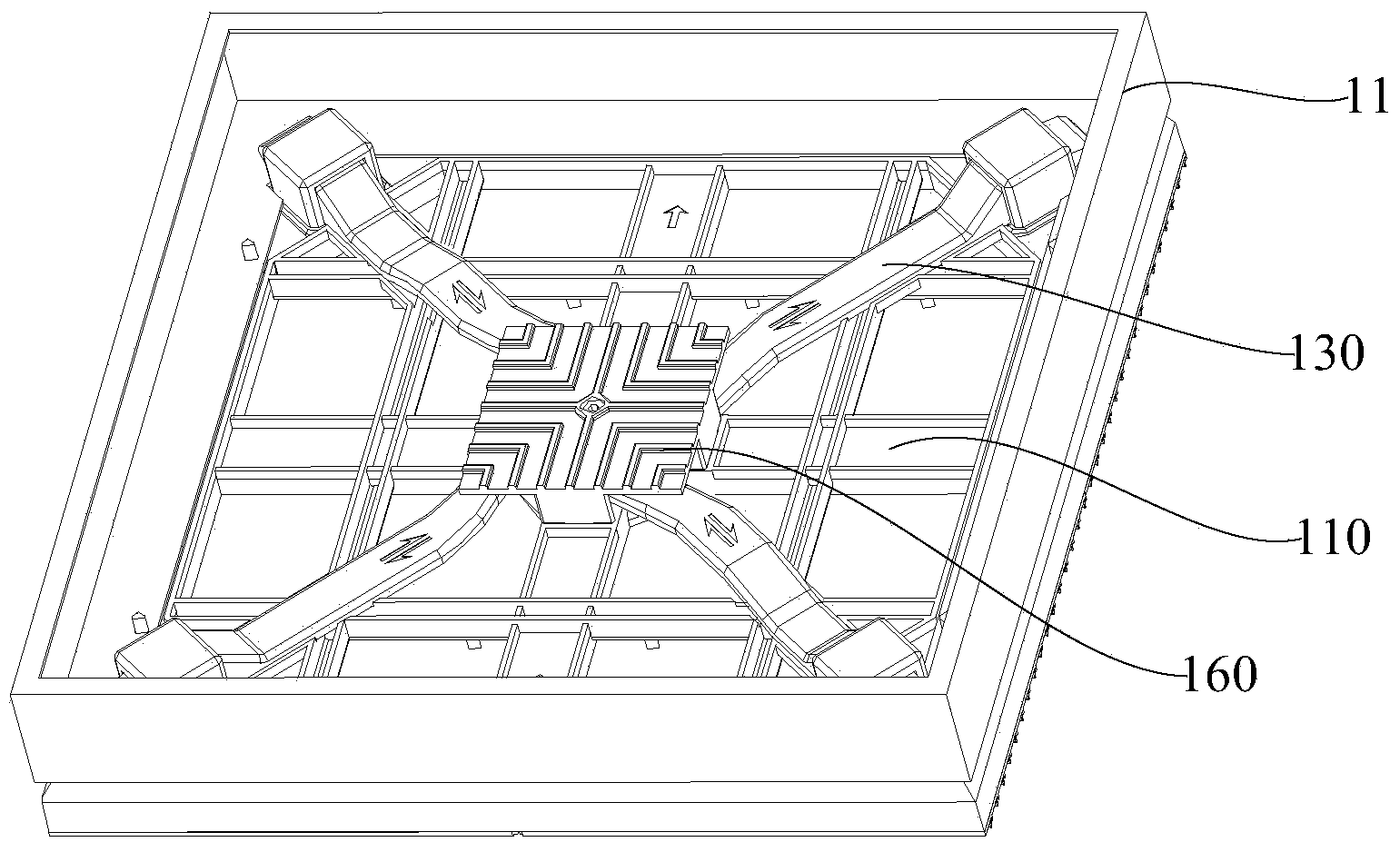

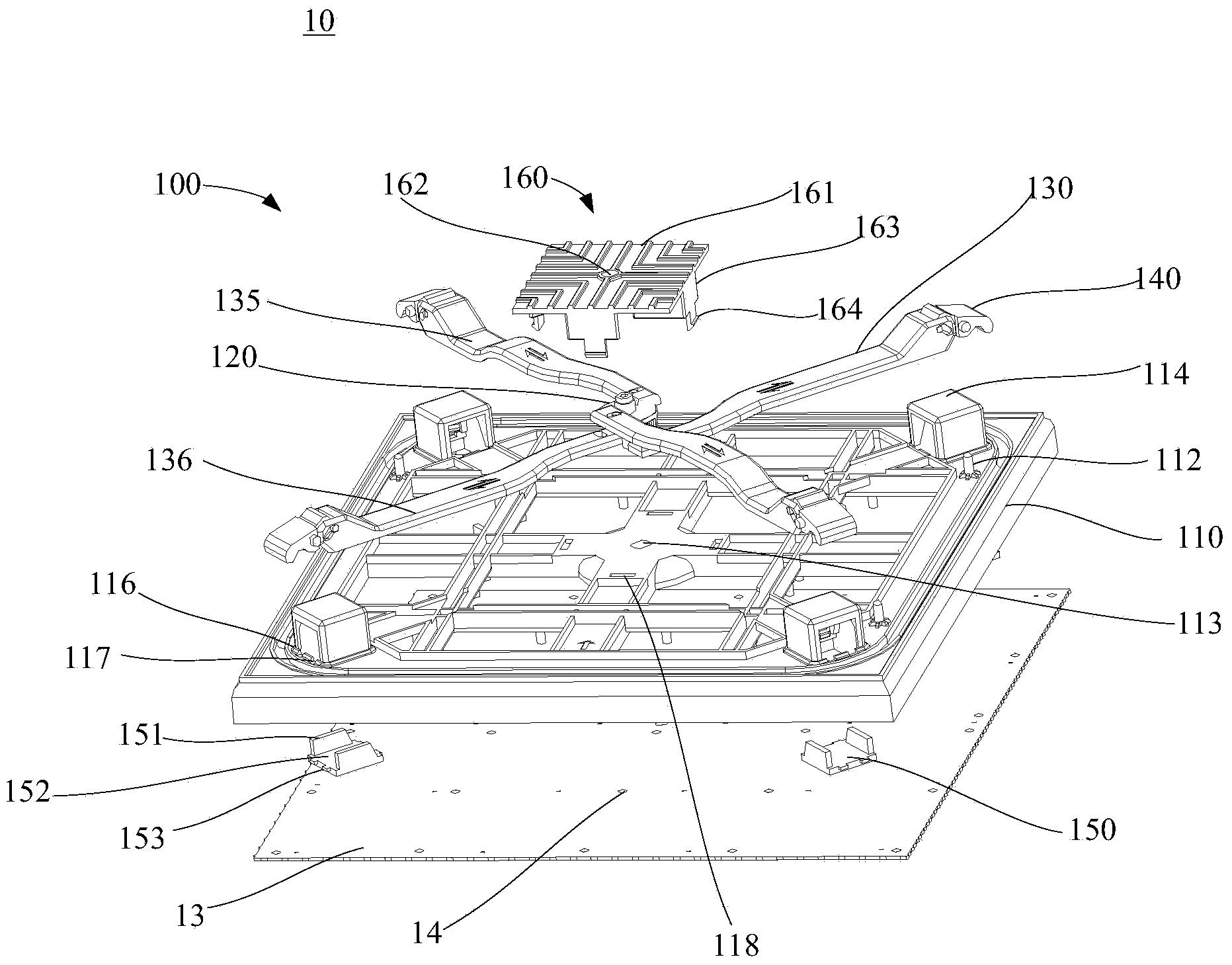

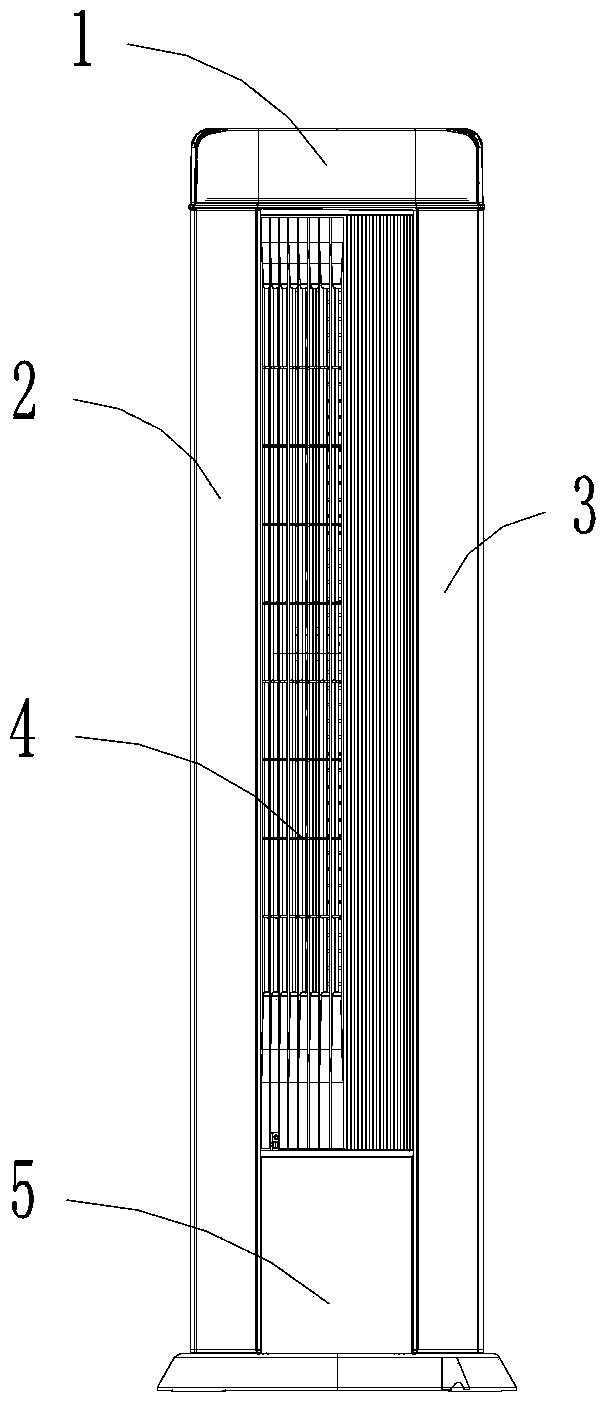

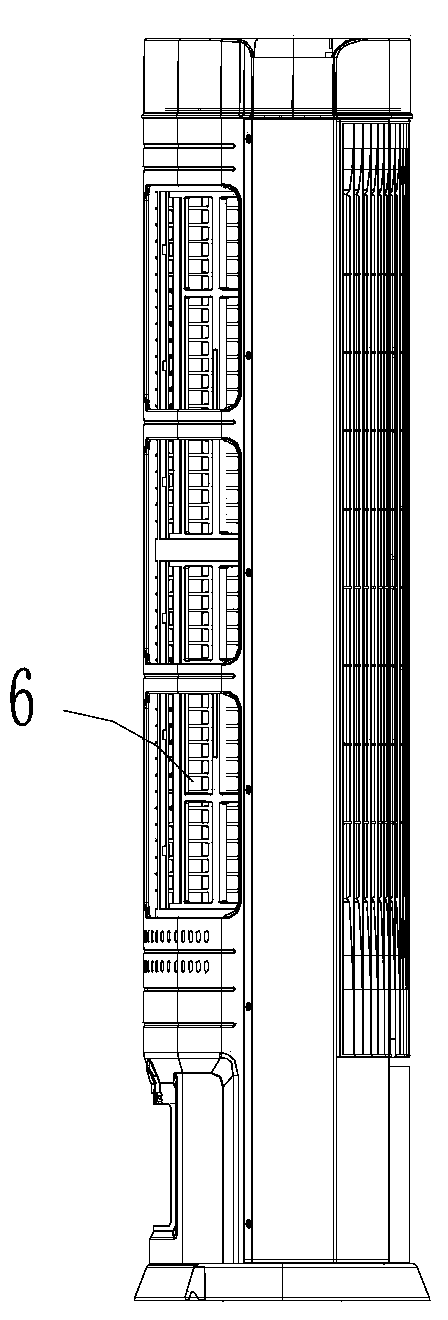

Air guide plate assembly and air conditioner

ActiveCN111121161AReduce jitterSmooth motionLighting and heating apparatusAir conditioning systemsGear wheelEngineering

The invention relates to the field of air conditioners. The air guide plate assembly comprises an air guide plate, an end part base body, a swinging piece and a flexible damping piece; the air guide plate is rotatably arranged on the end part base body; the swinging piece is fixedly connected with the air guide plate; the flexible damping piece is extruded between the swinging piece and the end part base body; the flexible damping piece is fixedly connected with the swinging piece; or the flexible damping piece is fixedly connected with the end part base body. According to the air guide plateassembly, the flexible damping piece is arranged between a fan-shaped gear and the end part base body in an extruding manner, and the flexible damping piece provides damping for the rotation of the fan-shaped gear, which is beneficial to ensuring smooth movement of the air guide plate and the fan-shaped gear and is beneficial to reducing the vibration of the air guide plate in a process that the air guide plate and the fan-shaped gear rotate relative to the end part base body.

Owner:GREE ELECTRIC APPLIANCES INC

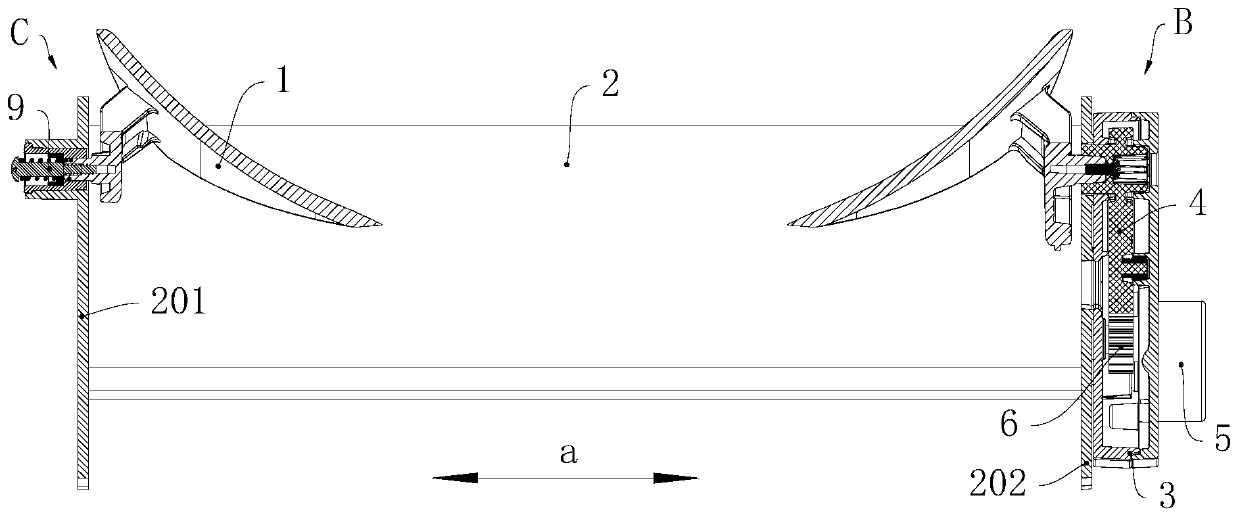

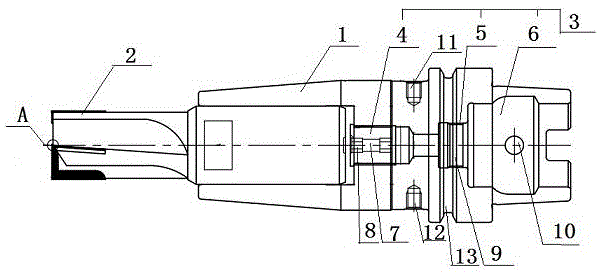

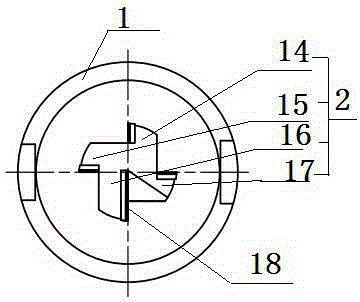

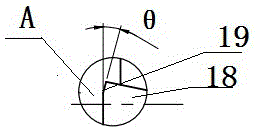

Novel PCD milling tool generating few accumulated chips at tool edge

InactiveCN105149666AGuaranteed installation reliabilityNot easy to looseMilling cuttersTool bitEngineering

The invention relates to a novel PCD milling tool generating few accumulated chips at a tool edge. The novel PCD milling tool comprises a tool handle and a four-blade tool bit; the tail end of the tool handle is provided with an installing groove towards the interior of the tool handle, the installing groove is composed of a shaft-end connecting groove, a sealing groove and a locking positioning groove, a shaft pin is arranged in the shaft-end connecting groove, the inner wall of the sealing groove is provided with multiple seal rings, the locking positioning groove is provided with a positioning hole, and the two sides of the tool handle are provided with a first connecting hole and a second connecting hole respectively; the four-blade tool bit comprises a first blade, a second blade, a third blade and a fourth blade which are each provided with a PCD blade point, and an axial positive rake angle theta is formed at the top end of each PCD blade point and is 15 degrees. According to the novel PCD milling tool generating the few accumulated chips at the tool edge, generation of the accumulated chips at the tool edge is reduced, the service life of the PCD milling tool is effectively prolonged, the machining efficiency and the surface smoothness of a machined workpiece are improved, and the cost is lowered.

Owner:江苏中晟钻石工具有限公司

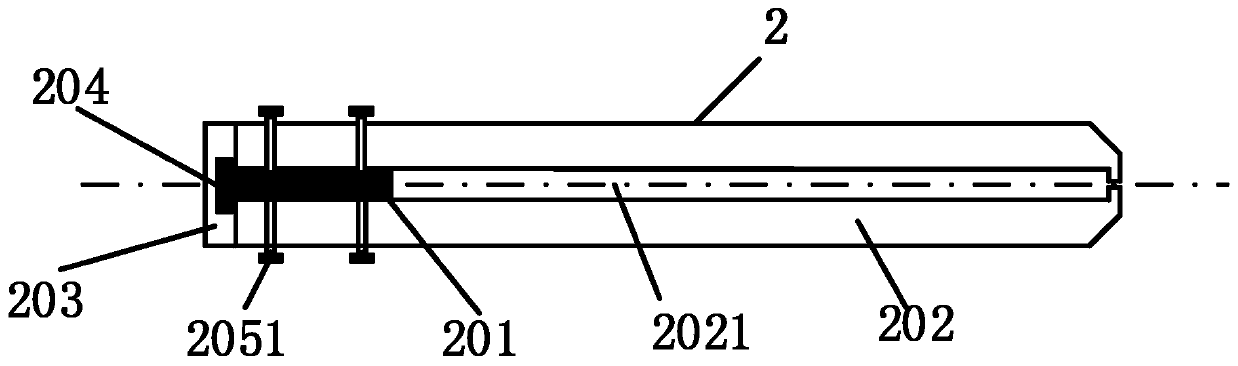

Mounting tool and assembling method of array structural permanent magnet

ActiveCN104097174APrecise positioningThe positioning mandrel is positioned accuratelyMetal-working hand toolsEngineeringMagnet

The invention discloses a mounting tool and an assembling method of an array structural permanent magnet. The mounting tool of the array structural permanent magnet comprises a guide sleeve and a pushing piece, wherein the guide sleeve is communicated with a mounting tube of the permanent magnet in a butt joint manner, the pushing piece is used for pressing a permanent magnet block in the guide sleeve into the mounting tube, one end of the pushing piece is sheathed into the guide sleeve and can push the permanent magnet block in the guide sleeve along the length direction of the guide sleeve. The assembling method comprises the steps of communicating the guide sleeve and the mounting tube in the butt joint manner; placing the permanent magnet block into the guide sleeve, and pushing the permanent magnet block into the mounting pipe by the pushing piece. The mounting tool and the assembling method have the advantages that the operation is simple and convenient, safety and reliability are realized, and the permanent magnet block is effectively mounted.

Owner:NAT UNIV OF DEFENSE TECH

Heat insulation pipe joint structure

InactiveCN104019302AImprove sealingGood insulation performanceSleeve/socket jointsThermal insulationRadial motionEngineering

The invention discloses a heat insulation pipe joint structure and relates to the technical field of pipe joints, and the heat insulation pipe joint structure can be used for solving the problems that the existing heat insulation pipe joint is poor in heat insulation effect, unreliable in structure and the like. According to the heat insulation pipe joint structure provided by the invention, a sealing sleeve ring is sleeved at the periphery of a heat insulation sleeve; sealing pieces are arranged between two ends of the sealing sleeve ring and the conventional section of a heat insulation pipe; the two sealing pieces are respectively positioned on two sides of the heat insulation sleeve, so that secondary heat insulation is formed at a butted part of the heat insulation pipe due to the sealing pieces, and the sealing and heat insulation effects are good. The joint part of the heat insulation pipe is arranged on a supporting seat, so that the reliability of the joint part of the heat insulation pipe is guaranteed; a semicircular slot is formed in the supporting seat; a clamping hoop is also arranged on the supporting seat; the joint part of the heat insulation pipe is fixedly arranged on the supporting seat by virtue of the clamping hoop; the clamping hoop can limit the radial motion of the joint of the heat insulation pipe; the joint of the heat insulation pipe can do axial micro motion in a containing space formed between the clamping hoop and the semicircular slot, so that the mounting reliability of the joint of the heat insulation pipe is guaranteed.

Owner:王向林

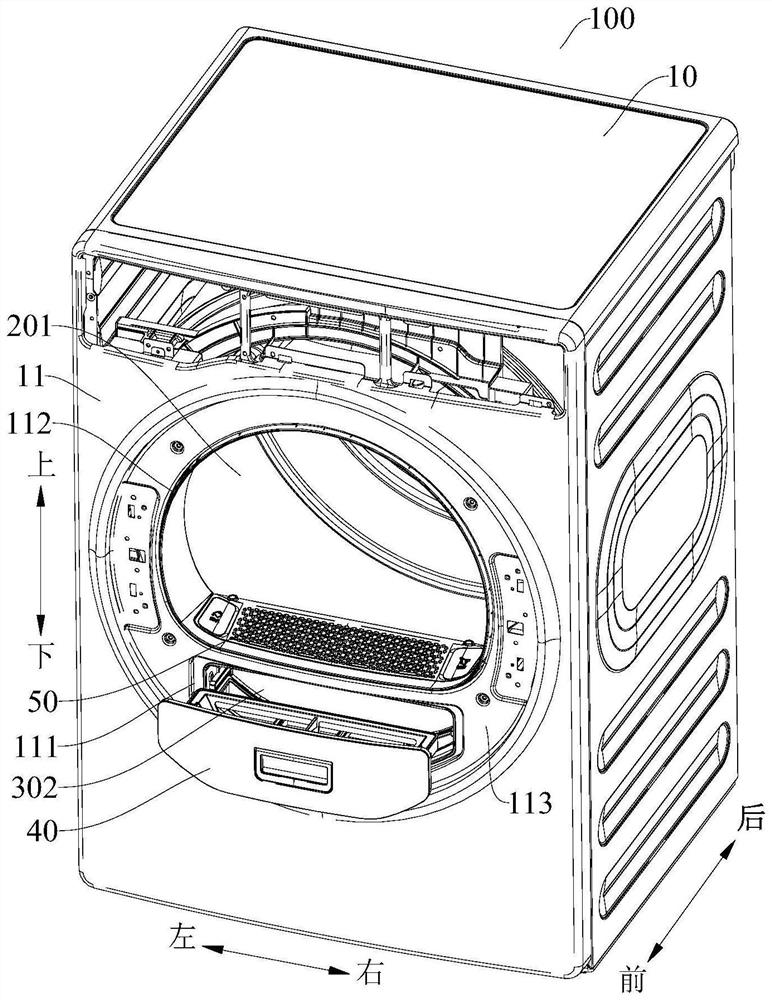

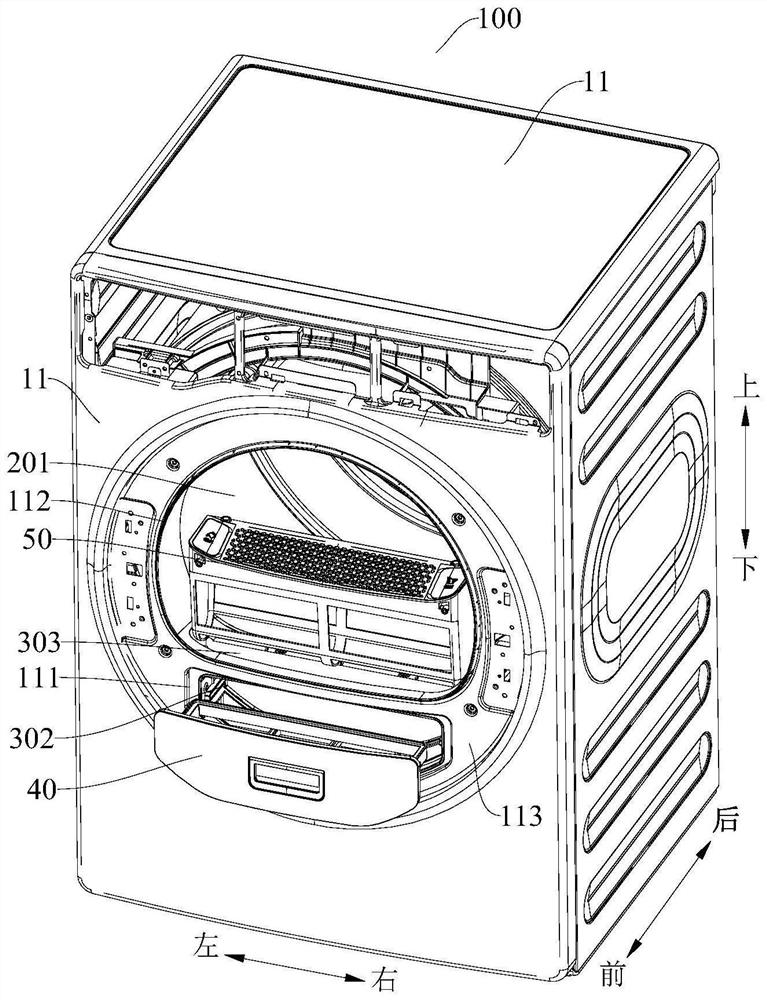

Front supporting assembly of clothes processing device and clothes processing device

PendingCN113638205AGuaranteed installation reliability and stabilityPrevent prolapseTextiles and paperLaundry driersEngineeringMechanical engineering

The invention discloses a front support assembly of a clothes processing device and the clothes processing device. The front support assembly of the clothes processing device comprises a front support and a filtering device, wherein the front support defines an air duct, and the front part of the front support is provided with a side opening communicated with the air duct; and the filtering device is suitable for being movably arranged in the air duct from the side opening, a locking part is arranged on the inner wall face of the air duct, the filtering device is provided with a locking matching part, and when the filtering device is installed in place in the air duct, the locking part is matched with the locking matching part so as to fix the filtering device. According to the front support assembly of the clothes processing device, the locking part is arranged on the inner wall face of the air duct, the locking matching part is arranged on the filtering device, the locking part and the locking matching part are matched, the filtering device is fixed in the air duct, the filtering device is prevented from being disengaged from the air duct, and the installation reliability and stability of the filtering device are guaranteed, therefore, the filtering device can work normally.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Flexible foot mechanism of humanoid robot

InactiveCN101823517BImprove the absorption of vertical impact on the sole of the footCompact structureVehiclesEngineeringHumanoid robot

The invention discloses a flexible foot mechanism of humanoid robot. The bottom surface of a sole plate is provided with a skid-proof shock pad; a hollow cylinder is fixed above the sole plate; four cylinders are uniformly distributed on the outer circumferential wall of the hollow cylinder; a rubber shock pad and a six-dimensional force sensor base with a hollow cylinder and four lugs are arranged in each cylinder; the six-dimensional force sensor base is fixed with four cylinders through the rubber shock pad; the central cylinder of the six-dimensional force sensor base is put into the hollow cylinder; a lubricating washer is arranged on the contact surface between the six-dimensional force sensor base and the hollow cylinder; and the six-dimensional force sensor is installed in the six-dimensional force sensor base. With simple and compact integral structure, the flexible foot mechanism of the humanoid robot has double shock absorption effects through the sole plate and the rubber shock pad, is beneficial to absorbing the impact force vertical to the sole direction by the robot and prolonging the service life of the shock absorption material, is convenient to install and ensures the installation precision and reliability.

Owner:ZHEJIANG UNIV

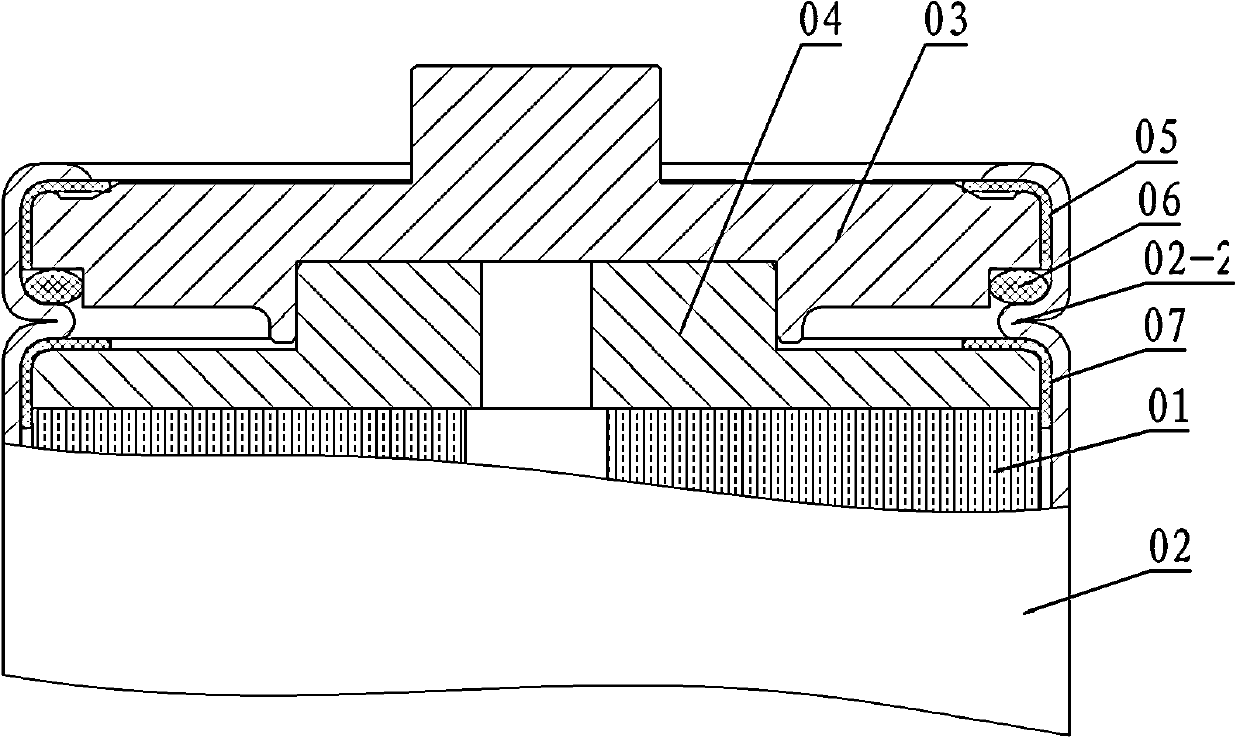

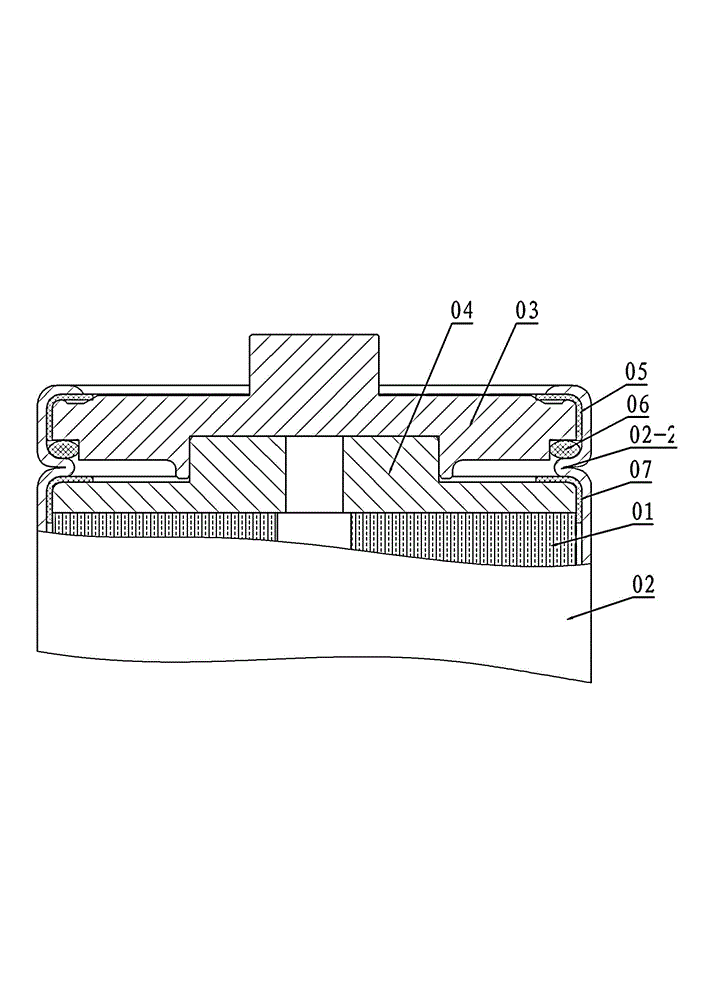

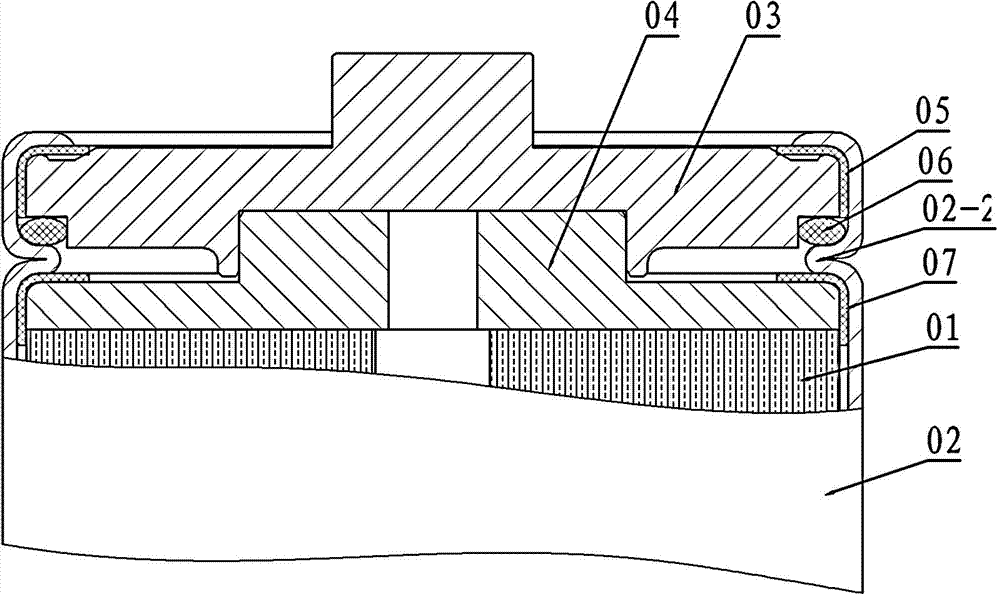

Insulated sealing structure of electrode

ActiveCN103151475AConvenience setGuaranteed installation reliabilityCapacitorsCell component detailsWrinkle skinEngineering

The invention discloses an insulated sealing structure of an electrode. An insulated sealing body of the insulated sealing structure of the electrode is an insulated sealing cover which is sheathed on the periphery of a lead-out structure of the electrode. One end of the insulated sealing cover is erected on the end face of a cell at the back of the lead-out structure of the electrode and the periphery of the cell is sheathed with the other end of the insulated sealing cover. A positioning wrinkle which is matched and complementary with a deforming wrinkle and is embedded into a groove is arranged at the periphery of the middle part of the insulated sealing cover. Thus, the integrated insulated sealing cover is adopted to separate the lead-out structure of the electrode from a shell. The periphery of the lead-out structure of the electrode can be sheathed with the insulated sealing cover conveniently and rapidly and the insulated sealing cover is pressed tightly against the lead-out structure of the electrode by virtue of a seal turned edge and the deforming wrinkle, so that the assembly process is simplified, the assembly cycle is shortened, the assembly efficiency is increased, the loss of materials in power storage devices is reduced and the manufacturing cost is reduced.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

Mounting method of torsion bar component and torsion bar component mounting structure

ActiveCN110254459ASimple structureDoes not affect the reliability of useBogiesBogie-underframe connectionsOccupancy rateBogie

A mounting method of a torsion bar component is characterized in that a mounting hole corresponding to the torsion bar component is machined in a framework of a bogie; the torsion bar component transversely penetrates through the mounting hole, and the torsion bar component is connected with the mounting hole in the form of interference fit; a stopper used for axially limiting the torsion bar component is arranged in the mounting hole; and the stopper is in contact with the torsion bar component in an abutting manner. According to the mounting method of the torsion bar component, as the torsion bar component is directly mounted on the framework, a supporting seat component in an anti-roll torsion bar system is eliminated, the structure of an anti-roll torsion bar component is simplified, the production cost is reduced, the use reliability of the torsion bar component is not affected in the case of guaranteeing that the supporting seat component is eliminated, the connection between the torsion bar component and the framework is easy to realize, the connecting mode is simpler, the labor intensity of mounting the torsion bar component on the framework can be effectively reduced, and moreover, the space occupancy rate of the a connecting structure between the torsion bar component and the framework is small, and the structural compactness of the connecting structure between the torsion bar component and the framework is high. The invention further provides a torsion bar component mounting structure.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Induction type stamping die and plate positioning device thereof

InactiveCN104707909AImprove the pressing effectSmall structureShaping toolsMetal-working feeding devicesVertical planeEngineering

The invention discloses an induction type stamping die and a plate positioning device thereof. The plate positioning device comprises a supporting assembly installed on a die body, a movable positioning plate installed on the supporting assembly, and an induction plate rotationally installed on the movable positioning plate through a first rotating shaft. The induction plate is matched with a sensor and rotationally installed on the supporting assembly through a second rotating shaft. The movable positioning plate is installed on the supporting assembly in a sliding mode, the sliding direction of the movable positioning plate is close to or away from the direction of the sensor, the first rotating shaft horizontally extends and is perpendicular to the sliding direction of the movable positioning plate, the first rotating shaft is located below the sensor, the induction plate rotates around the second rotating shaft in the vertical plane and inducts or does not induct the sensor. Accordingly, the structure of the movable positioning plate is small, the inward contraction type movement form is adopted, the moving track is small, and therefore the receding range of the die on the movable positioning plate is reduced, the machining difficulty of a die receding part is lowered, and the pressing effect of panel blanks is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Assembling process of electrode insulating sealing structure

ActiveCN103199204AConvenience setGuaranteed installation reliabilityCell component detailsHybrid/EDL manufactureSolid structureEngineering

The invention discloses an assembling process of an electrode insulating sealing structure. According to the assembling process, an integrated insulating sealing sleeve is used for separating an electrode lead-out structure from a shell, can be sleeved at the periphery of the electrode lead-out structure conveniently and quickly and is tightly pressed on the electrode lead-out structure by depending on sealed turnups and deformed drapes on the shell, so that the assembling process is simplified, the assembling period is shortened, the assembling efficiency is improved, the loss of materials of an energy storage device is reduced, and the manufacturing cost is reduced. Positioning is performed in the axial direction of an end cover by virtue of the sealed turnups and the deformed drapes on the shell, so that the mounting reliability and stability of the end cover are guaranteed, and the mounting reliability of the whole electrode lead-out structure is further guaranteed. The assembling process can solve the problems of long time, complex structure and poor insulating sealing effect of an electrode insulating sealing assembling process in the prior art.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

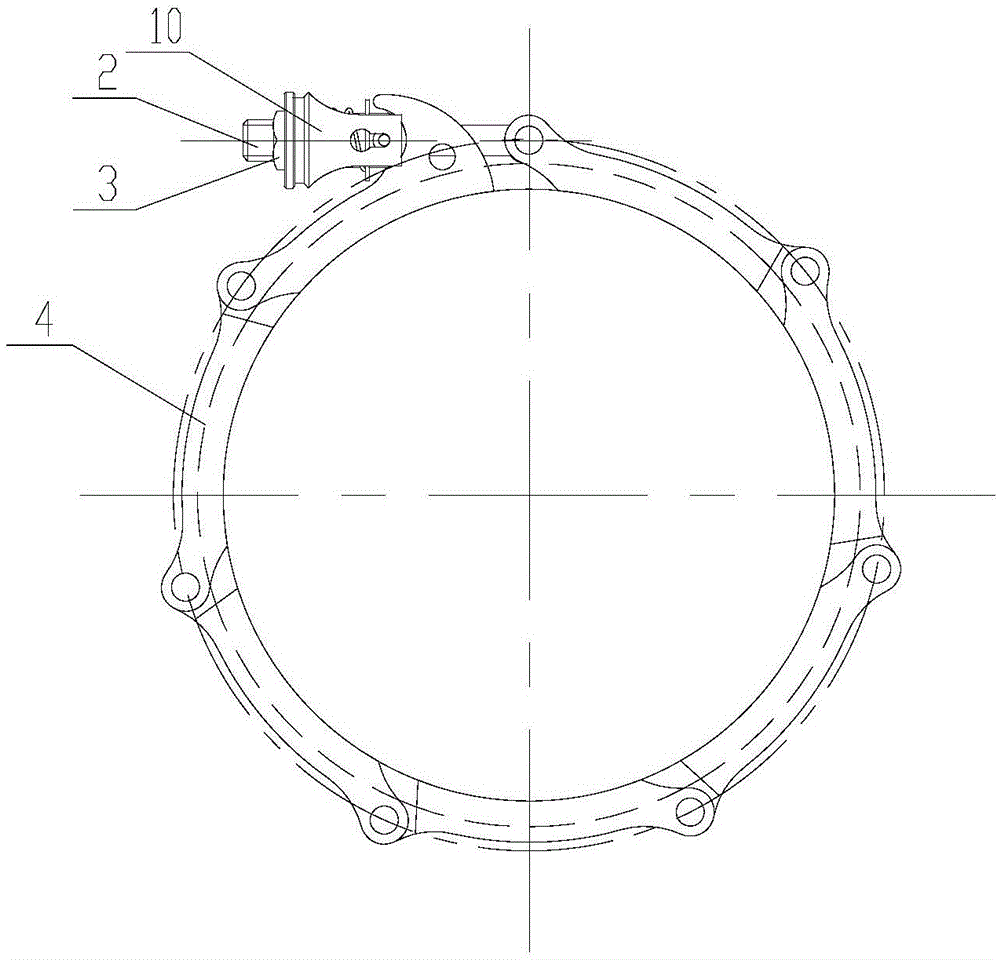

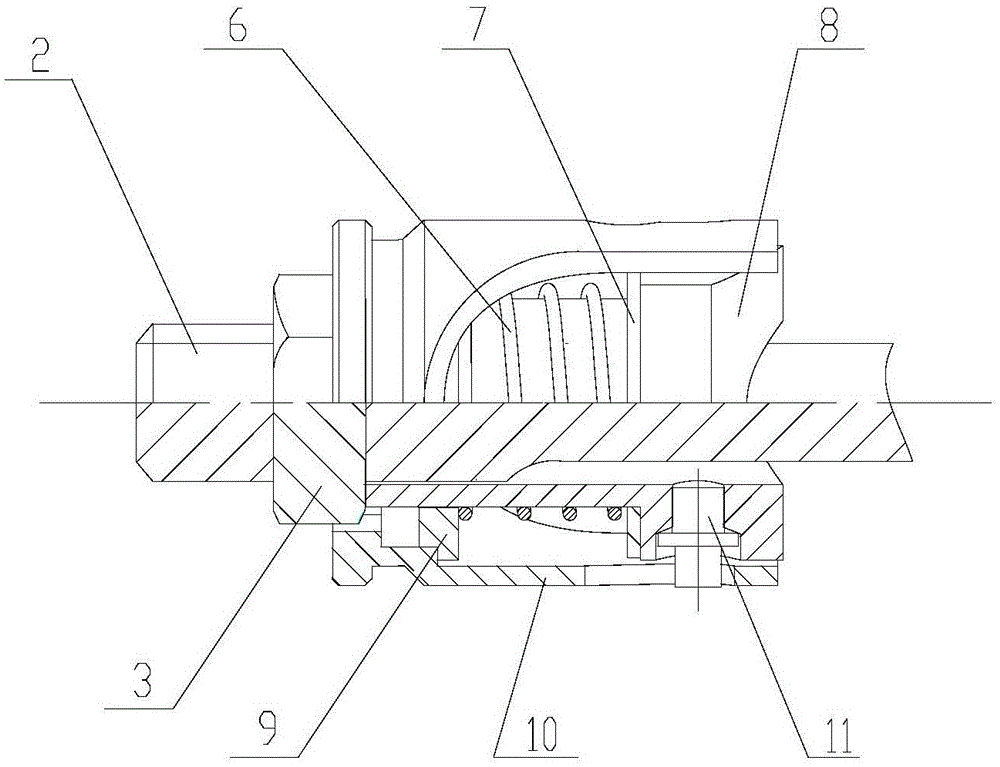

Self-locking snap ring

ActiveCN105156417AClamp firmlyQuick installationFriction grip releasable fasteningsSelf lockingEngineering

The invention relates to a self-locking snap ring which comprises a snap ring body composed of multiple connecting joints hinged together in sequence, and a lock assembly. One end of a bolt of the lock assembly is hinged to one end of the snap ring body. The other end of the bolt penetrates the other end of the snap ring body and a swivel nut and is then provided with a nut. A lock shell is arranged outside the swivel nut. A spring is pressed on the lock shell and the swivel nut. The end of the lock shell is matched with the outer contour of the nut. The swivel nut is provided with a pin. The pin extends into an axial groove of the bolt and an axial through hole of the lock shell respectively. Compared with a traditional quick-detached snap ring, the self-locking snap ring has the beneficial effects that the self-locking and detaching functions are more convenient, the snap ring is rapidly installed, locked and detached, and the requirements for installation reliability and repair economic efficiency of the snap ring are met.

Owner:HARBIN DONGAN ENGINE GRP

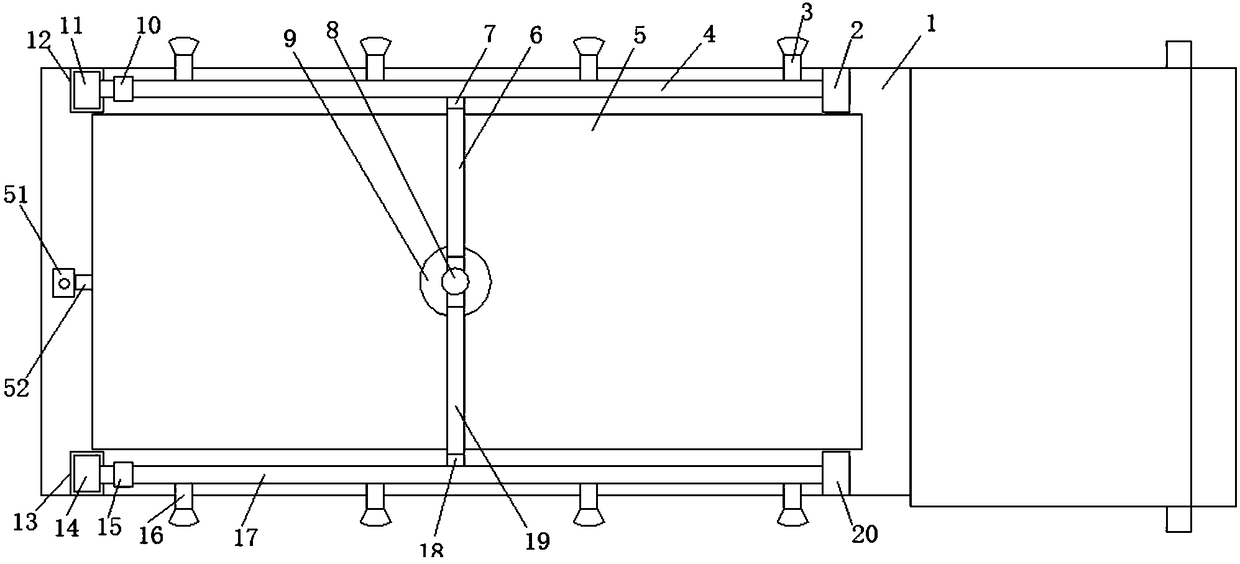

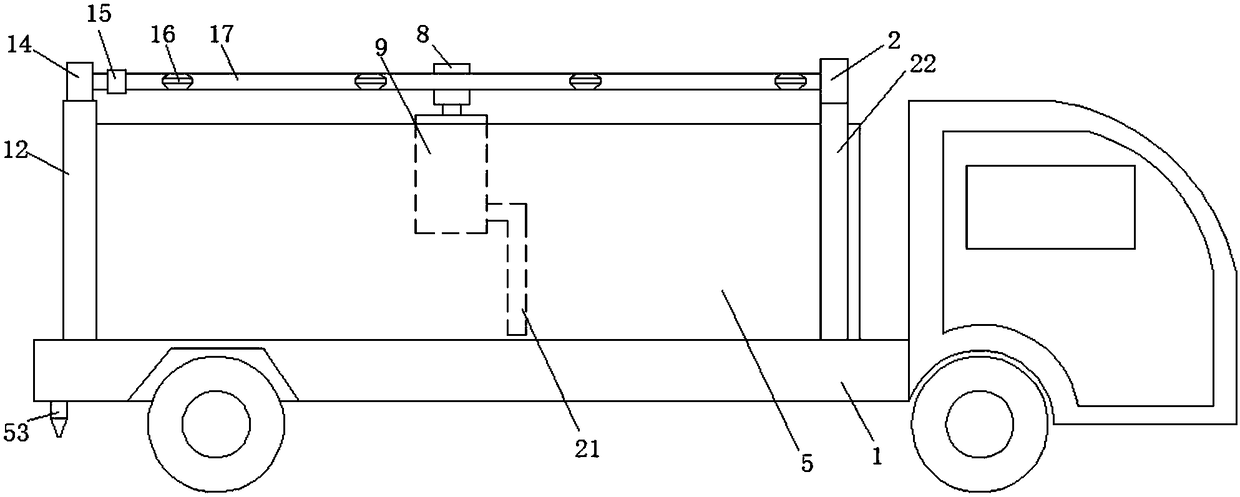

Vehicle-mounted large-scale dust removal device

InactiveCN108385591AExpand the spraying rangeImprove dust removal efficiencyRoad cleaningVehicle frameEngineering

The invention relates to a vehicle-mounted large-scale dust removal device, which comprises a loading vehicle, a water tank, a water pump and a three-way valve. The water tank is installed on the frame of the loading vehicle; the water pump is installed on the top of the water tank, the water inlet is located in the water tank, and the water outlet of the water pump is located outside the water tank and connected with the water inlet of the three-way valve; a first hard water pipe and a second hard water pipe are arranged on the frame of the loading vehicle and on the both side of the water tank, wherein the two ends of the first hard water pipe and the two ends of the second hard water pipe are sealed; the first hard water pipe and the second hard water pipe extend horizontally along thelength of the water tank; a plurality of first water spouts communicating with the first hard water pipe are arranged on the side wall of the first hard water pipe side by side; a plurality of secondwater spouts communicating with the second hard water pipe are arranged on the side wall of the second hard water pipe side by side; one of the two water outlets of the three-way valve communicates with the first hard water pipe through a first soft water pipe, and the other water outlet of the three-way valve communicates with the second hard water pipe through a second soft water pipe. The vehicle-mounted large-scale dust removal device has the advantages of spraying water in air, large spraying scale, high dust removal efficiency and low water consumption.

Owner:亓新广

Installation module and LED (Light Emitting Diode) display component comprising installation module

InactiveCN103413501AGuaranteed installation reliabilityAchieve self-locking functionCasings/cabinets/drawers detailsIdentification meansLED displayEngineering

The invention relates to an installation module, which comprises a bottom shell, a rotating wheel, a push rod, a pressure block and a pressure cover; the rotating wheel rotates to drive the push rod to move along the extension direction in a reciprocating manner; the push rod drives the pressure block to slide in a containing space; when the pressure block moves to the tail end of the containing part, the side wall of the containing part of the bottom shell prevents the pressure block from sliding continuously; the first convex shaft of the pressure block slides from one end of a chute to the other end; one end of the pressure block close to the push rod is titled; the convex corner of the pressure block is contained in a slot of the containing part to limit the pressure block; one end, far away from the push rod, of the pressure block is pressed downwards to tightly press a box body; the push rod moves reversely to drive the convex corner to slide out of the slot of the containing part; the pressure block is separated from the box body. A wrench is only necessary to rotate the rotating wheel bilaterally in the whole installation process, so that installation and disassembly of an LED display component can be realized; the process is completed through one step; the repetitive steps of fixing screws are avoided; convenient installation and disassembly of unit modules are realized. The invention further provides the LED display component.

Owner:深圳市恒利普智能显示有限公司

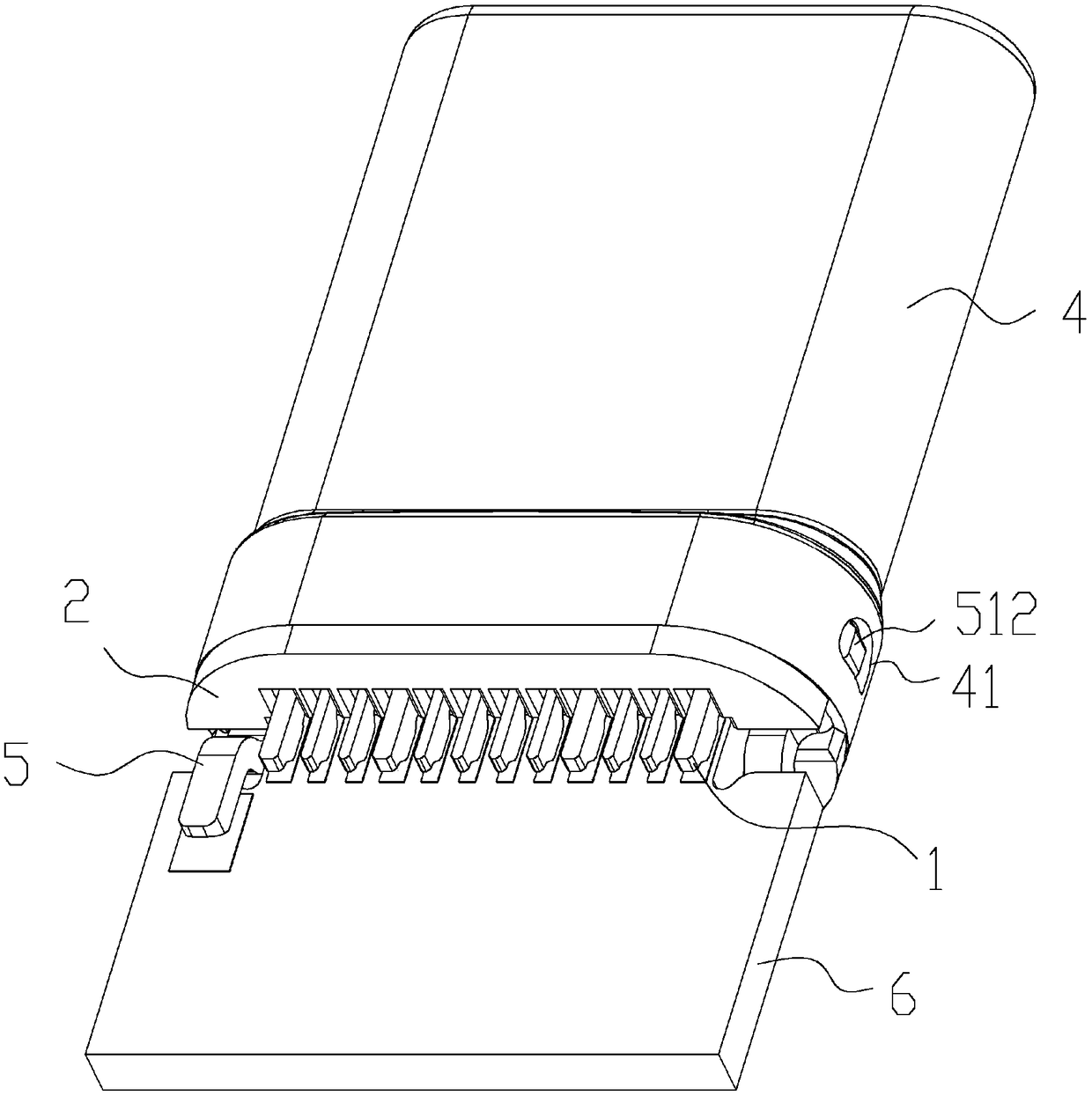

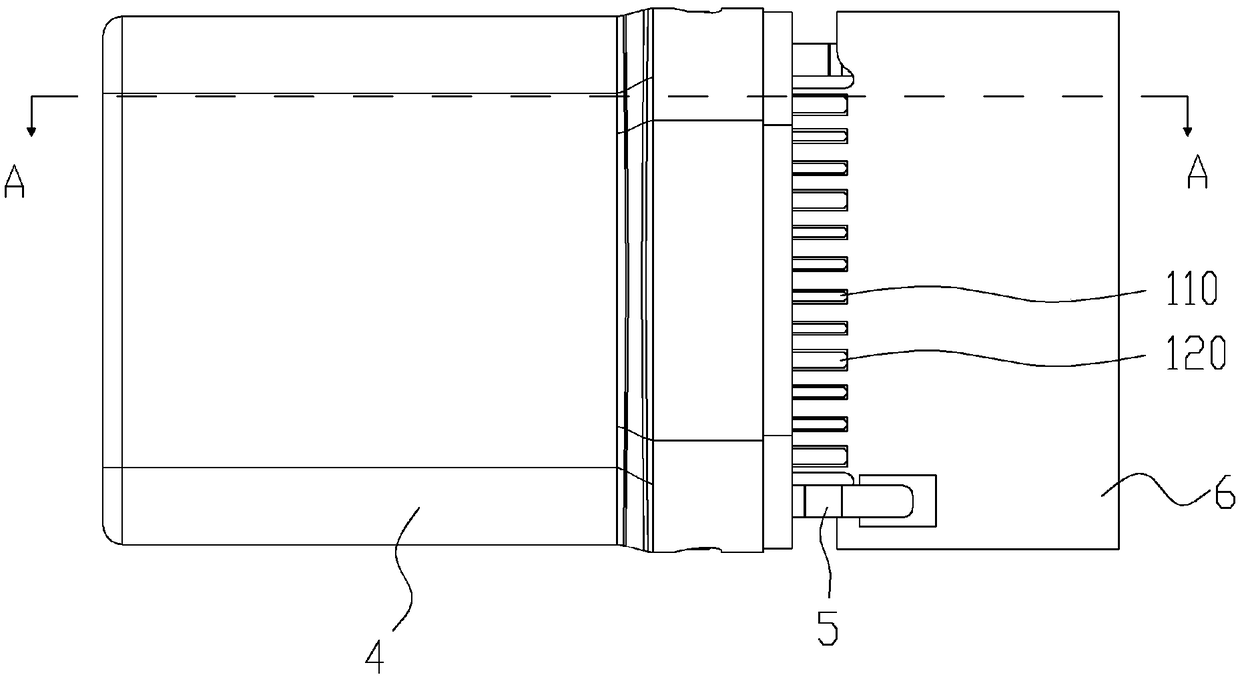

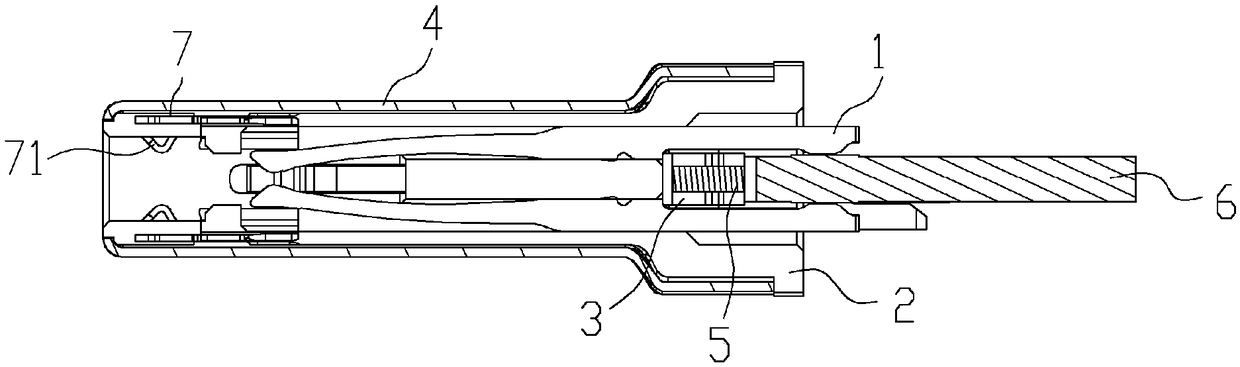

New USB 3.0 male head

PendingCN109149185ALess interferencePrevent force backSecuring/insulating coupling contact membersCoupling contact membersEngineeringProcessing cost

The invention discloses a novel USB3.0 male head, which comprises a terminal, a rubber core, a PCB, a housing, a fixing bracket, a stopper and an EMC elastic plate. The USB3.0 male head comprises a terminal, a rubber core, a PCB, a housing, a fixing bracket, a stopper and an EMC elastic plate. In this invention, Terminals shall be installed in plug-in manner, so that that terminal groove is provide, to reduce interference between the terminals, As such, injection mol of that terminal fixing house and subsequent riveting processing are no longer necessary for manufacture the present invention,so that that processing steps are simplify, so that that processing cost is reduced, In addition, the hole position required for riveting can be greatly reduced on the rubber core, and the terminal isstuck on the one hand by a protrusion provided by the terminal itself, on the other hand, so that the terminal can be securely fixed in the terminal slot, and the fixing bracket can be fixedly connected with the housing to realize the locking of the whole mechanism. In order to realize the USB3.0 protocol and cooperate with the USB3.0 master, the PCB can be arranged to conduct static electricitygenerated in use to the housing and reduce static electricity interference.

Owner:DONGGUAN GAODUAN ELECTRONICS CO LTD

Cable holder

InactiveCN103453227AGuaranteed installation reliabilityEasy to installPipe supportsTorsion springEmbedded system

The invention discloses a cable holder which is stable in structure, reliable in installation and high in construction efficiency. The cable holder comprises an embedded part and a supporting member, wherein the embedded part is embedded in a wall body; the supporting member is arranged in the embedded part; the supporting member comprises a cuboid-shaped sliding mounting member; a spacer pin is convexly arranged on at least one side face of the sliding mounting member; the supporting member is fixedly arranged at one end of the sliding mounting member far away the wall body; a cable penetrating frame is arranged on the supporting member; the embedded part comprises an embedded sleeve which is embedded in the wall body; the embedded sleeve is in a cuboid-shaped tubular structure; the sliding mounting member is completely stretched into the embedded sleeve; a mounting groove is formed in the inner side face of the embedded sleeve corresponding to the position of the spacer pin; the spacer pin can slide in the mounting groove; a limit bar is arranged in the mounting groove and is fixedly arranged on a rotating shaft; two ends of the rotating shaft are arranged on the groove wall of the mounting groove; a torsion spring is arranged on the rotating shaft.

Owner:江苏安荣电气设备有限公司

Displaying device and air conditioner

ActiveCN103544883AEasy to useGuaranteed installation reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusComputer moduleDisplay device

Owner:GREE ELECTRIC APPLIANCES INC

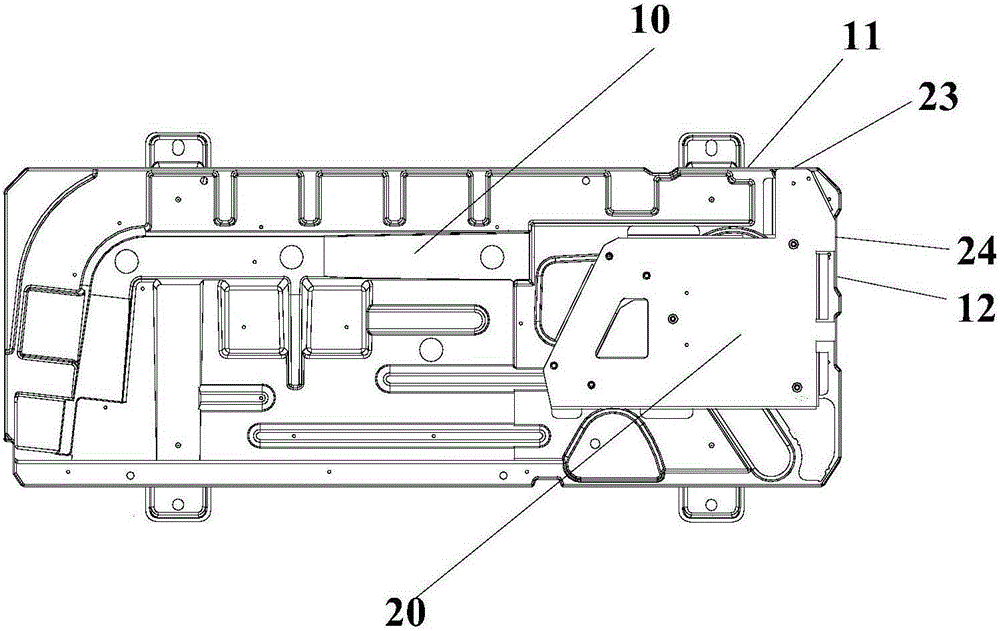

Mounting base and air conditioner with same

ActiveCN105180306AIncrease profitGuaranteed installation qualityLighting and heating apparatusAir conditioning systemsEngineeringUtilization rate

The invention discloses a mounting base and an air conditioner with the same. The mounting base comprises a chassis and a chassis welding assembly fixed to the chassis. The chassis welding assembly comprises a first mounting portion for mounting a liquid storage pipe and a second mounting portion for mounting a compressor, and the first mounting portion and the second mounting portion are integrally arranged. By the adoption of the technical scheme, the first mounting portion for mounting the liquid storage pipe and the second mounting portion for mounting the compressor are integrally arranged, and the problems that an existing air conditioner mounting base is inaccurate in welding and positioning, the number of parts is large, the welding error is large, and it is difficult for products to assemble are solved; the mounting base is designed more scientifically, reasonably and exquisitely; and on the premise that the mounting quality and reliability are guaranteed, the utilization rate of materials can be increased, the material cost and machining cost of products are lowered, and production efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com