Patents

Literature

97results about How to "Avoid unbalanced force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

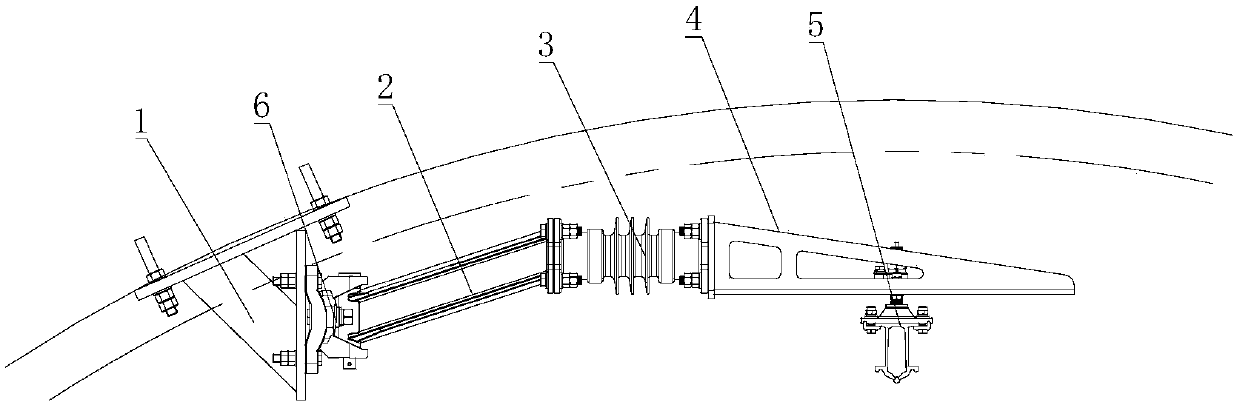

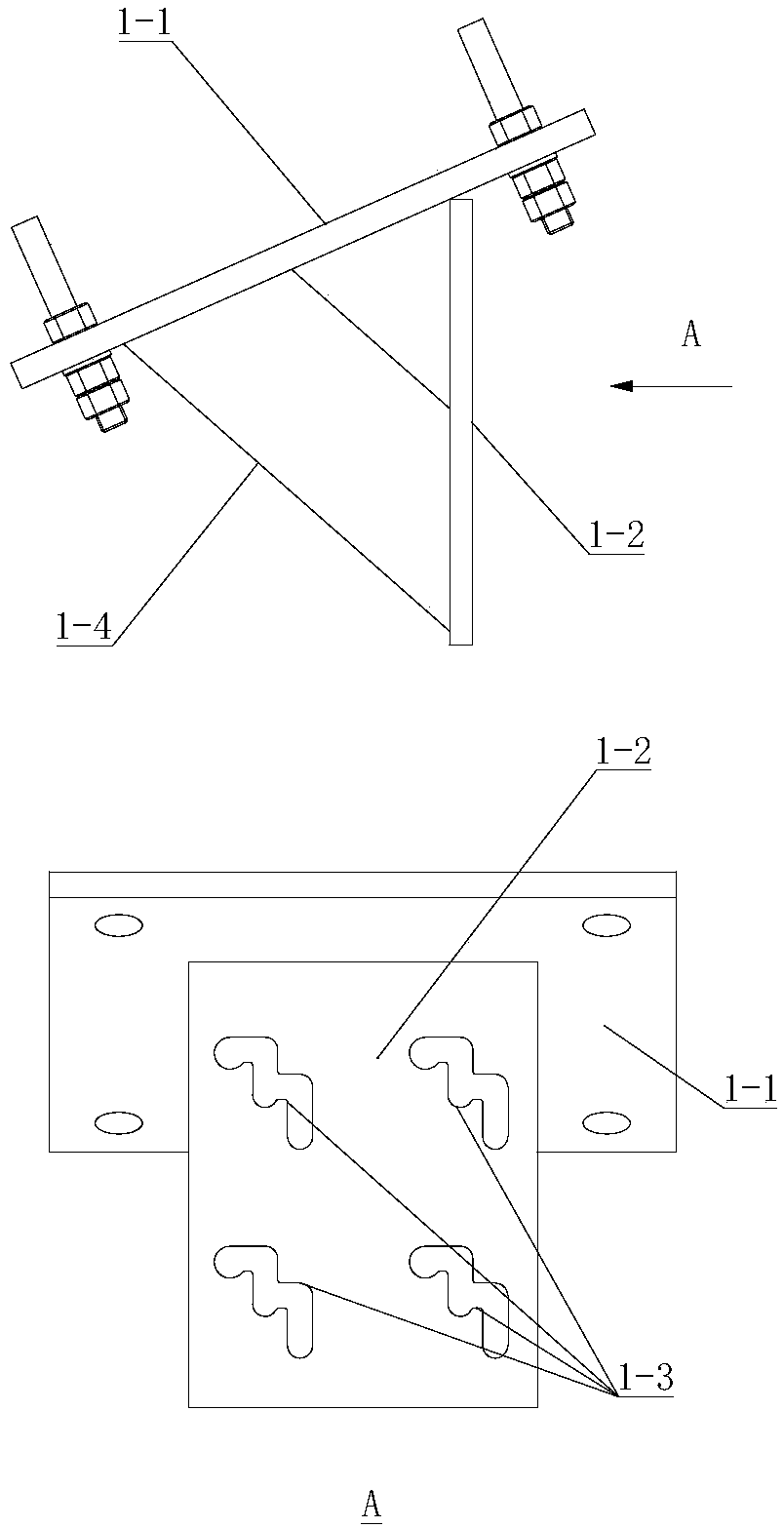

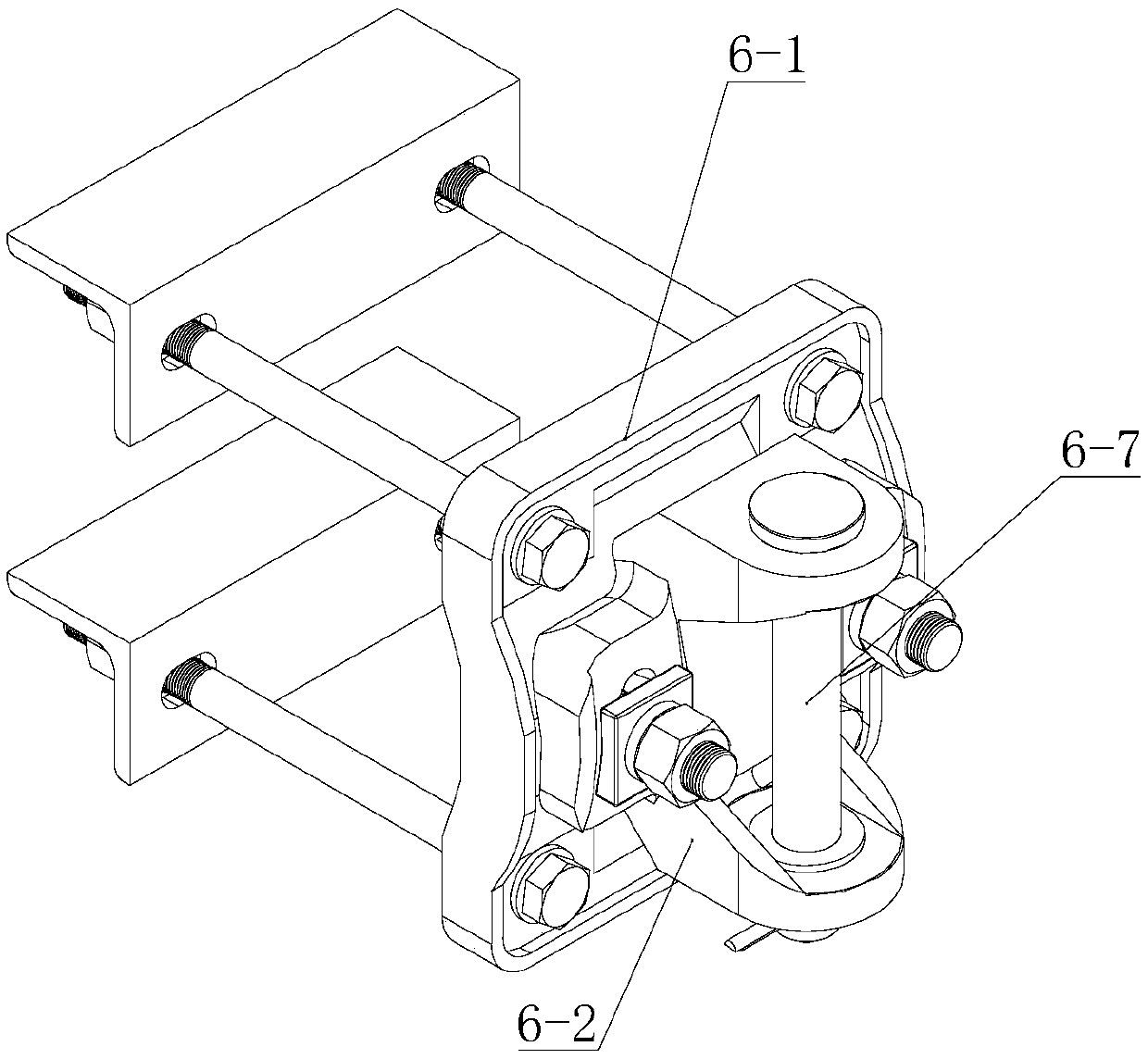

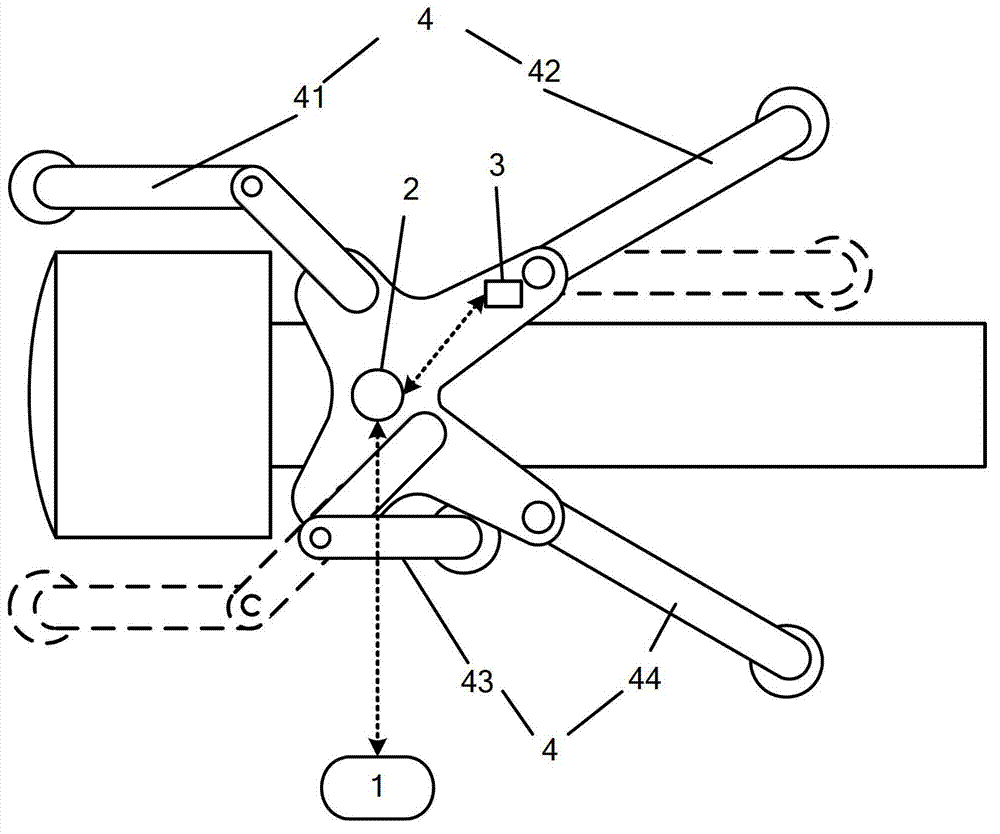

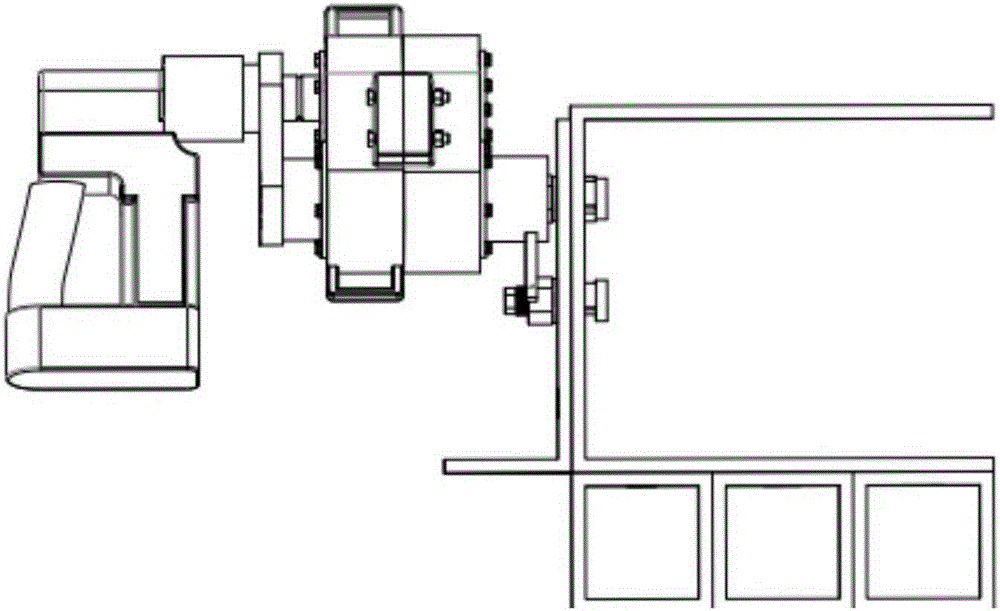

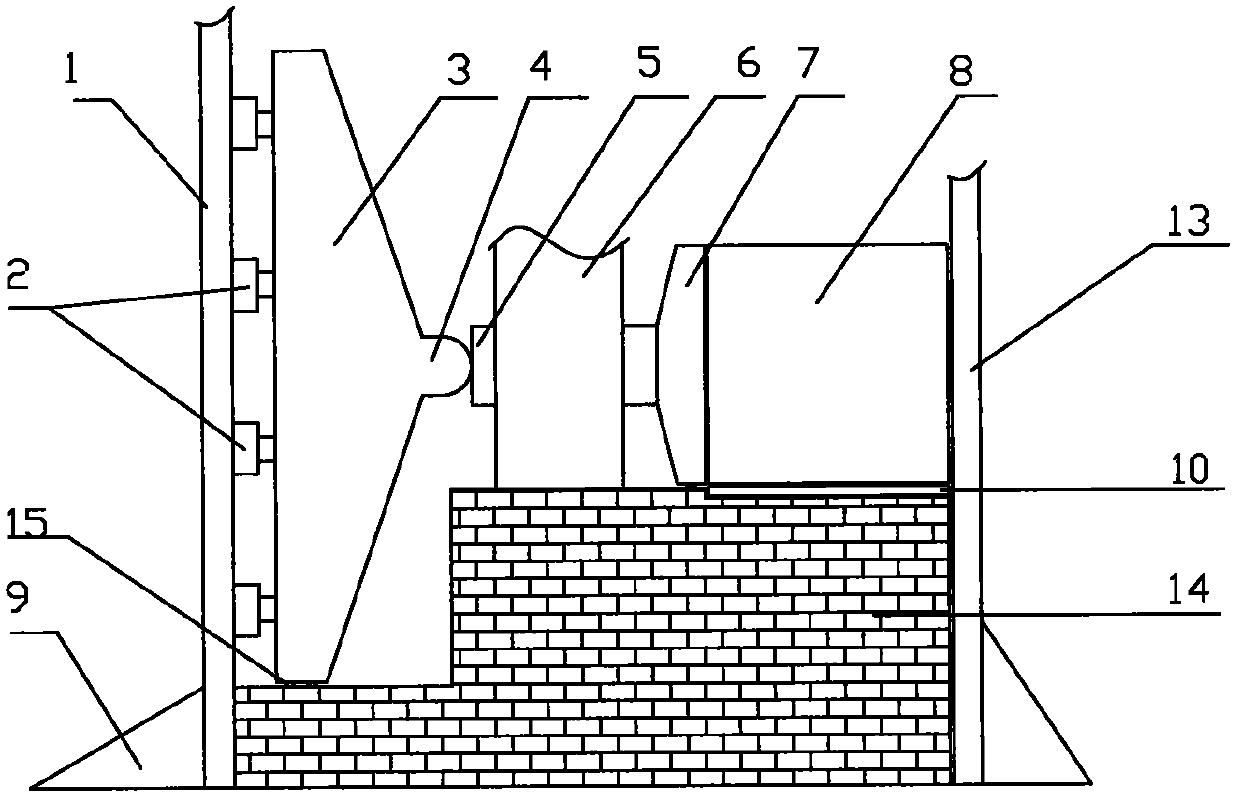

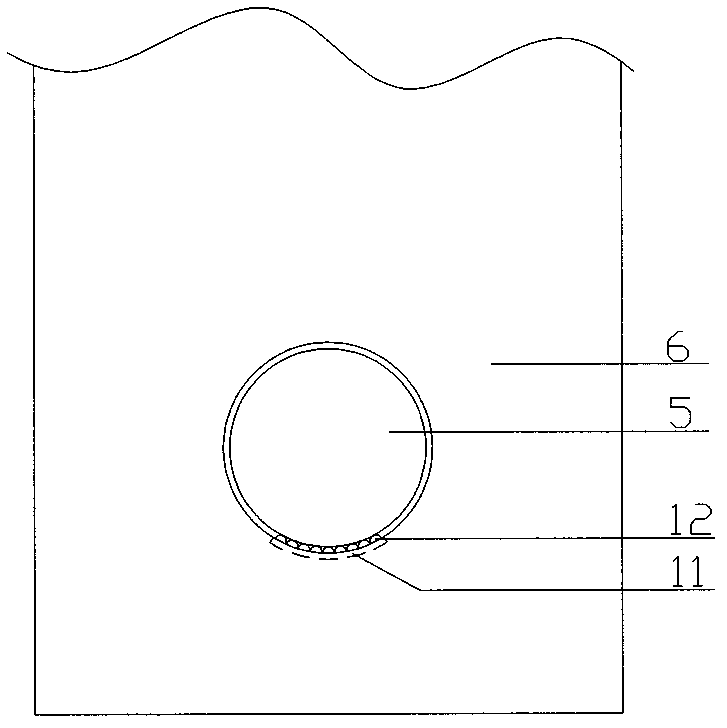

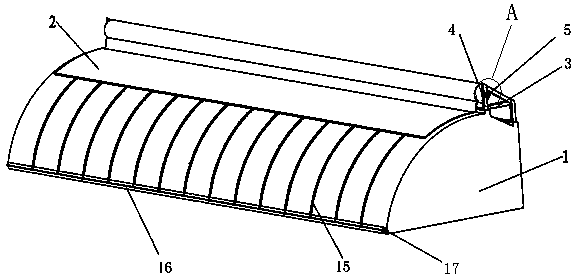

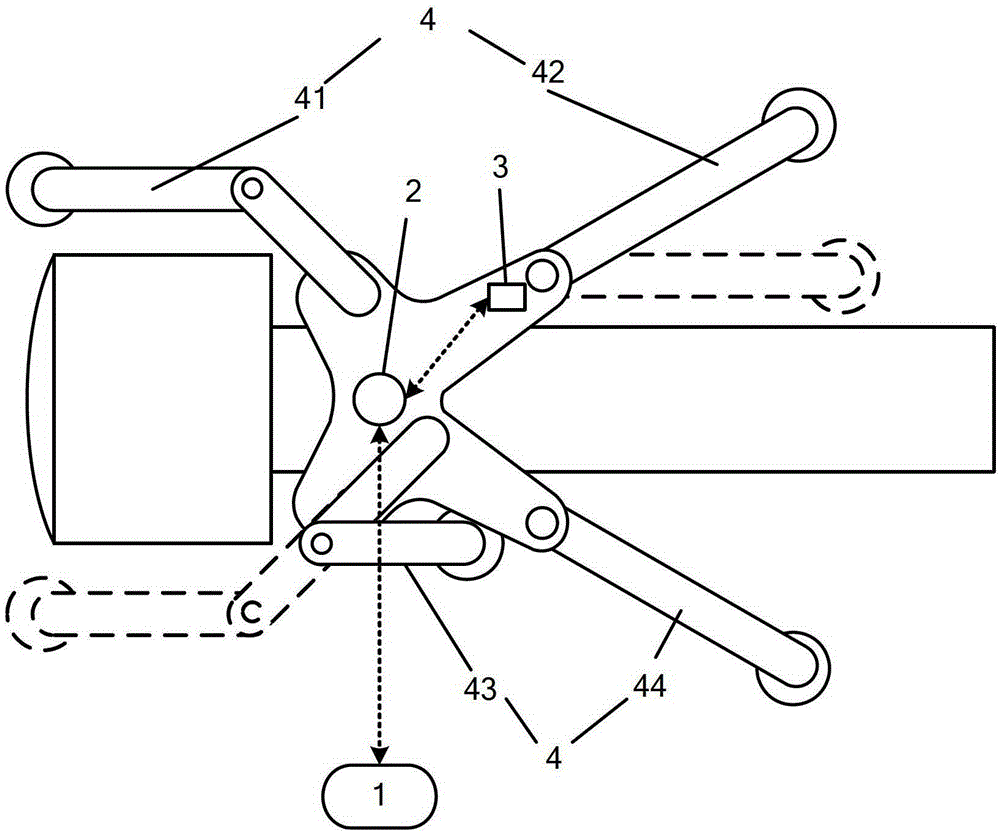

Low clearance tunnel rigid overhead line system cantilever supporting device

The invention discloses a low clearance tunnel rigid overhead line system cantilever supporting device. The device comprises a supporting base (1) fixedly mounted on a tunnel wall, wherein the supporting base (1) is movably connected with a support frame (2); the support frame (2) is arranged slantly along a tunnel vault; the end of the support frame (2) is connected with an insulating part (3); the insulating part (3) is connected with an adjusting support (4); a suspension clamp (5) capable of moving on the adjusting support (4) for adjusting is arranged on the adjusting support (4). The support frame is slantly arranged along the tunnel vault, so that the whole set of device is arch-shaped, the mounting space of a low clearance tunnel can be met, the device also can reach or even be higher than the function of the conventional cantilever supporting device, the structure is simple, and the mounting technology is simplified.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

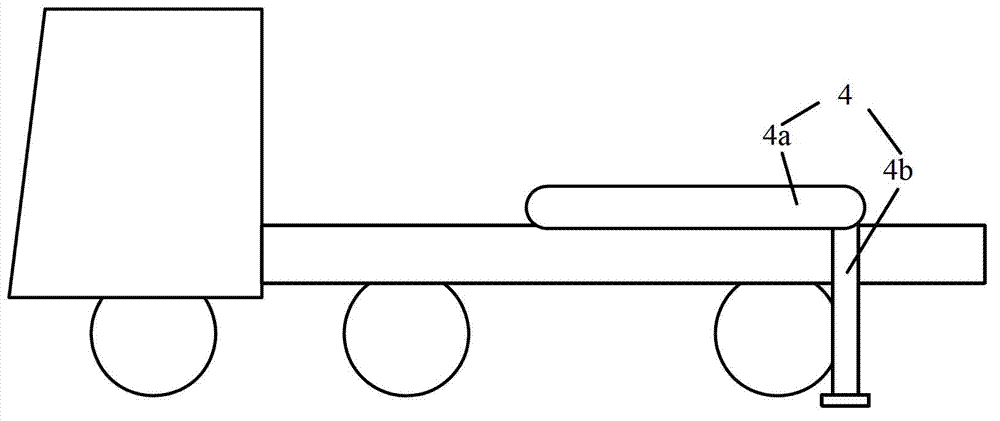

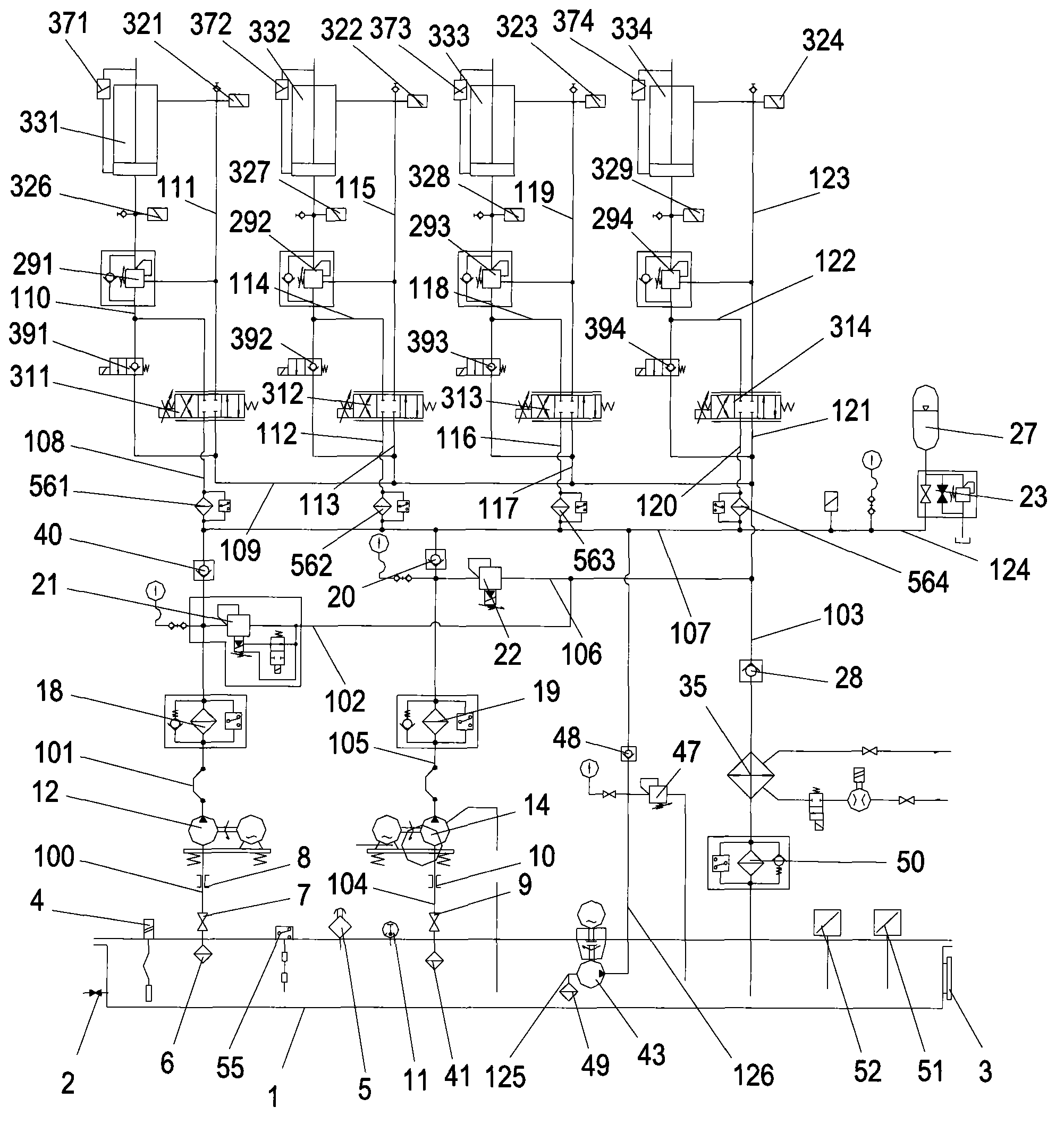

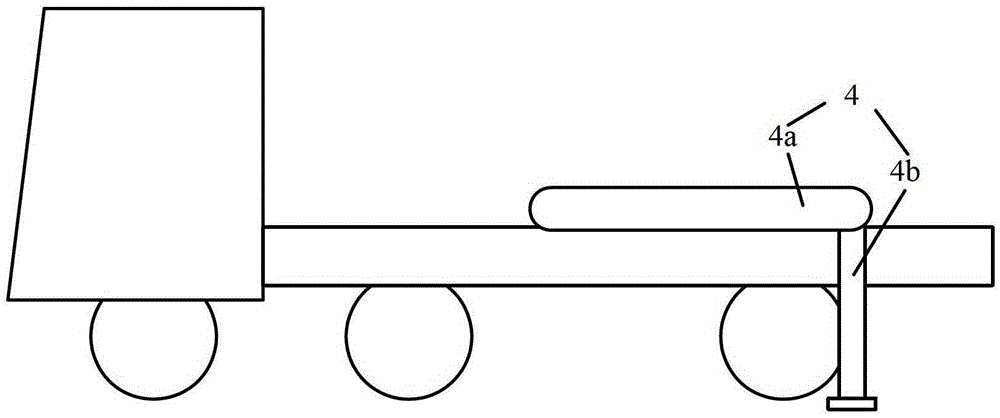

Leg control system and engineering machine

ActiveCN102880145AAvoid unbalanced forceSoil-shifting machines/dredgersCranesControl systemElectromagnetic valve

The invention provides a leg control system which comprises a command transmitting unit, leg controllers and electromagnetic valves for controlling actions of a plurality of legs. The command transmitting unit is used for transmitting a leg control command; the leg controllers simultaneously transmit action instructions to the electromagnetic valves of the legs according to the received leg control command transmitted from the command transmitting unit; and the electromagnetic valves are reversed according to the control instructions so as to control the actions of the legs. Correspondingly, the invention provides an engineering machine. According to the technical scheme, the leg control system and the engineering machine have the advantages that the legs can be controlled simultaneously, and problems of uneven stress and the like when a single leg is controlled are avoided.

Owner:SANY AUTOMOBILE MFG CO LTD

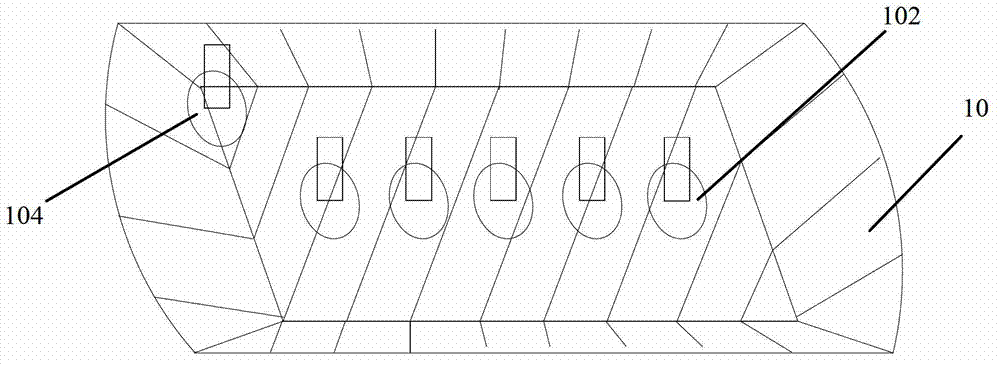

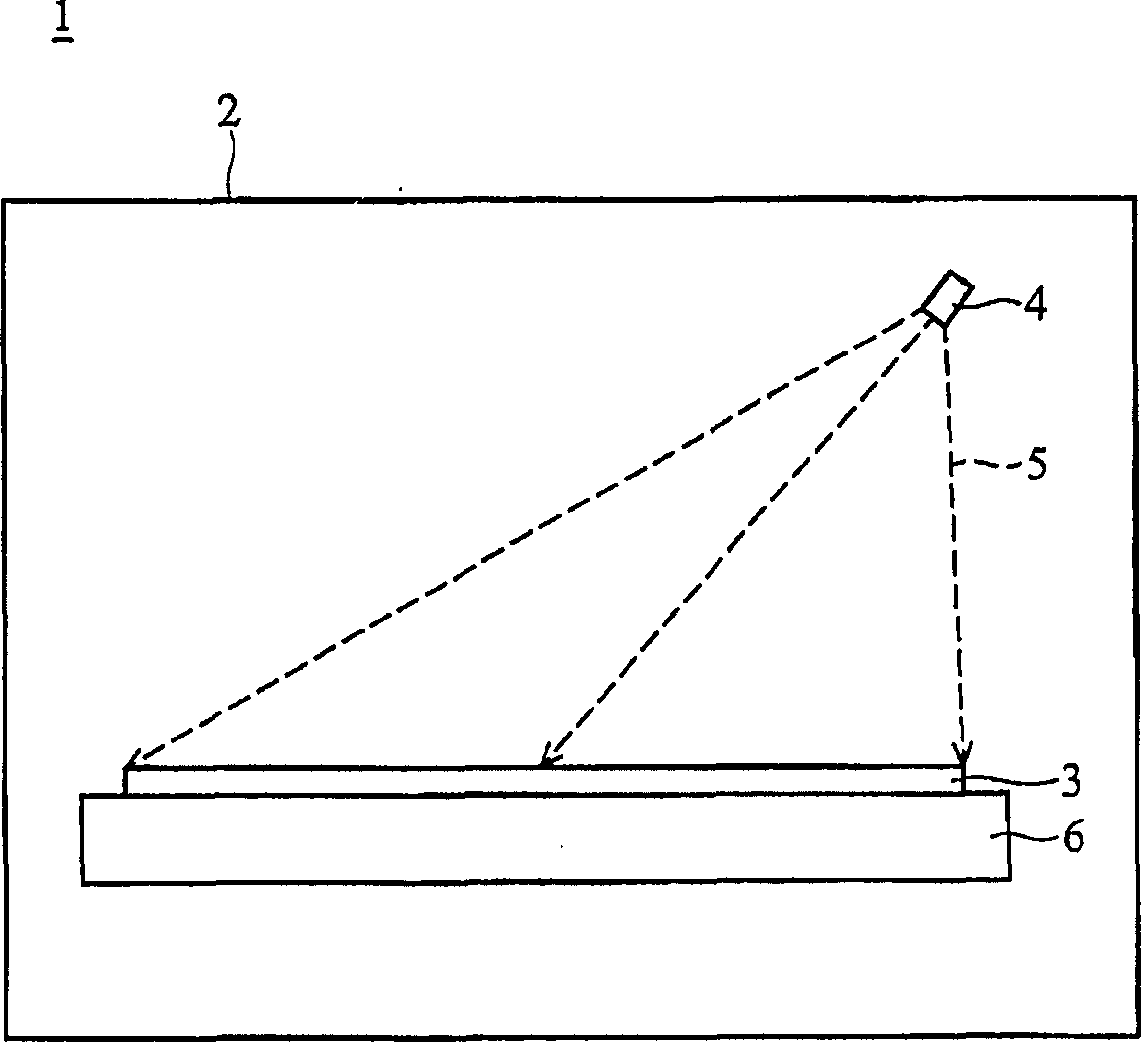

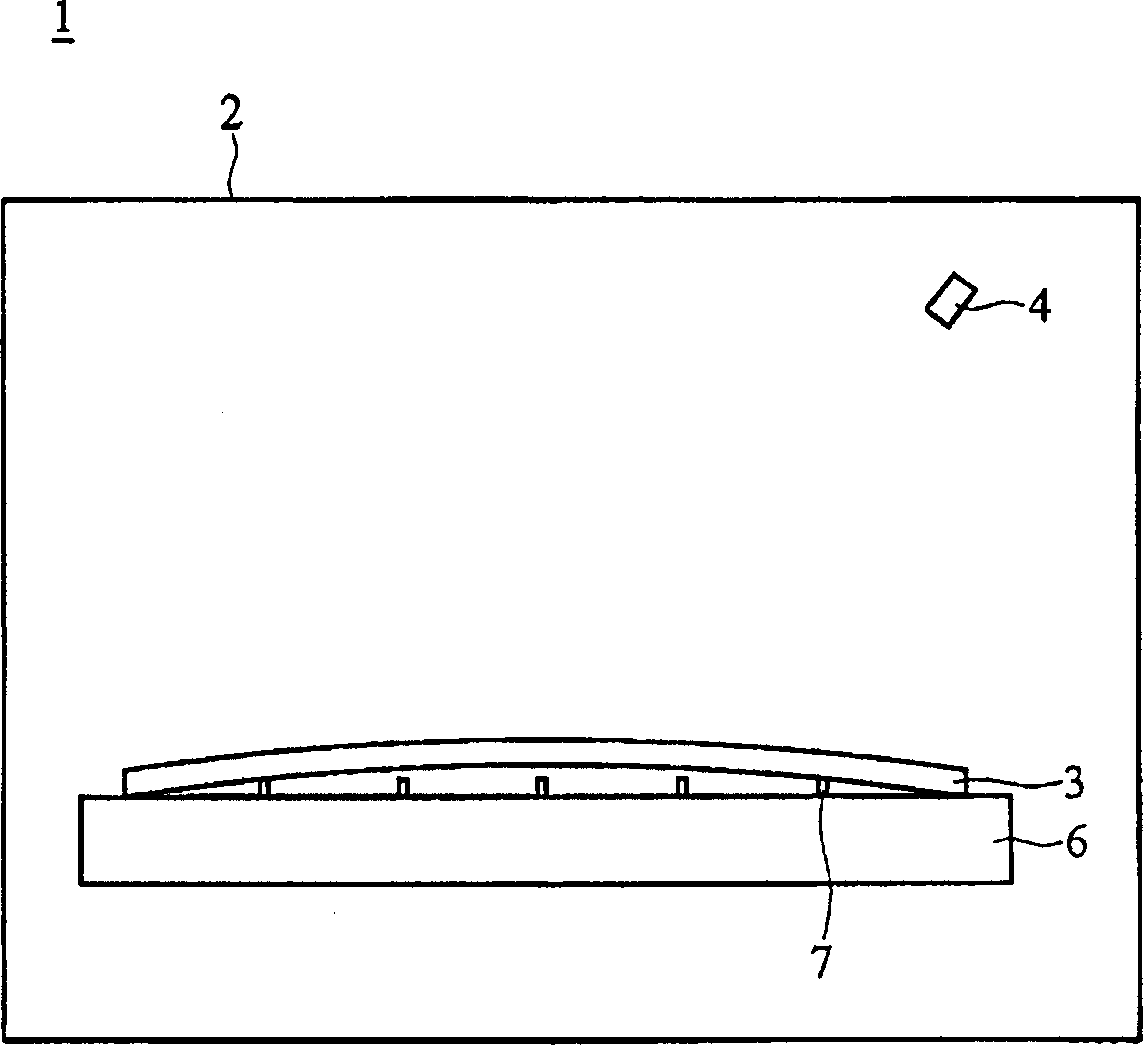

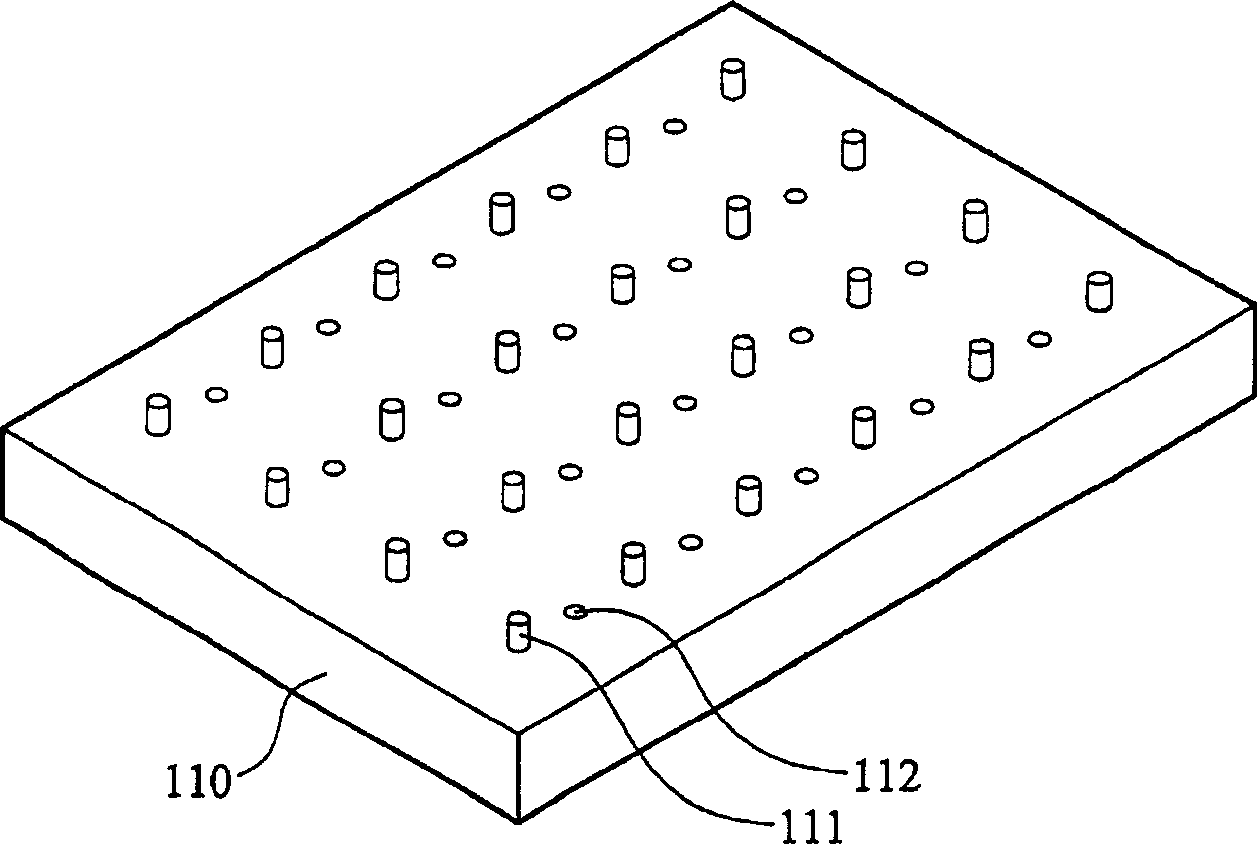

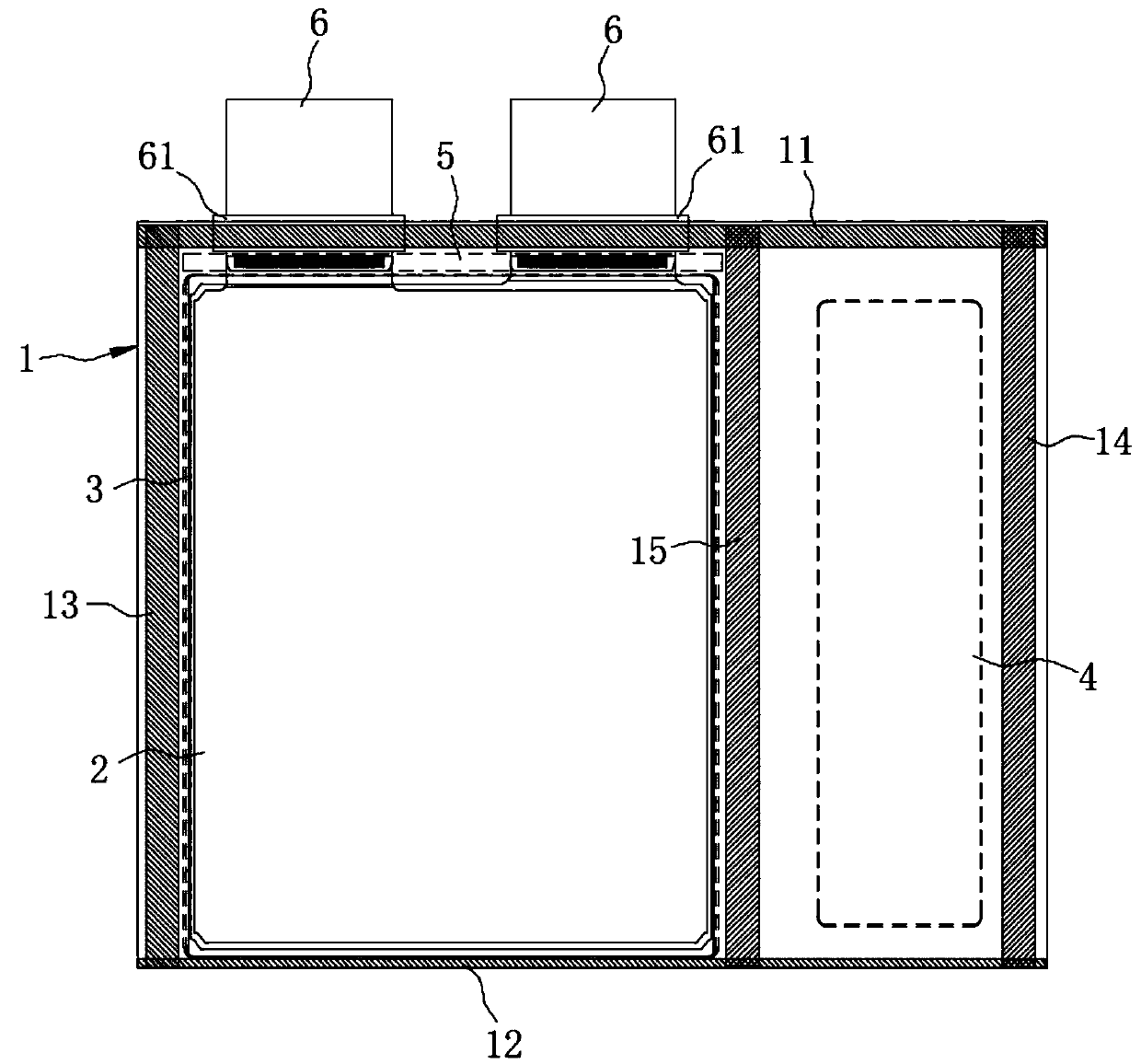

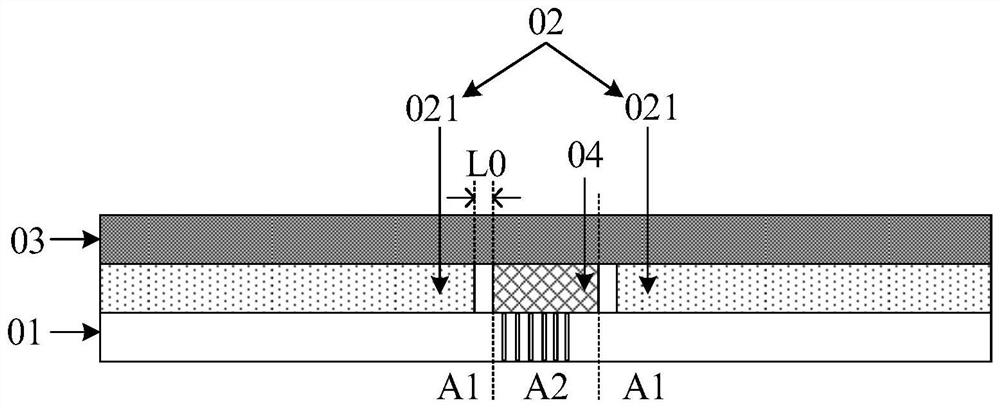

Method for removing static on substrate, apparatus and base thereof

ActiveCN1808280AEliminate static electricityAvoid unbalanced forceSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineering

Disclosed is a machine bench for processing base boards. The machine bench comprises a base plate, a supporting structure and a projecting column. The supporting structure is placed on the base plate and supports the base plate. The projecting column is placed on the base plate, where in the ion gas can be sprayed out by the supporting structure and / or the projecting column for eliminating statistic charge on the base board.

Owner:AU OPTRONICS CORP

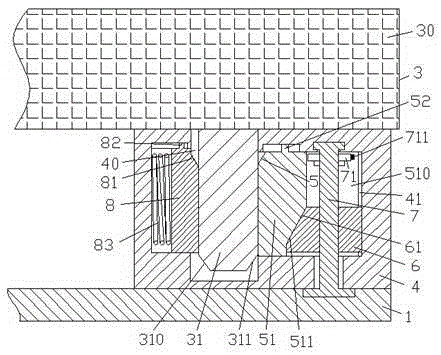

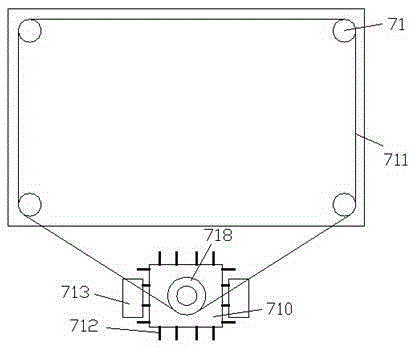

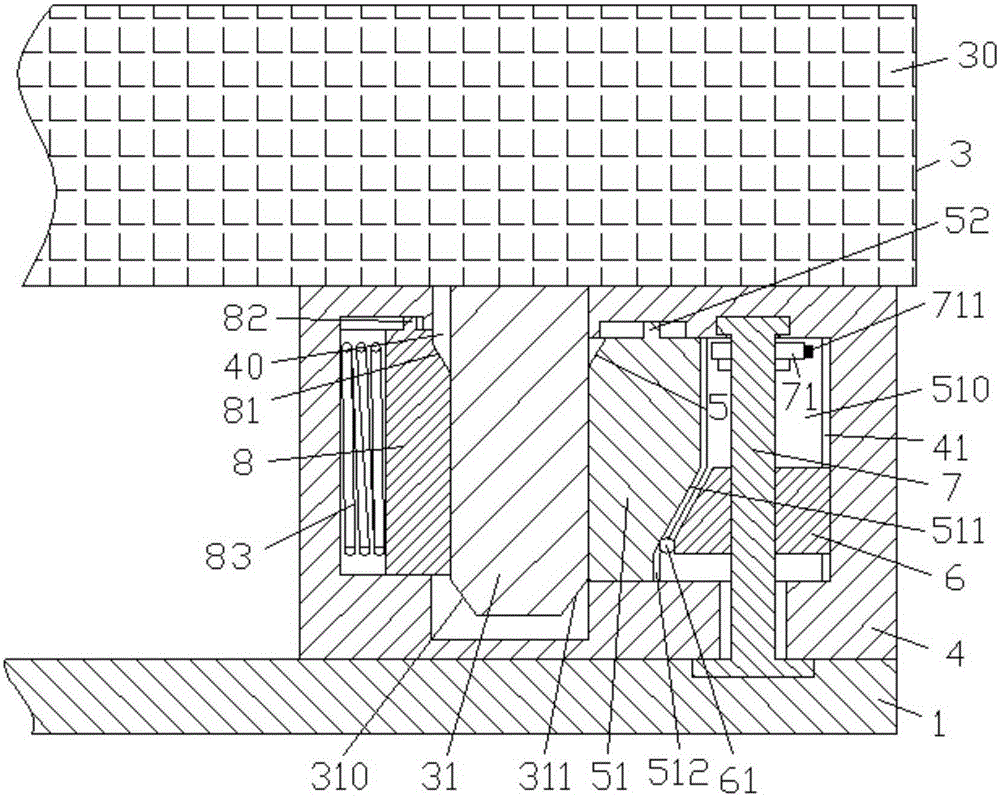

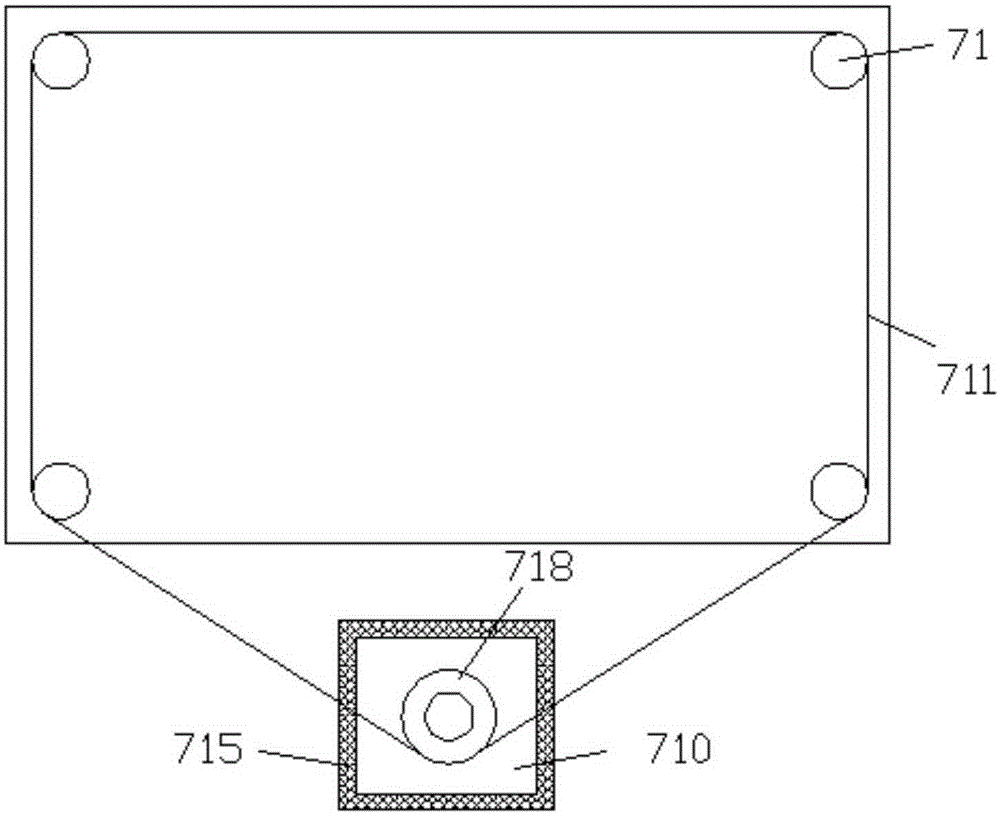

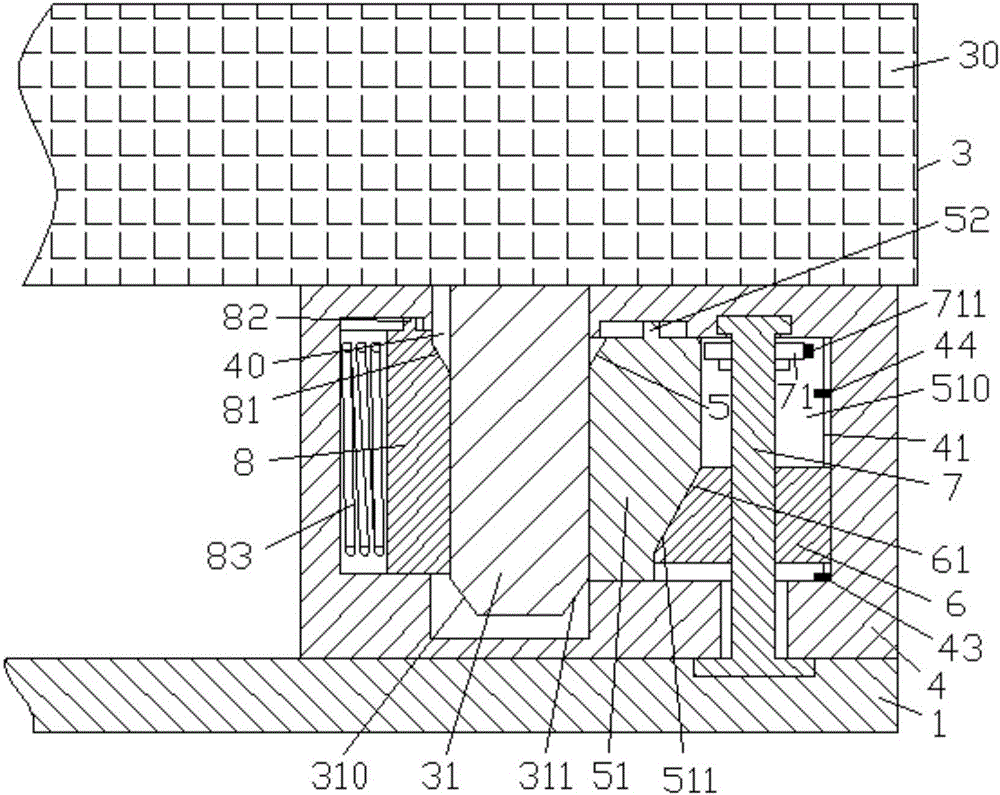

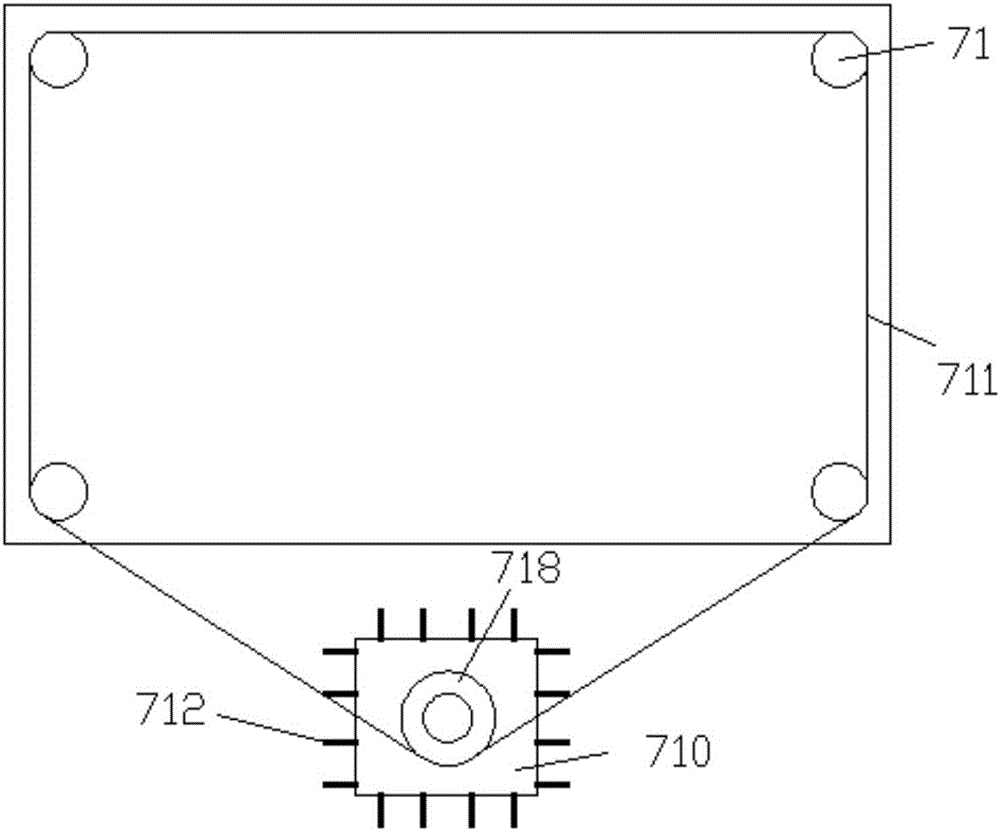

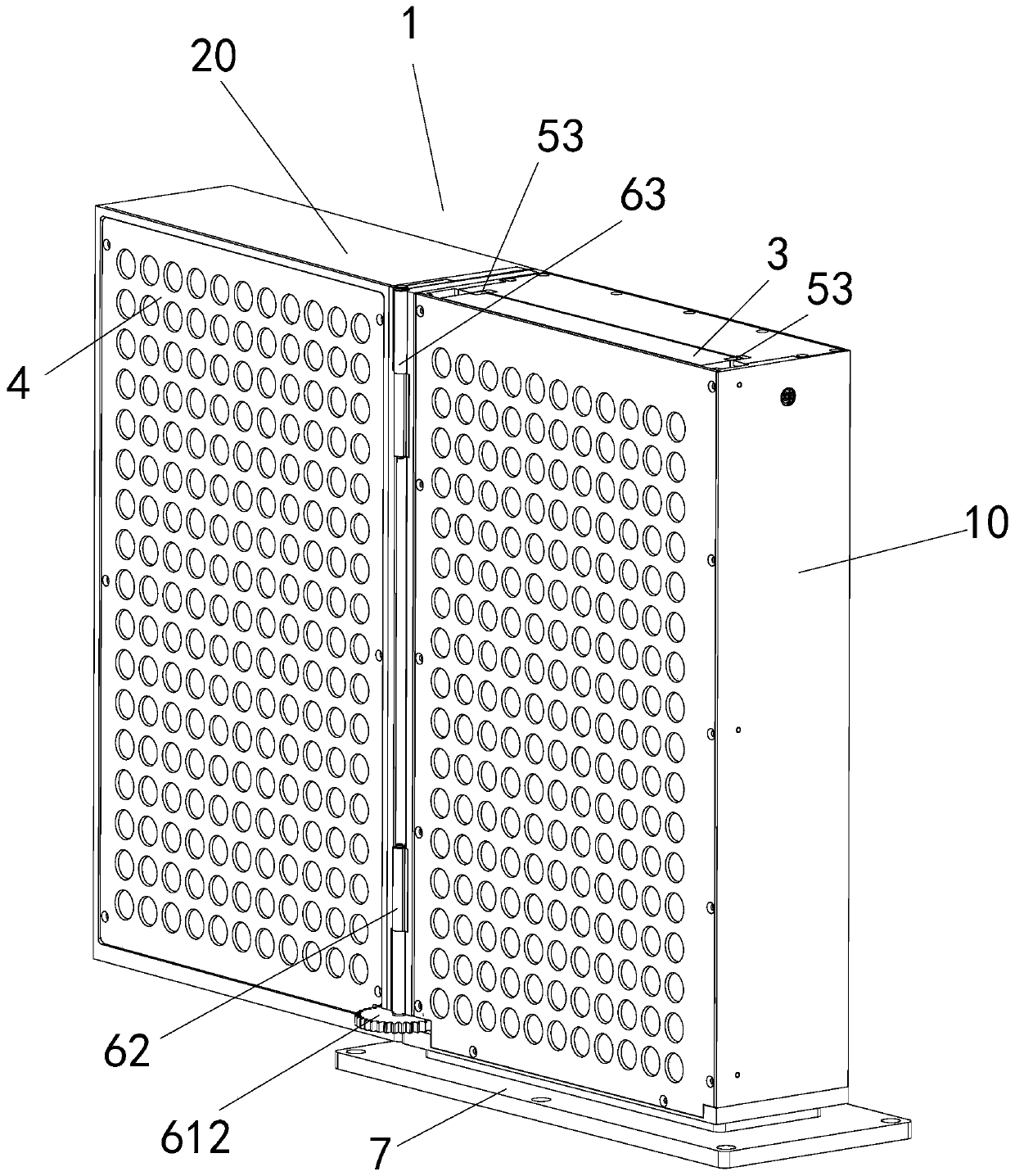

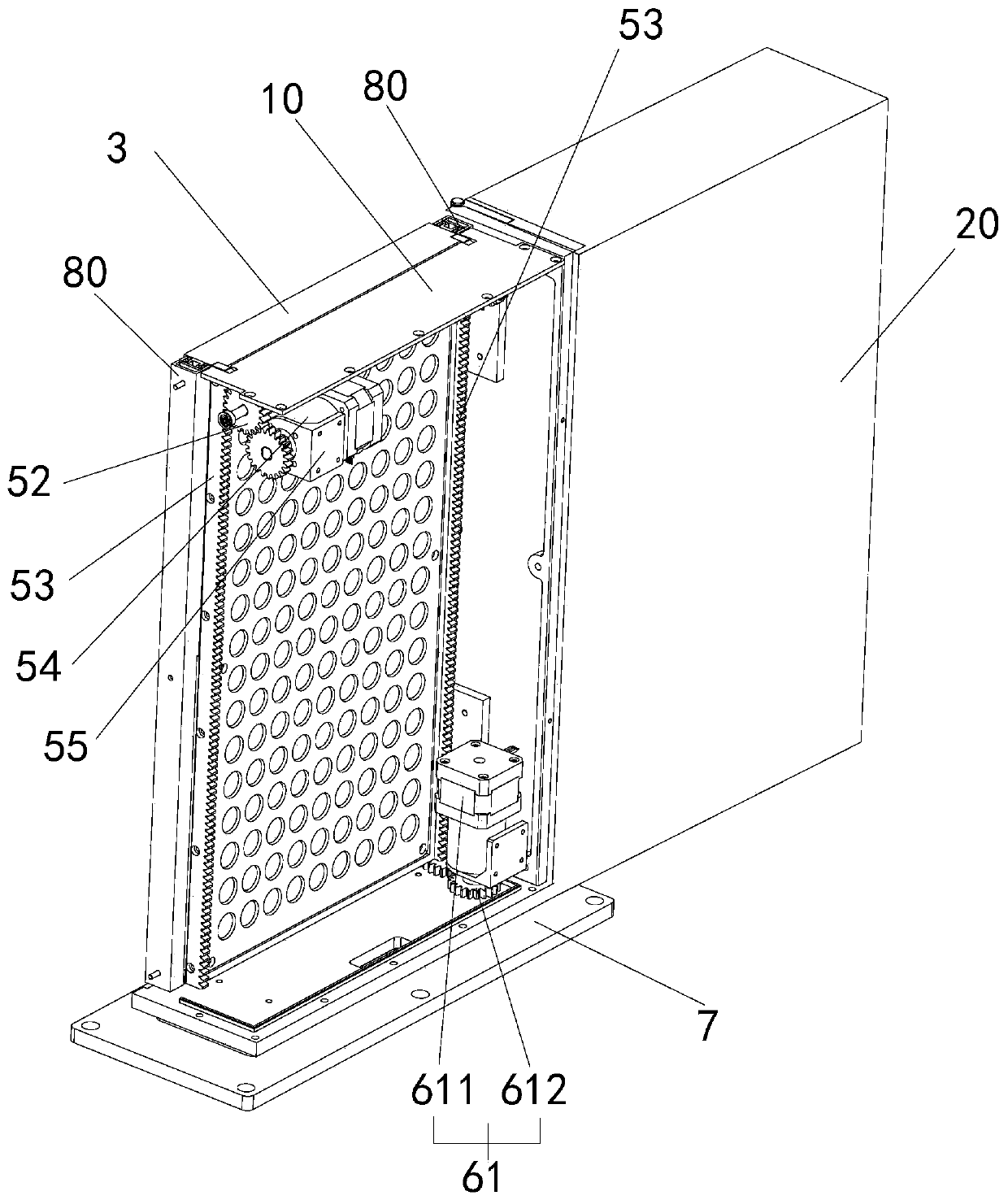

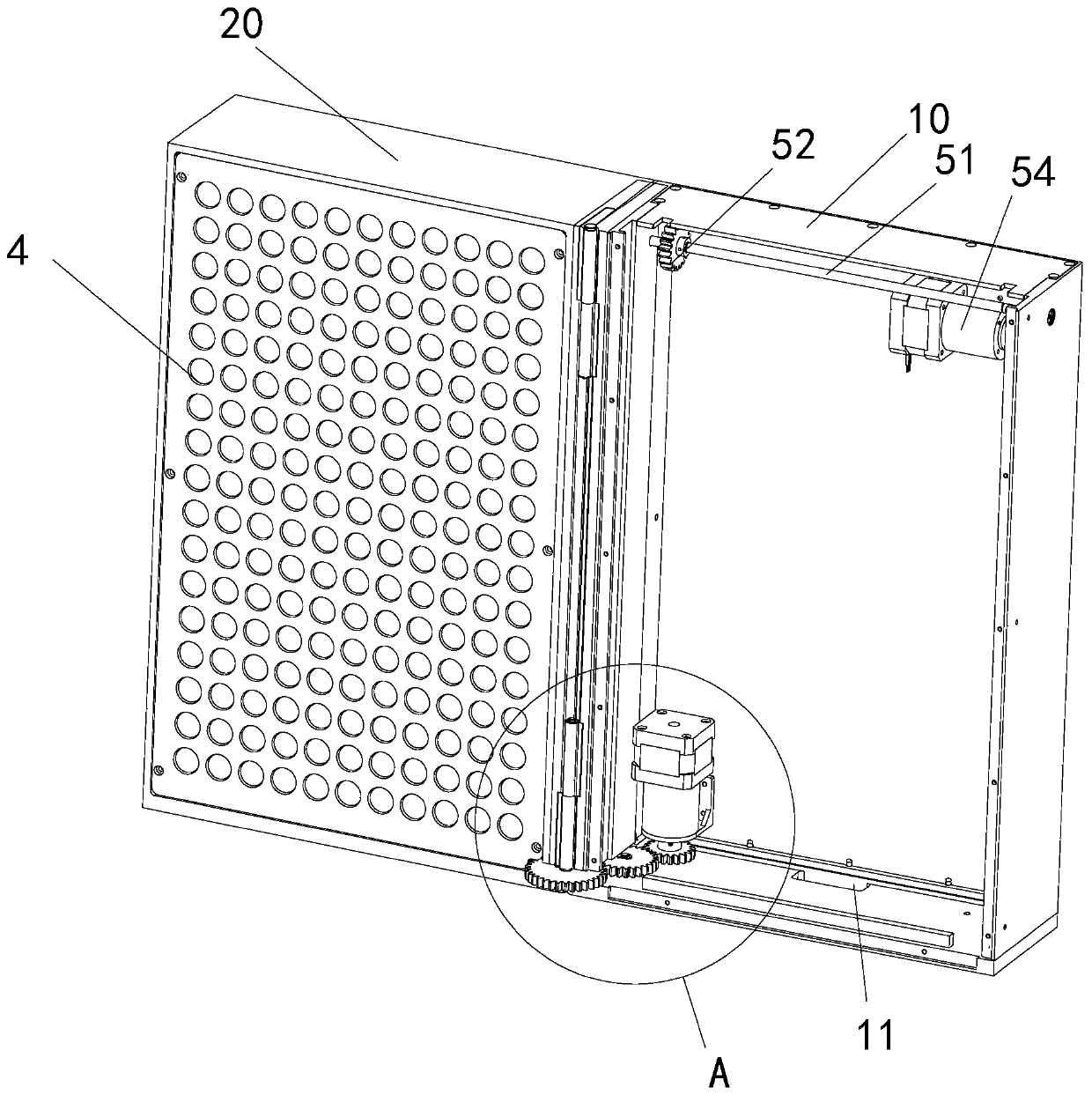

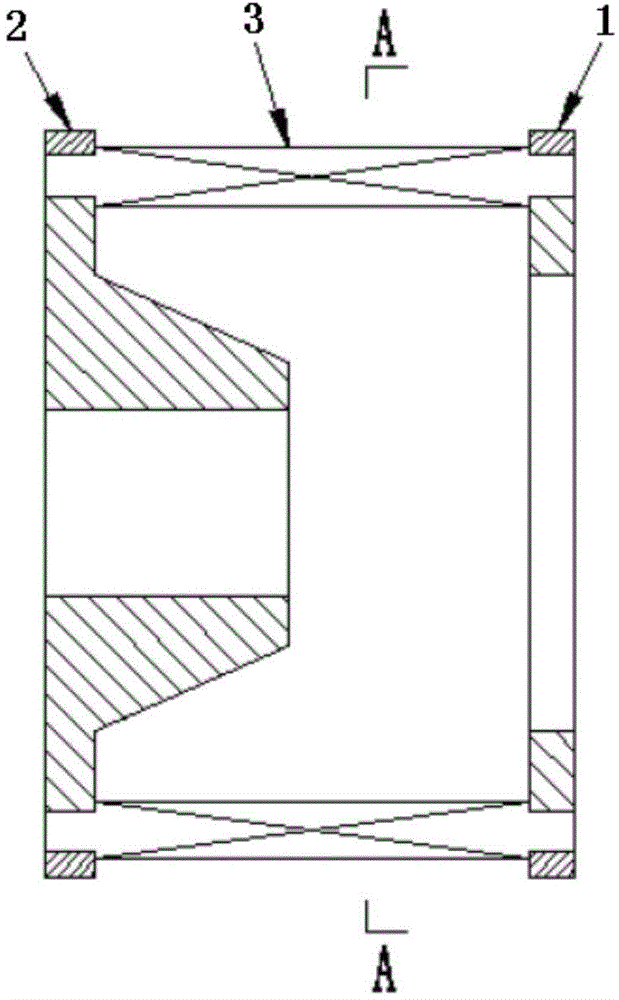

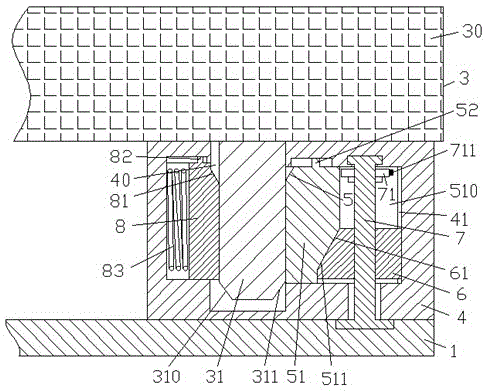

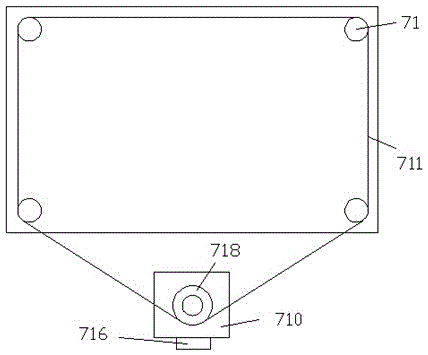

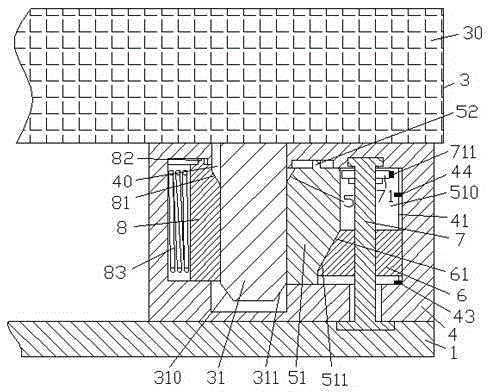

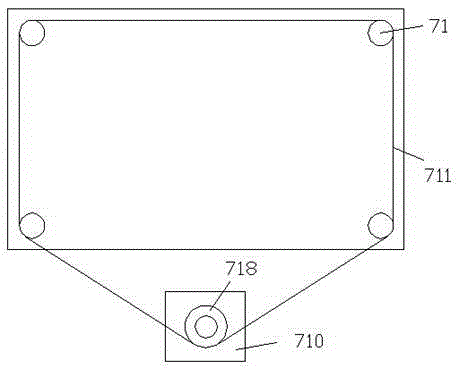

Circuit board assembly driven by chain and provided with locking indicator lamp

InactiveCN105240359AAvoid mounting fixesRealize the installation and fixationSheet joiningEngineeringElectrical and Electronics engineering

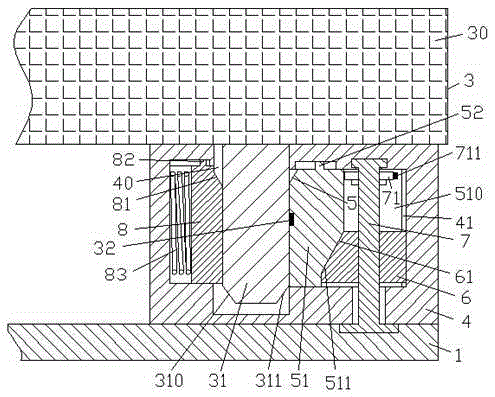

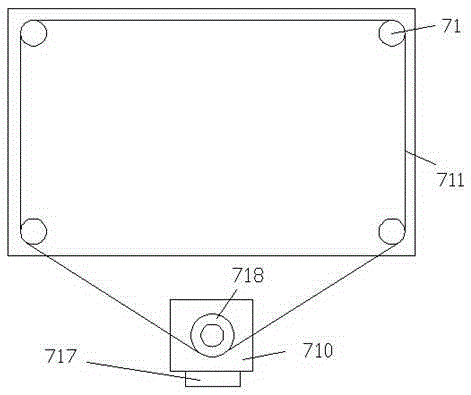

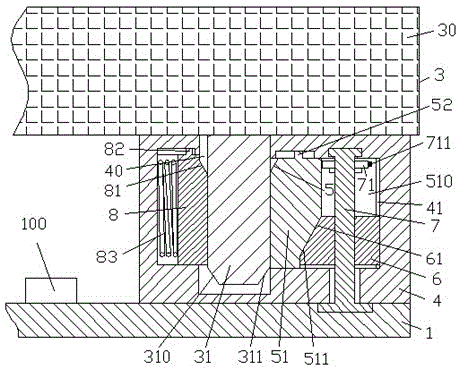

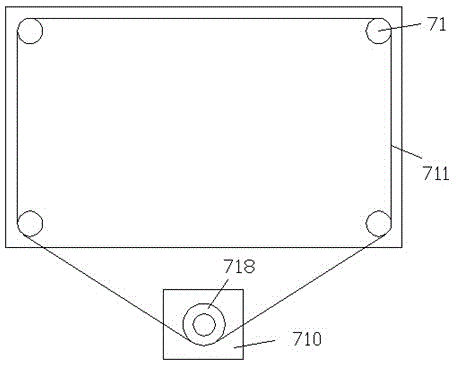

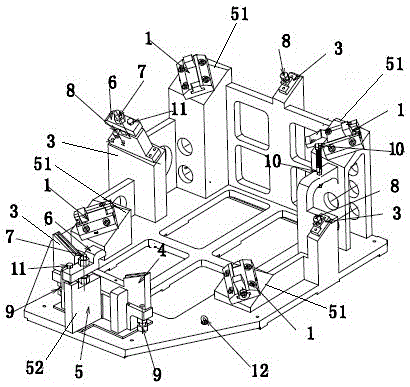

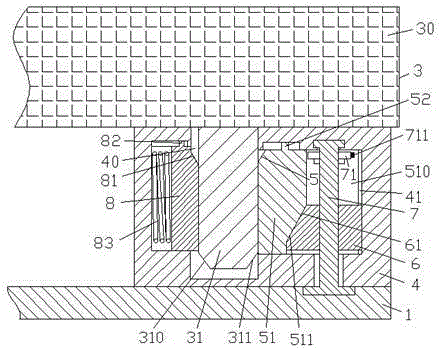

The invention discloses a circuit board assembly driven by a chain and provided with a locking indicator lamp. The circuit board assembly comprises a circuit board device (3) and a base fixing device. The circuit board device (3) comprises a rectangular body part (30) and four fixed feet (31) located at the corners of the rectangle respectively. The base fixing device comprises a base (1) and four mounting frames (4) which are fixed to the base (1) and correspond to the four fixed feet (31) respectively. Inserting grooves (40) allowing the fixed feet (31) to be inserted are formed in the mounting frames (4), and inside clamping blocks (8) which are biased by the jacking and pressing springs (83) and can stretch into the inserting grooves (40) are arranged at the inner sides, close to the inner side of the body part (30) of the circuit board device (3), of the inserting grooves (40) of the mounting frames (4).

Owner:肖锐

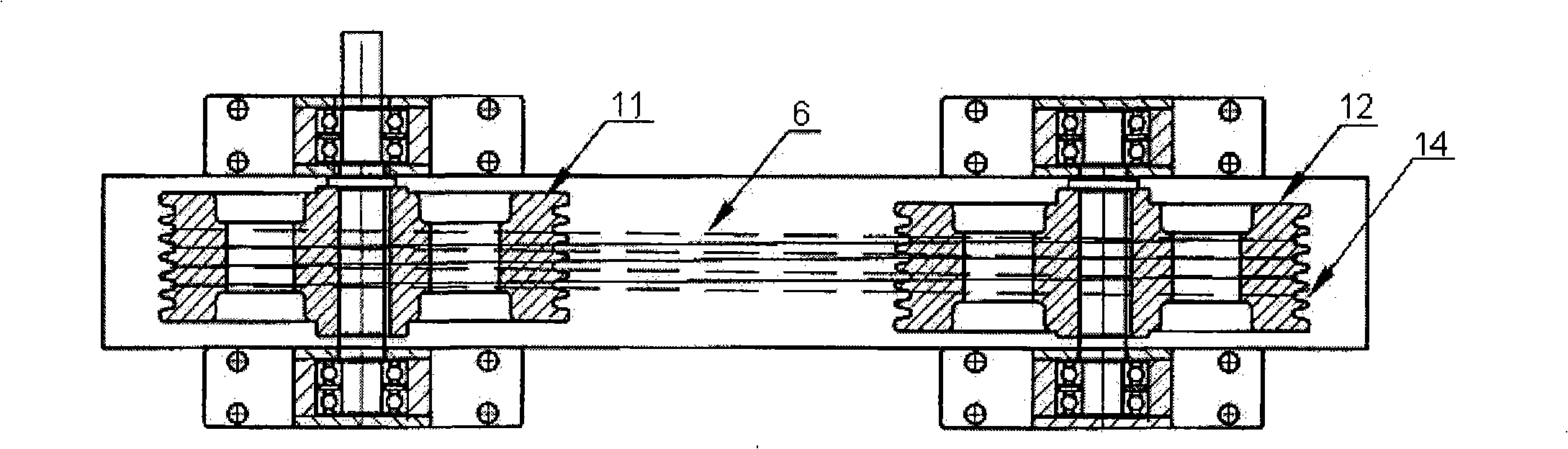

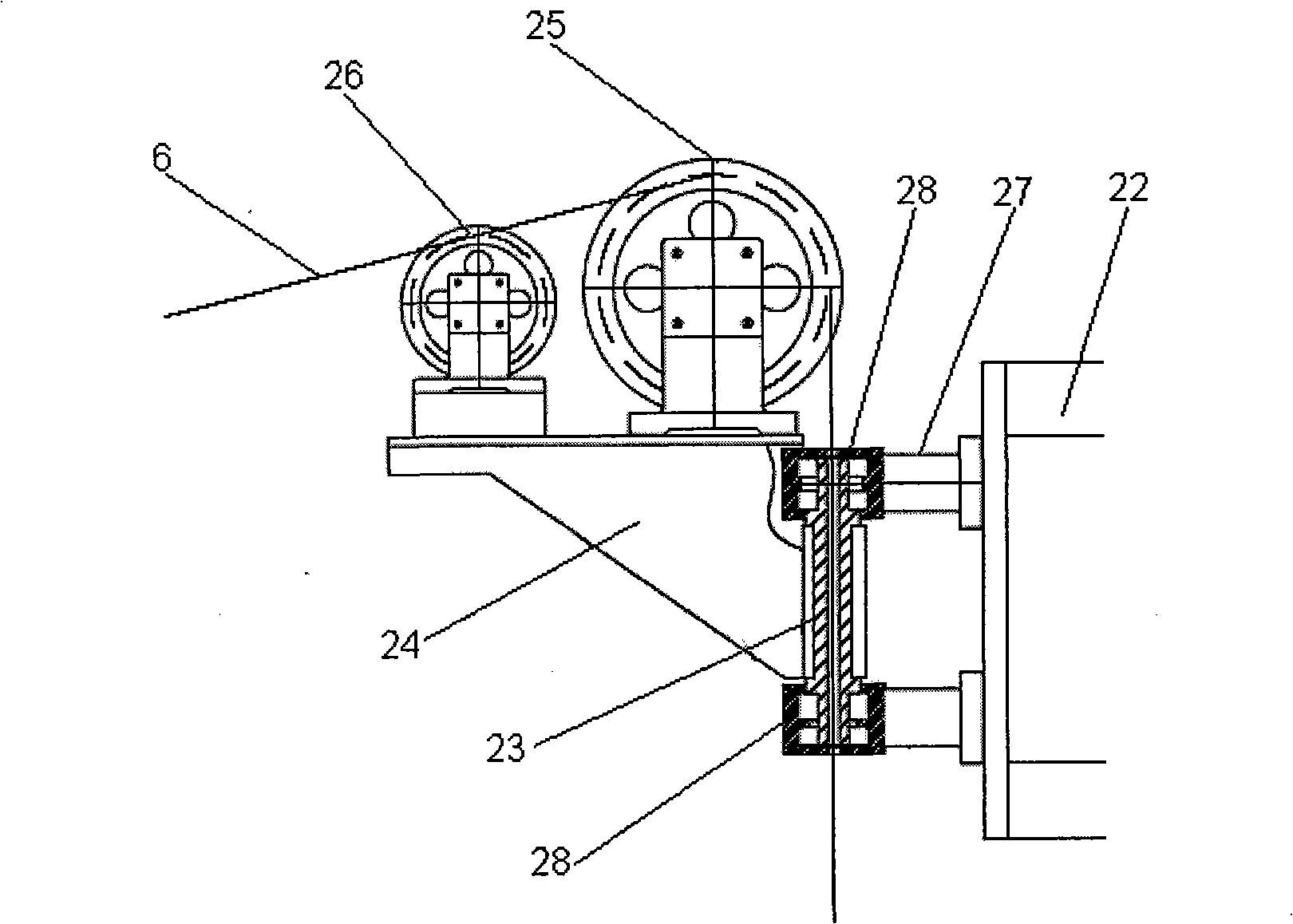

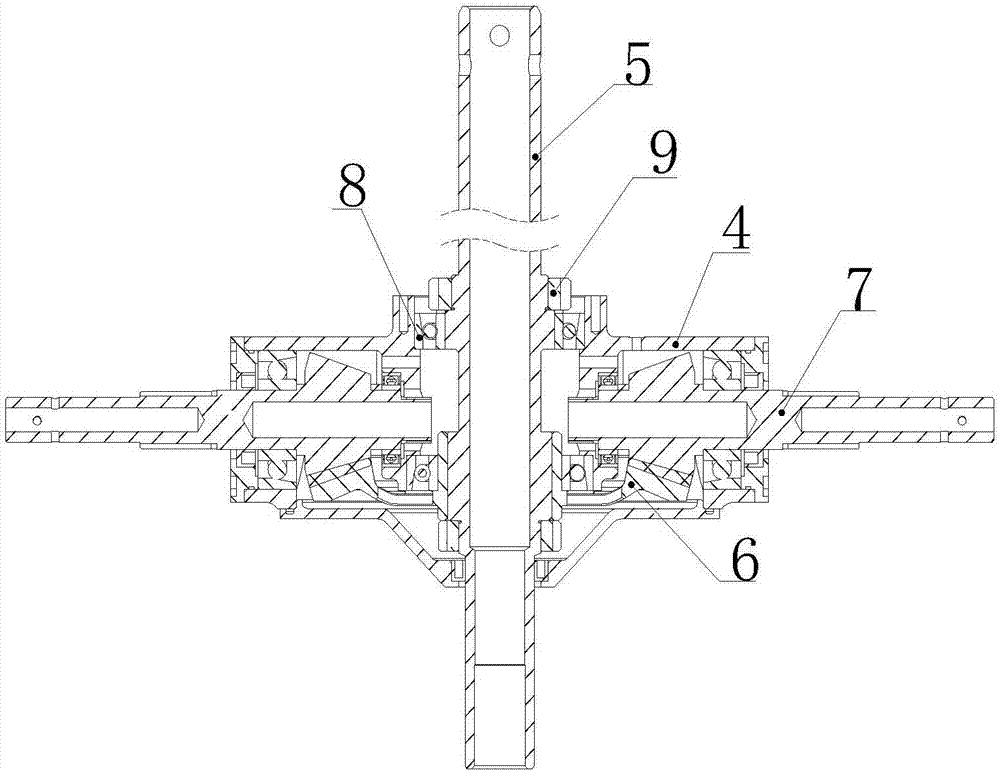

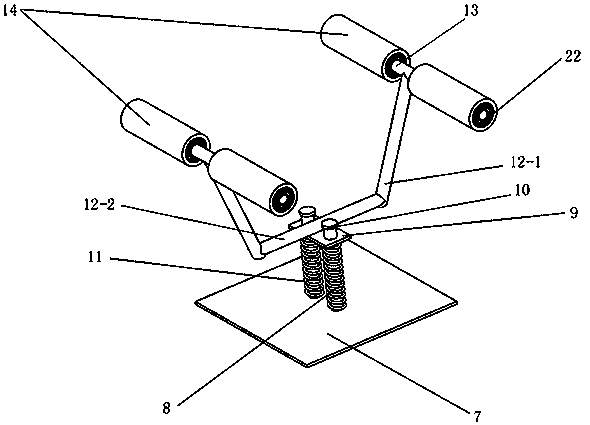

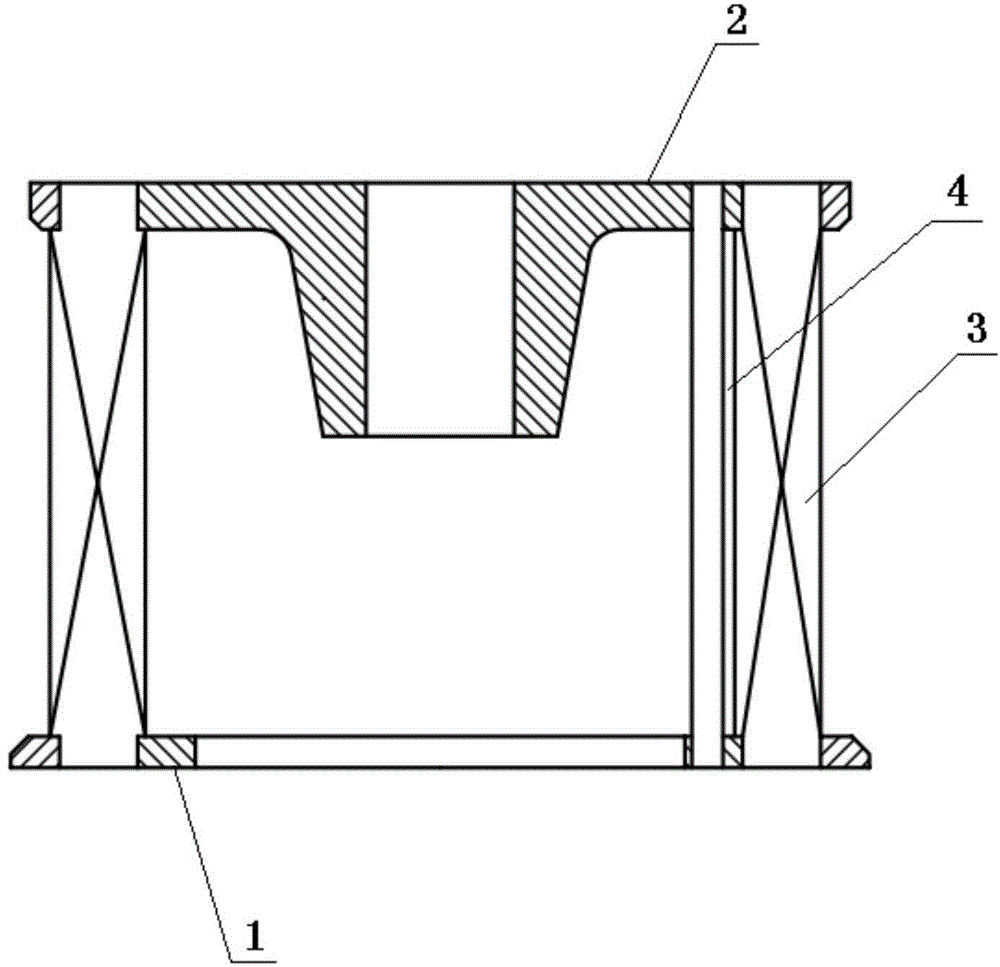

Cable parallel mechanism automatic tracking steering transmission gear

The invention relates to an automatic tracking steering transmission device of a rope parallel mechanism which is characterized in that the device comprises an endless rope transmission mechanism, a pulley steering tracking mechanism, a weight mechanism, a bracket, a base and a rope; the endless rope transmission mechanism and the bracket are respectively arranged at the two sides of the top of the base; the endless rope transmission mechanism comprises a wire-out driving wheel and a wire-out driven wheel; the wire-out driving wheel and the wire-out driven wheel are respectively processed with ring grooves which have consistent multi-channel pitch circles and are independently sealed, and are staggered by half groove position when being installed; the pulley steering tracking mechanism comprises a bottom wire-out pulley, a hollow shaft seat, a hollow shaft, a rotating frame and a top wire-out pulley; the bottom wire-out pulley is arranged on the base at the outside of the bracket; the hollow shaft seat is fixed at the top of the bracket and arranged on the hollow shaft seat vertically and rotatablely by two bearings; the rotating frame is fixed on the hollow shaft; the top wire-out pulley is fixed on the rotating frame. The invention is an ideal transmission device of the rope parallel mechanism and can be widely applied to the rope transmission of various rope parallel mechanisms.

Owner:TSINGHUA UNIV

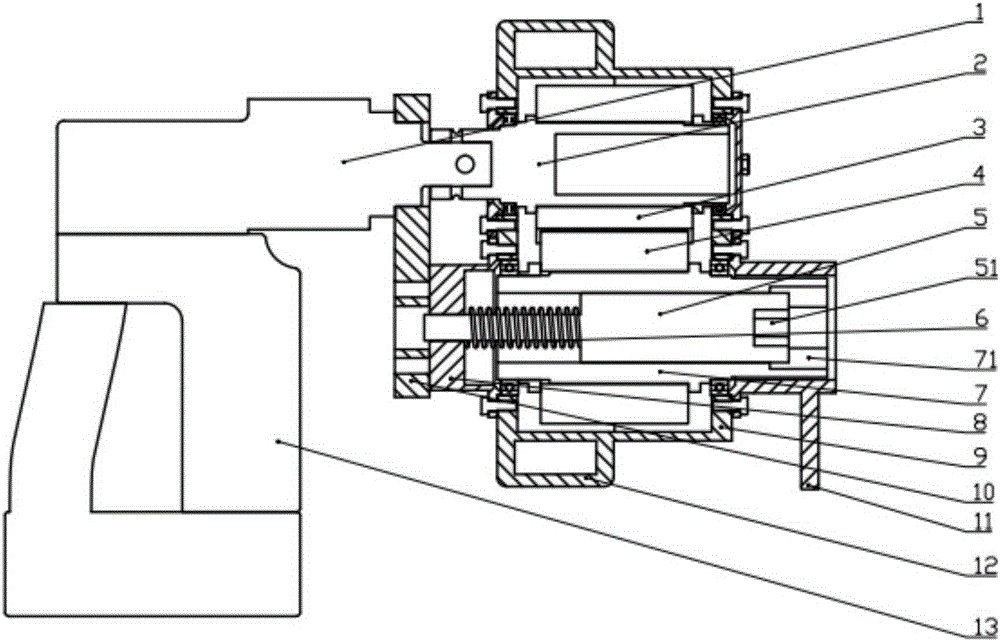

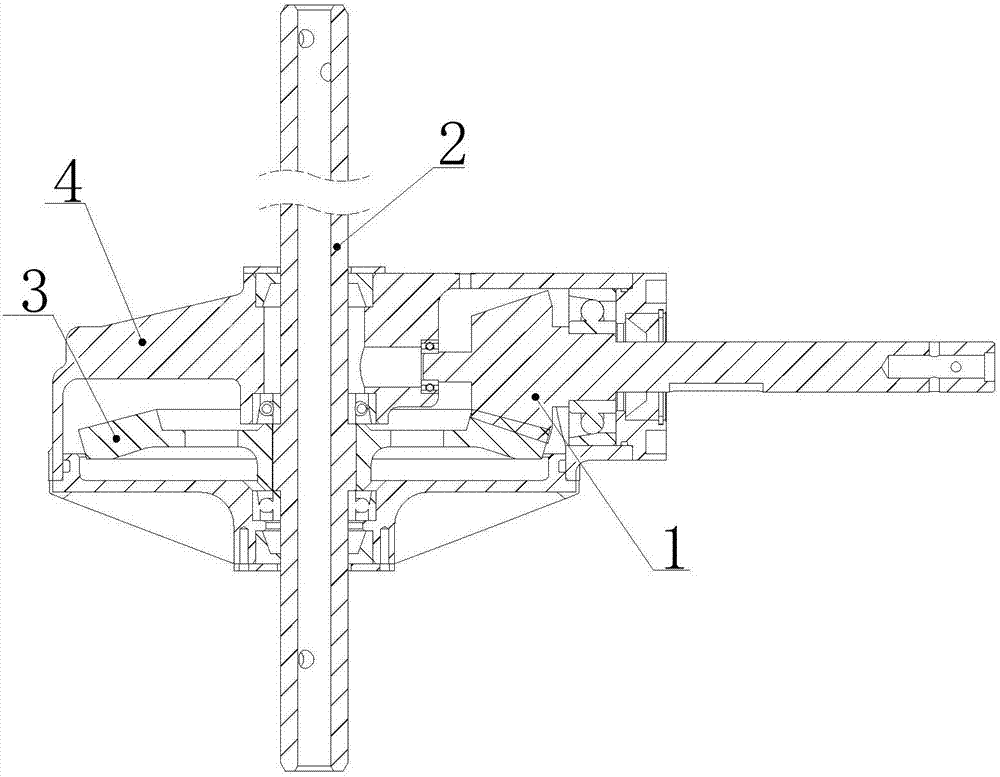

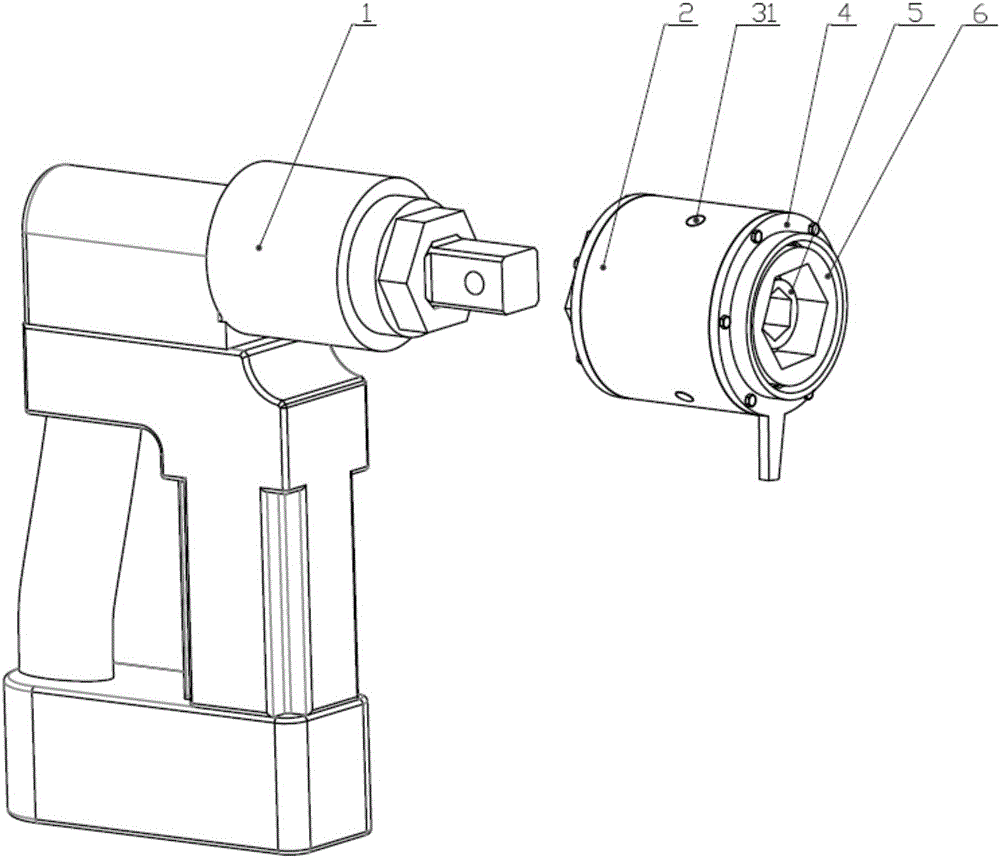

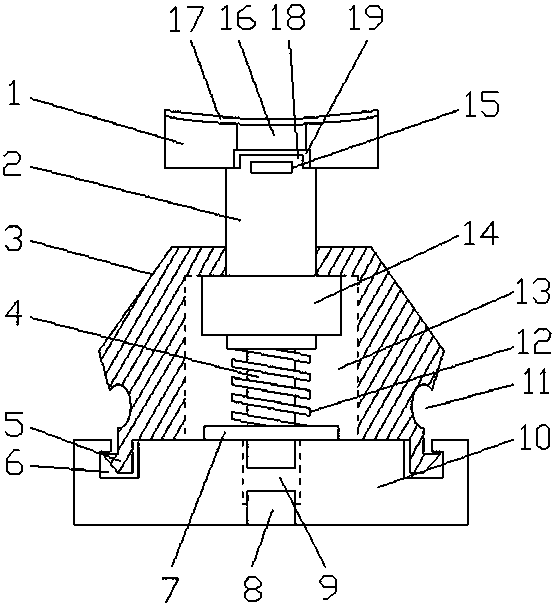

Electric mounting tool for split nested one-sided bolt fastener

ActiveCN105328650AGuaranteed installation reliabilityGood mechanical propertiesPortable power-driven toolsPower driven toolsFastenerGasket

The invention relates to an electric mounting tool for a split nested one-sided bolt fastener, which is used for mounting the split nested one-sided bolt fastener. The bolt fastener comprises a bolt (14), a nut (16) and a split gasket (15); the tool comprises a main body, an input mechanism and an output mechanism; the input mechanism and the output mechanism are arranged on the main body; the output mechanism comprises an inner output shaft sleeve (5) and an outer output shaft sleeve (7) sleeving the inner output shaft sleeve (5); a first gear (4) which is connected with the input mechanism in a meshing way is arranged on the outer wall of the outer output shaft sleeve (7); the inner output shaft sleeve (5) is fixed on the main body; the outer output shaft sleeve (7) is connected with the nut (16); the inner output shaft sleeve (5) is connected with the bolt (14); and the input mechanism rotates and drives the outer output shaft sleeve (7) to rotate via the first gear (4), so that the bolt (14) and the nut (16) rotate relatively to finish mounting. Compared with the prior art, the electric mounting tool has the advantages of high reliability, high adaptability and simple structure.

Owner:TONGJI UNIV

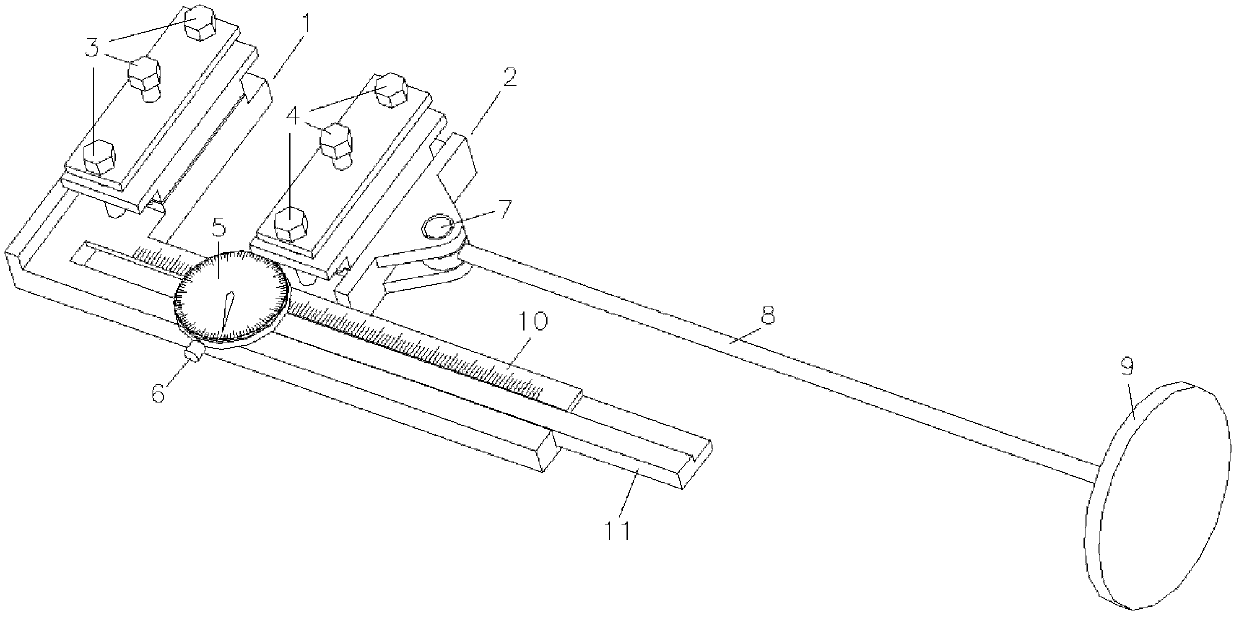

Clamp for measuring creep deformation of geo-grid material, and using method thereof

InactiveCN102607943AEven by forceReduce experimental errorStrength propertiesEngineeringEconomic shortage

The invention relates to a clamp for measuring creep deformation of a geo-grid material, and a using method thereof. The clamp comprises an upper clamp and a lower clamp; the upper clamp and the lower clamp are vertically connected with an outside measuring rule and an inside measuring rule at the same side, respectively; the outside measuring rule and the inside measuring rule are sleeved and slidingly connected; a graduated disc is arranged at the connection part between the inner side measuring rule and the lower clamp; the lower clamp is movably connected with a load rod through a rotating shaft; and the load rod is connected with a tray. According to the invention, the shortage in the existing creep deformation experiment process is avoided, the experimental error is reduced successfully, the stress born by the grid is more uniform, the load application is more normative, the accuracy rate is higher, the experimental error caused by manual factor is greatly avoided, the operation is convenient, the experiment efficiency is enhanced, and the practicality is higher.

Owner:SHANDONG UNIV

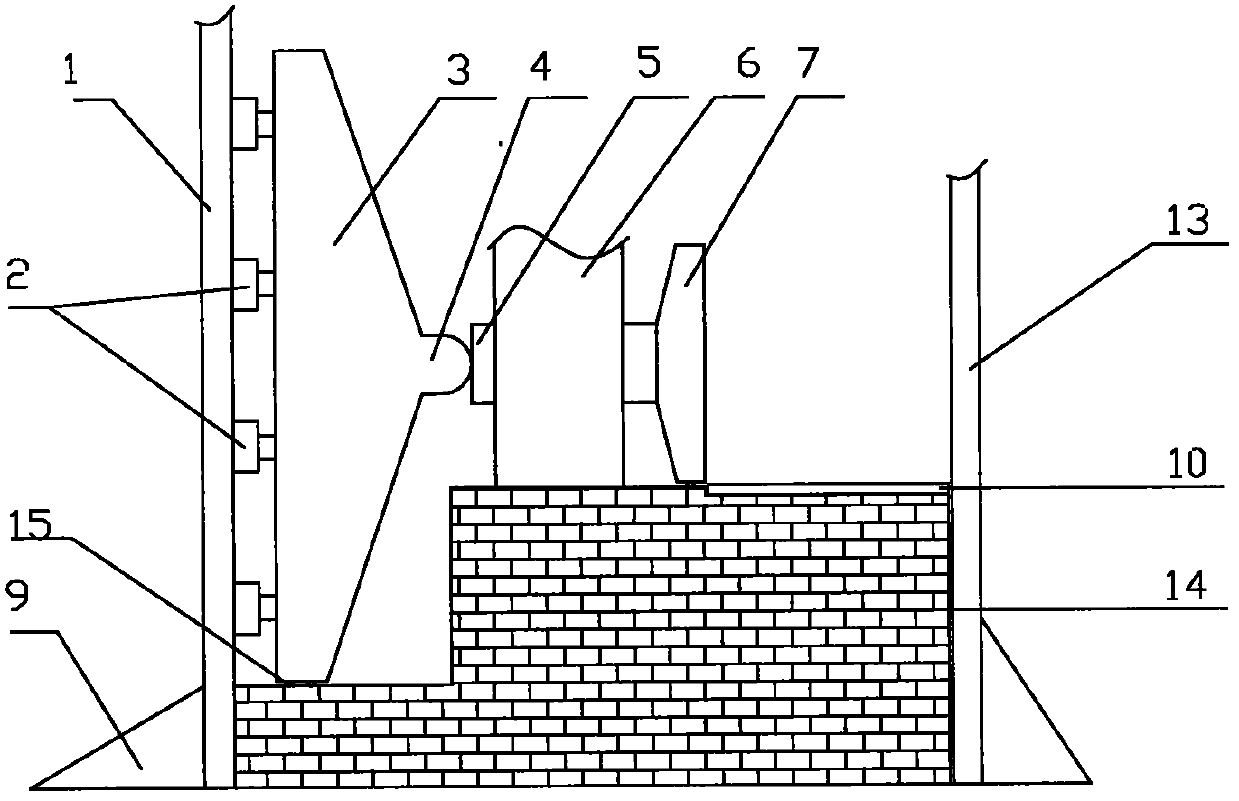

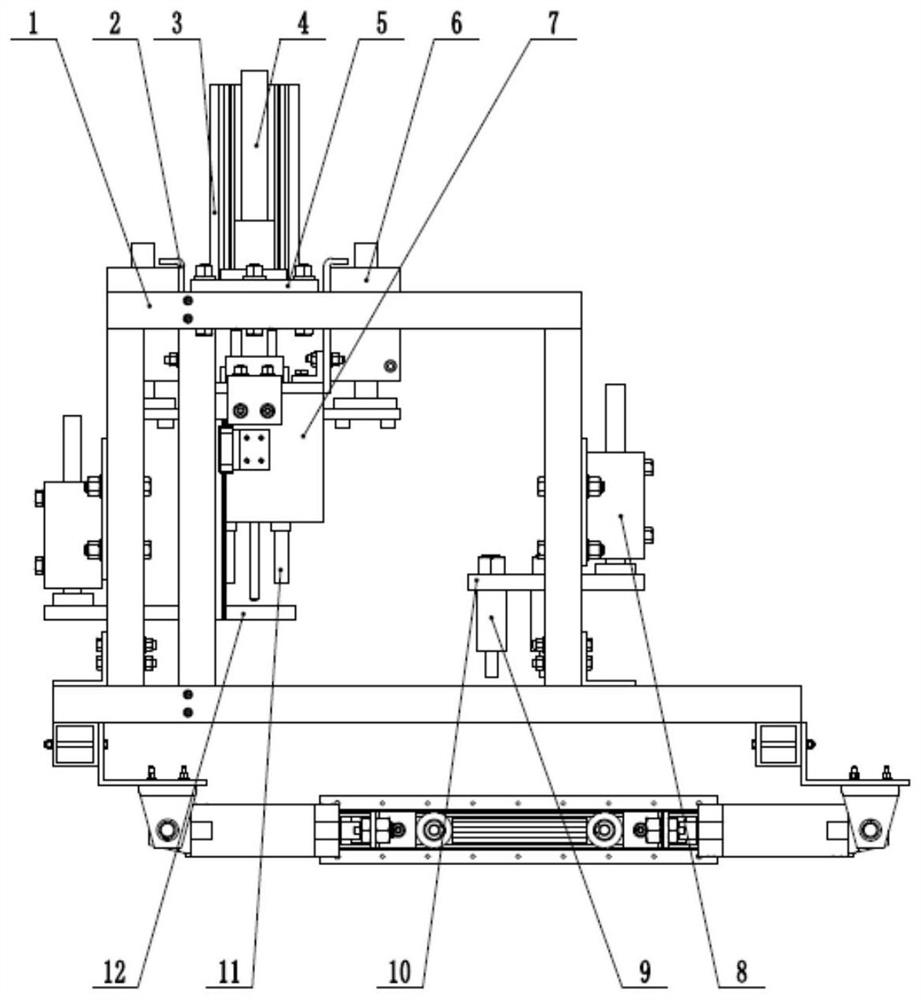

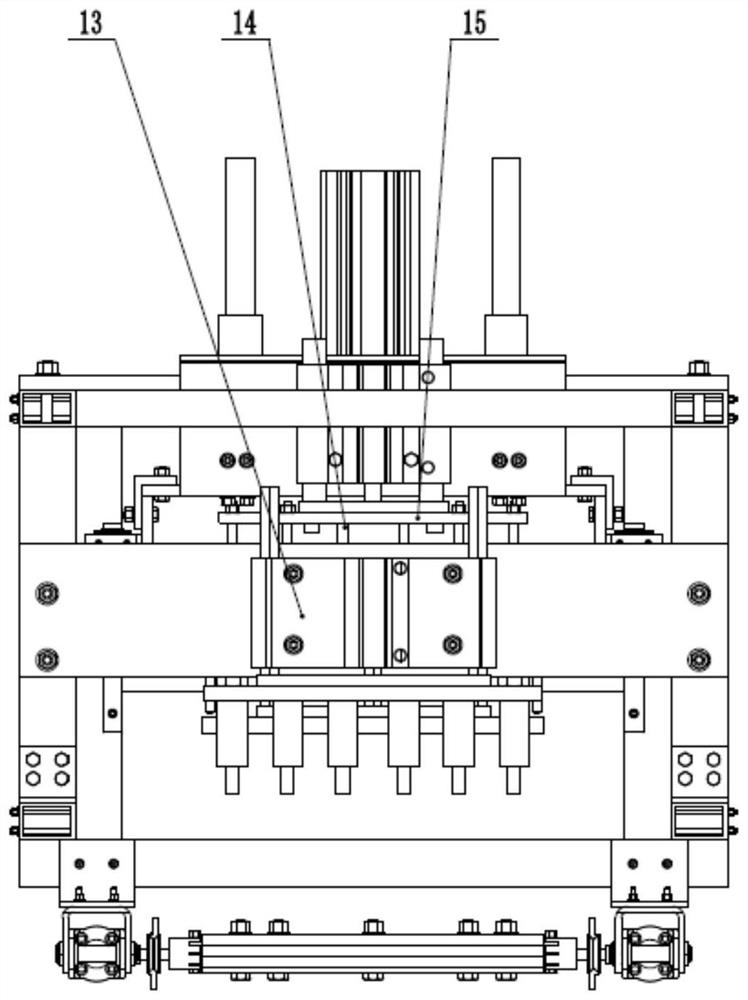

Large-tonnage uniform distribution concentrated loading system

InactiveCN102636386AMeet load requirementsMake up for the effects of test loadingStrength propertiesEngineeringModel test

The invention relates to a large-tonnage uniform distribution concentrated loading system used for geomechanics model tests, and belongs to the technical field of geotechnical engineering. The loading system comprises a hydraulic jack group fixedly arranged on a vertical support, a bearing plate, a reaction frame and a base; a guide rack is fixedly arranged on the base; a force transmission column is movable arranged in a horizontal through hole arranged on the guide rack; a force concentrating board is arranged between the jack group and the force transmission column; and a spherical contact is arranged at the front end face of the force concentrating board. The loading system provided by the invention can provide large-tonnage load to meet loading requirements by the model test under deeply-buried high stress; the design of the spherical contact can ensure that the load vertically acts on surface of a model, so as to lead the model to be stressed regularly and improve the accuracy and reliability of results of the model test.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

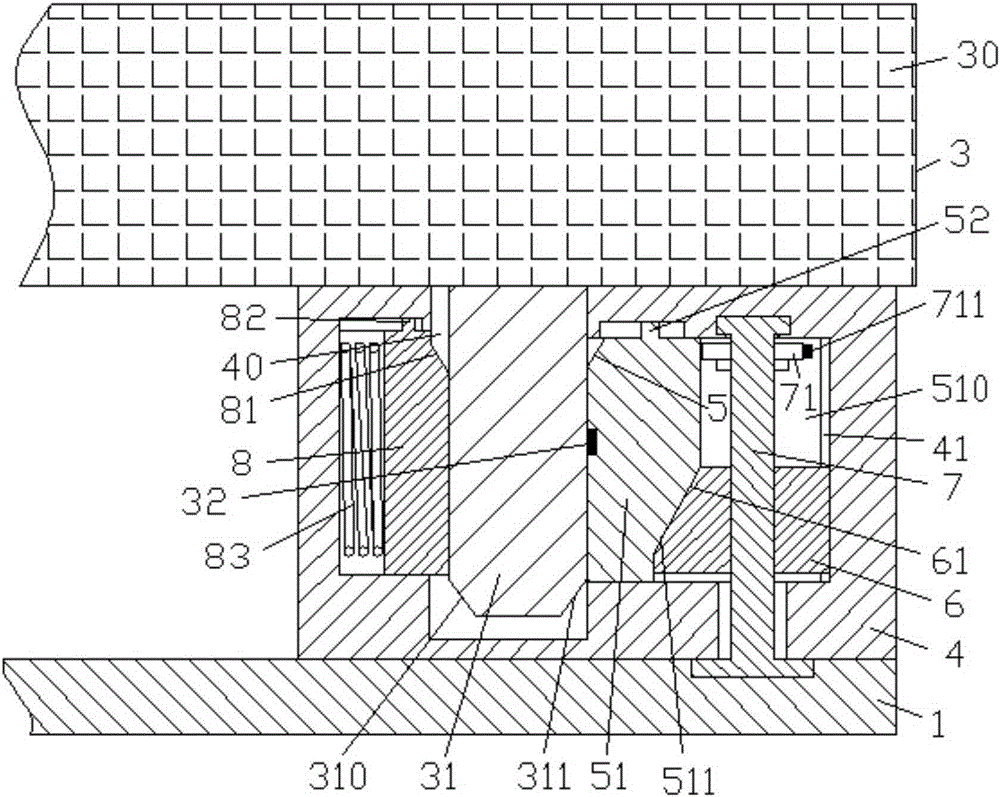

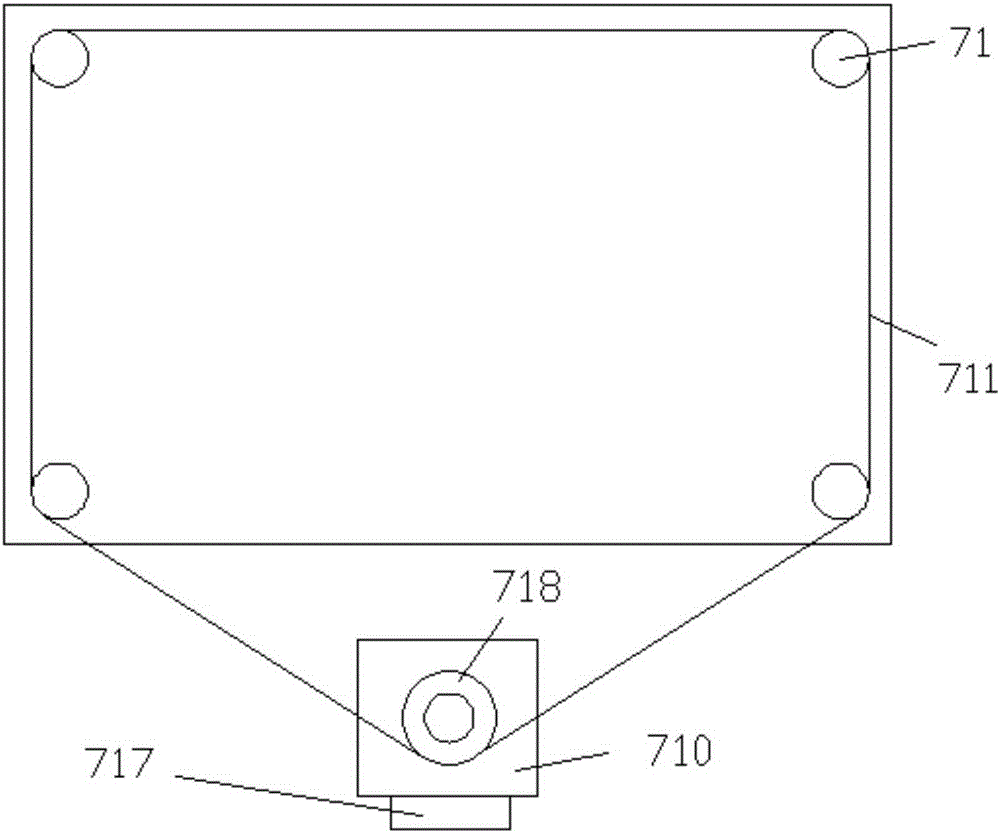

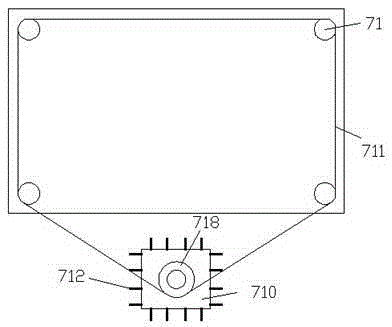

Circuit board assembly with alarm

InactiveCN105338779AAvoid forceRealize the installation and fixationPrinted circuit board receptaclesEngineeringElectrical and Electronics engineering

Provided is a circuit board assembly with an alarm. The circuit board assembly comprises a circuit board device (3) and a base fixing device. The circuit board device (3) comprises a rectangular body part (30) and four fixed feet (31) respectively arranged on rectangular corners. The base fixing device comprises a base (1) and four installation frames (4) which are fixed on the base (1) and respectively correspond to the fixed feet (31). Inserting grooves (40) in which the fixed feet (31) can be inserted are arranged in the installation frame (4). Inner side clamp blocks, which are pressed by pressing springs (83) in an inclined manner and are capable of stretching into the inserting grooves (40), are arranged on inner side parts, near the inner sides of the body part (30) of the circuit board device (3), of the inserting grooves, on the installation frames (4).

Owner:叶晓东

Hydraulic pressing machine capable of machining transformer coil

ActiveCN103671313AIncrease productivityAvoid unbalanced forceServomotorsCoils manufactureRelief valveEngineering

A hydraulic pressing machine capable of machining a transformer coil comprises an oil tank which is connected with an oil inlet of a quantitative vane pump through a low pressure oil feeding pipeline, an oil outlet of the quantitative vane pump is connected with an oil inlet of a low pressure oil conveying pipeline, a low pressure inlet oil filter and a low pressure one-way valve capable of enabling hydraulic oil to flow towards the outlet end are sequentially arranged on the low pressure oil conveying pipeline in series from the inlet end to the outlet end, the section, located between the low pressure inlet oil filter and the low pressure one-way valve, of the low pressure oil conveying pipeline is connected with an oil inlet of a low pressure oil discharging pipeline, and the low pressure oil discharging pipeline is connected with a low pressure normally-open unloading electromagnetic relief valve in series. The hydraulic pressing machine capable of machining the transformer coil is high in production efficiency, and can avoid damage to winding insulation caused by imbalanced stress of the coil, avoid the situation that press power is too small to generate a large air gap to lead to eddy-current loss and flux leakage and therefore the transformer emits heat, avoid the situation that the press power is too large to damage wire insulation and cause deformation of a winding, and better guarantee quality of the transformer coil produced by the hydraulic pressing machine.

Owner:BEIJING SUPER HYDRAULIC

Convenient-detachment and quick-heat-radiating circuit board assembly

InactiveCN105392321AAvoid forceRealize the installation and fixationMounting boards securingModifications by conduction heat transferEngineeringMechanical engineering

A convenient-detachment and quick-heat-radiating circuit board assembly comprises a circuit board device (3) and a base fixing device. The circuit board device (3) comprises a rectangular body part (30) and four fixing legs (31) which are arranged at corners of the rectangular body part. The base fixing device comprises a base (1) and four mounting frames (4) which are fixed on the base (1) and correspond with the four fixing legs (31). Each mounting frame (4) is internally provided with an insertion trough (40) for insertion of the fixing leg (31). The mounting frame (4) is provided with an inside clamping block (8) which is pressed by a pressing spring (83) and can extend into the insertion trough (4) at the inside part of the insertion trough (40), wherein the inside part of the insertion trough is next to the inside of the body part (30) of the circuit board device (3).

Owner:俞海东

Double-engine unmanned helicopter deceleration transmission system and unmanned helicopter

PendingCN107380412AAchieve "symmetrical" effectExtended service lifeAircraft power transmissionRotocraftControl theoryBevel gear

The invention discloses a double-engine unmanned helicopter deceleration transmission system and an unmanned helicopter. The transmission system comprises a deceleration box connected with a rotor main shaft, and an output end large bevel gear connected with the rotor main shaft is arranged in the deceleration box. Two input end small bevel gears engaged with the output end large bevel gear are connected to the output end large bevel gear, connected with engines correspondingly and symmetrically located on the two sides of rotor main shaft. The unmanned helicopter comprises the double-engine unmanned helicopter deceleration transmission system. The input end small bevel gears connected with the engines correspondingly are symmetrically arranged on the two sides of the rotor main shaft, and the acting force of the two input end small bevel gears on the output end large bevel gear are the same, so that the phenomenon of uneven stressing of the output end large bevel gear is avoided, abrasion of the output end large bevel gear is avoided, the service life is longer, and the safe and reliable effects are achieved; and the unmanned helicopter is safe and reliable, the service life of the unmanned helicopter is longer, and the cost is saved.

Owner:天津凤凰智能科技有限公司

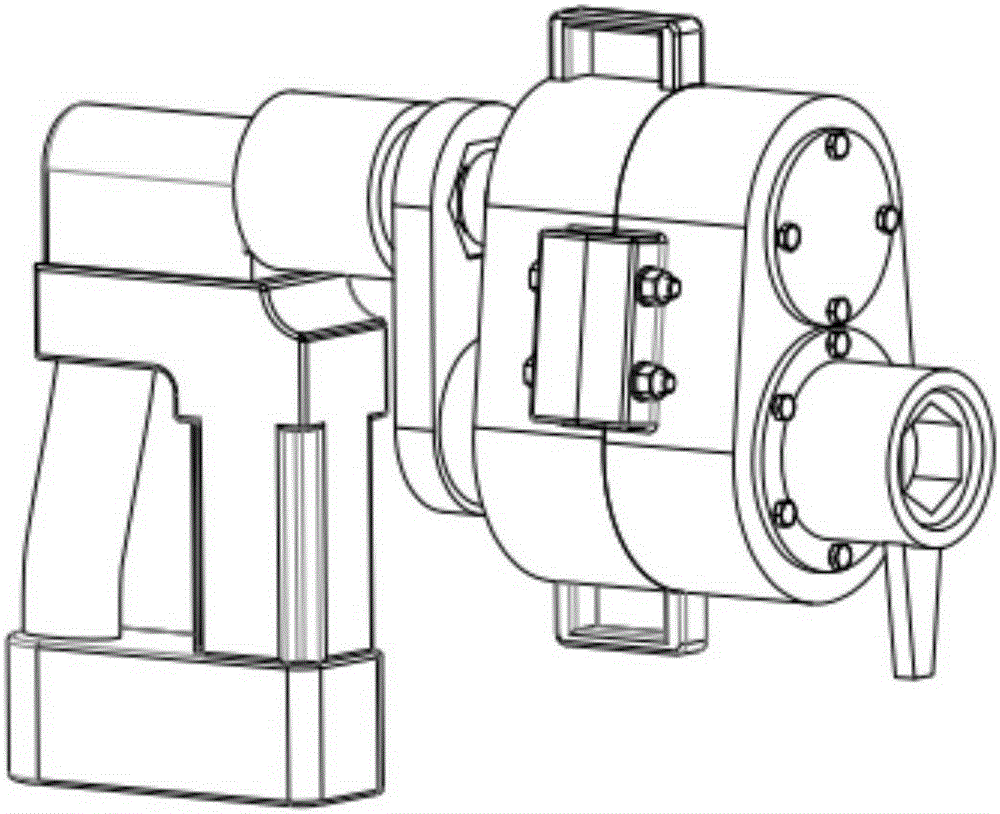

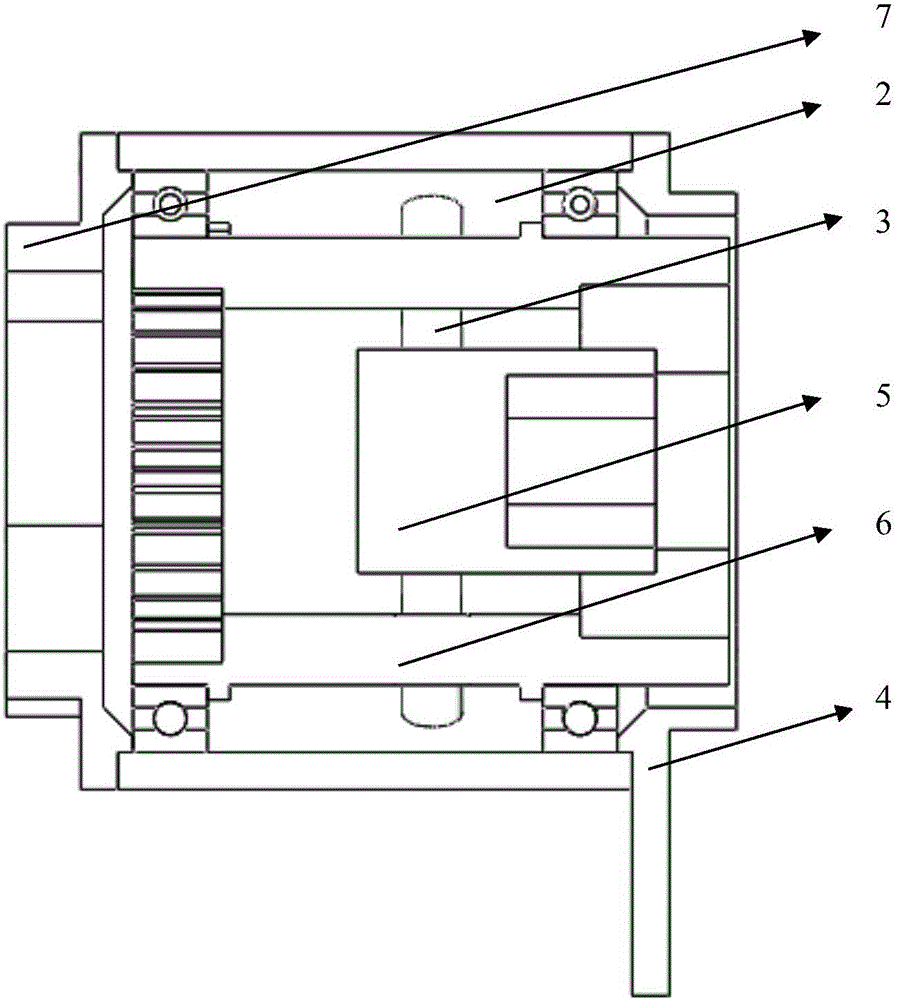

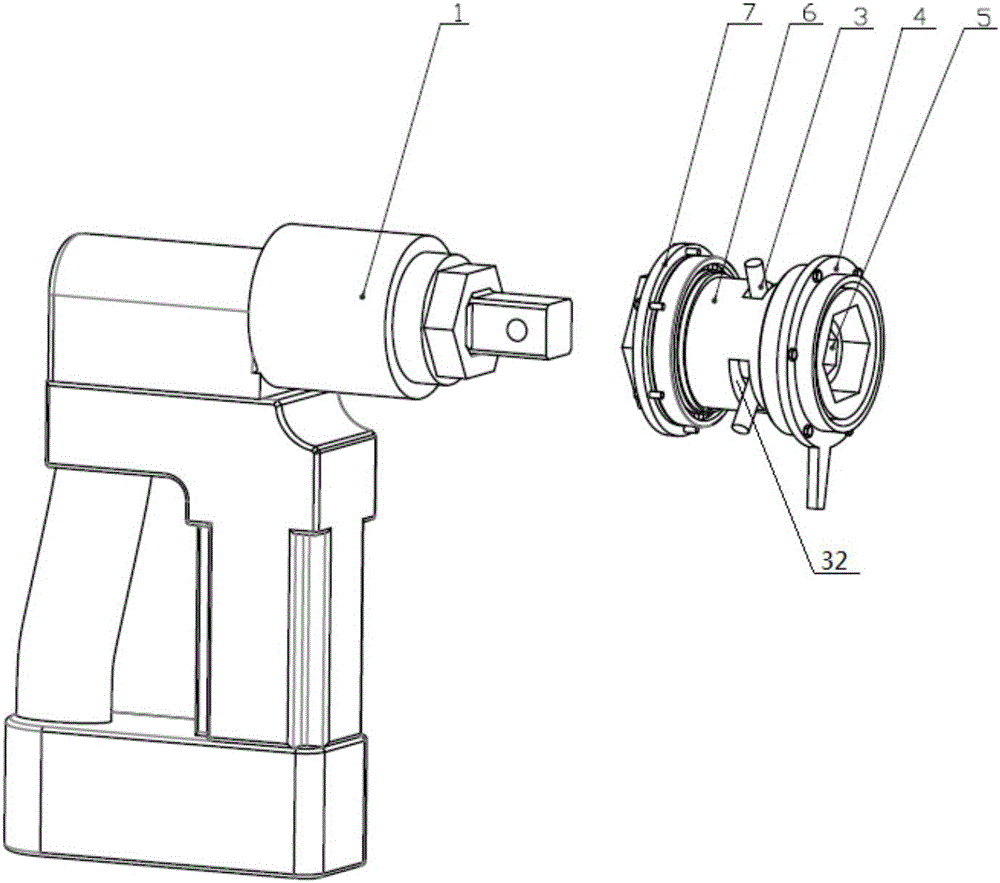

Mounting adapter for split nested unilateral bolt fastener

InactiveCN105952742ARealize one-sided installationAvoid unbalanced forceRod connectionsEngineeringFastener

The invention relates to a mounting adapter for a split nested unilateral bolt fastener. The mounting adapter comprises a main body, an inner sleeve (5) fixed on the main body and an outer sleeve (6) arranged outside the inner sleeve (5) in a sleeving manner, wherein the inner sleeve (5) is used for accommodating and fixing a bolt (9); the outer sleeve (6) is connected with a rotation output shaft of a driving mechanism and used for accommodating and driving a nut (11) to rotate; an inner gear is arranged on the inner wall of the outer sleeve (6) and used for being meshed with an outer gear (8) on the rotation output shaft of the driving mechanism; the main body comprises a cylindrical housing (2) arranged outside the outer sleeve (6) in a sleeving manner; hinge pin holes (31) are formed in the cylinder body of the housing (2); circular-arc-shaped holes (32) are formed in the cylinder body of the outer sleeve (6); and hinge pins (3) are fixedly mounted on the outer wall of the inner sleeve (5) and penetrate the corresponding circular-arc-shaped holes (32) and hinge pin holes (31). Compared with the prior art, the mounting adapter has the advantages of small space occupation and high reliability.

Owner:TONGJI UNIV

Circuit board assembly convenient to maintain

InactiveCN105142372AAvoid forceRealize the installation and fixationResilient/clamping meansCircuit Board Device ComponentEngineering

The invention discloses a circuit board assembly convenient to maintain, which comprises a circuit board device (3) and a base fixing device, wherein the circuit board device (3) comprises a rectangular body part (30) and four fixing pins (31) located at corners of the rectangle respectively; the base fixing device comprises a base (1) and four mounting frames (4) fixed on the base (1) and corresponding to the four fixing pins (31) respectively; each mounting frame (4) is provided with a slot (40) for enabling each fixing pin (31) to be inserted; and an inner side clamping block (8) is arranged at the inner side part, close to the inner side of the body part (30) of the circuit board device (3), of the slot (40), and the inner side clamping block (8) is pressed by a top pressing spring (83) in an unsymmetrical mode and can extend to the slot (40).

Owner:范含波

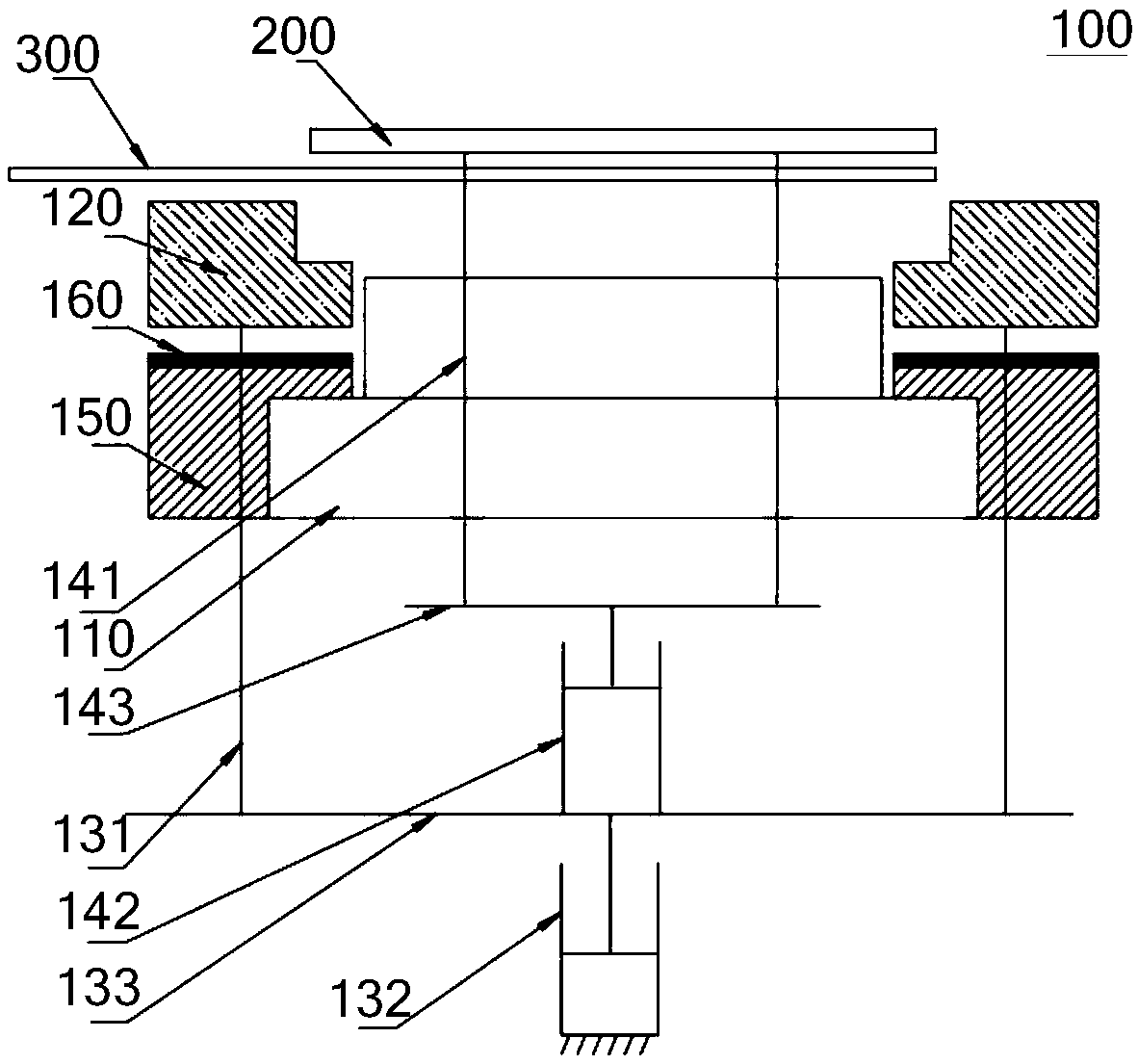

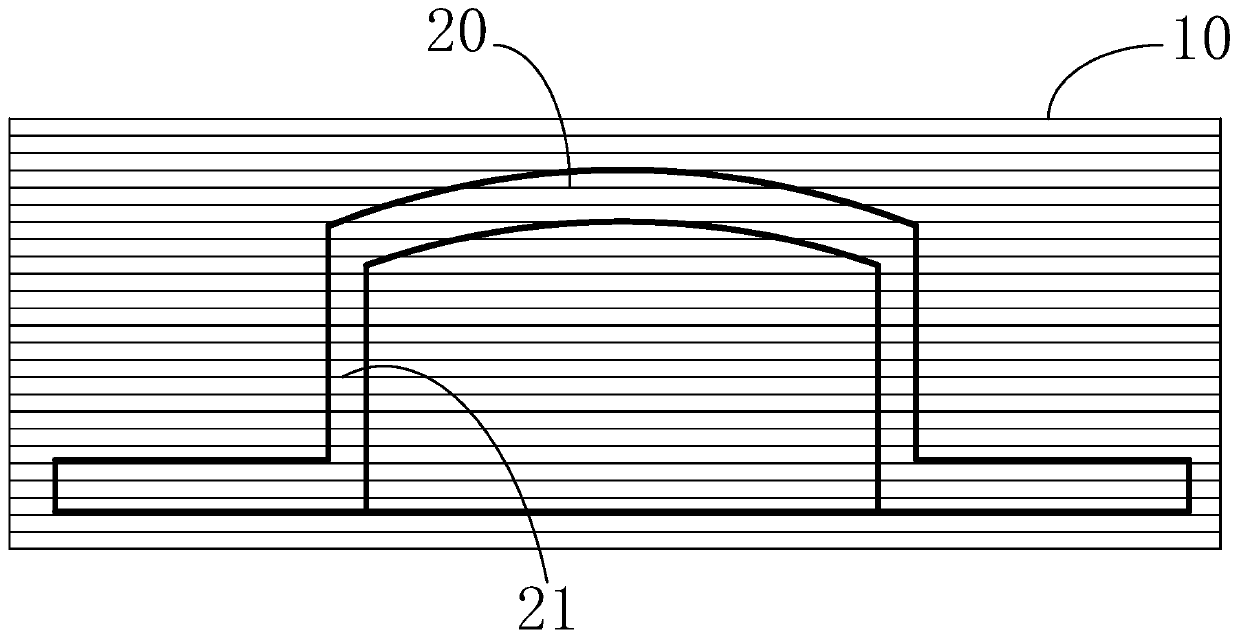

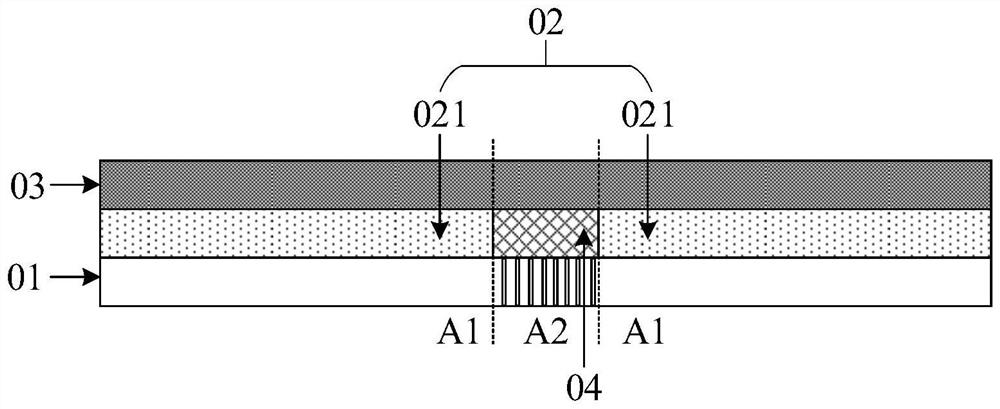

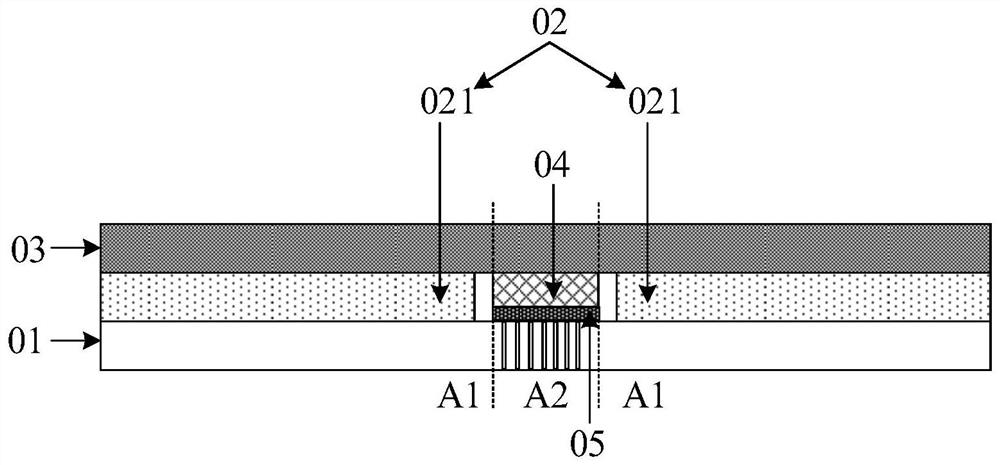

Bearing device, process chamber and semiconductor processing equipment

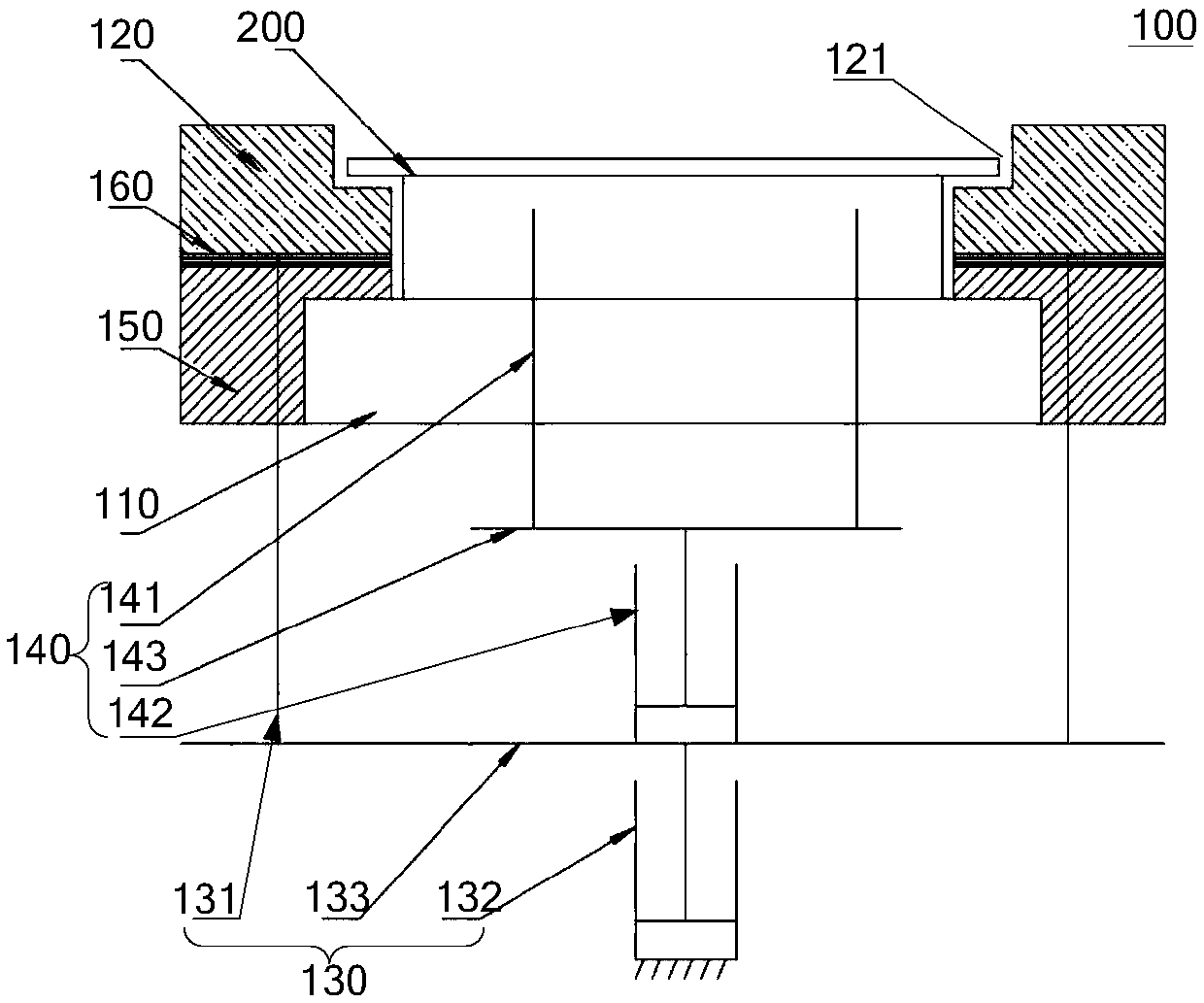

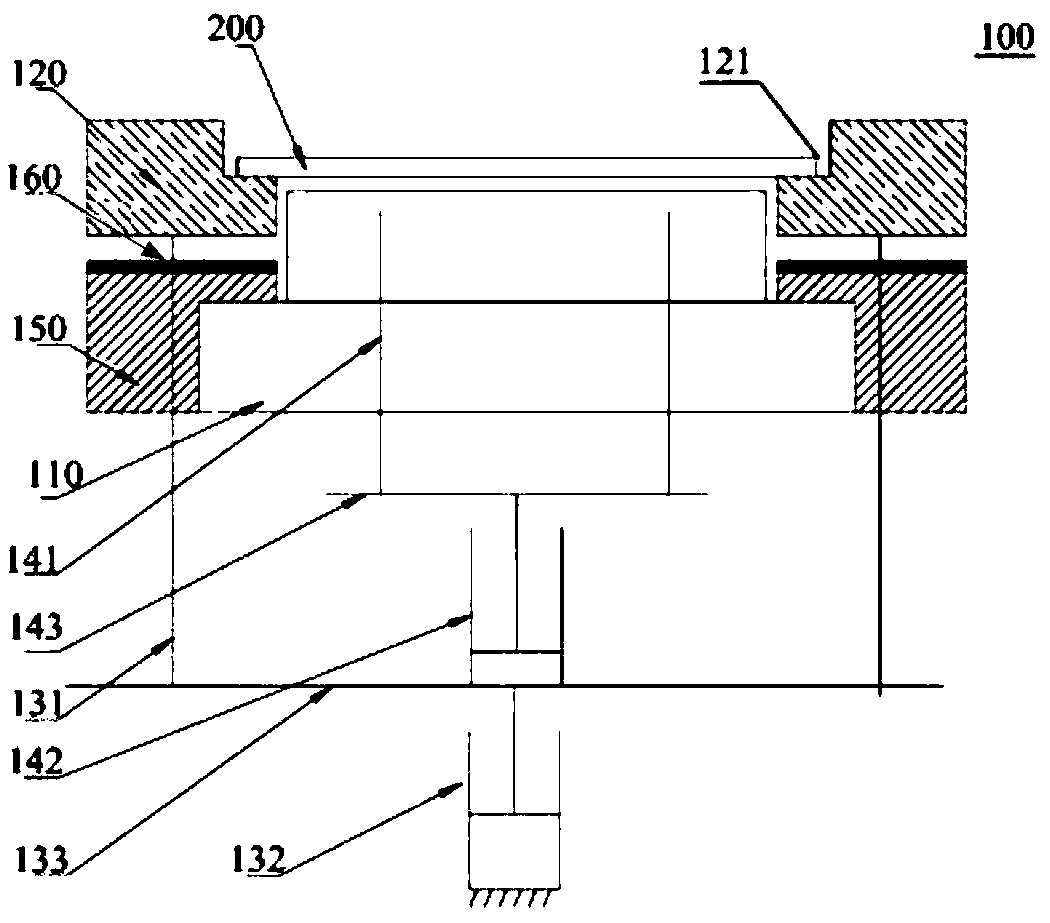

ActiveCN110797292AAvoid unbalanced forceThere will be no deviationSemiconductor/solid-state device manufacturingMachine partsEngineering

The invention discloses a bearing device, a process chamber and semiconductor processing equipment. The bearing device comprises an electrostatic chuck and a supporting ring arranged around the circumferential side wall of the electrostatic chuck, wherein the electrostatic chuck and the supporting ring jointly bear a to-be-machined part. The bearing device further comprises a first driving assembly and a second driving assembly, wherein the first driving assembly is used for driving the supporting ring to move to a first unloading position so as to separate the to-be-machined part from the electrostatic chuck; and the second driving assembly is used for driving the to-be-machined part to move to a second unloading position so as to separate the to-be-machined part is separated from the supporting ring. When the supporting ring jacks up the to-be-machined part, the supporting ring is in uniform annular surface contact with the to-be-machined part, the phenomenon that the to-be-machinedpart is uneven in stress due to piece sticking and the like can be avoided. In addition, when the to-be-machined part is jacked up by the second driving assembly, only the weight of the to-be-machinedpart needs to be overcome, and thus the phenomenon that the to-be-machined part deviates is avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

De-noising circuit board assembly equipped with roller groove

InactiveCN105163553AAvoid mounting fixesAvoid forceResilient/clamping meansEngineeringElectrical and Electronics engineering

Provided is a de-noising circuit board assembly equipped with a roller groove. The de-noising circuit board assembly comprises a circuit board device (3) and a pedestal fixing device. The circuit board device (3) comprises a rectangular body portion (30) and four fixing pins (31) on the corners of the rectangular body portion. The pedestal fixing device comprises a pedestal (1) and four installing racks (4) fixed to the pedestal (1) and corresponding to the four fixing pins (31) respectively. Each installing rack (4) is equipped with a slot (40) into which the corresponding fixing pin (31) can be inserted. The inner side portion, close to the inner side of the body portion (30) of the circuit board device (3), of the slot (4) of each installing rack (4) is provided with an inner-side clamping block (8) which is biased by a pushing spring (83) and which can be inserted into the slot (40).

Owner:邱林新

Heat-dissipating circuit board assembly equipped with upper stopping sensor and lower stopping sensor

InactiveCN105163554AAvoid forceRealize the installation and fixationResilient/clamping meansCooling/ventilation/heating modificationsElectrical and Electronics engineering

Provided is a heat-dissipating circuit board assembly equipped with an upper stopping sensor and a lower stopping sensor. The heat-dissipating circuit board assembly comprises a circuit board device (3) and a pedestal fixing device. The circuit board device (3) comprises a rectangular body portion (30) and four fixing pins (31) on the corners of the rectangular body portion. The pedestal fixing device comprises a pedestal (1) and four installing racks (4) fixed to the pedestal (1) and corresponding to the four fixing pins (31) respectively. Each installing rack (4) is equipped with a slot (40) into which the corresponding fixing pin (31) can be inserted. The inner side portion, close to the inner side of the body portion (30) of the circuit board device (3), of the slot (4) of each installing rack (4) is provided with an inner-side clamping block (8) which is biased by a pushing spring (83) and which can be inserted into the slot (40).

Owner:邱林新

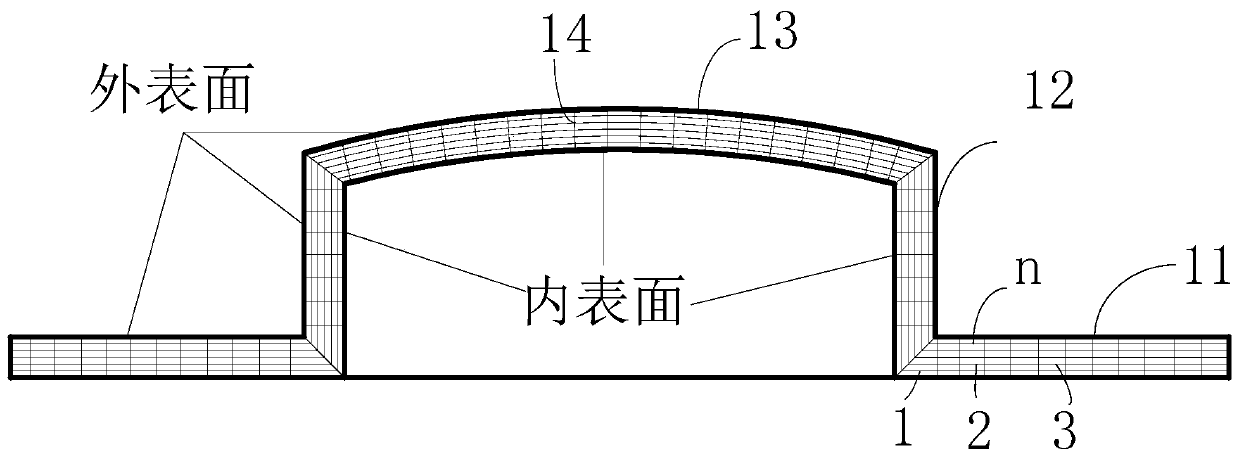

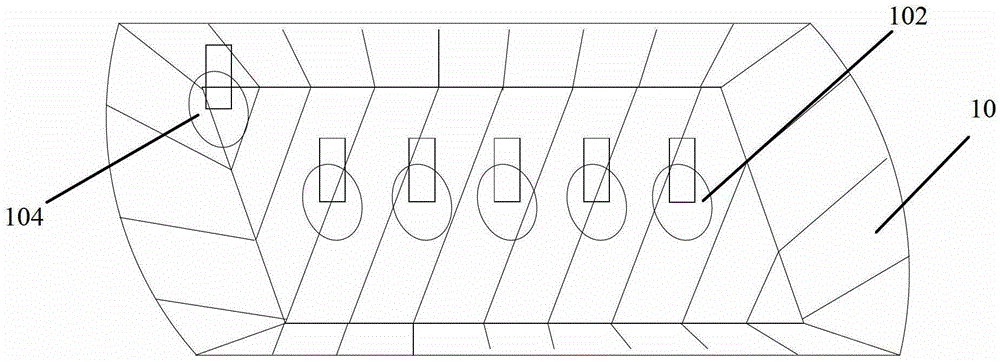

Antenna cover plate profiling prefabricated member puncture method and antenna cover plate forming method

The invention discloses an antenna cover plate profiling prefabricated member puncture method and an antenna cover plate forming method. The puncture method comprises the following steps that a layerof fiber cloth is continuously laid on the outer surface of a mold; the fiber gap of the fibre cloth on the protruding part of the mold is adjusted to enable the fiber cloth to be matched with the outer surface of the mold, and a fiber cover is formed; laying and adjusting of multiple layers of fiber cloth are repeated, when the laid fiber cloth layers reach the preset number, laying of one stacking unit is finished; laying of multiple stacking units is repeated, in the laying process of the stacking units, at least two adjacent units are sewn until the preset thickness is achieved; and through sewing is carried out on the mold along a sewing groove, demolding is carried out, and in the whole thickness direction, through sewing is achieved. The problem that in the prior art, local stress is weak, and the raw material is wasted is solved, strength of an antenna cover plate profiling prefabricated member is improved, and the cost is reduced.

Owner:CHANGSHA JINGYOU NEW MATERIAL TECH CO LTD

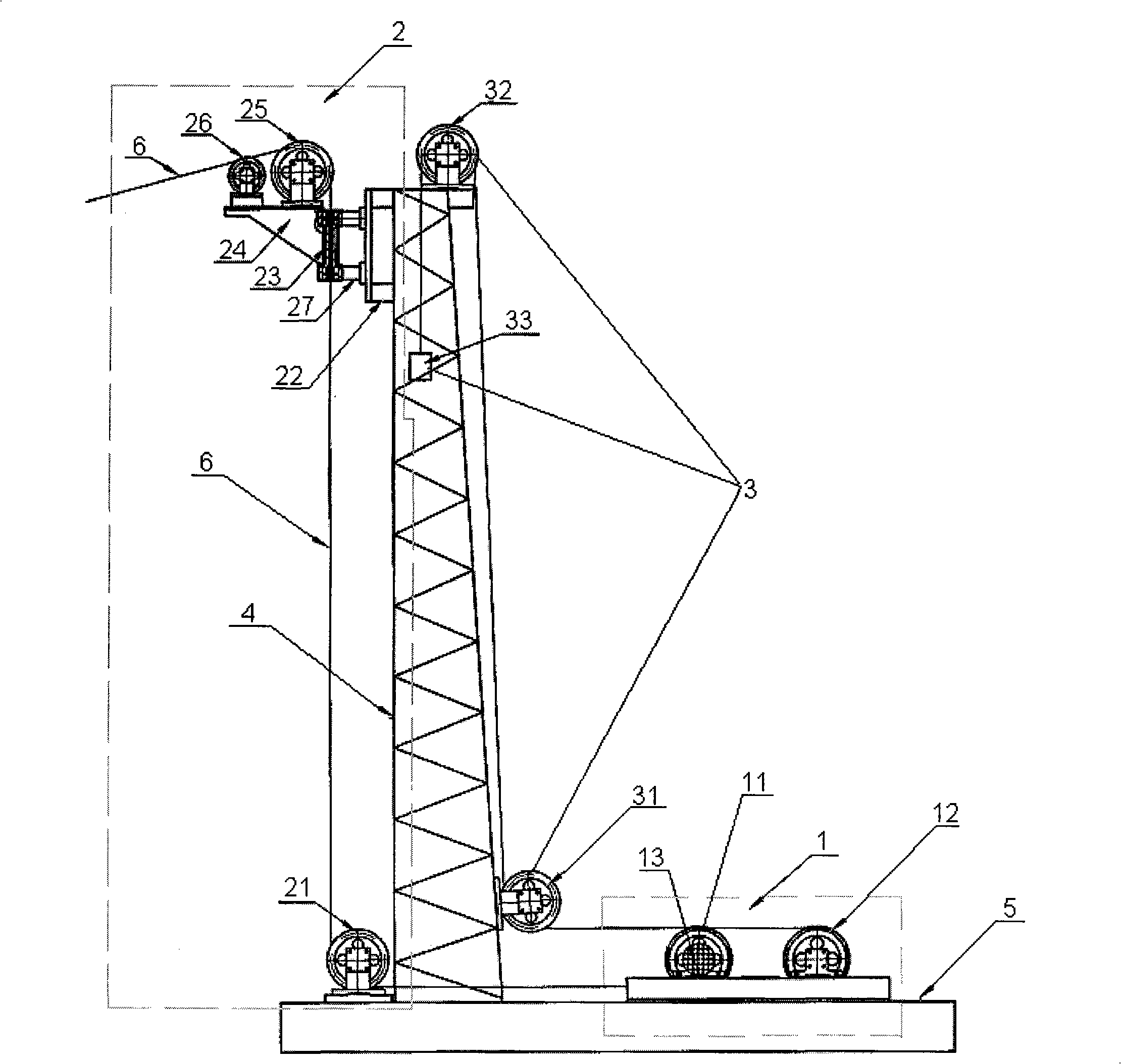

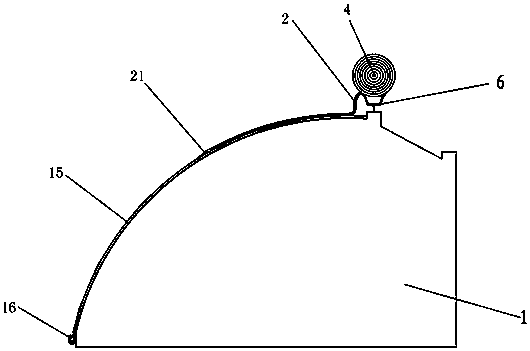

Pull-down and roll-up type solar greenhouse roller shutter device and using method

PendingCN109348934ASimple structureAvoid dangerous accidentsClimate change adaptationGreenhouse cultivationEngineeringPulley

The invention relates to a pull-down and roll-up type solar greenhouse roller shutter device and a suing method. A roller shutter shaft is arranged above a greenhouse, a plurality of auxiliary bearingdevices are arranged above a greenhouse body, a strip-shaped roller is arranged on each auxiliary bearing device, the strip-shaped rollers and the roller shutter shaft are parallel and can relativelyslide with a heat preservation quilt; a plurality of sliding ways are arranged on the face of the greenhouse, a rolling rope shaft is arranged at the bottom of the front part of the greenhouse, and asupporting pulley is arranged inside each sliding way; a plurality of rolling ropes are fixedly connected to the tail end of the heat preservation quilt, rolling rope bodies are arranged inside the sliding ways and are in overlapped connection with the supporting pulleys; when the heat preservation quilt is placed down, the rolling rope shaft rotates and drives the heat preservation quilt to slide downwards, when the heat preservation quilt is rolled up, the roller shutter shaft rotates, the heat preservation quilt and the strip-shaped rollers slide relatively so that the heat preservation quilt can be rolled up; the roller shutter shaft and the wound heat preservation quilt do not directly act on the surface of a front slope of the solar greenhouse under gravity loads, the phenomenon that peril incidents are caused by dynamic loads in the front slope greenhouse surface unfolding and folding processes is avoided, and the whole structure of the roller curtain device is improved.

Owner:SHENYANG AGRI UNIV

Battery package structure and package method thereof

InactiveCN109860444AAvoid unbalanced forceImprove structural stabilityFinal product manufactureCell component detailsEngineeringElectrolyte

The invention discloses a battery package structure and a package method thereof. The battery package structure comprises a housing, the housing is internally provided with a cell holding cavity and an air chamber, the housing is provided with a top package area, a bottom package area, a side package area, a pre-package area and a final package area, the housing is further internally provided withan anti-fake package cavity, and the anti-fake package cavity mutually communicates with the cell holding cavity. The housing is provided with the anti-fake package cavity which can hold part of an electrolyte to reduce the electrolyte between the interlayers of the housing of the battery, prevent the electrolyte in the interlayers of the housing from be extracted out to the final package area inthe battery final package process to influence the package effect of the final package area so as to ensure the final package quality of the battery. At the same time, the electrolyte located in theanti-fake package cavity can replenish the electrolyte inside the battery at any time so as to enhance the service life.

Owner:EVE ENERGY CO LTD

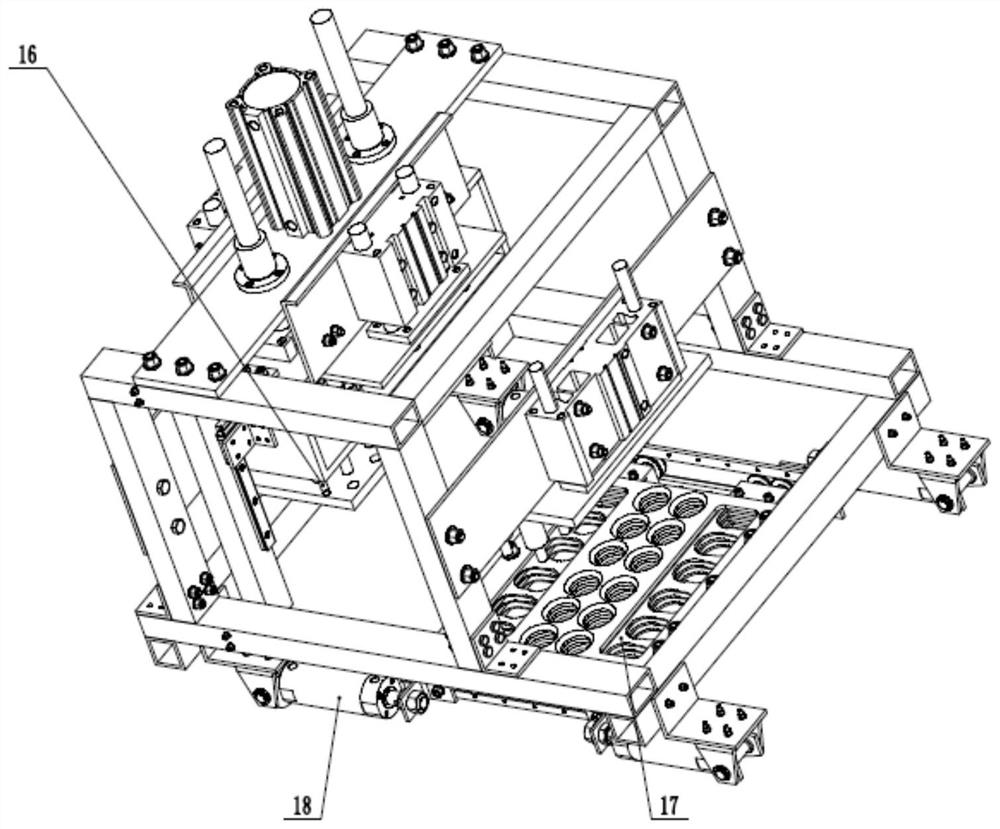

Deployable experiment box and material outboard exposure device

ActiveCN111001448AEfficient use ofIncrease profitAir-pressure/air-lock chambersStructural engineeringMechanical engineering

The invention relates to a deployable experiment box and material outboard exposure device. The device comprises a box body, the box body is provided with a first cavity for accommodating a first sample tray, the upper side wall of the box body is provided with an opening, the first sample tray can extend out of or retract into the first cavity from the opening; and two sides of the first sample tray are used for mounting exposed material samples. After the first sample tray extends out of the opening, the exposed material sample on the first sample tray is driven to be exposed, an exposure experiment is performed; the first sample tray extends out of the opening in the upper side of the box body, the upper side space of the box body is not occupied, the peripheral space of the experimentbox is not occupied, the space is effectively utilized; exposed material samples can be installed on two sides of the first sample tray, so that the experiment box bears more samples, and the utilization rate is optimized on the limited platform space.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

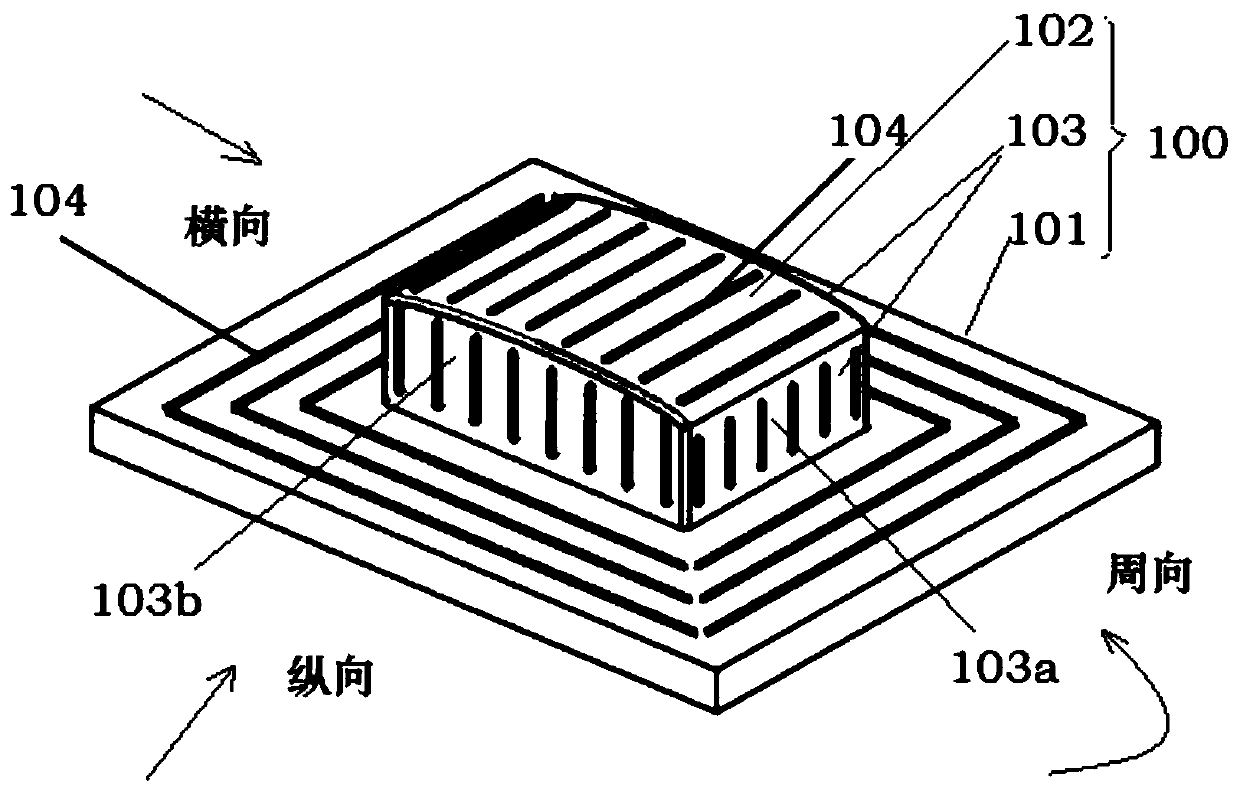

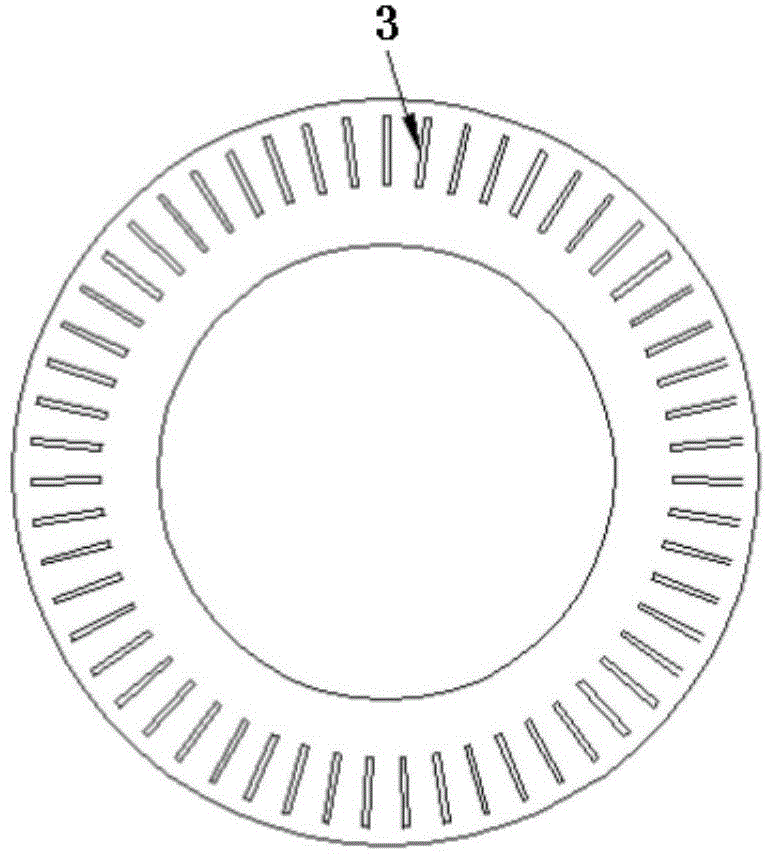

High-efficiency grading wheel for jet mill

InactiveCN104668193AHigh strengthAvoid unbalanced forceGas current separationGrain treatmentsImpellerEngineering

The invention discloses a high-efficiency grading wheel for a jet mill. The high-efficiency grading wheel comprises a front impeller disc, a rear impeller disc and a plurality of blades, wherein the blades are fixedly connected between the front impeller disc and the rear impeller disc and form a circle in an enclosing mode; a feeding gap is formed between adjacent blades, and a cavity is formed on the inner side of the circle of the blades; the rear impeller disc is used for being fixedly connected with a power input shaft of the grading wheel. The high-efficiency grading wheel is characterized by further comprising a plurality of pull rods; the pull rods are fixedly connected between the front impeller disc and the rear impeller disc; the blades form certain angles with the direction of shaft diameter, and are uniformly distributed. According to the high-efficiency grading wheel, overall strength of the grading wheel can be increased, the grading fineness is improved, eddy flows are effectively eliminated, the wind resistance is reduced, the energy consumption is reduced, the grading efficiency is improved, and the high-efficiency grading wheel is simple in structure and easy to carry out.

Owner:KUNSHAN MIYOU EQUIP MFG

Circuit board assembly easy to install and uninstall and with adjustable clamping speed

InactiveCN105163551AAvoid forceRealize the installation and fixationResilient/clamping meansEngineeringMechanical engineering

Provided is a circuit board assembly easy to install and uninstall and with adjustable clamping speed. The circuit board assembly comprises a circuit board device (3) and a pedestal fixing device. The circuit board device (3) comprises a rectangular body portion (30) and four fixing pins (31) on the corners of the rectangular body portion. The pedestal fixing device comprises a pedestal (1) and four installing racks (4) fixed to the pedestal (1) and corresponding to the four fixing pins (31) respectively. Each installing rack (4) is equipped with a slot (40) into which the corresponding fixing pin (31) can be inserted. The inner side portion, close to the inner side of the body portion (30) of the circuit board device (3), of the slot (4) of each installing rack (4) is provided with an inner-side clamping block (8) which is biased by a pushing spring (83) and which can be inserted into the slot (40).

Owner:方剑

Circuit board component with upper and lower limit sensors

InactiveCN105283024AAvoid forceRealize the installation and fixationResilient/clamping meansLower limitMechanical engineering

The invention discloses a circuit board component with upper and lower limit sensors. The circuit board component with the upper and lower limit sensors comprises a circuit board device (3) and a base fixing device, wherein the circuit board device (3) comprises a rectangular main body part (30) and four fixed feet (31) respectively located at corner parts of the rectangle; the base fixing device comprises a base (1), and four mounting racks (4) fixed on the base (1) and respectively corresponding to the four fixed feet (31); each mounting rack (4) is internally provided with a slot (40) for insertion of the fixed foot (31), and the inner side part of each slot (40) of each mounting frame (4), close to the inner side of the main body part (30) of the circuit board device (3), is provided with an inner side fixture block (8) which is partially pressed by a top pressure spring (83) and can stretch into the slot (40).

Owner:俞升洋

Keyboard switch convenient for combined installation

InactiveCN107706027AEasy to replaceEasy to assembleEmergency casingsOperation facilitationEngineeringScrew thread

Owner:HUIZHOU JINWANHE IND CO LTD

Supporting module and preparation method thereof, and preparation method of display device

The invention provides a supporting module and a preparation method thereof, and a preparation method of a display device, and belongs to the technical field of display. The supporting module comprises a metal supporting layer, a release layer, a supporting cushion block and a bonding layer with a plurality of spaced bonding patterns. The metal supporting layer, the bonding layer and the release layer are sequentially stacked; the supporting cushion block is located between every two adjacent bonding patterns; the orthographic projection of the supporting cushion block on the metal supporting layer is located in a bending area of the metal supporting layer; and the orthographic projection of the bonding patterns on the metal supporting layer is located in a non-bending area of the metal supporting layer; namely, in the supporting module provided by the invention, the bending area and the non-bending area of the metal supporting layer are provided with the supporting cushion block and the bonding patterns respectively; and no segment difference is generated between the bending area and the non-bending area, so that the phenomenon that when the supporting module and the display module are attached, the display module is uneven in stress is avoided, and attaching imprint cannot be generated on the display module.

Owner:BOE TECH GRP CO LTD +1

Outrigger control system and construction machinery

ActiveCN102880145BAvoid unbalanced forceSoil-shifting machines/dredgersLoad-engaging elementsControl systemMechanical engineering technology

The invention provides an outrigger control system, which includes a command sending unit, an outrigger controller and a solenoid valve for controlling the action of the outrigger, wherein: the command sending unit is used to send out a leg control command; the outrigger The controller simultaneously sends action instructions to the solenoid valves corresponding to the plurality of legs according to the leg control commands received from the command sending unit; the solenoid valves perform reversing according to the action instructions to control Action of the plurality of outriggers. Correspondingly, the present invention also proposes an engineering machine. Through the technical scheme of the invention, multiple outriggers can be controlled simultaneously, avoiding the situation of uneven force that may occur when controlling a single outrigger.

Owner:SANY AUTOMOBILE MFG CO LTD

Pneumatic Chinese pear-leaved kernel removal and cutting device

PendingCN111887435ASimple mechanical structureEasy to disassemble and maintainFruit stoningAgricultural engineeringStructural engineering

The invention discloses a pneumatic Chinese pear-leaved kernel removal and cutting device which is suitable for processing Chinese pear-leaved. The pneumatic Chinese pear-leaved kernel removal and cutting device comprises a horizontal supporting plate, a kernel removing cutter, a fruit pressing cylinder, a kernel impacting shaft, a kernel impacting shaft fixing plate, a kernel impacting cylinder,a fruit jacking cylinder, a fruit jacking column, a slicing cylinder and a positioning needle, wherein the horizontal supporting plate is positioned on a frame; a main cylinder and a cylindrical guiderail are arranged on the horizontal supporting plate; the main cylinder is connected with a lifting box; the kernel removing cutter is arranged at the lower end of the lifting box; the fruit pressingcylinder is connected with a fruit pressing plate; a side wall of the fruit pressing cylinder is fixed on the frame; the lower end of the kernel impacting shaft is arranged inside the kernel removingcutter, and the upper end of the kernel impacting shaft is arranged on the kernel impacting shaft fixing plate; the kernel impacting shaft fixing plate is connected with the kernel impacting cylinder; the kernel impacting cylinder is fixed on the lifting box through a vertical plate; a side wall of the fruit jacking cylinder is fixed on the frame and is connected with the fruit jacking shaft fixing plate; the upper end of the fruit jacking column is fixed on the fruit jacking shaft fixing plate; the slicing cylinder is arranged at the lower end of the frame and is connected with the slicing cutter; and the positioning needle is arranged at the lower end of the lifting box. Compared with existing equipment, the pneumatic Chinese pear-leaved kernel removal and cutting device has the advantages that the fruit jacking fixing plate is independently arranged and is independently controlled, so that the problem of unbalanced stress of a lifting main plate is effectively solved, the Chinese pear-leaved kernel removal and cutting effect is good, and the pneumatic Chinese pear-leaved kernel removal and cutting device is convenient to maintain, and is also suitable for kernel removal and slicing of other multi-kernel fruits.

Owner:BEIJING FORESTRY UNIVERSITY

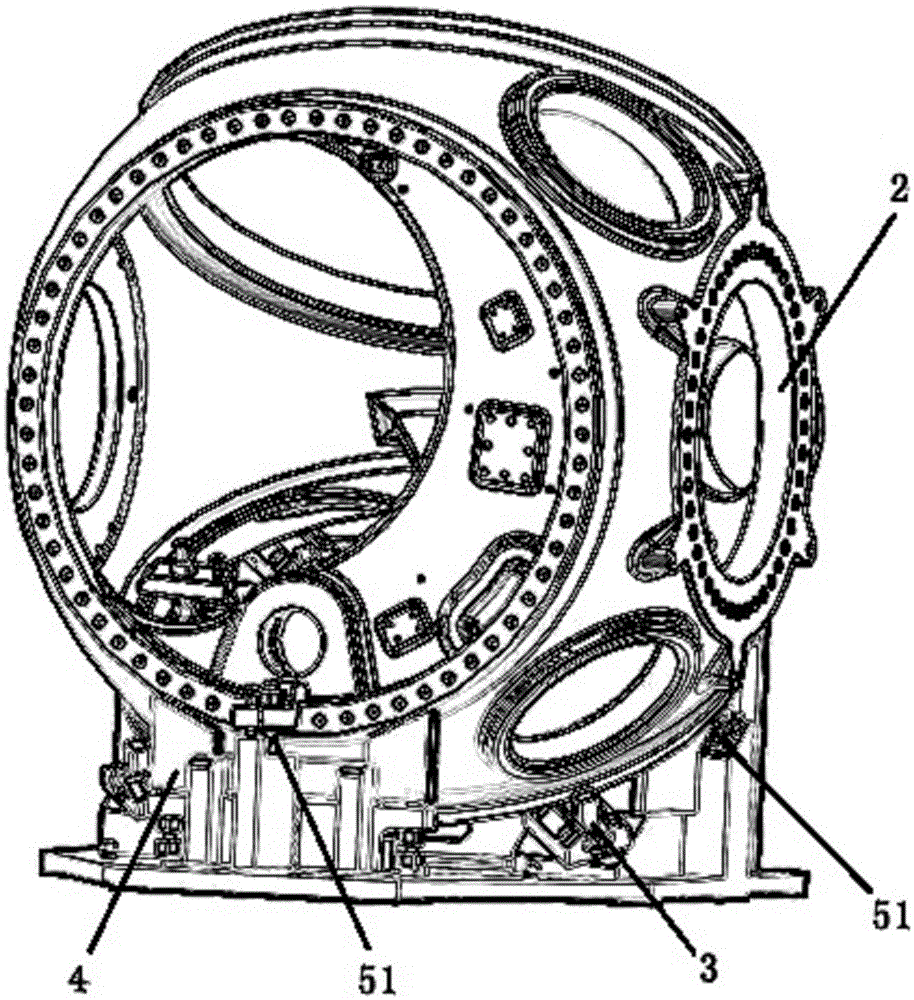

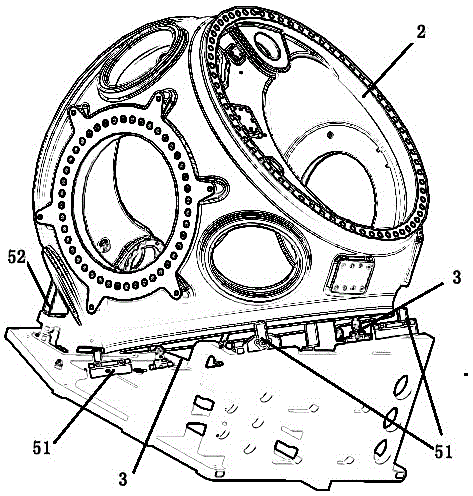

Clamp for large spherical casting multi-hole multi-plane same-direction machining

ActiveCN105058097AAdjust the positioning angleAdjuster displacementPositioning apparatusMetal-working holdersEngineeringSpherical shaped

The invention discloses a clamp for large spherical casting multi-hole multi-plane same-direction machining. The clamp comprises a V-shaped supporting body arranged on a framework, and at least three angle supports arranged between supporting bases and end supporting bases in a staggered manner. The V-shaped supporting body comprises at least two sets of symmetric supporting bases and end supporting bases, wherein the end supporting bases are arranged on the symmetry axis of the two sets of symmetrically-arranged supporting bases and located at one ends of the supporting bases. The end supporting bases and the supporting bases are each provided with a clamping pawl. Each angle support is provided with a supporting nail. The clamp is simple in structure, low in cost and high in clamping stability. The integral strength and rigidity of the clamp are guaranteed, and the phenomenon of cutter vibration generated during cutting of a to-be-machined large spherical casting or other large spherical components is avoided. The smoothness of workpiece machining surfaces and the precision of machining sizes are improved, and the production machining quality of products is improved.

Owner:ANHUI YONGCHENG MACHINERY

Convenient-detachment heat radiation type circuit board assembly

InactiveCN105392322AAvoid forceRealize the installation and fixationMounting boards securingEngineeringMechanical engineering

A convenient-detachment heat radiation type circuit board assembly comprises a circuit board device (3) and a base fixing device. The circuit board device (3) comprises a rectangular body part (30) and four fixing legs (31) which are arranged at corners of the rectangular body part. The base fixing device comprises a base (1) and four mounting frames (4) which are fixed on the base (1) and four mounting frames (4) which correspond with the four fixing legs (31). Each mounting frame (4) is provided with an insertion trough (4) for insertion of the fixing leg (31). The mounting frame (4) is provided with an inside clamping block (8) which is pressed by a pressing spring (83) and can extend into the insertion trough (4) at the inside part of the insertion trough (40), wherein the inside part of the insertion trough is next to the inside of the body part (30) of the circuit board device (3).

Owner:朱雪君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com