Hydraulic pressing machine capable of machining transformer coil

A transformer coil and hydraulic technology, which is applied in coil manufacturing, fluid pressure actuators, servo motors, etc., can solve problems such as unbalanced coil force, low efficiency, and large pressing force, so as to avoid unbalanced force and improve quality. Guaranteed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

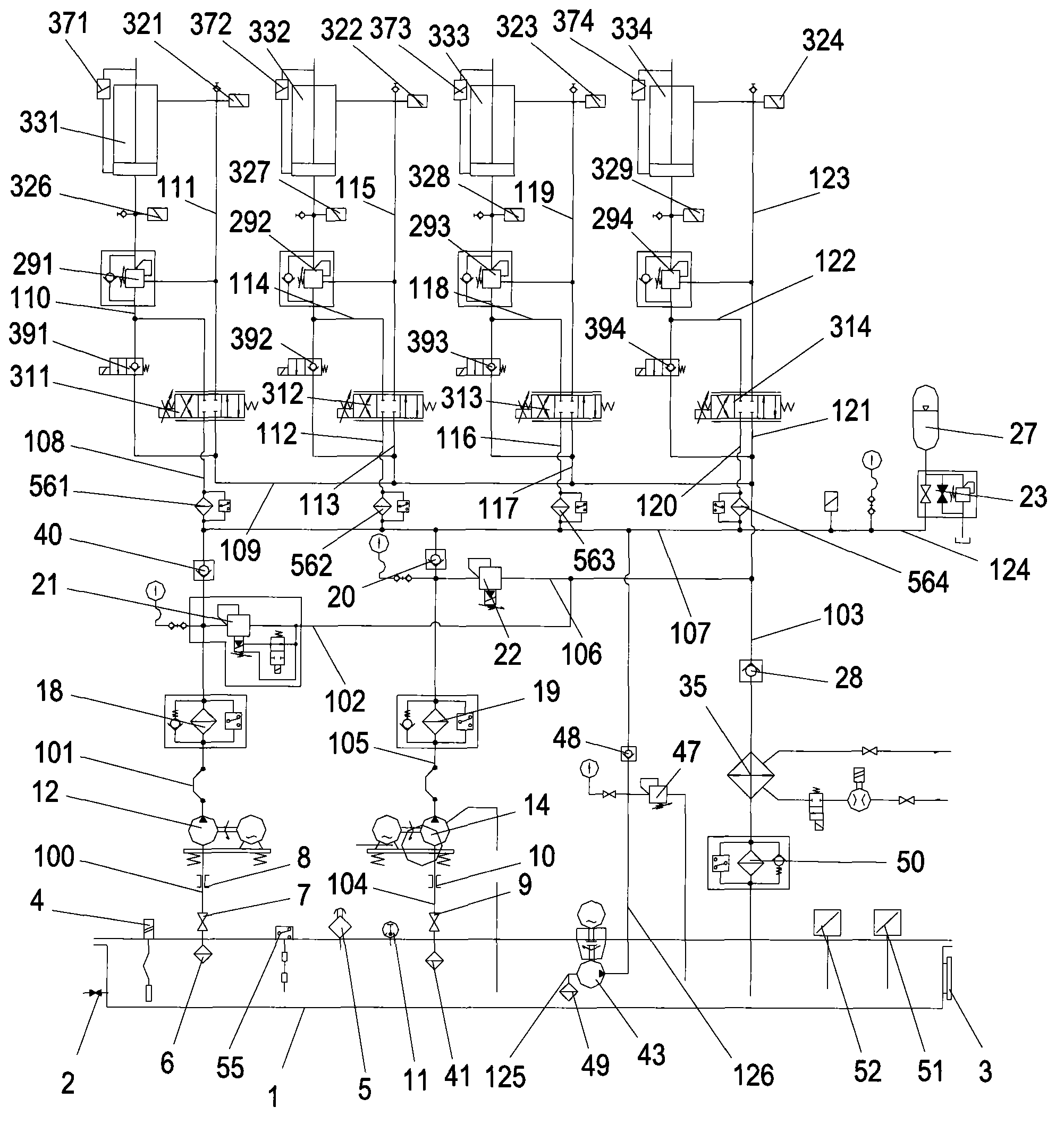

[0027] Such as figure 1 As shown in the figure, the hydraulic press that can process transformer coils of the present invention includes a frame, a workbench, and an oil tank 1. The oil tank 1 is used to store oil to meet the oil suction of the pump, prevent the pump from being sucked, and collect the oil of the system at the same time. Back to the oil. The lower part of the oil tank 1 is provided with an internal thread oil discharge ball valve 2. When the oil tank 1 needs to be cleaned, the oil in the oil tank 1 can be emptied through this valve; The glass window on the liquid level gauge 3 with temperature display can conveniently observe the liquid level in the oil tank 1, and also display the temperature in the oil tank 1; the upper part of the oil tank 1 is equipped with a liquid level transmitter with analog signal output 4. The liquid level transmitter 4 with analog signal output has a remote transmission function, and can monitor the change of the liquid level in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com