Large-tonnage uniform distribution concentrated loading system

A loading system and centralized technology, which is applied in the field of geotechnical engineering, can solve the problems of unbalanced force on the model, identical output of difficult jacks, and influence on the accuracy of test results, etc., to achieve uniform force and avoid unbalanced force on the model Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

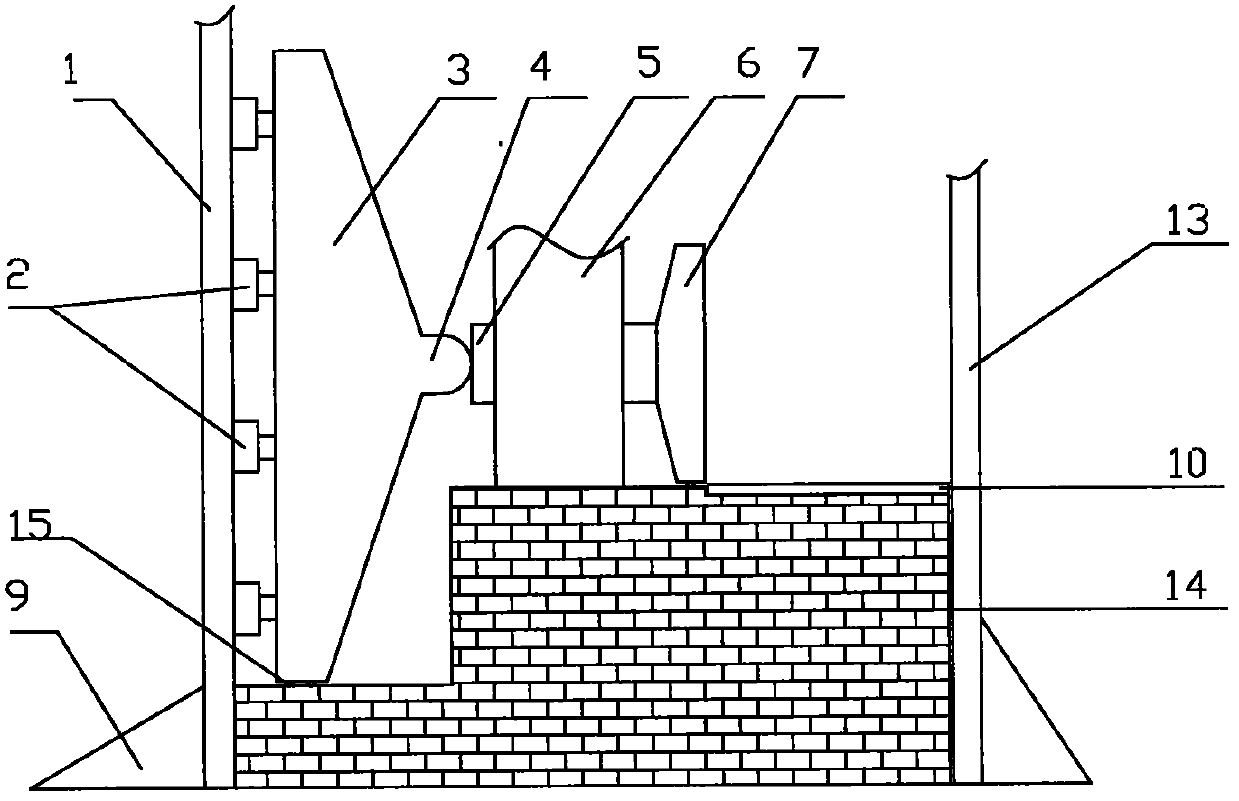

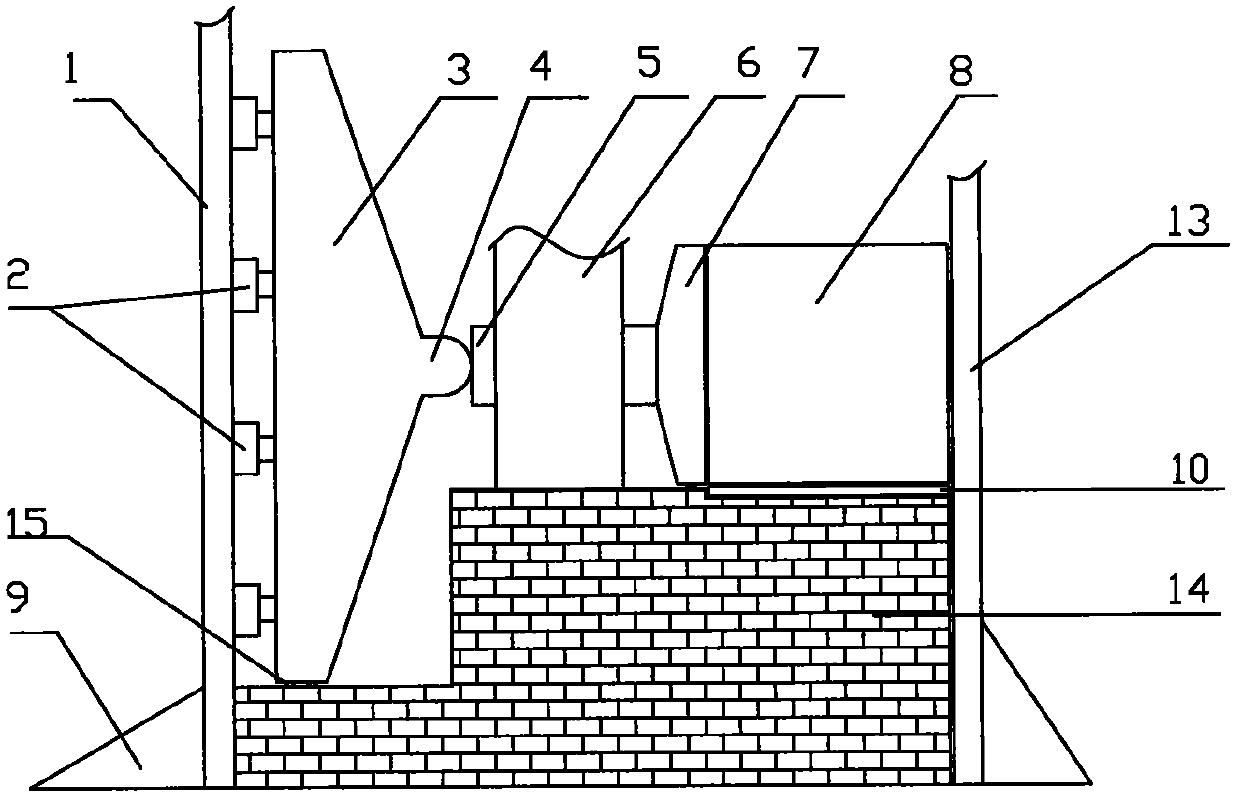

[0023] The large tonnage evenly distributed-concentrated loading system of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] see Attachment

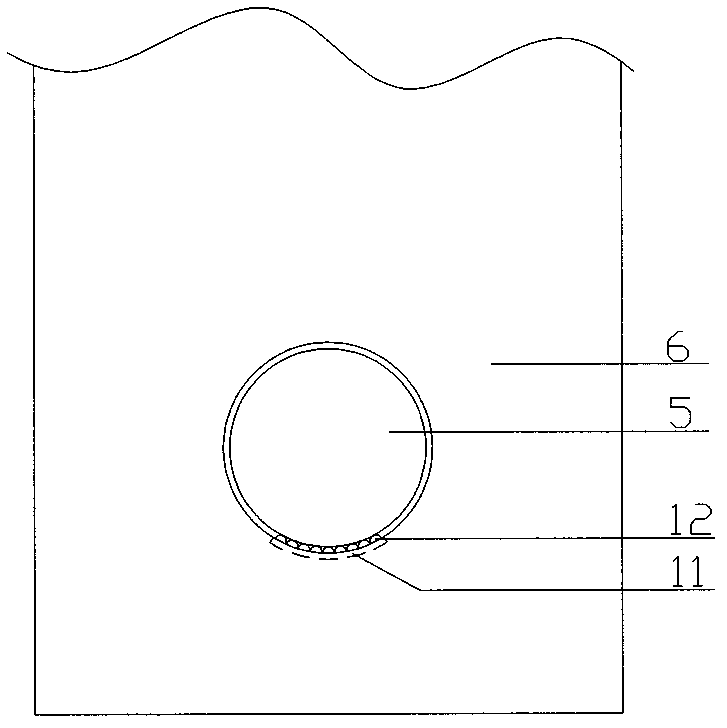

[0025] Uniform distribution of large tonnage-centralized loading system, the loading system consists of vertical support 1, hydraulic jack group 2, force collecting plate 3, spherical contact 4, force transmission column 5, guiding platform 6, pressure bearing plate 7, to-be-tested Model 8, fixing device 9, base bearing plate 10, groove 11, ball 12, reaction force frame 13, base 14, roller shaft 15 etc. constitute.

[0026] The base 14 is fixedly provided with a guide stand 6, and the guide stand 6 is provided with a horizontal through hole, and the bottoms of the two ports of the horizontal through hole are provided with symmetrical grooves 11, and the grooves 11 are provided with evenly arranged The ball 12 and the force transmission column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com