Patents

Literature

168results about How to "There will be no deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

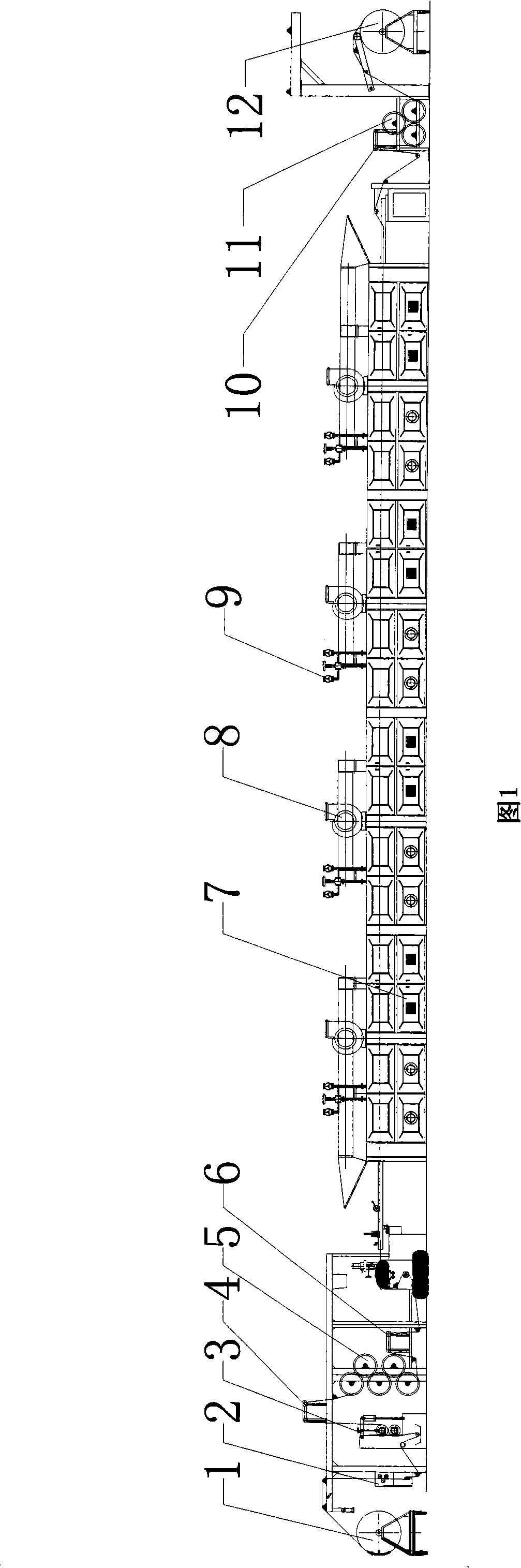

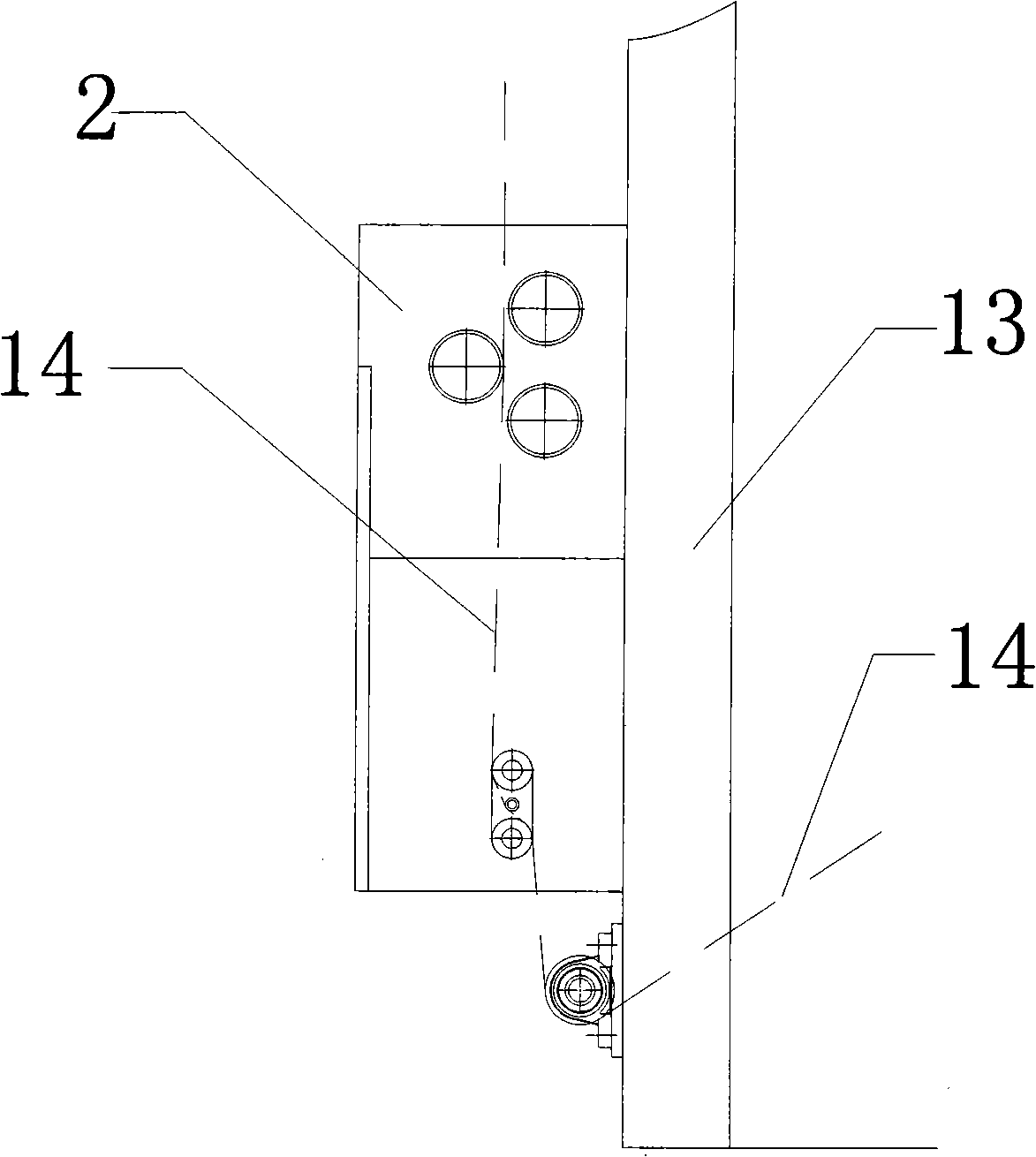

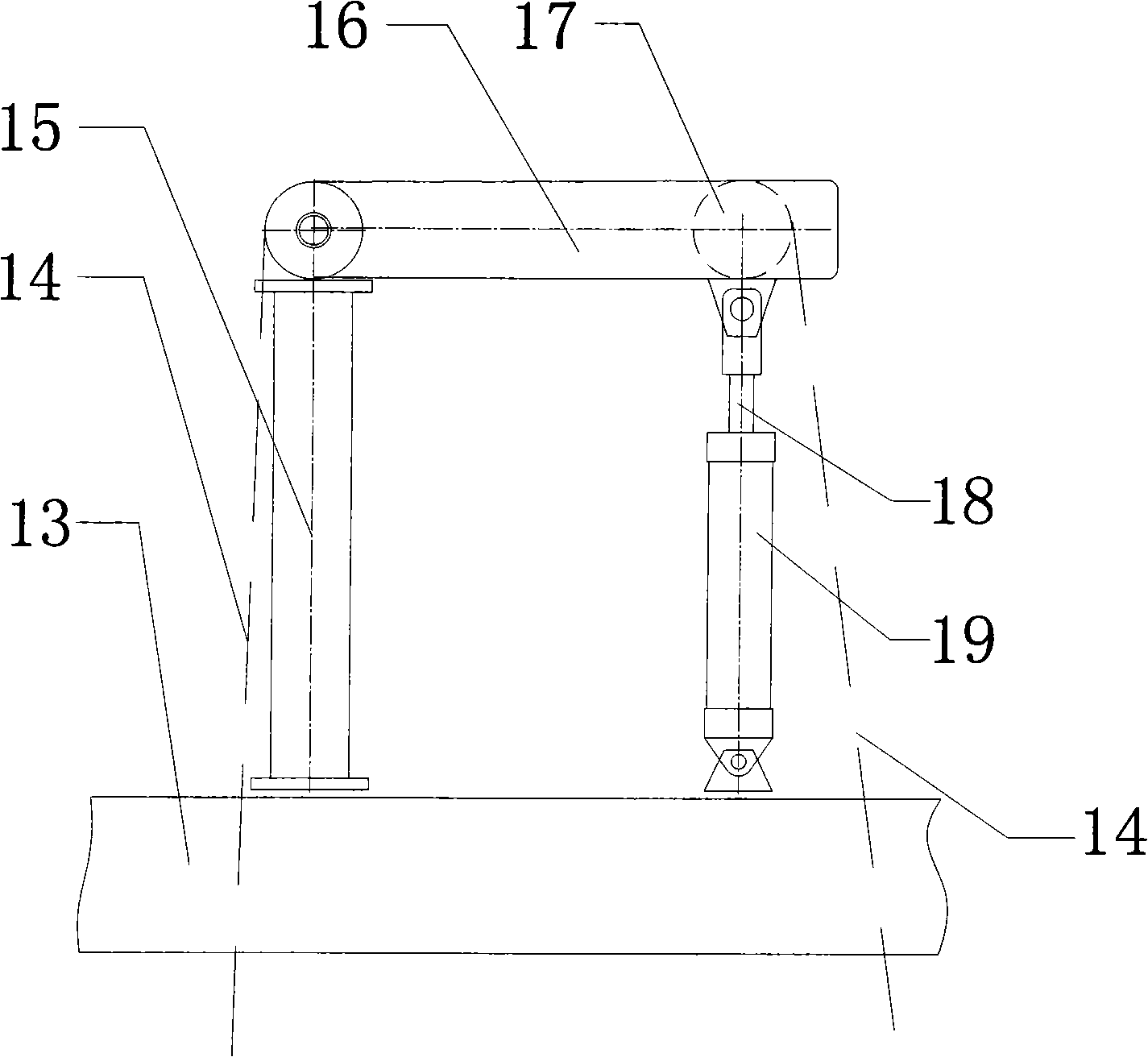

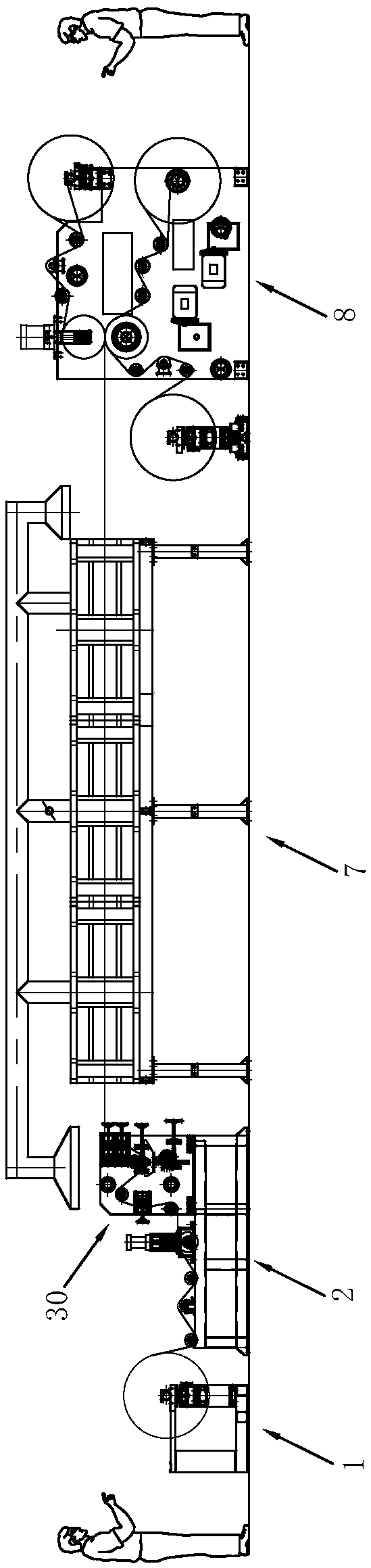

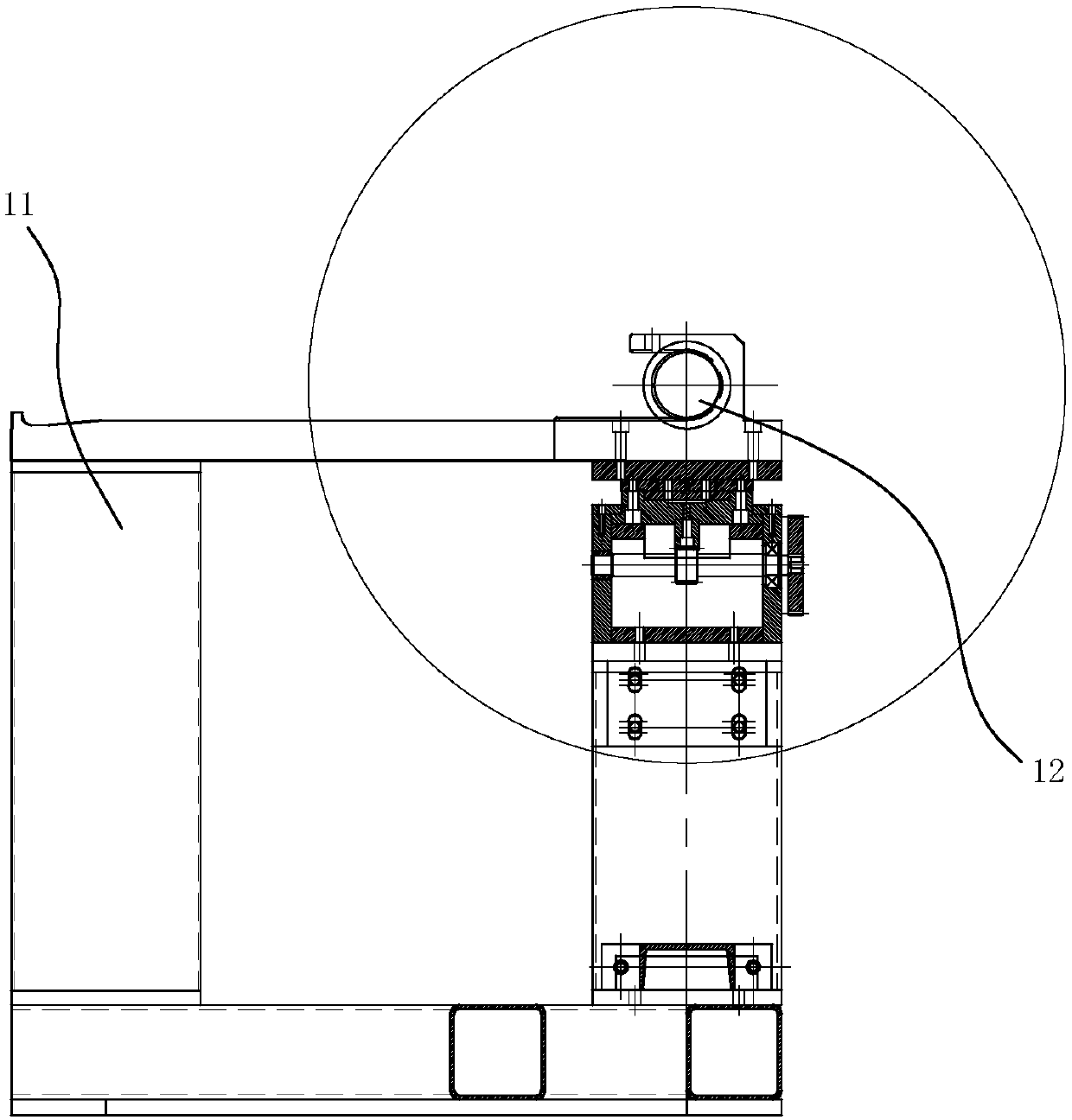

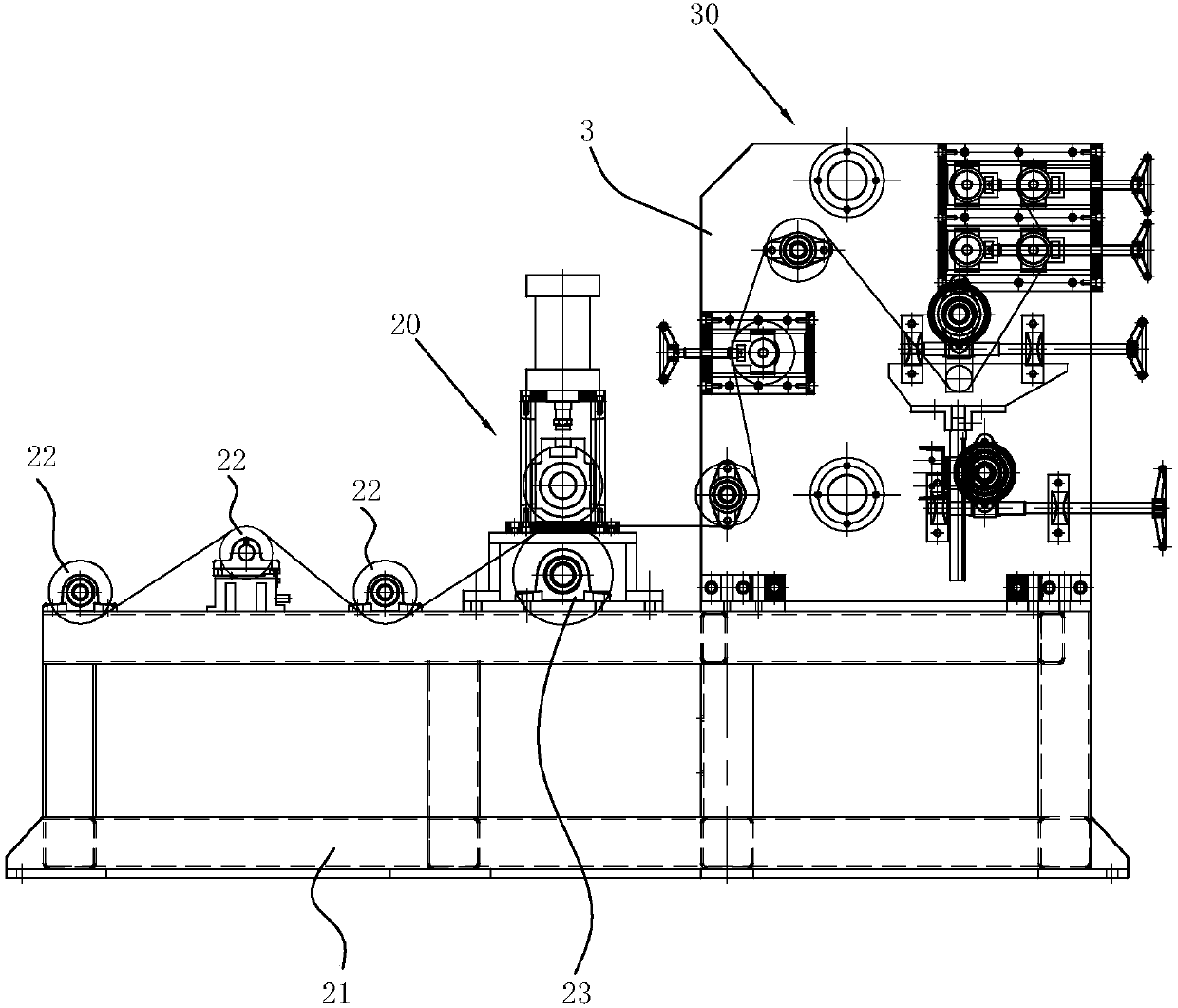

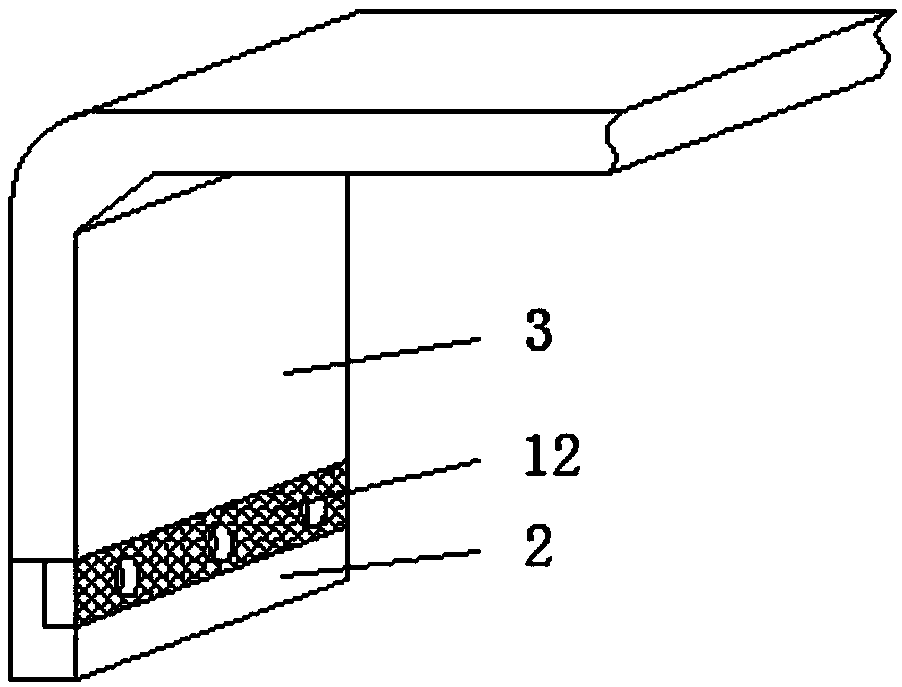

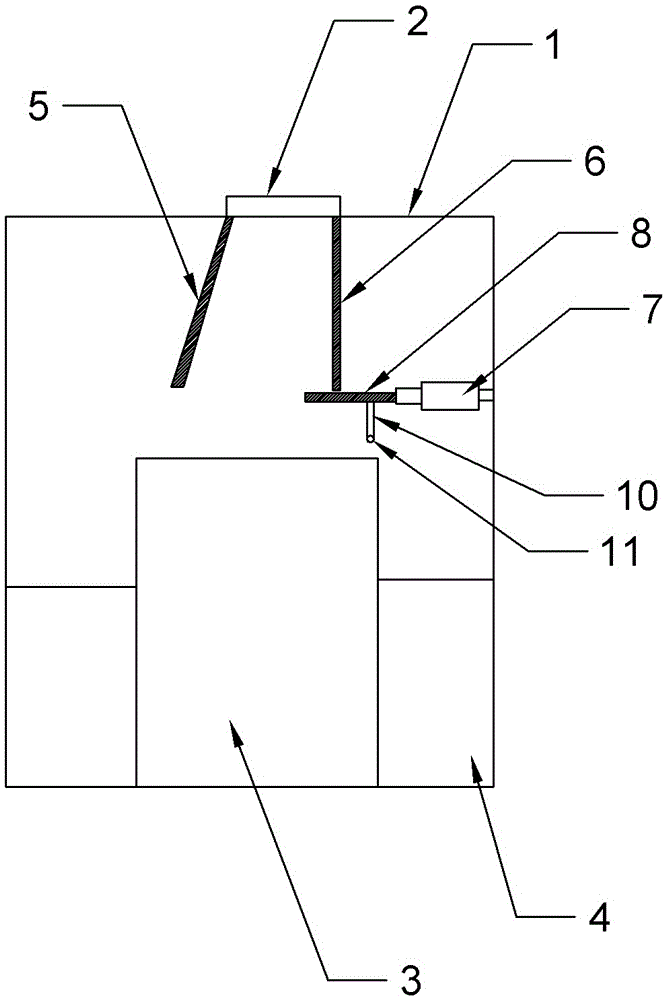

Production method of cloth coating

InactiveCN101337213AThere will be no deviationUniform amount of gluePretreated surfacesCoatingsWaste productEngineering

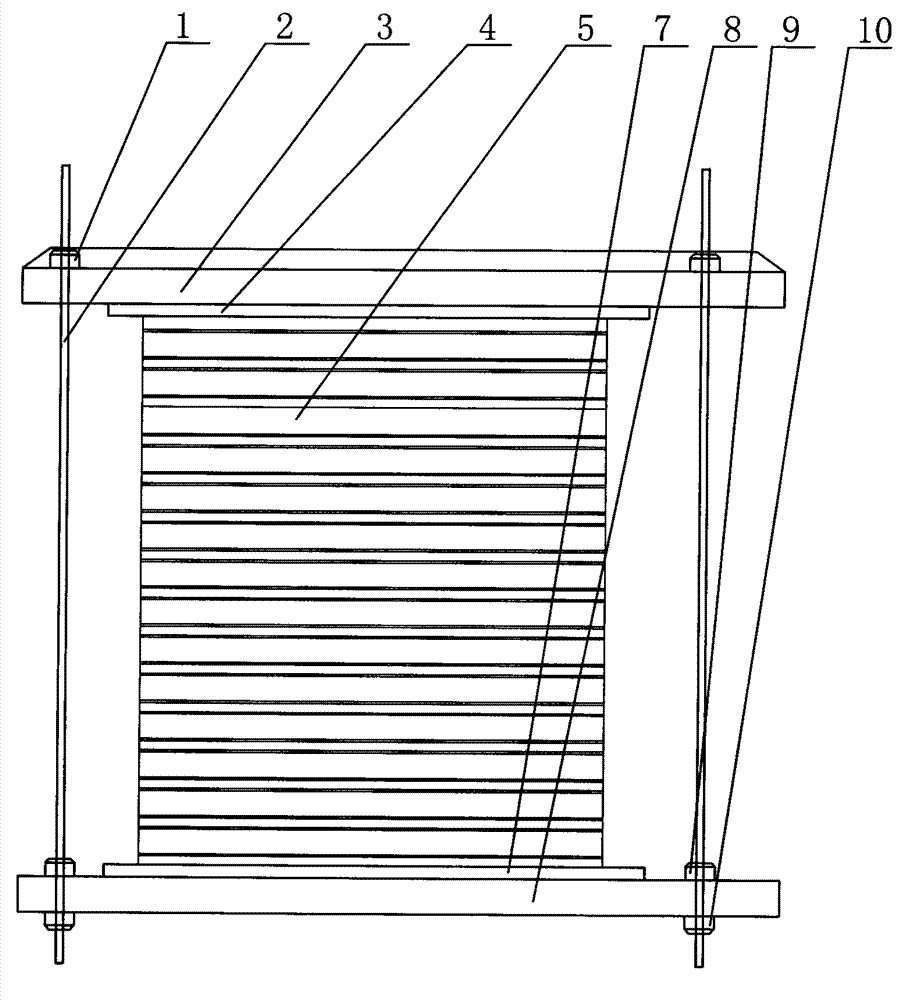

The invention relates to equipment for producing a cloth coating layer, and comprises a cloth delivering device, a cloth padding and pasting device, a cloth preheat ironing device, a drying oven, a cooling device and a cloth wrapping-up device which are arranged on a production line in sequence. The equipment is characterized in that a centering device is arranged between the cloth delivering mechanism and the cloth padding and pasting device; an automatic cloth adjusting tension roller is arranged between the cloth preheat ironing device and the cloth padding and pasting device; another automatic cloth adjusting tension roller is also arranged between the drying oven and the cooling device. The equipment has the advantages of novel design, compact structure, good use effect, no cloth running deviation phenomenon, uniform cloth gluing amount, good quality and few waste products; furthermore, the equipment has great popularization and application value.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

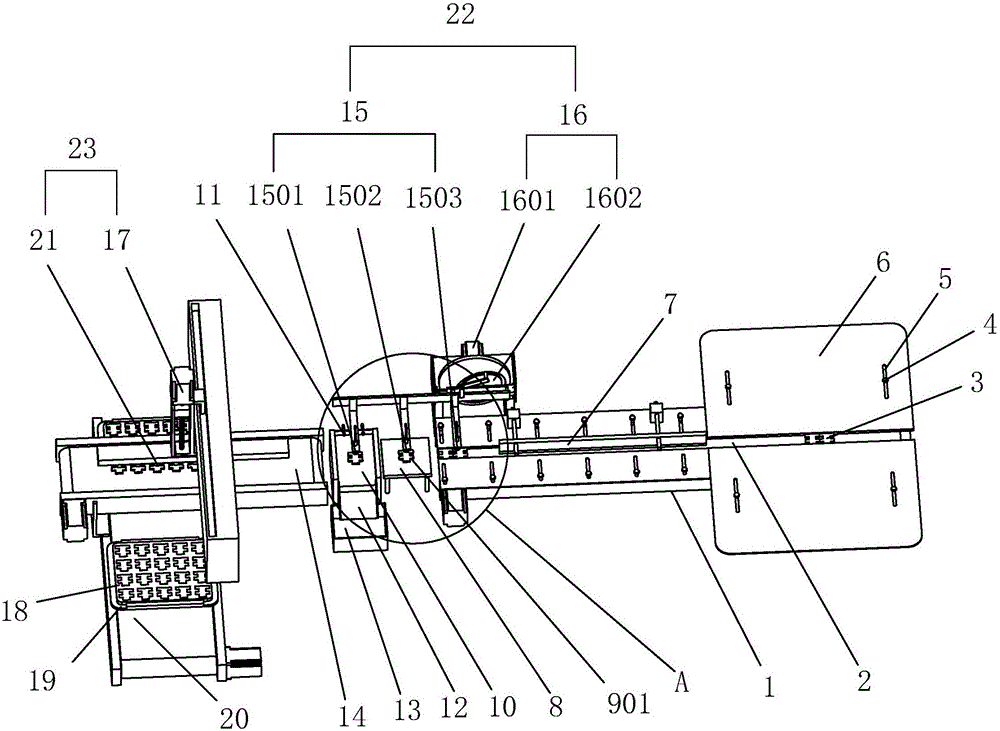

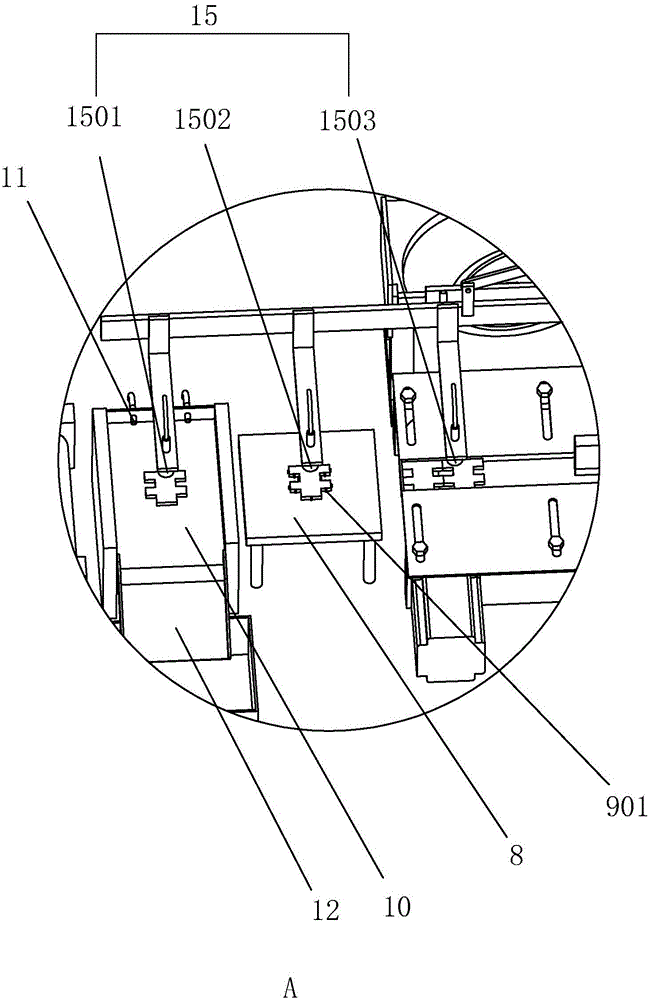

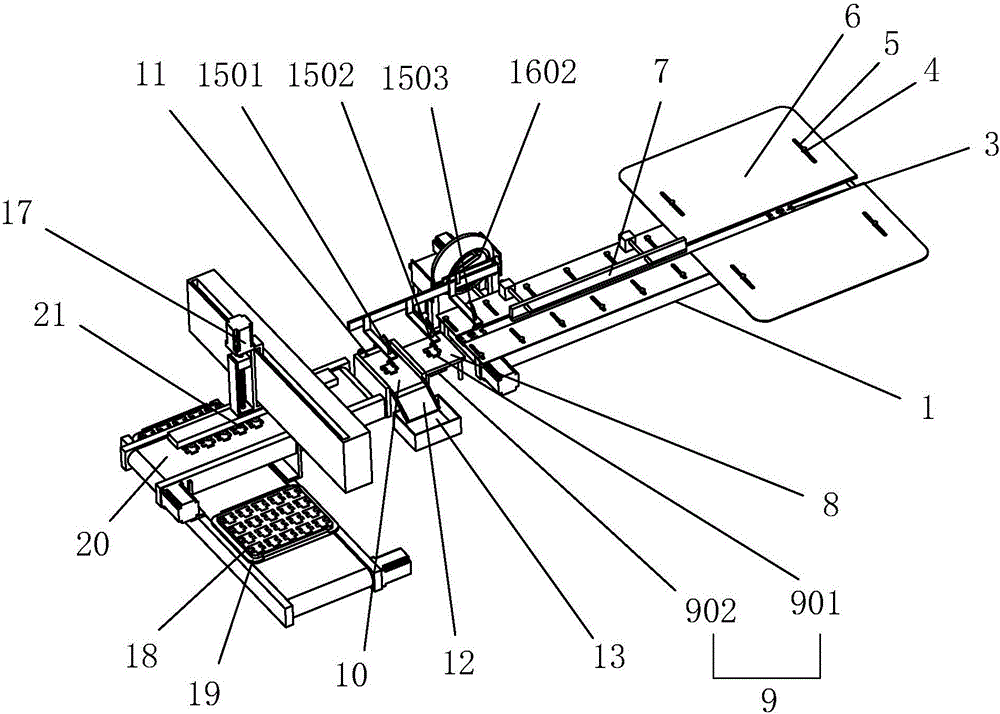

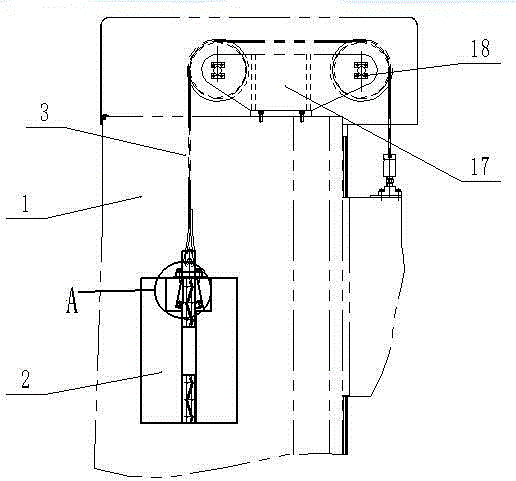

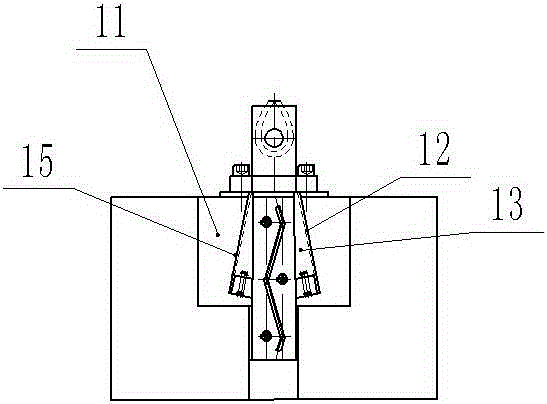

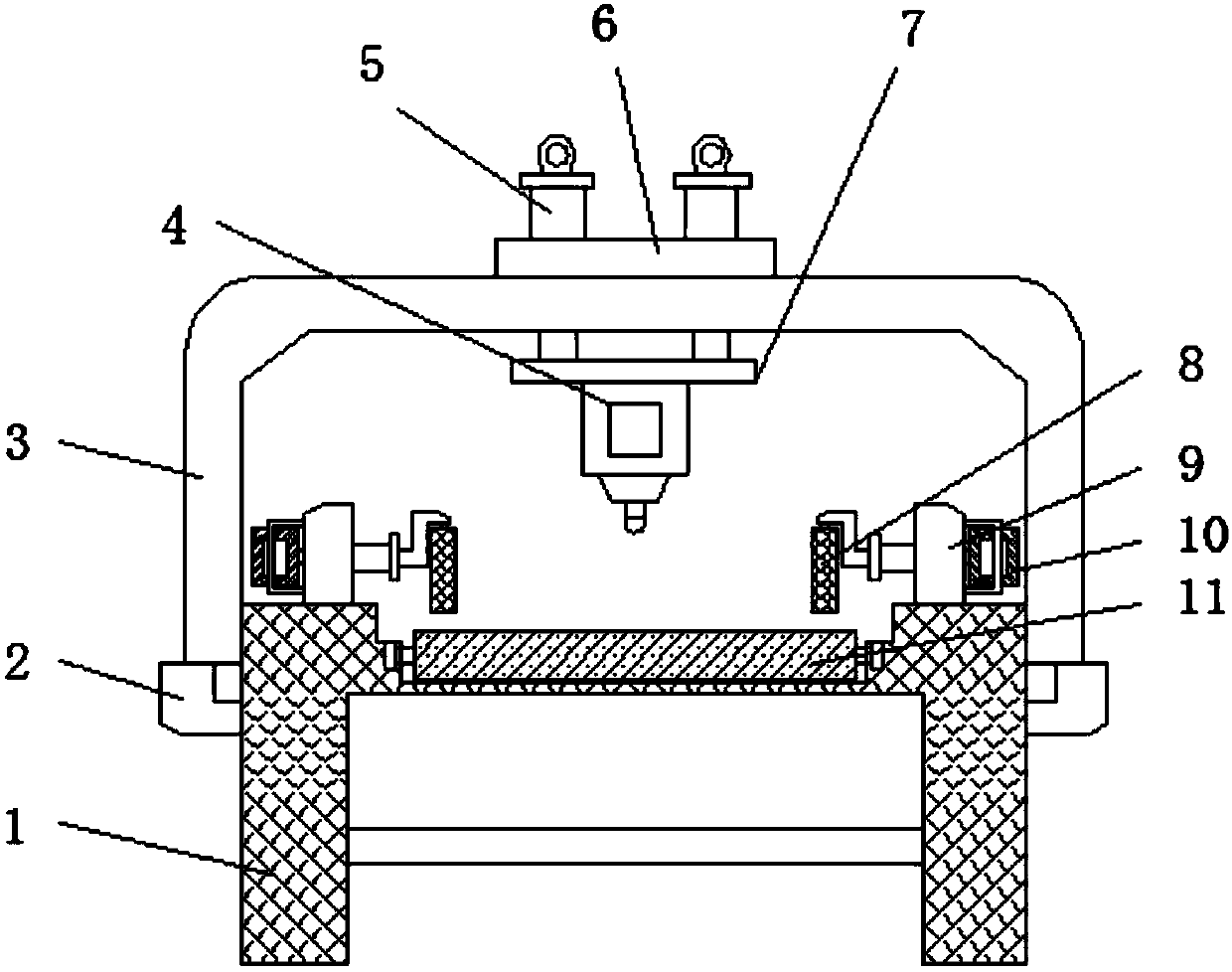

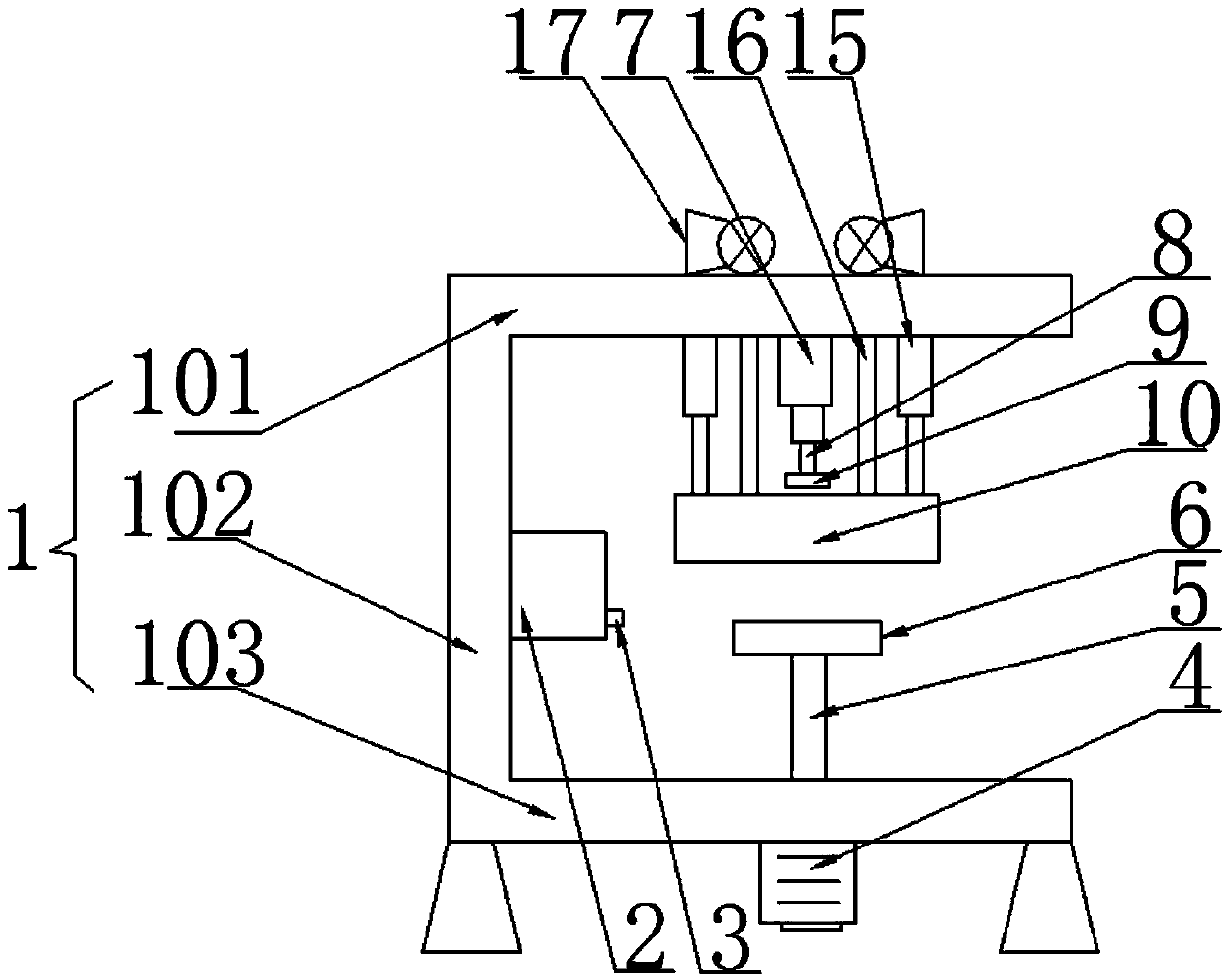

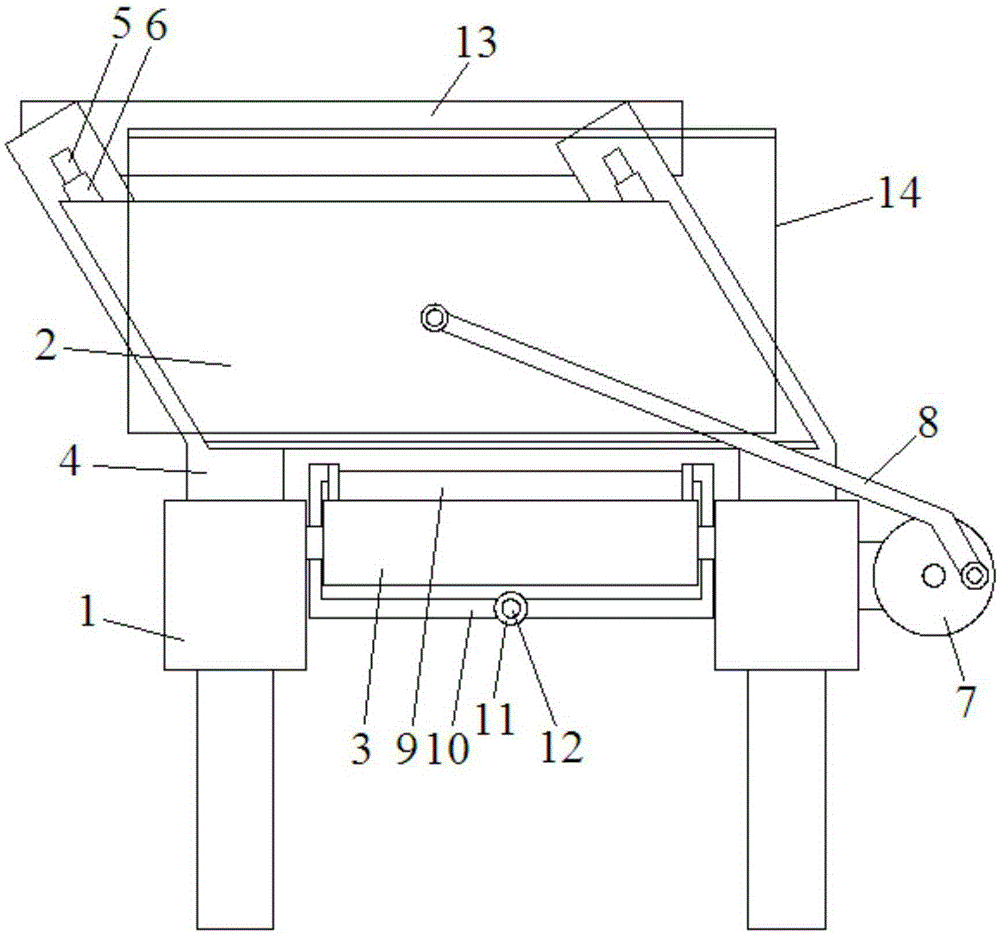

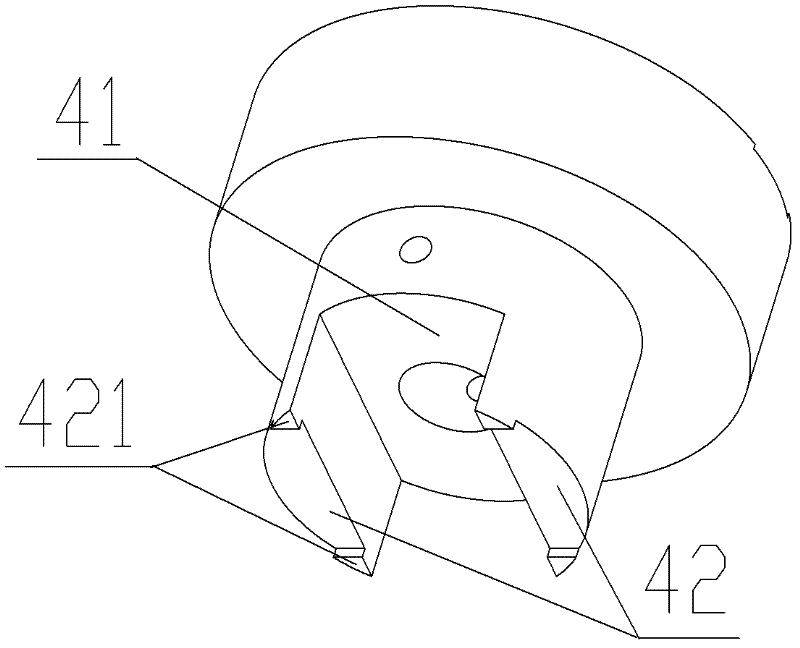

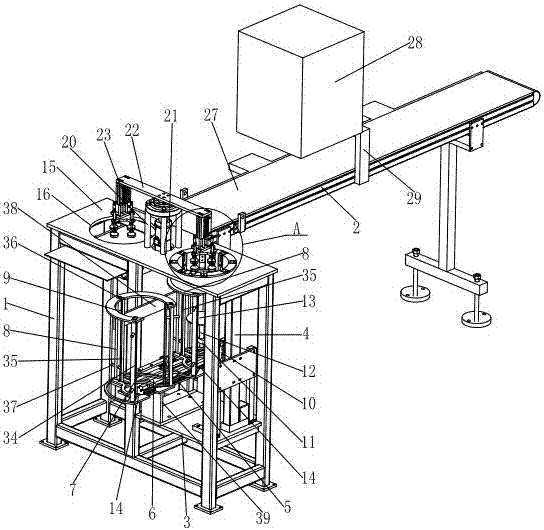

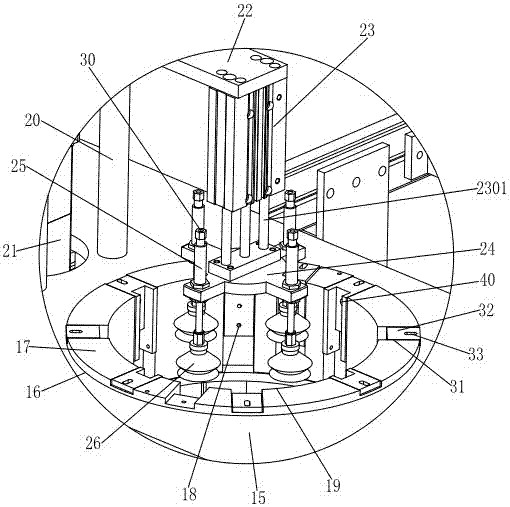

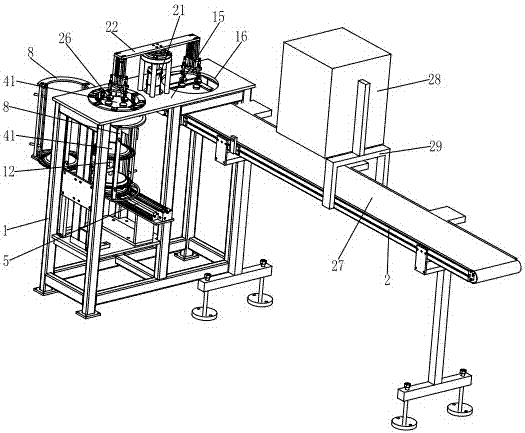

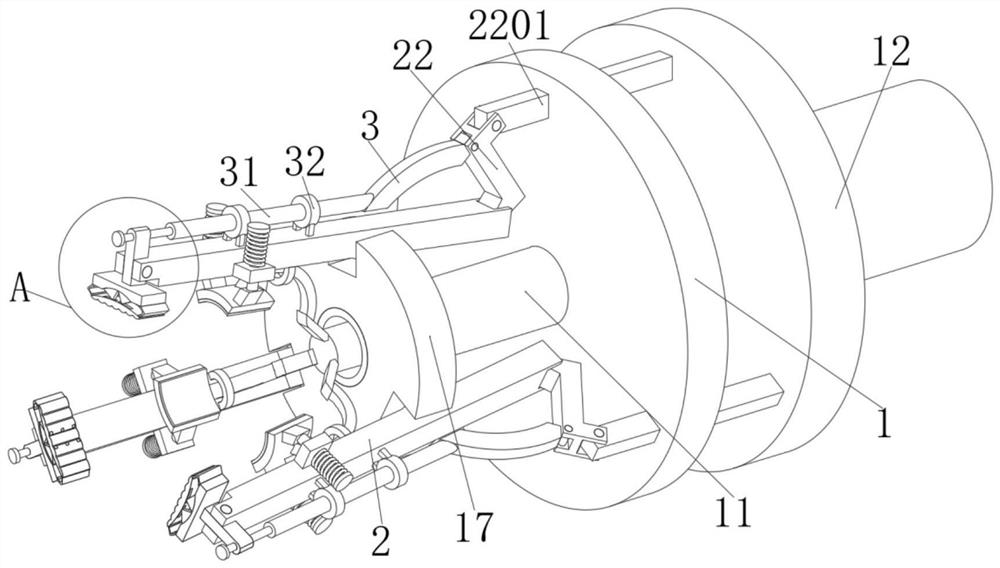

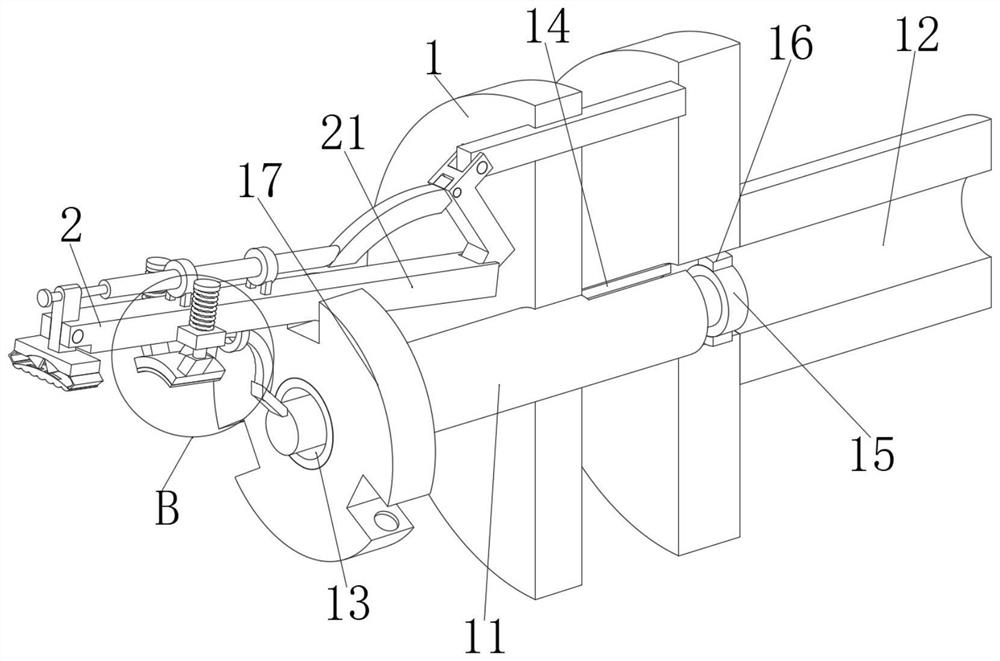

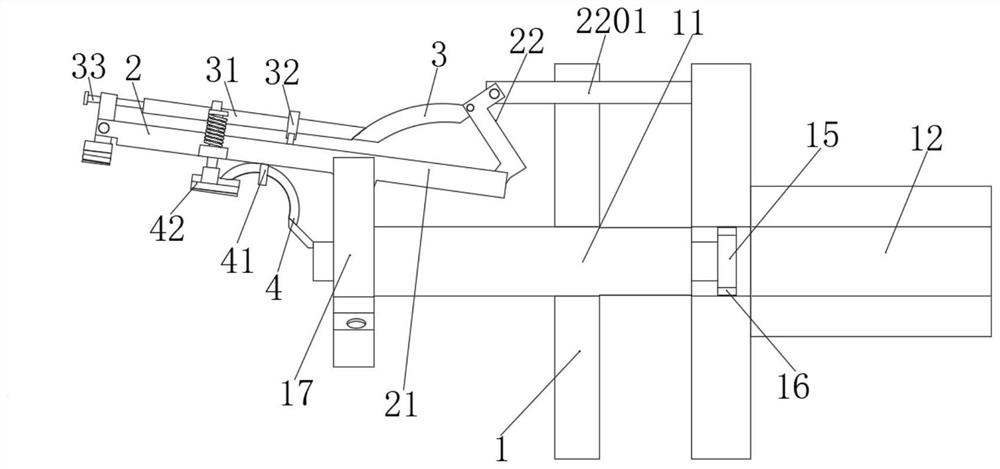

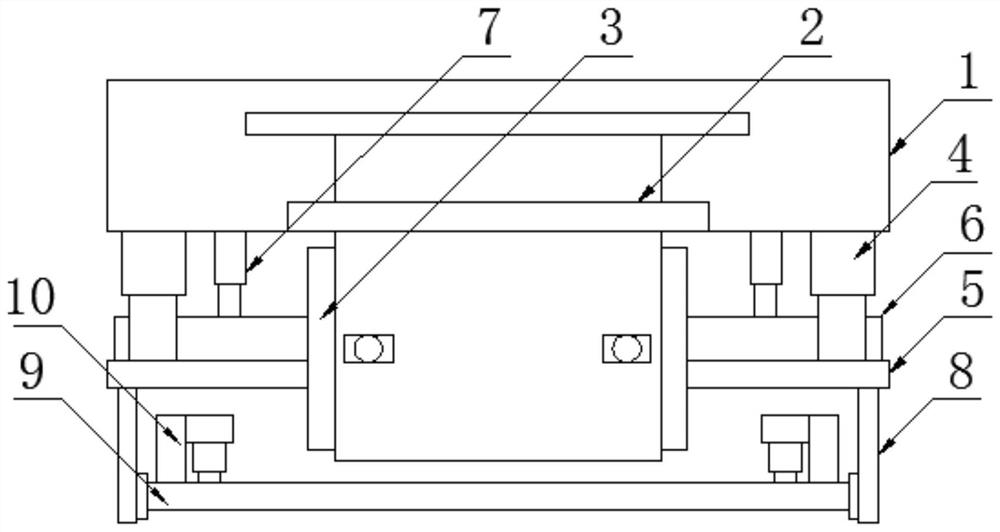

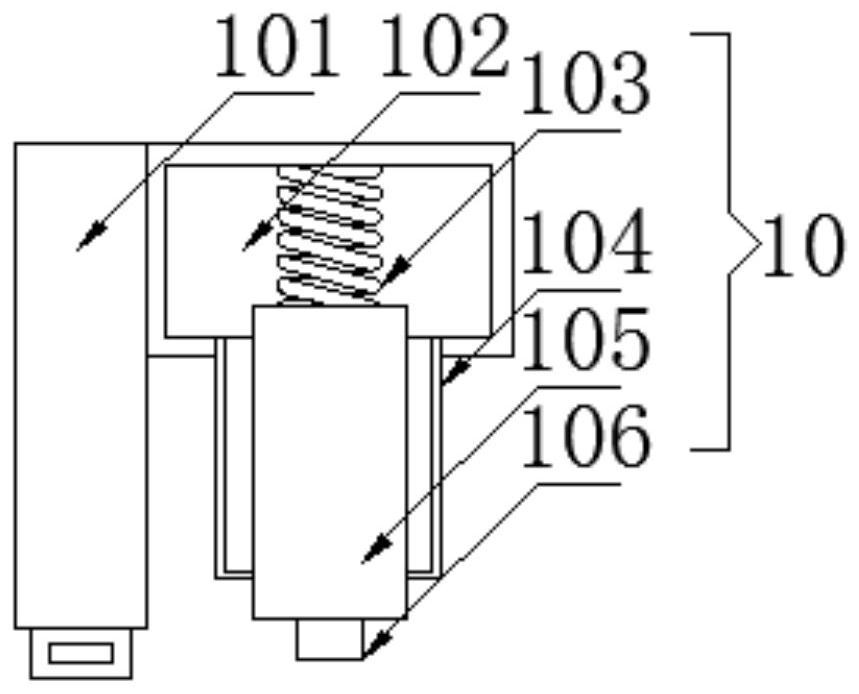

Bending piece detection equipment

ActiveCN106040610AHigh degree of automationImprove detection efficiencySortingMetal working apparatusEngineeringAutomation

The invention discloses bending piece detection equipment which solves the problem that in the prior art, a bending piece needs to be taken down from detection equipment in a manual mode. According to the technical scheme, the bending piece detection equipment comprises a rack; and a positioning and detection mechanism used for detecting the bending condition of the bending face on a workpiece, a material collecting part, and a wafting mechanism used for wafting detected defective products into the material collecting part. The defective products are wafted into the material collecting part through the wafting mechanism, the bending piece does not need to be taken down in the manual mode, the automation degree is high, and the detecting efficiency of the equipment is greatly improved.

Owner:德坤精密五金科技(苏州)有限公司

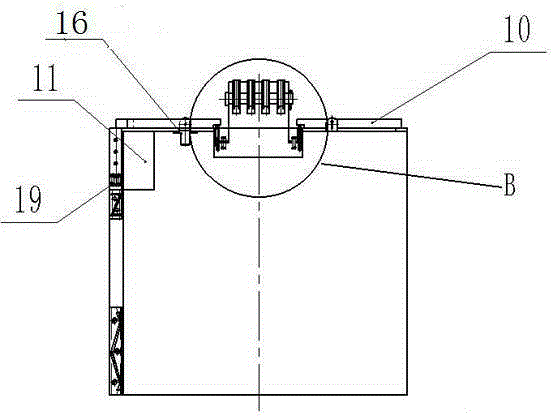

Balance weight device of boring-milling machine

ActiveCN105290870AThere will be no deviationAvoid fallingMaintainance and safety accessoriesEngineering

A balance weight device of a boring-milling machine comprises a hollow stand column, a balance weight block arranged in the stand column, a supporting device located above the stand column, and a connecting rope connected with the balance weight block and a drive device through the supporting device. The balance weight device is characterized in that vertical guide rails are oppositely arranged on the inner walls of the stand column respectively, grooves corresponding to the guide rails are formed in the two sides of the balance weight block, the grooves are provided with buckle devices capable of fixing the balance weight block to the guide rails, and the balance weight block is provided with a control structure used for controlling the buckle devices.

Owner:TONGYU HEAVY IND

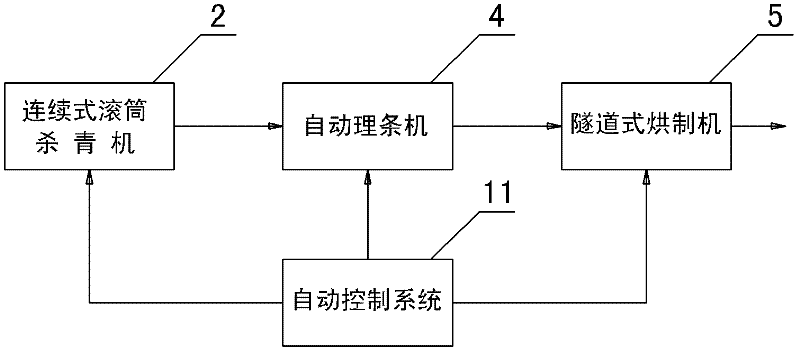

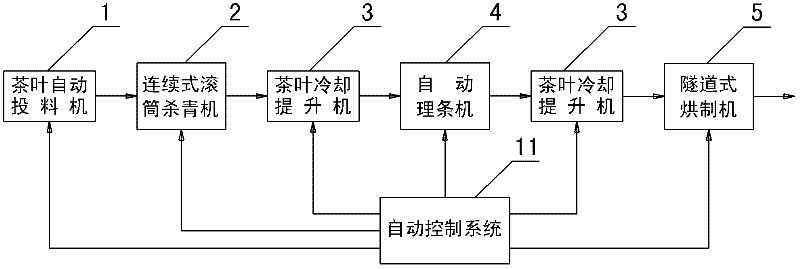

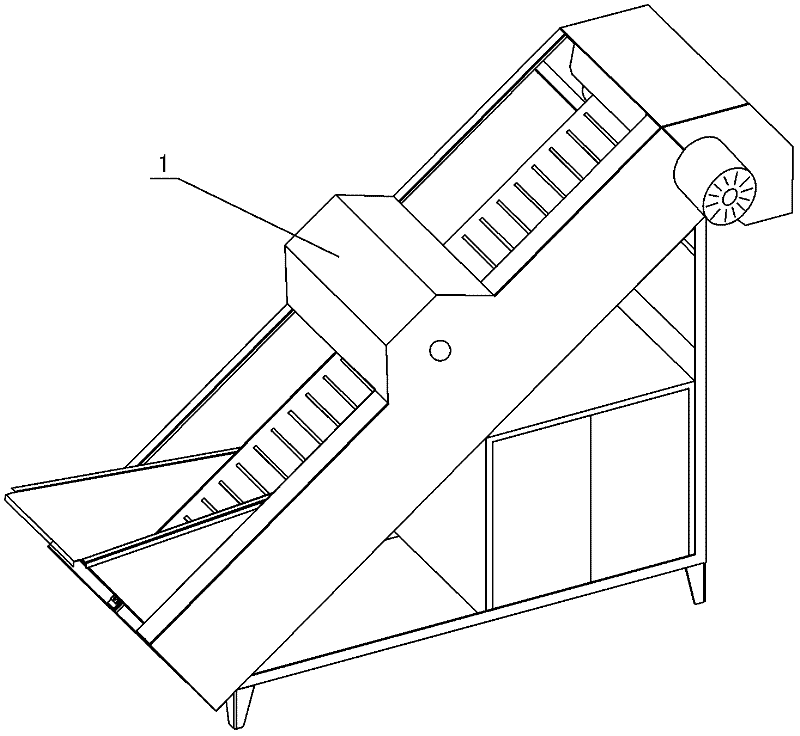

Automatic production complete plant for Maofeng tea

ActiveCN102630767AAchieve continuous flowFully automatedPre-extraction tea treatmentFlavorAutomatic control

The invention discloses an automatic production complete plant for Maofeng tea. The automatic production complete plant comprises a continuous rotary-drum type de-enzyming machine, an automatic tea management machine and a tunnel drier, all of which are mutually connected, wherein the tunnel drier comprises a stand and a drying tunnel, the drying tunnel is arranged on the stand, two sides of the drying tunnel are of sealing structures, the top of the drying tunnel is provided with a heater, and the bottom of the drying tunnel is provided with a tea conveyer belt. The automatic production complete plant for the Maofeng tea further comprises an automatic control system which is connected with and controls all machining devices on the automatic production complete plant. The automatic production complete plant disclosed by the invention effectively solves problems that the machining of the Maofeng tea is dispersive, the quality of the Maofeng tea is irregularly and labor and device resources are waste during present Maofeng tea production. The automatic production complete plant for the Maofeng tea, disclosed by the invention, has the advantages of high automation degree, stability and safety in operation, small dust pollution, no damage on the Maofeng tea, and Maofeng tea finished products have fragrant flavor and high quality grade, thus being high in promotion value.

Owner:浙江丰凯机械股份有限公司

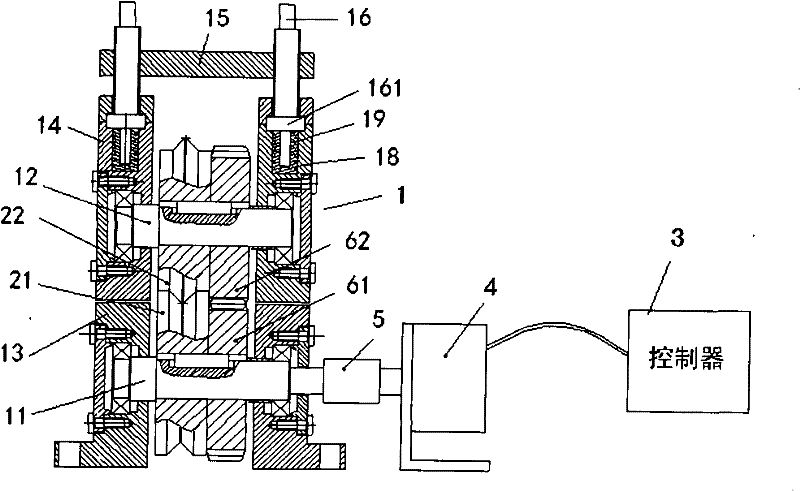

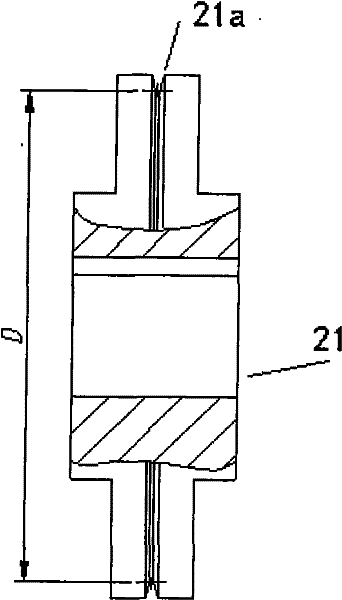

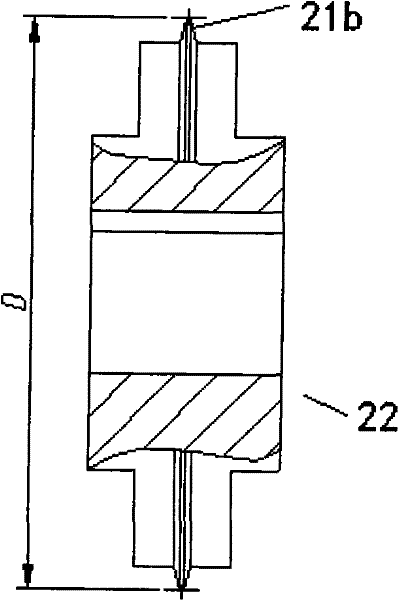

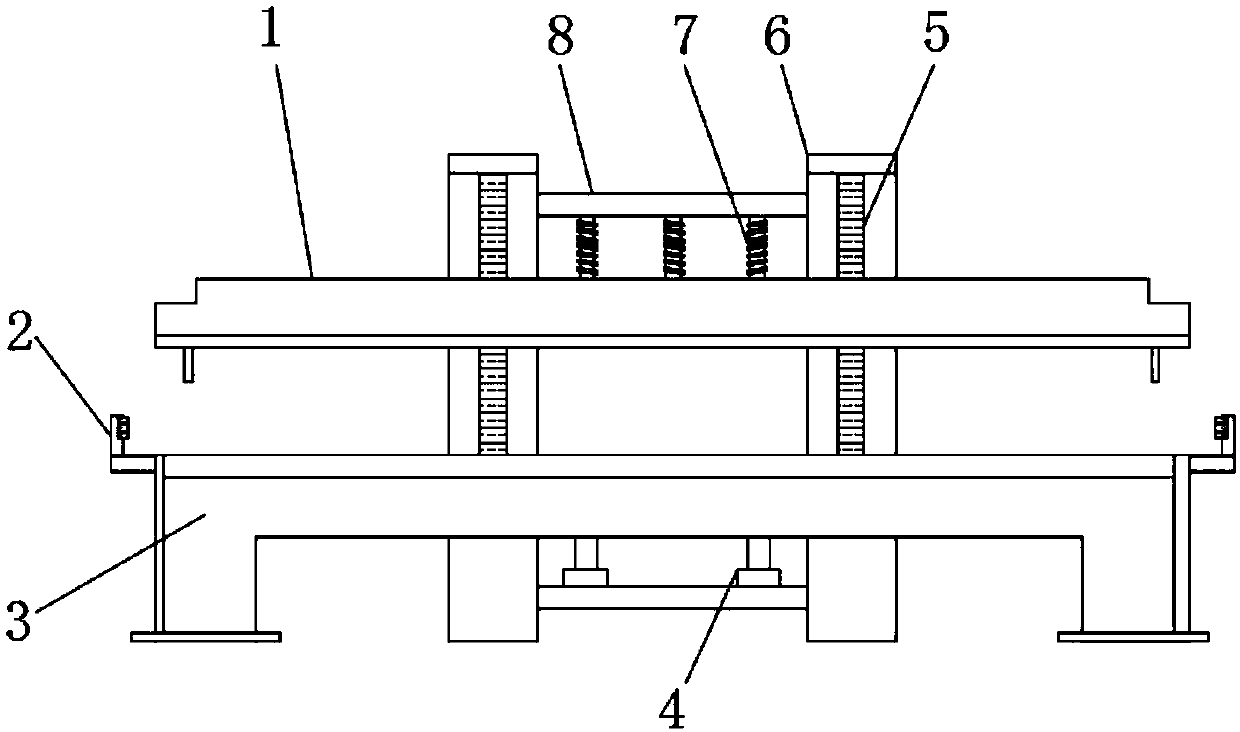

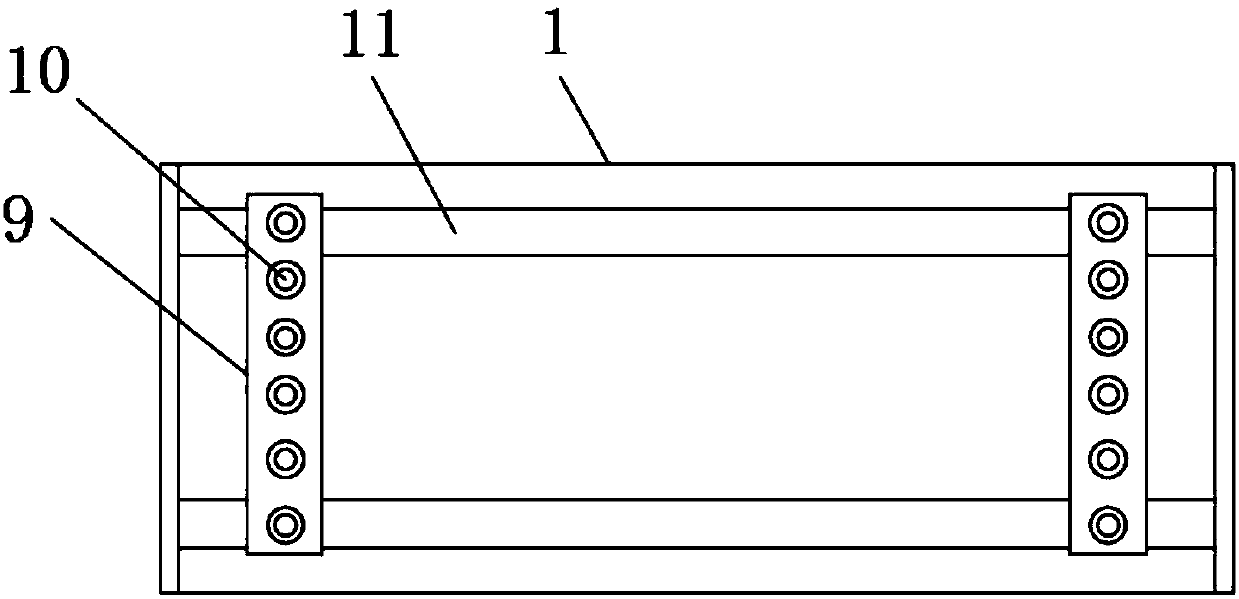

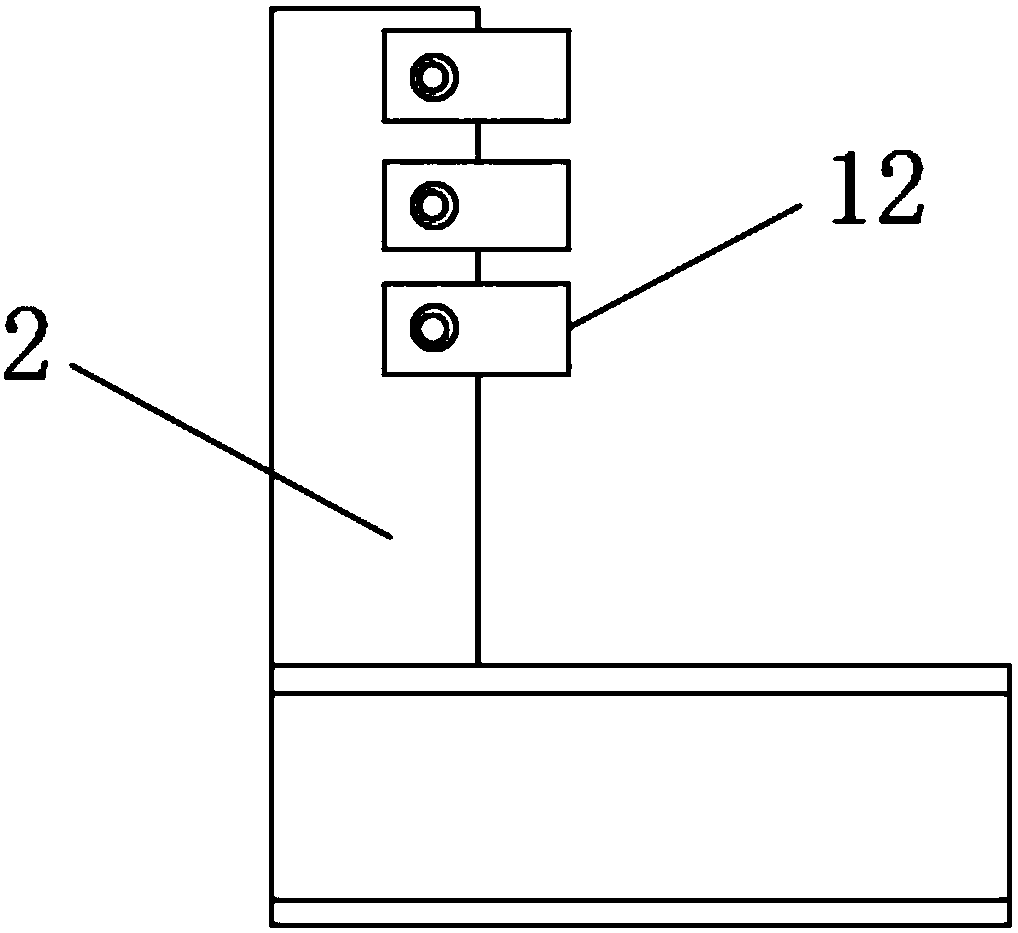

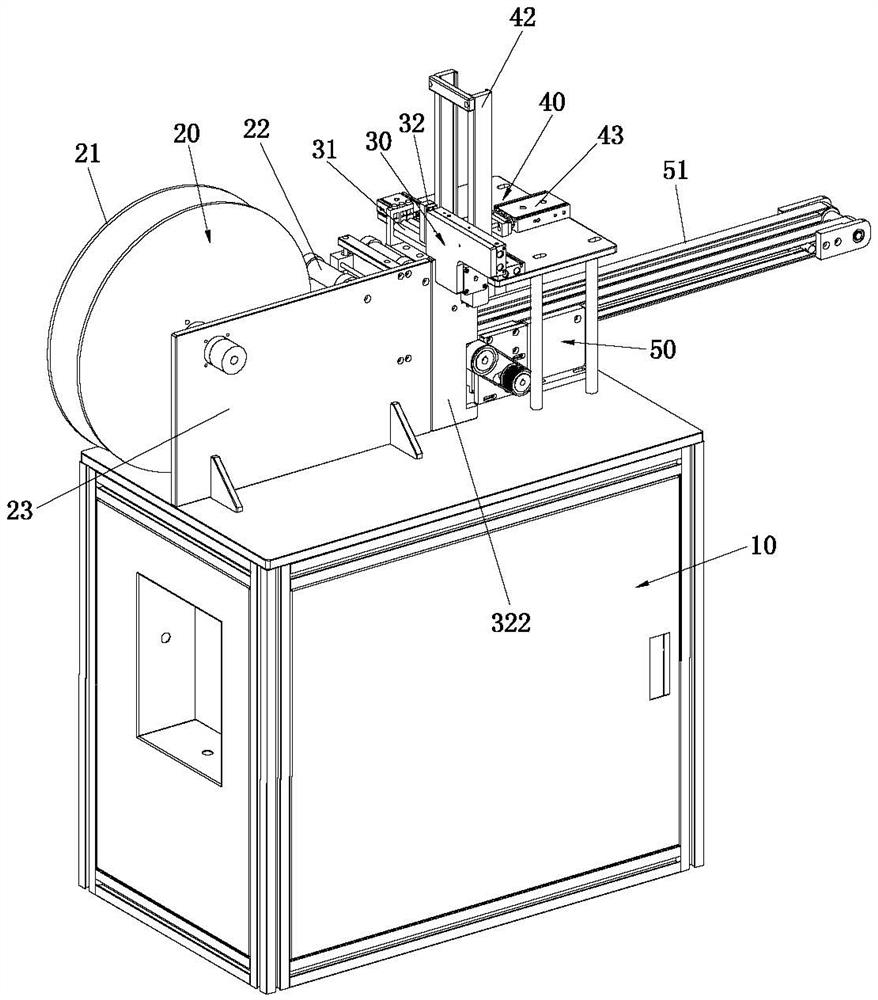

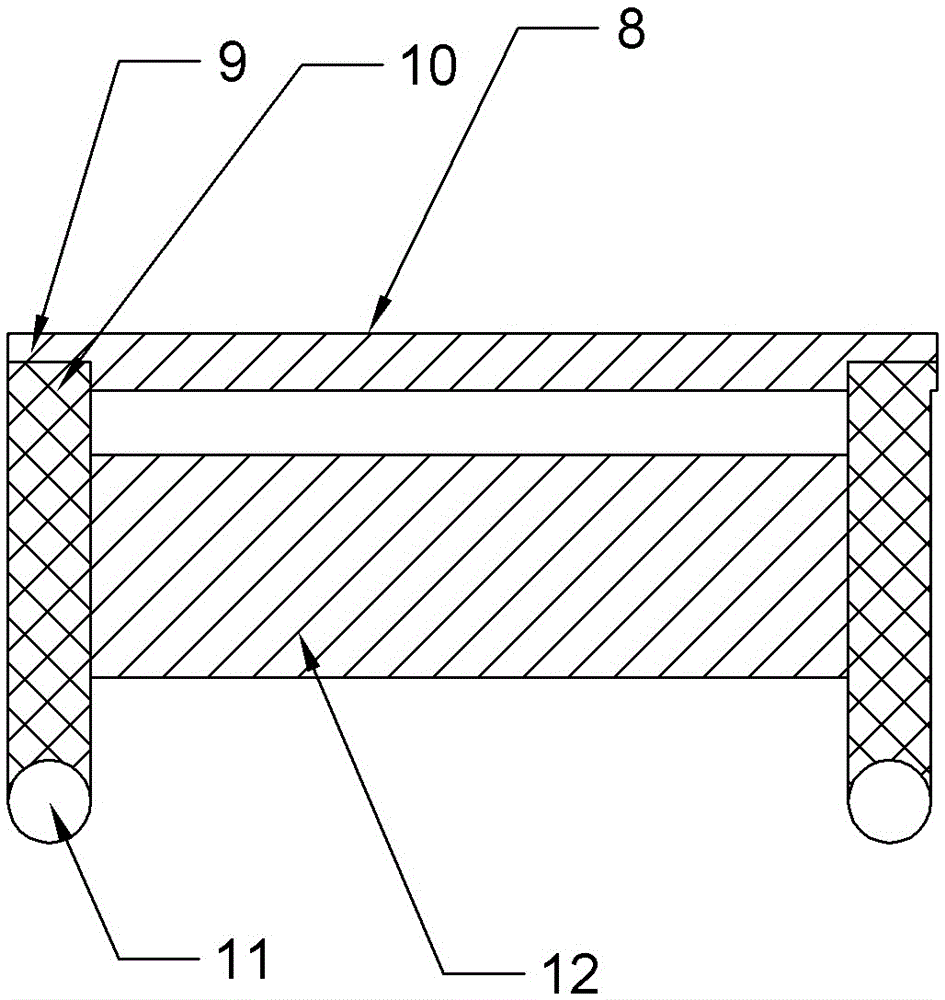

Fixed-length wire feeding device and wire feeding method

The invention discloses a fixed-length wire feeding device which comprises a stander, a pair of wire feeding wheels, a motor, a controller and a transmission mechanism, wherein the stander is provided with a driving shaft and a driven shaft; the pair of wire feeding wheels comprise a driving wheel sleeved on the driving shaft and a driven wheel sleeved on the driven shaft; the motor is used for driving the driving shaft to rotate; the controller is used for controlling the rotation angle of the motor; and the transmission mechanism is used for delivering power output by the motor to the driven wheel, so that the driven shaft and the driving shaft rotate synchronously at a constant speed. The invention also discloses a wire feeding method. In the method, the controller is utilized to control the rotation angle of the motor so as to control the rotation angles of the driven wheel and driving wheel which are used for feeding wires, thereby realizing the fixed-length wire feeding. According to the invention, the rotation angle of the motor is completely controlled by the controller, so that the fixed-length wire feeding can be realized; and in a wire feeding process, the position of the driven wheel can adaptively move up and down according to the diameter of a fuse wire under the action of a compensating spring, thereby eliminating the influence of the diameter error of the fuse wire on the wire feeding driving power and improving the wire feeding size precision.

Owner:SHANGHAI UNIV OF ENG SCI

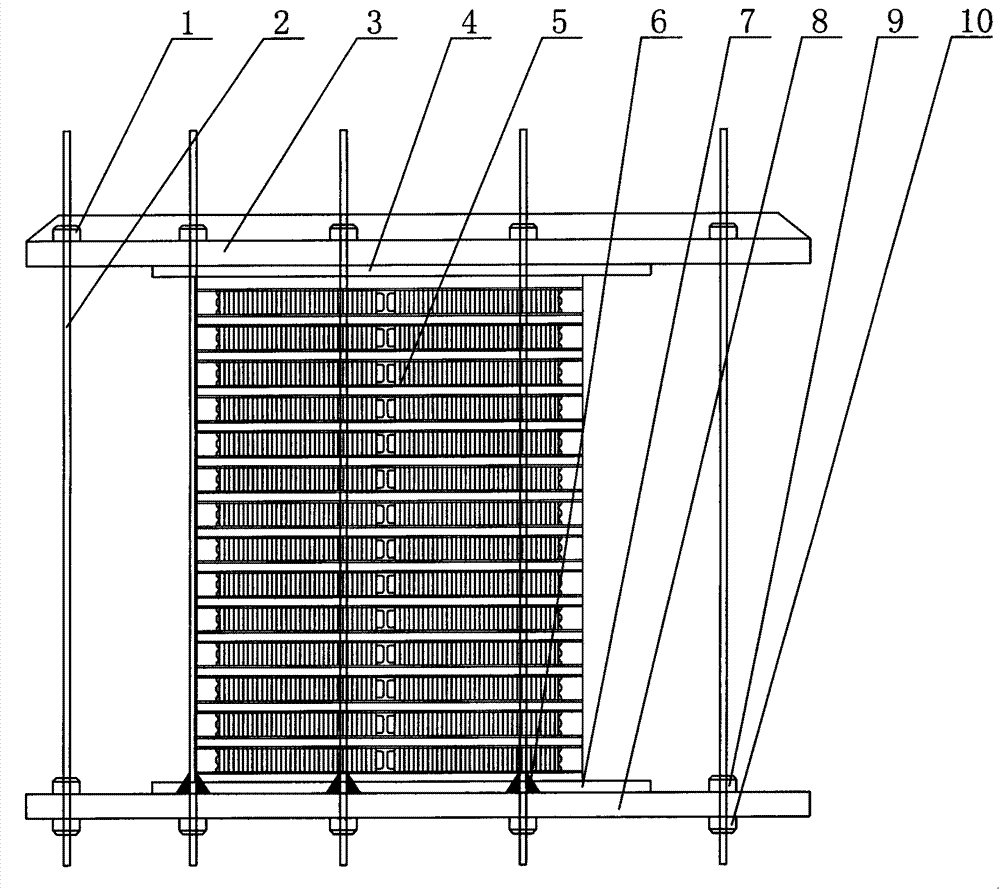

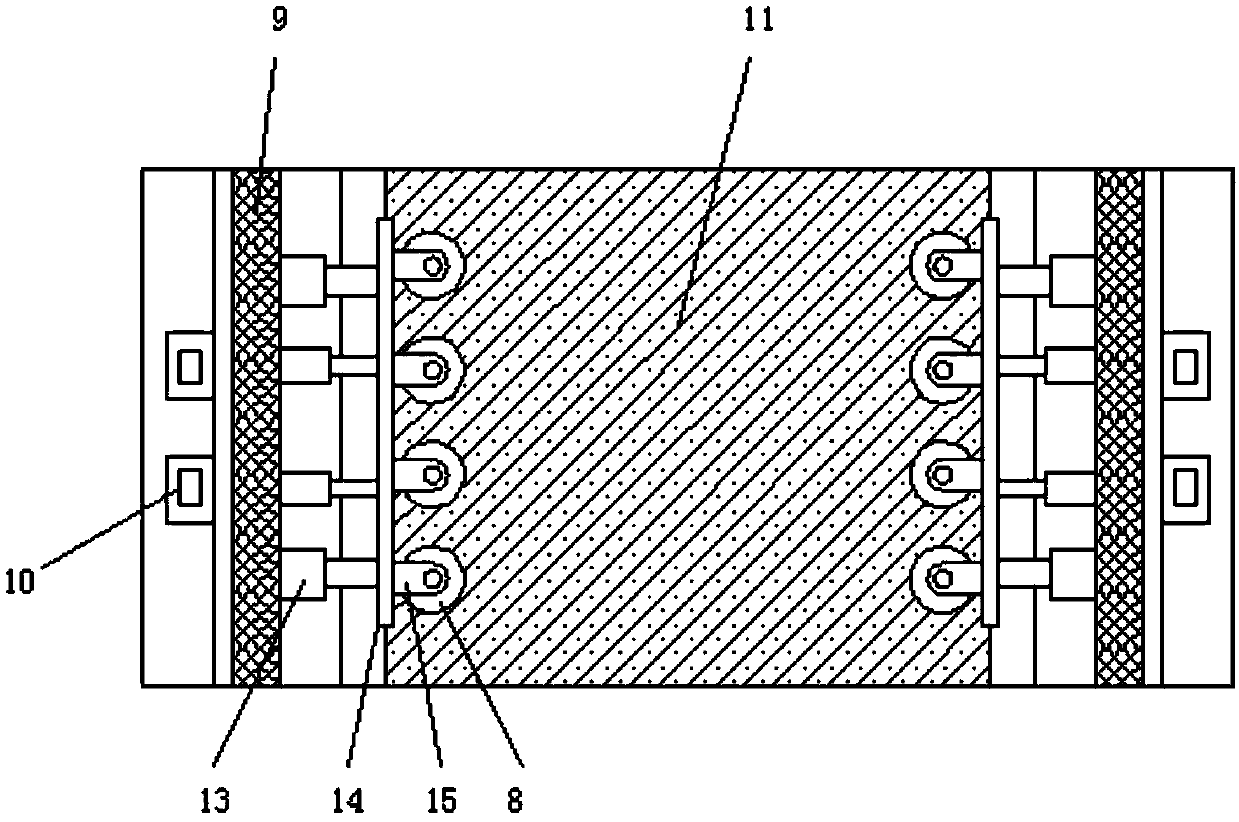

Small multi-assembly brazing clamping device

InactiveCN103394854AAvoid misalignmentGuaranteed verticalityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal expansion

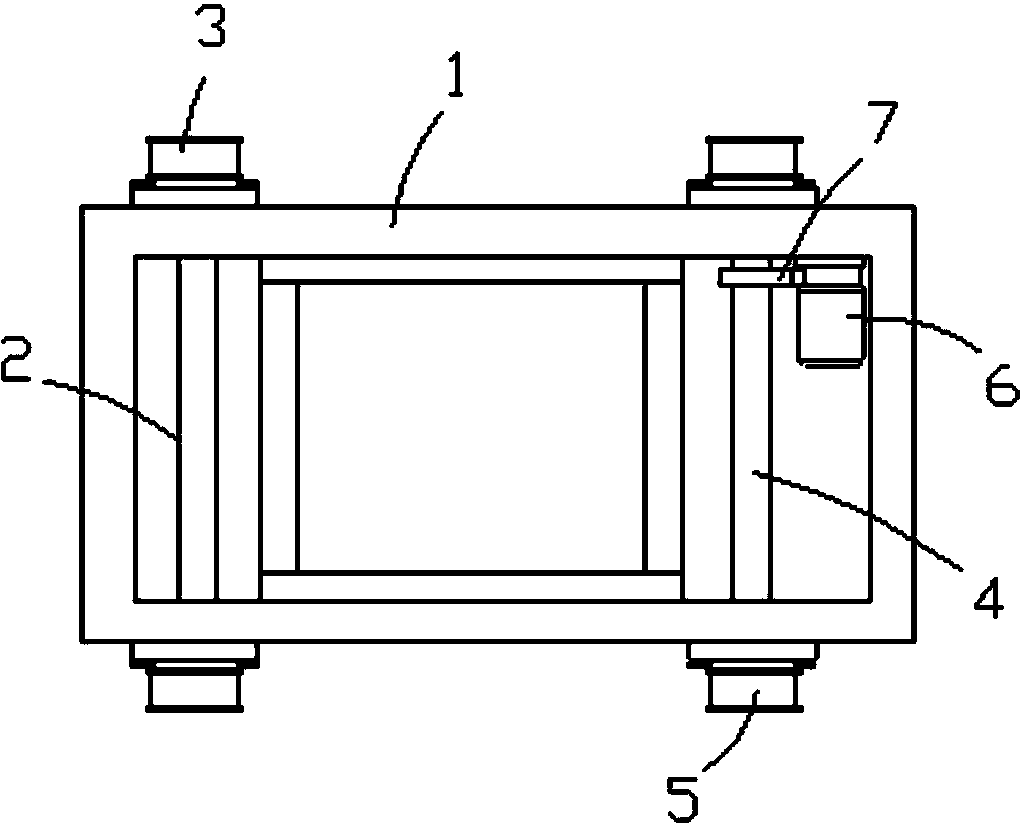

Provided is a small multi-assembly brazing clamping device. The small multi-assembly brazing clamping device comprises cores, wherein an upper supporting board is installed on a cover board at the tops of the cores, a lower supporting board is installed on a cover board at the bottoms of the cores, an upper base board is installed at the top of the upper supporting board, a lower base board is installed at the bottom of the lower supporting board, the two sides of the upper base board and the two sides of the lower base board are respectively provided with a plurality of through holes, and screws are installed in the through holes and are perpendicular to the upper base board and the lower base board respectively; the head portions of the screws are fixed on the top of the upper base board through first nuts, the bottoms of the screws are fixed at the upper end of the lower base board through second nuts, and the bottoms of the screws are fixed at the lower end of the lower base board through third nuts. The cores are installed between the upper base board and the lower base board, and the screws which are perpendicular to the cores are installed, so that the phenomenon of dislocation of the cores when thermal expansion stress occurs in the brazing process is prevented; the head portions and the root portions of the screws are respectively fixed on the base boards through the nuts, so that the structure is firm, the shifting phenomenon does not happen, the perpendicularity of the cores is guaranteed, and accordingly the brazing quality of the cores is ensured.

Owner:WUXI FANGSHENG HEAT EXCHANGER MFG

Single and double girder crane trolley of electric hoist

The invention relates to the technical field of cranes and discloses a single and double girder crane trolley of an electric hoist. The single and double girder crane trolley comprises a trolley frame, wherein the front part of the vehicle frame is connected with two driven wheels by virtue of a driven rotary shaft, the back part of the vehicle frame is connected with two driving wheels by virtue of a driving rotary shaft, and the driving rotary shaft is linked with a motor. As one motor drives the two driving wheels so as to drive the single and double girder crane trolley to run, the synchronism without off tracking of the trolley in the running process is ensured, the manufacturing cost is also lowered, and the working efficiency is improved.

Owner:陈高兵

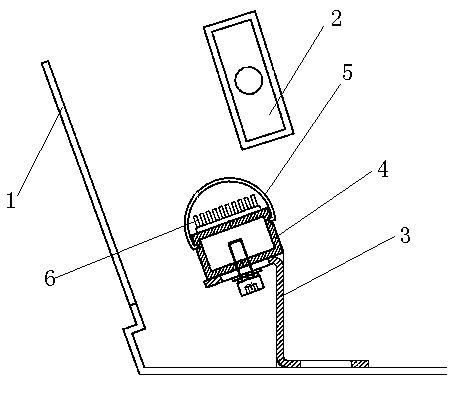

Low-voltage coil winding tool for transformer

InactiveCN105355420AThere will be no deviationReduce in quantityInductances/transformers/magnets manufactureWinding machineLow voltage

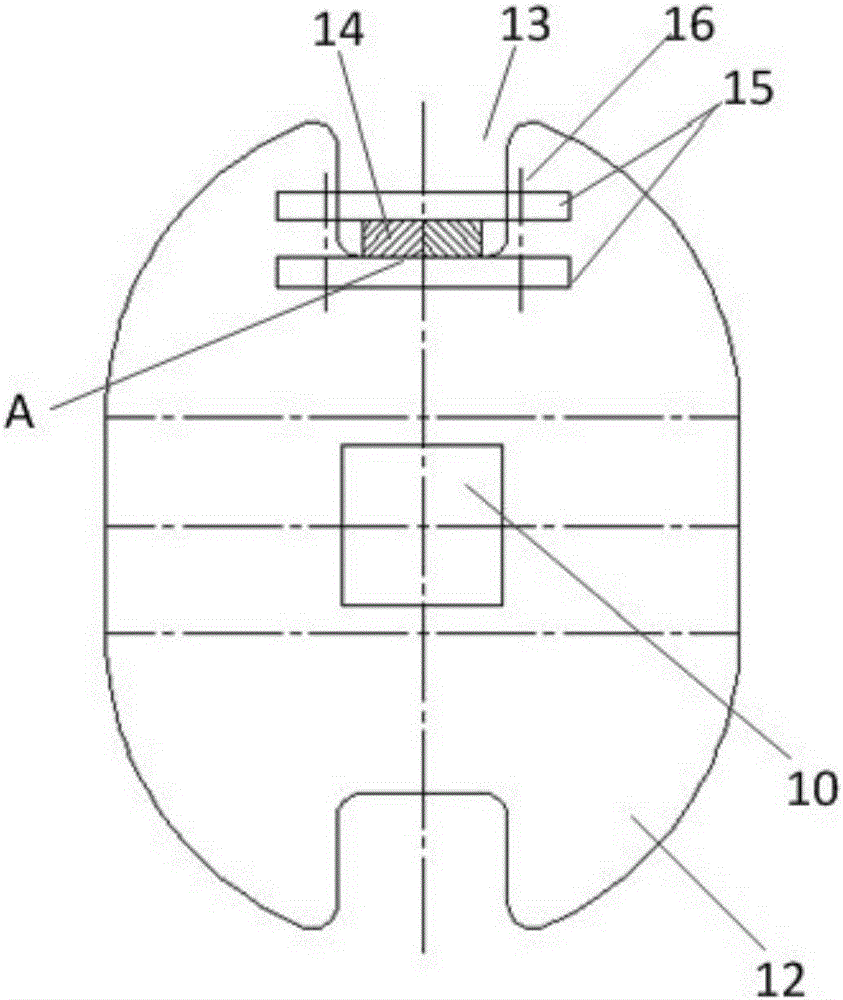

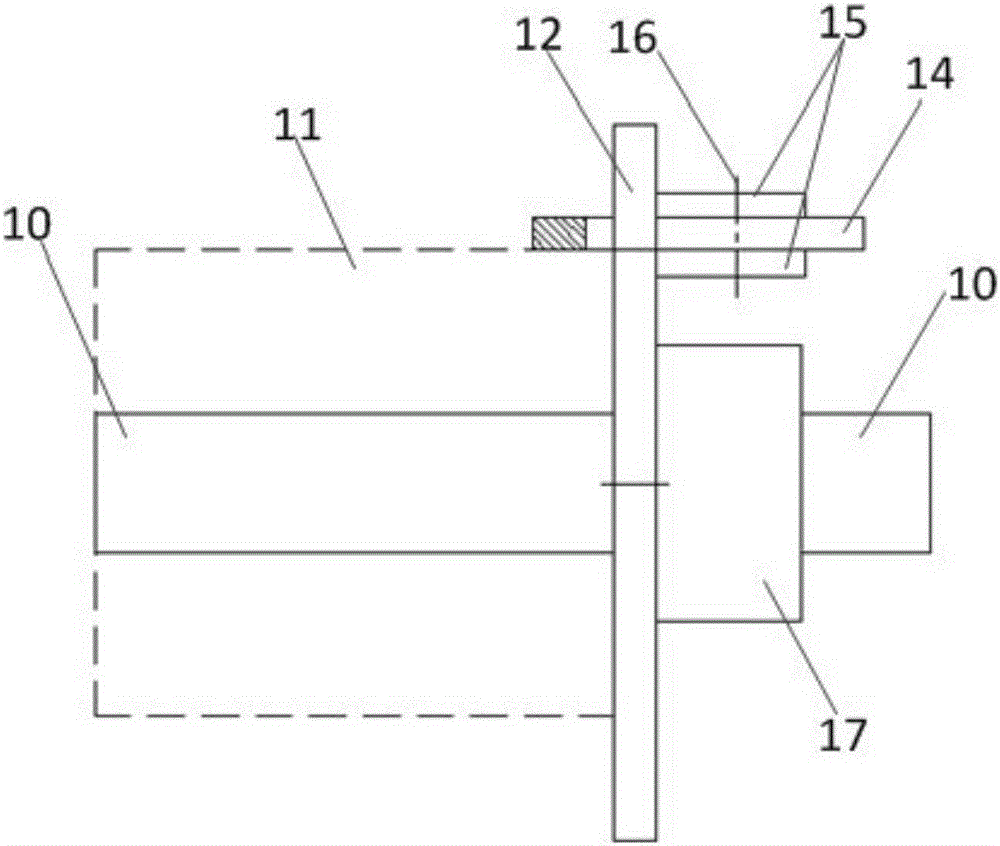

The invention discloses a low-voltage coil winding tool for a transformer. The low-voltage coil winding tool for the transformer comprises a low-voltage winding mold arranged on the shaft of a winding machine in a sleeving manner, a positioning plate having an inverse-L-shaped longitudinal section, and a clamping piece, wherein a baffle is arranged at one end of the low-voltage winding mold; a through hole is formed in the center of the baffle; the baffle is arranged on the shaft of the winding machine by the through hole; a baffle gap from which the head of a low-voltage coil can be led out is formed in the edge of the baffle; the positioning plate is arranged at the outer side of the baffle; a strip-shaped hole is formed in the middle of the vertical end of the positioning plate; the positioning plate is arranged on the shaft of the winding machine in a penetrating manner by the strip-shaped hole; the positioning plate can move upwards relative to the shaft of the winding machine by the strip-shaped hole, so that the horizontal end of the positioning plate can be lifted up relative to the baffle gap; the positioning plate and the baffle are connected in a dismountable manner; the clamping piece is used for clamping the positioning plate and the low-voltage coil when the horizontal end of the positioning plate is supported on the head of the low-voltage coil. The low-voltage coil winding tool has the universality and can be suitable for winding of low-voltage coils of transformers with different capacities.

Owner:重庆吉能变压器有限公司

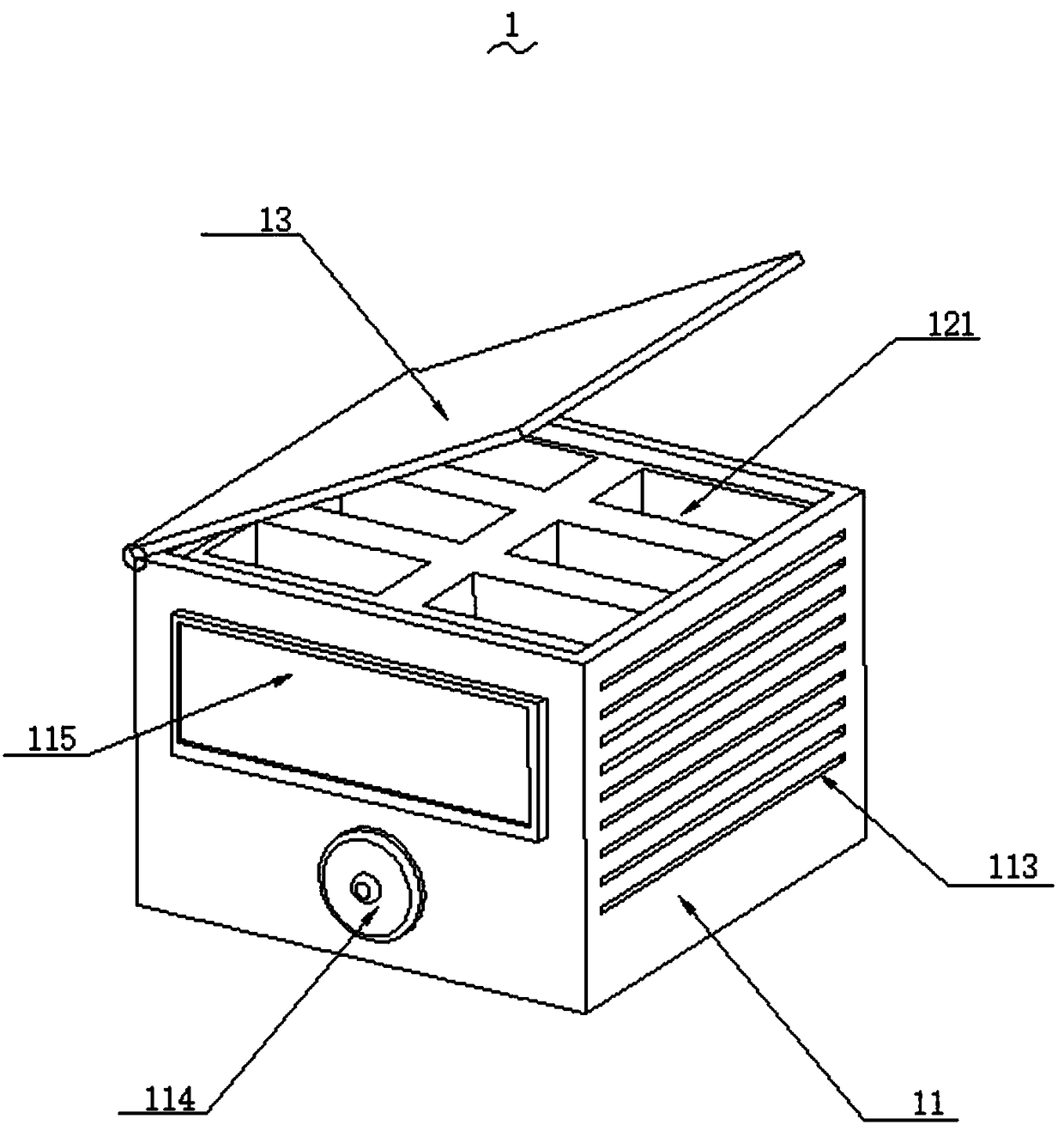

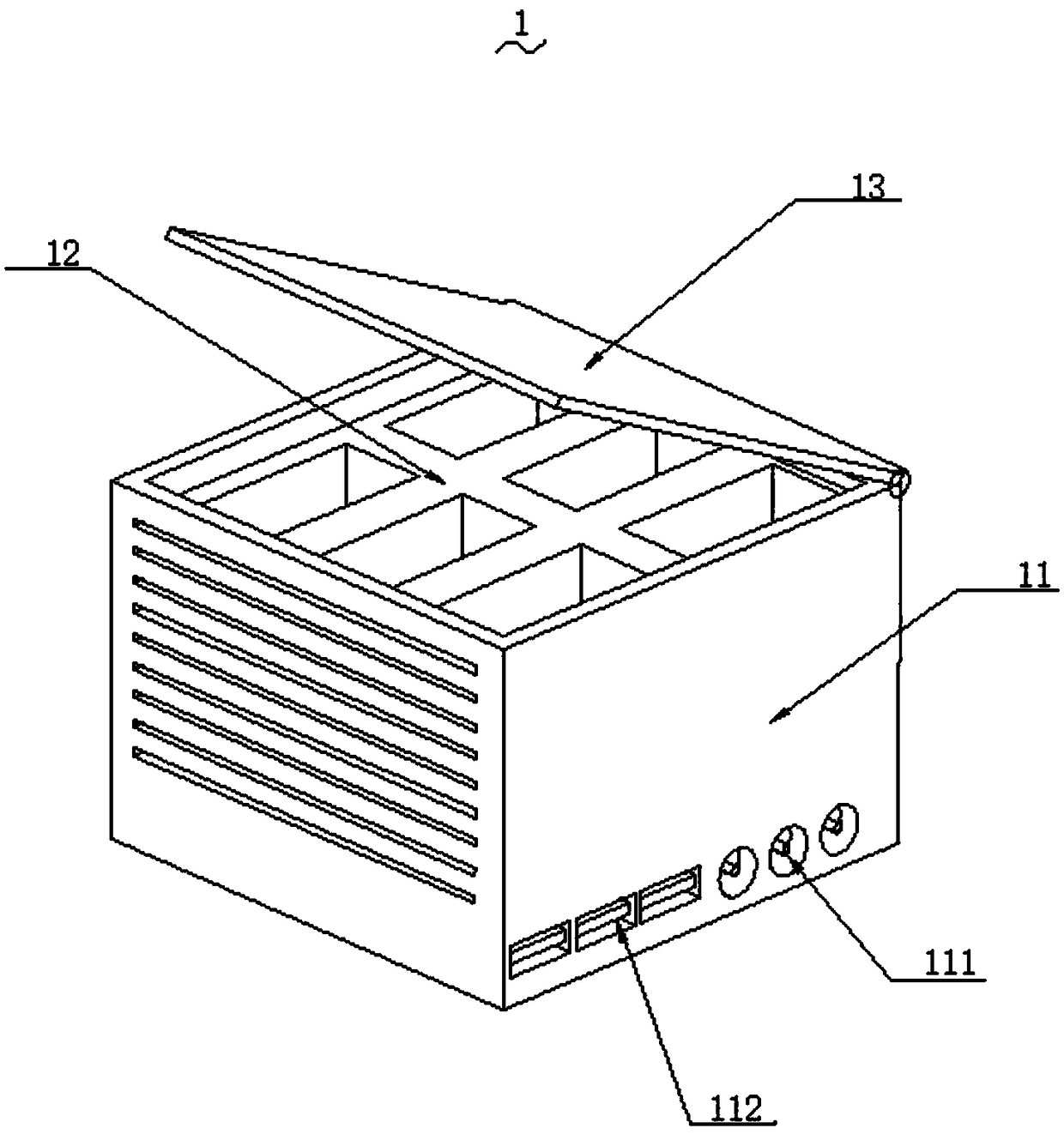

Multifunctional intelligent lithium battery charger

InactiveCN108879861AFast chargingEasy to fixBatteries circuit arrangementsElectric powerFast chargingEngineering

The invention provides a multifunctional intelligent lithium battery charger. The multifunctional intelligent lithium battery charger comprises a box body, a power source arranged in the box body, a controller, a data storage, a wireless communication transmission unit, a lithium battery charging groove assembly, a radiator, an alarm, a temperature sensor and a lithium battery charging circuit control unit, wherein the wireless communication transmission unit is used for being in communication connection with the external mobile terminal; the lithium battery charging groove assembly is used for uniformly placing the lithium batteries to be charged; the radiator is used for carrying out real-time heat dissipation treatment on the equipment; the alarm is used for carrying out alarm processing under an emergency condition; the temperature sensor is used for sensing the internal temperature of the equipment in real time; and a touch display screen used for displaying the charging state information and a control knob are arranged on the front surface of the box body. In the actual use process, the lithium battery can be rapidly charged through the device, the fixing effect of the lithium battery is outstanding, a deviation phenomenon cannot occur, and the reliability is high.

Owner:刘肖俊

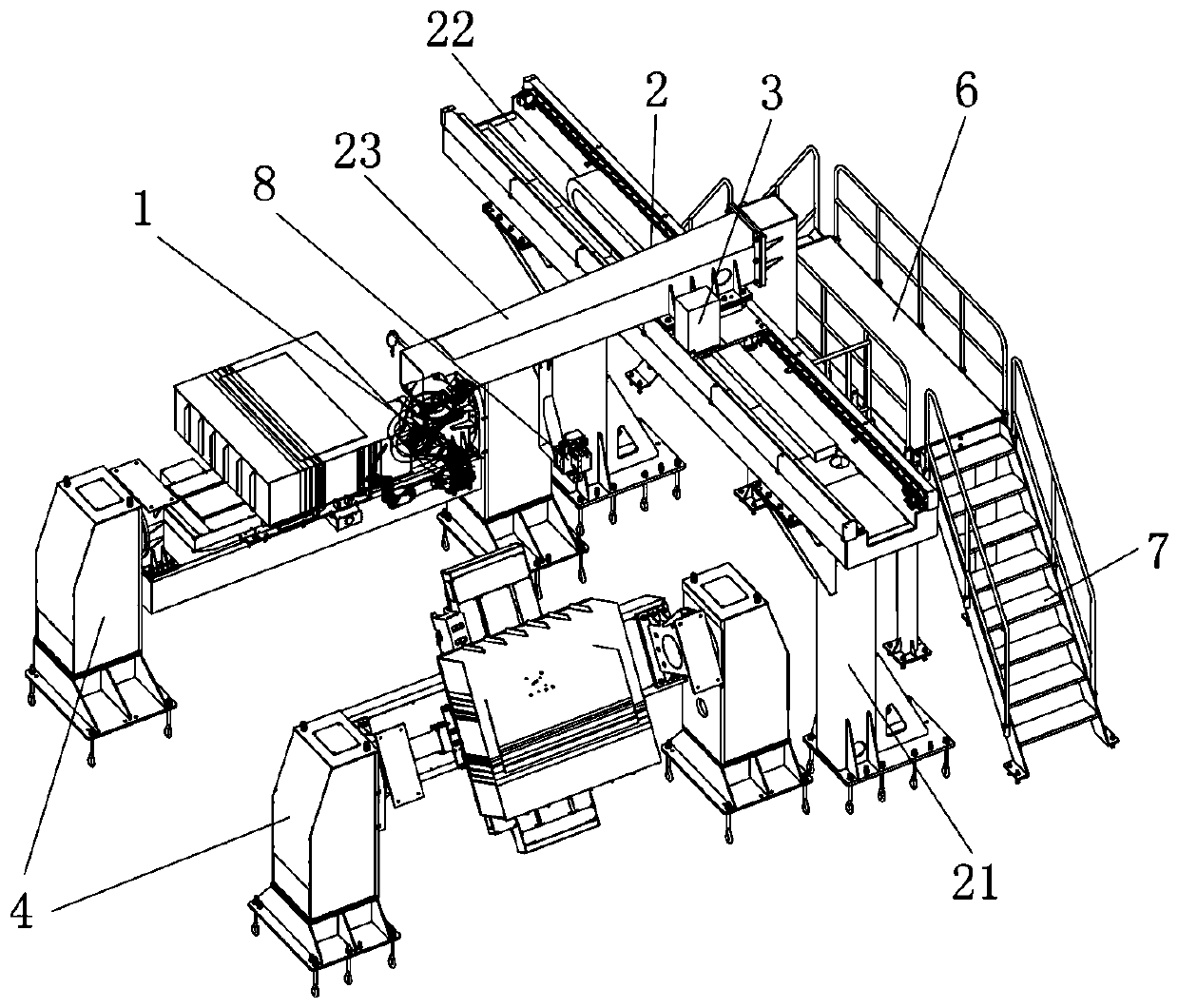

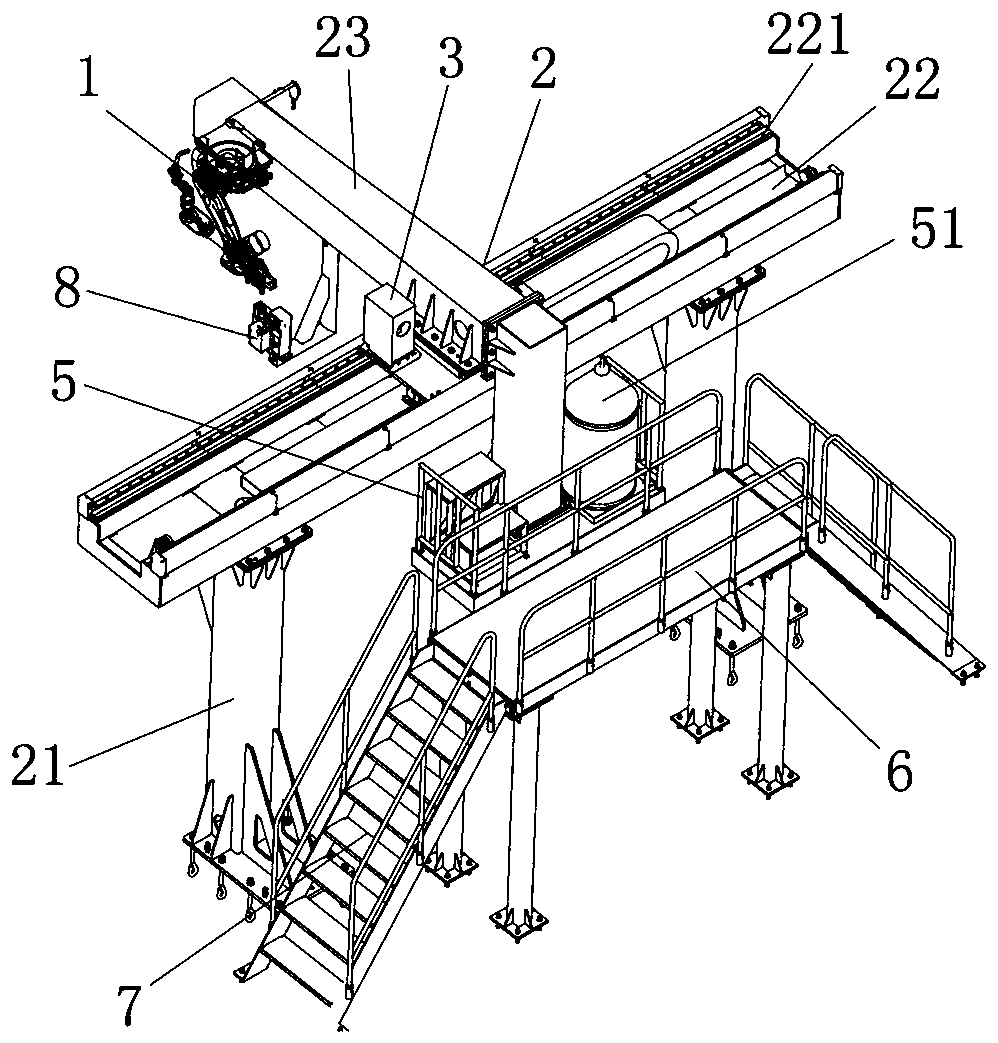

Double-workstation welding device for box parts automatic welding flow production line

InactiveCN107755940AIncrease profitImprove work productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a double-workstation welding device for a box parts automatic welding flow production line. The double-workstation welding device comprises a welding robot for welding a workpiece and a traveling mechanism enabling the welding robot to reciprocatingly travel between two workstations, the traveling mechanism comprises a portal frame, a traveling rail and a longitudinal beamfor realizing traveling of the welding robot along the traveling rail, the traveling rail is arranged on a top crossbeam of the portal frame, and one end of the longitudinal beam is fixedly connectedwith the welding robot while the other end of the same is arranged on the traveling rail and can travel and move along the same. The double-workstation welding device does not need to stop and wait, so that working efficiency of equipment can be improved substantially, investment of the equipment is reduced, and utilization rate of the equipment is increased.

Owner:ZHUZHOU TIANYI AUTOWELDING SYST CO LTD

Punching device

InactiveCN107627393AThere will be no deviationConvenient punching operationMetal working apparatusPunchingPulp and paper industry

The invention discloses a punching device which comprises an operating platform. A pressing plate is slidably arranged above the operating platform through two supporting plates, cross rods are symmetrically fixed between the upper ends and the lower ends of the two supporting plates, and punching strips are slidably embedded in the inner sides of sliding grooves; and punching needles are fixed tothe bottoms of the punching strips at equal intervals. According to the punching device, firstly, clamping pins are slidably embedded in the two sides of the top of the operating platform, when labelpaper is placed on the operating platform, limiting buckles on the clamping pins can be rotated to fix the label paper, and thus when the label paper is punched, the off-tracking phenomenon can be avoided; and secondly, since the pressing plate is connected with the cross rod between the upper ends of the two supporting plates through springs, when the label paper is punched, the pressing plate can be sprung back to the original position after punching is completed, and the punching is easier and more convenient accordingly.

Owner:TIANJIN GRAND PAPER IND

Three-in-one coating compound machine

InactiveCN108016118ANo creasesThere will be no deviationLaminationLamination apparatusPulp and paper industryRaw material

The invention discloses a three-in-one coating compound machine. The three-in-one coating compound machine comprises an unwinding device, a transition device, a gluing device, a drying oven and a compound winding device, wherein the transition device is equipped with a pressing mechanism, so that raw materials are prevented from folding or deflection in the unwinding process. A gluing mechanism and a scraper mechanism are arranged on the gluing device, so that double-sided quantitative and uniform gluing of the raw materials can be realized, and preparation is provided for a following compoundprocess; the compound winding device is provided with a first auxiliary material unwinding roller, a second auxiliary material unwinding roller and a compound roller mechanism, therefore, a three-in-one material can be prepared from the raw materials through one-time compounding, working efficiency is improved, production cost is reduced, besides, compound effect is good, and product yield is high.

Owner:中山市恒嘉隆机械设备有限公司

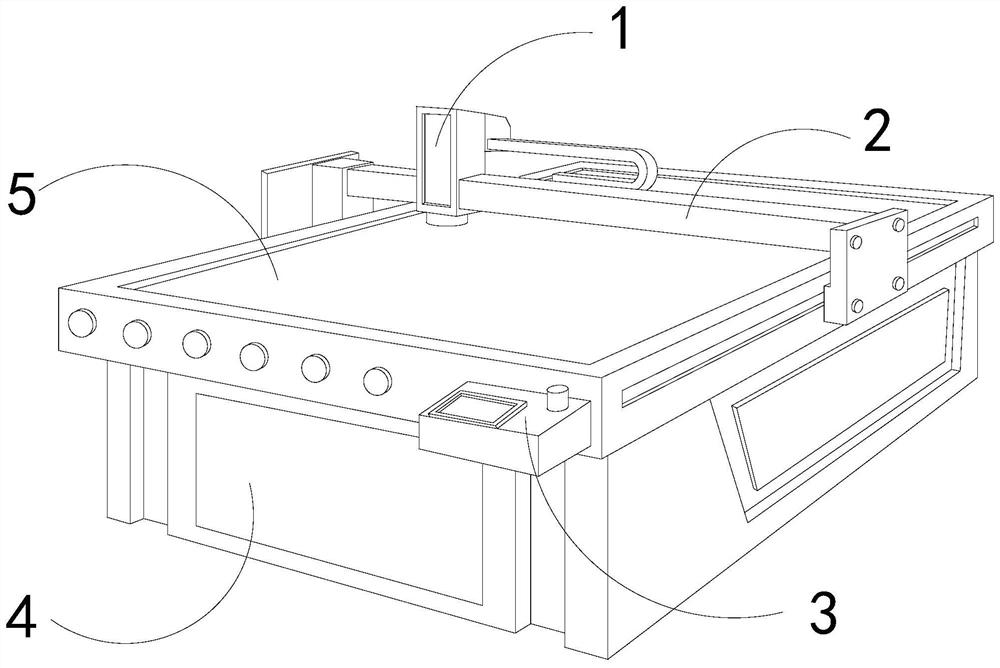

Wood carving device

ActiveCN109649056AEasy to moveEasy to transportOther artistic work equipmentsModel makingMortise and tenonEngineering

The invention discloses a wood carving device. The wood carving device comprises a main support, a main rack and a carving device. The main rack is located above the main support. Side mounting racksare welded to the upper portions of the two sides of the main support. The main rack is of a U-shaped structure. Pin plates are welded to the lower portions of the two vertical ends of the main rack.The main rack is in mortise and tenon connection with the side mounting racks through the pin plates. A mounting groove is formed in the center of the upper surface of the horizontal end of the main rack. A mounting plate is clamped to the mounting groove through alignment clamps. Electric push rods are welded to the mounting plate. The bottoms of the electric push rods penetrate through the mounting plate and the main rack to be provided with a lifting plate in a welded mode. The carving device is fixed below the lifting plate through bolts. The wood carving device is suitable for wood carving. The position of wood is not prone to skewing in the carving process. The wood carving device can be applicable to wood with different widths and is convenient to install, dismantle and move.

Owner:安徽天盛家具有限公司

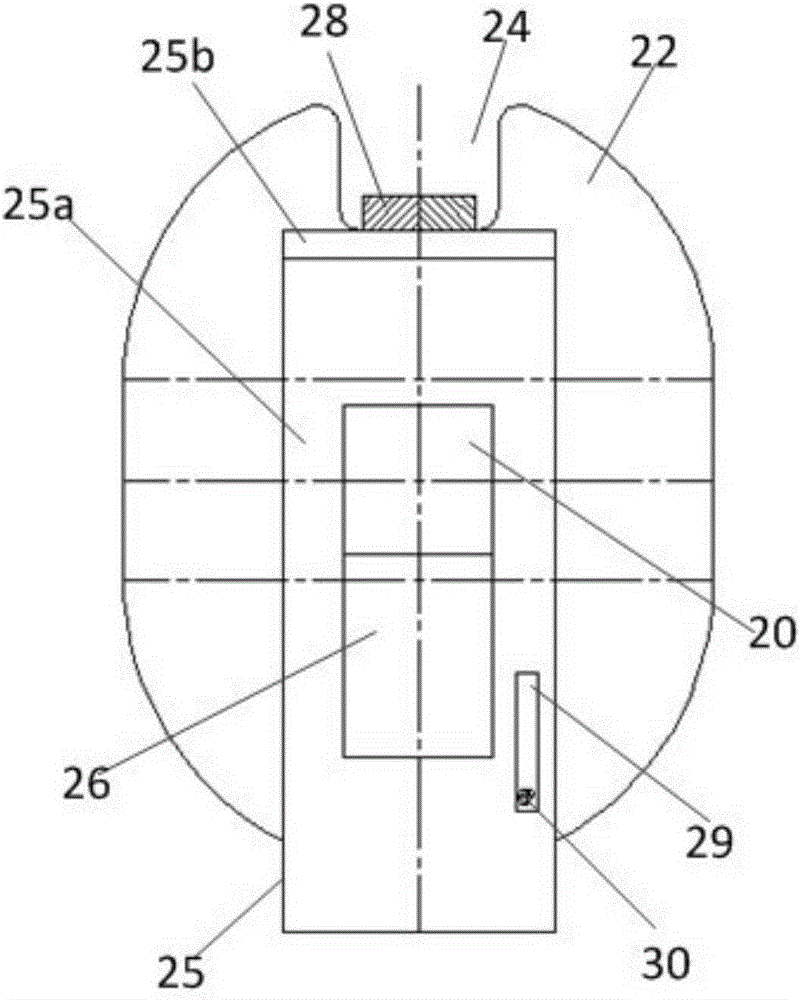

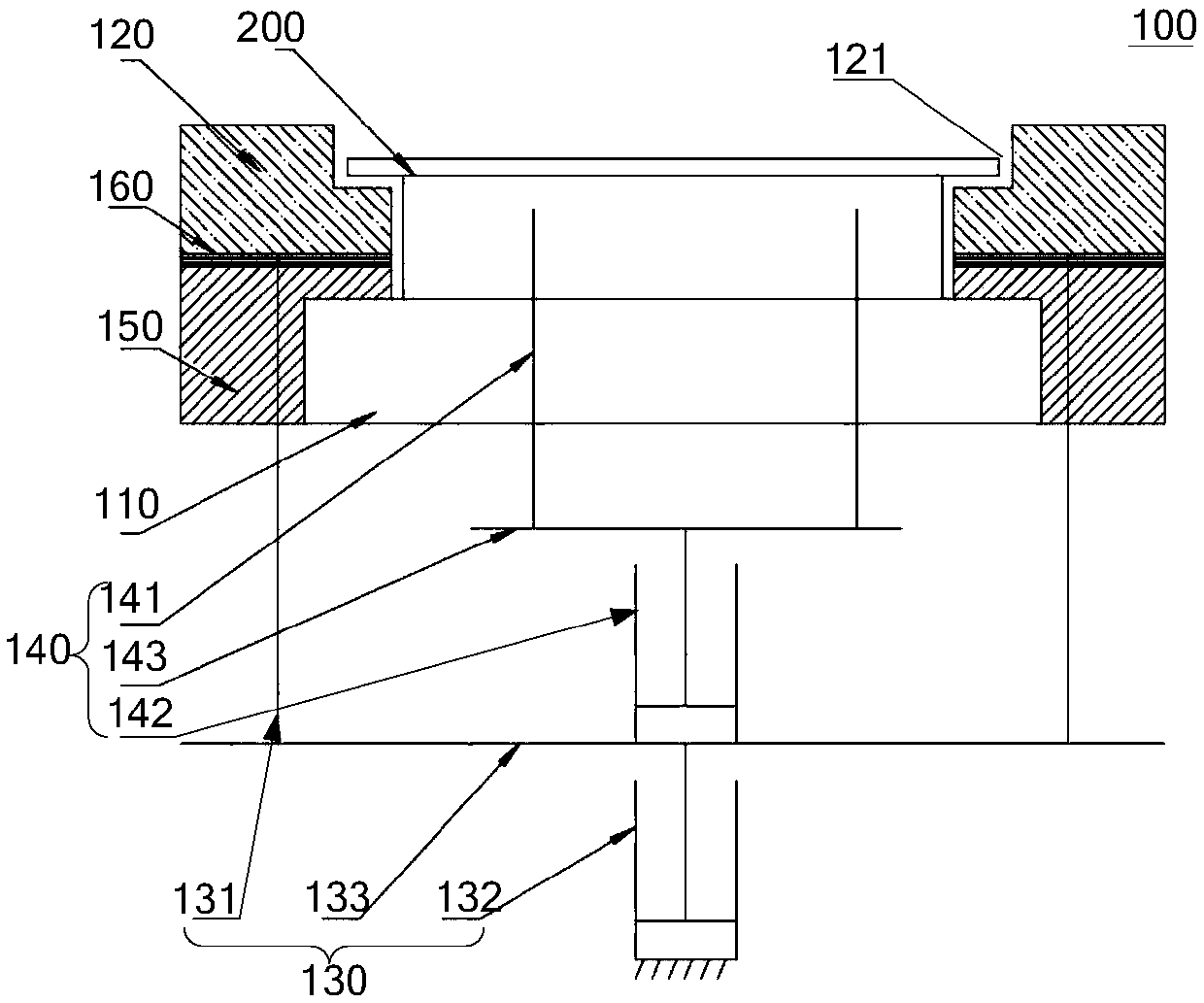

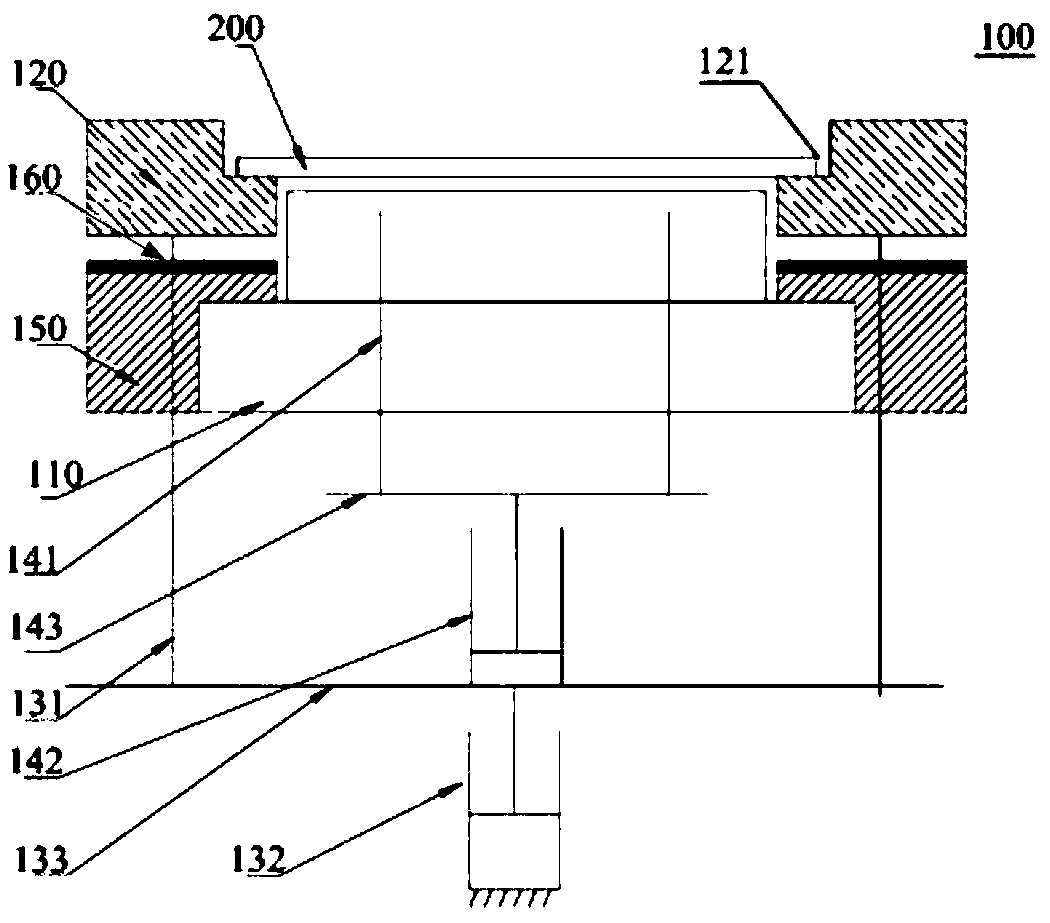

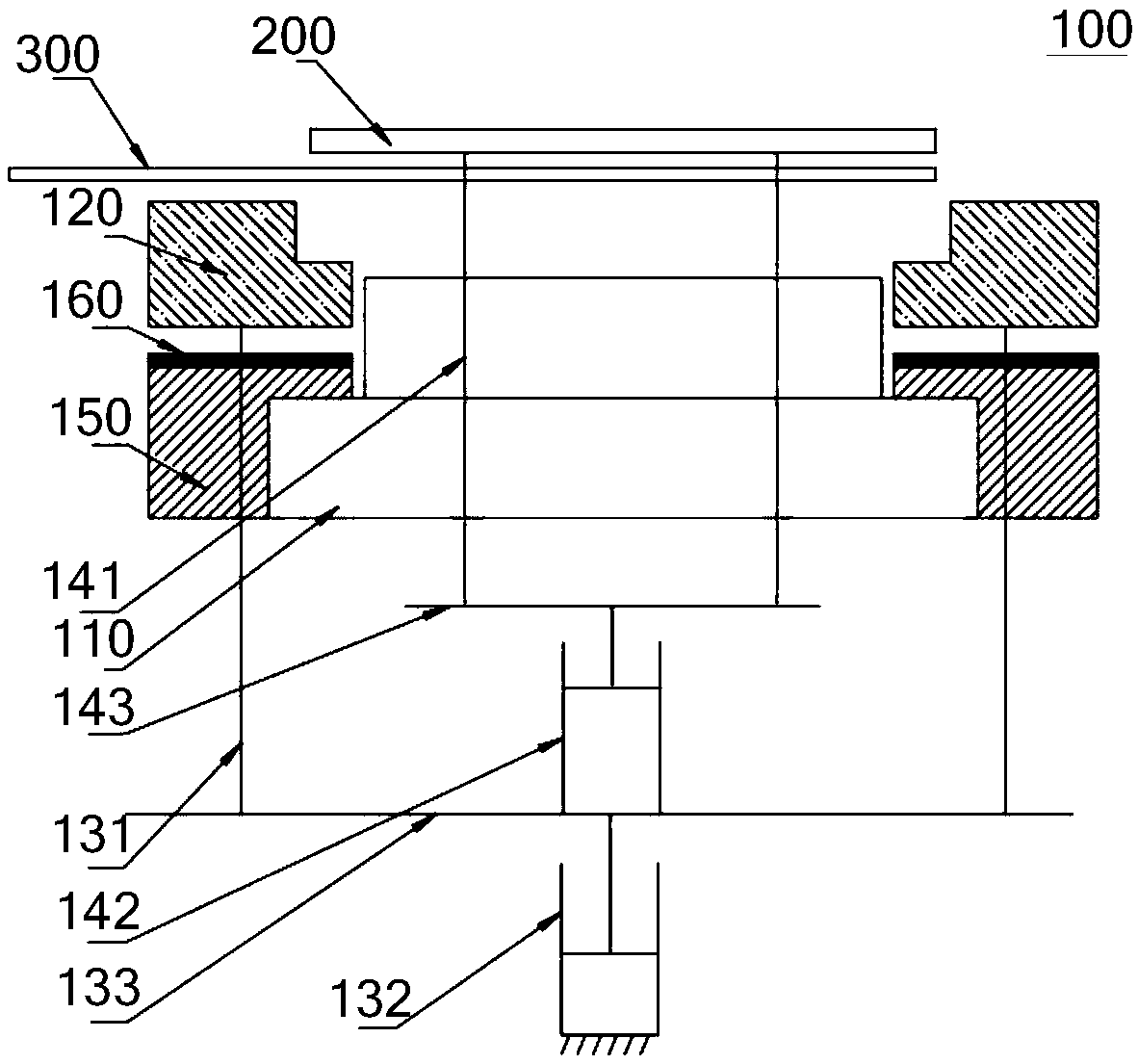

Bearing device, process chamber and semiconductor processing equipment

ActiveCN110797292AAvoid unbalanced forceThere will be no deviationSemiconductor/solid-state device manufacturingMachine partsEngineering

The invention discloses a bearing device, a process chamber and semiconductor processing equipment. The bearing device comprises an electrostatic chuck and a supporting ring arranged around the circumferential side wall of the electrostatic chuck, wherein the electrostatic chuck and the supporting ring jointly bear a to-be-machined part. The bearing device further comprises a first driving assembly and a second driving assembly, wherein the first driving assembly is used for driving the supporting ring to move to a first unloading position so as to separate the to-be-machined part from the electrostatic chuck; and the second driving assembly is used for driving the to-be-machined part to move to a second unloading position so as to separate the to-be-machined part is separated from the supporting ring. When the supporting ring jacks up the to-be-machined part, the supporting ring is in uniform annular surface contact with the to-be-machined part, the phenomenon that the to-be-machinedpart is uneven in stress due to piece sticking and the like can be avoided. In addition, when the to-be-machined part is jacked up by the second driving assembly, only the weight of the to-be-machinedpart needs to be overcome, and thus the phenomenon that the to-be-machined part deviates is avoided.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

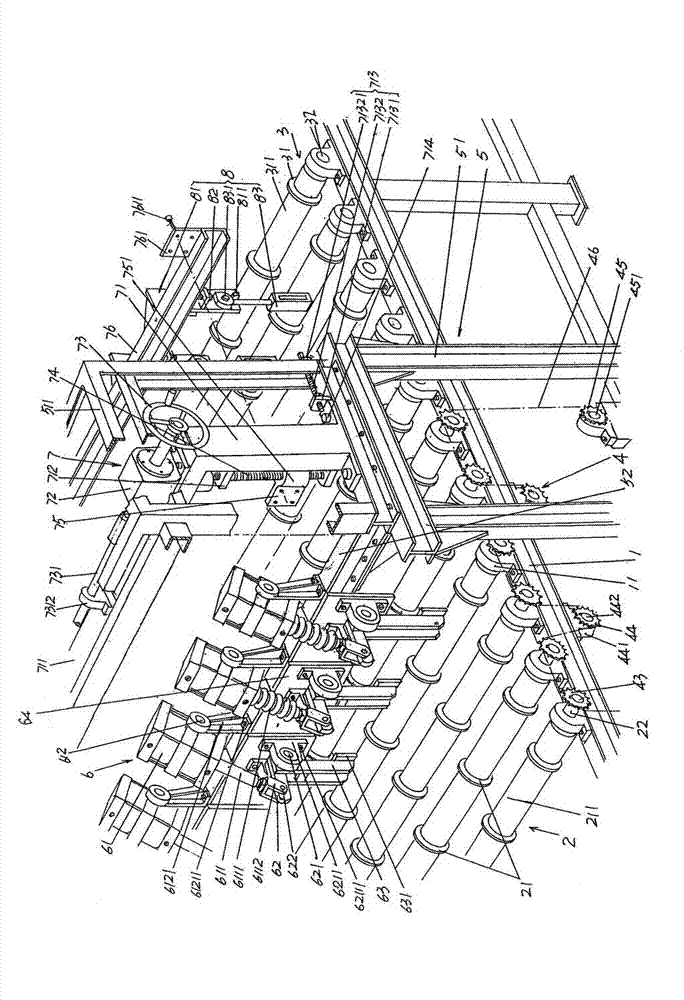

Automatic feeding mechanism for furnace

InactiveCN102767963AGuarantee the quality of heat treatmentAvoid getting togetherCharge manipulationPortal frameSignal acquisition

The invention discloses an automatic feeding mechanism for a furnace and belongs to the field of furnace facilities. The automatic feeding mechanism comprises a feeding roller rack, a feeding roller, a transition roller and a feeding roller driving device and also comprises an overhead frame, a workpiece channel opening / closing device, a workpiece signal acquisition unit adjusting device and a workpiece signal acquisition device, wherein the overhead frame comprises a pair of portal frames and a crossbeam; a workpiece channel opening / closing device is arranged along the length direction of the crossbeam; the workpiece signal acquisition unit adjusting device is fixed on the top of the pair of portal frames; the workpiece signal acquisition device is arranged on the workpiece signal acquisition unit adjusting device; a feeding roller workpiece isolating flange ring is arranged in the length direction of the feeding roller; a transition roller workpiece isolating flange ring is arranged in the length direction of the transition roller; a workpiece signal acquisition device is correspondingly arranged above a workpiece lead-in channel; and the transition roller is in transmission connection with the transition roller driving device. The working efficiency is guaranteed, the quality is ensured, the energy is saved, and the labor intensity is lightened.

Owner:SUZHOU HUIKE EQUIP CO LTD

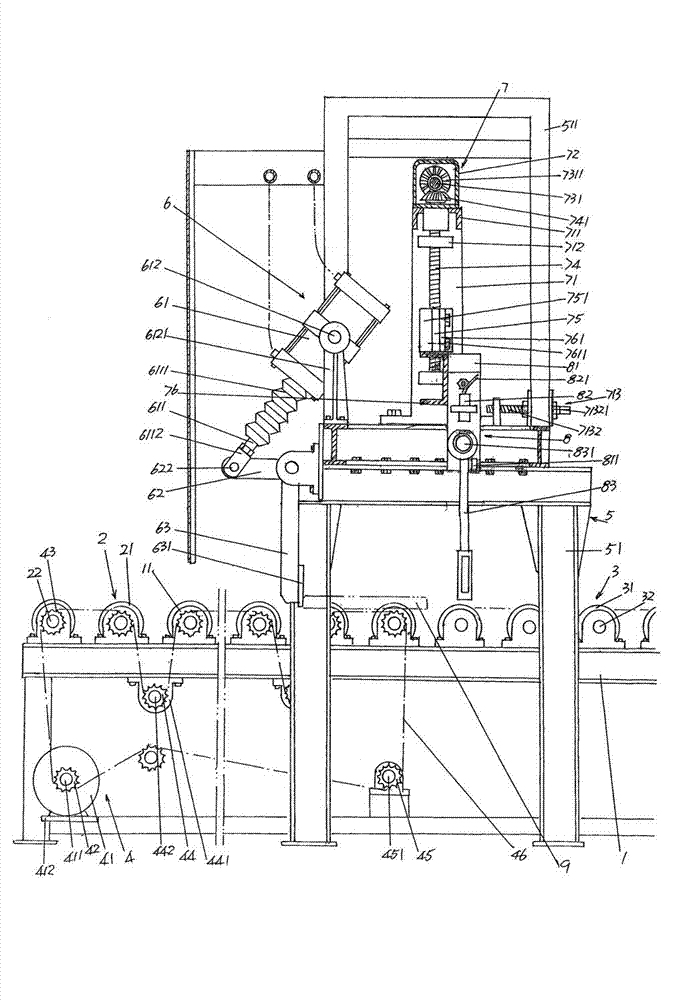

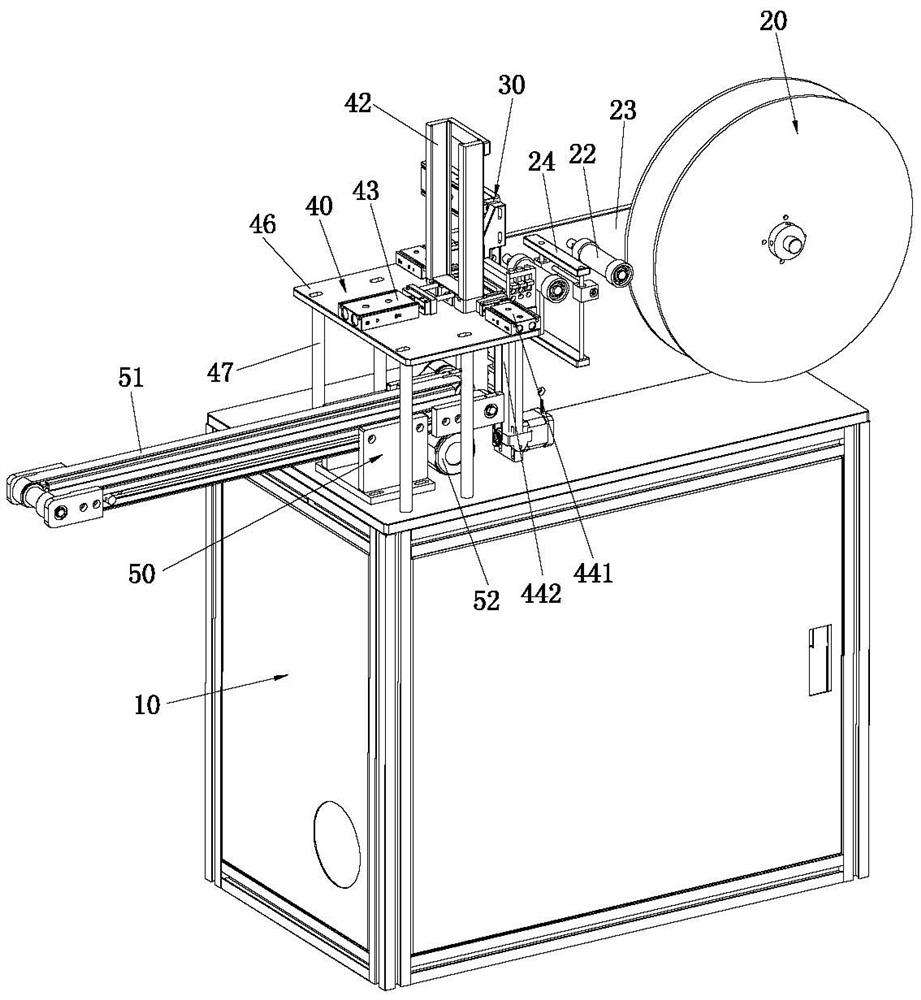

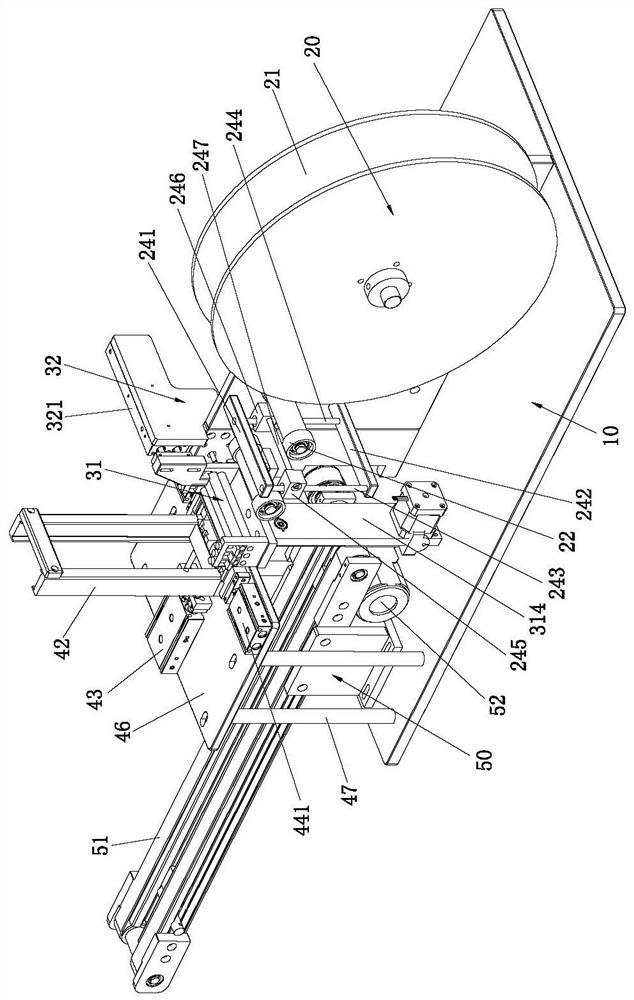

Full-automatic glass packing paper machine and process

PendingCN112758446APrecise positioningCutting stabilityPackagingIndustrial engineeringFully automated

The invention discloses a full-automatic glass packing paper machine and process. The full-automatic glass packing paper machine comprises a paper feeding device, a paper cutting device, a glass packing paper device and a discharging device. The paper cutting device comprises a drawing mechanism used for drawing and conveying paper and a cutting mechanism used for cutting the paper. The cutting mechanism comprises a cutting piece and a cutting driving unit, and the cutting driving unit drives the cutting piece to cut paper. The cutting piece is located above the output end of a driving wheel. The glass packing paper device comprises a stacking area used for stacking glass and paper, a jig used for loading the glass, a pushing mechanism used for pushing the glass out of the jig, a receiving mechanism used for bearing the glass and a stopping mechanism used for limiting and stopping the glass. Therefore, the degree of automation is improved, the production efficiency is improved, stable positioning of the glass is achieved, it is guaranteed that packing paper is fully covered, and the phenomenon that the packing paper cannot be completed due to glass overlapping is avoided.

Owner:东莞市创力自动化科技有限公司

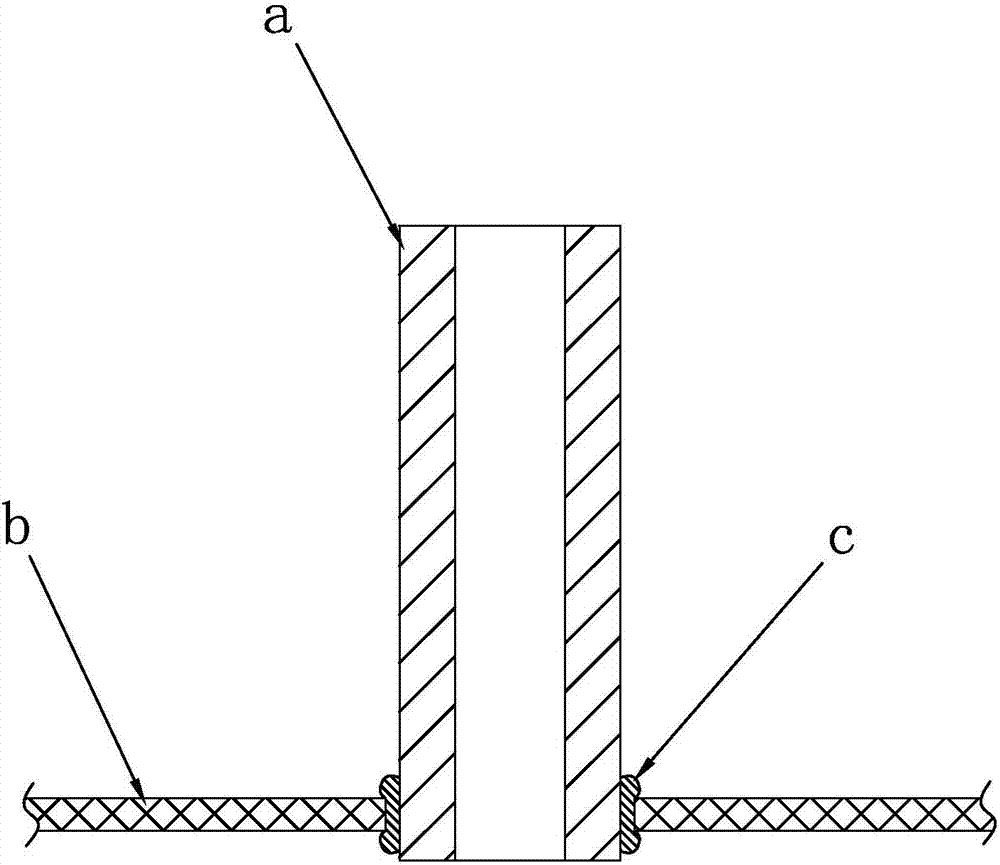

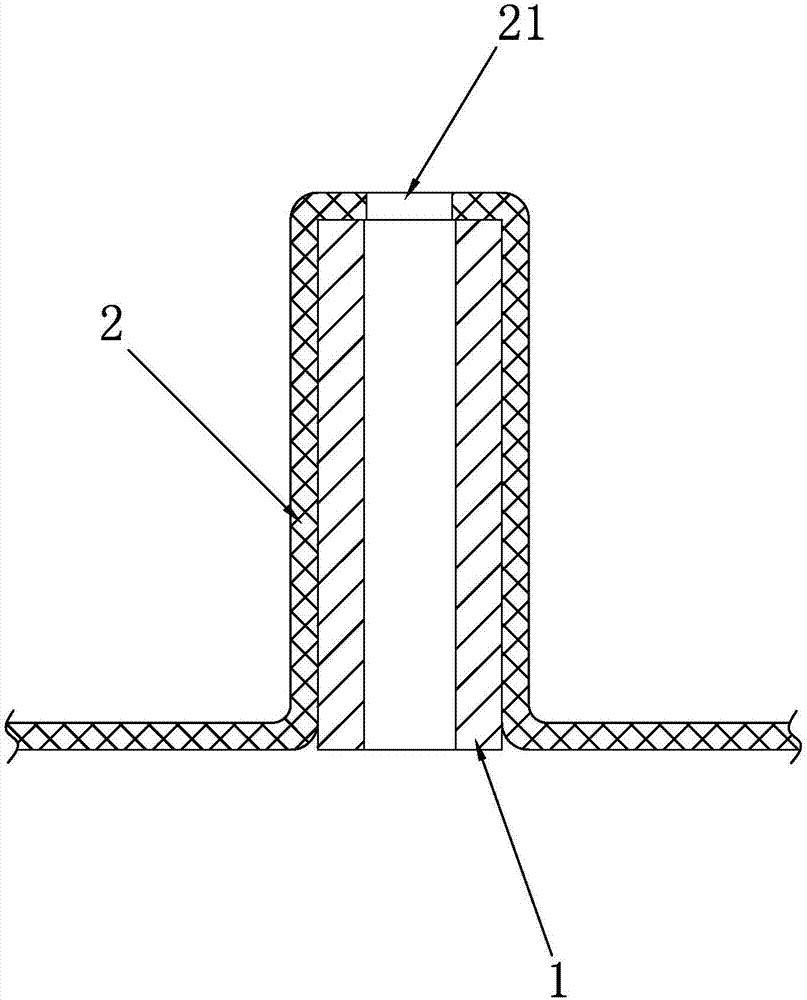

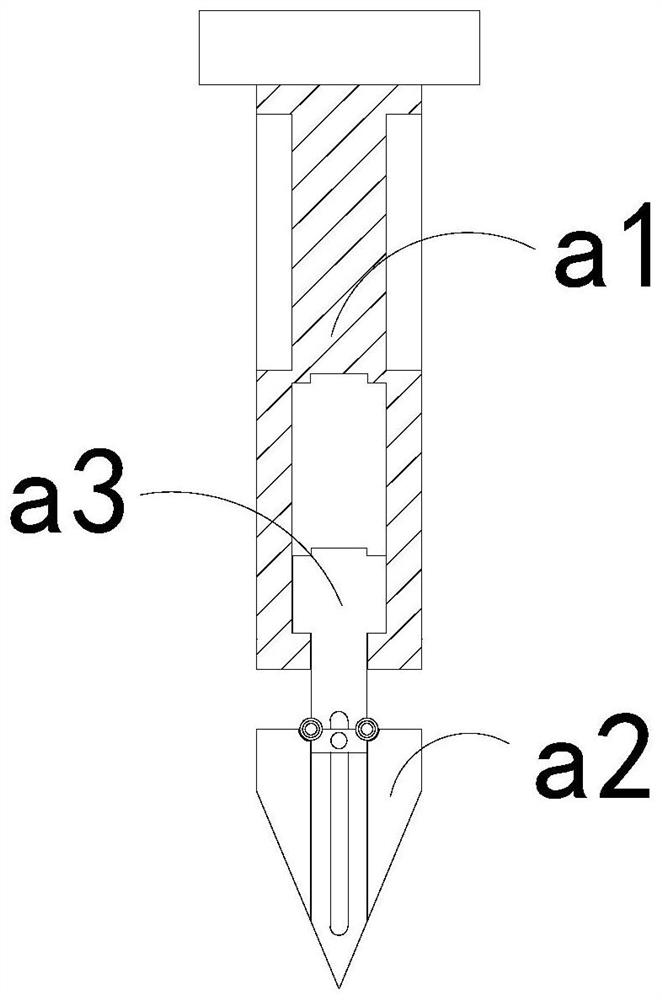

Dental implanting guide plate and preparation method thereof

The invention discloses a dental implanting guide plate and a preparation method thereof. The dental implanting guide plate comprises a main body and a guiding pipe, wherein the main body is formed by pressing a guiding plate plastic sheet, and comprises a positioning area which is cylindrical in shape, and both the outer circumferential surface and the upper end face of the guiding pipe are tightly fit with the inner wall of the positioning area. No adhesive exists between the positioning area and the guiding pipe. The preparation method of the dental implanting guide plate provided by the invention, being different from a traditional preparation method which stamps firstly and then drills, comprises the steps of firstly drilling and then stamping, so that the guiding pipe is tightly wrapped by the guiding plate plastic sheet without additionally using resin material for adhering; furthermore, a positioning rod is directly inserted into a prepared hole of a physical model, and the guiding pipe is fit with the positioning rod, so that the guiding pipe of the molded guiding plate is prevented from shifting.

Owner:FOSHAN UNIVERSITY

Glue spray device for making cartoon shoes

InactiveCN108030197AApply glue evenlyConvenient glue spraying operationShoe gluingEngineeringCoating

The invention discloses a glue spray device for making cartoon shoes. The glue spray device comprises a working frame, a first electric telescopic rod is arranged at the bottom end of a top plate, a positioning rod is arranged at the bottom end of the first electric telescopic rod, a first bearing is arranged at a joint of the positioning rod and the first electric telescopic rod, a fixed disk isarranged at the bottom end of the positioning rod, a dust removing cover is arranged below the fixed disk and comprises an outer cover body and an inner cover body, a suction fan is positioned at thetop end of the top plate, through holes are uniformly formed in the surface of the inner cover body in a penetrated manner, a second bearing is positioned in an inner cavity of a right shell of a mounting box, a second rotating motor is arranged in an inner cavity of the mounting box, and a rotating hairbrush is connected at the bottom end of the second rotating motor. The glue spray device for making the cartoon shoes has the advantages that glue coating operation in a plurality of directions is facilitated, so that glue is more uniformly sprayed, the shoes are cleaned in a plurality of directions before the glue is sprayed, tackiness in glue coating is improved, the shoes are not easily subjected to glue failure and the like.

Owner:温州市王方鞋业有限公司

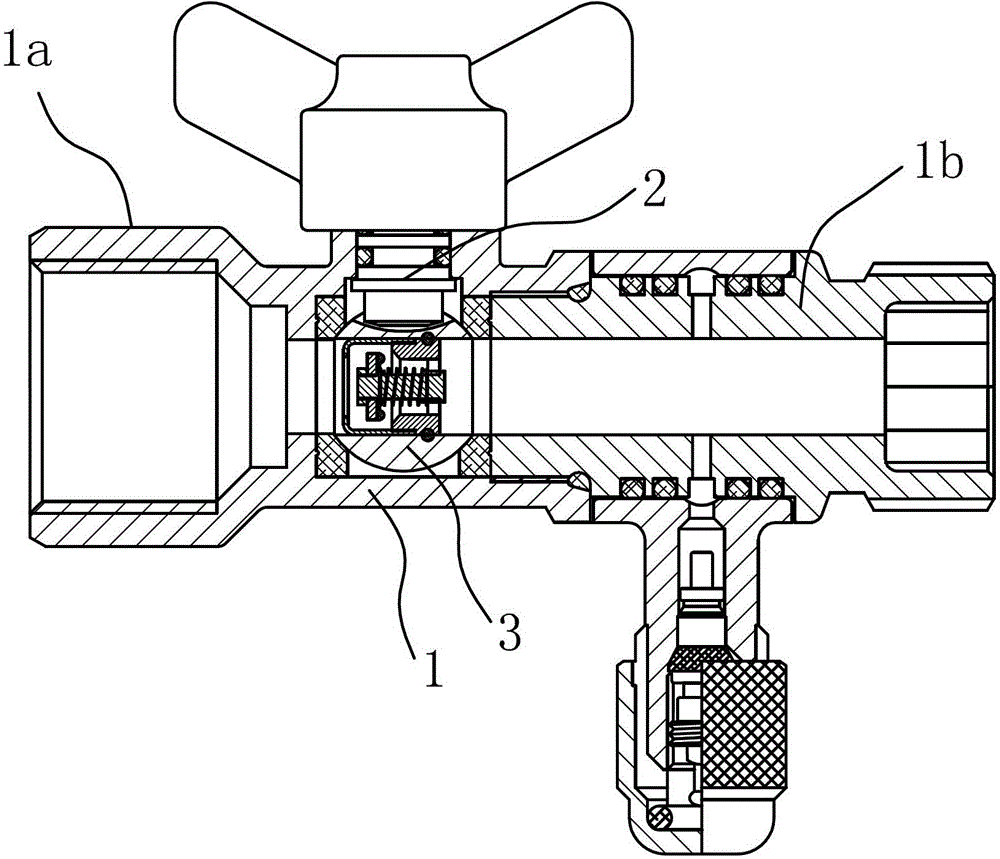

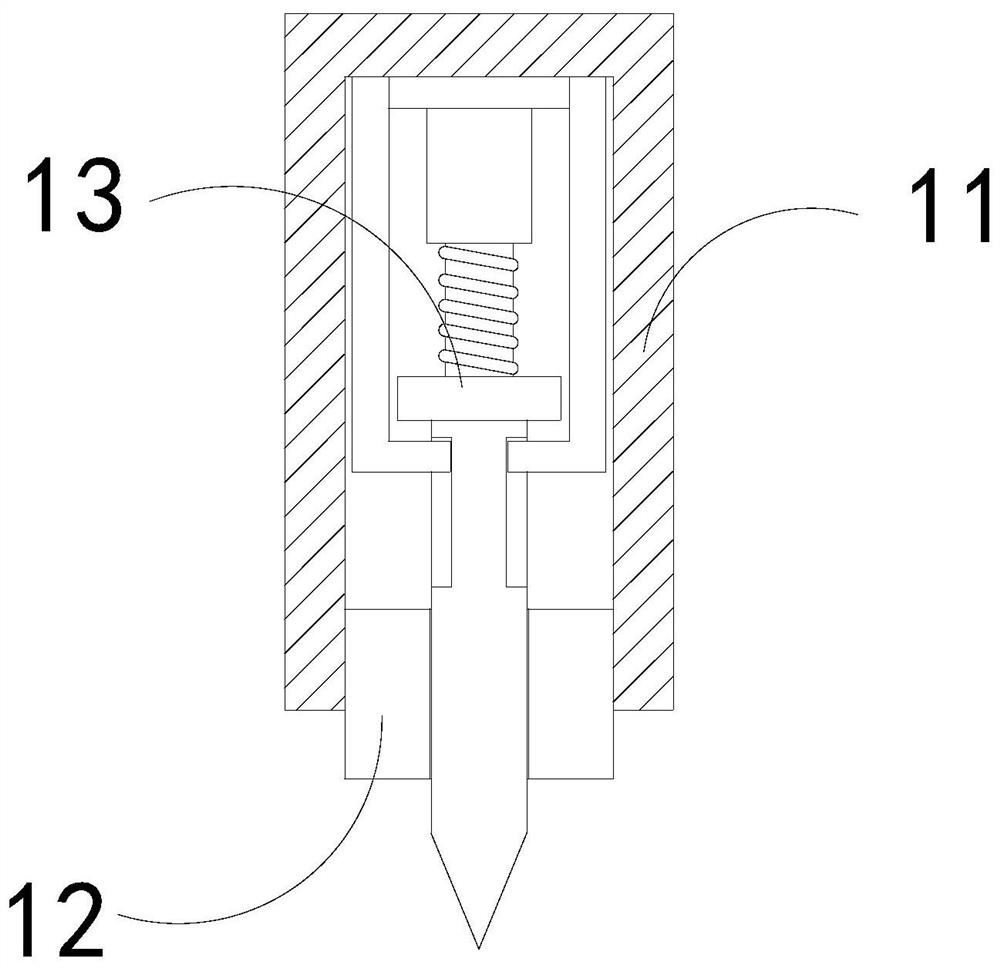

Protection device of fuel gas valve

ActiveCN103322257BPlay a protective effectSave time at workEqualizing valvesSafety valvesMechanical engineeringFuel gas

Owner:玉环燃具实业有限公司

Angle cutting machine

The invention discloses an angle cutting machine. The angle cutting machine comprises a rack, a cutter and a workbench. The two sides of the rack are fixedly connected with an inclined left supporting column and an inclined right supporting column respectively. The front face of the left supporting column and the front face of the right supporting column are fixedly connected with a left guide column and a right guide column respectively. The two sides of the back face of the cutter are fixedly connected with a left guide sleeve and a right guide sleeve respectively. The left guide sleeve and the right guide sleeve are correspondingly arranged on the left guide column and the right guide column in a sleeving manner respectively. A rotating wheel is rotationally arranged on one side of the rack. A connection rod is rotationally connected between the eccentric position of the rotating wheel and the front face of the cutter. A push plate is arranged on the workbench. A left connection rod and a right connection rod are fixedly connected to the two sides of the push plate respectively. A threaded sleeve is fixedly connected between the front end of the left connection rod and the front end of the right connection rod. A lead screw is rotationally arranged on the lower side of the rack. The lead screw is sleeved with the threaded sleeve through a thread in a matched manner. The angle cutting machine is reasonable in structure, small in slicing resistance and high in working efficiency, the spliced cake face is good, and the surface is smooth, so that the appearance and quality of products are improved, and the cake deviation phenomenon can be avoided in the slicing process.

Owner:TONGLING SONGMA FOOD PACKAGE MACHINERY MFG

Cutting equipment for rubber processing

InactiveCN112092066AThere will be no deviationIncrease frictionMetal working apparatusStructural engineeringRubber sheet

The invention discloses cutting equipment for rubber processing. The cutting equipment structurally comprises a cutting mechanism, a driving frame, a control table, a base and an operation table, wherein the driving frame is arranged at the upper end of the operation table, the control table is fixedly embedded in the front end of the operation table, the base and the operation table are of an integrated structure, and the cutting mechanism is movably clamped with the driving frame. Continuous reverse thrust is generated on a fixed framework through a rubber sheet, an outer swing plate can beunfolded outwards along a middle fixing block, so that a friction increasing surface can downwards extrude the rubber sheet, then the friction force between the rubber sheet and the friction increasing surface can be enhanced through the friction increasing surface, and deviation of the rubber sheet can be avoided when the rubber sheet is cut off; an outer unfolding plate can swing outwards alonga bearing plate to be unfolded through reverse pulling generated by the section of the rubber sheet on the outer unfolding plate, so that the outer unfolding plate can upwards push out a reset sheet;and the grabbing force on the section of the rubber sheet can be enhanced through a grabbing force groove in the outer unfolding plate, so that the fixed framework can be more easily pushed out of therubber sheet.

Owner:徐松

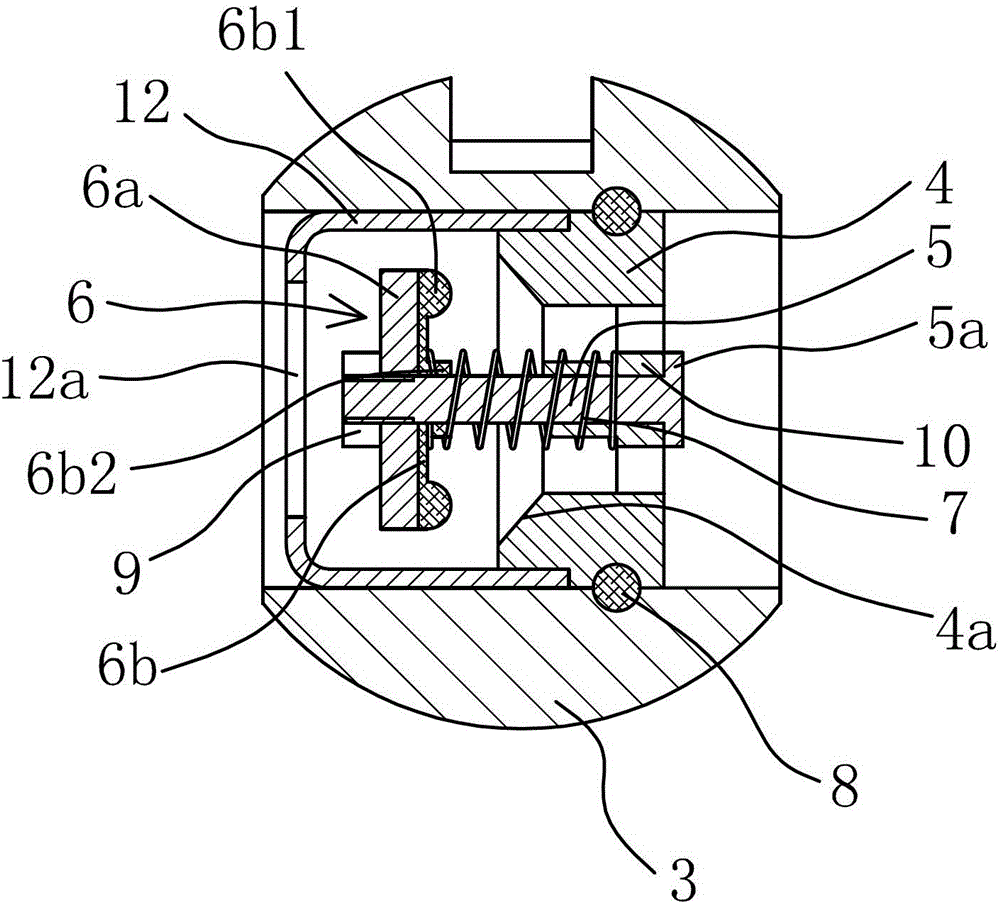

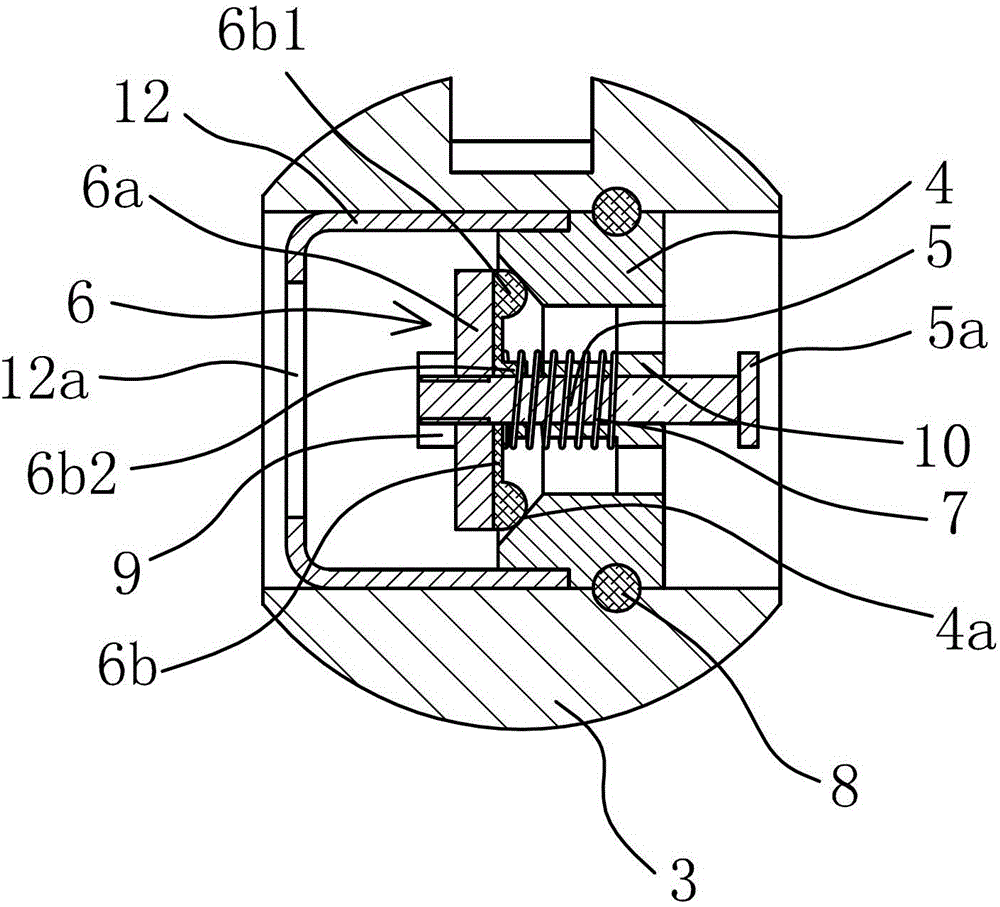

Polishing machine and main shaft takeup thereof

InactiveCN102335863AAchieve replacementPhenomena Affecting AccuracyPolishing machinesGrinding machine componentsEngineeringMechanical engineering

The invention provides a polishing machine and a main shaft takeup thereof. The main shaft takeup comprises a fixing part and a movable part, wherein the fixing part is fixedly arranged out of a main shaft of the polishing machine; the movable part is movably arranged relatively to the fixing part; the movable part comprises a contact part and a terminal; the contact part can be moved to the first position or the second position relatively to the fixing part; on the first position, the terminal of the movable part extends into the groove of the main shaft to clamp the main shaft; and on the second position, a preset distance is left between the terminal of the movable part and the main shaft to loosen the main shaft. In the main shaft takeup, the movable part has two different positions relatively to the fixing part; on the first position, a polishing wheel can be replaced; and on the second position, the polishing operation can be successfully carried out. Compared with the prior art, the main shaft takeup has the advantages of high working efficiency, stable performance, small influence on main shaft precision and the like.

Owner:SHANGHAI SANY PRECISION MACHINERY

Anti-tilt fruit slicing device

InactiveCN105459175AThere will be no deviationAvoid scratchesMetal working apparatusAgricultural engineering

The invention relates to the field of fruit processing, in particular to an anti-tilt fruit slicing device. The anti-tilt fruit slicing device comprises a shell and a slicing mechanism, wherein the slicing mechanism is mounted on the side wall of the shell, and a feeding opening is formed in the upper end of the shell; a slicing platform is arranged in the shell, and collecting boxes are respectively arranged at the two ends of the slicing platform; a guide plate and a vertical supporting plate are obliquely arranged at the lower end of the feeding opening outwards, and the guide plate and the supporting plate form a discharging channel; the supporting plate is hinged with the shell, and a section of distance exists between the port of the discharging channel and the slicing platform; the slicing mechanism comprises a blade and a push cylinder, and the blade is connected with the push cylinder through a support; sliding grooves are vertically formed in the two side walls of the blade, and limiting blocks are respectively arranged at the two ends of each sliding groove; a push rod is arranged in each sliding groove, a roller is arranged at the lower end of each push rod, and a push plate is arranged between the push rods. The anti-tilt fruit slicing device can automatically slice fruit and is strong in safety.

Owner:CHONGQING DONGYUAN AGRI DEV CO LTD

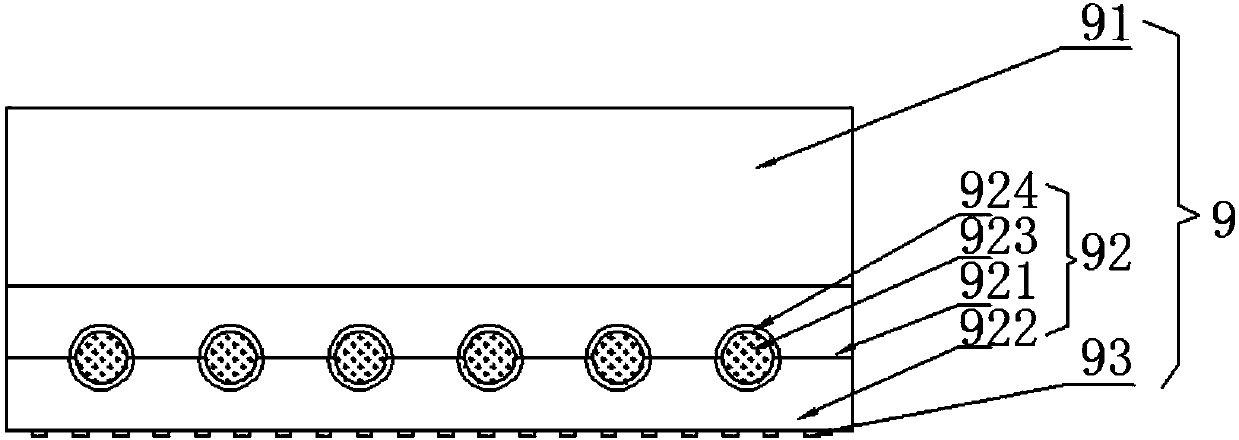

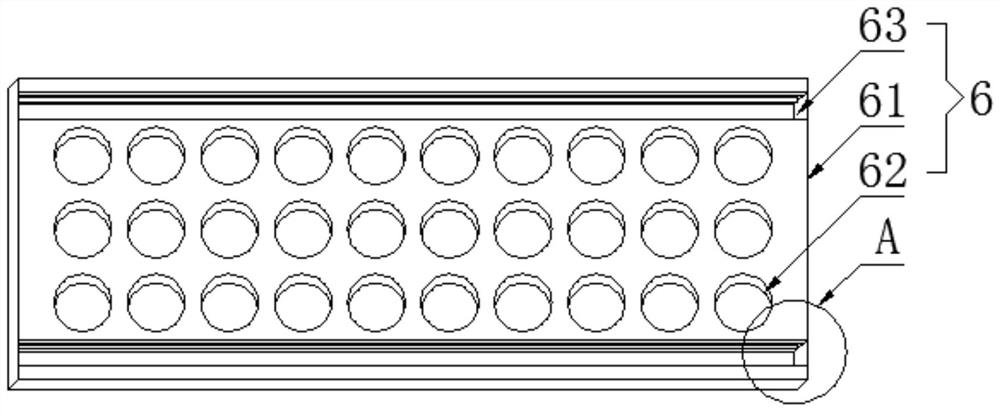

Background lamp for color selector

InactiveCN103672599AImprove color sorting efficiencyExtended service lifeLighting support devicesPoint-like light sourceEngineeringLED lamp

The invention belongs to the field of background lamps or color selectors and particularly relates to a background lamp. The background lamp which does not shake or rotate during operate to cause shadow comprises a background lamp support disposed on a box inside a color selector body. A background lamp body is disposed on the background lamp support. The background lamp body faces a background plate. A lamp holder is disposed on the background lamp support. An LED lamp body is disposed on the lamp holder. A lampshade is disposed outside the LED lamp body. The background lamp has the advantages that the lamp holder of the background lamp is fixed with the background lamp support, the background lamp support does not deviate during operation of the color selector, no shadow areas occur on the background lamp, color selecting efficiency is increased, and the service life of the background lamp is prolonged.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

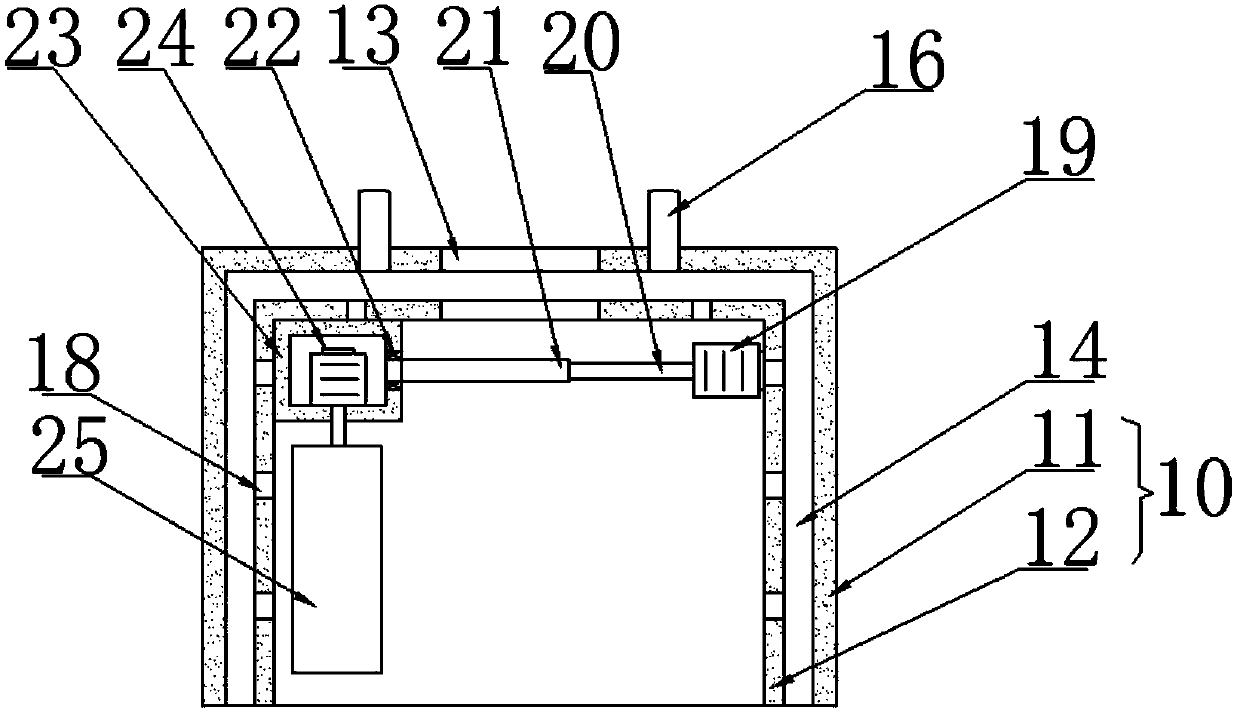

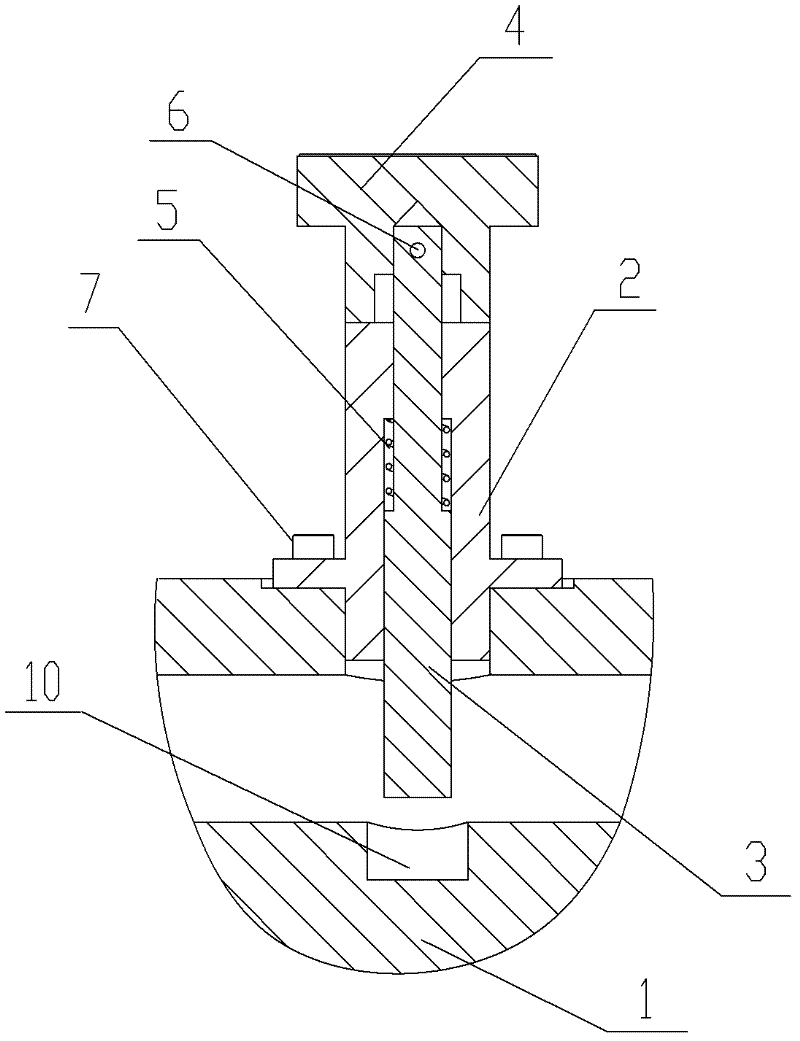

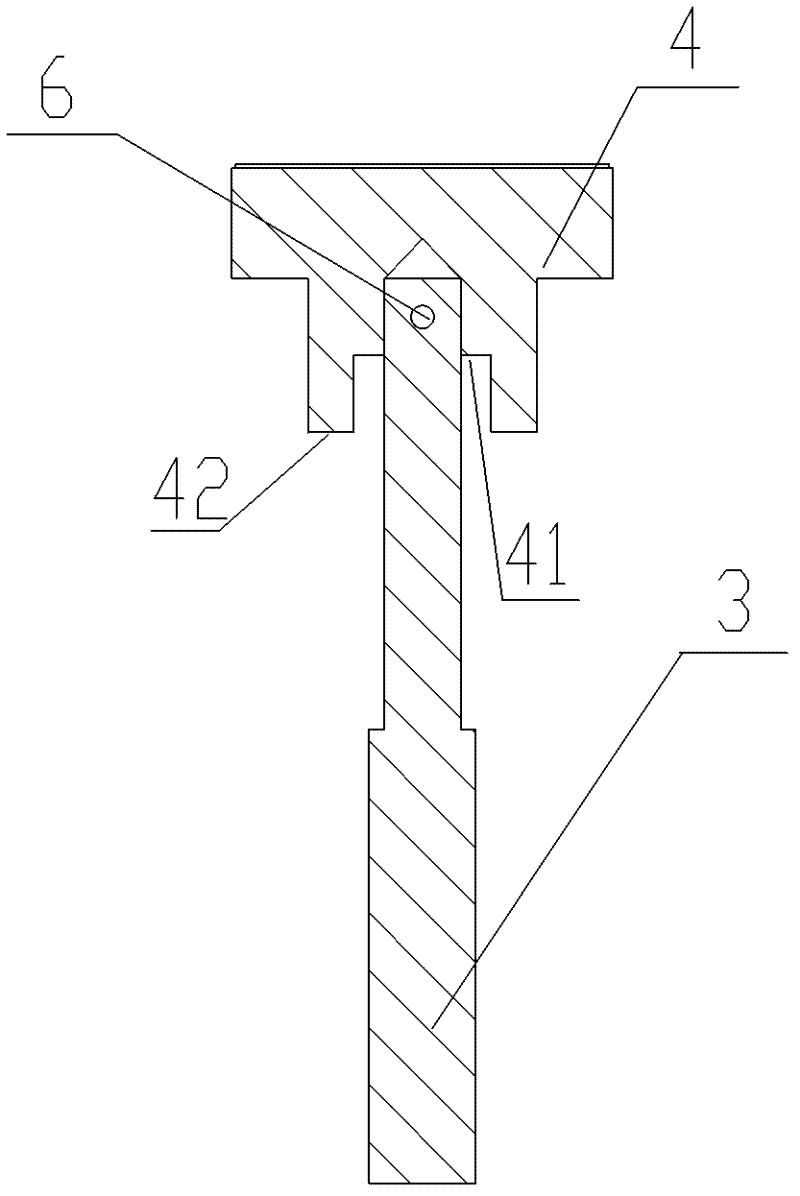

Device special for drying and sterilizing red dates

The invention relates to devices of a microwave drying technology, in particular to a device special for drying and sterilizing red dates. The device special for drying and sterilizing the red dates comprises an electric control device (4) and a support (7). A feeding opening (1) is installed at one end of the device. A first restraining system (2) is connected at one end of the feeding opening. A plurality of microwave effect cavities (5) mutually connected in a seamless mode are fixed on the support to form a microwave effect cavity channel. A dehumidifying system (3) is installed at the upper end of the microwave effect cavity channel. The device special for drying and sterilizing the red dates is characterized in that a microwave generation source is installed below the microwave effect cavity channel; a chain plate transmission device driven by a gear is placed in the microwave effect cavity channel; and a material turning-over and mixing device is placed on the rear section of the microwave effect cavity channel. The device special for drying and sterilizing the red dates has the advantages of being low in energy consumption, short in drying period, environment-friendly and energy-saving, and has sterilizing effect.

Owner:HENAN BODA MICROWAVE EQUIP

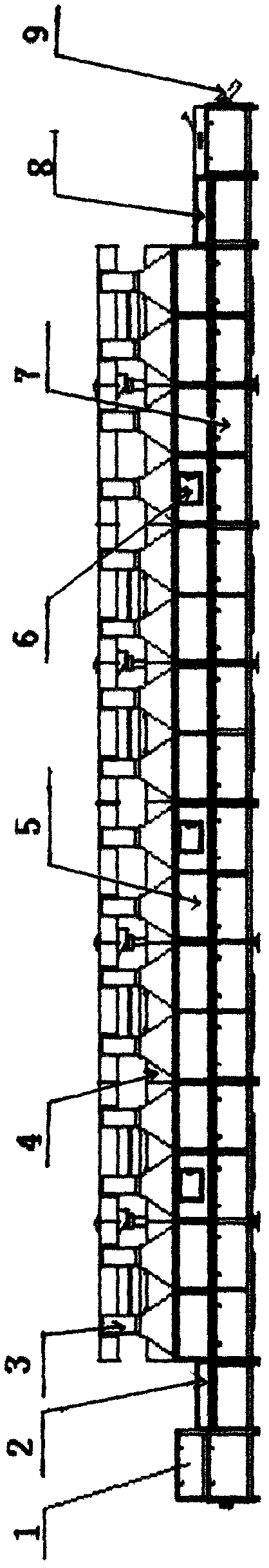

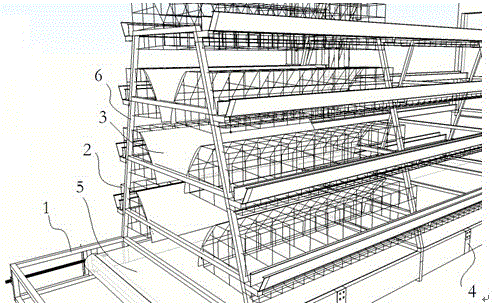

Belt-type centralized manure cleaning system for four-layer ladder-type chicken house

The invention discloses a belt-type centralized manure cleaning system for a four-layer ladder-type chicken house. A chicken house frame is of an isosceles trapezoid structure; four layers of chicken houses are arranged on two waist edges of the trapezoid; a layer of manure cleaning conveyor belt is arranged at the bottom end of the chicken house frame; a manure sliding baffle is arranged on each chicken layer, so that chicken manure on each layer can uniformly fall onto the manure cleaning conveyor belt through the manure sliding baffle. According to the belt-type centralized manure cleaning system for four-layer ladder-type chicken house, the manure cleaning work of the entire chicken house can be completed by using one layer of manure cleaning conveyor belt; the structure is better than that of the existing chicken house; the manure cleaning effect is better than that of the existing chicken house.

Owner:王昌俊

Diner plate inspection equipment

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

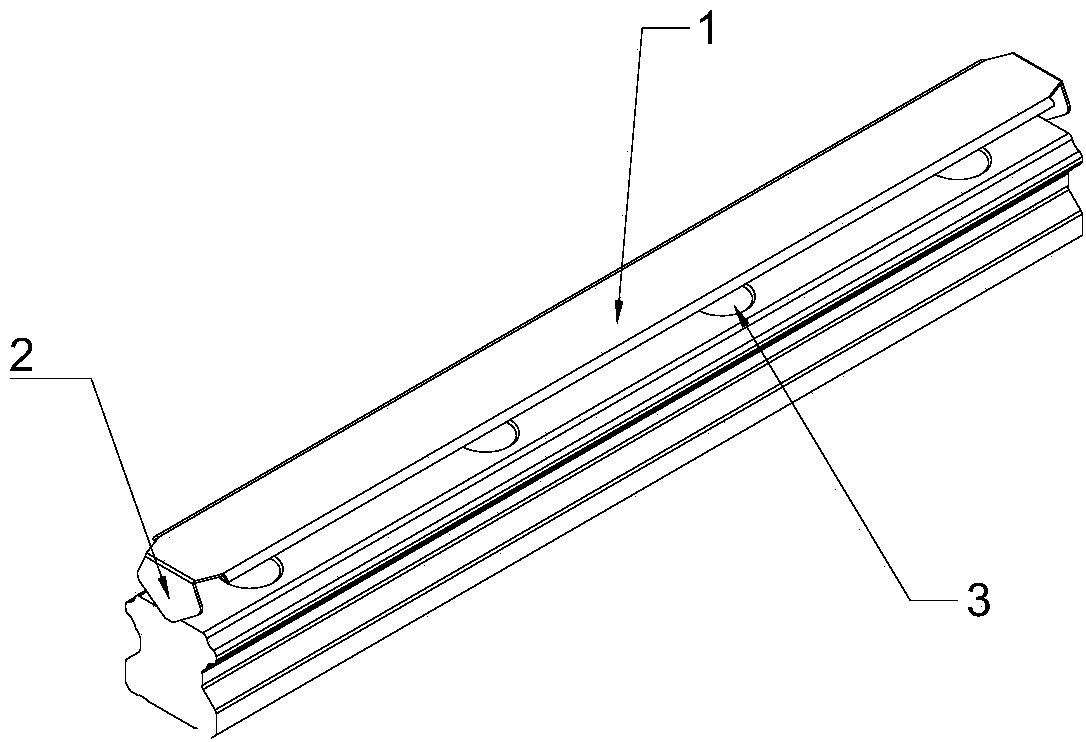

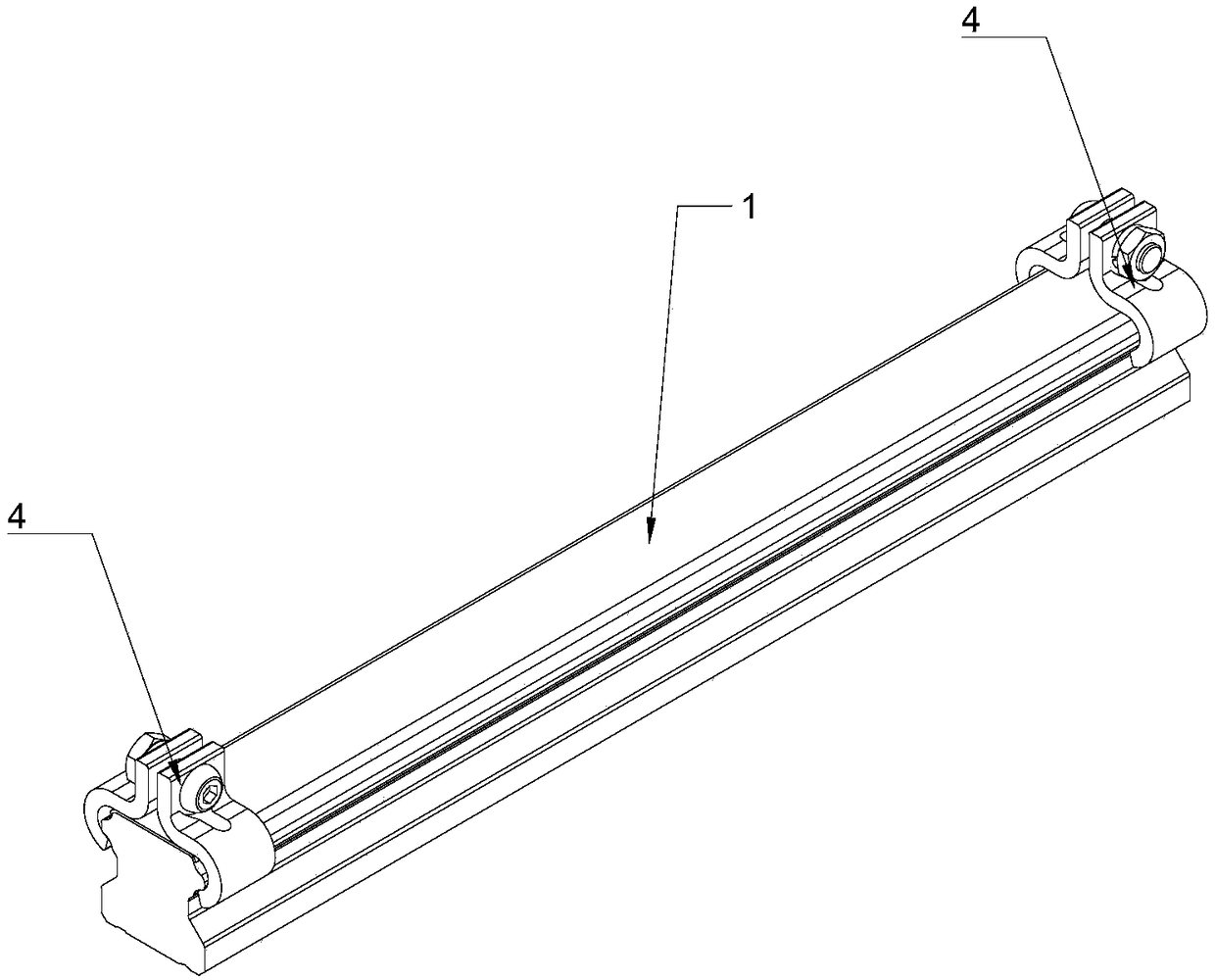

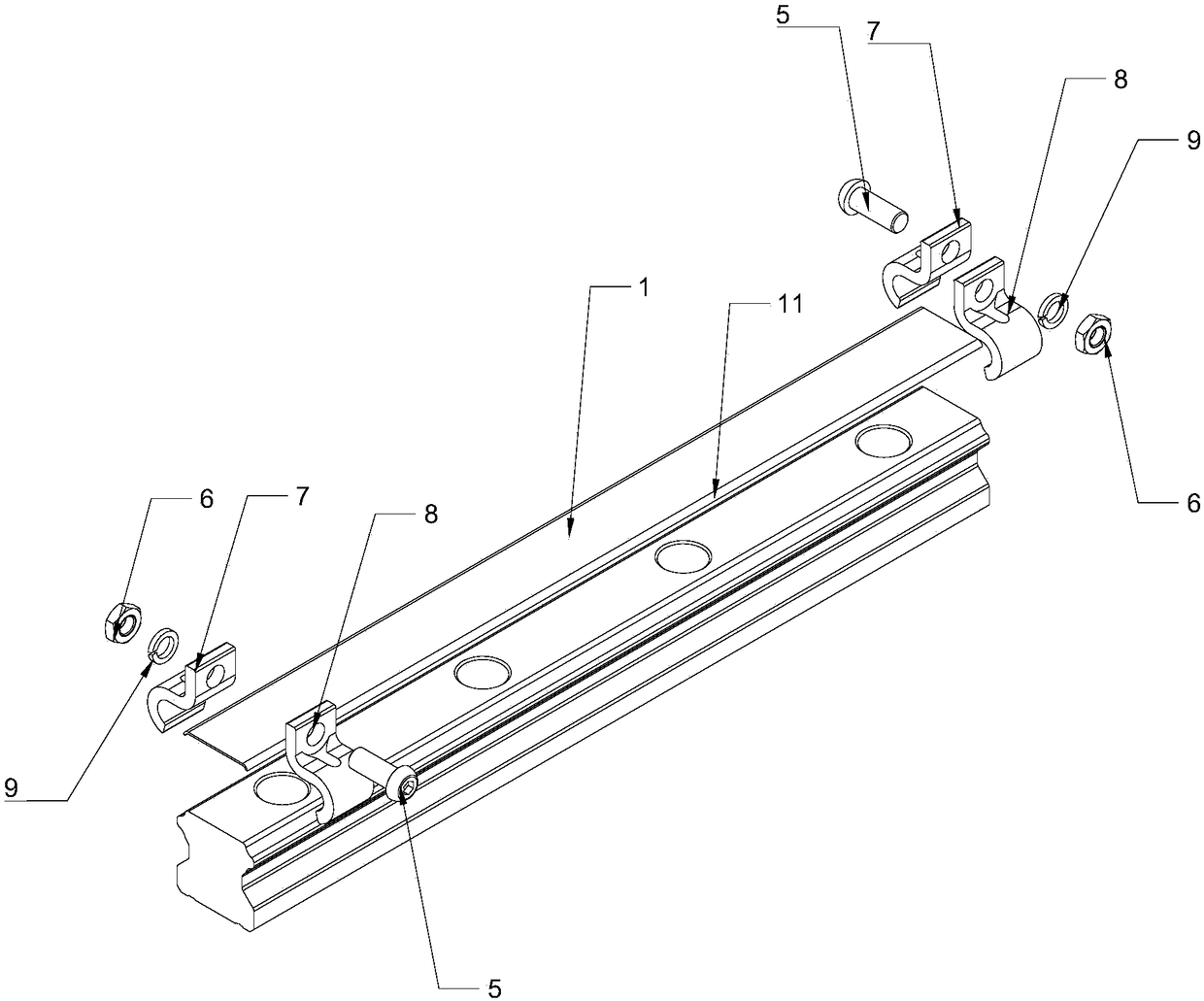

Detachable type linear sliding rail dustproof belt

Owner:JINAN LAND HEAD TRANSMISSION MACHINERY

Numerical control automation equipment facilitating feeding and discharging

InactiveCN112894454AInhibit sheddingGuaranteed uptimeGripping headsMetal working apparatusNumerical controlControl engineering

The invention relates to the technical field of numerical control automation equipment for feeding and discharging, in particular to numerical control automation equipment facilitating feeding and discharging. Through the arrangement of the numerical control automation equipment, the front end of a mechanical arm can incline inwards in the using process, then materials can be prevented from falling off from the front end of the mechanical arm, so that the feeding and discharging operation of the numerical control equipment can be ensured, and the device adopts linkage fixation between rods, so that the fixation by the manipulator to the materials can be completed in the same step; and through the arrangement of an arc-shaped stretching rod and an arc-shaped fixing plate, the materials can be fixedly clamped on the inner wall of the mechanical arm, so that it is guaranteed that the materials cannot deviate in the clamping process of the mechanical arm, errors generated after machining of the materials can be reduced, and meanwhile waste of raw materials can be avoided.

Owner:韦忠良

PERC battery back passivation gas spraying device

InactiveCN112349806AAvoid wastingTransmission does not affectFinal product manufactureSemiconductor devicesStructural engineeringMechanical engineering

The invention discloses a PERC battery back passivation gas spraying device in the technical field of PERC batteries. The PERC battery back passivation gas spraying device comprises a fixing support,a limiting clamping ring is arranged on the front end surface of the fixing support, a clamping sealing device is movably arranged on the inner wall of the limiting clamping ring, and telescopic sleeve rods are arranged on the left side and the right side of the bottom of the fixing support. The bottom of the telescopic sleeve rod is connected with a supporting plate block, the top of the supporting plate block is connected with a spraying device, the bottom of the spraying device is connected with a telescopic rod, fixing rods are arranged on the left side and the right side of the bottom ofthe supporting plate block, and fastening devices are movably arranged on the left side and the right side of the top of the conveying plate block. The height of the spraying device is adjusted to adjust the air spraying amount, air is sprayed according to the size of the battery, and the sprayed air is comprehensively and evenly sprayed to the back face of the battery, so that the waste phenomenon is avoided; and position adjustment is conducted according to the size of the battery, so that it is guaranteed that the battery can be more stable and cannot deviate during passivation, and the quality is guaranteed.

Owner:江苏晶旺新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com