Production method of cloth coating

A technology for production equipment and fabrics, which is applied to coatings, devices for coating liquids on surfaces, and surface pretreatment. The effect of uniform quantity, reducing scrap rate and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

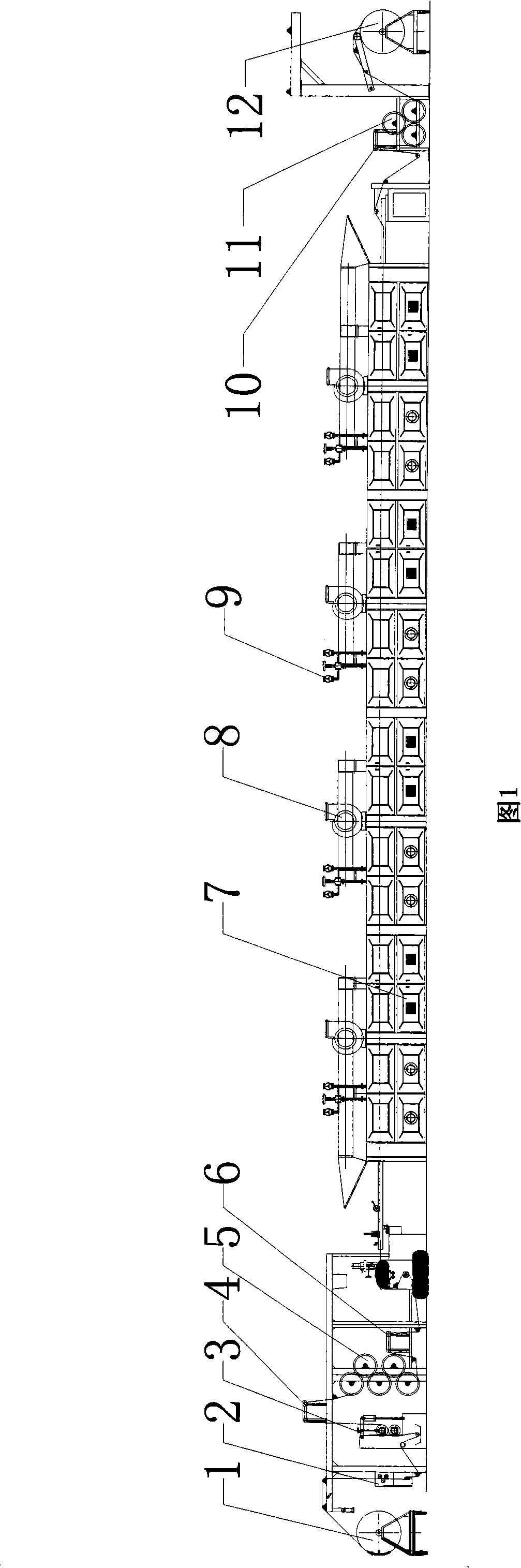

[0010] A cloth coating production equipment, comprising a cloth sending device, a cloth padding and pasting device, a cloth preheating and ironing device, an oven and a cooling device, and a cloth winding device arranged sequentially on a production line, characterized in that: the cloth A centering device and an automatic tension roller are arranged sequentially between the sending mechanism and the cloth preheating and ironing device, and an automatic tension roller is arranged between the cloth preheating and ironing device and the cloth padding and pasting device, and the oven There is an automatic adjustment tension roller between the cooling device and the cooling device.

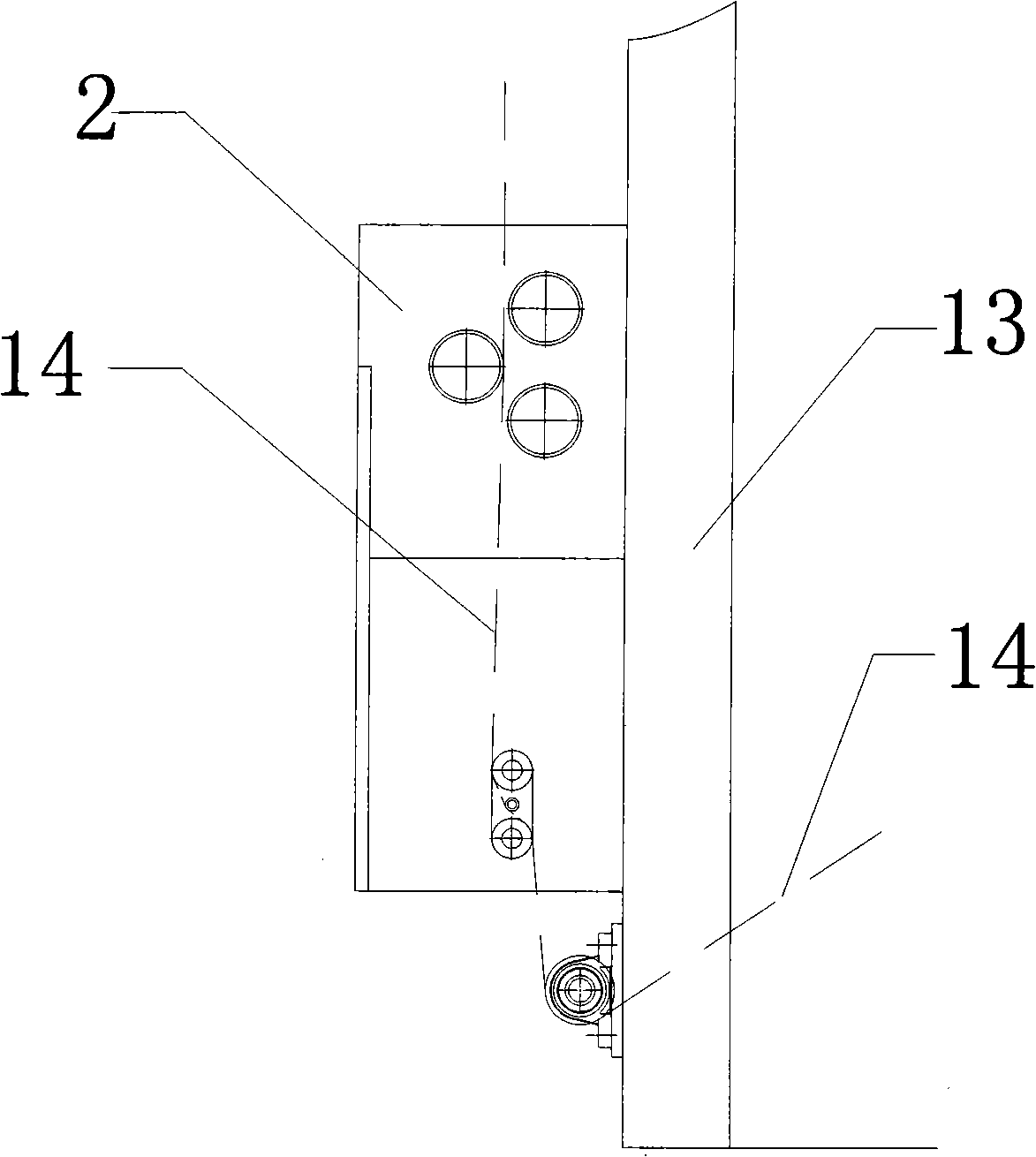

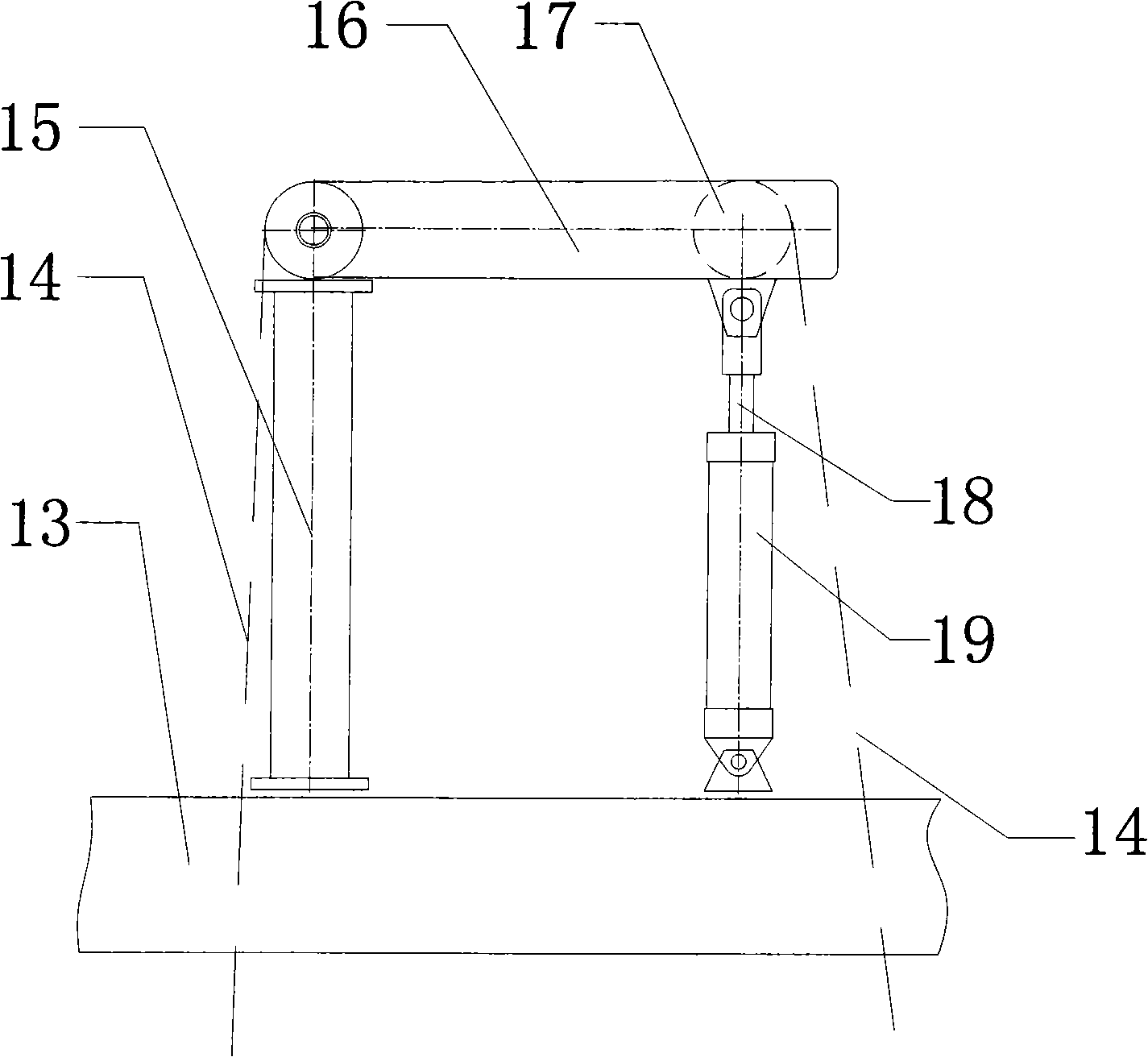

[0011] The above-mentioned centering device is a photoelectric centering machine, and the above-mentioned self-adjusting tension roller includes a pair of vertical struts arranged on the bracket, a pair of undulating swing rods whose front end is hinged with the two vertical struts, and a pair of undul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com