Patents

Literature

70results about How to "Uniform amount of glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paperboard gluing device

InactiveCN106040522ASimple structureReduce manufacturing costLiquid surface applicatorsCoatingsPaperboardPulp and paper industry

The invention relates to a paperboard gluing device. The paperboard gluing device comprises a glued paperboard, a coating support, guide rollers, a gluing roller and a transmission roller. The gluing roller is arranged under the transmission roller. A gap is reserved between the gluing roller and the transmission roller, and a channel for the glued paperboard to exactly pass is formed. The transmission roller is arranged on the top of the gluing support in a vertical adjusting manner through a hanging rod. A glue box is arranged at the bottom of the gluing roller and internally contains glue. Part of the wall barrel of the gluing roller is immersed in the glue, a glue scraping device is arranged at the position close to the gluing roller and comprises a scraper, a glue recycling box and a supporting rod arranged in the glue recycling box, the supporting rod is vertically arranged in the glue recycling box in a telescopic manner, and the scraper is movably arranged on the supporting rod. According to the paperboard gluing device, gluing is easy, the gluing amount is even, and the glue is not likely to pollute the gluing device; and the gluing device can be applied to the logistics field and other fields.

Owner:北京英格条码技术发展有限公司

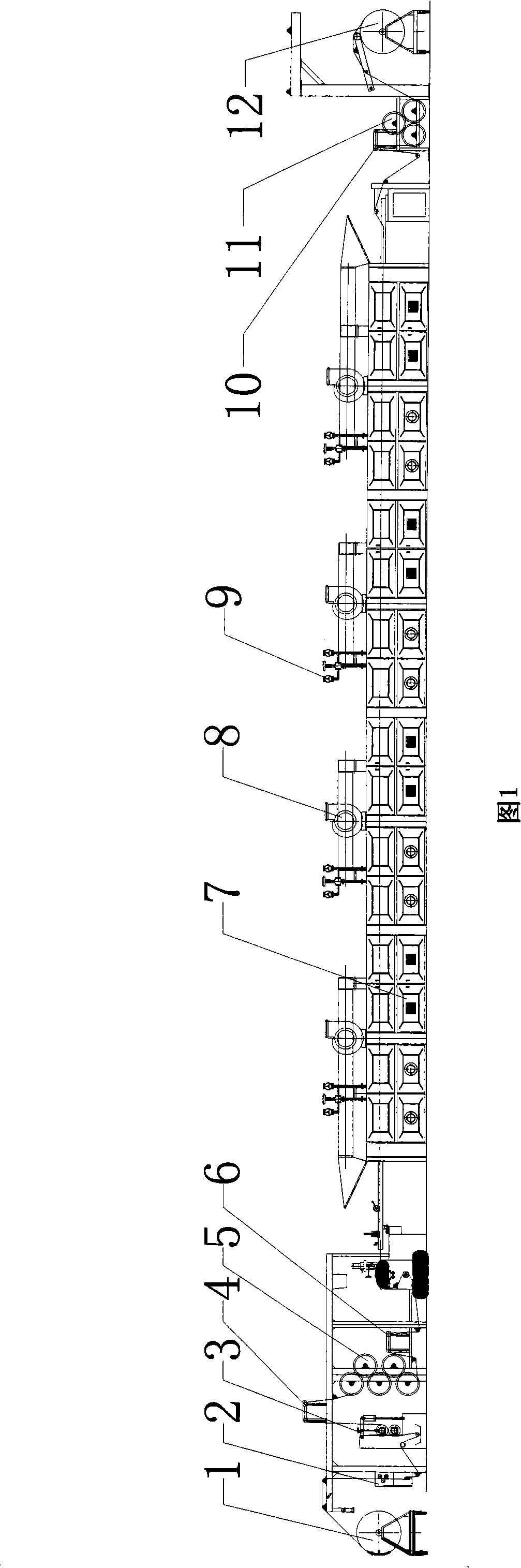

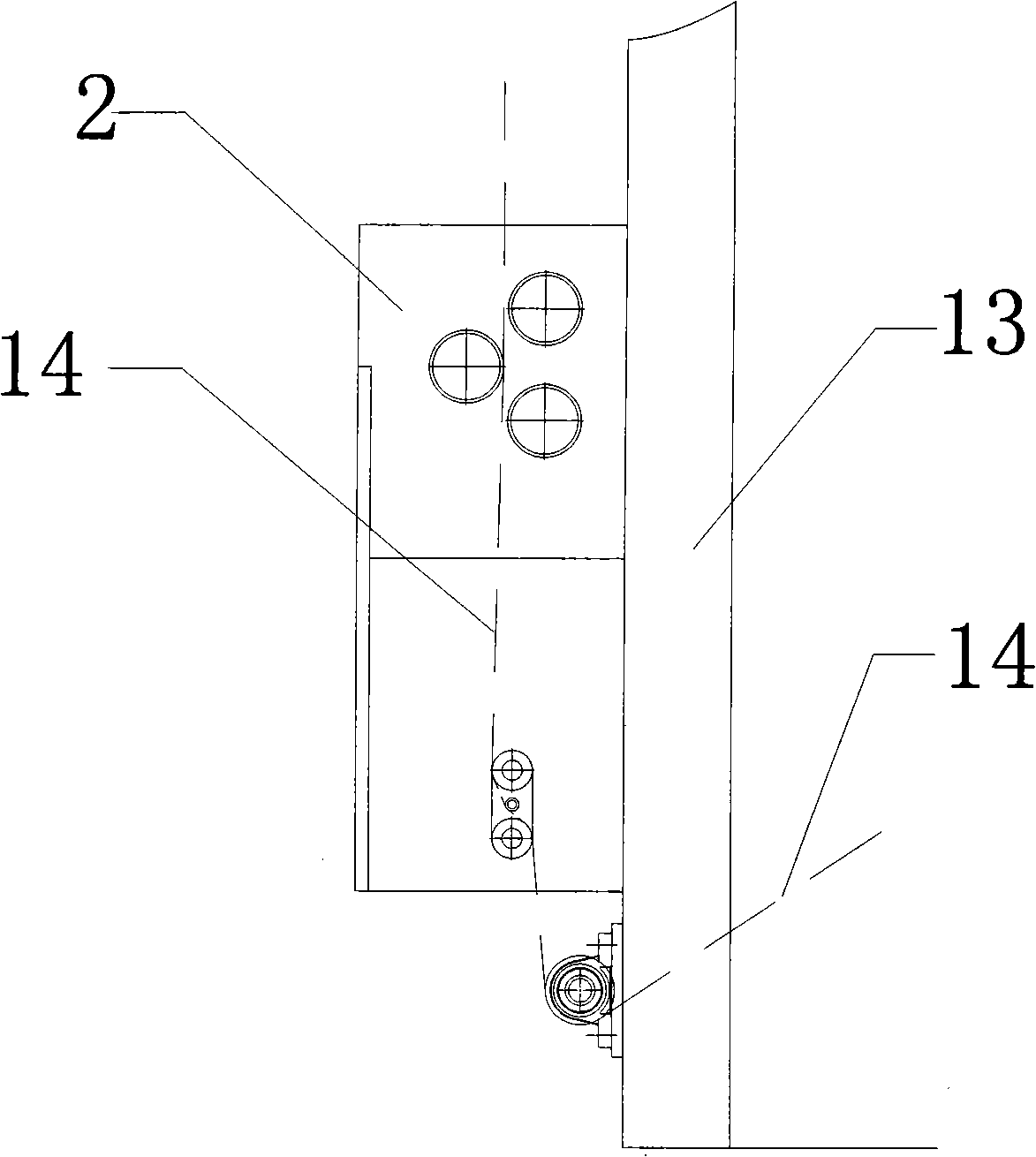

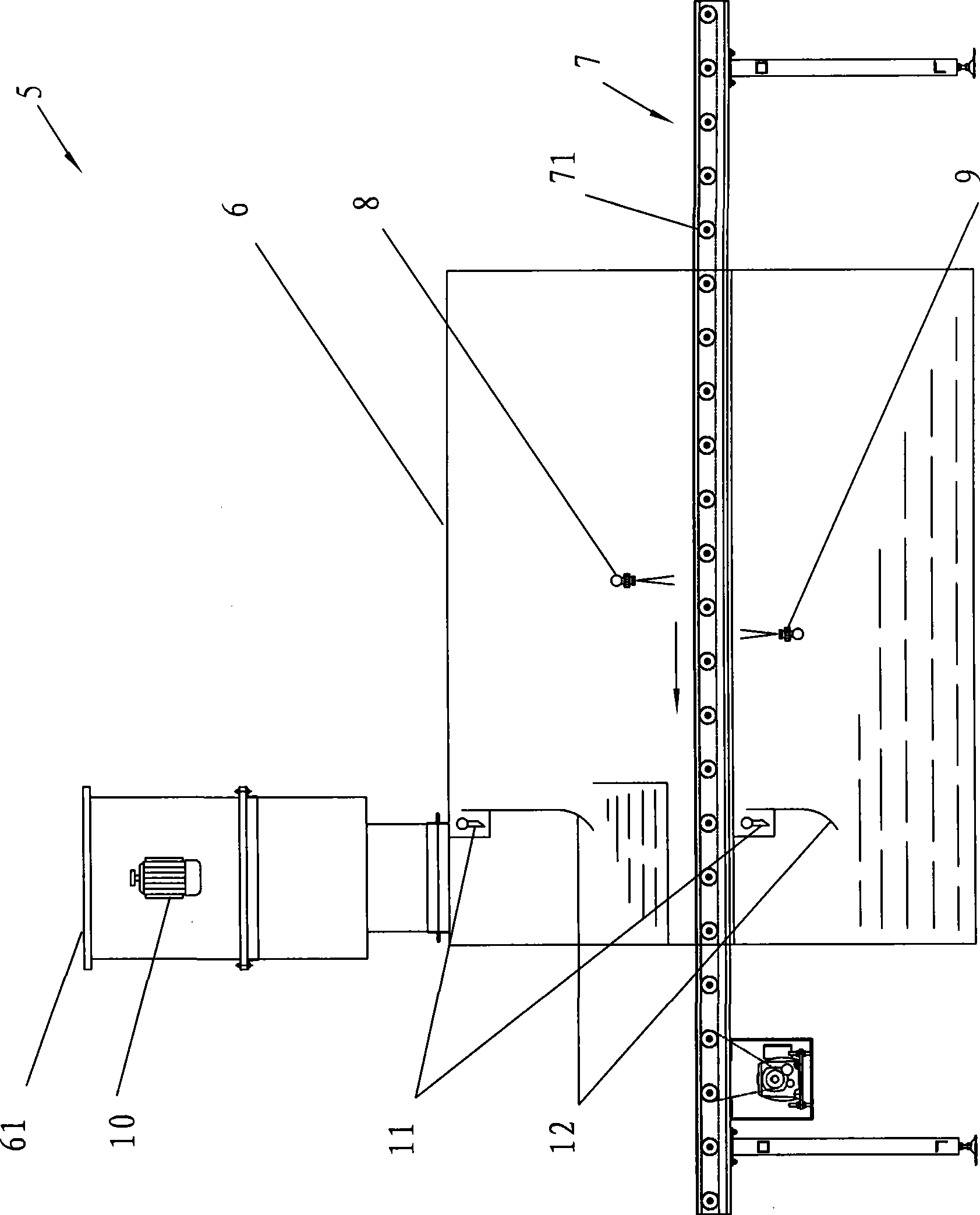

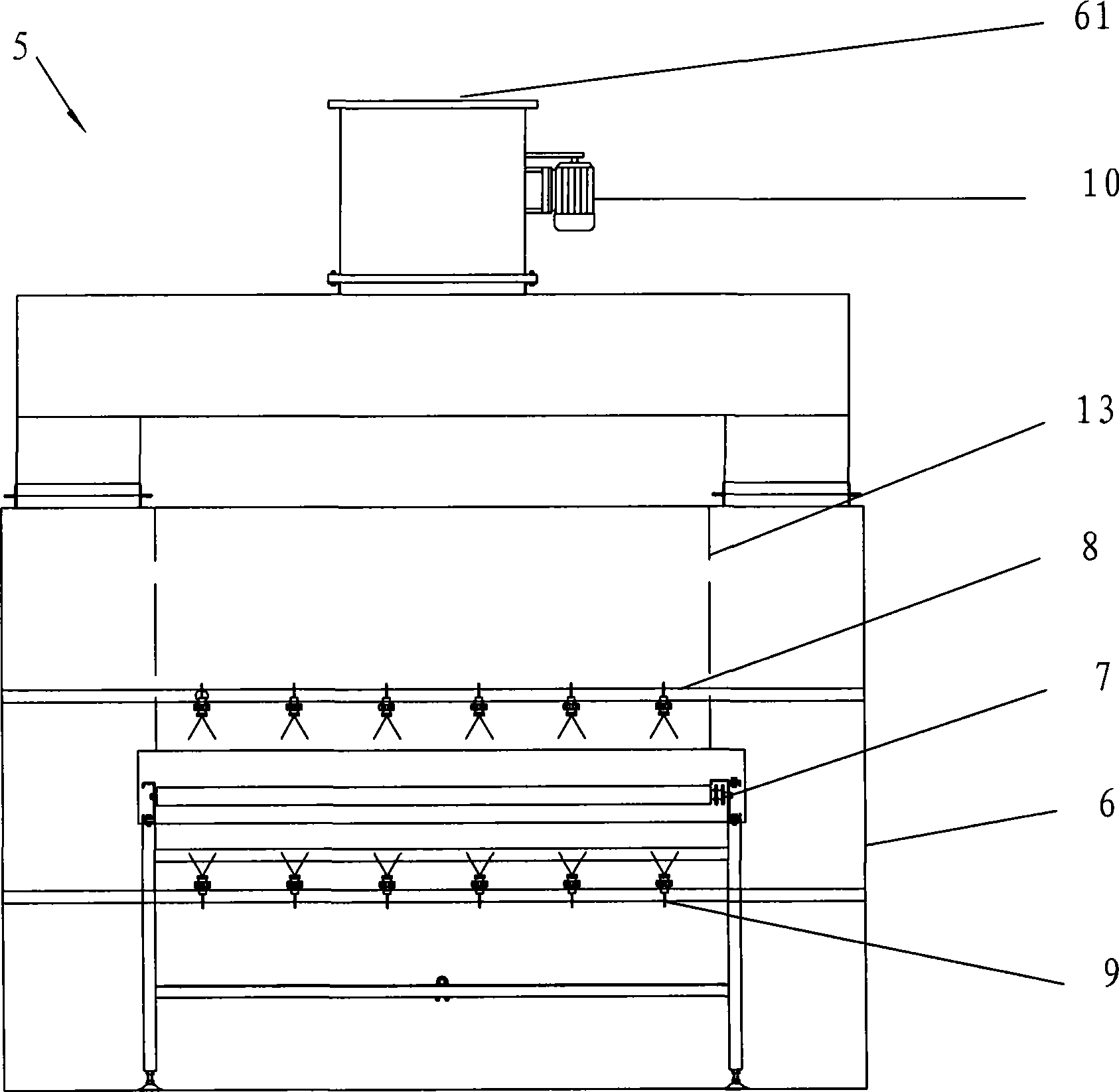

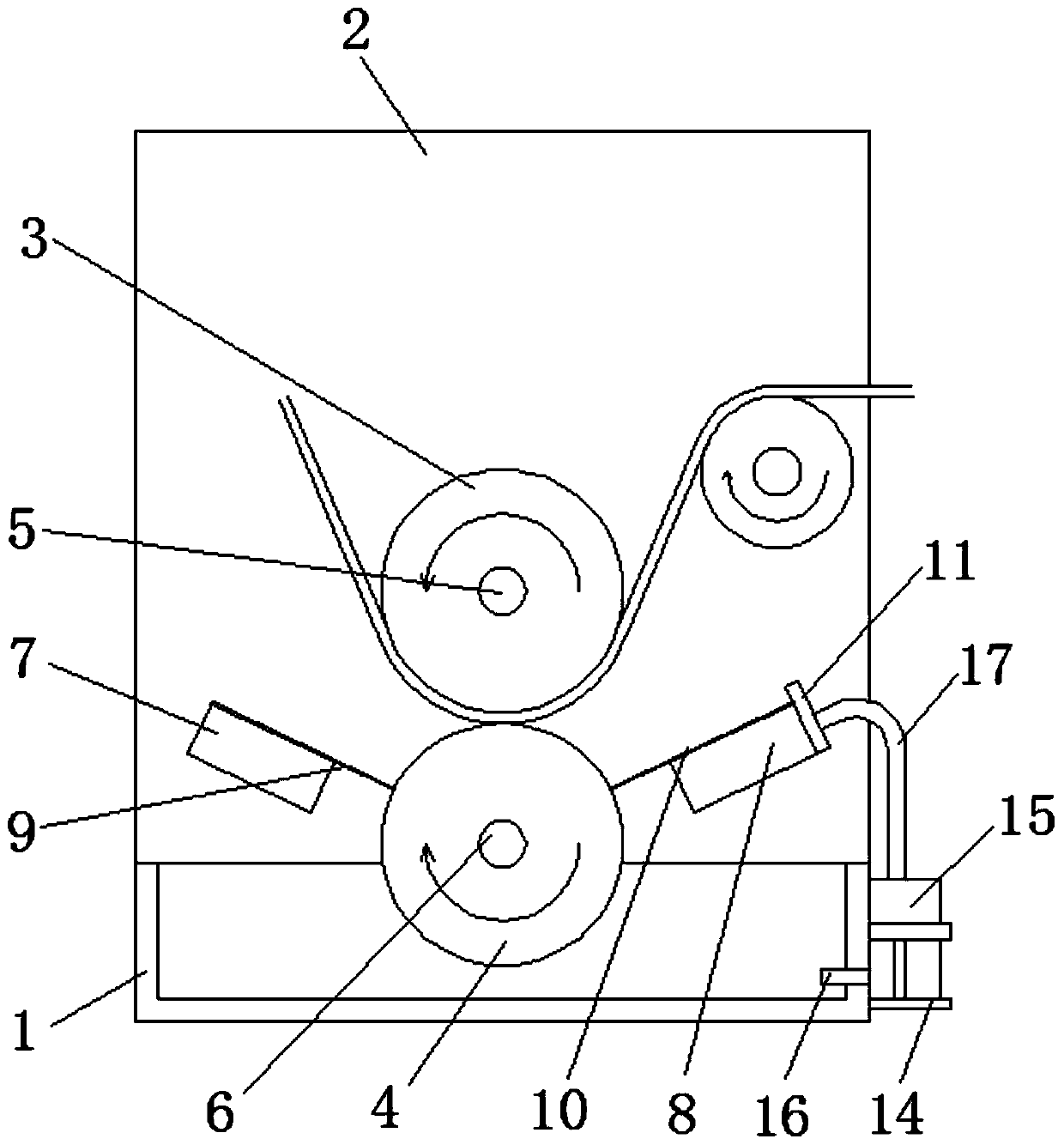

Production method of cloth coating

InactiveCN101337213AThere will be no deviationUniform amount of gluePretreated surfacesCoatingsWaste productEngineering

The invention relates to equipment for producing a cloth coating layer, and comprises a cloth delivering device, a cloth padding and pasting device, a cloth preheat ironing device, a drying oven, a cooling device and a cloth wrapping-up device which are arranged on a production line in sequence. The equipment is characterized in that a centering device is arranged between the cloth delivering mechanism and the cloth padding and pasting device; an automatic cloth adjusting tension roller is arranged between the cloth preheat ironing device and the cloth padding and pasting device; another automatic cloth adjusting tension roller is also arranged between the drying oven and the cooling device. The equipment has the advantages of novel design, compact structure, good use effect, no cloth running deviation phenomenon, uniform cloth gluing amount, good quality and few waste products; furthermore, the equipment has great popularization and application value.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

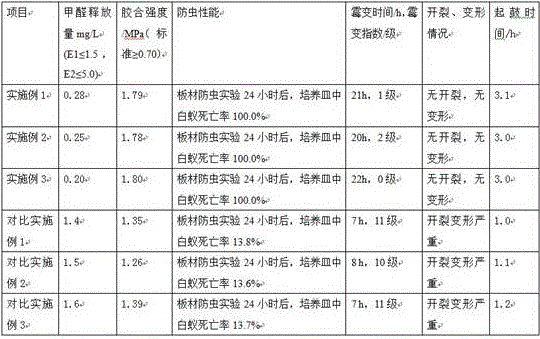

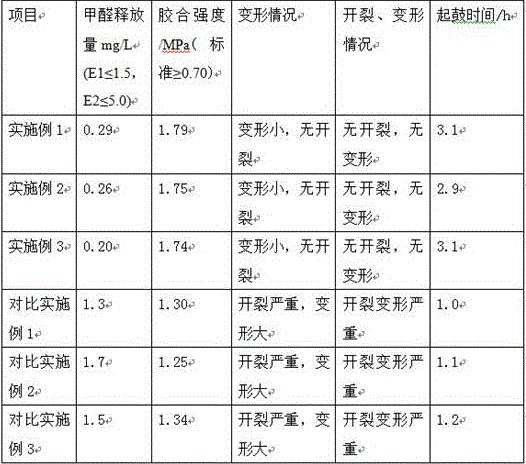

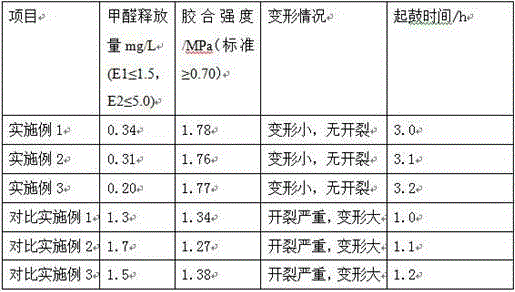

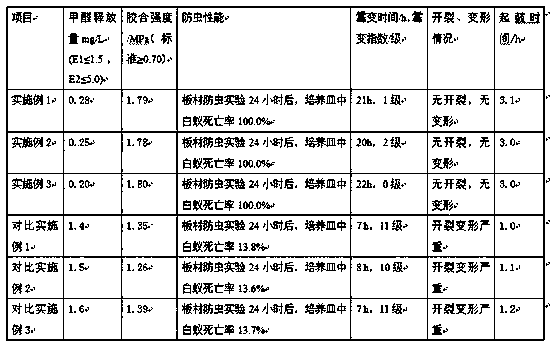

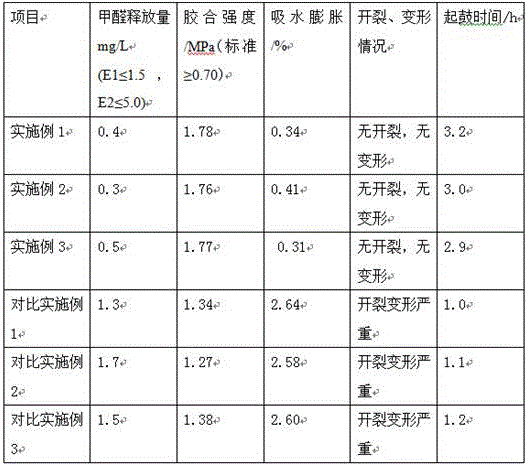

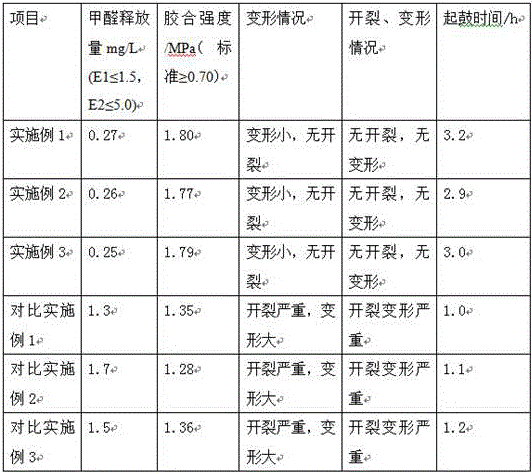

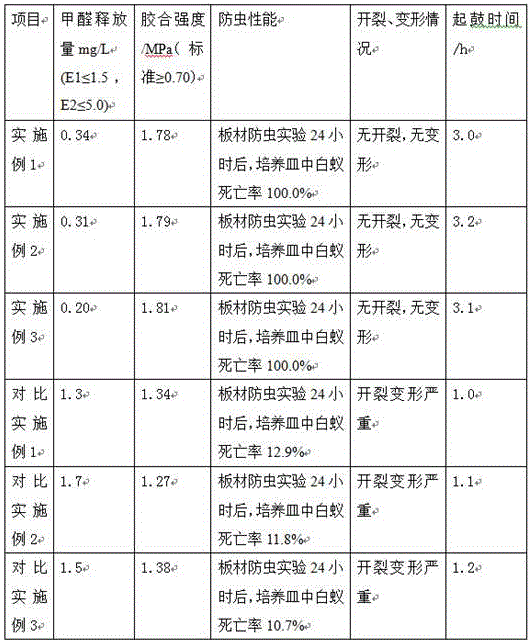

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

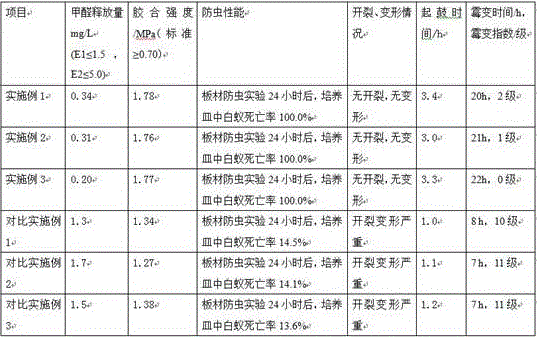

Method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin

ActiveCN106335120AReduce formaldehyde contentGood gluing propertiesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerSurface layer

A method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin comprises steps as follows: rotary cutting of a board to form pieces; single plate drying; adhesive coating; three times of cold pressing; leaving to stand for reconditioning; three times of hot pressing; heat dissipation for reconditioning; fixed-thickness sanding of plate blanks; adhesive coating of base material surface layers; reconditioning and grooving; paint coating, drying and setting. The key of the production method is that melamine modified urea-formaldehyde resin is used as a main adhesive material; oxidized starch is added as a viscous compound; polyvinyl alcohol is added as a toughening agent; hydrogenated rosin is added as an anti-oxidant; polyisocyanate is added as a curing agent; isobutyltriethoxysilane is added as a bridging agent; phenolated lignin is added as a formaldehyde catching agent; an anti-insect and anti-mildew agent is added; anti-insect and anti-mildew composite urea-formaldehyde resin is prepared; and the parquet prepared from anti-insect and anti-mildew composite urea-formaldehyde resin has the advantages of being low in formaldehyde residual amount and good in anti-insect and anti-mildew effect, has the relatively high inhibition effect on breeding of Aspergillus, Trichoderma and Penicillium and has the instant killing force and the long-acting preventive effect on board powder-pest beetles.

Owner:广西横县正林木业有限公司

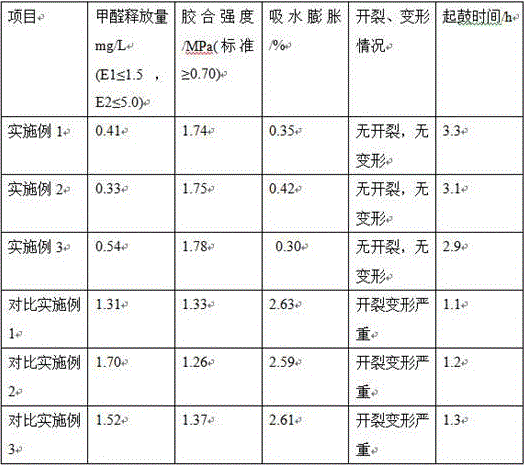

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

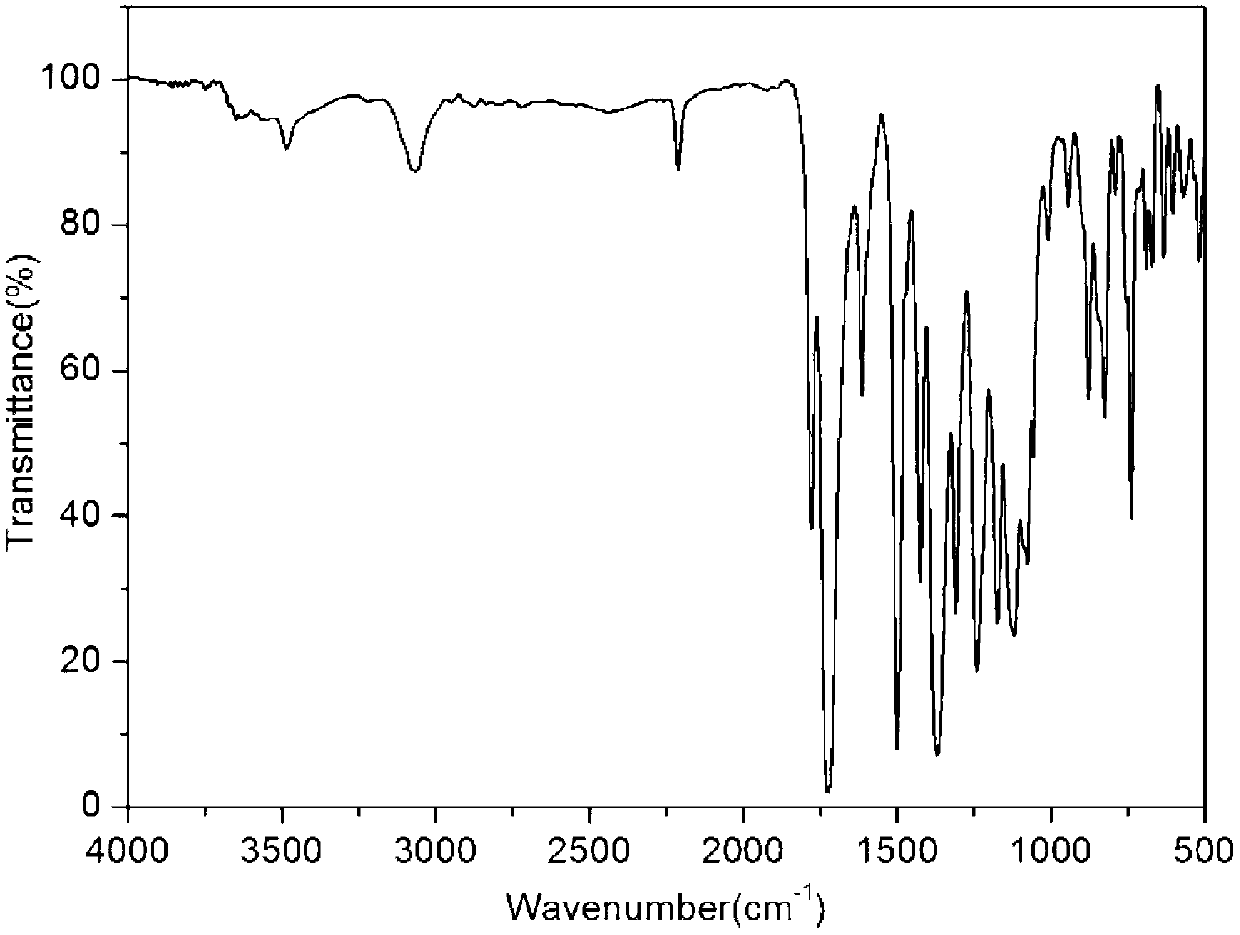

Winding moulding fiber-reinforced polyimide resin prepreg tape and preparation method and application thereof

The invention discloses a winding moulding fiber-reinforced polyimide resin prepreg tape and a preparation method and application thereof. The structure of polyimide resin prepared into the prepreg tape is shown as a formula I; and the polyimide resin is good in solubility and melt fluidity and excellent in heat resistance after being cured at the temperature of 370 DEG C, has a glass transition temperature of more than or equal to 300 DEG C and has good mechanical properties. A polyimide resin solution is used for directly impregnating and reinforcing a fiber, and after a heat drying process in air and removal of a solvent, the prepreg tape with uniform glue quantity and low residual solvent content (lower than or equal to 1%) can be obtained. The prepreg tape is simple in preparation process and convenient to store and transport; and a winding moulding composite material prepared from the prepreg tape has excellent mechanical properties and can be applied to manufacturing of composite material cylinders, pressure containers, storage tanks, pipes, fan blades and other high-temperature-resistant structural components.

Owner:INST OF CHEM CHINESE ACAD OF SCI

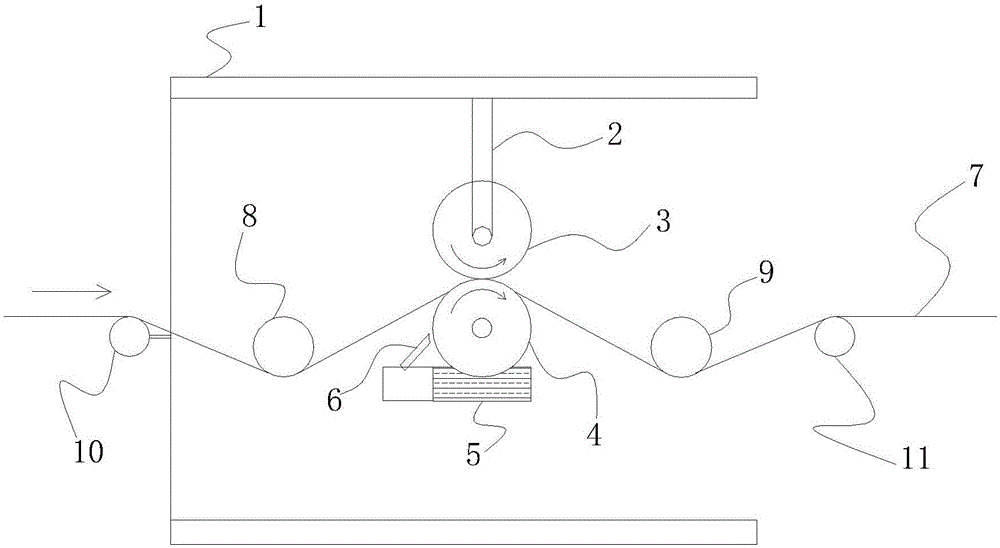

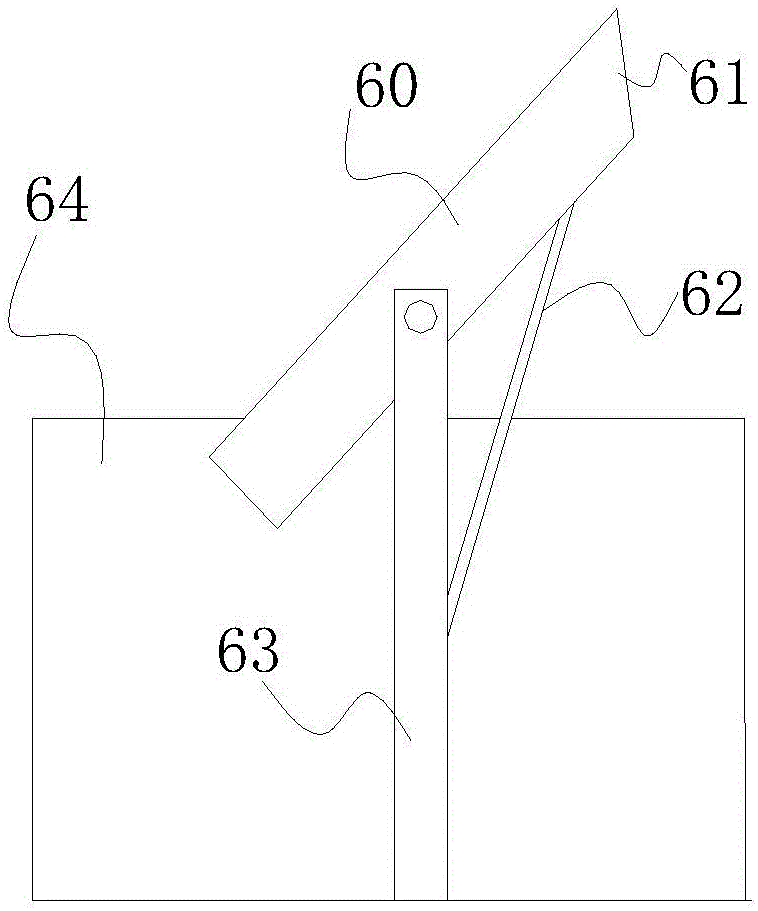

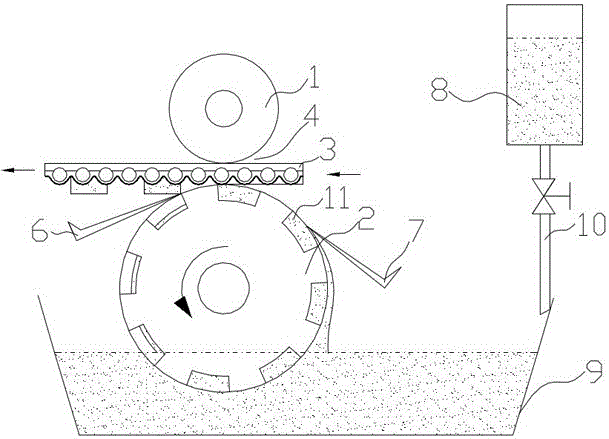

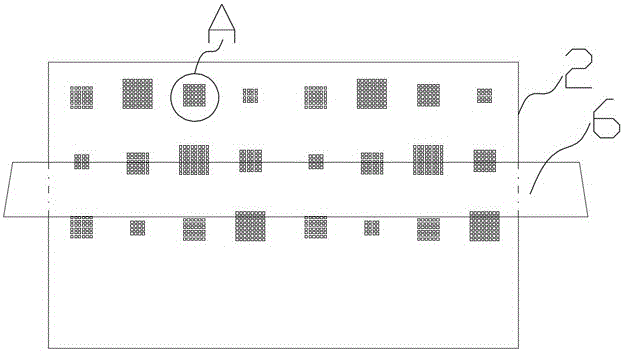

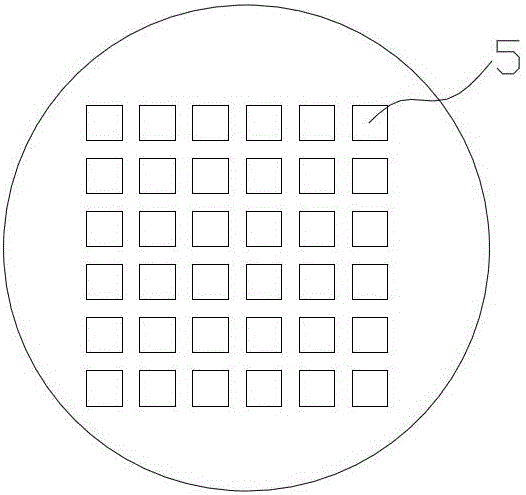

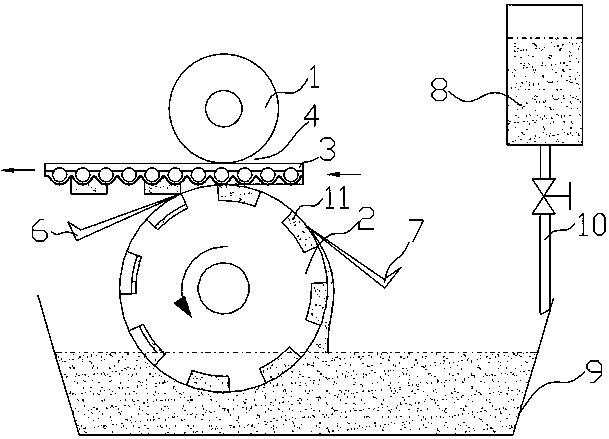

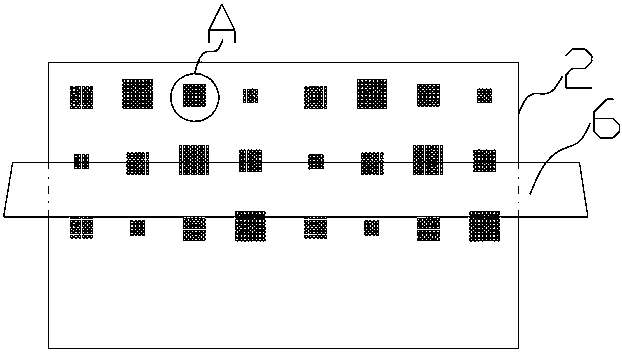

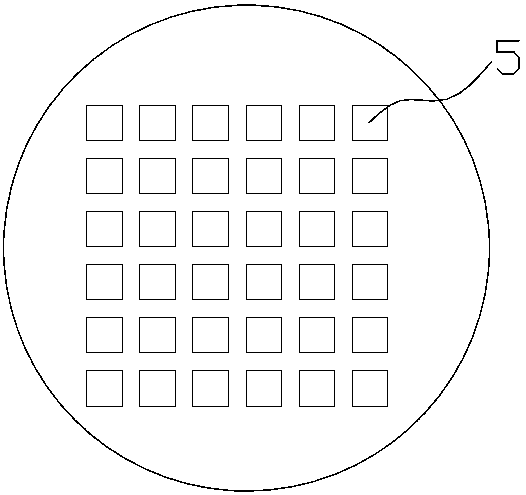

Gravure gluing apparatus and gluing method of large pattern of fancy light reflection fabric

ActiveCN106334649AEven amount of glueUniform adhesive layer thicknessLiquid surface applicatorsCoatingsLight reflectionPulp and paper industry

The invention discloses a gravure gluing apparatus of a large pattern of a fancy light reflection fabric. The apparatus comprises an upper pressure roller, a gravure gluing roller, a glue scraper knife and a glue supply mechanism, the upper pressure roller and the gravure gluing roller are arranged up and down, a transmission channel is arranged between the upper pressure roller and the gravure gluing roller, a bead planting membrane is in contact with the roller surface of the upper pressure roller and the gravure gluing roller respectively, the glue scraper knife is positioned at one side of the gravure gluing roller, the glue scraper knife is in contact with the surface of the gravure gluing roller, the surface of the gluing roller is provided with a printing pattern, the printing pattern is composed of a plurality of uniformly-distributed isotropic gluing grooves used for accommodating printing glue, and the bottom of the gravure gluing roller is placed in the glue supply mechanism and is in contact with the glue in the glue supply mechanism. The apparatus can effectively solve the problems of glue spilling and glue discontinuity, allows the thickness of a glue layer to be uniform, has no restriction on the size of the printing pattern, and can be used to produce large-pattern products. The invention also provides a gluing method of the large pattern of the fancy light reflection fabric. The method has the advantages of simple steps, good production continuity and suitableness for industrial production.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

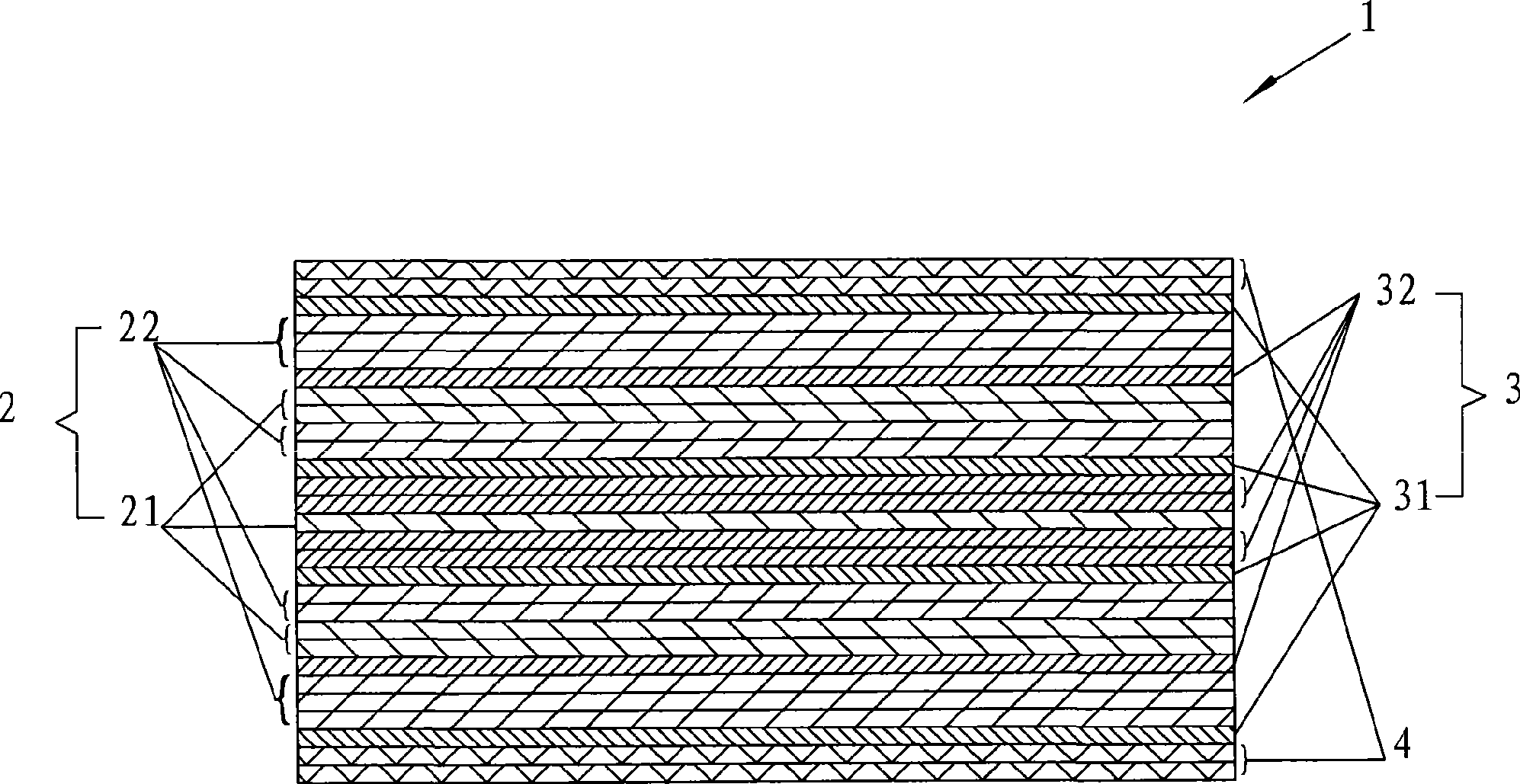

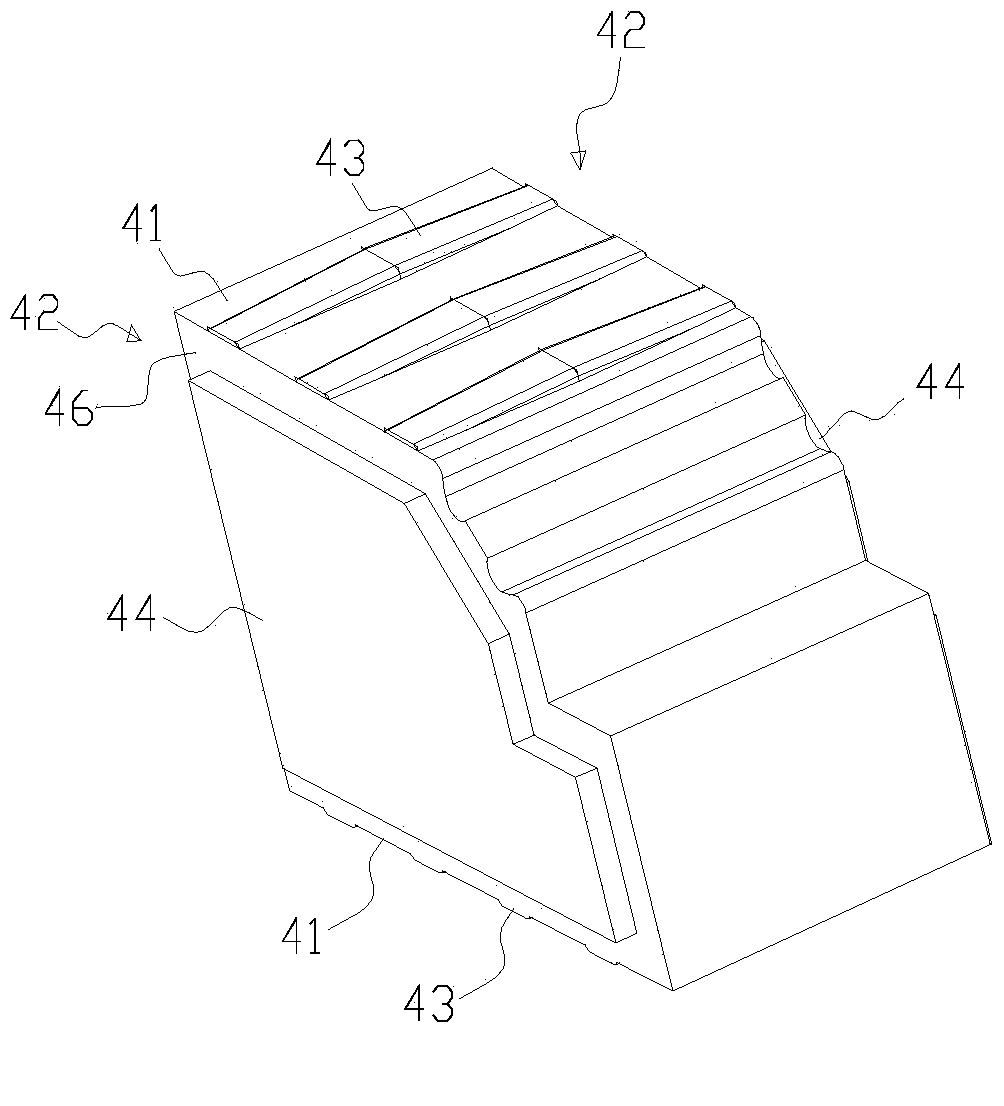

Bamboo wood composite container floor

ActiveCN101474810AUniform moisture contentUniform amount of glueWood veneer joiningWood layered productsHigh concentrationWood veneer

The present invention relates to a bamboo-wood composite container baseboard which is obtained through combining wood veneer, bamboo curtain and film coated paper. According to the invention, bamboo curtain and wood veneer are executed with blank forming according to a certain blank forming plan. Furthermore the surface of formed blank is covered with film-coated paper, wherein, the bamboo curtain is executed with adhesive spraying with a mode of high-pressure non-gas reciprocating spraying mist adhesive spraying. The high-concentration water soluble phenol resin is used for adhesive spraying. The bamboo-wood composite container baseboard of the invention adopts the mode of high-pressure non-gas reciprocating spraying mist adhesive spraying for executing adhesive spraying to bamboo curtain and has the advantages of no requirement of secondary drying, greatly reduced drying expense and labor expense, reduced cost, uniformity of adhesive amount and water content of bamboo curtain, and increased quality of produced board.

Owner:南通新洋环保板业有限公司

Method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin

InactiveCN106313200AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesAntioxidantAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher, and moreover an antioxidant and an ultraviolet absorbent are also added to prepare the weather-resistant composite urea resin; the composite urea resin has the advantages of low formaldehyde residual volume and good weather resistance. The total-eucalyptus plywood produced by the method disclosed by the invention is excellent in weather resistance and is relatively high in environmental disruption tolerance.

Owner:南宁市林润木业有限公司

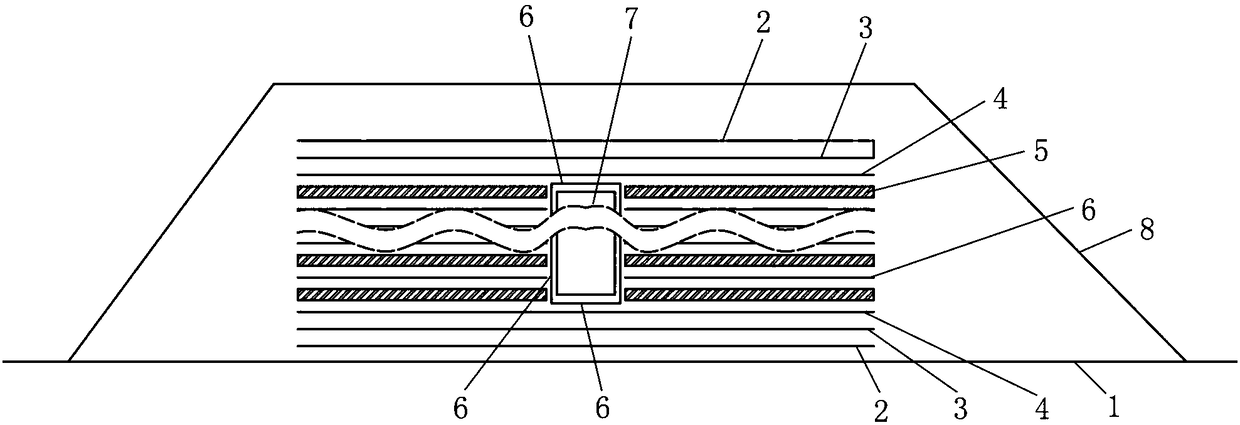

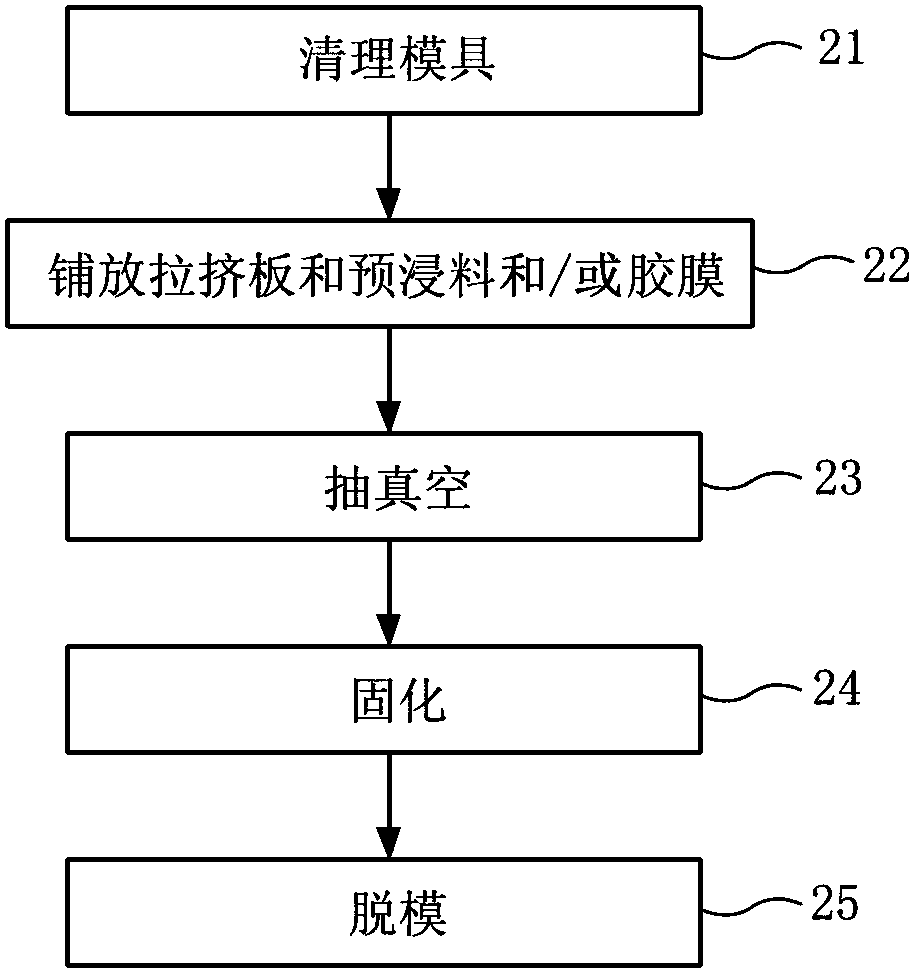

Manufacturing process of blade parts

InactiveCN108284623AOvercome uniformity issuesUniform amount of glueDomestic articlesEngineeringUltimate tensile strength

The invention discloses a manufacturing process of blade parts. The manufacturing process of blade parts comprises the following steps of laying multiple layers of pultrusion plates on a die in sequence, and laying prepreg and / or adhesive film between every two adjacent layers of pultrusion plates; vacuuming the laying area of the multiple layers of pultrusion plates, and compacting the pultrusionplates and the prepreg and / or adhesive film; and solidifying the prepreg and / or adhesive film in the vacuum environment. According to the manufacturing process of blade parts, because the pultrusionplates are glued with the prepreg and / or adhesive film, the resin infusion process is avoided, and the weight and the strength of a main beam or the blade parts can be accurately controlled.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

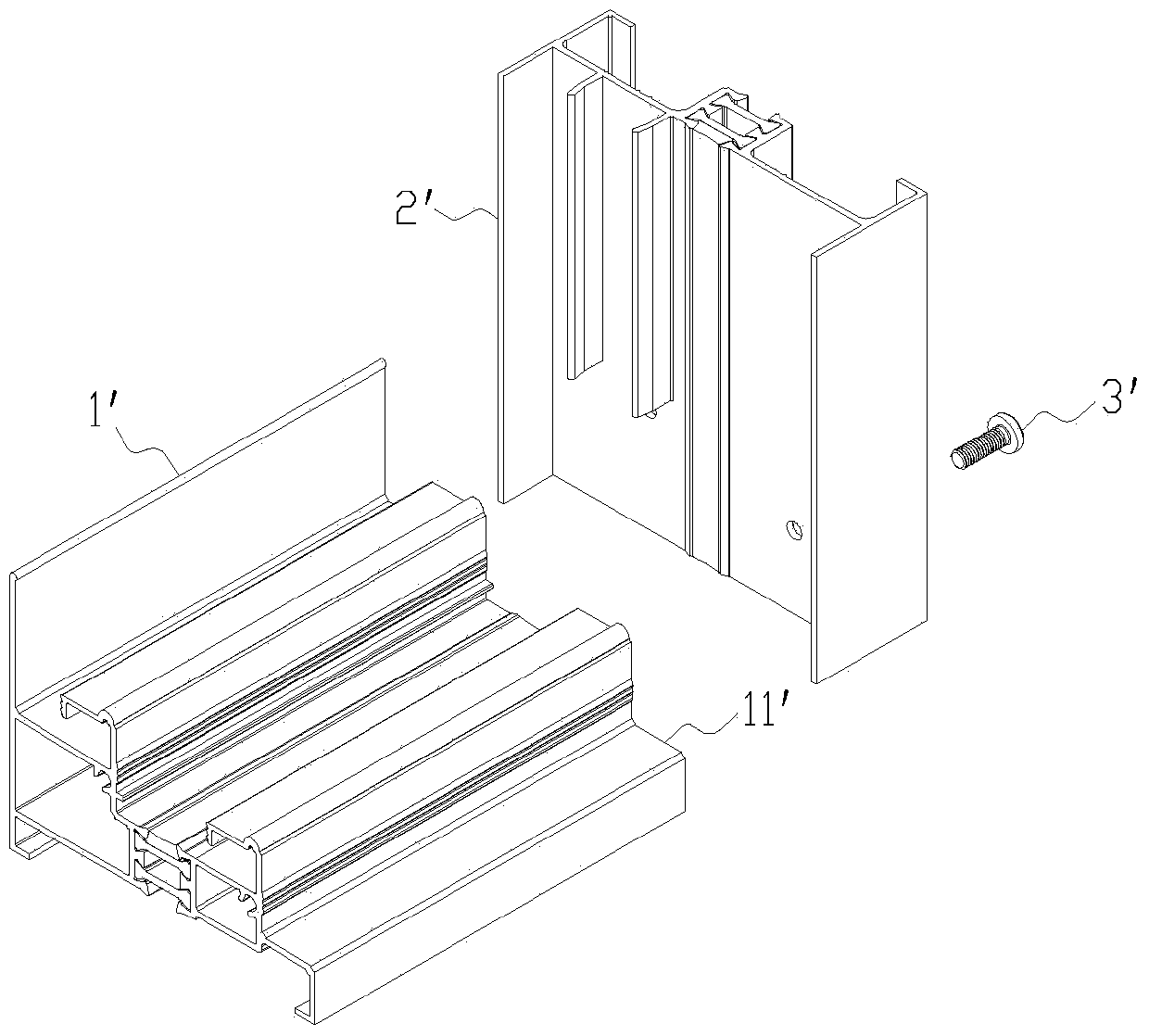

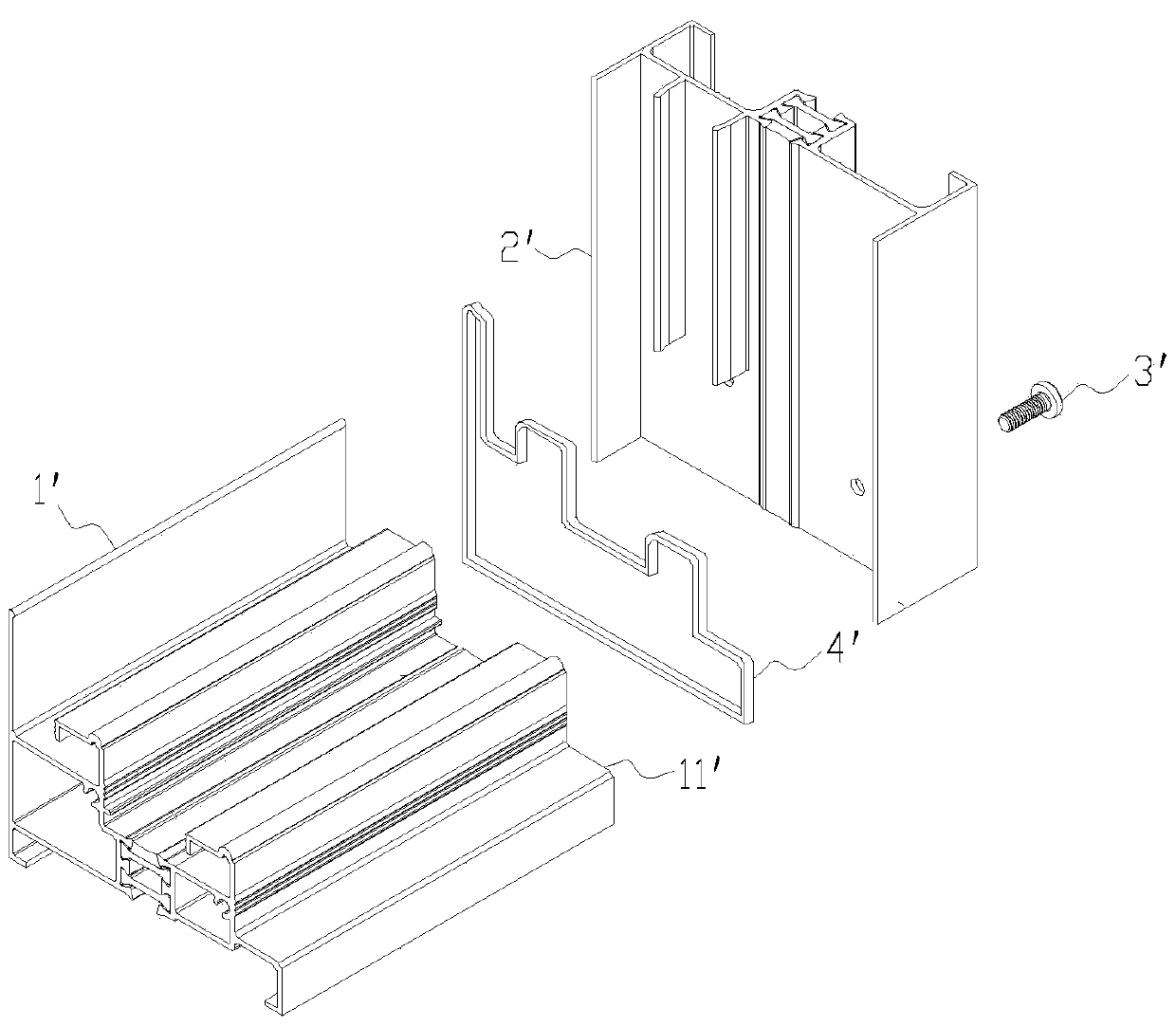

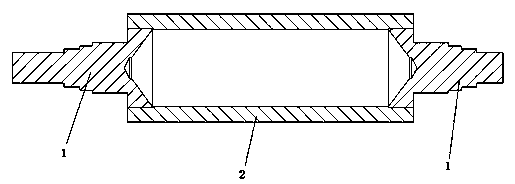

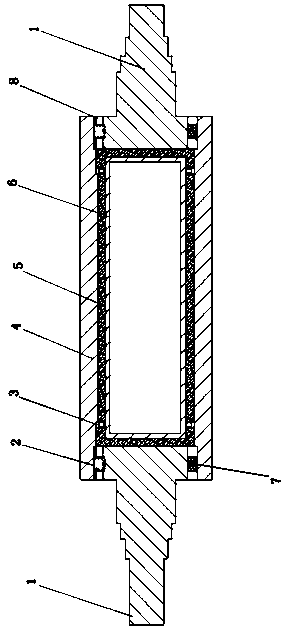

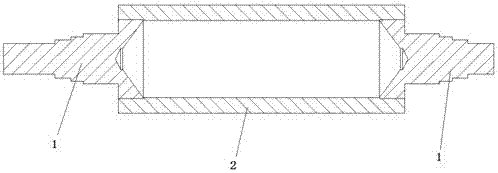

Connecting piece with cavity sectional material

ActiveCN103437666AIncrease profitOvercome water seepage gapsDoors/windowsUltimate tensile strengthMachining

The invention discloses a connecting piece with a cavity sectional material, and solves the defects that the connection of a connecting structure between the existing horizontal sectional material and the vertical sectional material is not firm and the water-proof property is poor. According to the technical scheme, the connecting piece provided by the invention is of a block shape, the outer shape of the connecting piece is matched with a cavity of the sectional material, so that the connecting piece is conveniently placed in the cavity, and the connecting piece comprises at least one inserting surface and a bonding surface which is perpendicular to the inserting surface. The connecting piece provided by the invention has the advantages that the block-shaped connecting piece arranged in the cavity of the horizontal sectional material is used for changing the line connection of a gluing position arranged among the sectional materials into surface connection, the connecting strength is effectively improved, a glue is subjected to extrusion so as to flow from inside to outside so as to rapidly and effectively fill a gap caused by the lower machining precision or sectional material specific structure requirement, the gap after solidifying is blocked, and the waterproof property is good.

Owner:ZHEJIANG BOAO ALUMINUM

Method for adopting high-temperature-resisting composite urea resin for producing whole-eucalyptus solid wood composite floor

ActiveCN106272849AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerAntioxidant

The invention discloses a method for adopting high-temperature-resisting composite urea resin for producing a whole-eucalyptus solid wood composite floor. The method includes the steps of board rotary slicing, veneer drying, gluing, three times of cold pressing, standing maintaining, three times of hot pressing, heat dissipating maintaining, slab fixed-thickness sanding, base material surface layer gluing, maintaining grooving and paint spraying, drying and sizing. The production method is characterized in that the high-temperature-resisting composite urea resin is prepared by adopting melamine modified urea resin as the main material of an adhesive, adding oxidized starch as a viscosity complexing agent, adopting polyvinyl alcohol as a toughening agent, adopting hydrogenated rosin as an antioxidant, adopting polyisocyanate as a curing agent, adopting isobutyl triethoxy silane as a bridging agent, adopting phenolate lignin as a formaldehyde catching agent and adding high-temperature-resisting filler. The high-temperature-resisting composite urea resin prepared through the method is used for producing the whole-eucalyptus solid wood composite floor so that the whole-eucalyptus solid wood composite floor can have good heat resistance performance, no obvious crack phenomenon happens under high-temperature and high-strength ultraviolet irradiation or long-time ultraviolet irradiation, and economic losses are reduced.

Owner:广西横县正林木业有限公司

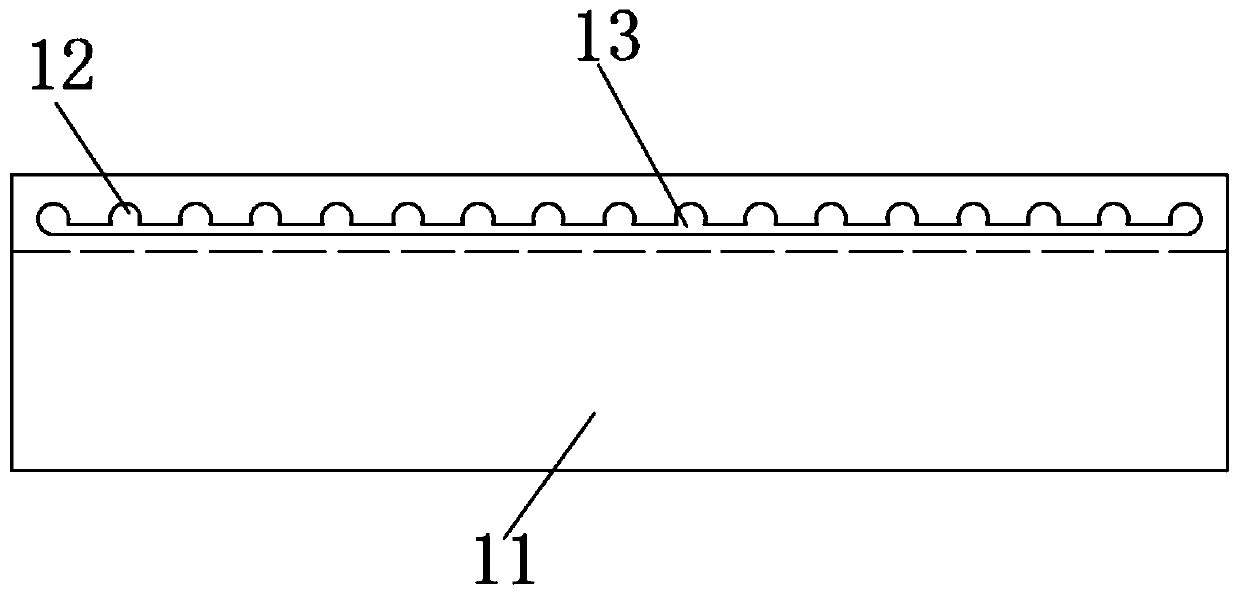

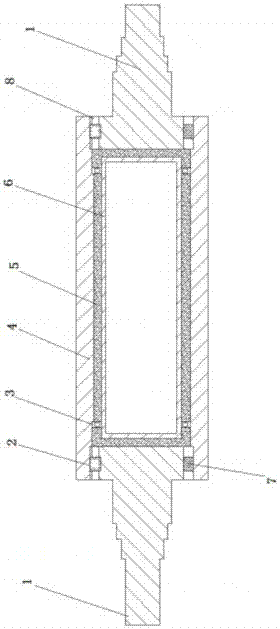

Novel single facer glue spreading roller

ActiveCN104209237AUniform temperatureExtended service lifeLiquid surface applicatorsCoatingsCardboardShrink-fitting

The invention discloses a novel single facer glue spreading roller. The novel single facer glue spreading roller comprises a hollowed cylinder, and shaft heads fixedly and tightly connected with the two ends of the cylinder, wherein the cylinder and the shaft heads are connected through shrink-fitting and welding; annular grooves are formed in the outer end surfaces of the shaft heads; liquid injecting holes are evenly distributed in the grooves; a closed hollow liner is arranged in the cylinder; the two ends of the liner are fixedly connected with the inner wall of the cylinder through annular pipe plates; inner rings of the annular pipe plates are arranged around the liner, and are fixedly welded with the surface of the liner; through holes are evenly distributed in the circular surfaces of the annular pipe plates; the length and the end surface diameter of the liner are both smaller than the length and the end surface diameter of the cylinder; and a liquid injecting space is formed between the outer wall of the liner and the inner wall of the cylinder. The novel single facer glue spreading roller has the following beneficial effects: (1) the surface temperature of the glue spreading roller is uniform to reduce the friction with a corrugated roller; (2) the service lives of the corrugated roller and the gluing roller are prolonged; the spread of glue is uniform; and the paperboard quality is high; and (3) the replacement frequency of glue in a glue tray is largely reduced, so that the cost is decreased.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

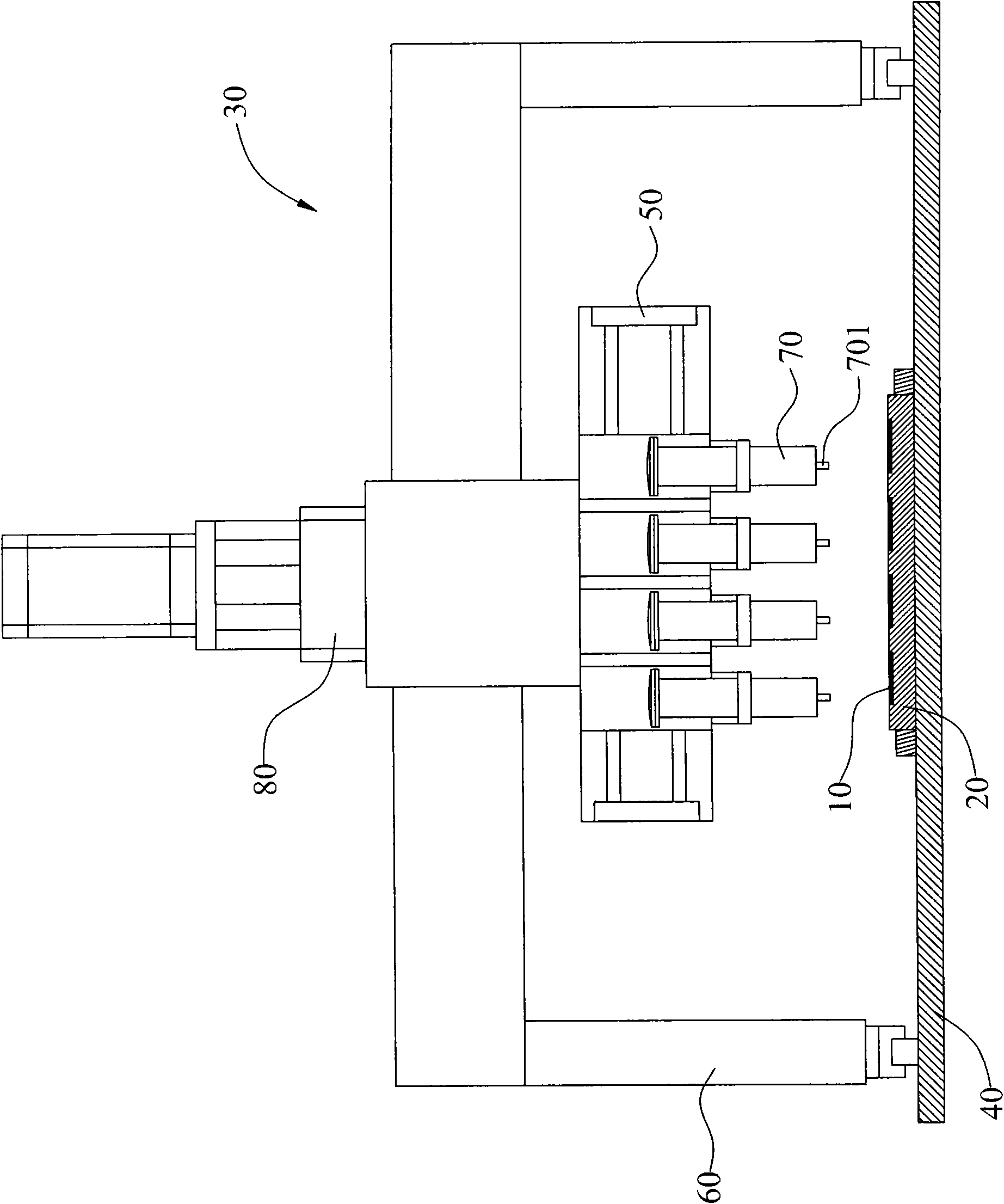

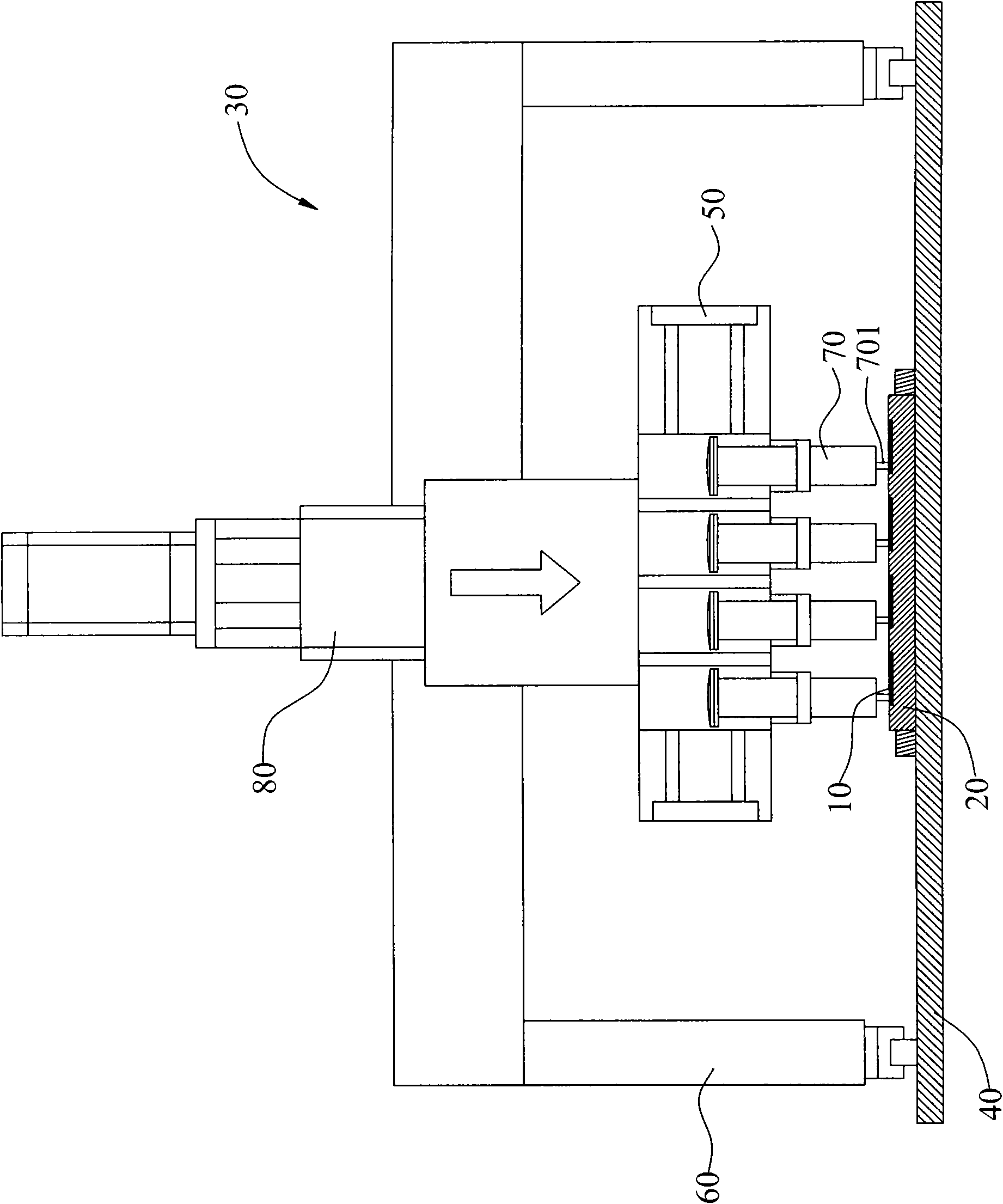

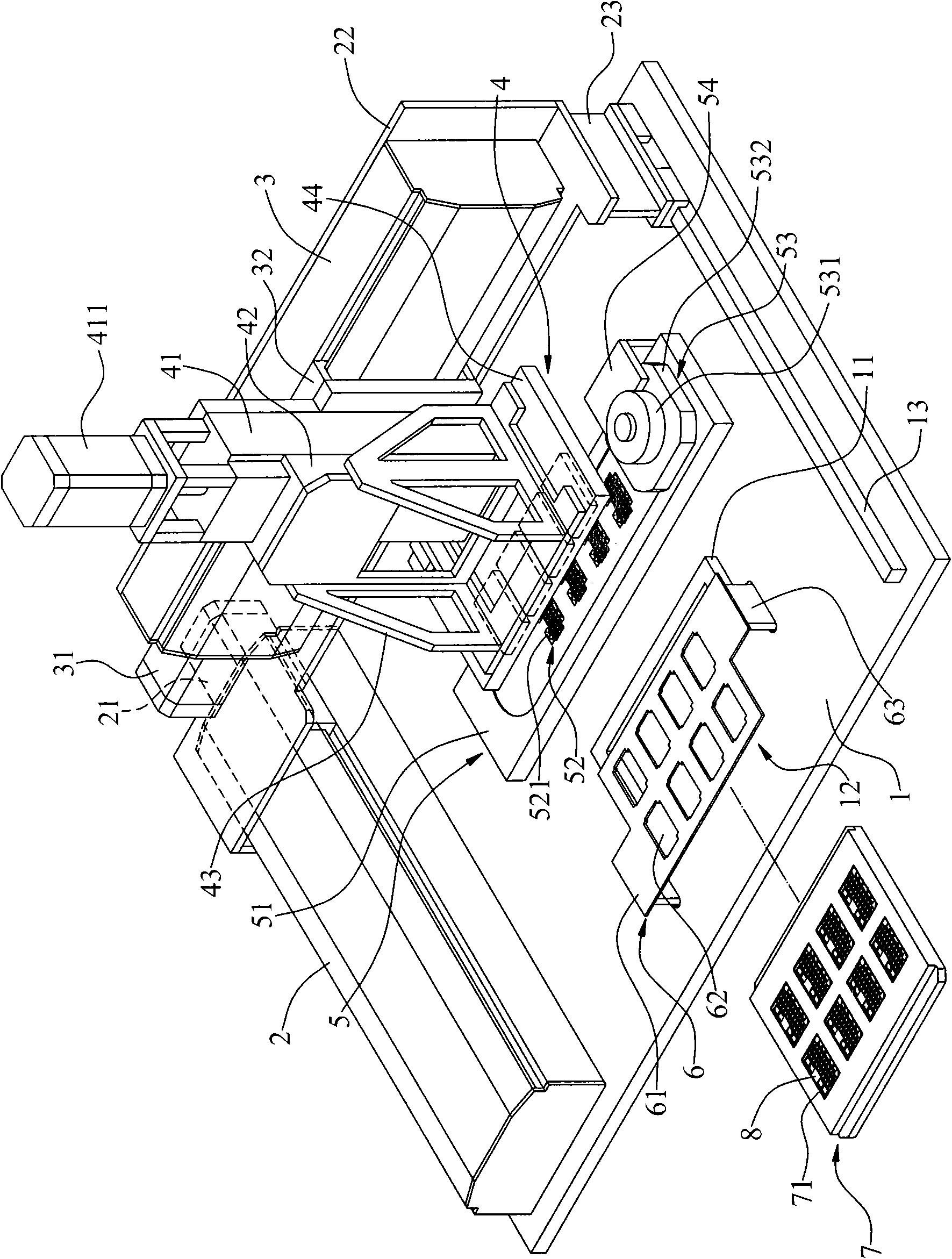

Transfer printing type glue dispensing method

InactiveCN101632980AUniform amount of glueSpraying apparatusSpecial surfacesTransfer printingOffset printing

The invention provides a transfer printing type glue dispensing method. The method comprises the following steps of: firstly, preparing a fixture plate and a glue dispenser; placing two or more glued objects on the fixture plate; sending the fixture plate into the glue dispenser; carrying out glue filling action with a glue storage mechanism of the glue dispenser; controlling a Z-axis moving mechanism on a transfer printing module to act with an external control box, and moving an anvil block on the transfer printing module to the glue storage mechanism to dip glue; controlling an X-axis moving mechanism and a Y-axis moving mechanism to act with a control box, and moving the transfer printing module dipped with the glue to the fixture plate; and driving the Z-axis moving mechanism on the transfer printing module with the external control box, and printing the glue dipped on the anvil block onto the glued objects.

Owner:ICHIA TECH

Method for producing whole eucalyptus plywood by using compound urea-formaldehyde resin against insects and mildew

ActiveCN106182218BReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAntioxidant

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

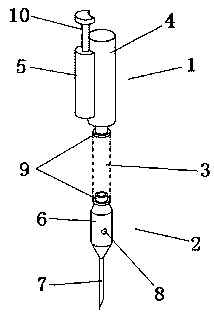

Manual air inflation and glue injection device for guitar processing

InactiveCN108970926ASimple structureEasy to holdLiquid surface applicatorsCoatingsAir compressionEngineering

The invention discloses a manual air inflation and glue injection device for guitar processing. The manual air inflation and glue injection device comprises an air compression section and a glue storage and injection section, and the air compression section and the glue storage and injection section are connected through a compressed air hose; the air compression section comprises a compression bin; an inflator pump is arranged on one side of the compression bin; the glue storage and injection section comprises a glue storage bin and a glue injection needle head; the glue injection needle headis arranged below the glue storage bin; and a glue injection switch is arranged on the glue storage bin; and a one-way valve is arranged at the joint of the air compression section and the compressedair hose as well as the joint of the glue storage and injection section and the compressed air hose. The manual air inflation and glue injection device has the advantages of being simple in structure, convenient to hold, convenient to use, capable of easily controlling the gluing amount, uniform in gluing, accurate in gluing position, capable of facilitating the gluing use at the corners and capable of improving the gluing quality of a guitar.

Owner:正安索尔乐器文化发展有限公司

Aluminum-plastic film bubble-free gravure coating device and coating technology thereof

The invention discloses an aluminum-plastic film bubble-free gravure coating device. The device comprises a material box. A dandy roll and a gravure roll are arranged on the upper portion of the material box from top to bottom in sequence. A first fixing block is arranged on one side of the gravure roll. A second fixing block is arranged on the other side of the gravure roll, and the first fixingblock and the second fixing block are arranged symmetrically. The top of the first fixing block is provided with a first scraper used for scraping off excessive slurry in mesh holes of the surface ofthe gravure roll. The top of the second fixing block is provided with a second scraper used for filling the mesh holes of the surface of the gravure roll with slurry. The mesh holes of the surface ofthe gravure roll sequentially pass through the material box, the first scraper, the dandy roll and the second scraper in sequence while rotating. According to the aluminum-plastic film bubble-free gravure coating device, by arranging the second scraper and the flowing slurry on the scraper, the mesh holes in the gravure roll can be filled with the slurry before the gravure roll enters below the slurry liquid level inside the material box, the problem that bubbles are mixed into the slurry is effectively solved, the transfer coating slurry feeding amount is uniform, and no missing coating occurs.

Owner:LIYANG EXCELLENCE NEW MATERIAL TECH CO LTD

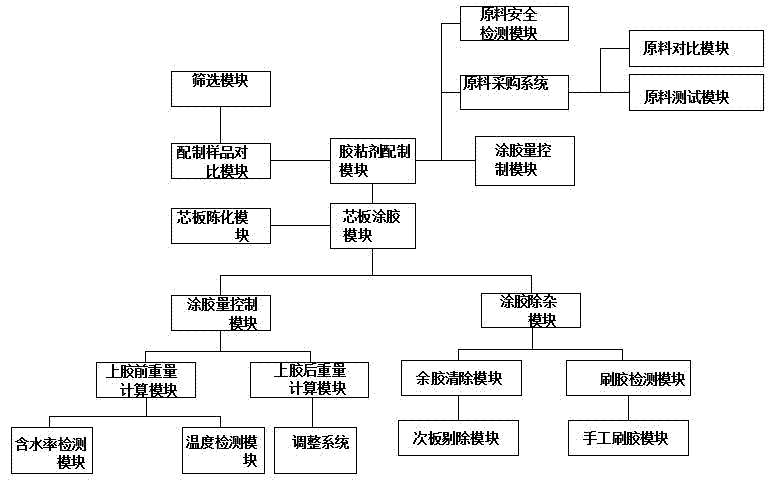

Gluing technology for plywood core veneer

InactiveCN107234686AImprove gluing qualityHigh strengthAdhesive application devicesEngineeringHigh intensity

The invention discloses a gluing technology for a plywood core veneer. A glue preparation module and a core veneer gluing module are included. The adhesive preparation module and the core veneer gluing module are matched with each other, excellent glue, a precise gluing strategy during gluing, and various kinds of correction and screening after gluing are provided for the plywood core veneer, and the high quality of preparation of the glue before gluing, and the high quality of the plywood core veneer after gluing are ensured; the situation that after gluing, a part of the core veneer is not glued or is over glued is avoided, and the high strength of adhesion of the plywood core veneer is ensured; a raw material purchasing system is connected with a raw material comparison module and a raw material test module, a raw material which is higher in quality and safer is provided for the glue used for being applied to the plywood core veneer, and the application safety of the glue and the gluing quality of the plywood core veneer are improved; a gluing and sundry removing module is connected with a surplus glue removing module and a glue brushing detection module, a veneer connection worker needs to remove sundries on the core veneer, the part which is not coated with glue needs to be glued manually, and the effect that the gluing amount is more uniform is ensured.

Owner:广西防城港市昌海木业有限公司

Method for producing full-eucalyptus parquet through dampproof composite urea resin

InactiveCN106239646AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesFiberPolyvinyl alcohol

A method for producing a full-eucalyptus parquet through dampproof composite urea resin comprises the following steps of wood board sheet rotary cutting, veneer drying, gluing, three-time cold pressing, standing curing, three-time hot pressing, heat dissipation curing, slab fixed-thickness sanding, base material surface layer gluing, curing slotting and spraying drying sizing. According to the key of the production method, melamine modified urea resin is adopted as a main adhesive material, and oxidized starch is added as a sticky complexing agent; polyvinyl alcohol serves as a toughening agent; magnesium oxide serves as an anti-aging agent; hexamine and triglycidyl isocyanurate serve as a curing agent; vinyltriethoxysilane serves as a bridging fiber agent; and phenolate lignin is the dampproof composite urea resin prepared through a formaldehyde capture agent and an added dampproof agent. The composite urea resin has the beneficial effects of being low in formaldehyde residual volume and good in water resistance and dampproof performance, so that the produced full-eucalyptus parquet is low in formaldehyde residual volume and is not prone to expansion after absorbing water, arching and deformation are not likely to happen, and an abrasion resisting layer is not prone to damage.

Owner:南宁市创锦胶合板有限责任公司

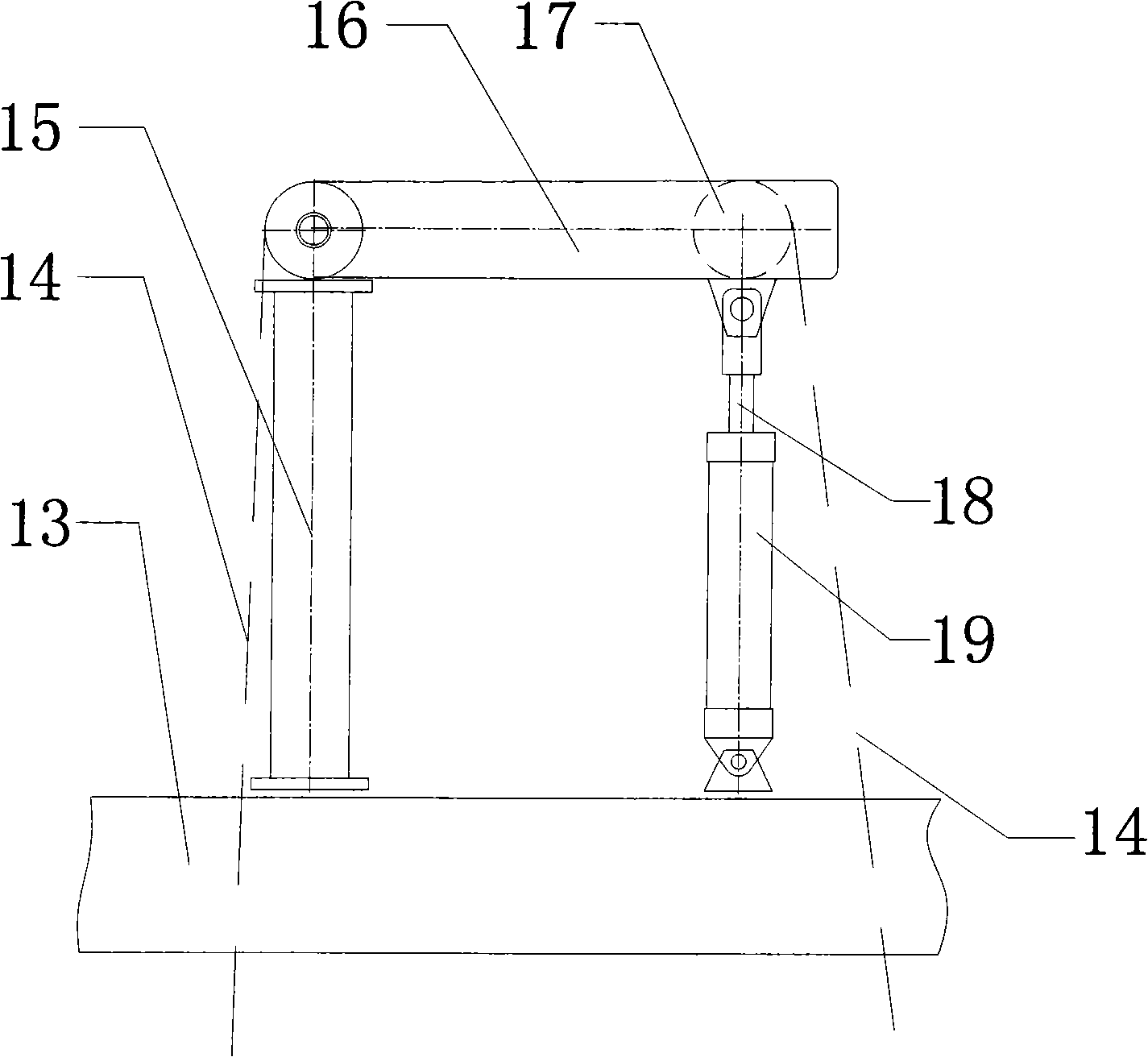

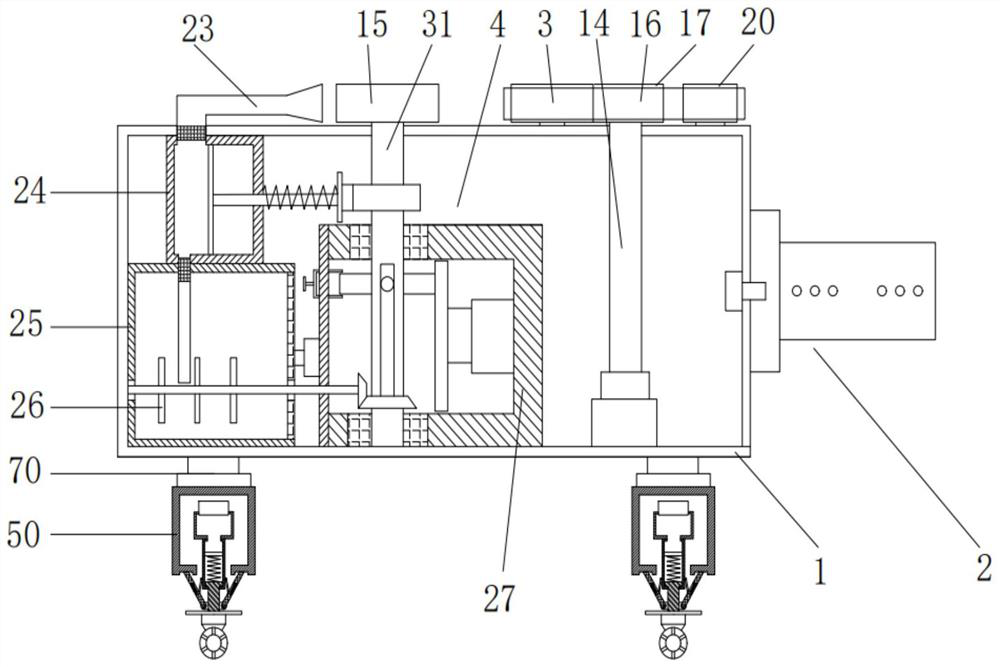

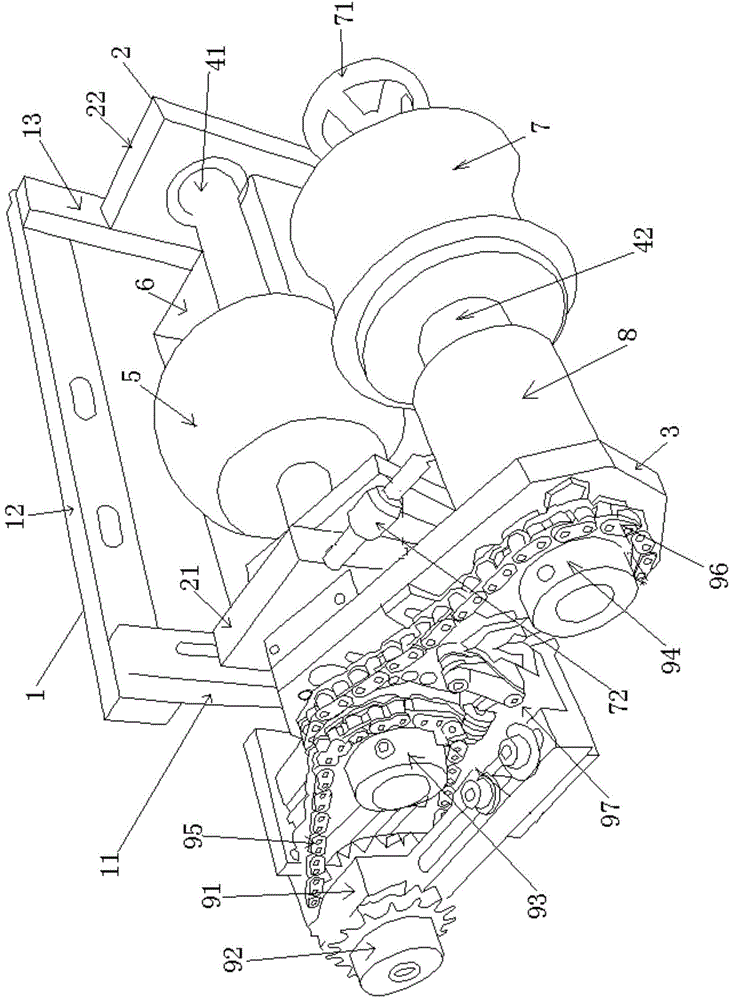

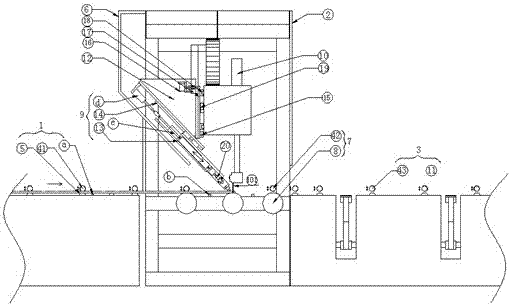

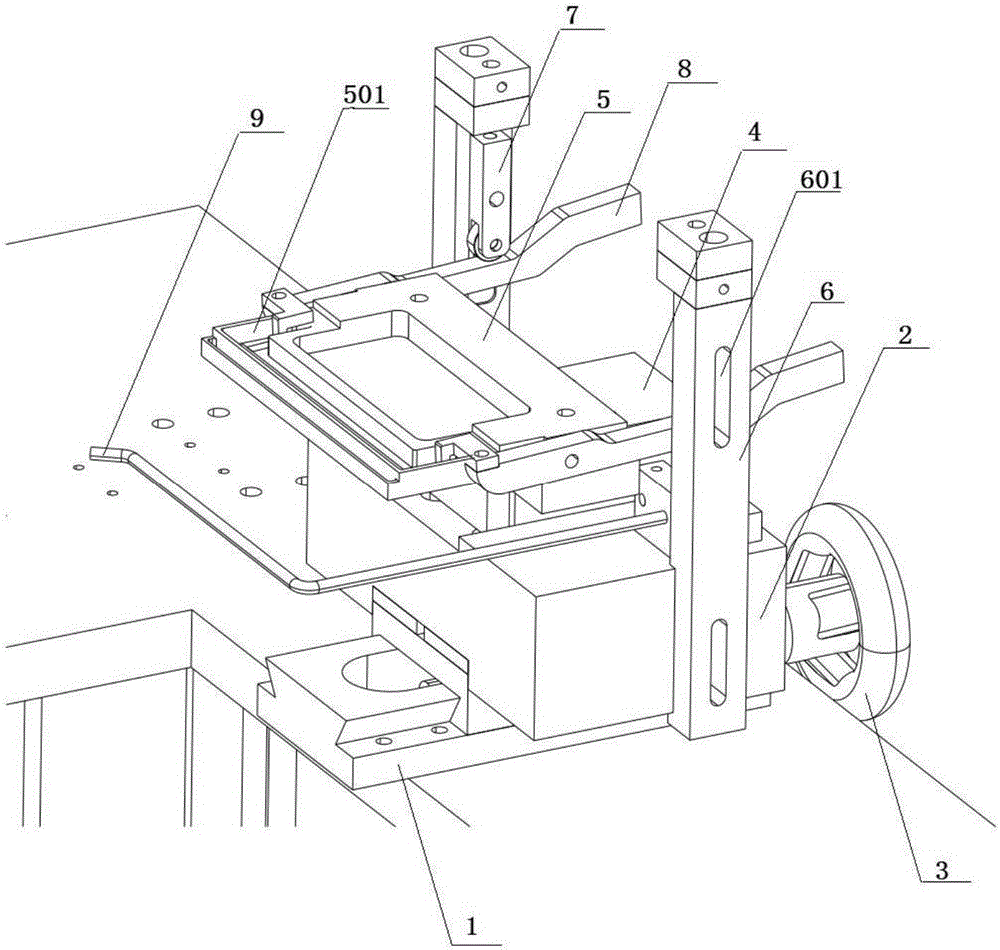

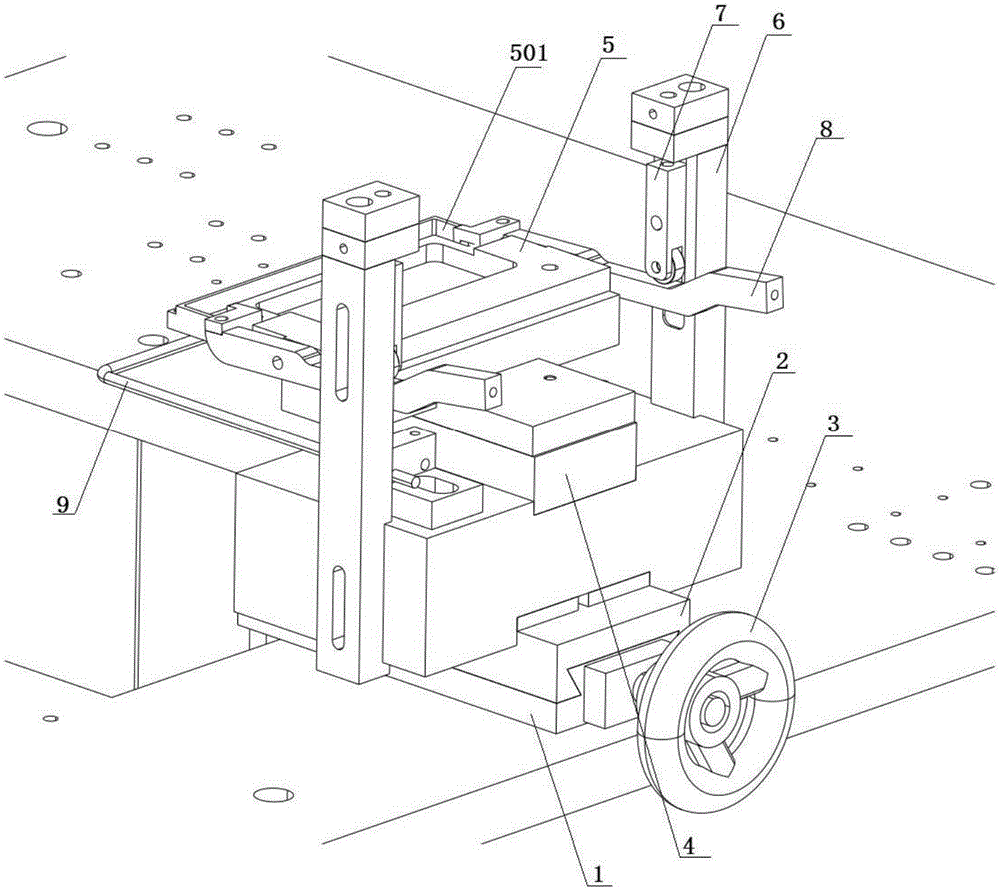

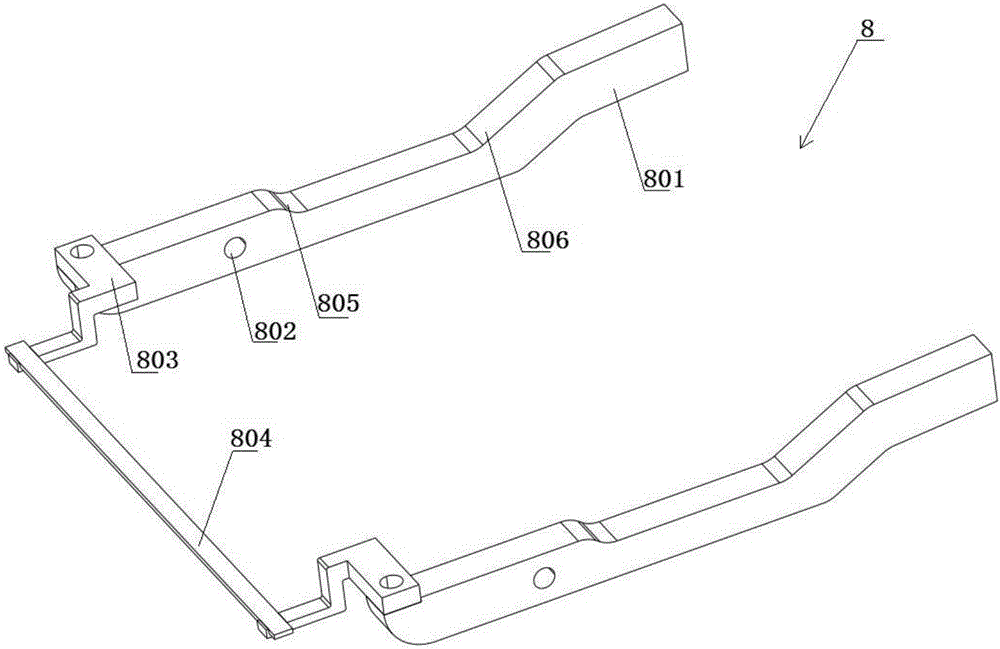

Top type prestress reinforcing machine used in field of building structure repairing and reinforcing

ActiveCN113047656ARealize automatic dischargeLow strength utilizationBuilding repairsFiberCarbon fibers

Owner:GUANGZHOU SHENGTE BUILDING TECH DEVCO

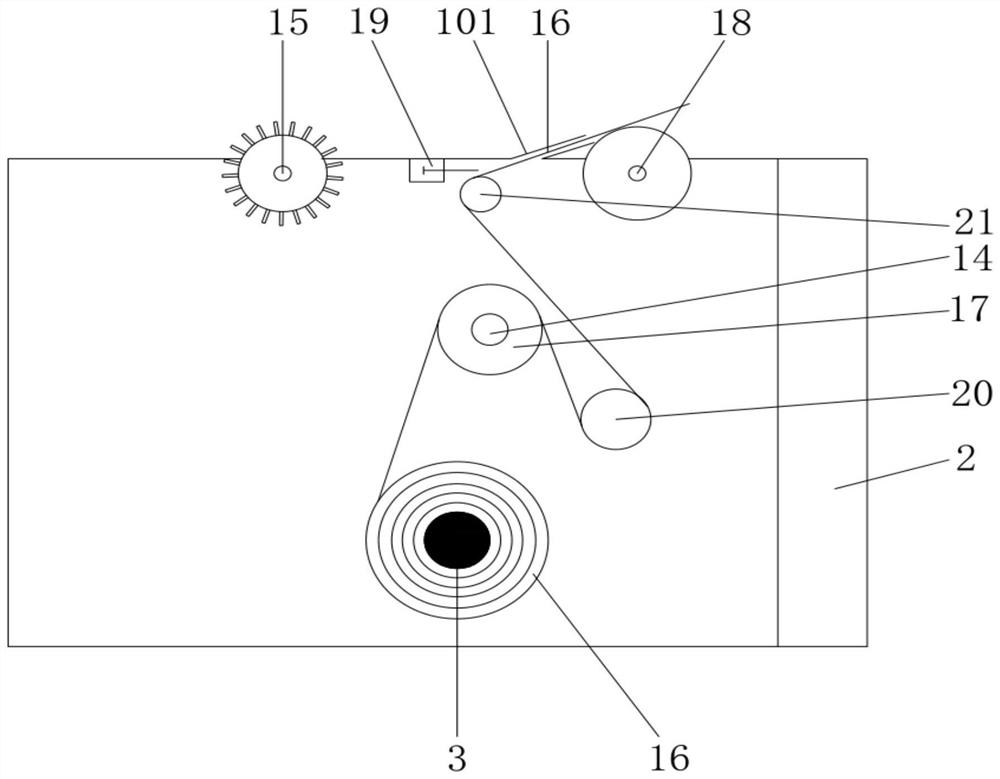

Bookbinding automatic glue spreader

InactiveCN105751726AReduce manpowerUniform amount of glueBookbinding adhesiveEngineeringMechanical engineering

The invention relates to a bookbinding automatic glue spreader which comprises a support, a first bed, a second bed, a first glue roller shaft, a steel roller, a glue box, a second glue roller shaft, a rubber roller, a shaft sleeve and a transmission gear.The transmission gear is positioned on the left side of the second bed and comprises a gear tension support, a first transmission gear, a second transmission gear, a third transmission gear, a steel roller transmission chain and a rubber roller transmission chain.According to the technical scheme, the bookbinding automatic glue spreader has the advantages that glue can be automatically applied to book spines and is uniform in glue application quantity, quality problems due to insufficient glue application quantities during manual operation can be solved, staffs can be reduced, the cost can be saved, and the production efficiency can be improved.

Owner:上海中华商务联合印刷有限公司

Method of producing full-eucalyptus wood plywood by adopting high-temperature resistance composite urea-formaldehyde resin

InactiveCN106239644AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAntioxidant

The invention discloses a method of producing full-eucalyptus wood plywood by adopting high-temperature resistance composite urea-formaldehyde resin. The method comprises the following steps: rotary cutting a wood board into a sheet; drying a veneer; gumming; cold pressing for three times; standing, and curing; hot pressing for three times; carrying out heat dissipation and curing; and defining the thickness of a board blank and sanding. The production method has the key points that melamine modified urea-formaldehyde resin is adopted as a major ingredient of an adhesive, and oxidized starch is added as a viscous complex additive; polyvinyl alcohol is taken as a toughening agent; hydrogenated rosin is taken as an antioxidant; polyisocyanate is taken as a curing agent; isobutyltriethoxysilane is taken as a bridging agent; and phenolized lignin is taken as a formaldehyde scavenger, and then a high-temperature resistance filler is added to prepare the high-temperature resistance composite urea-formaldehyde resin. By using the high-temperature resistance composite urea-formaldehyde resin prepared by the method to be used for producing the full-eucalyptus wood plywood, the full-eucalyptus wood plywood is excellent in heat resistance and does not have obvious cracking phenomenon under high temperature, high-strength ultraviolet irradiation or long-time ultraviolet irradiation, thus the economic loss is reduced.

Owner:南宁市创锦胶合板有限责任公司

A single-sided machine gluing roller

ActiveCN104209237BUniform temperatureExtended service lifeLiquid surface applicatorsCoatingsCardboardShrink-fitting

The invention discloses a novel single facer glue spreading roller. The novel single facer glue spreading roller comprises a hollowed cylinder, and shaft heads fixedly and tightly connected with the two ends of the cylinder, wherein the cylinder and the shaft heads are connected through shrink-fitting and welding; annular grooves are formed in the outer end surfaces of the shaft heads; liquid injecting holes are evenly distributed in the grooves; a closed hollow liner is arranged in the cylinder; the two ends of the liner are fixedly connected with the inner wall of the cylinder through annular pipe plates; inner rings of the annular pipe plates are arranged around the liner, and are fixedly welded with the surface of the liner; through holes are evenly distributed in the circular surfaces of the annular pipe plates; the length and the end surface diameter of the liner are both smaller than the length and the end surface diameter of the cylinder; and a liquid injecting space is formed between the outer wall of the liner and the inner wall of the cylinder. The novel single facer glue spreading roller has the following beneficial effects: (1) the surface temperature of the glue spreading roller is uniform to reduce the friction with a corrugated roller; (2) the service lives of the corrugated roller and the gluing roller are prolonged; the spread of glue is uniform; and the paperboard quality is high; and (3) the replacement frequency of glue in a glue tray is largely reduced, so that the cost is decreased.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

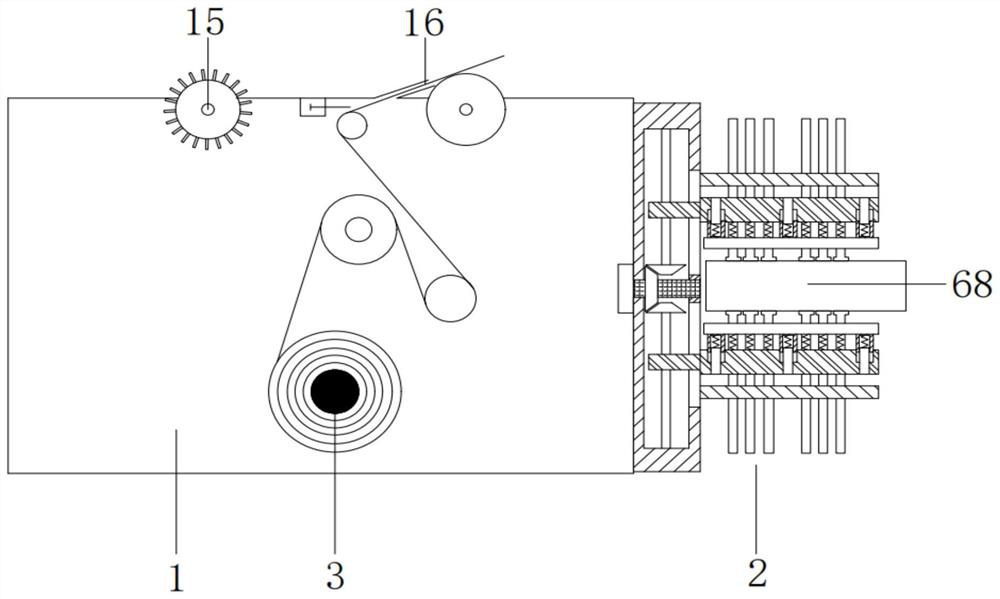

Sheet automatic glue coating machine

ActiveCN105197590BUniform amount of glueSqueegee evenlyArticle feedersConveyor partsComputer control systemElectricity

Fully automatic gluing machine for sheet materials, including a feeder, a host, a discharge turning device, and a computer control system. The feeder includes a conveying wheel and a pressure wheel placed above the conveying wheel. It is characterized in that the host The frame, the conveying part, also includes a multi-degree-of-freedom glue spraying assembly connected to the frame that can move laterally and rotate with a fixed axis, and a squeegee assembly that can move vertically on the frame. The host part is also equipped with sensor The sensing element b of the plate position, the discharge turning device is connected with the conveying part, and the computer control system is electrically connected with the feeder, the host and the discharging turning device for motion detection and control. The present invention can complete the board gluing process without manual operation, fully automatic feed gluing, scraping, and automatic plate turning, and can ensure that the amount of glue applied to each batch of boards is uniform and appropriate while completing the gluing work quickly and automatically , squeegee evenly; and the equipment can be applied to a variety of boards of different sizes.

Owner:苏州市锲镒机械科技有限公司

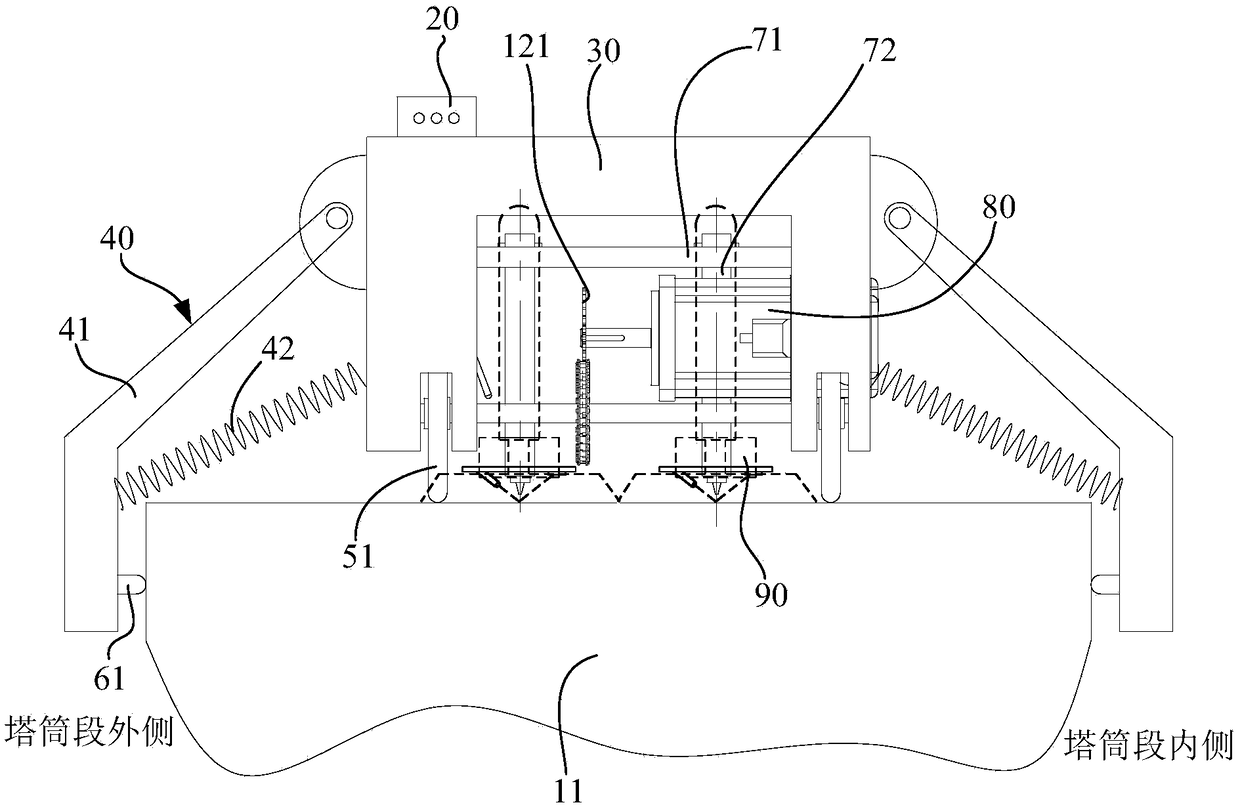

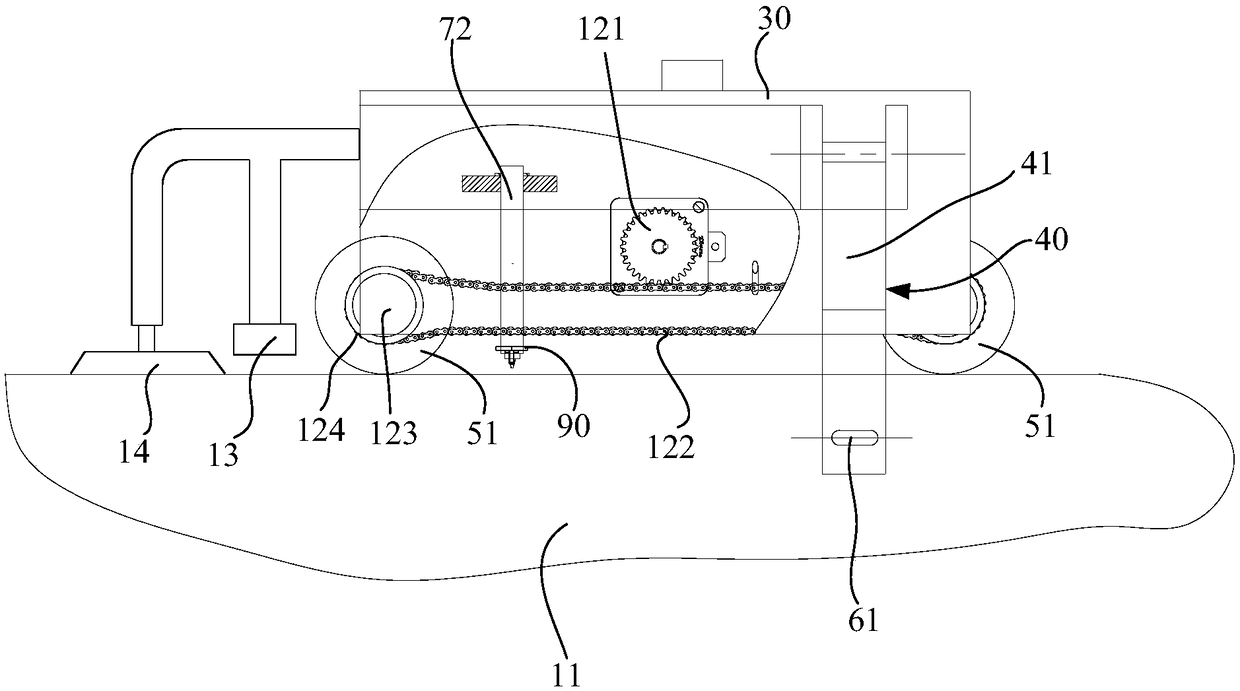

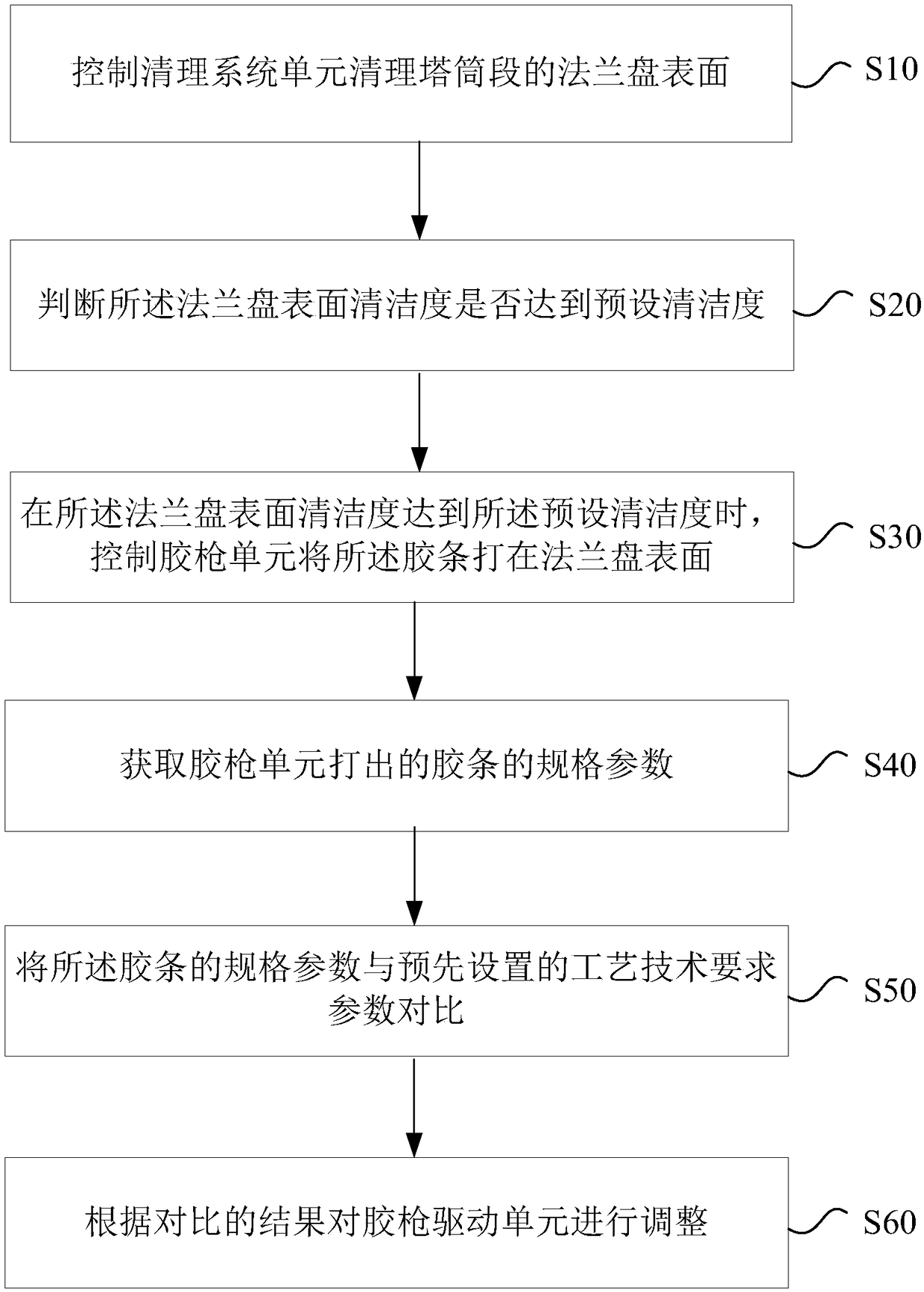

Gluing device, gluing system and gluing method

ActiveCN109013190AImprove sealingAvoid the problem of inconsistent sealingPretreated surfacesCoatingsElectricityAutomatic control

The invention relates to the technical field of wind power, in particular to a gluing device, a gluing system and a gluing method. The gluing device comprises a bracket platform unit, a glue gun unit,a power driving unit mounted on the bracket platform unit and used for driving the gluing device to move along the surface of a flange plate of a tower cylinder section, and an oriented rotating unitfor limiting a moving trajectory of the gluing device on the surface of the flange plate; through arrangement of the bracket platform unit, an automatic glue gun capable of automatically providing glue bars is mounted on the bracket platform unit; meanwhile, the power driving unit and the oriented rotating unit are provided, so that the gluing device moves along the given moving trajectory, and the automatic glue gun can uniformly pave the glue bars on the surface of a tower cylinder; and compared with a manual gluing mode, as the human factor influence is eliminated, the gluing procedure isautomatically controlled, the gluing quantity is more uniform, the problem of different tightness of one circle of the tower cylinder is prevented, and the tightness performance of the tower cylinderis improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

A gravure gluing device and gluing method for fancy reflective fabric with large patterns

ActiveCN106334649BUniform thicknessEven amount of glueLiquid surface applicatorsCoatingsTransmission channelLight reflection

The invention discloses a gravure gluing apparatus of a large pattern of a fancy light reflection fabric. The apparatus comprises an upper pressure roller, a gravure gluing roller, a glue scraper knife and a glue supply mechanism, the upper pressure roller and the gravure gluing roller are arranged up and down, a transmission channel is arranged between the upper pressure roller and the gravure gluing roller, a bead planting membrane is in contact with the roller surface of the upper pressure roller and the gravure gluing roller respectively, the glue scraper knife is positioned at one side of the gravure gluing roller, the glue scraper knife is in contact with the surface of the gravure gluing roller, the surface of the gluing roller is provided with a printing pattern, the printing pattern is composed of a plurality of uniformly-distributed isotropic gluing grooves used for accommodating printing glue, and the bottom of the gravure gluing roller is placed in the glue supply mechanism and is in contact with the glue in the glue supply mechanism. The apparatus can effectively solve the problems of glue spilling and glue discontinuity, allows the thickness of a glue layer to be uniform, has no restriction on the size of the printing pattern, and can be used to produce large-pattern products. The invention also provides a gluing method of the large pattern of the fancy light reflection fabric. The method has the advantages of simple steps, good production continuity and suitableness for industrial production.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

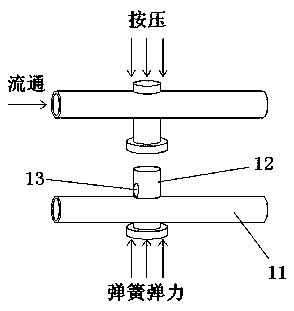

Glue dispensing device of head rope machine

InactiveCN106513246AReasonable designAdhesion enoughLiquid surface applicatorsCoatingsEngineeringHolding tank

The invention discloses a glue dispensing device of a head rope machine. The device comprises an adjustable base, an extension part, a glue holding disc and a glue hoisting frame; the extension part is fixed on the adjustable base; the glue holding disc is fixed on the extension part; the glue hoisting plate at the front end of the glue hosting frame is positioned in a glue holding tank in front of the glue holding disc; fixed rods are arranged on two sides of the adjustable base; limiting parts are arranged on one opposite sides of the two fixed rods; the glue hoisting frame is hinged to two sides of the glue holding disc; and the limiting parts are butted against two sides of the glue hoisting frame. The glue dispensing device of the head rope machine is reasonable in design, guarantees attachment of enough glue at the end parts of head ropes through synchronous matching between front-back movement of the glue holding disc and hoisting-descending of the glue hoisting plate, is uniform in glue loading quantity, and cannot generate the condition of excessive or insufficient gluing.

Owner:JINHUA SHENGCHANG MACHINERY

Method for producing all-eucalyptus solid wood composite floor by corrosion-resistance composite urea resins

InactiveCN106239645AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAdhesive

The invention discloses a method for producing an all-eucalyptus solid wood composite floor by corrosion-resistance composite urea resins. The method comprises the steps of: board rotary slicing-veneer drying-gluing-three times of cold pressing-standing maintenance-three times of hot pressing-cooling maintenance-blank fixed-thickness sanding-substrate surface layer gluing-maintenance grooving-paint drying shaping. The key point of the method is to adopt melamine modified urea resins as a main material of adhesive; oxide starch is added as a viscous compounding agent; polyvinyl alcohol serves as a toughening agent; hydrogenated rosin serves as antioxidant; polyisocyanate serves as a curing agent; isobutyltriethoxysilane serves as a bridging agent; phenolated lignin serves as a formaldehyde capturing agent; and a preservative is added to prepare the corrosion-resistance composite urea resins; and the solid wood composite floor produced by the corrosion-resistance composite urea resins has the advantages of low formaldehyde residual volume and good corrosion resistance, is better in resistance on wood rotting fungus, mould and termites, and prolongs the service life of the all-eucalyptus solid wood composite floor.

Owner:南宁市林润木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com