Winding moulding fiber-reinforced polyimide resin prepreg tape and preparation method and application thereof

A technology of polyimide resin and polyimide, which is applied in fiber-reinforced polyimide resin prepreg tape for winding molding and its preparation and application field, to achieve excellent heat resistance, low solvent residue, and improved melting The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

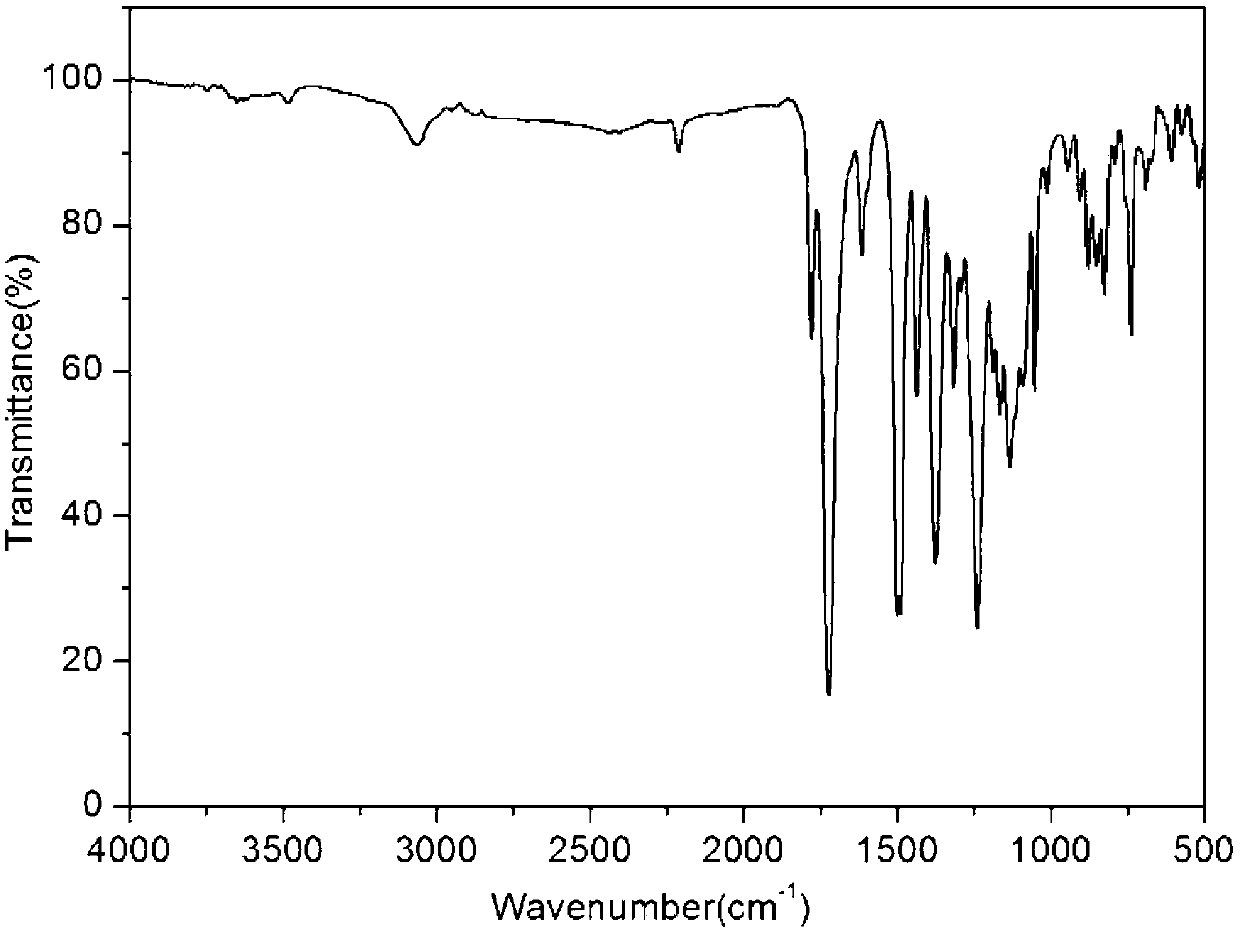

Embodiment 1

[0051] In a three-neck round bottom flask equipped with mechanical stirring, water separator, nitrogen inlet and outlet, and thermometer, add 35.90 g (0.08 mole) of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy) Benzene (6FAPB), 16.78 g (0.08 mol) of 4,4'-diaminodiphenyl ether (4,4'-ODA) and 241.17 ml of N-methylpyrrolidone (NMP), stirred until completely dissolved under nitrogen protection , add 43.43 g (0.15 mole) of 2,3,3',4'-biphenyltetralic acid dianhydride (α-BPDA) and 9.93 g (0.04 mole) of 4-phenylethynylphthalic anhydride (PEPA), and stir until completely dissolved , to obtain a homogeneous solution with a solid content of 30wt.%. 18 milliliters of toluene was added in the above-mentioned homogeneous solution, and the reaction system was warmed up to 180° C. after reacting for 10 hours, the toluene was evaporated, and the heating was stopped. The reaction solution was cooled to 80°C and then poured into ethanol, the precipitated fibrous crude product was collected, washe...

Embodiment 2

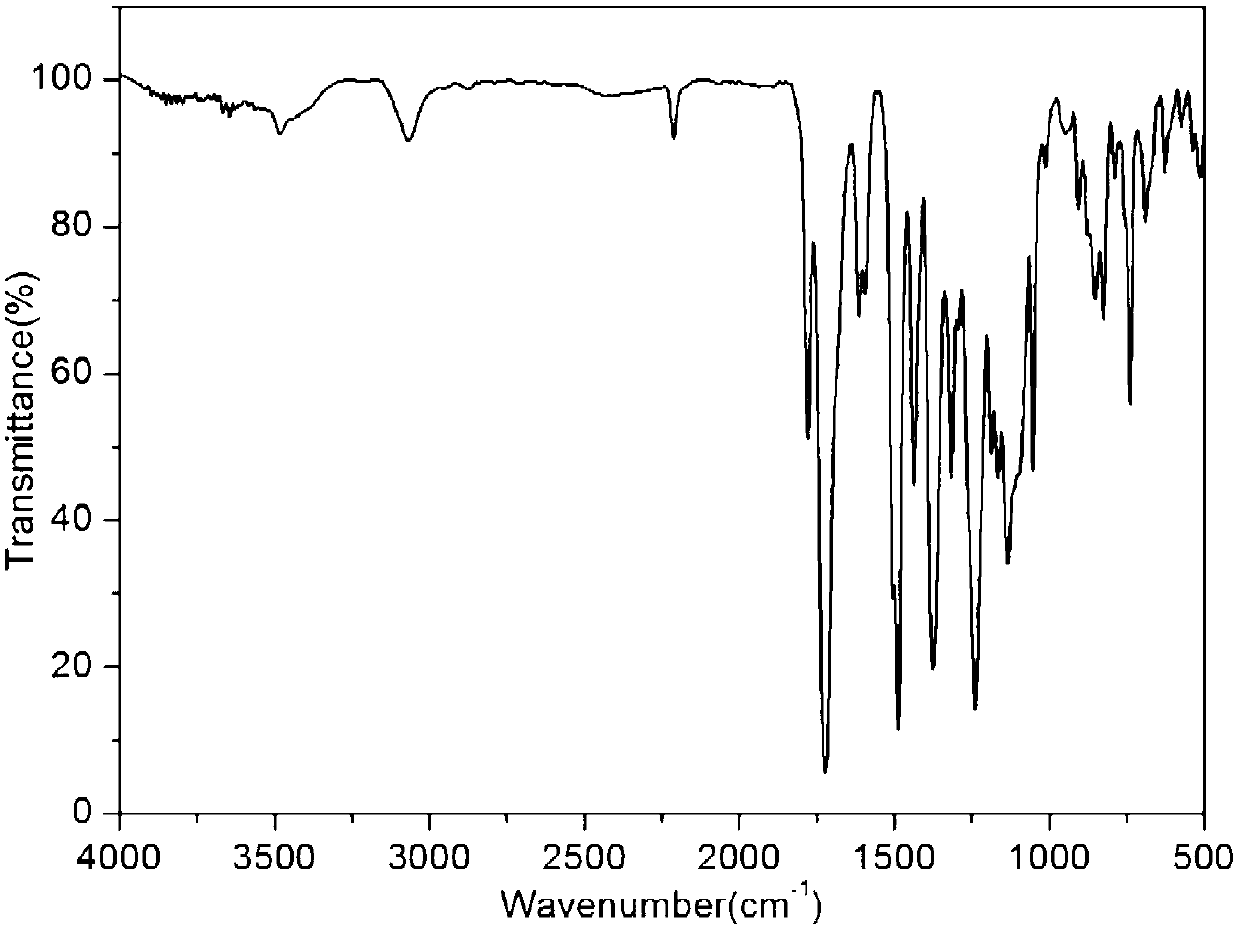

[0055] In a three-neck round bottom flask equipped with mechanical stirring, water separator, nitrogen inlet and outlet, and thermometer, add 130.78 grams (0.31 moles) of 1,4-bis(4'-amino-2'-trifluoromethylphenoxy)benzene (6FAPB), 30.57 g (0.15 mol) of 3,4'-diaminodiphenyl ether (3,4'-ODA) and 501 ml of N-methylpyrrolidone (NMP), stirred under nitrogen until completely dissolved, Add 105.33 grams (0.36 moles) of 2,3,3',4'-biphenyltetralic acid dianhydride (α-BPDA) and 49.65 grams (0.20 moles) of 4-phenylethynylphthalic anhydride (PEPA), stir until completely dissolved, A homogeneous solution with a solid content of 30 wt.% was obtained. 40 milliliters of toluene was added in the above-mentioned homogeneous solution, and the reaction system was warmed up to 180° C. after 12 hours of reaction, the toluene was evaporated, and the heating was stopped. Cool the reaction solution to about 60°C and pour it into the mixture of ethanol and water (the mixing volume ratio is 2:1), colle...

Embodiment 3

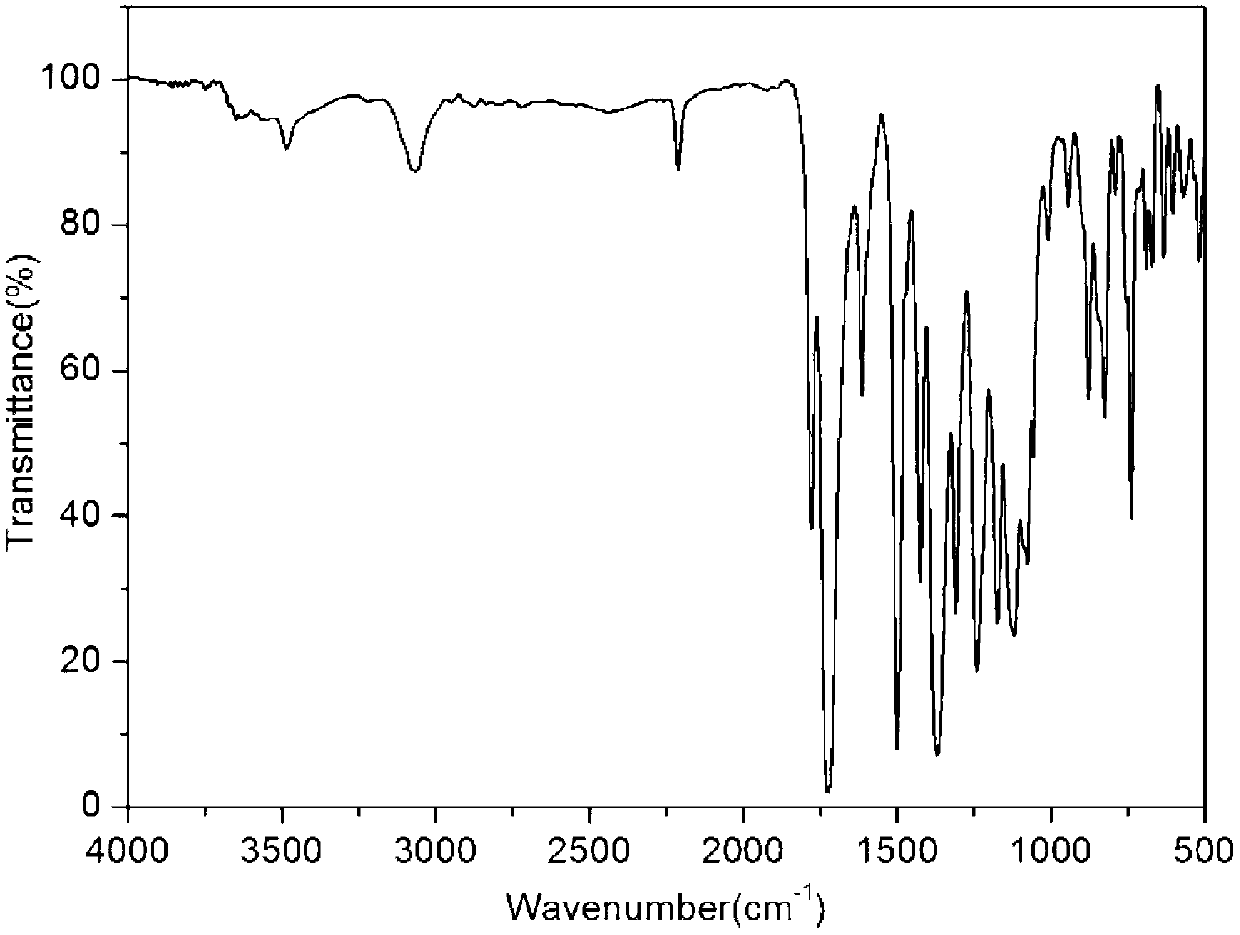

[0059] In a three-neck round bottom flask equipped with mechanical stirring, water separator, nitrogen inlet and outlet, and thermometer, add 86.41 g (0.27 moles) of 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (TFDB) , 54.03 g (0.27 mol) of 4,4'-diaminodiphenyl ether (4,4'-ODA) and 740 ml of N-methylpyrrolidone (NMP), stirred under nitrogen protection until completely dissolved, then added 129.36 g (0.44 mol) 2,3,3',4'-biphenyltetraacid dianhydride (α-BPDA) and 49.65 g (0.20 mol) 4-phenylethynylphthalic anhydride (PEPA), stirred until all dissolved to obtain solid content It is a homogeneous solution of 30wt.%. 70 milliliters of toluene was added in the above-mentioned homogeneous solution, and the reaction system was warmed up to 180° C. after reacting for 12 hours, the toluene was evaporated, and the heating was stopped. Cool the reaction liquid to 60°C and pour it into the mixture of methanol and water (the mixing volume ratio is 1:1), collect the precipitated fibrous cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com