Manual air inflation and glue injection device for guitar processing

A technology of gluing device and guitar, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of cumbersome gluing and replenishing operations, uneven gluing, and difficulty in controlling the amount of gluing. The amount is easy to control, the position of the glue is accurate, and the effect of avoiding the backflow of the glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

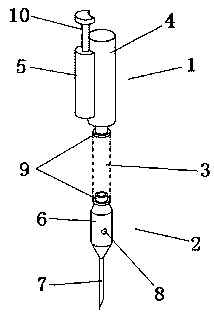

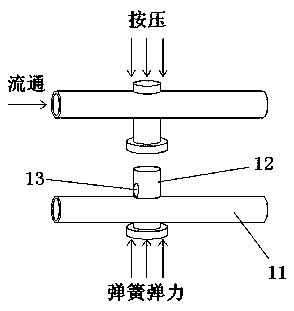

[0016] Example. A manual air-filled glue injection device for guitar processing, such as figure 1 and figure 2 As shown, it includes an air compression section 1 and a rubber storage injection section 2. The air compression section 1 and the rubber storage injection section 2 are connected by a compressed air hose 3; the air compression section 1 includes a compression chamber 4, and one side of the compression chamber 4 is provided There is an inflatable cylinder 5; the glue storage injection section 2 includes a glue storage bin 6 and a glue injection needle 7; the glue injection needle 7 is arranged under the glue storage bin 6, and a glue injection switch 8 is arranged on the glue storage bin 6; the air A one-way valve 9 is provided at the connection between the compression section 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com