Patents

Literature

140results about How to "Good gluing properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

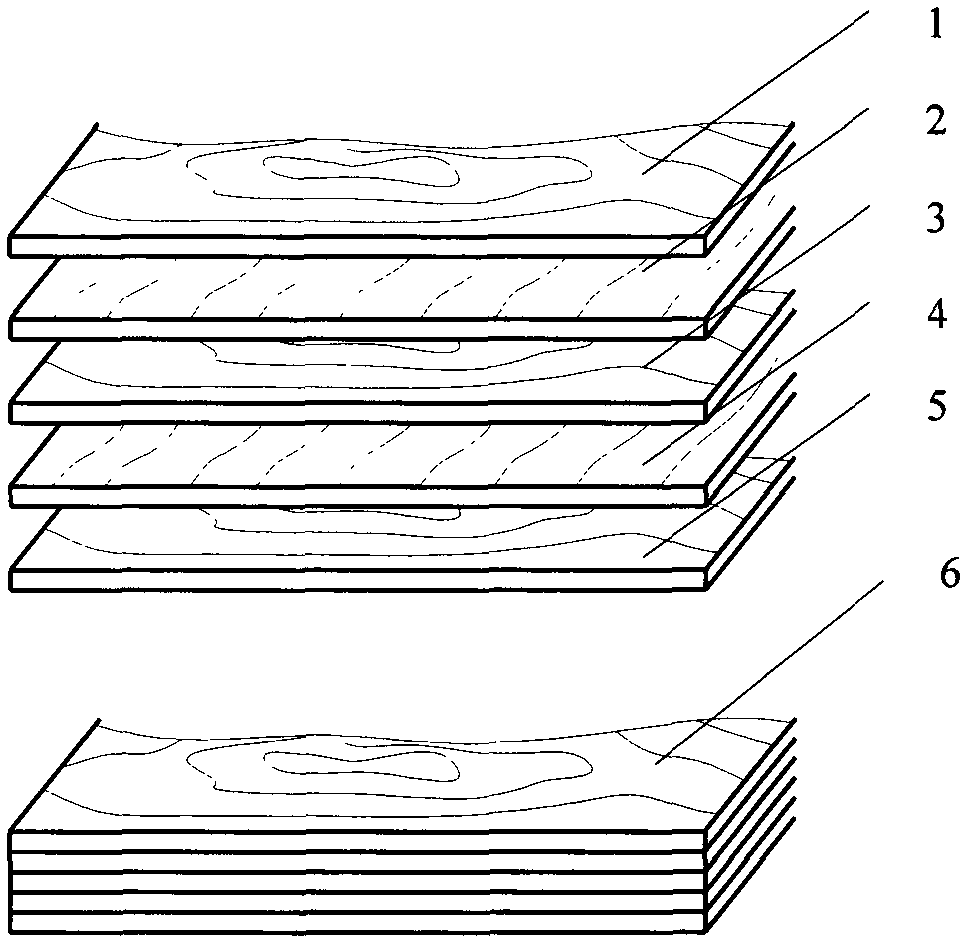

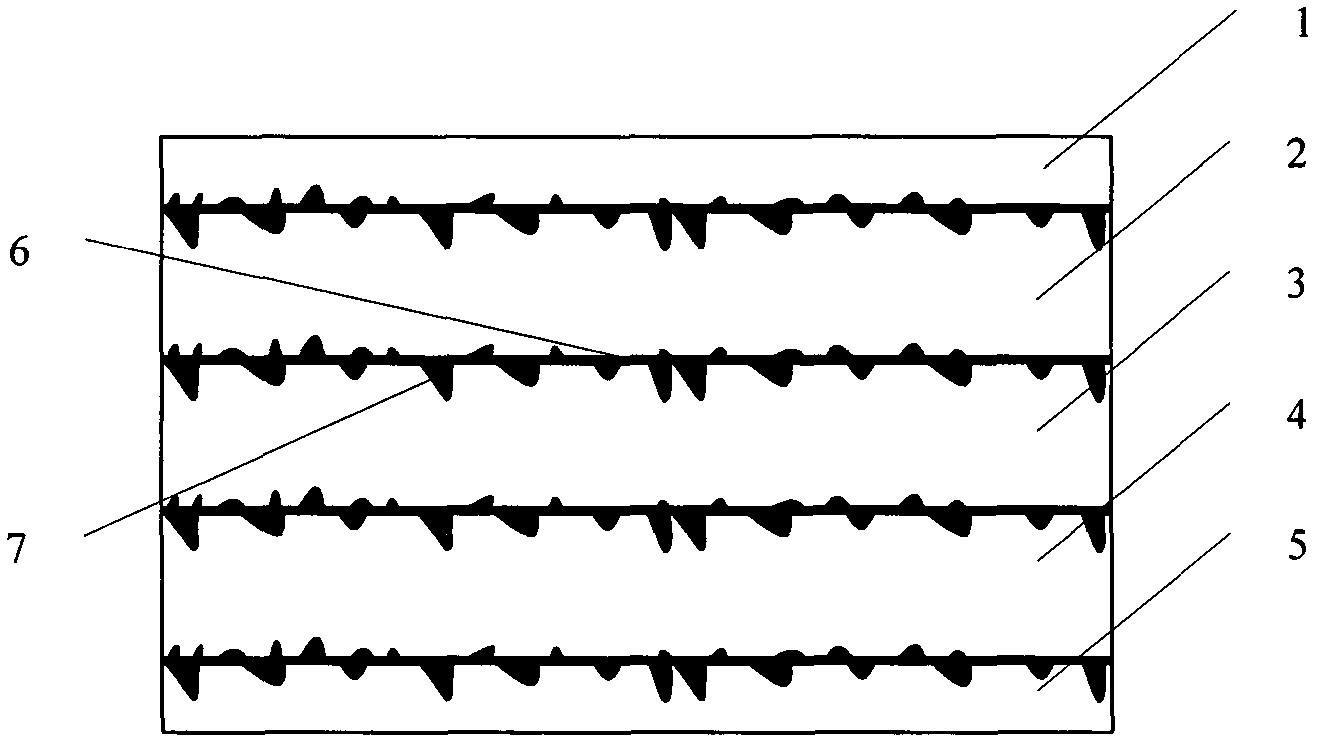

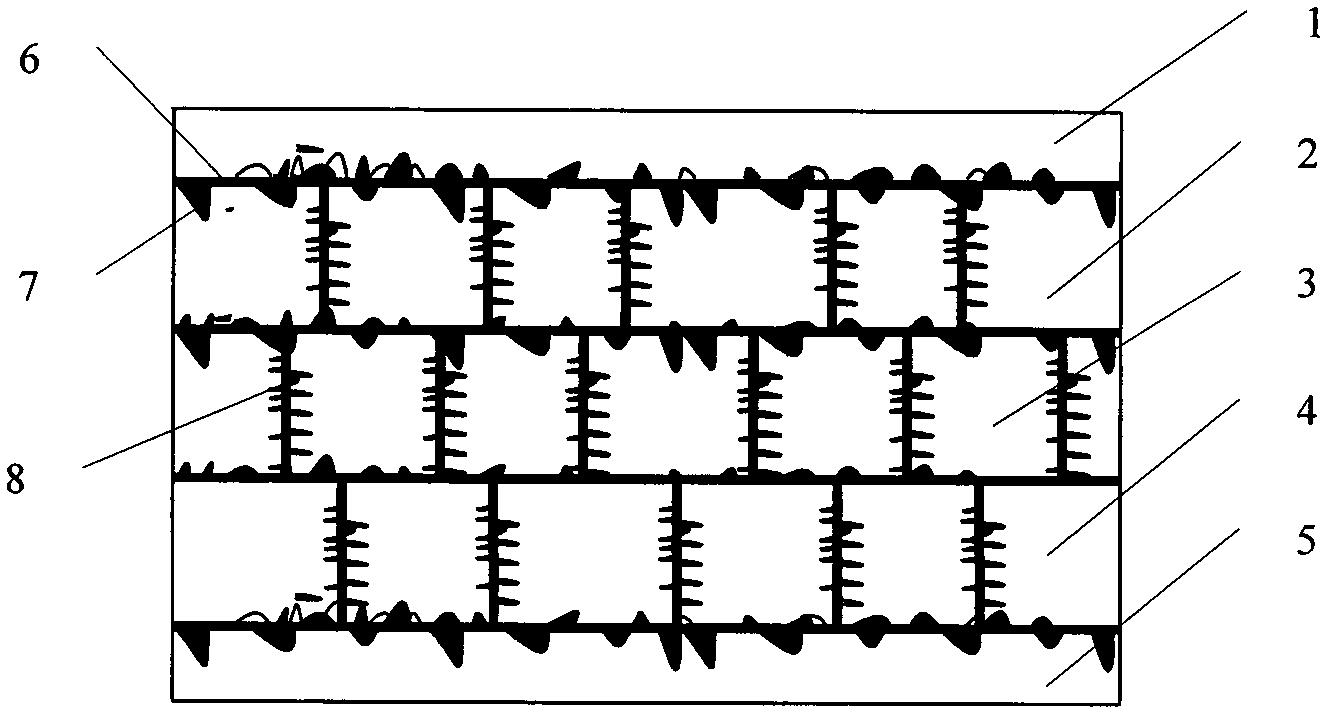

Gluing method for wood veneer

InactiveCN103072161AGood gluing propertiesHigh strengthLaminationLamination apparatusWood veneerPunching

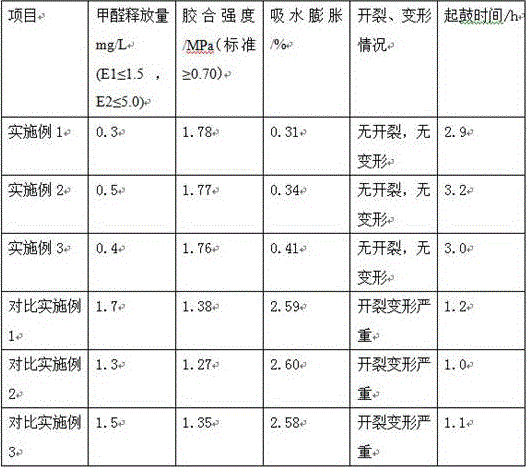

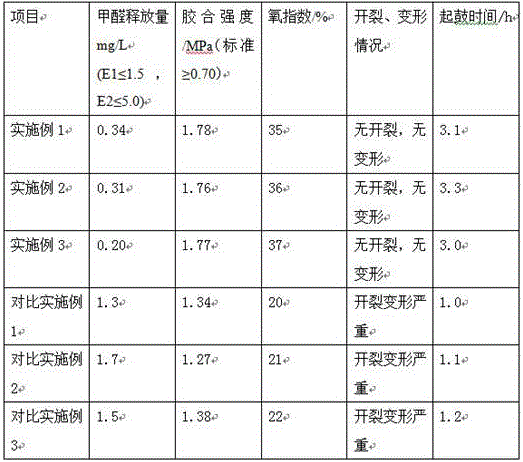

The invention discloses a gluing method for a wood veneer. The wood veneer which is manually punched is used as a basic constitution unit and a to-be-glued object. The wood veneer is subjected to random or regular punching treatment along the thickness direction of the veneer by adopting the mechanical methods of drilling and punching or physical methods of laser drilling and microwave drilling, and the size, shape, depth and number of holes are not limited. The wood veneer which is subjected to punching is glued, the adjacent glue layers are connected together to form a three-dimensional reticular-layered glue layer composite structure, mechanical rivet force is formed, and the gluing strength is accordingly improved. Glue liquid penetrates into the wood veneer via the periphery of manually holes, and the body strength of the wood veneer is strengthened. A manufacturing method of the wood veneer comprises the following steps of (1) veneer manufacturing; (2) veneer drying; (3) veneer glue application; (4) assembly; (5) gluing; and (6) post treatment. The wood veneer manufactured by the gluing method has the characteristics of high gluing strength, good water resistance, high compressive strength and good size stability.

Owner:唐忠荣

Flame-retardant decorative plate, preparation method thereof and flame-retardant material comprising flame-retardant decorative plate

ActiveCN102756404AImprove flame retardant performanceGood gluing propertiesFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesAdhesivePyrophosphate

The invention provides a flame-retardant decorative plate and a preparation method thereof. The flame-retardant decorative plate comprises a plate component and a flame-retardant adhesive layer which is at least attached on at least one side surface of the plate component in the thickness direction and formed by an adhesive containing a flame-retardant adhesive, the plate component at least comprises a layer of wood veneer, the flame-retardant adhesive contains water-soluble amine resin, a dehydration catalyst, a char forming agent and auxiliaries, and the flame-retardant adhesive contains water or does not contain the water; the dehydration catalyst is selected from one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate; and the degree of polymerization of the ammonium polyphosphate is above 20. The invention further provides a flame-retardant material. The gluing performance of the flame-retardant decorative plate prepared by the method disclosed by the invention can meet the requirements of national standard and the flame retardance can be given to a base material; furthermore, the mechanical properties of the base material can not be affected, the formaldehyde release amount is also above E1 grade, and the flame-retardant decorative plate is safe and environment-friendly; and simultaneously, the natural texture of wood is kept and the decorative effect is good.

Owner:固安盛辉阻燃材料有限公司

Method for producing multi-layer board using poplar board, enzyme treated lumber and stalk fibre

InactiveCN101439525AExpand sourceImprove bonding performanceCane mechanical workingWood veneer joiningFiberHigh density

The invention relates to a method for manufacturing a multilayer board by a poplar veneer, enzyme treated wood and straw fiber. The method is characterized by comprising the following steps: (1) manufacturing wood fiber; (2) manufacturing the straw fiber; (3) processing the wood and the straw fiber by enzyme; (4) manufacturing a high-density fiber board; and (5) assembling and compregnating the poplar veneer and the fiber board into the multilayer board. The method has the advantages of improving the bonding performance by the enzyme treated wood and straw fiber, manufacturing the high-density fiber board by the enzyme treated wood and straw fiber, being capable of enlarging material sources of the multilayer board by manufacturing the multilayer board by replacing part of the veneers, and using the wood felling and processing remainders and crop straw materials. The enzyme treated wood and straw fiber improve the wetting property of the multilayer board (a surface contact angle is reduced by 10-20%), improve the bonding performance and reduces the application amount of urea formaldehyde resin adhesive by 6-8%. Generally, the application amount of urea formaldehyde resin adhesive is 10-14%.

Owner:NANJING FORESTRY UNIV

Treatment method for wood surface defects

InactiveCN102632528AWon't fall offPromote infiltrationIrregularity removal devicesPolymer scienceAdhesive

The invention provides a treatment method for wood surface defects. The treatment method comprises the following steps: (1) cleaning up wood surface defect parts; (2) spraying or wetting the peripheries of the defect parts by using alcohol, an acrylic paint or an adhesive; (3) coating the defect parts by directly using the acrylic paint / the isocyanate adhesive or firstly filling in repairing putty and then coating by using the acrylic paint / the isocyanate adhesive; (4) carrying out indoor natural surface drying for over 3 hours or after baking for 20-120 minutes at the temperature of 30-80 DEG C for complete curing, carrying out light sand treatment on the surface for painting to enable the adhesive or paint to evenly penetrate into the defects so as to achieve a better bonding effect, and ensure that the defect parts cannot crack again in the using process of a repaired wood board, and the acrylic paint and the isocyanate adhesive do not have volatility, thus not polluting the environment and being environmentally-friendly.

Owner:GUANGDONG YIHUA TIMBER IND

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

Medical stone ceramic product and preparation method thereof

The invention discloses a medical stone ceramic product prepared from the following raw materials in percentage by weight: 41-45% of medical stone powder, 16-20% of potassium feldspar powder, 10-14% of soda feldspar powder, 8-10% of quartz powder and 12-17% of Laiyang soil. The preparation method comprises the following steps: weighing raw materials in percentage by weight, grinding and filtering the raw materials by a sieve with the granularity of 100-150 meshes, and uniformly mixing for later use; grinding the powder in a ball miller for 1-2 hours according to the condition that the ratio of the material to balls to water is 1:2:0.5, filtering mud through a sieve with the granularity of 32-35 meshes, and pugging to obtain a finished mud product; performing slip-casting, demoulding, correcting and grinding, and drying for 12-24 hours; sintering a dried mud blank in a furnace in steps and cooling to obtain the required product. The medical stone ceramic product is reasonable in material proportion and scientific in sintering method, so that the medical stone has improved performance, good air permeability and high plasticity, and the yield is up to 97%; the medical stone is free from toxicity and radiation, and has no change in original property and precipitated trace elements; the medical stone can be prepared into various beautiful new material tea sets, cups and other finished products.

Owner:马仁水

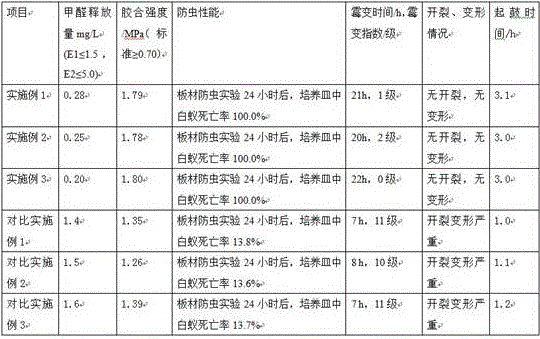

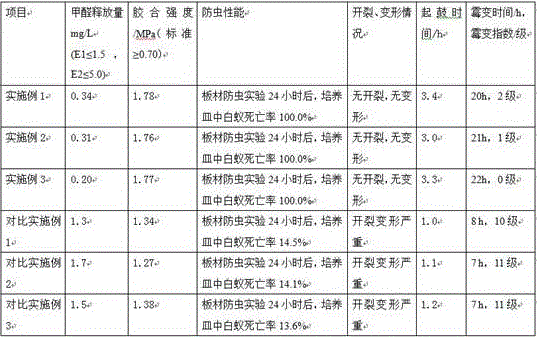

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

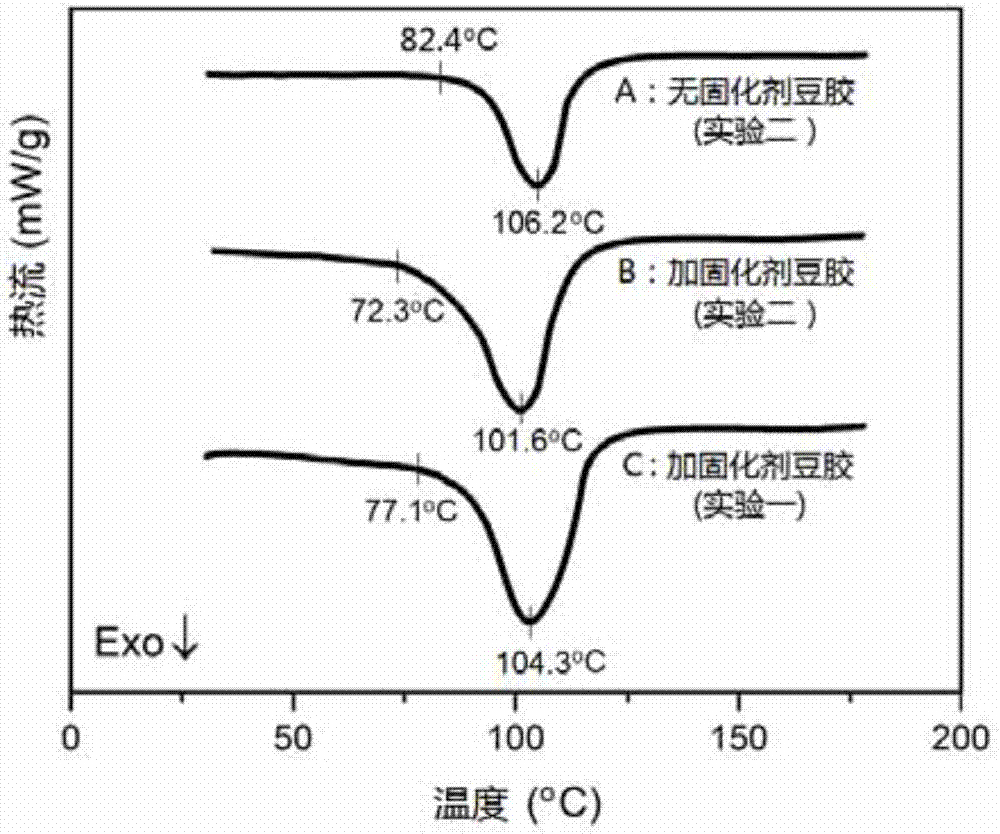

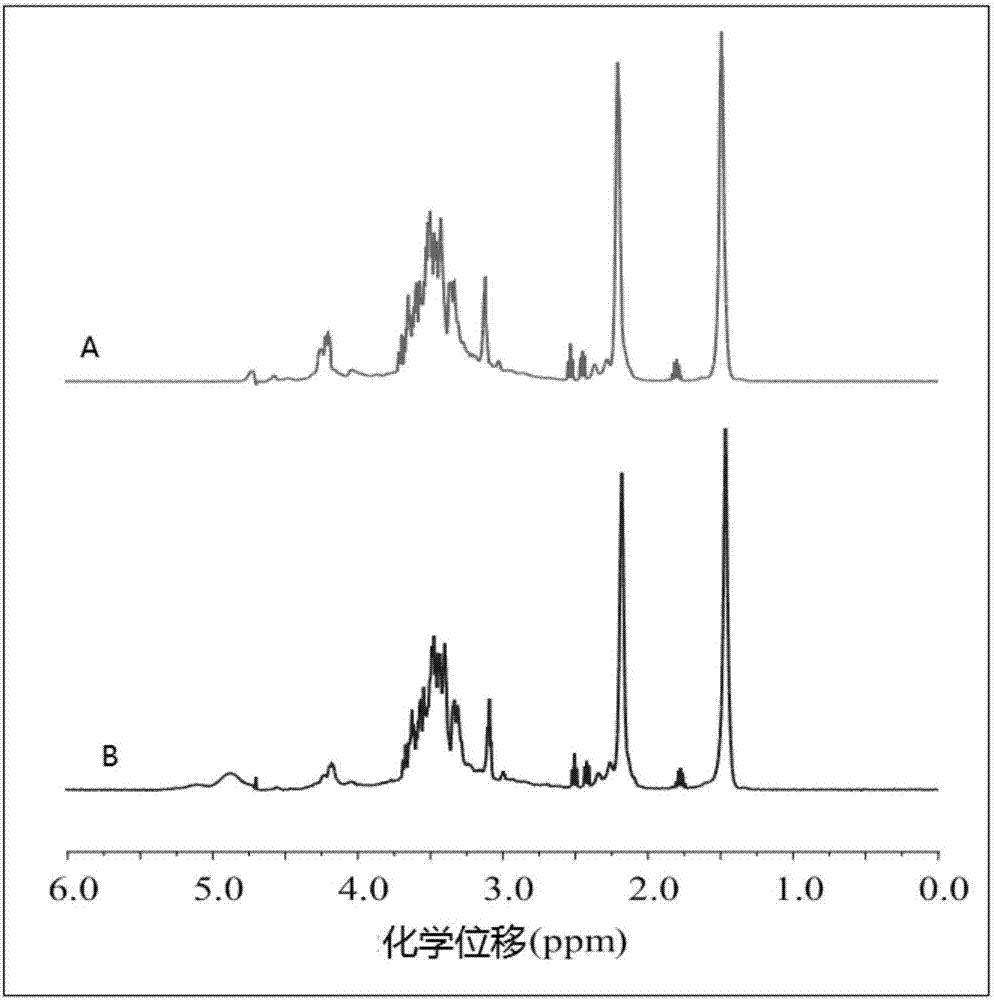

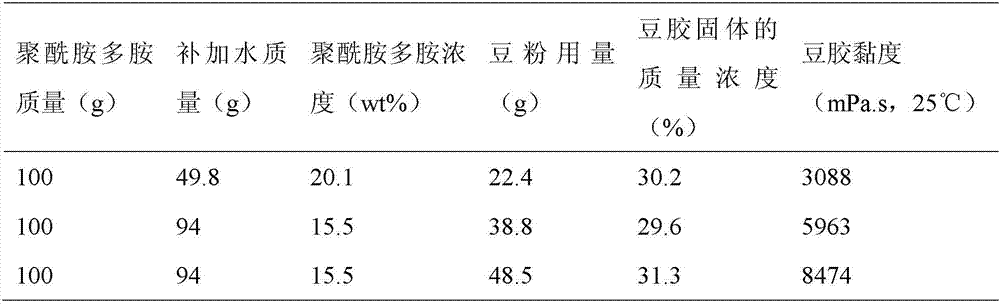

Soybean adhesive for water-resistant shaving board and preparation method thereof

ActiveCN107216849AMeet spraying requirementsEnsure water resistanceNon-macromolecular adhesive additivesProtein adhesivesProduction lineAdhesive

The invention discloses a soybean adhesive for a water-resistant shaving board and a preparation method thereof, and relates to an adhesive and a preparation method thereof, in particular to a modified soybean adhesive for production of boiling water boiling-resistant shaving boards, which aims at solving the technical problems of difficulty in adhesive applying in the production process of the shaving board due to large viscosity and difficulty in adapting to the production of the shaving board due to long hot pressing time in the existing soybean adhesive. The method comprises the following steps of 1, synthesizing of modified polyamide polyamine resin; 2, preparing of the adhesive. The prepared soybean adhesive for the water-resistant shaving board is prepared by adding 0.3 to 1.5% of curing agent and 10 to 25 parts of soybean meal into 100 parts of modified polyamide polyamine resin and mixing at room temperature. The soybean adhesive has the advantages that the viscosity is low, the adhesive is conveniently and uniformly sprayed onto the shaving board, the curing speed is high, the water-resistant property is good, and the soybean adhesive is especially suitable for preparing the boiling water boiling-resistant shaving board in the existing shaved board production line. The soybean adhesive belongs to the field of preparation of adhesives.

Owner:牡丹江恒源生化有限责任公司

Preparation method of high-flame-retardant artificial plate

InactiveCN106938488AImprove water resistanceGood gluing propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesWood shavingsSurface layer

The invention relates to a preparation method of a high-flame-retardant artificial plate. The preparation method comprises the following steps: sawdust and wood shavings are selected, impurities like silt, dust and scrap iron are removed through sieving and magnetic attraction, pulverizing is carried out, then an obtained material is steamed at 110-120 DEG C for 15-30min, and then is dried till a water ratio is lower than 5.0%, an obtained dried raw material and high-flame-retardant adhesive powder are mixed uniformly in a material mixing machine, and after blank loading, primary hot pressing and cooling are carried out, a sandwich layer is obtained; and an upper surface layer and a lower surface layer which are made of 1.0-1.2mm thick veneers are prepared, the surfaces, fitted with the sandwich layer, of the upper surface layer and the lower surface layer are coated with appropriate amounts of molten high-flame-retardant adhesive powder, then the upper surface layer and the lower surface layer are combined with the sandwich layer together, and after secondary hot pressing, cooling, edge cutting and polishing processes are carried out, the high-flame-retardant artificial plate is produced. The temperature of the primary hot pressing is 110-120 DEG C, the time is 20-50s, the pressure is 6-8MPa; and the temperature of the secondary hot pressing is 120-130 DEG C, the time is 10-15s, and the pressure is 4-6MPa. The high-flame-retardant artificial plate has the excellent flame retardant property, and can be cut freely as required in a using process, and the color of the cut edge does not affect the using effect.

Owner:孙子阳

Plywood and preparation method thereof

ActiveCN106827109AImprove anti-corrosion performanceImprove water resistanceOther plywood/veneer working apparatusWood treatment detailsAdhesivePreservative

The invention discloses a plywood and a preparation method thereof. The plywood comprises multiple layers of veneers; and one or more layers of veneers on the surface of the plywood contain preservatives and / or flame retardants. The method comprises the following steps: adhesive is coated on the surfaces of the veneers; the veneers are laminated for hot pressing after cold prepressing, or the adhesive is cured by hot pressing; and finally, through impregnation, one or more layers of veneers on the surface of the plywood contain the preservatives and / or the flame retardants. The plywood is excellent in corrosion resistance, can synchronously achieve corrosion and flame resistance, and is controllable in inpregnation depth, low in needed impregnation medicine quantity, high in gluing strength, excellent in water resistance and excellent in size stability.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

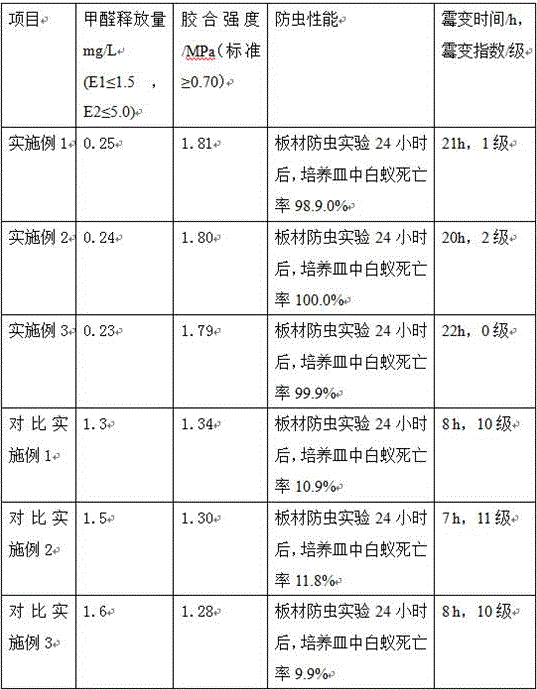

Method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin

ActiveCN106335120AReduce formaldehyde contentGood gluing propertiesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerSurface layer

A method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin comprises steps as follows: rotary cutting of a board to form pieces; single plate drying; adhesive coating; three times of cold pressing; leaving to stand for reconditioning; three times of hot pressing; heat dissipation for reconditioning; fixed-thickness sanding of plate blanks; adhesive coating of base material surface layers; reconditioning and grooving; paint coating, drying and setting. The key of the production method is that melamine modified urea-formaldehyde resin is used as a main adhesive material; oxidized starch is added as a viscous compound; polyvinyl alcohol is added as a toughening agent; hydrogenated rosin is added as an anti-oxidant; polyisocyanate is added as a curing agent; isobutyltriethoxysilane is added as a bridging agent; phenolated lignin is added as a formaldehyde catching agent; an anti-insect and anti-mildew agent is added; anti-insect and anti-mildew composite urea-formaldehyde resin is prepared; and the parquet prepared from anti-insect and anti-mildew composite urea-formaldehyde resin has the advantages of being low in formaldehyde residual amount and good in anti-insect and anti-mildew effect, has the relatively high inhibition effect on breeding of Aspergillus, Trichoderma and Penicillium and has the instant killing force and the long-acting preventive effect on board powder-pest beetles.

Owner:广西横县正林木业有限公司

Coal briquette adhesive employing defatted soybean protein as raw material and preparation method of coal briquette adhesive

InactiveCN106883816AImprove water resistanceGood gluing propertiesNon-macromolecular adhesive additivesProtein adhesivesCoal briquetteCellulose

The invention relates to a coal briquette adhesive employing defatted soybean protein as a raw material and a preparation method of the coal briquette adhesive. The coal briquette adhesive is prepared by processing the following raw materials in parts by weight: 20-30 parts of cement, 80-120 parts of modified defatted soy flour, 8-12 parts of organobentonite, 8-12 parts of propolis powder and 400-600 parts of water; the preparation method of the modified defatted soy flour comprises the steps of adding the defatted soy flour, a proper amount of compound enzyme and a proper amount of deionized water to a reaction container, adjusting the pH to 5.5-6.0, carrying out enzymolysis at 45-55 DEG C for 1-2h, heating a product to 85-95 DEG C, inactivating for 2-3min, cooling to 30-35 DEG C, adding 1-2% of a coupling agent and 0.3-0.5% of an oxidizing agent on the basis of the mass of the defatted soy flour and carrying out stirring treatment for 0.5-1h; filtering out impurities, and carrying out vacuum concentration and drying to obtain the modified defatted soy flour, wherein the compound enzyme is a mixture of cellulose, alpha-amylase and protease. The adhesive has good water resistance and bonding property; main raw materials all are natural raw materials; the coal briquette adhesive is wide in source, convenient to process and low in processing cost; the adhesive is long in expiration date; and the coal briquette processed by the coal briquette adhesive is high in quality and not easy to mildew and deliquescence caused by moisture absorption is not easily caused.

Owner:瑞安市智造科技有限公司

Method for producing particle board through anti-insect and anti-mold composite urea formaldehyde resin

ActiveCN106363760AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantPolyvinyl alcohol

The invention discloses a method for producing a particle board through anti-insect and anti-mold composite urea formaldehyde resin. The method comprises the procedures like material preparation, drying, veneer removing and grit removing, mixing glue, and hot press molding. The key of the production method is that melamine modified urea formaldehyde resin is adopted as a main material of an adhesive; oxidized starch is added as a viscous complexing agent; polyvinyl alcohol is adopted as a flexibilizer; hydrogenated rosin is adopted as an antioxidant; polyisocyanate is adopted as a curing agent; and triethoxyisobutylsilane is adopted as a bridging agent. According to the method, the anti-insect and anti-mold composite urea formaldehyde resin is prepared through adopting phenolated lignin as a formaldehyde capture agent and adding an anti-insect and anti-mold agent, and the particle board produced through the anti-insect and anti-mold composite urea formaldehyde resin has the advantages that the residual amount of formaldehyde is low and the anti-insect and anti-mold effect is good, has a quite high inhibiting effect on breeding of aspergillus, trichoderma and penicillia, and has instantaneous killing force and a long-term prevention effect on board powder-post beetles.

Owner:广西横县新威林板业有限公司

Environment-friendly wallpaper adhesive and preparation method thereof

InactiveCN106753224AImprove error correctabilityAvoid damageNon-macromolecular adhesive additivesProtein adhesivesSodium BentoniteAdhesive

The invention relates to an environment-friendly wallpaper adhesive and a preparation method thereof. The environment-friendly wallpaper adhesive comprises an agent A and an agent B, wherein the agent A is prepared by processing the following raw materials in parts by weight: 60-80 parts of modified defatted soybean meal paste, 6-8 parts of water-soluble glucan, 4-6 parts of leveling agent, 2-3 parts of organic bentonite and 1-3 parts of assistant which is a mixture of at least two of flame-retardant powder, nano negative ion powder and antistatic agent; the component B is prepared by processing the following raw materials in parts by weight: 8-15 parts of propolis powder, 1-3 parts of antioxidant, 30-40 parts of substrate, 1-2 parts of emulsifier, 40-60 parts of 75-85% of ethanol solvent by volume and appropriate pH regulator; the substrate is any one of natural rubber, vitamin derivative and modified starch; the pH of the agent B is 6-8. In the environment-friendly wallpaper adhesive provided by the invention, the raw materials of the agents A and B are reasonably selected and in proper compatibility; compared with existing glue, the prepared adhesive has the advantages of excellent water resistance and gluing property, good uniformity in drying, high flatness and excellent antibacterial property, antistatic property and flame retardance.

Owner:张晨杨

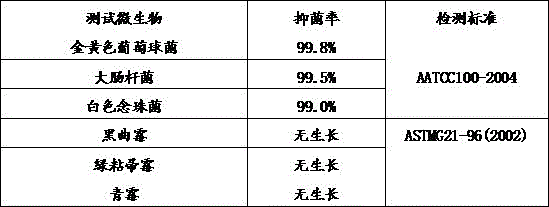

Preparation method for antibacterial mould-proof environment-friendly chipboard

InactiveCN106863528AImprove water resistanceGood gluing propertiesNon-macromolecular adhesive additivesProtein adhesivesSurface layerAdhesive

The invention relates to a preparation method for an antibacterial mould-proof environment-friendly chipboard. The chipboard comprises an upper surface layer, a core layer and a lower surface layer which are bonded and subjected to hot pressing and recombination. The preparation method comprises the following steps that firstly, the core layer is prepared, (1) raw materials are prepared; (2) pretreatment is conducted on the raw materials; (3) the materials are stirred; and (4) mixed materials obtained in the step (3) are subjected to blank packing, primary hot pressing and cooling, and the core layer is obtained; and secondly, the upper surface layer and the lower surface layer are prepared and are both made of single plates with the thickness of 0.8-1.0 mm, the faces, attached to the core layer, of the upper surface layer and the lower surface layer are evenly coated with an appropriate number of adhesives, then the upper surface layer and the lower surface layer are combined with the core layer, and through secondary hot pressing, cooling, edge cutting and polishing procedures, the antibacterial mould-proof environment-friendly chipboard is obtained. Raw materials of an adhesive A and an adhesive B of the environment-friendly adhesives used in the preparation method are selected reasonably, compatibility is appropriate, the prepared adhesives have excellent water resistance and bonding performance, and the drying process is good in uniformity, the smoothness is good, and excellent antibacterial performance, antiatativity and flame resistance are also achieved.

Owner:田德谦

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

Novel halogenide-resistant and fireproof plate

InactiveCN107244875AImprove flame retardant performanceHigh smoke suppression effectGlass fiberFiberglass mesh

The invention discloses a novel halogenide-resistant and fireproof plate. The novel halogenide-resistant and fireproof plate aims at solving the problem of no fundamental solving of the halogenide moisture absorption condition due to the existence of magnesium chloride in a formula, especially the severe halogenide moisture absorption condition in plum rain seasons having a large air humidity. The novel halogenide-resistant and fireproof plate comprises a forming agent, a reinforcing material, a lightweight filler, a modifier and water, wherein the forming agent includes alum, magnesium hydroxide and sodium fluorosilicate, the reinforcing material is a glass fiber gridding cloth or other reinforcing materials, and the modifier includes a brightener, a stabilizer and a color toner. No magnesium chloride is used in the invention, so the halogenide phenomenon is thoroughly solved, and people's demands are met.

Owner:深圳市博之雅新材料科技有限公司

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

Method for preparing biomass adhesive from alfalfa meal

ActiveCN103205230AExpand the planting areaImprove adhesionPolyureas/polyurethane adhesivesFiberAdhesive

The invention relates to a method for preparing a biomass adhesive from alfalfa meal. The method comprises the following steps of: weighing the alfalfa meal, soaking the alfalfa meal into water, adding ethanol, stirring uniformly and filtering; adjusting the pH of the filtrate, then heating the filtrate, preserving the heat, cooling to room temperature, filtering, and drying filter cakes; weighing the filter cakes, putting the filter cakes into a three-necked bottle filled with distilled water, adding sodium dodecyl benzene sulfonate, heating for a period of time, dripping NaOH, adjusting the pH of the solution to 9, adding poly(phenyl methylene isocyanate), and reacting, thus obtaining the biomass adhesive. By adopting the method, the biomass adhesive with good adhesive property is prepared from the meal raw material of alfalfa with wide planting area, high yield and reproducibility, a deep processing product of the alfalfa with industrialized value is obtained, the additional value is improved, meanwhile, the obtained adhesive does not contain the components such as formaldehyde and aromatic hydrocarbon harmful to human bodies, the cost is low, the process is simple, and the adhesive can be applied in the fields of wood veneers, shaving boards, fiber board and the like.

Owner:广东好上好科技有限公司

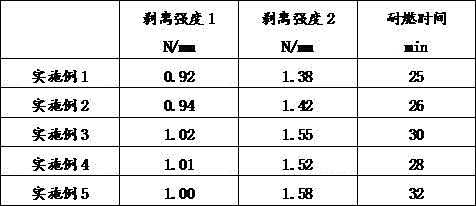

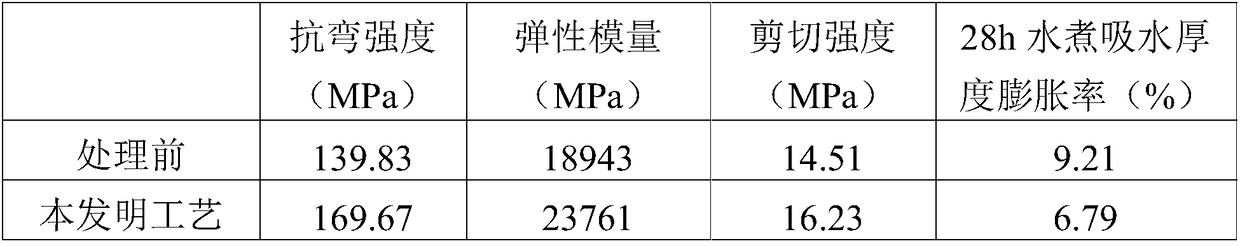

Method for improving bonding performance of reconstituted bamboo

ActiveCN108162105AGood gluing propertiesEasy to operateWood treatment detailsCane mechanical workingWaxCarbonization

The invention discloses a method for improving bonding performance of reconstituted bamboo. The method includes the steps of bamboo defibering, bonding improvement treatment, drying, gum dipping, secondary drying of bamboo, reconstituting forming and the like. According to the method, the bamboo is subjected to mechanical defibering, then the bamboo is subjected to spraying treatment and high-temperature carbonization treatment with NaOH, and thus a silicon layer and a wax layer on the surface of the bamboo are effectively removed and damaged; and on the basis, gum dipping and secondary dryingare carried out, and finally reconstituting forming is carried out. According to the reconstituted bamboo prepared by the method, the bonding performance of the bamboo is improved, and in the processing progress, operation is simple, poison, harm and waste are avoided, and the physical mechanical strength is remarkably improved, wherein the horizontal shearing strength is improved by 10% or above, the water-absorbing thickness swelling rate is lowered by 26% or above, the bending strength is improved by 16% or above, and the elastic modulus is improved by 20% or above.

Owner:GUANGDONG ACAD OF FORESTRY

Environmentally-friendly dry powder emulsion paint for inner wall and preparation method thereof

The invention relates to an environmentally-friendly dry powder emulsion paint for an inner wall and a preparation method thereof. The environmentally-friendly dry powder emulsion paint for the inner wall is prepared through the following raw materials in parts by weight: 20-35 parts of white cement, 20-35 parts of calcium carbonate powder, 8-18 parts of ash calcium powder, 30-40 parts of modified degreased soybean powder pulp, 5-10 parts of titanium dioxide, 10-20 parts of propolis powder, 6-8 parts of water soluble glucan, 4-6 parts of flatting agent, 2-3 parts of organobentonite, 1-3 parts of nanometer magnetic ordered mesoporous medium, 2-3 parts of antioxidant, and 1-3 parts of additive, wherein the additive is at least one of flame-retardant powder, nanometer negative ion powder and an antistatic agent; the flatting agent is a liquid acrylic flatting agent. The environmentally-friendly dry powder emulsion paint for the inner wall is reasonable in raw material selection, and proper in matching; compared with an existing emulsion paint, the prepared dry powder emulsion paint has the advantages of being outstanding in water resistance, outstanding in bonding performance, high in consistency in the drying process, and high in flatness; in addition, the emulsion paint is high in stability during the drying process, is influenced slightly by the outside condition, and is hard to discolor; in addition, the emulsion paint is outstanding in antibacterial capacity, high in static resistance and high in fire retardance.

Owner:陈浩谦

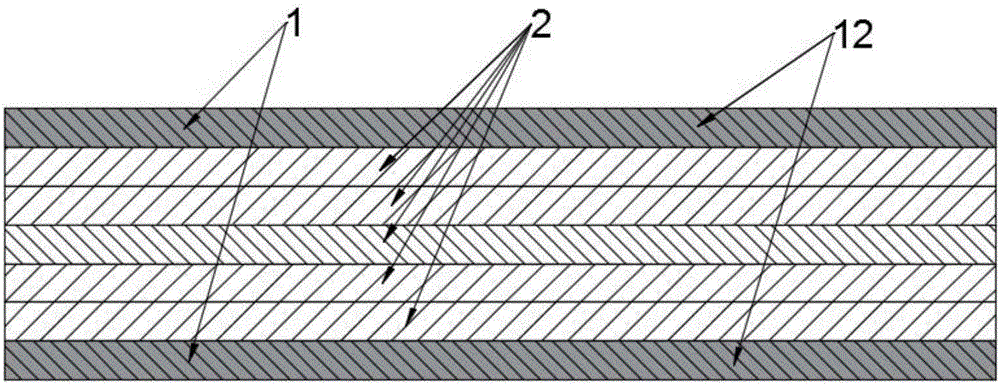

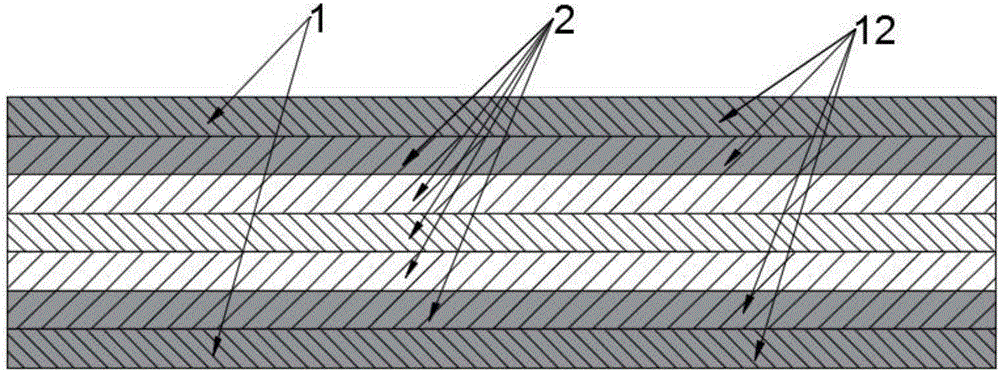

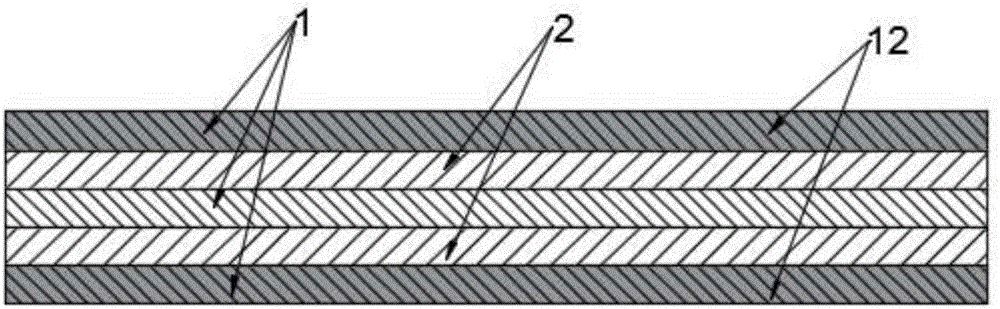

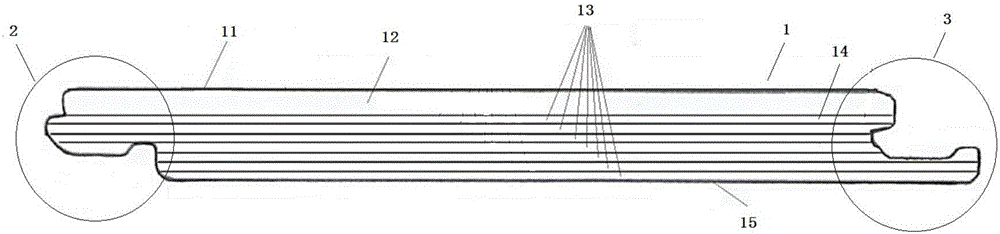

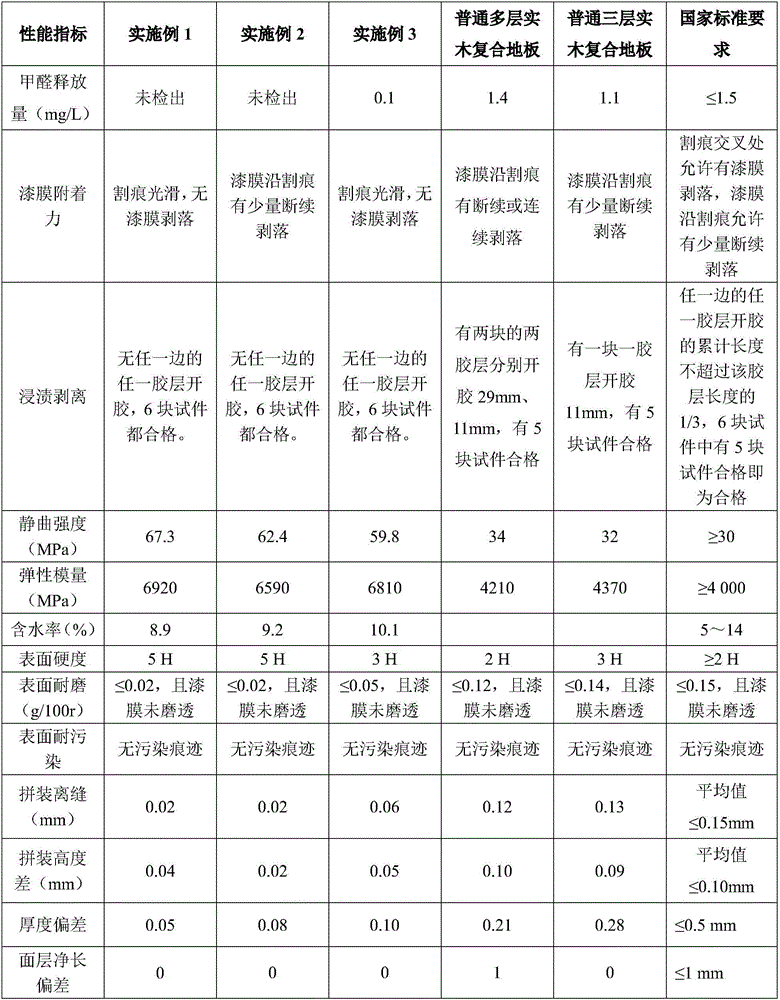

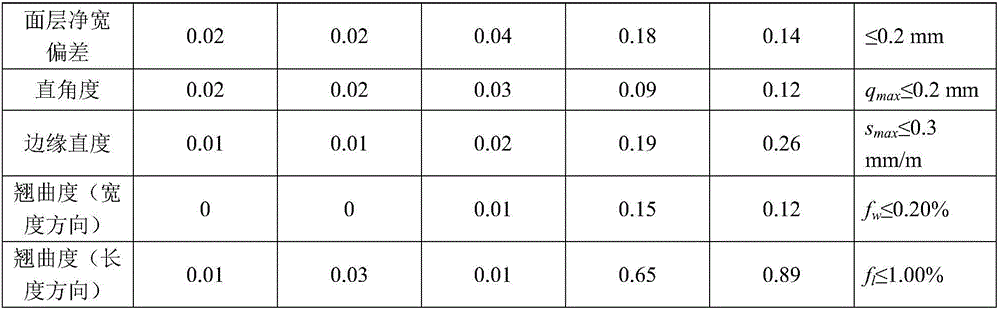

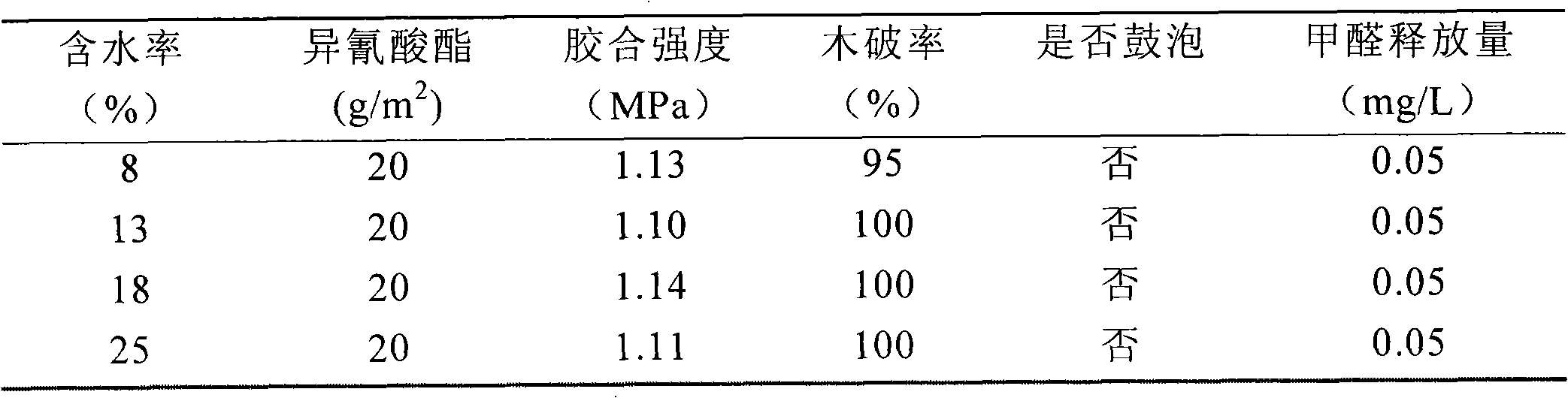

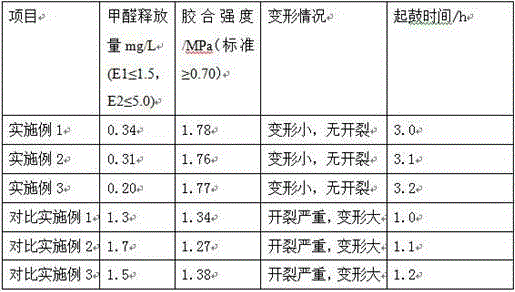

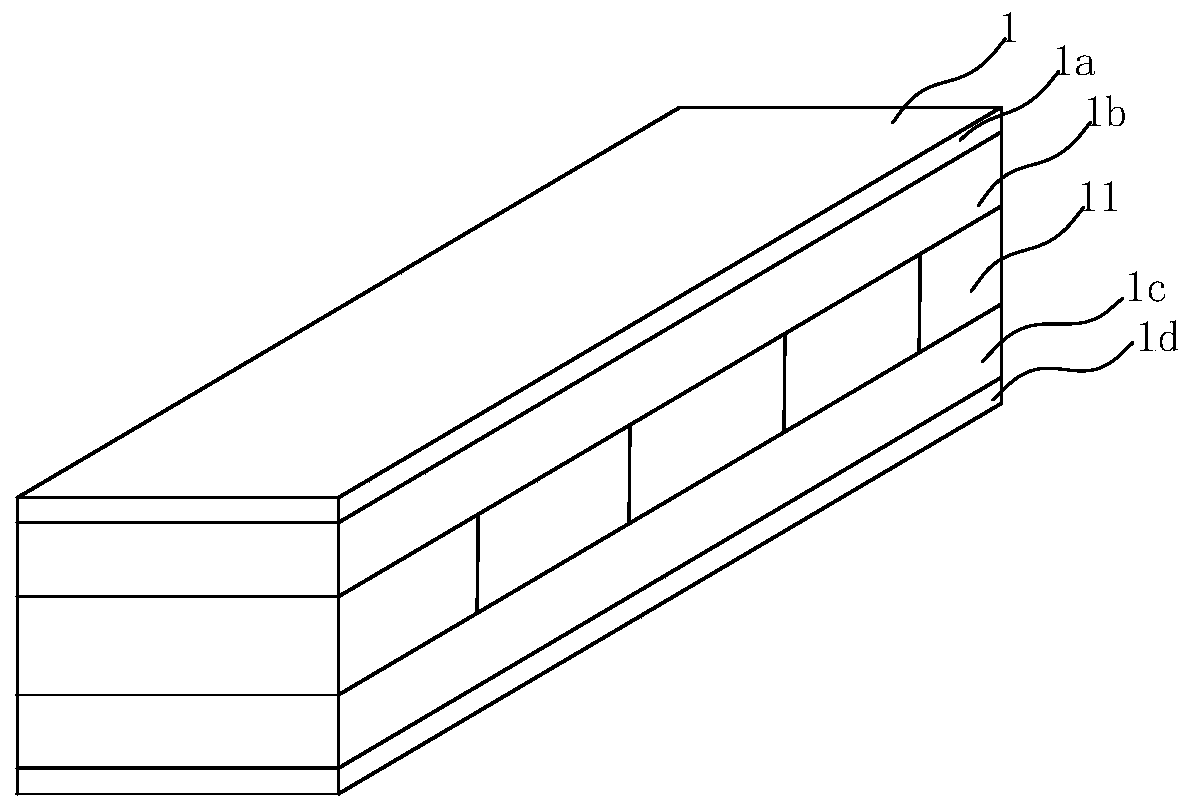

Locking multi-layer solid wood composite floor and preparation method thereof

InactiveCN106836726ASolve the release problemImprove water resistanceFlooring insulationsSolid woodHazardous substance

The invention discloses a locking multi-layer solid wood composite floor and a preparation method thereof. The locking multi-layer solid wood composite floor comprises a floor body (1), a tenon (2) and a mortise (3) matched with the tenon (2) in shape. The floor body (1) comprises a wearing layer (11), a wood panel (12) and a base material layer (13), wherein double-face sanding is conducted on the wood panel (12) and the base material layer (13). According to the locking multi-layer solid wood composite floor and the preparation method thereof, the problems that hazardous substance-free formaldehyde is released by an existing solid wood composite floor and glue failures and layering of all layers of veneer occur after the board is used for a period of time are solved; and the problems that the existing multi-layer solid wood composite floor has a large mat formation gap, big assembly height differences and serious buckling deformation and needs to be renovated to be used again after being used for a period of time are also solved.

Owner:南京久扬家居有限公司

Aldehyde-free veneer and producing method thereof

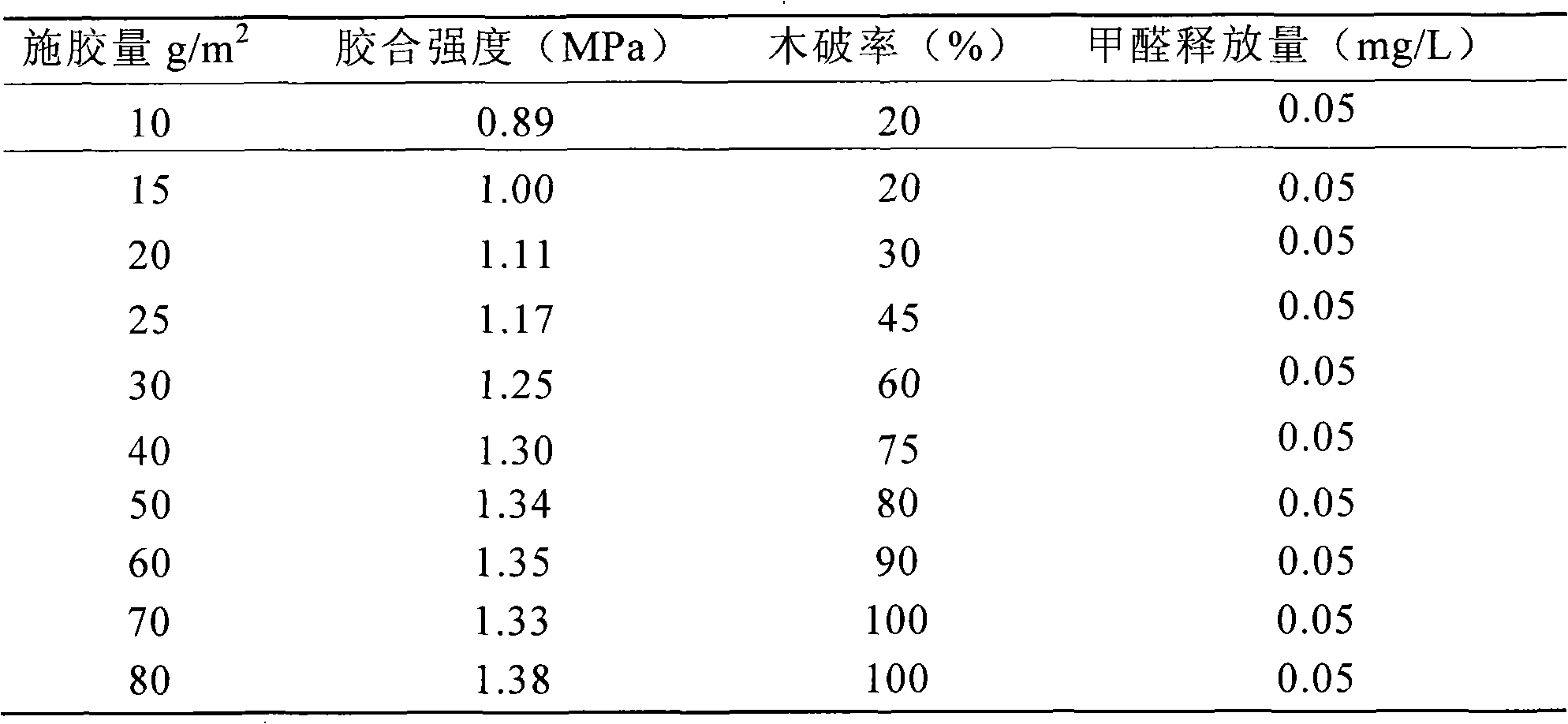

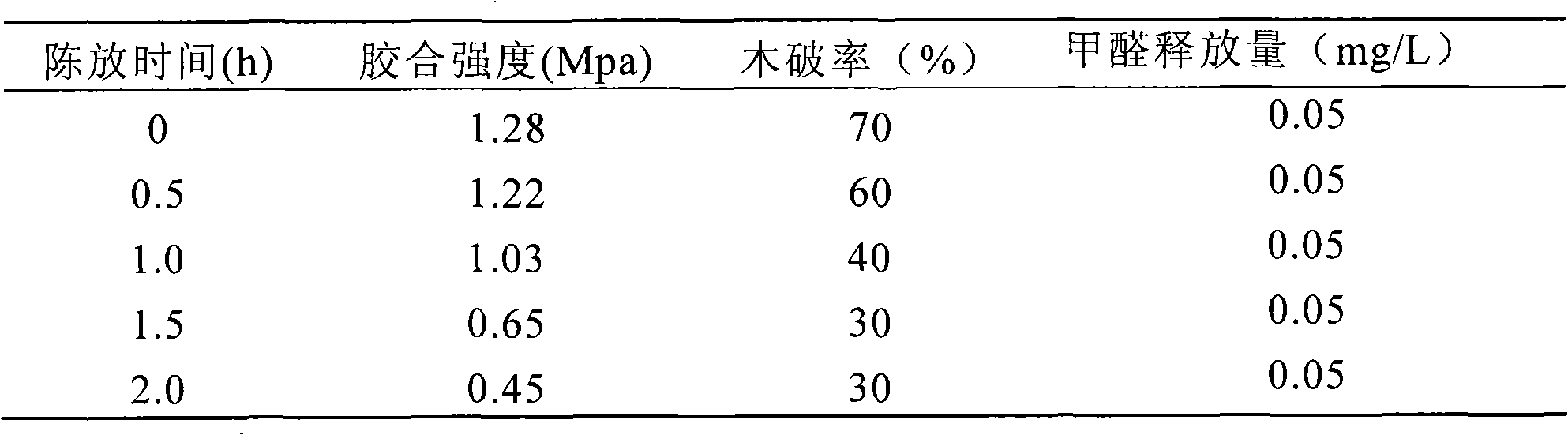

ActiveCN101524857BLow costReduce drying energy consumptionWood veneer joiningWood layered productsAdhesiveSingle plate

The invention provides an aldehyde-free veneer which comprises a plurality of combined single plates, the contiguous layers of the single plates are in a crossed structure or a parallel structure, a glue layer is arranged between contiguous single plates, and the adhesive of the glue layer is isocyanate. The invention also includes the producing method of the aldehyde-free veneer. In the normal producing method of veneer, isocyanate adhesive is used, the hot pressing time in the work procedures is shortened, the hot pressing temperature is lowered, and the requirement of the water content of the single plate is lowered. Spraying glue application method is used in the work procedure of applying glue to the veneer to greatly reduce the applied glue amount of the veneer, thus besides the formol release amount is greatly lower than that of the relevant standard, and the aldehyde-free veneer also has more reasonable technology.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

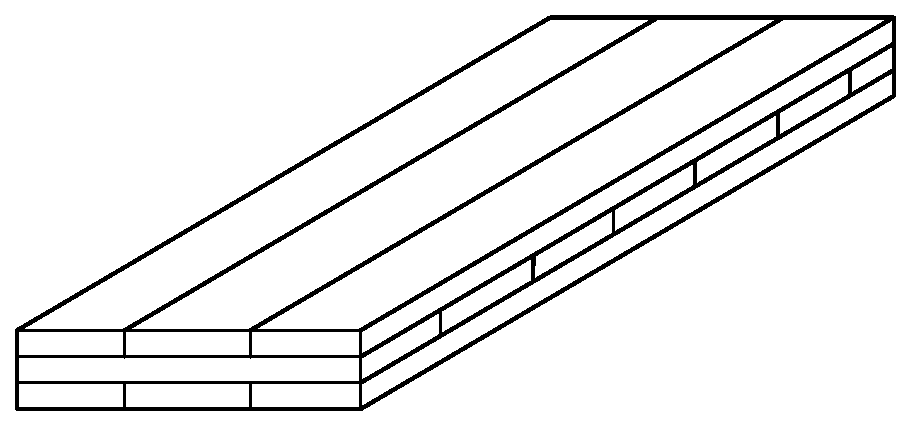

Bamboo veneer integrated panel and production technological method thereof

InactiveCN103753657AGood gluing propertiesReduce generationLaminationLamination apparatusEngineeringMachining

The invention belongs to the technical field of bamboo wood artificial panels, and particularly relates to a bamboo veneer integrated panel and a production technological method thereof. The bamboo veneer integrated panel is formed by odd-layer overlapping bamboo veneers layer by layer and sizing and pressing the bamboo veneers. A face panel, a back panel and odd-layer middle panels from top to bottom are bamboo shoot type bamboo veneers, and even-layer core panels from top to bottom is tabasheer type bamboo core panels. According to the bamboo veneer integrated panel and the production technological method thereof, arc bamboo chips are flatly unfolded, bamboo green layers are removed, tabasheer layers are rolled to be cracked, the bamboo green faces of the plane wedge bamboo chips with green-removing and tabasheer-rolling conducted is used as a machining benchmark, a layering device is adopted to layer the bamboo chip into multiple layers of bamboo shoot type bamboo chips and a layer of tabasheer type wedge bamboo chip, bamboo shoot type bamboo chips are used as unit bodies to manufacture the bamboo shoot type bamboo veneers, and the tabasheer type wedge bamboo chip is used an a unit body to manufacture the tabasheer type bamboo core panel. According to the bamboo veneer integrated panel and the production technological method of the bamboo veneer integrated panel, the bamboo panel use ratio is higher, machining is convenient, and continuous machining can be achieved.

Owner:彭亮 +1

Method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin

InactiveCN106313200AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesAntioxidantAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher, and moreover an antioxidant and an ultraviolet absorbent are also added to prepare the weather-resistant composite urea resin; the composite urea resin has the advantages of low formaldehyde residual volume and good weather resistance. The total-eucalyptus plywood produced by the method disclosed by the invention is excellent in weather resistance and is relatively high in environmental disruption tolerance.

Owner:南宁市林润木业有限公司

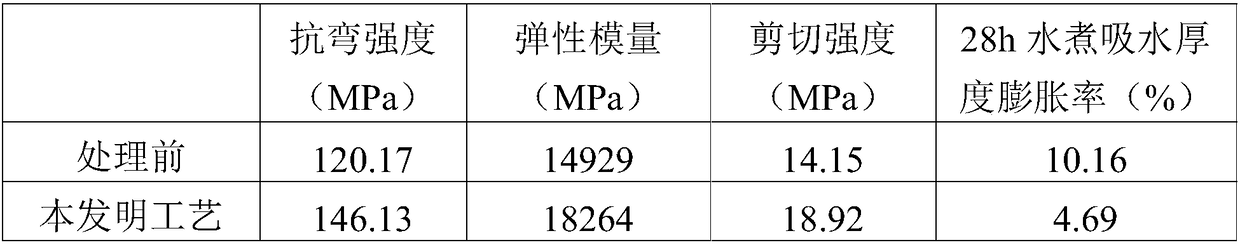

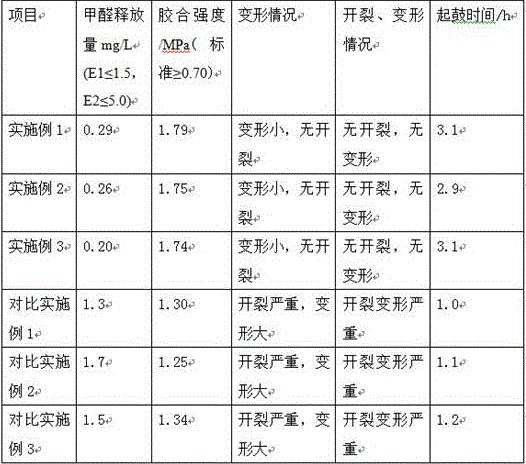

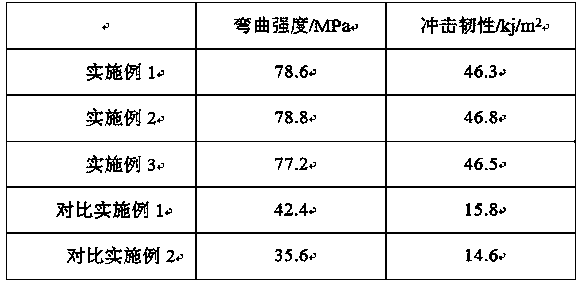

High performance fiberboard

ActiveCN110239168AImprove bending performanceImprove impact resistanceImpregnation spraying apparatusSynthetic resin layered productsAdhesivePolyvinyl alcohol

The invention discloses a high performance fiberboard. The prepared board has superior bending property and impact property, and is better in mechanical properties. By reasonably compounding camphor wood powder, birch wood powder and maple wood powder, the fiberboard is enabled to be uniform in size and density and better in harmony; the wood powder is subjected to modification treatment by using glucuronolactone, acetaminophen and polyvinyl alcohol, so that the fiberboard is enabled to contain multiple active groups, the gluing effect between the fiberboard and an adhesive component is facilitated; furthermore; furthermore, the compatibility of the fiberboard with modified basalt fibers is promoted, so that the mechanical properties of the board are improved; diatomaceous earth and tapioca flour are used for modifying basalt fibers, and a porous interface is formed on the surface of basalt, so that the interaction between the basalt fibers and wood fibers as well as between the basalt fibers and an adhesive is promoted, and a framework effect is achieved; therefore, the bending strength and impact toughness of the board are remarkably improved.

Owner:阜阳大可新材料股份有限公司

Method for adopting high-temperature-resisting composite urea resin for producing whole-eucalyptus solid wood composite floor

ActiveCN106272849AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerAntioxidant

The invention discloses a method for adopting high-temperature-resisting composite urea resin for producing a whole-eucalyptus solid wood composite floor. The method includes the steps of board rotary slicing, veneer drying, gluing, three times of cold pressing, standing maintaining, three times of hot pressing, heat dissipating maintaining, slab fixed-thickness sanding, base material surface layer gluing, maintaining grooving and paint spraying, drying and sizing. The production method is characterized in that the high-temperature-resisting composite urea resin is prepared by adopting melamine modified urea resin as the main material of an adhesive, adding oxidized starch as a viscosity complexing agent, adopting polyvinyl alcohol as a toughening agent, adopting hydrogenated rosin as an antioxidant, adopting polyisocyanate as a curing agent, adopting isobutyl triethoxy silane as a bridging agent, adopting phenolate lignin as a formaldehyde catching agent and adding high-temperature-resisting filler. The high-temperature-resisting composite urea resin prepared through the method is used for producing the whole-eucalyptus solid wood composite floor so that the whole-eucalyptus solid wood composite floor can have good heat resistance performance, no obvious crack phenomenon happens under high-temperature and high-strength ultraviolet irradiation or long-time ultraviolet irradiation, and economic losses are reduced.

Owner:广西横县正林木业有限公司

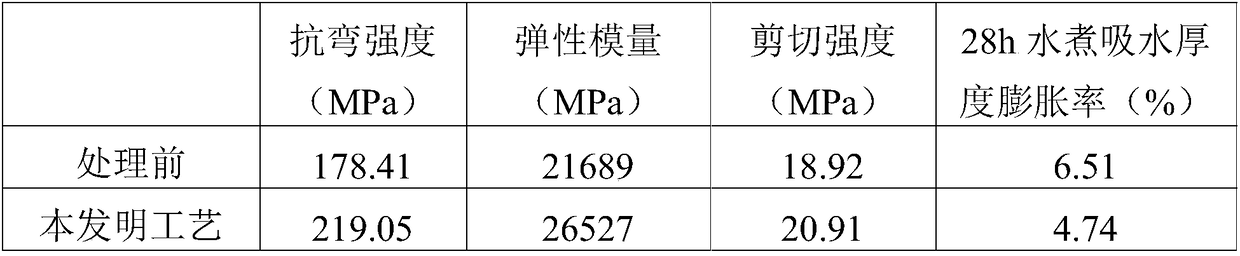

Processing method of bamboo-wood composite orthogonal laminated wood and obtained product

ActiveCN110228111AHigh rolling shear strengthImprove flexural strengthOther plywood/veneer working apparatusTransportation and packagingEngineered woodWood product

The invention relates to a processing method of a bamboo-wood composite orthogonal laminated wood and an obtained product, and belongs to the technical field of engineering wood product structures. The processing method of the bamboo-wood composite orthogonal laminated wood comprises the steps of material selection, light planing, humidity regulation, layer selection, gluing, assembling and pressurizing and solidifying, wherein the processed bamboo-wood composite orthogonal laminated wood comprises a parallel layer and a transverse layer which are orthogonal to each other, and the processed bamboo-wood composite orthogonal laminated wood further comprises a composite outer layer which is located on the upper surface and the lower surface of the bamboo-wood composite orthogonal laminated wood, a bamboo material and a wood material which form the composite outer layer are arranged in the length direction parallel to the laminated wood, the parallel layer between the two composite outer layers are made of wood materials, and the transverse layer between the two composite outer layers are made of bamboo materials. The bamboo-wood composite CLT has the advantages of high rolling shear strength, bending strength, rigidity and transverse grain pressure-bearing strength, the bending strength and the bending resistance elasticity modulus are higher than that of a common structure CLT by40% or higher, and the full-surface transverse grain pressure-bearing strength is up to 50% or higher.

Owner:NANJING FORESTRY UNIV

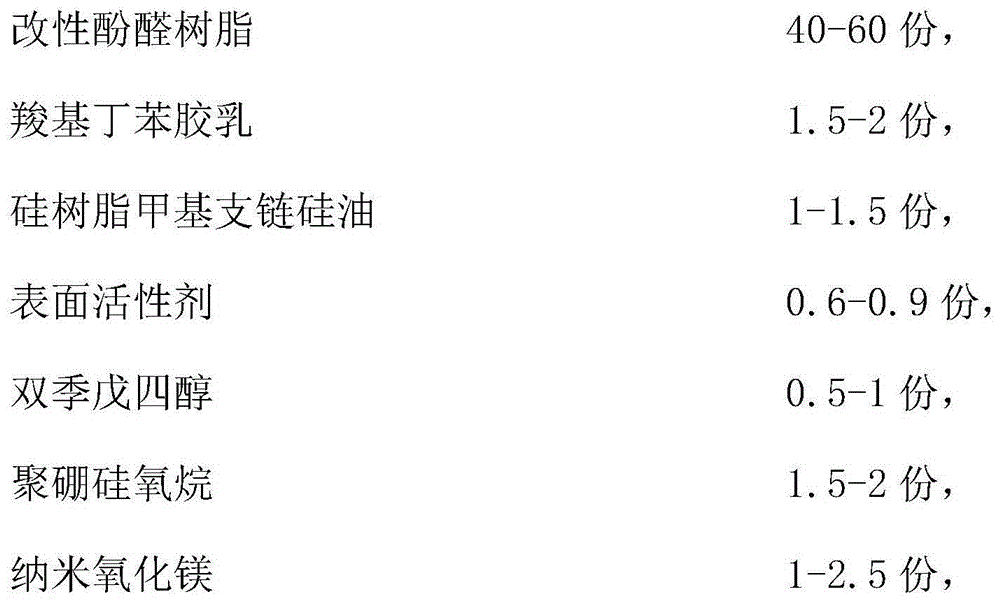

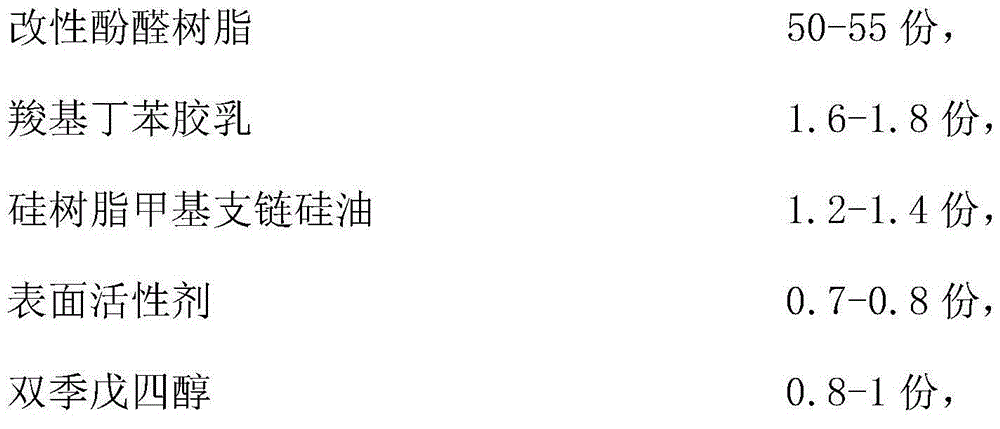

Modified phenolic resin adhesive for chemical resistant laminate

InactiveCN104559870AResilientFast toughnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesChemistryRaw material

The invention discloses a modified phenolic resin adhesive for a chemical resistant laminate. The adhesive is prepared from the following raw materials in parts by weight: 40-60 parts of modified phenolic resin, 1.5-2 parts of carboxylic butadiene-styrene latex, 1-1.5 parts of silicon resin methyl branched chain silicone oil, 0.6-0.9 part of surfactant, 0.5-1 part of dipentaerythritol, 1.5-2 parts of polyborosiloxane, 1-2.5 parts of nano-magnesium oxide, 10-15 parts of poplar bark powder, 4-8 parts of natural sodium bentonite and 2-6 parts of anti-aging agent TCY. The modified phenolic resin adhesive has the advantages of low cost, good mechanical performance, good heat resistance, excellent adhering performance and good toughness.

Owner:ANHUI XIMA OUMEIJIA DECORATIVE MATERIAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com