Patents

Literature

89results about How to "Solve the release problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for improving biological dephosphorizing and denitriding efficiency of low carbon source sewage

InactiveCN102060412ASmall volumeReduce initial investmentSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSolubilityHigh concentration

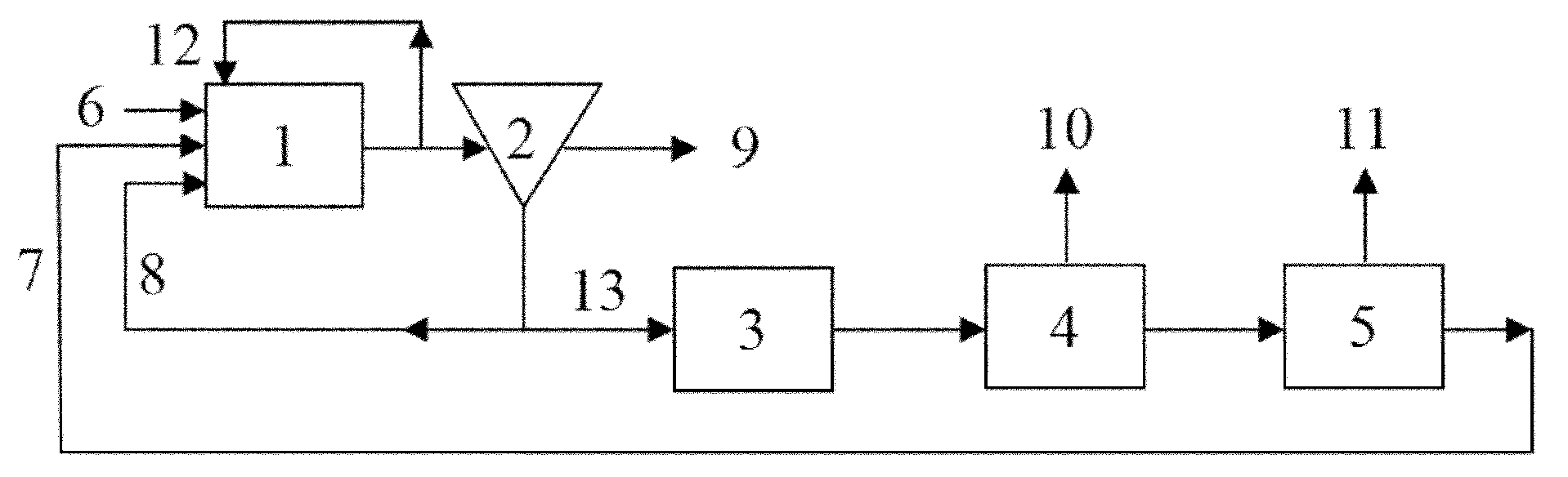

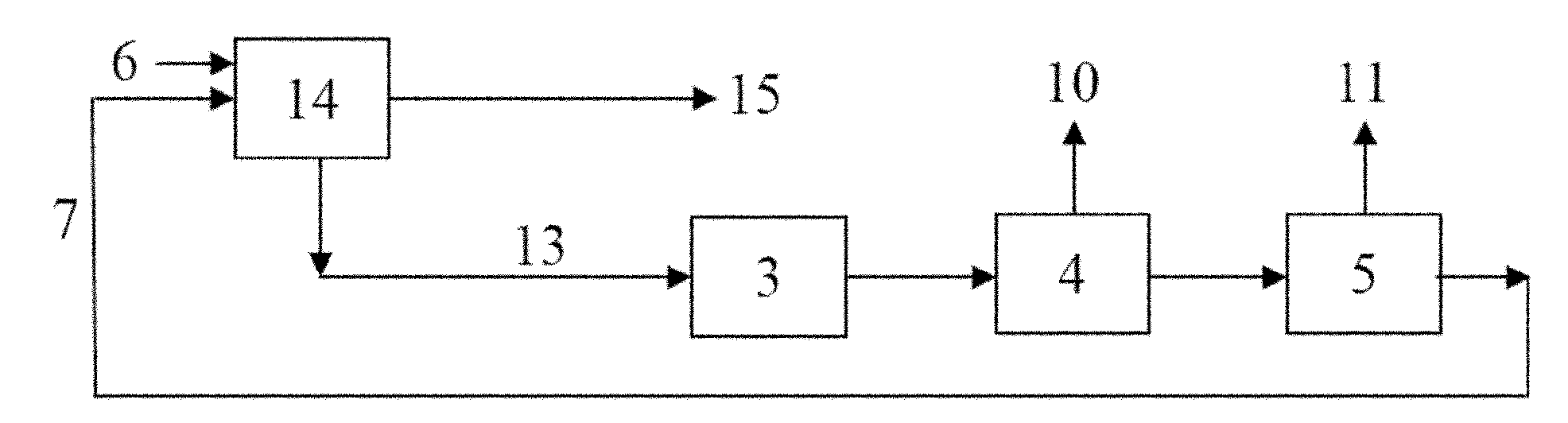

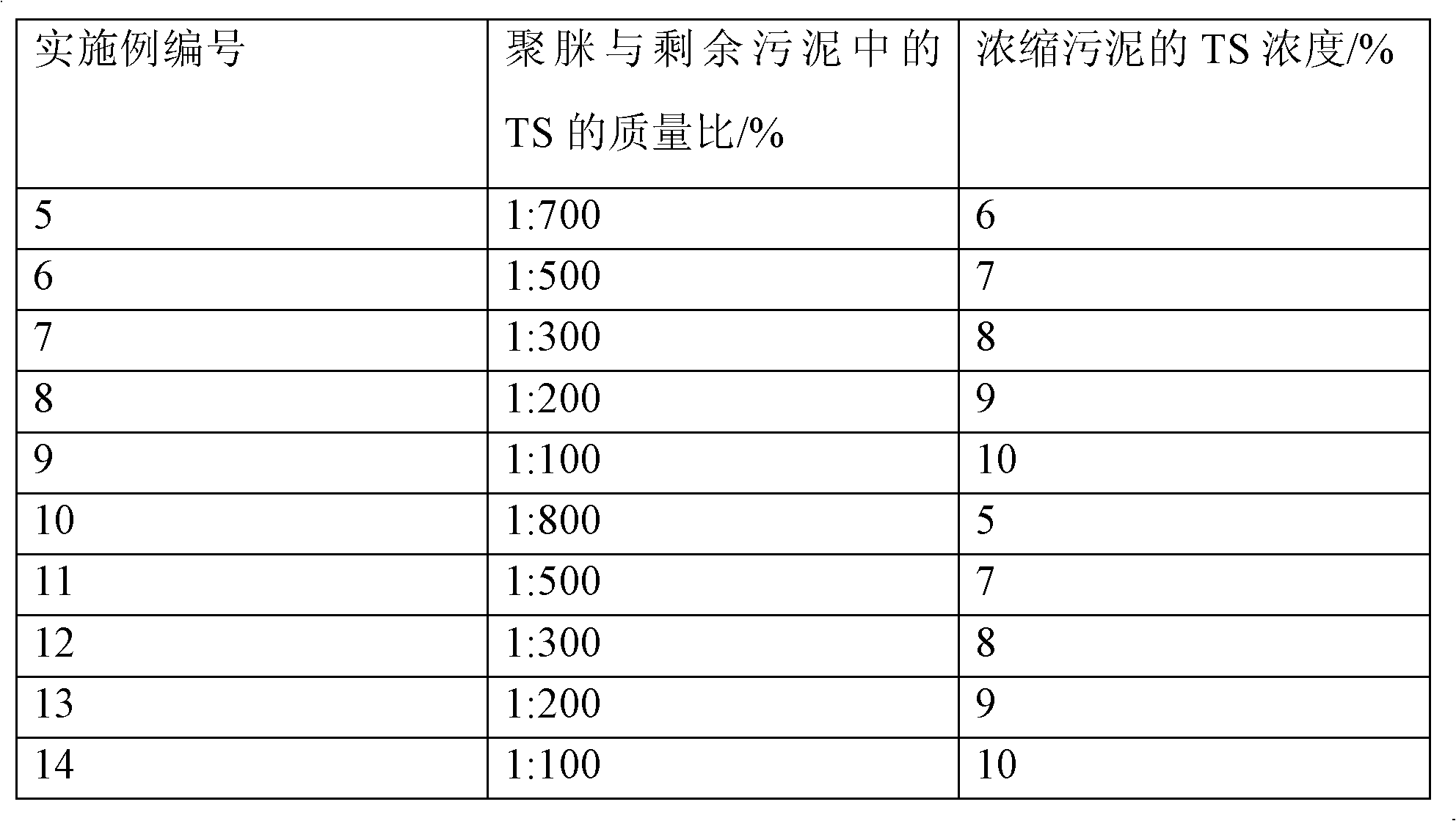

The invention provides a device and a method for improving the biological dephosphorizing and denitriding efficiency of low carbon source sewage, belonging to the technical fields of sewage treatment and residual sludge treatment. The method comprises the following steps of: under the microwave alkaline hydrolysis condition, hydrolyzing solid organic matters in the residual sludge into soluble organic matters; recovering and hydrolyzing nitrogen and phosphor in supernate by adopting a magnesium ammonium phosphate setting method; and adding the hydrolyzed supernate subjected to dephosphorizing and denitriding treatment in the low carbon source sewage and carrying out biological dephosphorizing and denitriding treatment on the hydrolyzed supernate so as to improve the biological dephosphorizing and denitriding efficiency of the low carbon source sewage. According to the invention, by carrying out the microwave alkaline hydrolysis treatment on the residual sludge to produce high-concentration soluble organic matters easy to biodegrade, the product can be used as a low-price carbon source subjected to biological dephosphorizing and denitriding treatment in the lower carbon source sewage, and the biological dephosphorizing and denitriding efficiency in the lower carbon source sewage can be improved; meanwhile, sludge minimization, reclamation and harmlessness can be realized. The VSS (Volatile Suspended Solids) solubility in the sludge can be improved to 82 percent, so that the effluent quality of the low carbon source sewage treated by the device and the method achieves the first-class B standard 'Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant' (GB18918-2002).

Owner:TIANJIN URBAN CONSTR COLLEGE

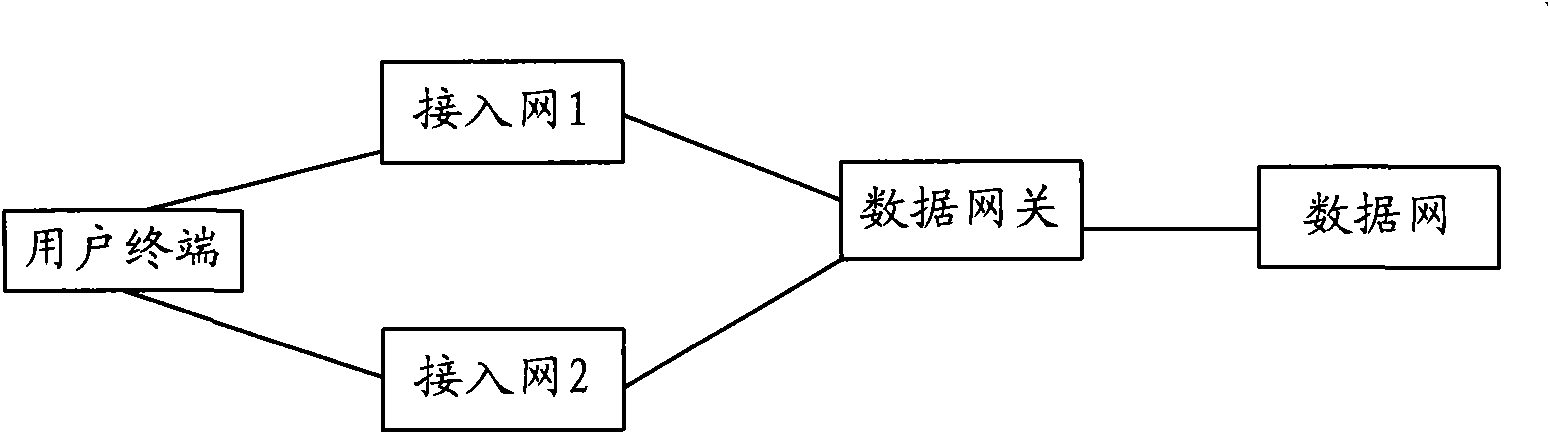

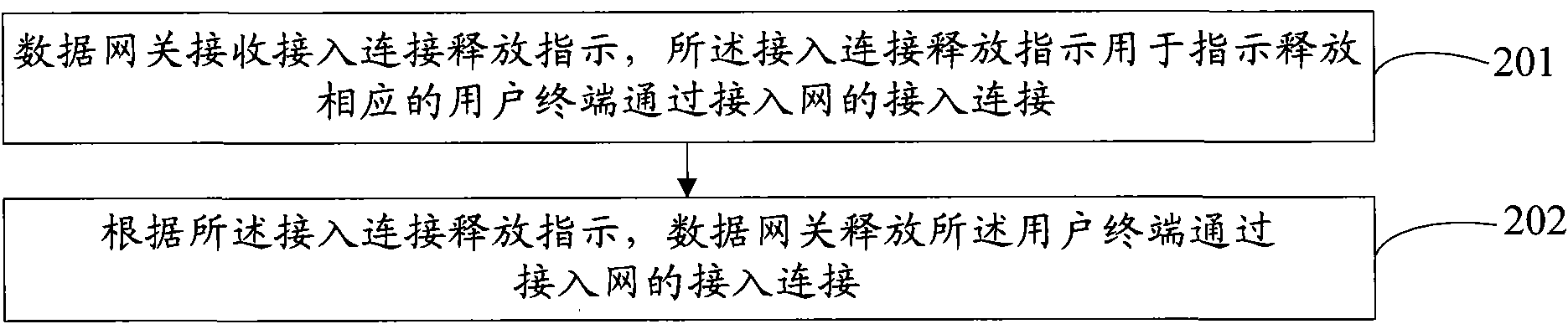

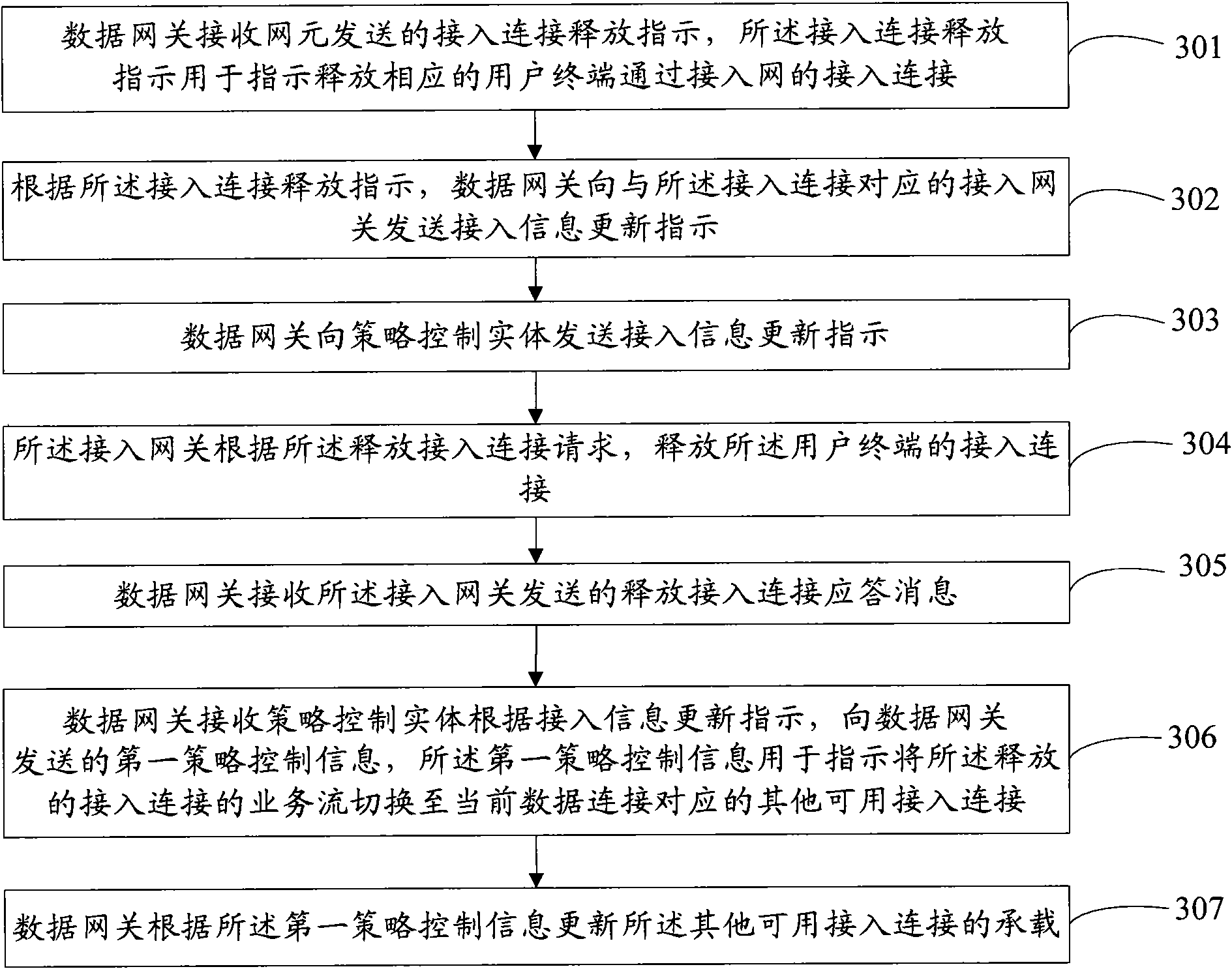

Method, device, strategic control entity and system for releasing switch-in connection

The embodiment of the invention discloses a method, a device, a strategic control entity and a system for releasing a switch-in connection. The method comprises the following steps: a switch-in connection release indication is received by a data gateway, wherein the the switch-in connection release indication is used for indicating to release switch-in connection of a corresponding user terminal through a switch-in network; and the switch-in connection of the user terminal through the switch-in network is released by the data gateway according to the switch-in connection release indication. The embodiment of the invention can specifically indicate the released objects to certain or some switch-in connection (s), thus directly releasing the indicated switch-in connection, and solving the problem that a plurality of switch-in connections corresponding to the data connection can not be released in the prior art.

Owner:HUAWEI TECH CO LTD

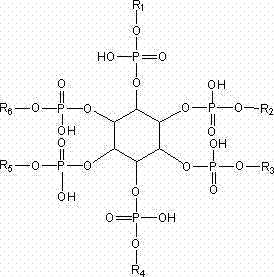

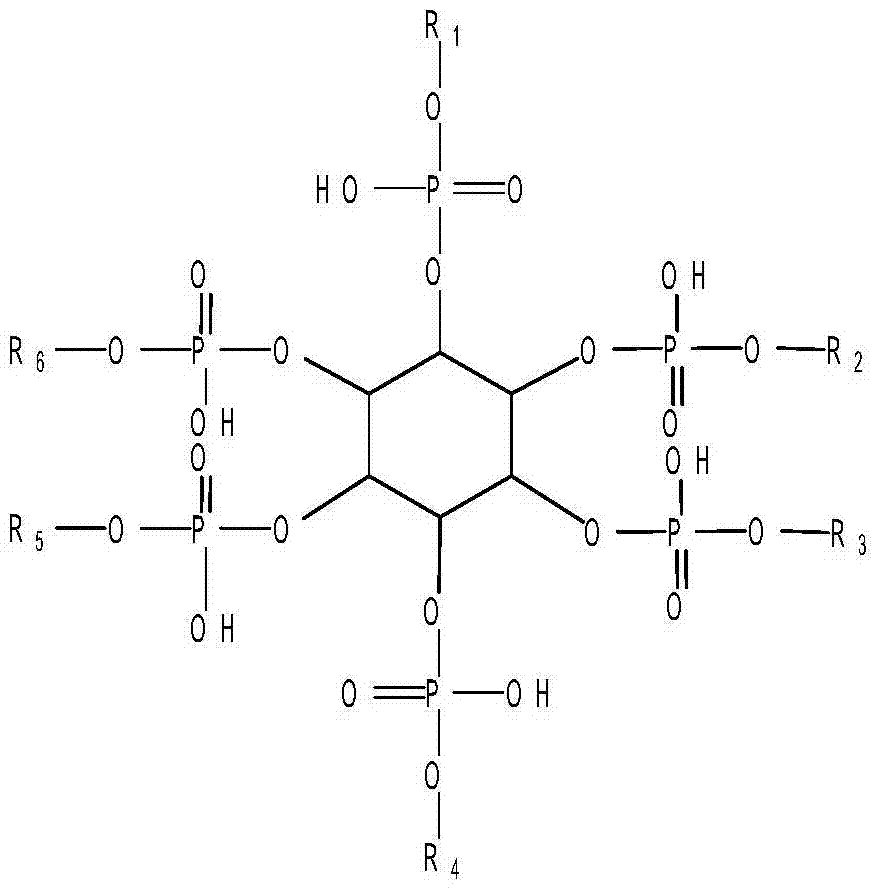

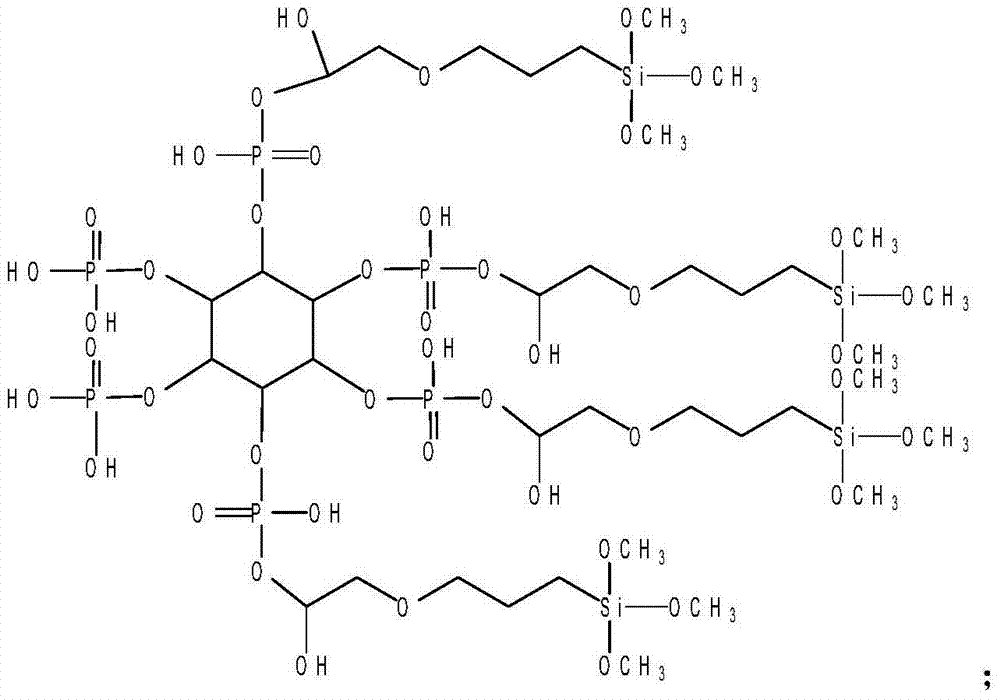

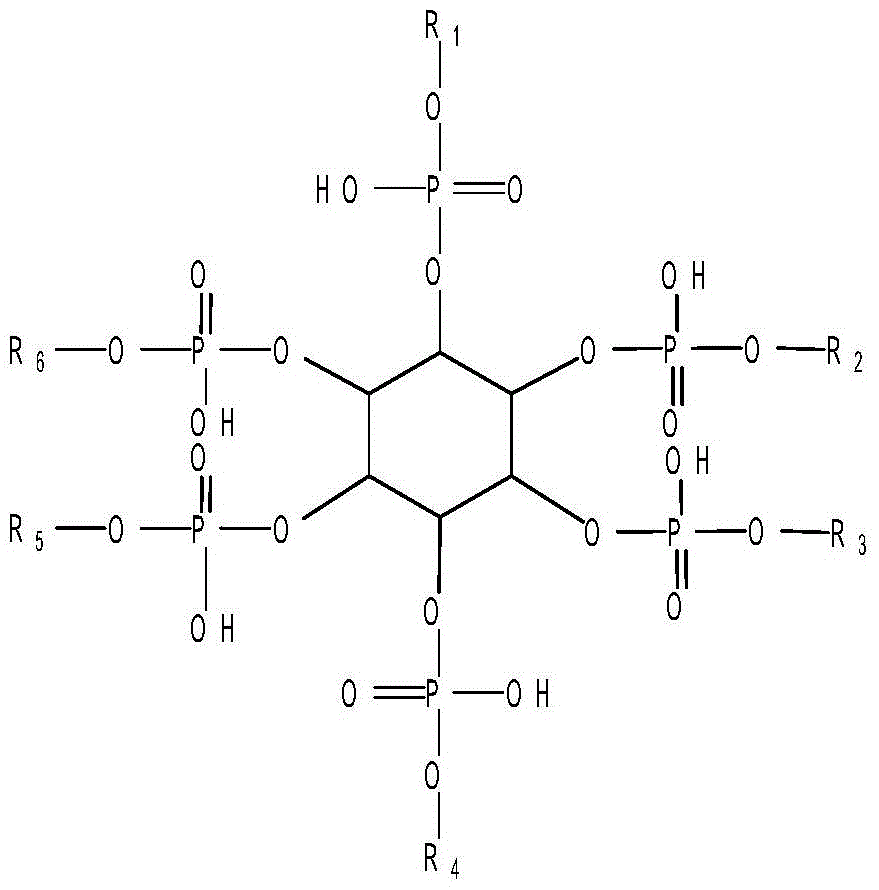

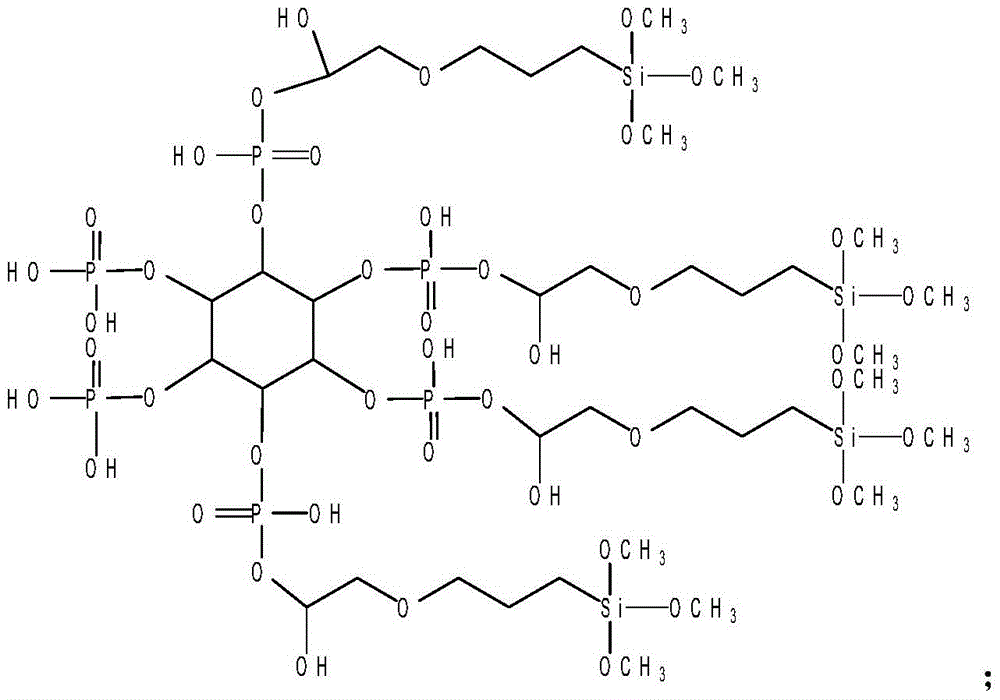

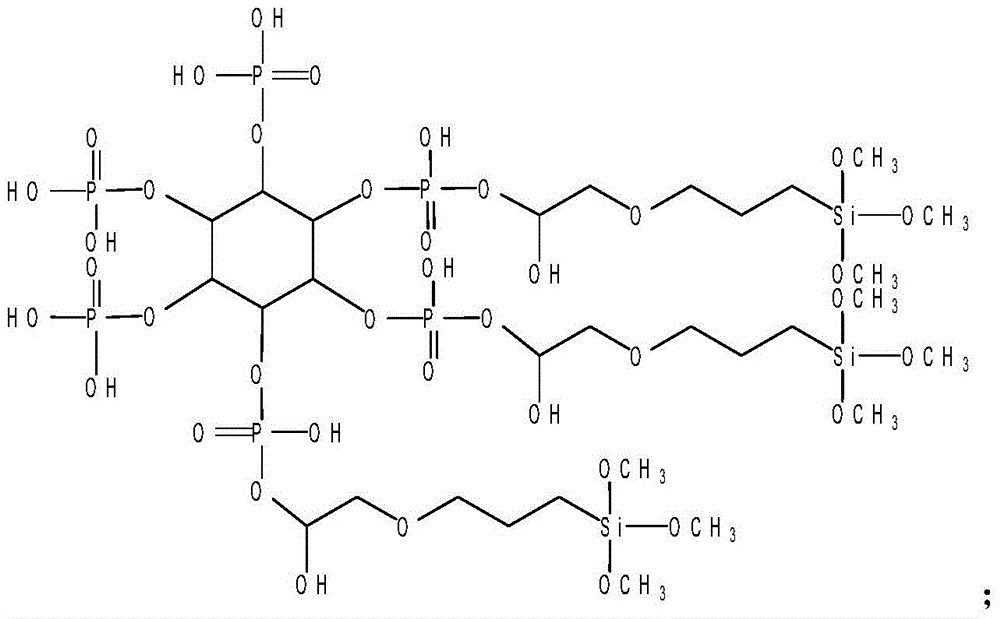

Preparation method of flame-retardant cotton fabric

ActiveCN104264467ASolve the durability problemSimple processGroup 5/15 element organic compoundsVegetal fibresFire retardantSilanes

The invention discloses a preparation method of a flame-retardant cotton fabric. The preparation method comprises the following steps: adding natural phytic acid compounds and gamma-epoxy propoxy trimethoxy silane into an organic solvent, stirring and reacting for 0.5-2 hours at 50-80 DEG C to obtain a flame-retardant finishing liquid, soaking a cotton fabric into the flame-retardant finishing liquid for 8-15 minutes, then soaking and rolling twice, then drying the cotton fabric at 60-90 DEG C, baking the cotton fabric for 2-8 minutes at 150-180 DEG C, and finally performing water washing, soaping and drying. The preparation method disclosed by the invention adopts natural phytic acid as a reaction raw material, a prepared flame-retardant textile cannot release free formaldehyde, the problem of formaldehyde release of most of current flame retardants can be solved, gamma-epoxy propoxy trimethoxy silane is introduced into flame retardant molecules, the prepared flame retardants contain a plurality of reactive groups, and the problem of flame-retardant finishing durability of the cotton fabric can be solved. The technical scheme disclosed by the invention is simple in process and convenient to operate, and has wide application prospects.

Owner:新乡市新科防护科技有限公司

Production method of flame-retardant and antibacterial cotton-linen blended fabric

InactiveCN106436309AHigh flame retardant efficiencyAbundant resourcesBiochemical fibre treatmentLiquid/gas/vapor removalPhosphoric acidChemistry

The invention discloses a production method of a flame-retardant and antibacterial cotton-linen blended fabric. The production method comprises the specific process steps that a rolling and baking process is adopted to conduct functional finishing on the cotton-linen blended fabric, wherein a flame retardant CP, a fiber protectant, chitosan, citric acid, sodium hypophosphite, a penetrant JFC and phosphoric acid are dissolved in water to prepare a finishing solution, the cotton-linen blended fabric is put in the finishing solution to be dipped for 5-20 minutes, then two times of dipping and two times rolling are performed, the solution detention rate is 70%-100%, and then the cotton-linen blended fabric is dried under the condition of 60-90 DEG C, then is baked under the condition of 130-170 DEG C and is washed and dried to obtain the flame-retardant and antibacterial cotton-linen blended fabric. The flame retardant CP adopted by the method is a phosphorus based flame retardant, the flame-retardant efficiency is high, the antibacterial agent chitosan is rich in resource, is biodegradable, good in absorption performance, safe and non-toxic and can also produce a phosphorus-nitrogen synergistic effect with phosphorus based flame retardant CP, and the flame-retardant effect is improved.

Owner:新乡市新科防护科技有限公司

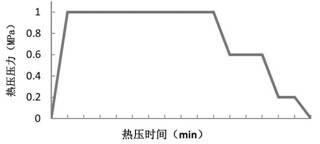

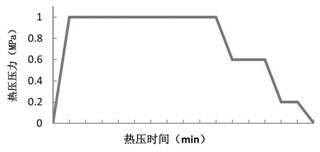

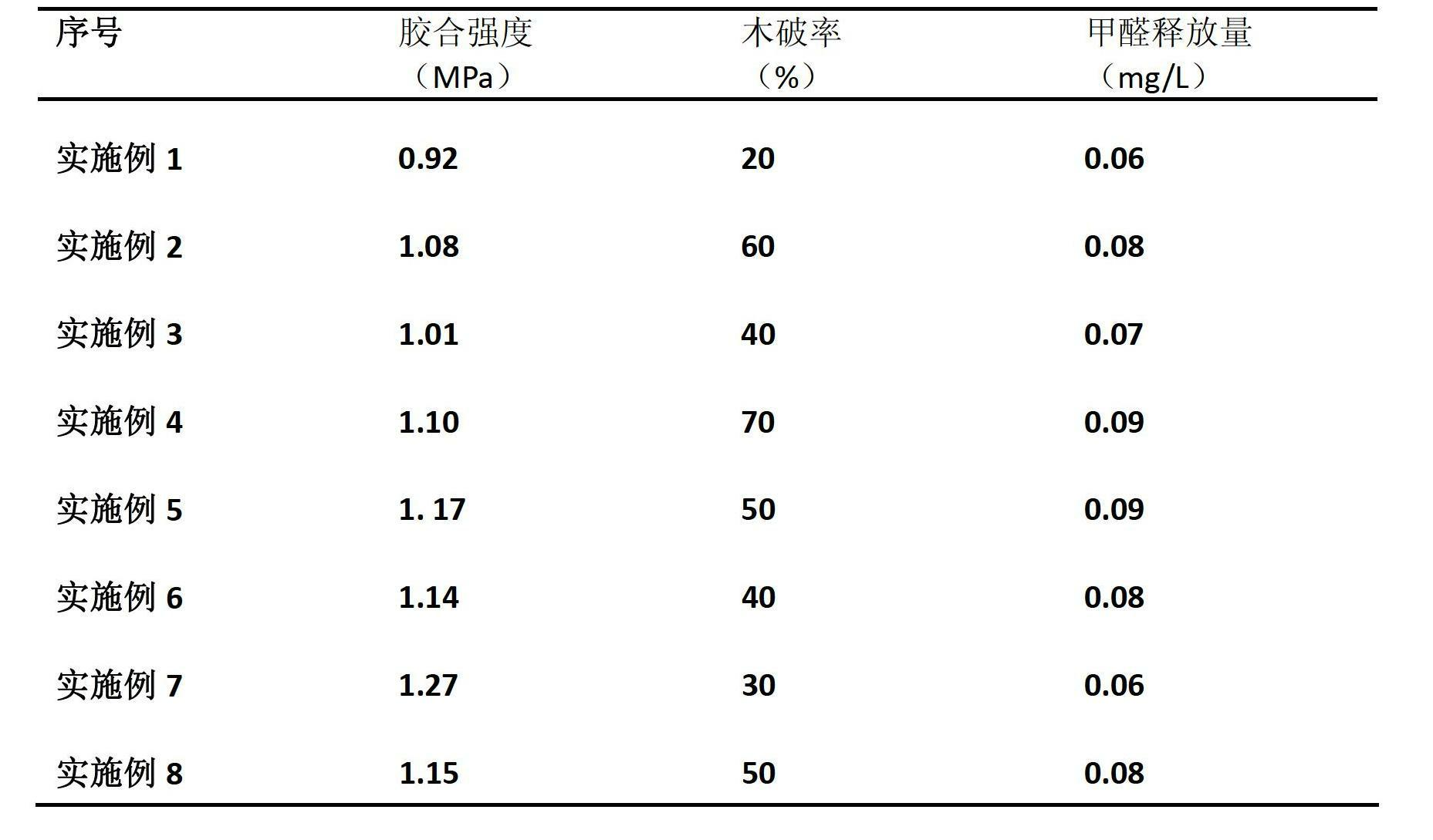

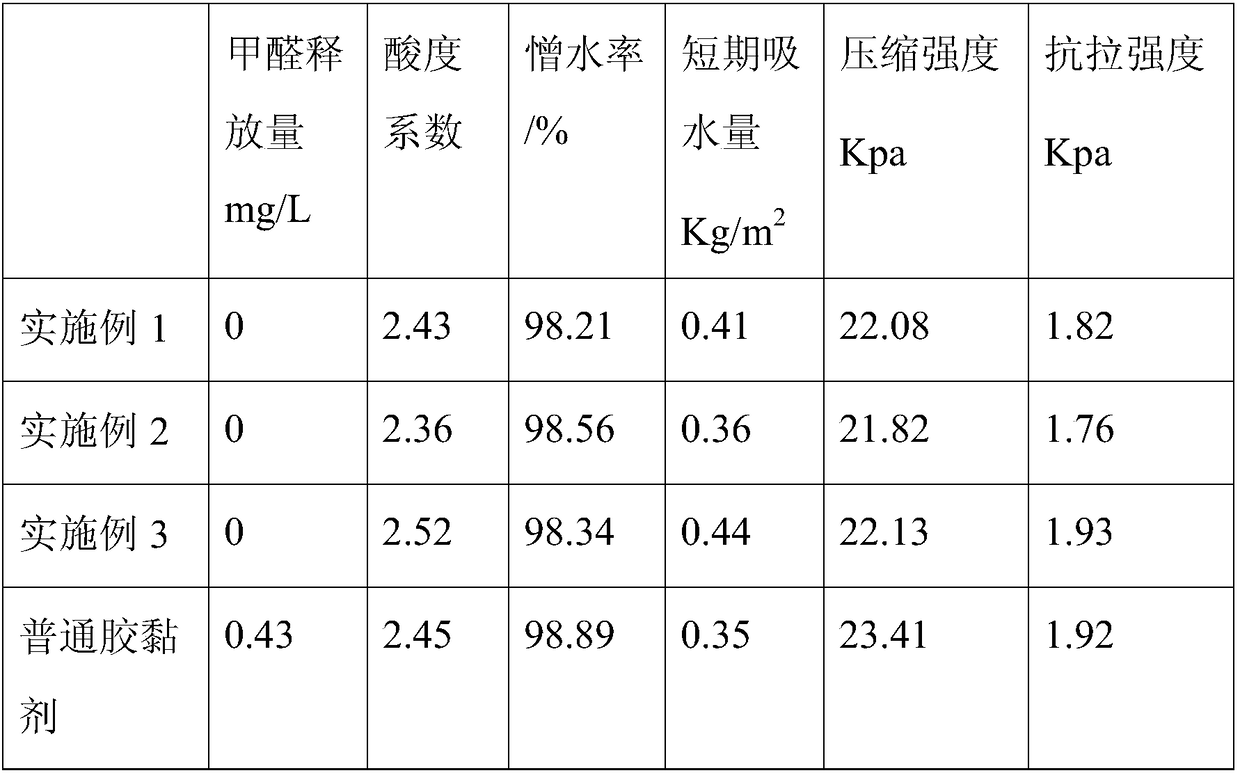

Method for preparing aldehyde-free veneer boards by biological oil starch adhesives

InactiveCN102642222ALow costImprove performanceStarch derivtive adhesivesWood veneer joiningFiberPersulfate

The invention relates to a method for preparing aldehyde-free veneer boards by biological oil starch adhesives and belongs to the field of artificial board production. The method comprises the steps of biological oil starch adhesive preparation: vacuum filtration and reduced pressure distillation method are adopted for carrying out pretreatment on biological oil; wild cassava starch is added into water, starch emulsion and concentrated hydrochloric acid are prepared, after the temperature is raised, oxidants of persulfate are then added, and acidolysis oxidized starch emulsion is prepared through reaction; the biological oil is added into the emulsion, polyving akohol solution is added, then, alkali liquor and oxalic acid are repeatedly and alternately added; and then, borax is added until the viscosity reaches the requirements, and main agents of biological oil starch adhesives are obtained; and aldehyde-free veneer board preparation: single boards are dried and are subjected to adhesive coating at two sides by adopting the prepared adhesives, the single board blank assembly is carried out according to the odd layer principle and in a mode that the fiber directions of adjacent single boards are mutually vertical, the veneer boards are pressed and manufactured under the hot pressing curve, and the aldehyde-free veneer boards are obtained. The preparation process is simple, and the intensity of the prepared veneer boards reaches the requirements of II type veneer boards.

Owner:BEIJING FORESTRY UNIVERSITY

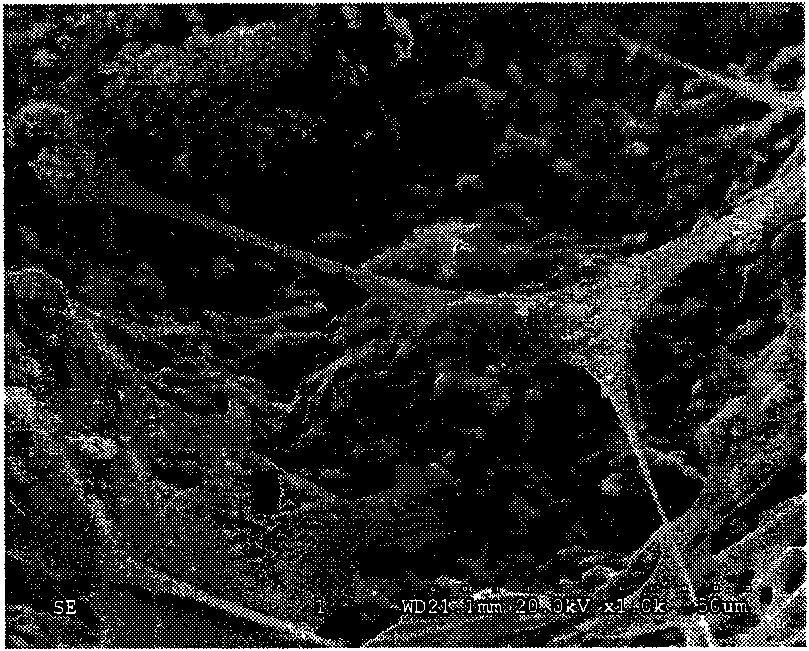

Tissue engineering bone implant and method for constructing the same

The invention provides a tissue engineering bone implant and a method for constructing the same, which includes stent material and seeded cell transfected with adenovirus vector. The seeded cell adheres to the stent material, and constitutes a cell vector complexes with a certain spatial structure and bioactivity. The stent material uses nano hydroxyapatite (Nano-HA) prepared by sol-flocculation method, and marrow mesenchymal stem cell with transfected virus is adhered to the nano hydroxyapatite. The tissue engineering bone provided by the invention, which includes marrow mesenchymal stem cell, adenovirus containing BMP-2 target gene and nano hydroxyapatite, and is constructed by a certain process and method, is bionic artificial bone with a certain spatial structure and bioactivity. The constructed bionic artificial tissue engineering bone provided by the invention can be used as bone implant for repairing bone with large defective segment, and has been proved to repair bone with large defective segment in animal experiment.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

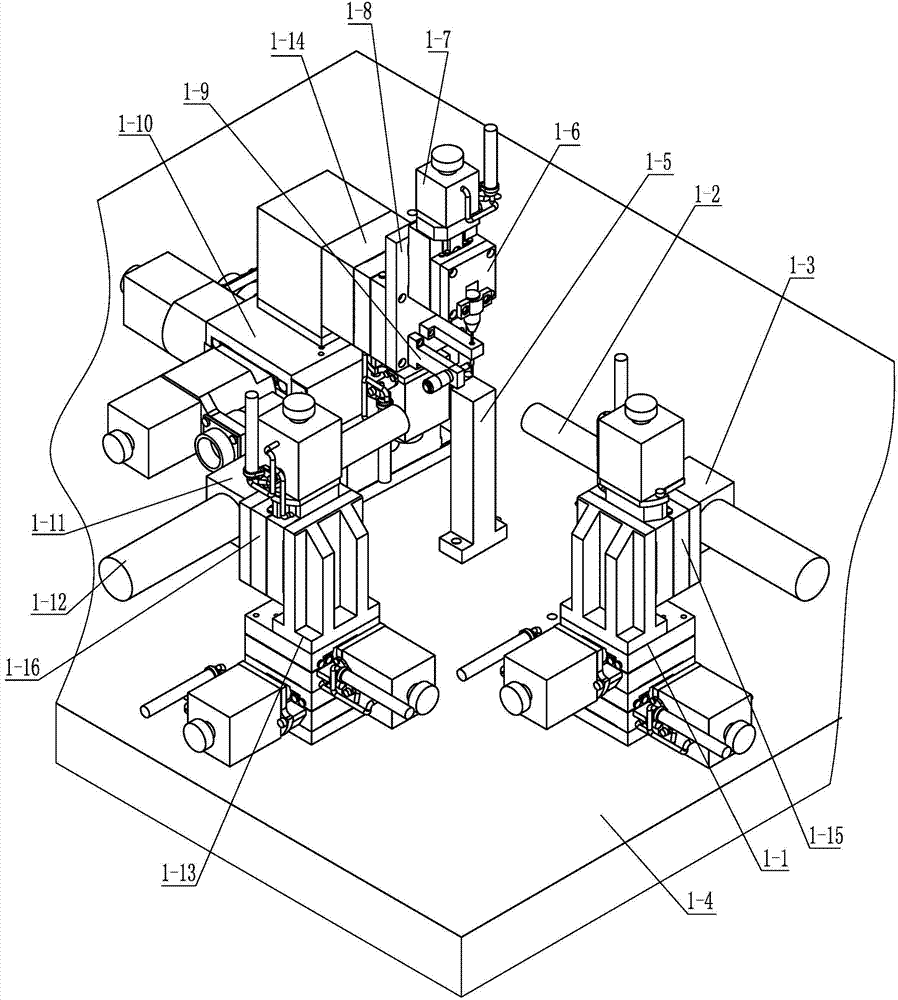

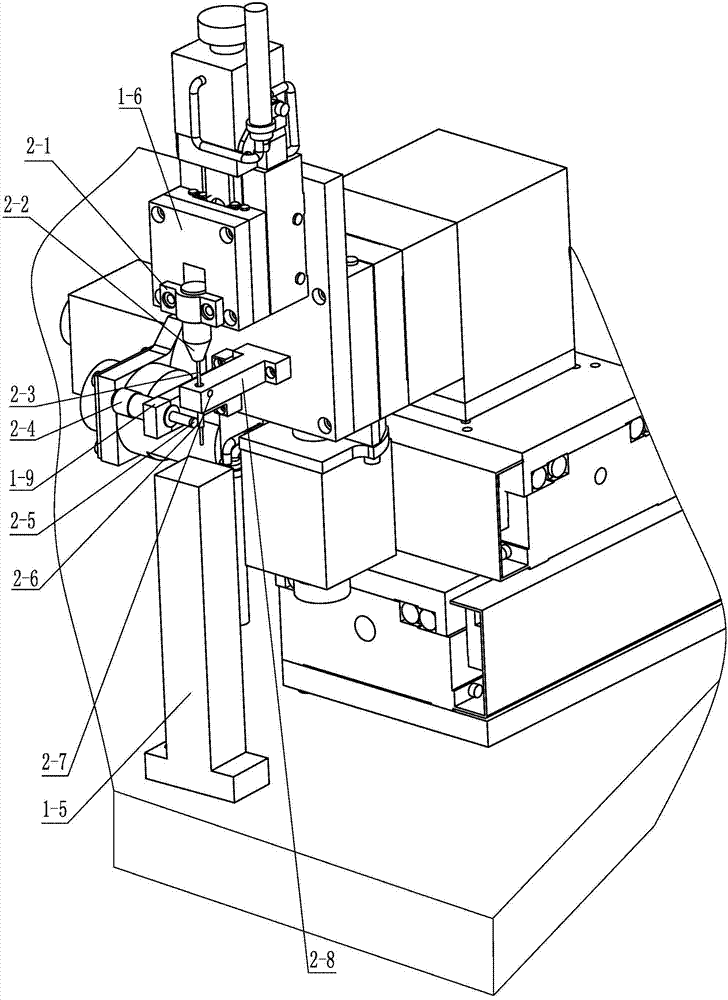

Single-needle type micron-sized object picking and releasing device and method

ActiveCN104290056AAvoid stress concentrationRelease stabilityWork holdersElectrical resistance and conductanceMicrometer

The invention discloses a single-needle type micron-sized object picking and releasing device and method and relates to a device and method for picking and releasing a micron-sized object gently to solve the problem that micron-sized object picking operation fails due to high local stress generated through traditional mechanical clamping and vacuum absorption. The device comprises a second three-axis electric horizontally-moving table, a vibration isolation table, a first three-axis electric horizontally-moving table, a third three-axis electric horizontally-moving table, a self-tightening chuck, a probe, a spiral micrometer head, a thermistor element, a capillary tube and a capillary tube clamp, wherein the first three-axis electric horizontally-moving table comprises a second connecting plate, a probe driving motor, a first connecting plate, a micrometer head clamp and a first connecting base, the second three-axis electric horizontally-moving table comprises a first microscope, a first microscope clamp and a second connecting base, and the third three-axis electric horizontally-moving table comprises a second microscope, a second microscope clamp and a third connecting base. The device and method are used for gentle picking, transferring and releasing of micron-sized objects.

Owner:HARBIN INST OF TECH

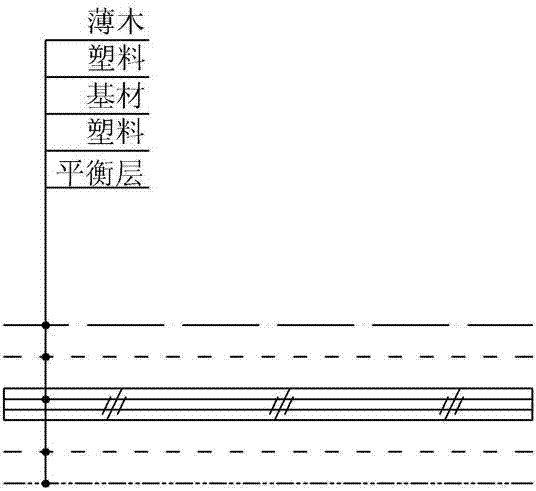

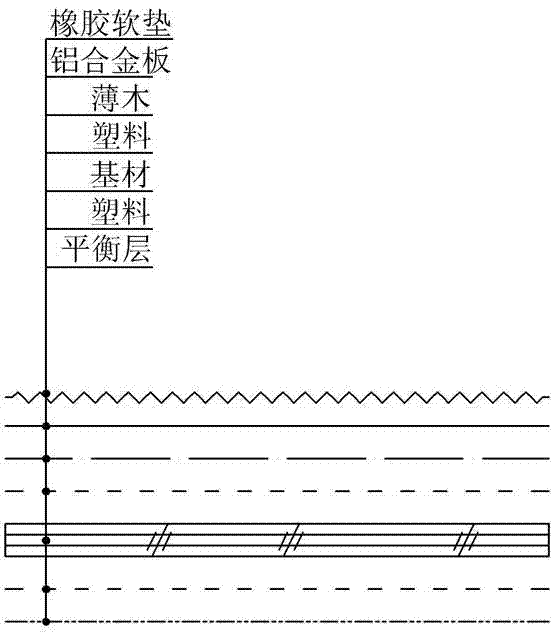

Process for quickly laminating veneers of formaldehyde-free wood-plastic composite plates

ActiveCN103538125ASolve the release problemHigh surface bonding strengthWood veneer joiningWood layered productsEnvironmental resistanceSingle plate

The invention relates to a process for quickly laminating veneers of formaldehyde-free single plates / plastic composite plates. The process includes that prefabricated formed polypropylene plastic films are used as veneering adhesion materials. The process has the advantages that shortcomings of glue penetration, blister, glue failure and the like which are easy to occur when liquid adhesive is used for veneering in the traditional process can be overcome, surface quality shortcomings such as discoloration of veneers formed during wood-plastic composite plate veneering and composite plate manufacturing can be overcome, and the environmental protection performance of the decorative wood-plastic composite plates and the optimal decorative performance of the veneers can be maintained.

Owner:FUJIAN AGRI & FORESTRY UNIV

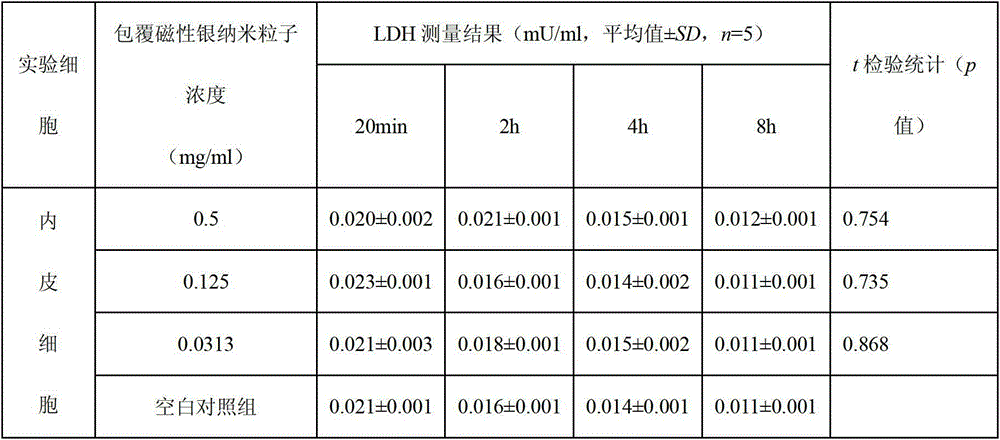

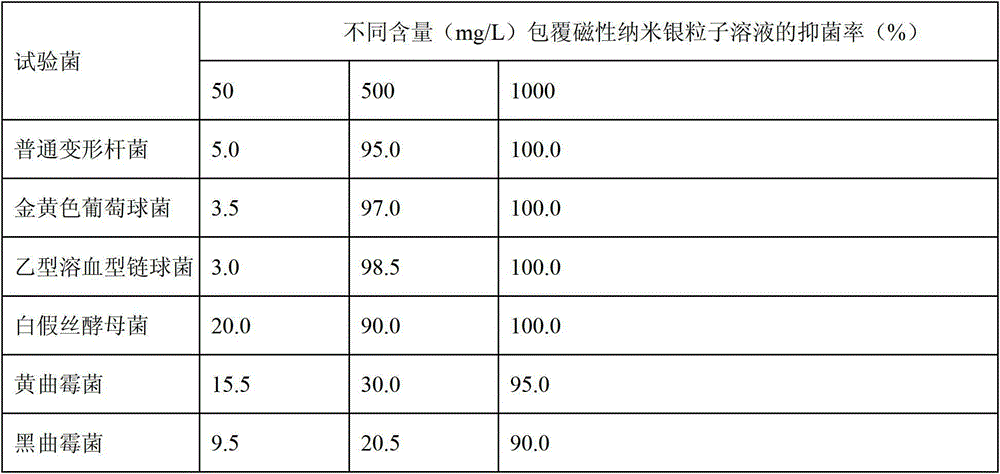

Preparation method of amylose-coated I3<->-complexed silver-coated iron composite nanoparticles

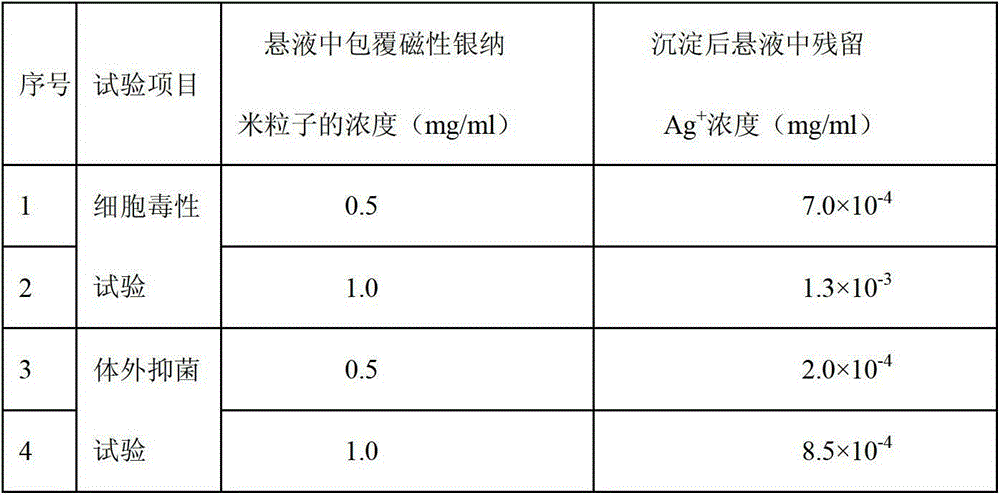

InactiveCN103142649AAddress targeting issuesAddress toxicityAntibacterial agentsEnergy modified materialsSilver iodideIron nanoparticle

The invention discloses a preparation method of amylose-coated I3<->-complexed silver-coated iron composite nanoparticles, which comprises the following steps: synthesizing silver-coated iron nanoparticles, coating amylose on the nanoparticles, and complexing the I3<-> into the amylose molecular spiral structure to finally form the composite magnetic silver nanoparticles. By designing and synthesizing the silver-coated iron composite nanoparticles, the invention solves the problem of targeted entry of silver; by coating the starch on the nano silver, the invention solves the problems of toxicity and stability in the nano silver; by complexing the iodine ions with the amylose, the invention solves the problem of introduction of iodine; under the magnetocaloric effect, the invention solves the problem of release of iodine complex ions; by using the specific fusion action of the iodine complex ions on the nano silver, the invention solves the problem of release of silver ions in the nano silver; and by generating the silver iodide, the invention solves the problem of removal of in-vivo silver ions. Meanwhile, the designed system can comprehensively utilize the thermotherapeutic benefit of magnetic particles as well as the broad spectrum and efficient sterilization characteristics of the silver.

Owner:赵华文

Formaldehyde scavenger for urea-formaldehyde glue and technique for producing the same

InactiveCN101486887ASolve the release problemEliminate fumigated ammonia processAldehyde/ketone condensation polymer adhesivesWood veneer joiningScavengerHydrazine compound

The invention relates to formaldehyde scavenger which belongs to novel aldehyde remover used in urea-formaldehyde glue; the formaldehyde scavenger essentially solves the problems that the urea-formaldehyde glue adhesive materials reduce the release of formaldehyde during the production and use processes, which belongs to the aldehyde reducing technology during the urea-formaldehyde glue use process; the formaldehyde scavenger is characterized by comprising compositive polyphosphate, monadic organic amine, binary organic amine, phenolic compounds, lignin-containing compounds, hydrazine compounds, urea and products thereof produced by the reaction with acid, sulfite and the like, being added with water according to the weight ratio of the materials. The synthesis and composite technology of the formaldehyde scavenger is a special method to prepare formaldehyde scavenger for man-made board. The formaldehyde scavenger has the advantages of easy and even mixture with glue, good aldehyde removing effectiveness without changing the plate, no impact on the strength and other physical and chemical properties of the plate when being added simultaneously with a curing agent when adjusting the glue, convenient use, storage and transportation, cheap price and the like, and is a novel aldehyde remover of environmental protection, high efficiency and excellent aldehyde removing performance.

Owner:袁晓东 +1

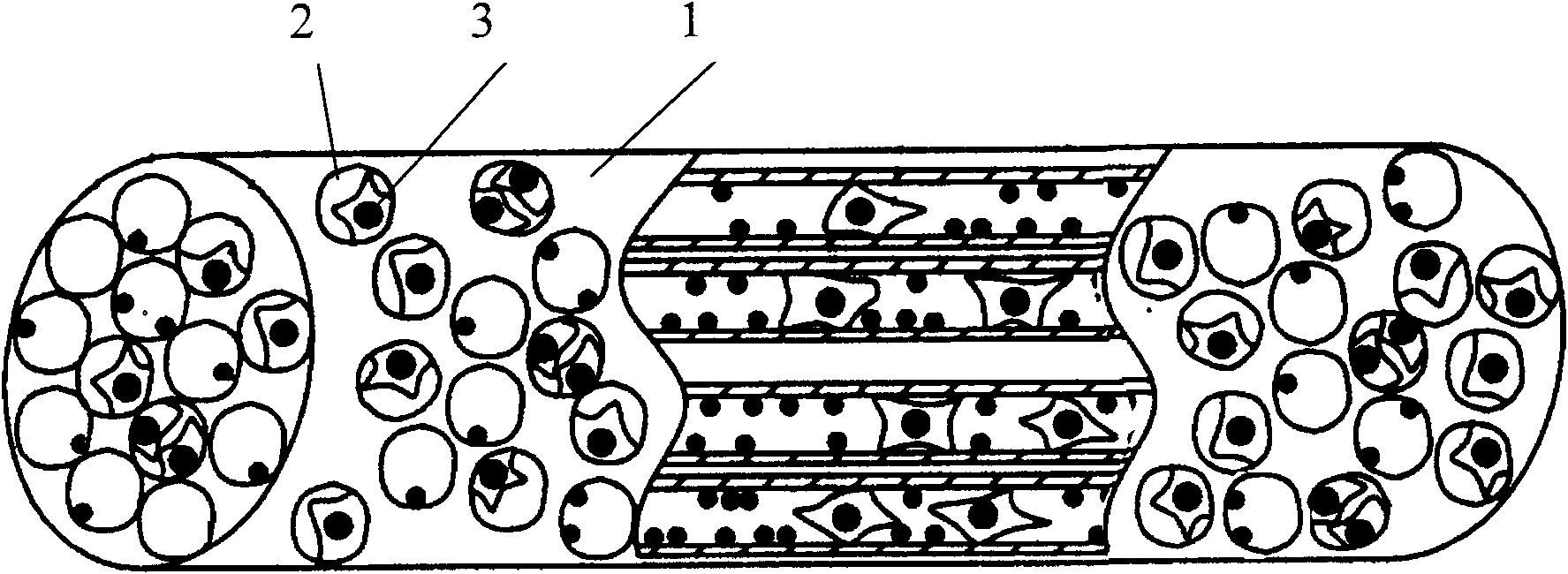

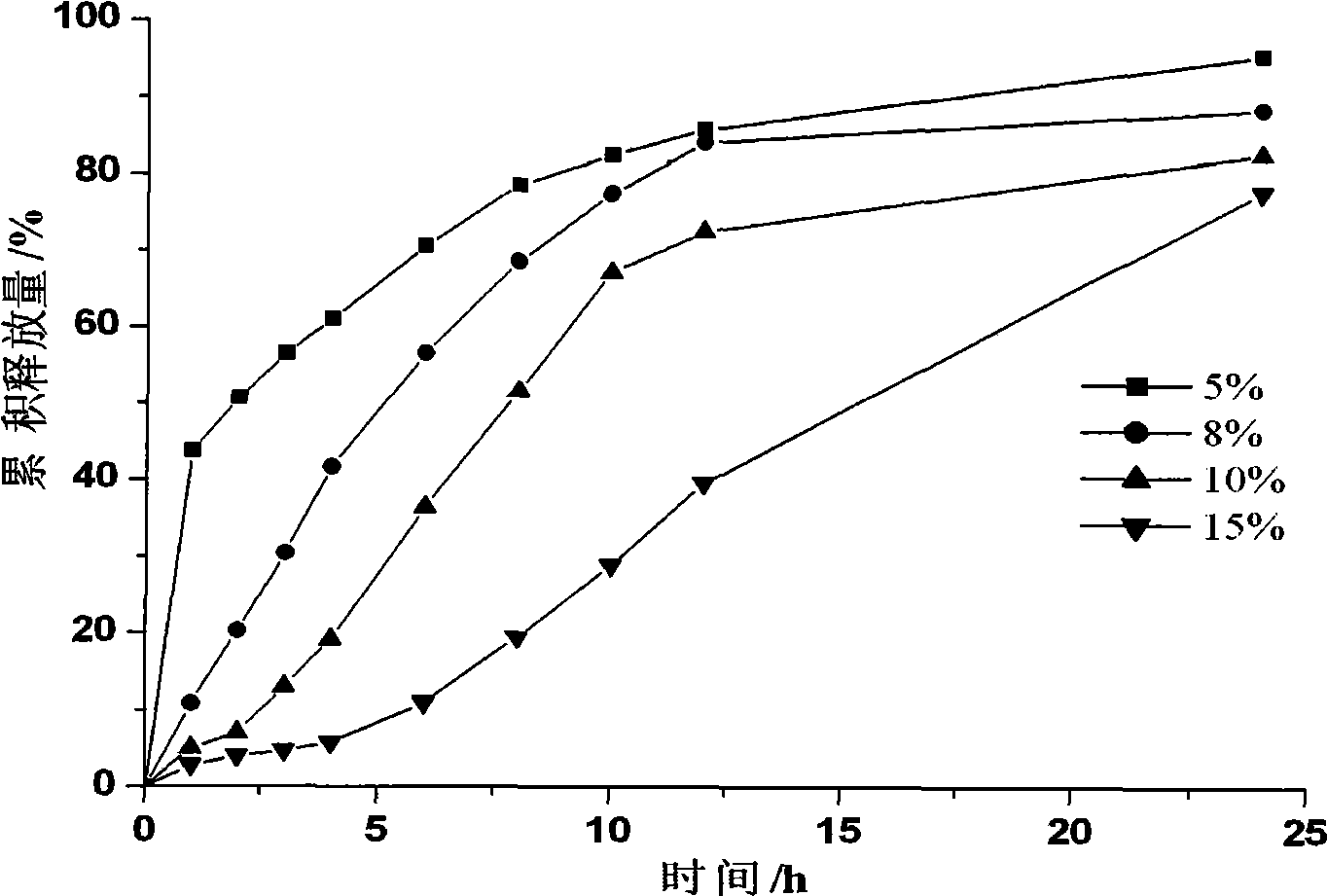

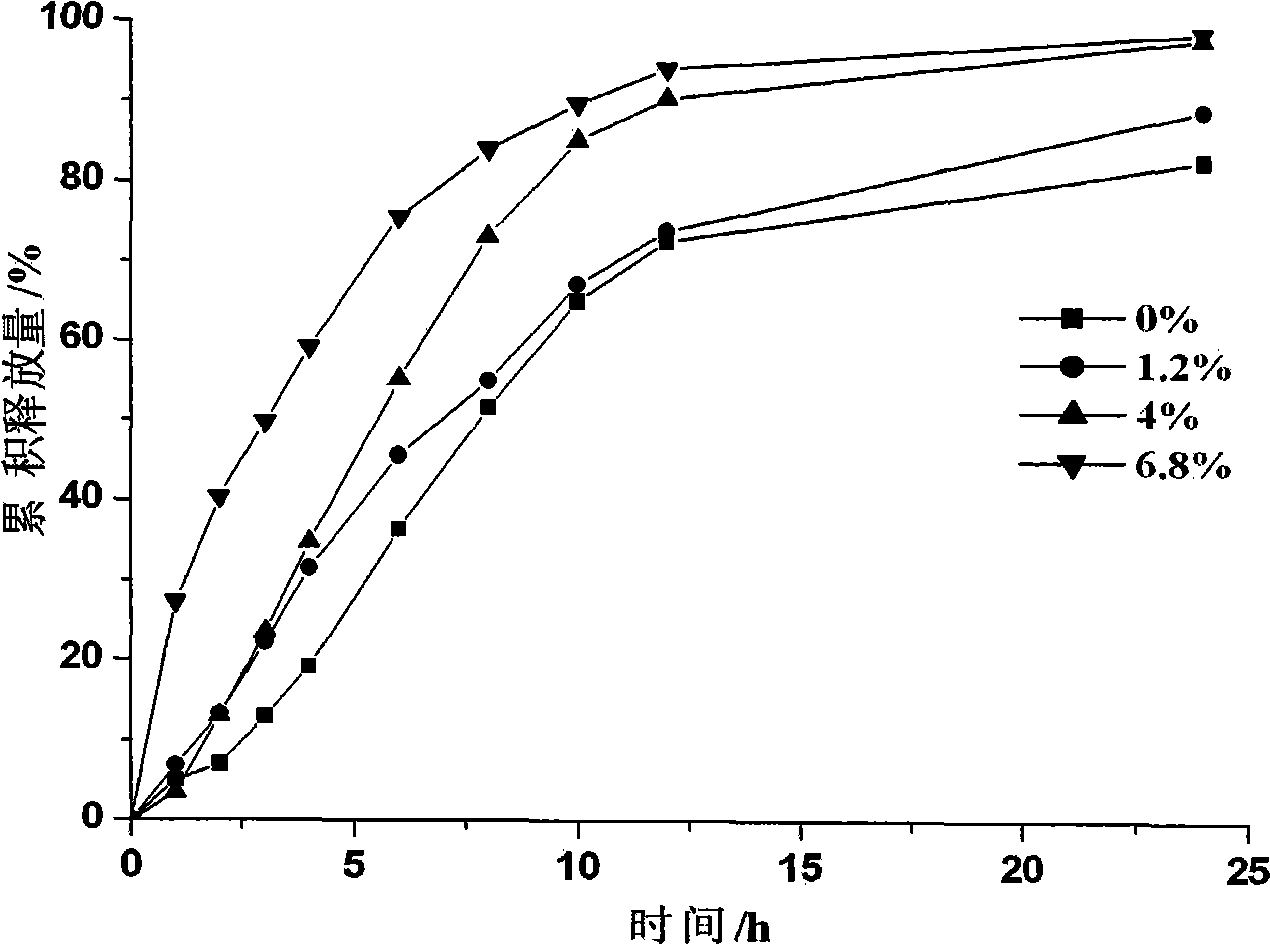

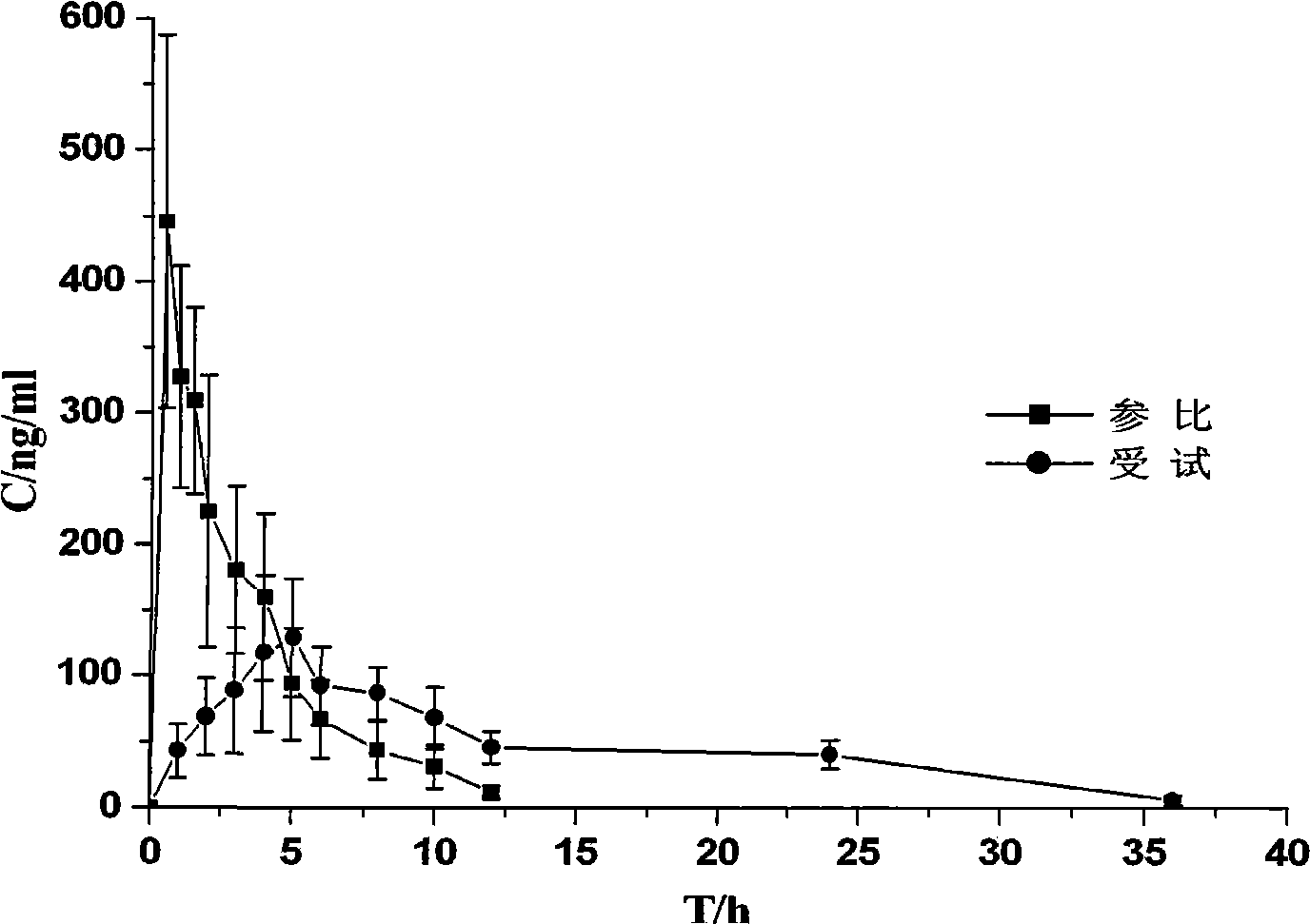

Bupropion hydrochloride sustained-release pellet and preparation method thereof

InactiveCN101485633AImprove solubilityNo pH dependenceOrganic active ingredientsNervous disorderSustained release pelletsBupropion hydrochloride

The invention relates to the field of a drug preparation, in particular to a hydrochloric acid bupropion slow release micro pill and a method for preparing the same. The micro pill consists of a drug containing pill core and a slow release coating layer which consists of slow release materials and a pore-forming agent, wherein the weight of the slow release materials against the weight of the drug containing pill core is between 8 and 15 percent, and the weight of the pore-forming agent against the weight of the slow release materials is between 1 and 6 percent. The micro pill does not need to be combined by a plurality of micro pills with different release modes, and only adopts a single micro pill to achieve the good release performance, thereby lowering production cost and simplifying production process.

Owner:CHINA PHARM UNIV

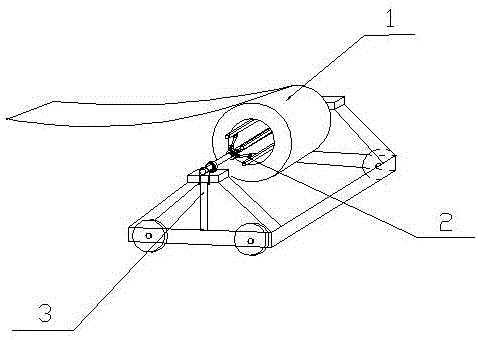

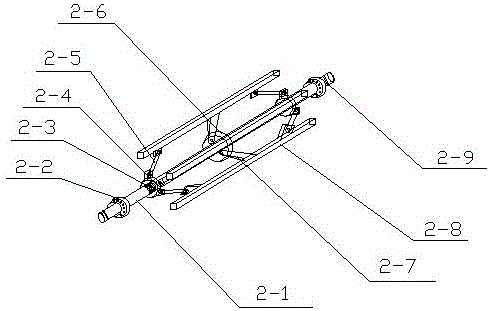

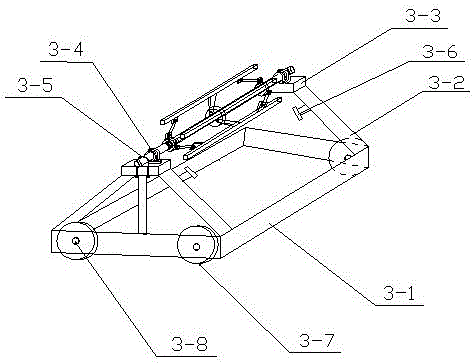

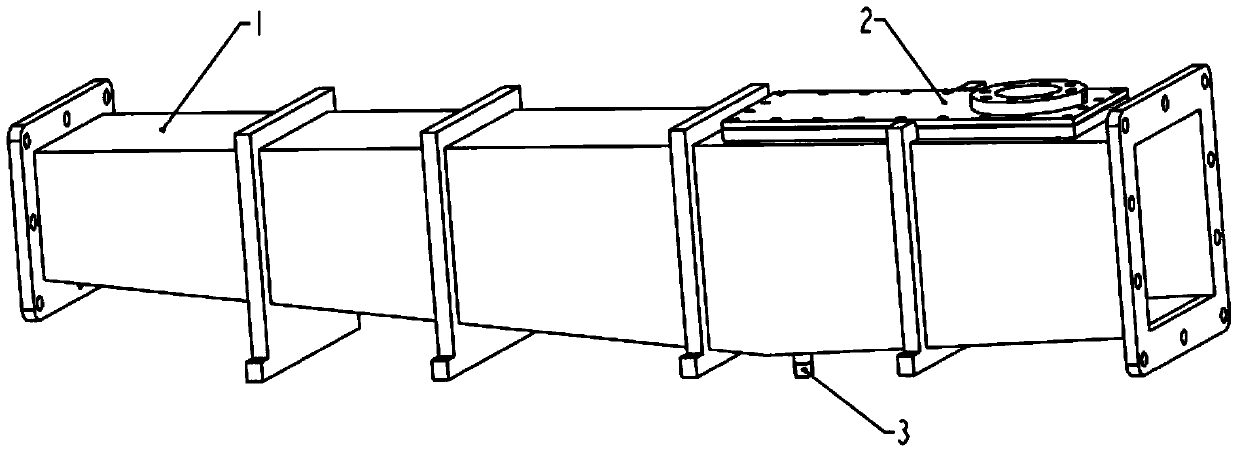

Automatic releasing device and method of color steel tile coil on construction site

ActiveCN105019610ASolve the release problemReasonable structureRoof toolsEngineeringBuilding construction

The invention discloses an automatic releasing device and method of a color steel tile coil on a construction site, and belongs to building construction devices and methods thereof. The automatic releasing device is characterized by further comprising a releaser 2 and supports 3; connecting rods 2-5 are correspondingly installed on a shaft sleeve 2-4 of the releaser 2, coil supporting rods 2-8 are arranged on the front connecting rods 2-5 and the back connecting rods 2-5 which are located on the same sides, the releaser 2 is installed on the supports 3, speed controllers 3-5 are installed between a rotating shaft 2-1 of the releaser 2 and bearing beams 3-3 on the supports 3 respectively, and coil stop blocks 3-6 are correspondingly installed on slant support bodies of the supports 3. The automatic releasing method of the color steel tile coil on the construction site includes the steps that 1, the coil supporting rods are contracted and sleeved with the coil; 2, the coil supporting rods are stretched to support the coil; 3, the coil is installed on the supports to be in place; 4, the releasing speed of the coil is controlled; 5, shifting of the coil is controlled; 6, the coil is released, and color steel tiles are manufactured. The labor efficiency and the product quality are improved, and potential safety hazards are reduced.

Owner:CHINA MCC17 GRP

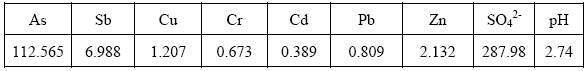

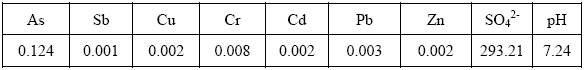

Method for cooperatively treating arsenic-containing waste liquid by using sulfate reducing bacteria and lead-zinc smelting slag

ActiveCN113788593AHigh removal rateEfficient governanceWater contaminantsMultistage water/sewage treatmentSodium lactateMicroorganism

The invention discloses a method for cooperatively treating arsenic-containing waste liquid by using sulfate reducing bacteria and lead-zinc smelting slag. The method comprises the following steps: (1) stirring and mixing the lead-zinc smelting slag and the arsenic-containing waste liquid in an anaerobic environment and conducting reacting to obtain to-be-treated waste liquid; and (2) adding sulfate reducing bacteria into the to-be-treated waste liquid obtained in the step (1), adding sodium lactate, and carrying out microbiological treatment, so as to synergistically treat the arsenic-containing waste liquid by the sulfate reducing bacteria and the lead-zinc smelting slag. According to the method for cooperatively treating the arsenic-containing waste liquid through the sulfate reducing bacteria and the lead-zinc smelting slag, the sulfate reducing bacteria and the lead-zinc smelting slag cooperate with each other, the removal rate of arsenic in the arsenic-containing waste liquid is jointly increased, and the removal rate of arsenic in the arsenic-containing waste liquid reaches 99.80% or above.

Owner:CENT SOUTH UNIV

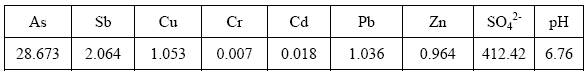

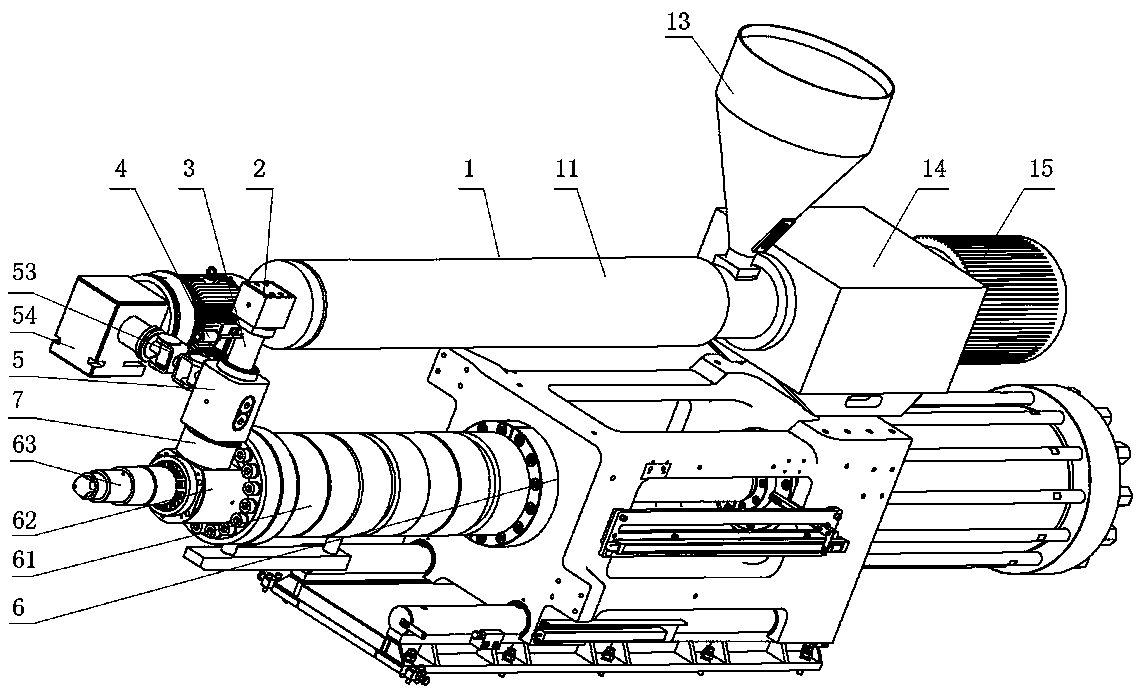

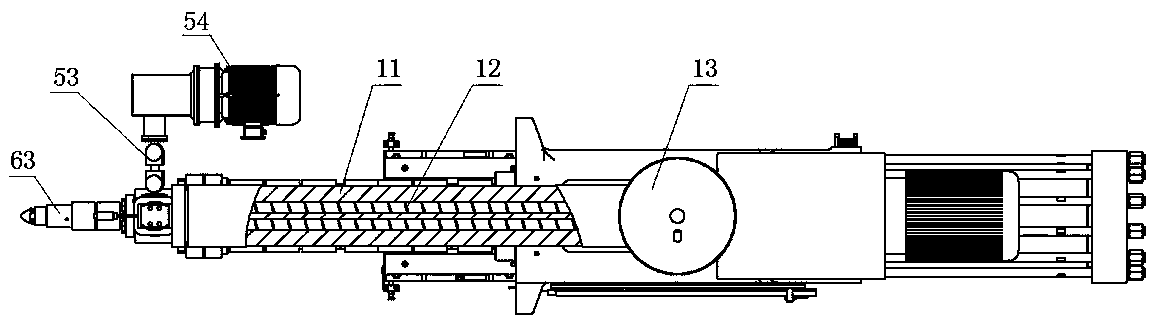

Wood plastic physical micro-foaming squeezing type injection molding machine and molding process

The invention relates to a wood plastic physical micro-foaming squeezing type injection molding machine and a molding process, and belongs to the field of wood plastic production equipment. The machine comprises a dual-screw extruder and an injection machine and is characterized in that the dual-screw extruder comprises a material cylinder, two screws are arranged in the material cylinder, a hopper is arranged at the input end of the material cylinder, a material cylinder front body is arranged at the output end of the material cylinder, a connecting body is arranged below the material cylinder front body, a supercutical fluid injector is arranged at the side end of the connecting body, a first cavity is formed in the connecting body, the upper end of the connecting body communicates withthe material cylinder front body through the first cavity, the side end of the connecting body communicates with the supercutical fluid injector through the first cavity, a gear pump is arranged belowthe connecting body, the injector comprises an injection oil cylinder, an injection cylinder front body, and a nozzle, and the lower portion of the gear pump is connected with the injection cylinderfront body through a check valve. The problems that a wood plastic product is not uniform in size, product molding is large in brittleness, compactness is poor, cracking is prone, and density is largecan be solved. The machine is simple in whole structure and convenient to machine.

Owner:山东通佳智能装备有限公司

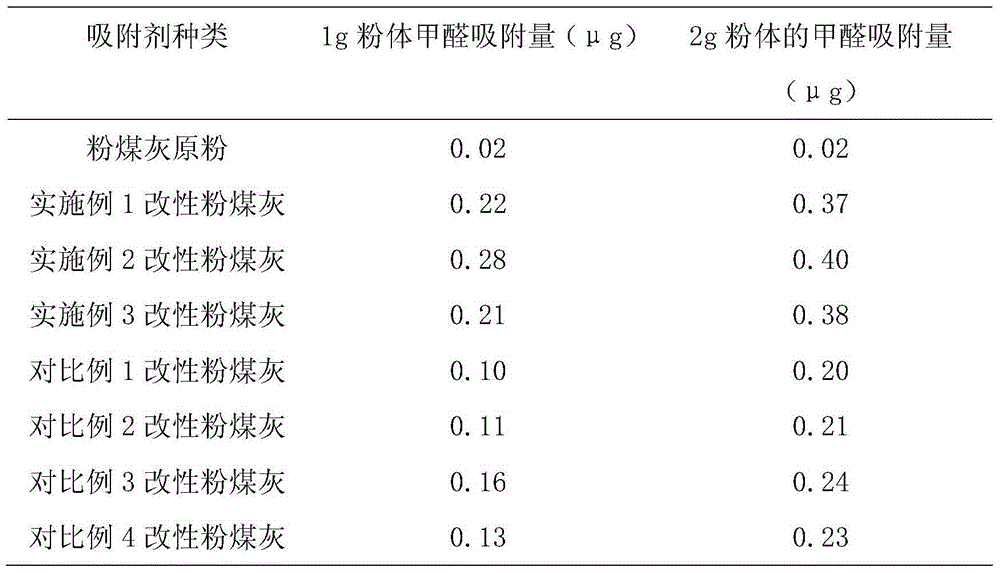

Coal ash capable of adsorbing formaldehyde and preparation method of coal ash

ActiveCN104353425ASave resourcesProtect environmentGas treatmentOther chemical processesFertilizerChemistry

The invention discloses a preparation method of coal ash capable of adsorbing formaldehyde. The coal ash is used as an adsorption material. The method comprises the steps of (1) modifying the coal ash by a surfactant, and stirring and soaking; (2) performing loading treatment on a product obtained in the step (1) by a formaldehyde catching agent, and soaking; and (3) performing normal temperature drying to remove most water, and performing freeze drying to prepare the coal ash capable of adsorbing the formaldehyde. The modified coal ash prepared by the preparation method disclosed by the invention can be used for further solving the problem of formaldehyde release from indoor air, and the health of a human body is guaranteed; meanwhile, the reacted coal ash can be used as a fertilizer, so that secondary pollution to the environment can be avoided.

Owner:安徽创能环保材料有限公司

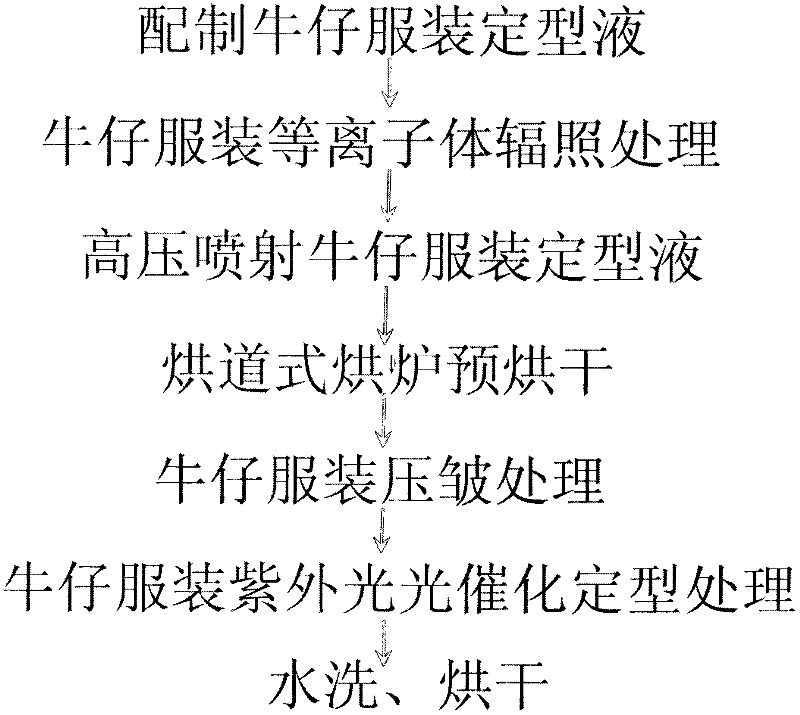

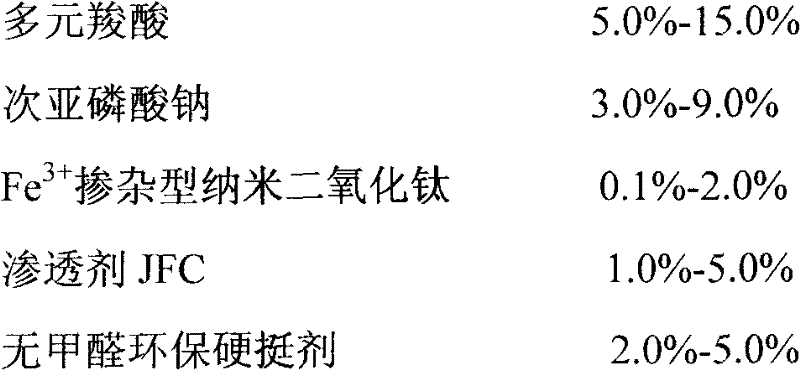

Jeans garment shaping liquid as well as preparation method and application thereof in ultraviolet light photocatalytic shaping and finishing method

InactiveCN102517893AGood shaping effectSolve the release problemPhysical treatmentSodium Hypophosphite MonohydrateUltraviolet lights

The invention provides a jeans garment shaping liquid as well as a preparation method and an application thereof in an ultraviolet light photocatalytic shaping and finishing method and relates to a jeans garment shaping liquid. The jeans garment shaping liquid comprises the following components in percentage by weight: 5.0-15.0 percent of polycarboxylic acid, 3.0-9.0 percent of sodium hypophosphite, 0.1-2.0 percent of Fe<3+>doped nanometer titanium dioxide, 1.0-5.0 percent of penetrating agents, 2.0-5.0 percent of formaldehyde-free environmentally-friendly stiffening agents, 3.0-5.0 percent of smooth brighteners and 59.0-85.9 percent of water. The invention also relates to the jeans garment ultraviolet light photocatalytic shaping and finishing method by adopting the shaping liquid, which comprises the following steps of: carrying out plasma radiation treatment on a part of a jeans garment required to be shaped, spraying the shaping liquid onto the treated part of the jeans garment, pre-drying on a drying tunnel-type drying oven and crinkling the treated part of the jeans garment; then carrying out photocatalytic shaping on the treated parts; and finally washing and drying. The method is high in catalytic efficiency, is environmental-friendly and energy-saving and is high in production efficiency. The finished jeans garment is durable, is good in shaping effect and good in handfeel and gloss, is environmental-friendly and generates no formaldehyde emission.

Owner:GUANGDONG JUNAN JEANS RES INST +1

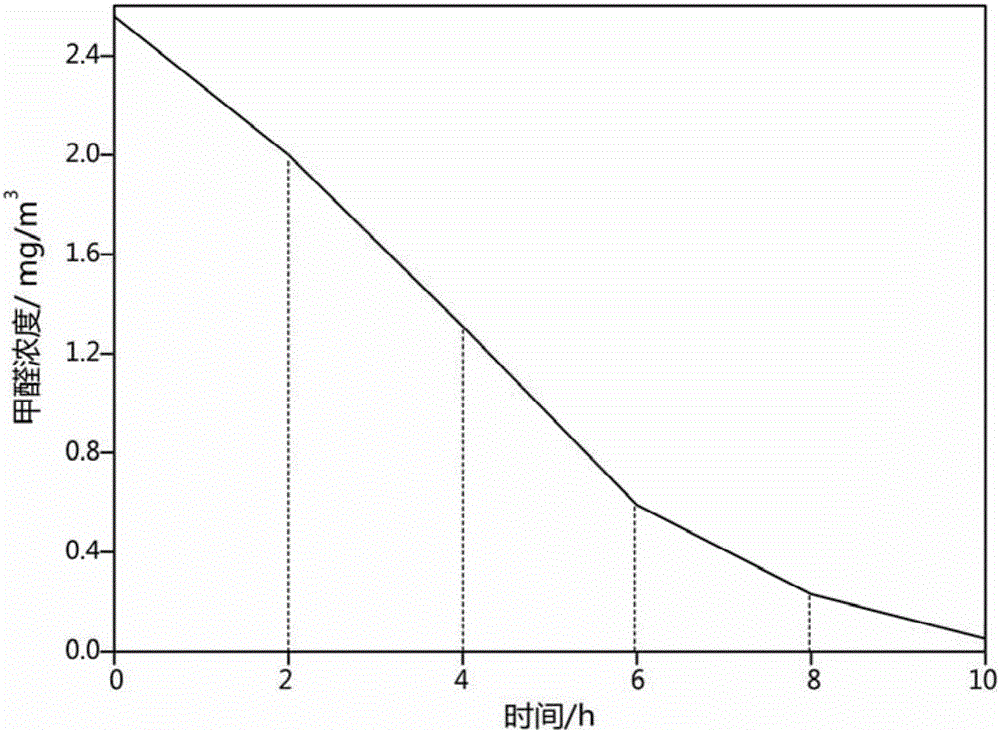

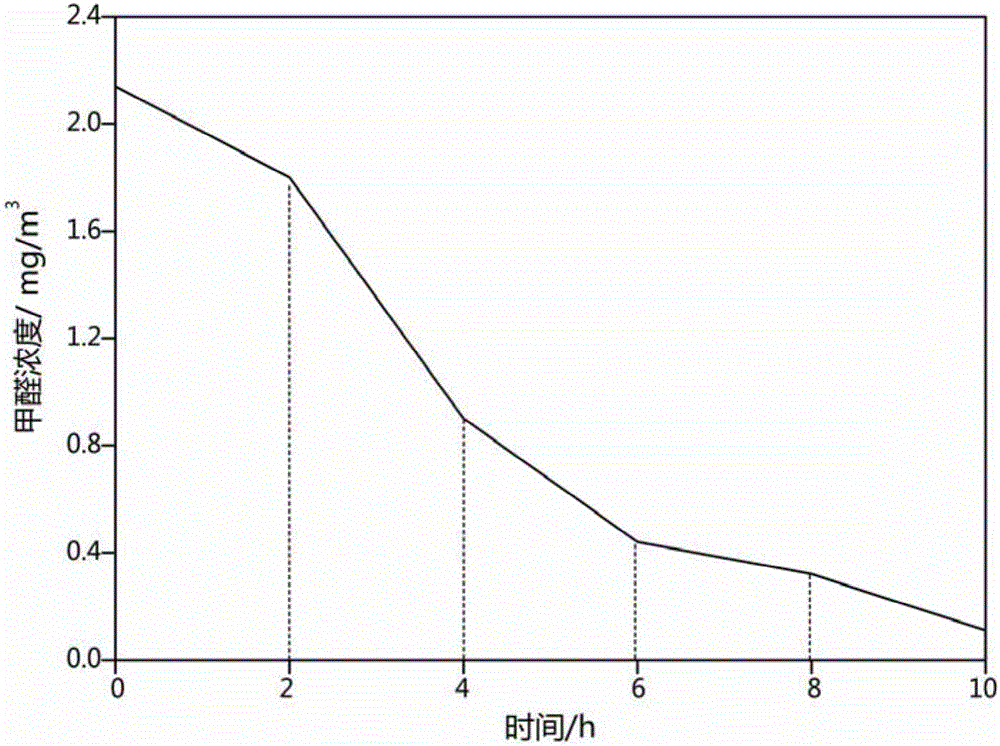

Sliver-titanium composite film loaded wood base material capable of degrading formaldehyde under visible light irradiation, and preparation method of sliver-titanium composite film loaded wood base material

InactiveCN105126923AHigh catalytic efficiencyHigh formaldehyde degradation efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationComposite filmPhotocatalytic degradation

The invention discloses a sliver-titanium composite film loaded wood base material for degrading formaldehyde under visible light irradiation, and a preparation method of the sliver-titanium composite film loaded wood base material, and relates to a wood base material capable of degrading formaldehyde under visible-light photocatalysis, and a preparation method of the wood base material. The sliver-titanium composite film loaded wood base material solves the problems that the conventional photocatalytic formaldehyde degradation method using single catalyst has the defects of small light-absorbing wavelength range, low catalytic efficiency and difficulty in recycle. The material is capable of degrading formaldehyde under the irradiation of visible light with wavelength of 400nm-800nm to reduce the concentration of formaldehyde to below 0.12mg / m3. Titanium dioxide loaded wood is firstly soaked in a Tollens' reagent to react; after the reaction, wood A is taken out of the Tollens' reagent, and the residual Tollens' reagent is obtained; the wood A is soaked in a glucose aqueous solution to react, and then the residual Tollens' reagent is added into the glucose aqueous solution in which the wood A is soaked to continue the reaction; and finally, performing washing and drying to obtain the sliver-titanium composite film loaded wood base material. The preparation method comprises: 1, preparing the titanium dioxide loaded wood; and 2, carrying out an impregnation reaction.

Owner:NORTHEAST FORESTRY UNIVERSITY

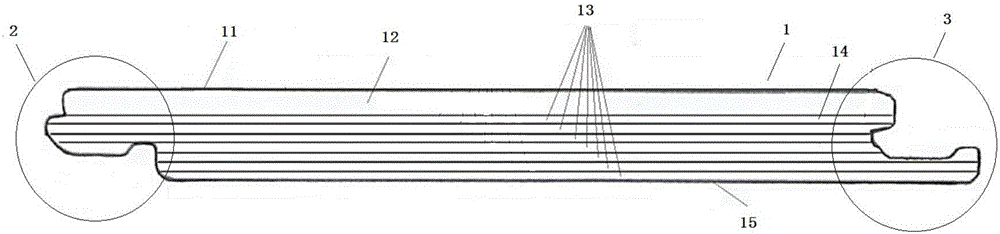

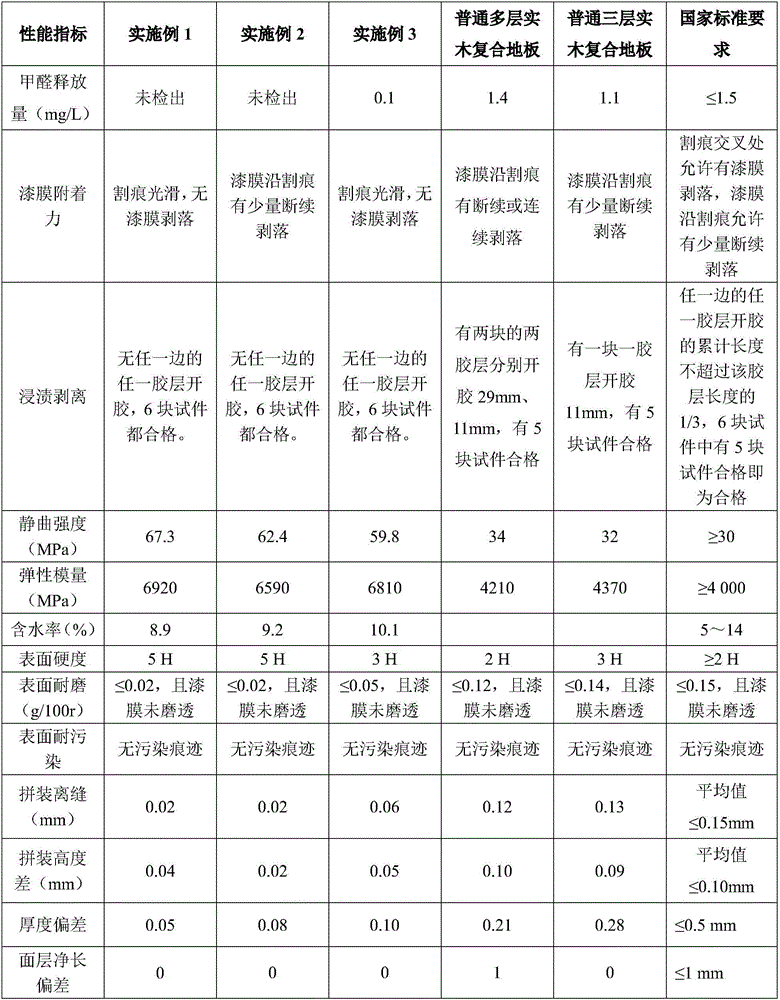

Locking multi-layer solid wood composite floor and preparation method thereof

InactiveCN106836726ASolve the release problemImprove water resistanceFlooring insulationsSolid woodHazardous substance

The invention discloses a locking multi-layer solid wood composite floor and a preparation method thereof. The locking multi-layer solid wood composite floor comprises a floor body (1), a tenon (2) and a mortise (3) matched with the tenon (2) in shape. The floor body (1) comprises a wearing layer (11), a wood panel (12) and a base material layer (13), wherein double-face sanding is conducted on the wood panel (12) and the base material layer (13). According to the locking multi-layer solid wood composite floor and the preparation method thereof, the problems that hazardous substance-free formaldehyde is released by an existing solid wood composite floor and glue failures and layering of all layers of veneer occur after the board is used for a period of time are solved; and the problems that the existing multi-layer solid wood composite floor has a large mat formation gap, big assembly height differences and serious buckling deformation and needs to be renovated to be used again after being used for a period of time are also solved.

Owner:南京久扬家居有限公司

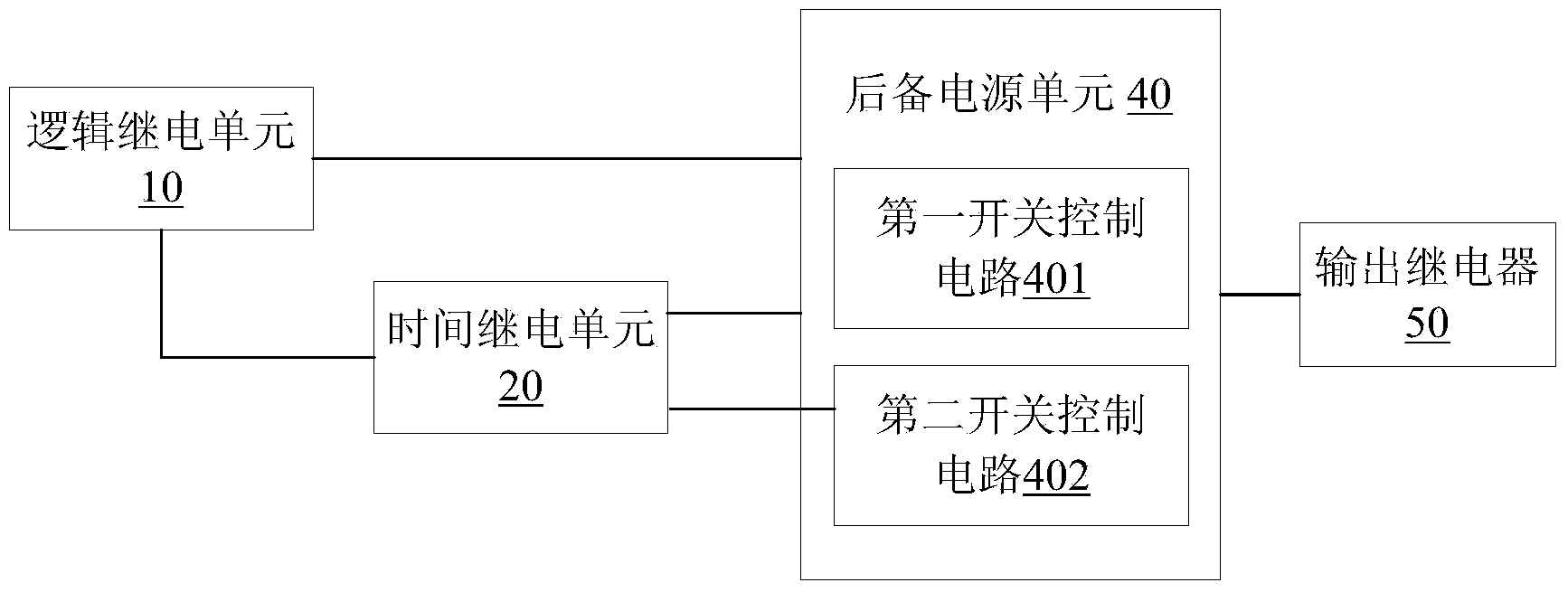

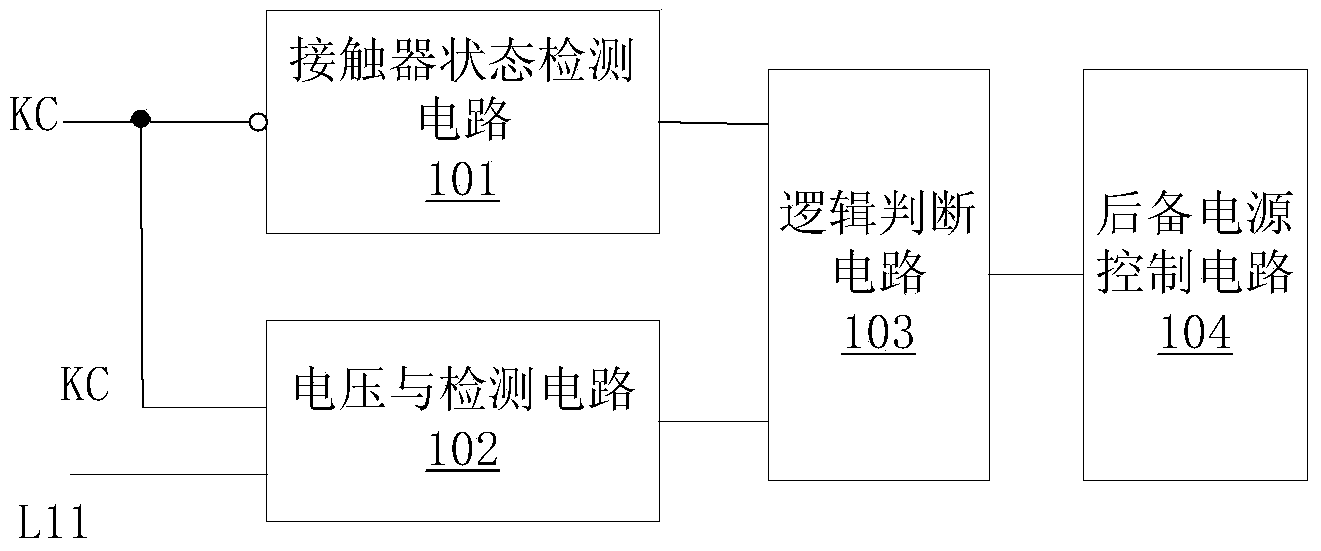

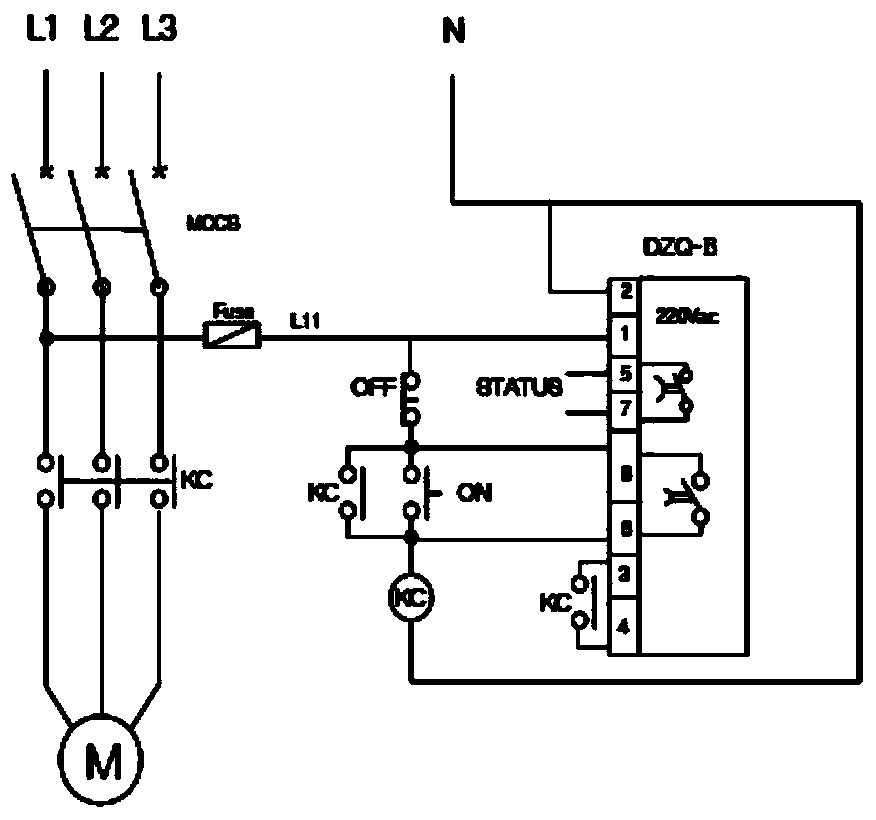

Motor restarting controller

ActiveCN103916053AResolve Quick ResponseSolve the release problemStarter detailsContactorFrequency changer

The invention discloses a motor restarting controller, and belongs to the technical field of industrial control. The motor restarting controller comprises a logic relay unit, a time relay unit, a standby power source unit and an output relay. The logic relay unit controls the instant closing of an output contact of the output relay when the opening moment of a normally-open auxiliary contact of a contactor or an operation signal contact of a frequency converter is detected. If the detected instant sunken amplitude of a power source voltage reaches to the preset amplitude before the opening of the auxiliary contact of the contactor or the opening of the operation signal contact of the frequency converter, the time relay unit controls the action mode of the output contact to be instant closing and delay opening within the allowed voltage-reducing time limit by controlling the opening or closing of a standby power source switch of the output relay within the preset allowed voltage-missing time limit.

Owner:SHENZHEN BEITON CONTROL TECH

Environment-friendly high-strength lignocellulose plate and preparing method thereof

InactiveCN105856379AHigh mechanical strengthHigh activityDomestic articlesFlat articlesCellulose fiberHigh intensity

The invention discloses an environment-friendly high-strength lignocellulose plate and a preparing method thereof. The preparing method of the environment-friendly high-strength lignocellulose plate comprises the following steps that firstly, plant raw material pretreatment is conducted, lignocellulose powder with the size smaller than 40 meshes is directly taken, or, plant raw materials rich in lignocellulose fiber are utilized for conducting flash explosion treatment, and the lignocellulose fiber is obtained, wherein the size of the plant raw materials rich in lignocellulose fiber ranges from 2 meshes to 80 meshes; secondly, the lignocelluloses fiber is mixed with a bonding agent, and the bonding agent is PVA and / or gelatin; thirdly, paving is conducted; fourthly, hot pressing is conducted; and fifthly, cooling forming is conducted. The preparing method of the environment-friendly high-strength lignocellulose plate is simple in process, usage of reagents such as acid and alkali is avoided in the whole process, pollution is avoided, and environment friendliness is achieved. The prepared environment-friendly high-strength lignocellulose plate is high in mechanical strength, and pollution-free and high-valued comprehensive utilization of renewable resources is achieved.

Owner:SOUTH CHINA UNIV OF TECH

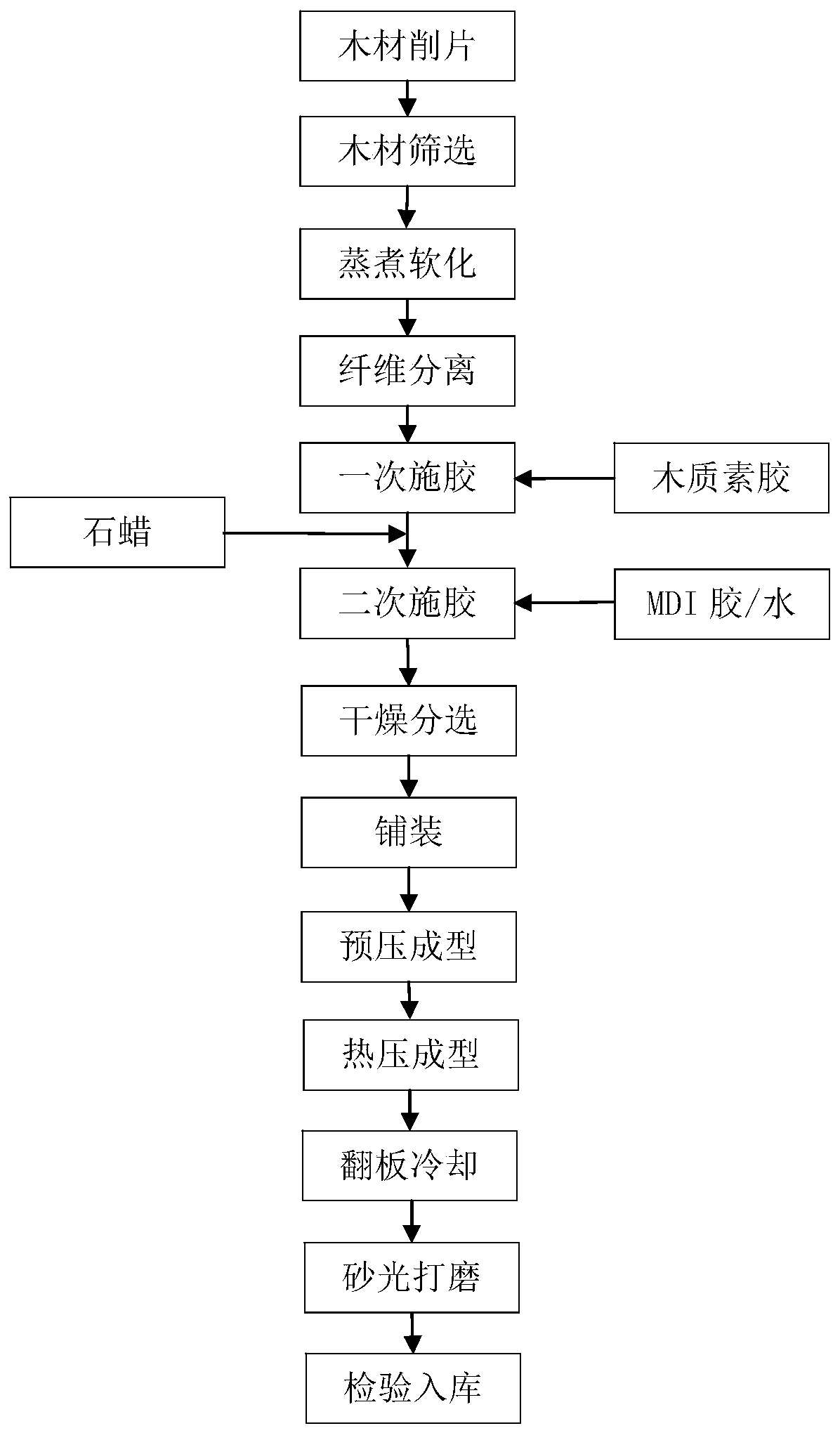

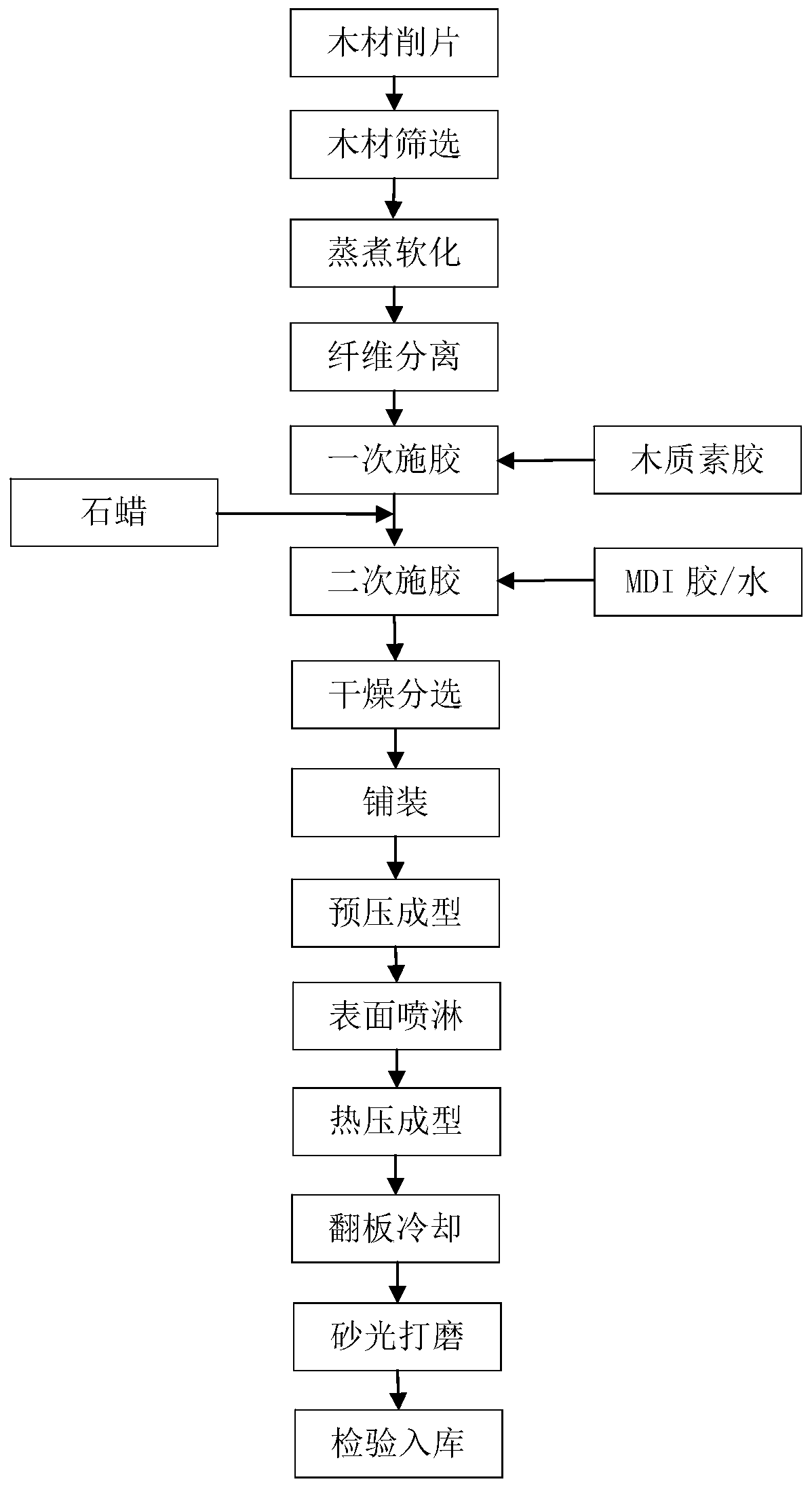

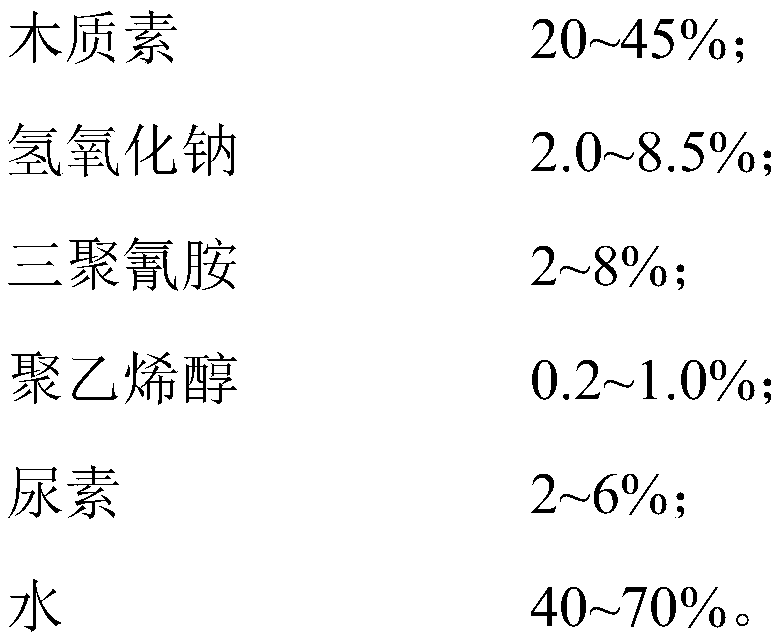

Formaldehyde-free medium-high-density board capable of meeting deep facing requirements and manufacturing method of medium-high-density board

ActiveCN110281341AImprove permeabilityMildew proofPolyureas/polyurethane adhesivesFlat articlesFiberHigh density

The invention relates to a formaldehyde-free medium-high-density board capable of meeting deep facing requirements and a manufacturing method of the medium-high-density board. The medium-high-density board comprises the following steps of wood chipping, screening, cooking and softening, fiber separating, gluing, drying and sorting, paving, pre-pressing, hot pressing, cooling, sanding, and inspection and warehousing. The gluing comprises two steps of gluing, and specifically comprises the steps of carrying out primary gluing by using lignin glue, carrying out waterproof treatment, and then carrying out secondary gluing by using MDI glue. According to the manufacturing method, a biomass adhesive and a formaldehyde-free adhesive are adopted, a curing agent, an anti-mildew agent and the like are not added, by virtue of a two-time gluing method, formaldehyde pollution is completely eradicated from a source, and formaldehyde-free production and formaldehyde-free products are realized; and the gluing process is controlled in sequence and glue types and proportion are controlled, so that the surface hardness of the products can be improved, and the final products can be subjected to deep facing so as to achieve 2-8 millimeters.

Owner:BEIJING FORESTRY UNIVERSITY +2

Method for controlling phosphorus and heavy metal release in pig manure

The invention provides a method for controlling phosphorus and heavy metal release in pig manure. In the method, a novel modified red mud fixative is prepared by roasting basic material waste slag red mud generated in the production process of the aluminum industry; and the red mud fixative is blended with a proper amount of the pig manure so as to effectively control the dissolution release of phosphorus and heavy metals in the pig manure and reduce the serious environmental pollution caused by the dissolution of the phosphorus and the heavy metal in the pig manure through the fixation of the fixative to the phosphorus and the heavy metals in the pig manure. The method realizes the recycling of waste resources, and has wide application prospect for area source pollution control.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method for polyurethane adhesive

InactiveCN102358831AAvoid harmAvoid pollutionPolyureas/polyurethane adhesivesChemical industryDiphenylmethanePropanoic acid

The present invention discloses a preparation method for a polyurethane adhesive. The preparation method comprises the following steps: heating polyether glycol to a temperature of 100-120 DEG C; carrying out vacuum pumping for 1-2 hours to remove moisture; adding diphenylmethane 4,4'- diisocyanate, and carrying out a reaction for 1-3 hours at the temperature of 40-60 DEG C; adding oven-dried dimethylol propionic acid, and carrying out a reaction for 2-6 hours at the temperature of 30-80 DEG C to prepare a prepolymer; cooling the prepolymer to the room temperature; adding an aqueous solution of triethanolamine; continuously stirring for 5-20 minutes when the color of the solution becomes transparent from yellow, and then becomes ivory white to obtain a uniformly-dispersed white polyurethane emulsion; adding a thickening agent to the polyurethane emulsion to obtain the polyurethane adhesive. The prepared polyurethane adhesive of the present invention can solve the harms to the human body and the pollution to the environment due to formaldehyde and volatile organic toxic materials during the wood-based panel production process and the furniture using process, and has characteristics of environmental protection, energy saving and good economic benefits.

Owner:DALIAN JIARUILONG TECH

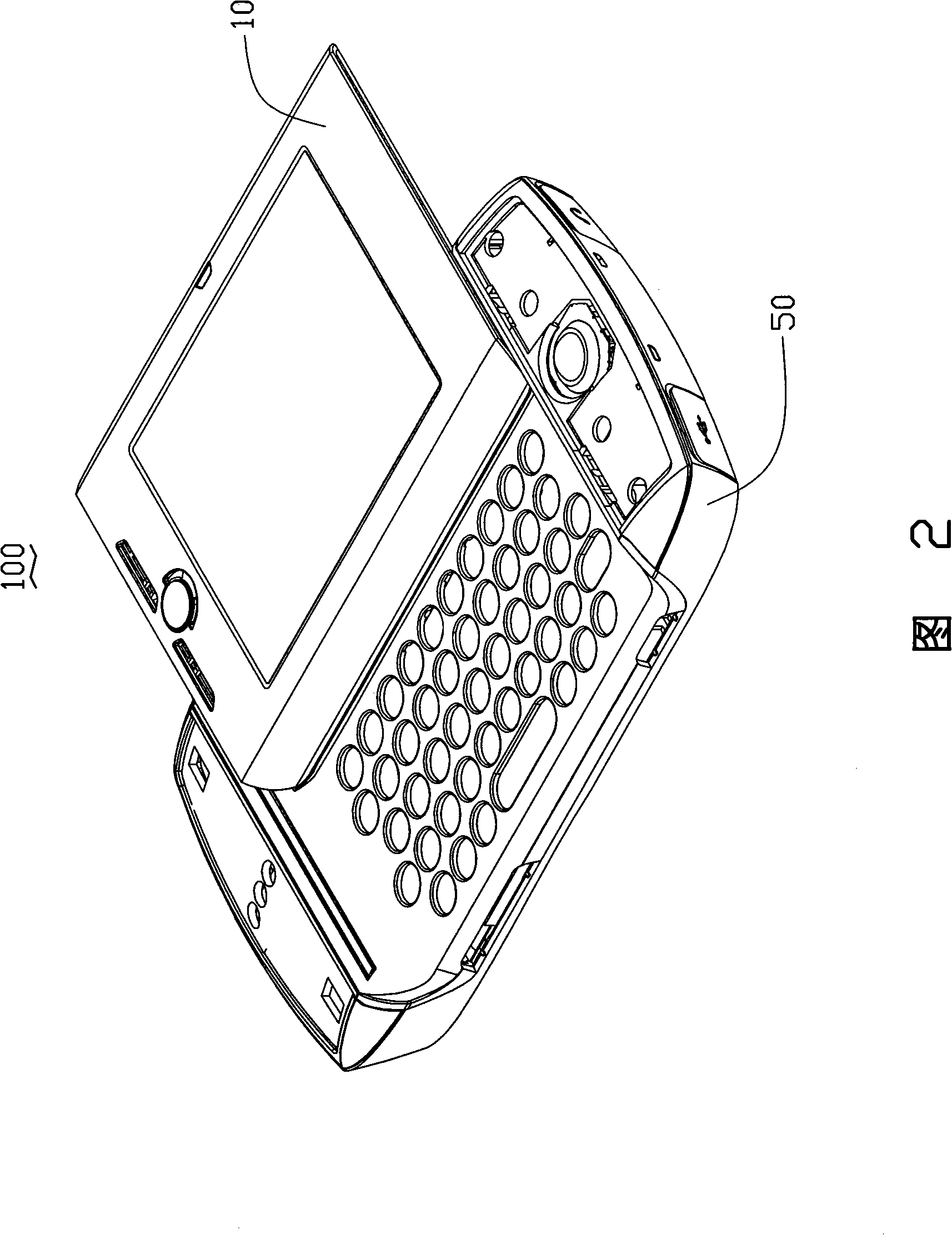

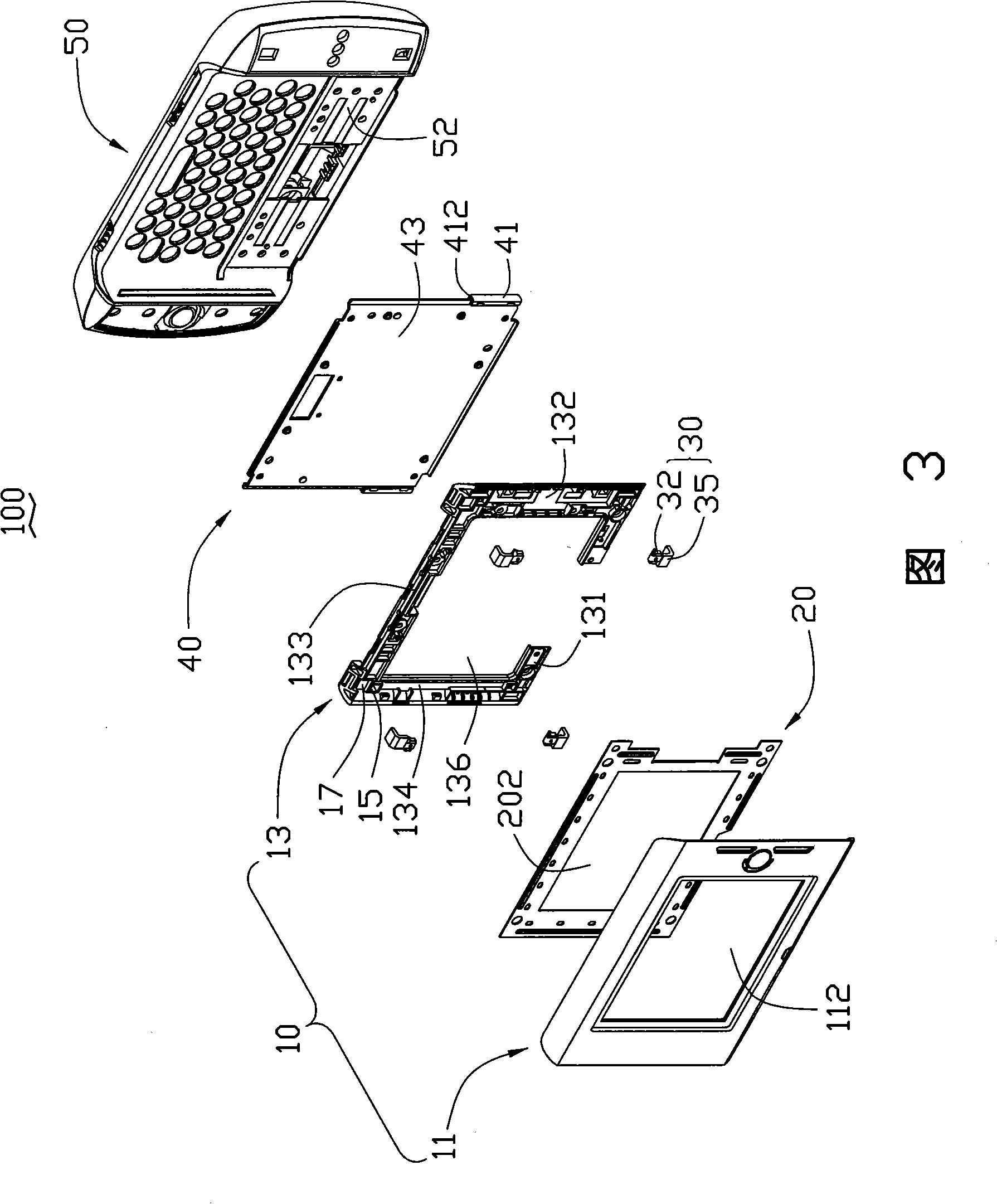

Earthing device of portable electronic apparatus

InactiveCN101359779ASolve the release problemAvoid damageDigital data processing detailsCoupling device detailsLiquid-crystal displayConductive materials

Disclosed is a grounding device used for a portable electronic device, and the portable electronic device comprises a liquid crystal display module group, a circuit board and a frame body. The circuit board is provided with a system grounding end. The grounding device includes an electro-conductive plate, at least one conduction device and a sliding mechanism, wherein, the electro-conductive plate is arranged on the frame body, and is connected with the liquid crystal display module group. The conduction devices are respectively connected with the electro-conductive plate and the sliding mechanism, and the sliding mechanism is made of electric conducting material and is connected with the system grounding end on the circuit board.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Modified composite adhesive and preparation method thereof

InactiveCN110283563AReduce crystallinityImprove thermal stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesUltimate tensile strengthAdhesive materials

The invention discloses a modified composite adhesive. The adhesive is prepared from the following raw materials in parts by weight: 40-50 parts of modified polyurethane, 50-60 parts of a curing agent, 15-20 parts of acetone, 30-36 parts of filler, 3-5 parts of chitosan, and 1-2 parts of dioctyl phthalate. The invention also discloses a preparation method of the modified composite adhesive. The method comprises the following steps: step S1, mixing the acetone, the curing agent and the chitosan to obtain a component A; step S2, mixing the filler and the modified polyurethane to obtain a component B; step S3, mixing the component A and the component B, then adding the dioctyl phthalate, and uniformly stirring to obtain the modified composite adhesive. According to the modified composite adhesive and the preparation method thereof, any aldehyde-containing substance is not introduced in the process of preparing the modified composite adhesive; through the modification of the adhesive material polyurethane, the adhesive has excellent bonding strength; in addition, through the addition of the filler, the bonding strength of the adhesive can be improved, the viscosity of the adhesive can be reduced, and coating is easier.

Owner:中著(杭州)知识产权运营有限公司

Preparation method of non-formaldehyde adhesive for thermal insulation material

InactiveCN109135618AHigh bonding strengthImprove water resistanceMacromolecular adhesive additivesPolysaccharide adhesivesThermal insulationChemical products

The invention discloses a preparation method of a non-formaldehyde adhesive for a thermal insulation material. Formaldehyde is not used as a raw material, the problem of formaldehyde release is solvedfundamentally, used raw materials are non-poisonous and harmless, environment protection and no pollution are really achieved, the adhesive can be applied to indoor rock wool and glass wool thermal insulation materials relievedly, and a user does not worry about the harm of chemical products. In addition, the prepared non-formaldehyde adhesive has the advantages of being high in bonding strength,good in water resistance, good in ageing resistance performance and the like, the raw materials are simple and easy to obtain, and the preparation method is simple.

Owner:金隅微观(沧州)化工有限公司

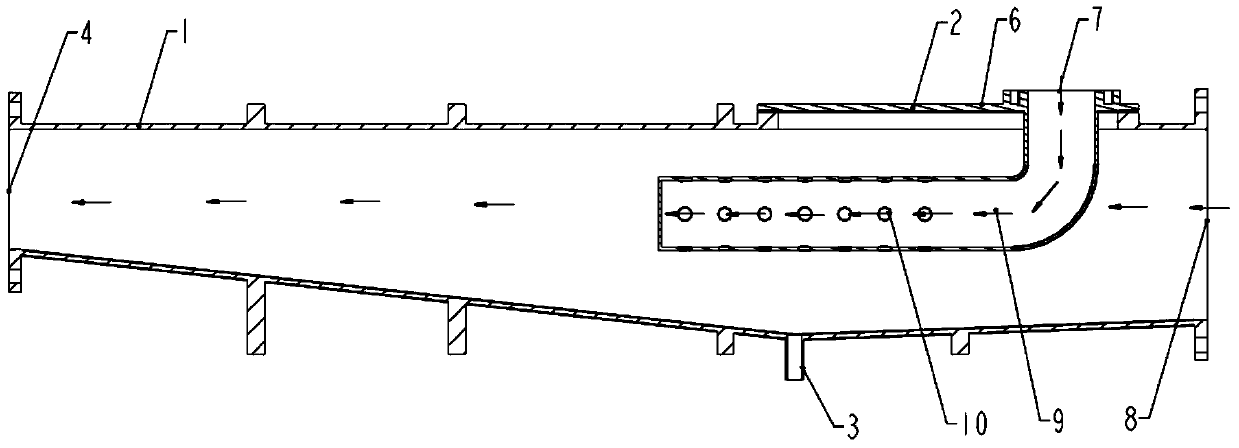

EGR (Exhaust Gas Recirculation) mixer for marine diesel engine

InactiveCN104005886ASolve the release problemGuarantee not to enterNon-fuel substance addition to fuelInternal combustion piston enginesExhaust gas recirculationDiesel engine

The invention provides an EGR (Exhaust Gas Recirculation) mixer for a marine diesel engine. The EGR mixer comprises a mixer housing, an EGR gas introducing device and a discharging hole; the EGR gas inducting device is arranged on the mixer housing; the discharging hole formed in the lowest part of the mixer housing is used for discharging acidic liquid that is separated out during mixing high-temperature EGR gas with inter-cooled fresh air. According to the EGR mixer for the marine diesel engine, the discharging hole is formed in the lowest part of the mixer housing, which effectively overcomes the problem of discharging acidic liquid and prevents acidic liquid from entering the cylinder, and thus the EGR mixer is applicable to the marine diesel engine; an outlet end of an EGR gas introducing pipe is closed, a gas spray hole that is axially vertical to the fresh air flowing direction is formed in the EGR gas introducing pipe, and thereby, the EGR gas is vertical to the fresh air in flowing direction to generate a local turbulence which is beneficial for full mixing of gas; the EGR mixer for the marine diesel engine is simple in structure, and can be integrally dismounted, so that parts of the mixer can be conveniently replaced and temporarily dismounted for examination.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

Glue for plywood with high weather resistance and processing technology of glue

InactiveCN111635732ASolve the release problemAvoid harmNon-macromolecular adhesive additivesProtein adhesivesAdhesive glueWeather resistance

The invention discloses glue for plywood with high weather resistance. The glue is prepared from, by mass, 20%-30% of weather-resistant materials, 10%-20% of mixed powder, 15%-25% of lignin mixed liquor, 0.5%-1% of protease, 2%-5% of an initiator, 1%-3% of cellulose and 30%-50% of water. The processing technology of the glue comprises the following steps: (1) adding water and the mixed powder intoa reaction kettle according to a ratio, stirring, adding the lignin mixed solution and cellulose according to a ratio, and stirring while keeping the temperature to obtain a mixed solution A, and (2)after cooling, adding a weather-proof material and protease into the mixed solution A according to a ratio, uniformly stirring, adding the initiator according to a ratio, and stirring to obtain a glue finished product. The preparation process is simple, the adopted raw materials are easy to obtain, the production cost is controllable, all the raw material components are reasonably matched, and the glue prepared through the method has the advantages of being free of formaldehyde content, high in bonding strength, good in water resistance, easy to apply and not prone to mildewing.

Owner:师宗腾信木业有限责任公司

Modified porous alumina formaldehyde adsorbent and preparation method thereof

ActiveCN109092257ASolve the release problemHigh affinityGas treatmentOther chemical processesEnvironmental resistanceActivated alumina

The invention provides a modified porous alumina formaldehyde adsorbent and a preparation method thereof. The adsorbent is prepared from raw materials in parts by weight as follows: 100 parts of activated alumina balls, 2-5 parts of compound amino acid, 0.2-0.5 parts of an alkali additive, 0.5-4 parts of pseudo-boehmite and 40-80 parts of deionized water. Compared with the prior art, porous alumina is adopted as a base material, an amino acid active substance is further adopted for modifying a carrier, and the adsorbent can be obtained by simple mixed impregnation and microwave drying; the method is simple, practicable and environmentally friendly, and the preparation cycle is short. The problem of release of smelly substances and ammonia gas of the modified materials can be solved, the modified porous alumina formaldehyde adsorbent suitable for the indoor formaldehyde pollution treatment is developed, the corresponding effective and feasible preparation method is proposed, the ever-increasing market requirement of the indoor formaldehyde pollution treatment is met, and quite good social benefit and economic benefit are obtained.

Owner:芜湖格丰环保科技研究院有限公司 +1

A kind of preparation method of flame-retardant cotton fabric

ActiveCN104264467BSolve the release problemSolve the durability problemGroup 5/15 element organic compoundsVegetal fibresPolymer scienceOrganic solvent

The invention discloses a method for preparing a flame-retardant cotton fabric. Natural phytic acid compounds and γ-glycidoxytrimethoxysilane are added to an organic solvent, and stirred and reacted at 50-80°C for 0.5-2 hours to obtain Flame retardant finishing solution, soak the cotton fabric in the above flame retardant finishing solution for 8-15 minutes, then dip and roll twice, then dry the cotton fabric at 60-90°C, and then bake it at 150-180°C for 2 ~8 min, finally wash with water, soap and dry. Using natural phytic acid as the reaction raw material, there is no release of free formaldehyde on the prepared flame retardant textiles, which solves the problem of formaldehyde release from most current flame retardants, and introduces γ‑glycidoxytrimethoxysilane into the flame retardant In the molecule, the prepared flame retardant contains multiple reactive groups, which solves the durability problem of flame-retardant finishing of cotton fabrics. The technical solution of the invention is simple in process, easy to operate, and has broad application prospects.

Owner:新乡市新科防护科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com