Method for preparing aldehyde-free veneer boards by biological oil starch adhesives

A starch adhesive and bio-oil technology is applied in the directions of starch-derived adhesives, bonding of wooden veneers, adhesive application devices, etc., and can solve the problems of complex preparation process, high volatility of polyisocyanates, and high proportion of bio-oil phenolic resins , to achieve the effect of promoting sufficient reaction, simple preparation process and preventing excessive degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

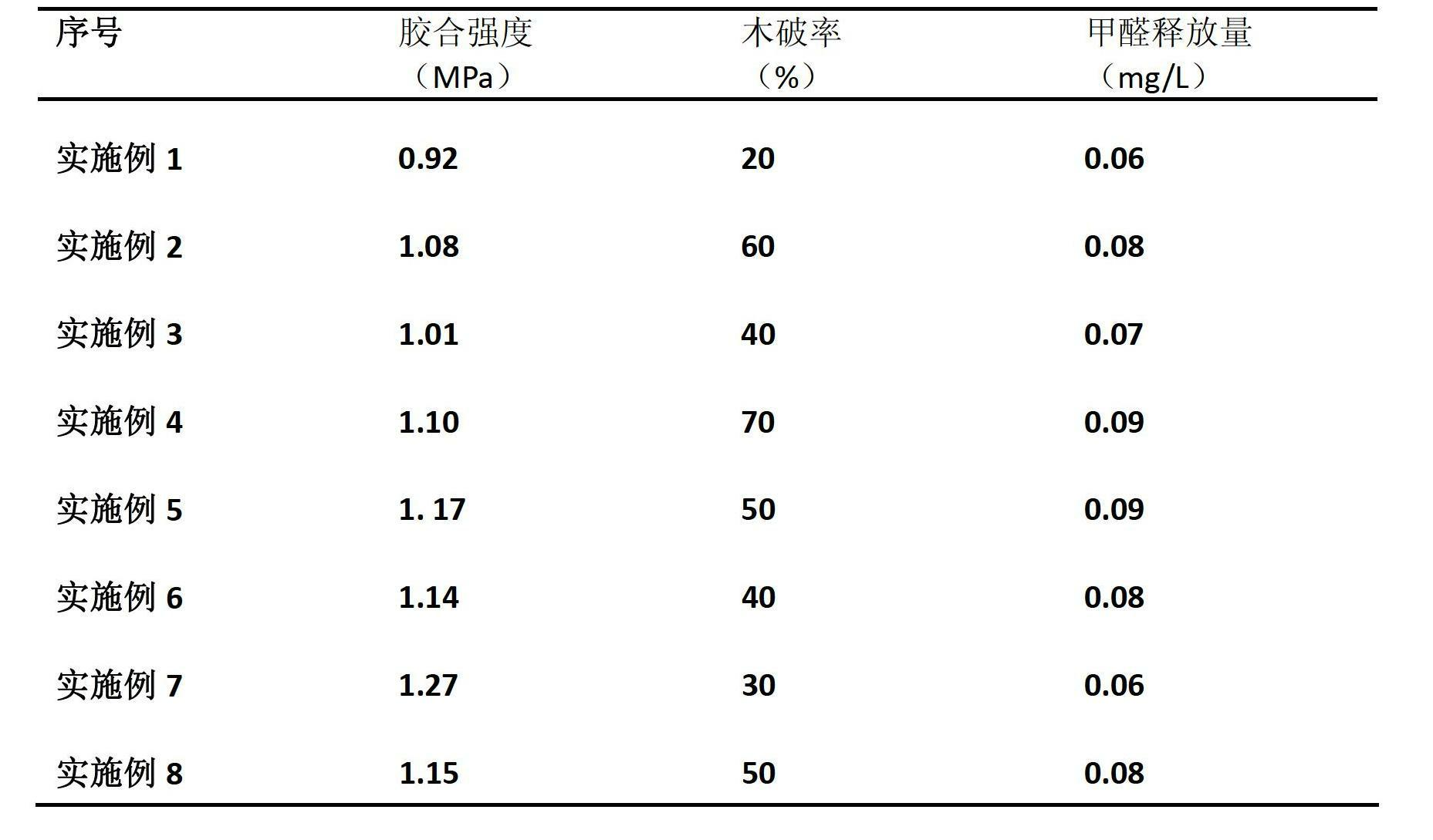

Examples

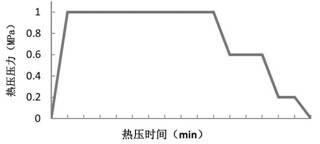

Embodiment 1

[0028] Step 1: Preparation of bio-oil starch adhesive: (1) Raw material pretreatment: pre-treat the bio-oil by vacuum filtration and vacuum distillation, and control the water content of the bio-oil to 30%; 25 parts of wild cassava starch Add 75 parts of water to prepare a starch emulsion with a mass fraction of 25%, add 6 parts of concentrated hydrochloric acid with a mass fraction of 37%, raise the temperature to 50°C, then add 0.7 parts of oxidant ammonium persulfate, and react for 30 minutes to obtain acid hydrolysis Oxidized starch emulsion; (2) Preparation of the main ingredient of bio-oil starch adhesive: add 40 parts of bio-oil to the acid-decomposed and oxidized starch emulsion, adjust the pH to 8 with a mass fraction of 10% sodium hydroxide solution, and set the temperature at 50°C React for 30 minutes, then raise the temperature to 60°C and react for 40 minutes; then add 20 parts of polyvinyl alcohol solution with a mass fraction of 10% evenly within 20 minutes, and ...

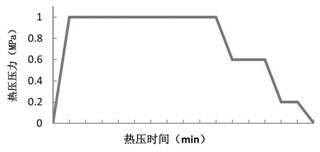

Embodiment 2

[0031] Step 1: Preparation of bio-oil starch adhesive: (1) Raw material pretreatment: pre-treat the bio-oil by vacuum filtration and vacuum distillation, and control the water content of the bio-oil at 35%; 30 parts of wild cassava starch Add 70 parts of water to prepare a starch emulsion with a mass fraction of 30%, add 7 parts of concentrated hydrochloric acid with a mass fraction of 37%, raise the temperature to 55°C, add 0.8 parts of oxidant potassium persulfate, and react for 60 minutes to obtain acid hydrolysis Oxidized starch emulsion; (2) Preparation of bio-oil starch adhesive main ingredient: add 50 parts of bio-oil to the acid-decomposed and oxidized starch emulsion, adjust the pH to 9 with a mass fraction of 10% sodium hydroxide solution, and set the temperature at 55°C React for 40 minutes, then raise the temperature to 70°C and react for 50 minutes; then add 25 parts of polyvinyl alcohol solution with a mass fraction of 10% evenly within 20 minutes, and then altern...

Embodiment 3

[0034] Step 1: Preparation of bio-oil starch adhesive: (1) Raw material pretreatment: pre-treat the bio-oil by vacuum filtration and vacuum distillation, and control the water content of the bio-oil to 40%; 35 parts of wild cassava starch Add 65 parts of water to prepare a starch emulsion with a mass fraction of 35%, add 8 parts of concentrated hydrochloric acid with a mass fraction of 37%, raise the temperature to 60°C, add 0.9 parts of oxidant sodium persulfate, and react for 90 minutes to obtain acid hydrolysis Oxidized starch emulsion; (2) Preparation of the main ingredient of bio-oil starch adhesive: add 60 parts of bio-oil to the acid-decomposed and oxidized starch emulsion, adjust the pH to 10 with a mass fraction of 10% sodium hydroxide solution, and set the temperature at 60°C React for 50 minutes, then heat up to 80°C and react for 60 minutes; then add 30 parts of polyvinyl alcohol solution with a mass fraction of 10% evenly within 20 minutes, and then alternately add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com