Method for cooperatively treating arsenic-containing waste liquid by using sulfate reducing bacteria and lead-zinc smelting slag

A synergistic treatment, sulfate technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage treatment, etc., can solve the problems of low efficiency and high cost, achieve low cost, save cost, and solve the release of heavy metals effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method of synergistically treating arsenic-containing waste liquid with sulfate-reducing bacteria and lead-zinc smelting slag. A small-scale test was carried out in the laboratory. The lead-zinc smelting slag came from an open-air lead-zinc smelting slag yard in Guangxi Province. The composition is shown in Table 1 Shown, phase composition analysis see figure 1 As shown, No. 1 arsenic-containing waste liquid was selected from an antimony ore smelter in Guangxi Province, and its composition is shown in Table 2.

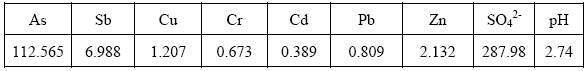

[0055] Table 1 Composition of lead-zinc smelting slag (wt.%)

[0056]

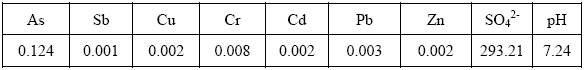

[0057] Table 2 Composition of No. 1 arsenic-containing waste liquid (mg / l)

[0058]

[0059] In this embodiment, the method for synergistically treating arsenic-containing waste liquid with sulfate-reducing bacteria and lead-zinc smelting slag includes the following steps:

[0060] (1) Take 10g of air-dried lead-zinc smelting slag and No. 1 arsenic-containing waste liquid accordin...

Embodiment 2

[0067] The lead-zinc smelting slag in this example comes from an open-air lead-zinc smelting slag stockyard in Guangxi Province, which is the same as in Example 1. The No. 2 arsenic-containing waste liquid comes from the drainage of a smelter near the stockyard. The contents of each component of the waste liquid are shown in Table 5. shown.

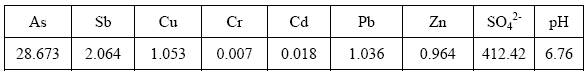

[0068] Table 5 Composition of No. 2 arsenic-containing waste liquid (mg / l)

[0069]

[0070] In this embodiment, the method for synergistically treating arsenic-containing waste liquid with sulfate-reducing bacteria and lead-zinc smelting slag includes the following steps:

[0071] (1) Mix 10g of air-dried lead-zinc smelting slag with No. 2 arsenic-containing waste liquid at a mass ratio of 1:10, react in an anaerobic bottle, set the shaking table speed at 180r / min, and the temperature at 30°C. After 12 hours of reaction, a small amount of supernatant was taken to detect the content of each element, as shown in Table 6.

[0072] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com