Preparation method of flame-retardant cotton fabric

A flame-retardant cotton and cotton fabric technology, applied in chemical instruments and methods, plant fibers, textiles and papermaking, etc., can solve the problems of free formaldehyde, release, etc., achieve simple process, broad application prospects, and solve durability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of preparation method of flame-retardant cotton fabric, its process is as follows:

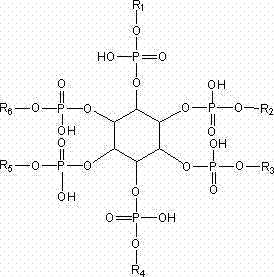

[0017] (1) Add 0.5mol of natural phytic acid compound and 2mol of γ-glycidoxytrimethoxysilane into 100ml of acetone, and stir and react continuously for 1h at 70°C to obtain a flame retardant finishing solution. The flame retardant finishing solution contains phytic acid derivatives with 4 active groups, and the structural formula is:

[0018]

[0019] (2) Immerse the cotton fabric in the above-mentioned flame-retardant finishing solution for 10 minutes, then soak it twice and roll it twice, and the excess rate is 90%, then dry the cotton fabric at 80°C for 5 minutes, then bake it at 170°C for 3 minutes, and finally wash the fabric with water, Soap, dry.

Embodiment 2

[0021] A kind of preparation method of flame-retardant cotton fabric, its process is as follows:

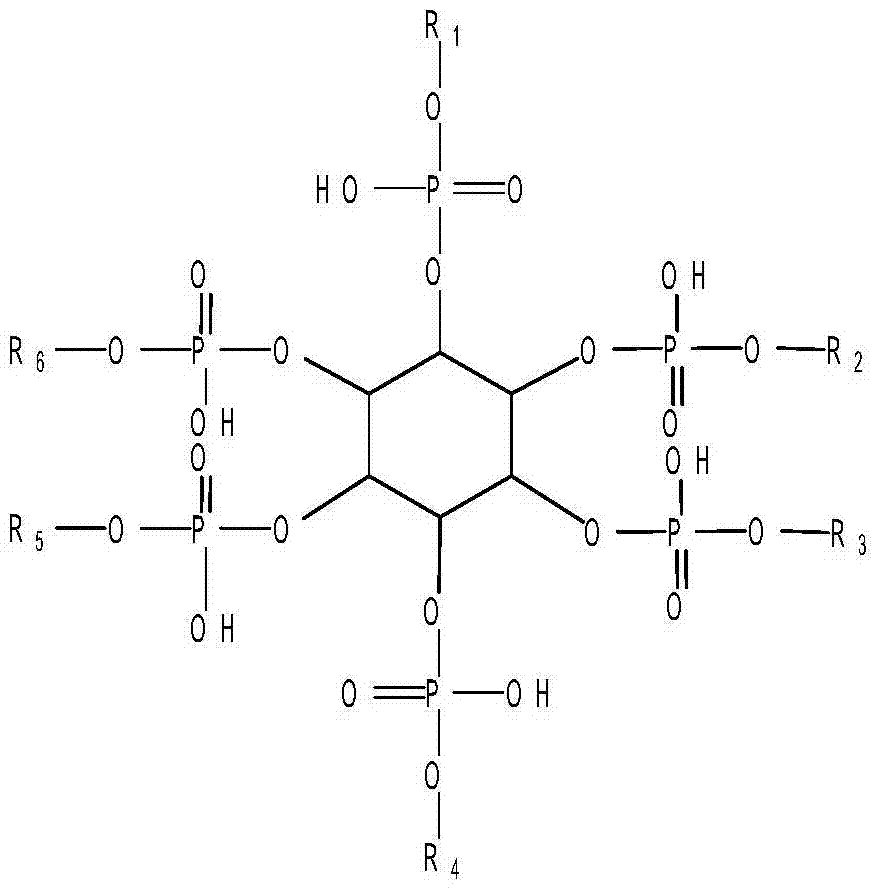

[0022] (1) Add 1 mol of natural phytic acid compound and 3 mol of γ-glycidoxytrimethoxysilane into 80 ml of isopropanol, and keep stirring and reacting for 0.5 h at 80° C. to obtain a flame retardant finishing solution. The flame retardant finishing solution contains phytic acid derivatives with 3 active groups, and the structural formula is:

[0023]

[0024] (2) Immerse the cotton fabric in the above-mentioned flame retardant finishing solution for 10 minutes, then soak it twice and roll it twice, and the excess rate is 80%, then dry the cotton fabric at 70°C for 6 minutes, then bake it at 160°C for 4 minutes, and finally wash the fabric with water, Soap, dry.

Embodiment 3

[0026] A kind of preparation method of flame-retardant cotton fabric, its process is as follows:

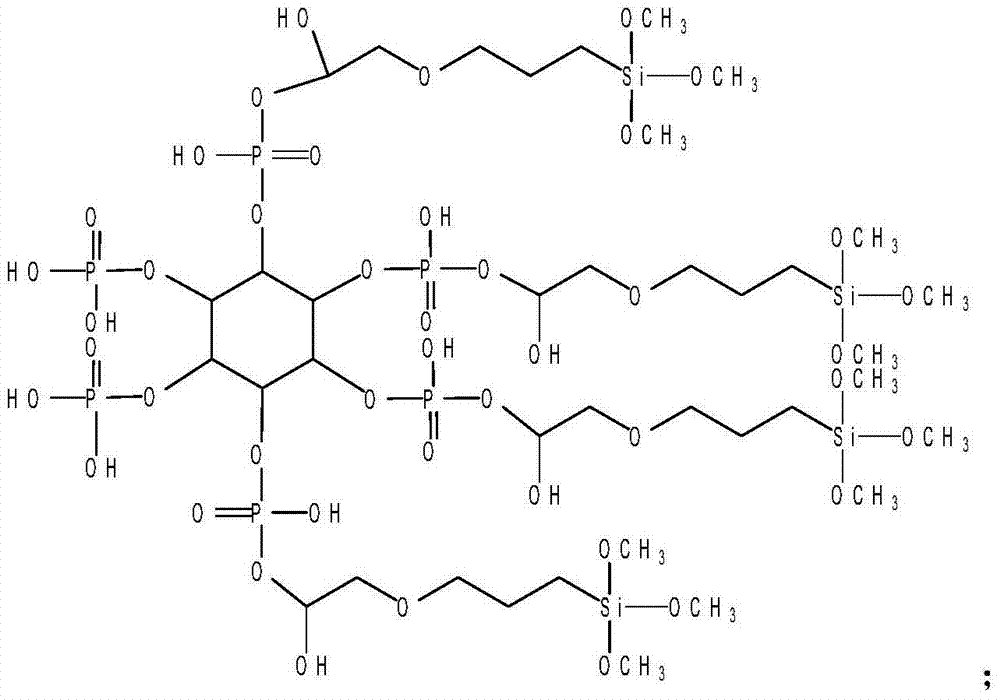

[0027] (1) Add 1 mol of natural phytic acid compound and 5 mol of γ-glycidoxytrimethoxysilane into 150ml of methanol, and keep stirring and reacting at 60°C for 2 hours to obtain a flame retardant finishing solution. The finishing solution contains phytic acid derivatives with 5 active groups, the structural formula is:

[0028]

[0029] (2) Immerse the cotton fabric in the above-mentioned flame-retardant finishing solution for 10 minutes, then soak it twice and roll it twice, and the excess rate is 100%, then dry the cotton fabric at 60°C for 10 minutes, then bake it at 180°C for 1.5 minutes, and finally wash the fabric with water , Soap, Dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com