Preparation method of anti-microbial conductive acrylic fiber/copper sulphide complex fiber

A composite fiber and acrylic fiber technology, which is applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of many processing steps, poor bonding force between metal layer and fiber, waste of medicines, etc., and achieve good bonding fastness and increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

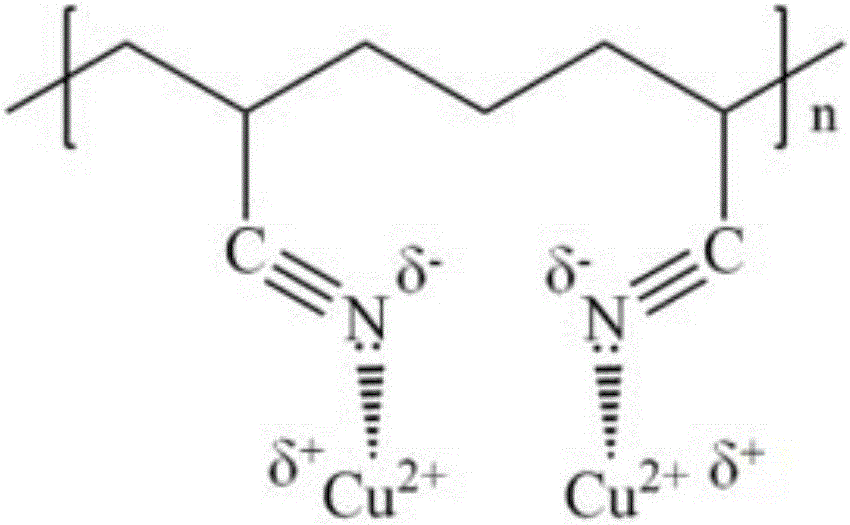

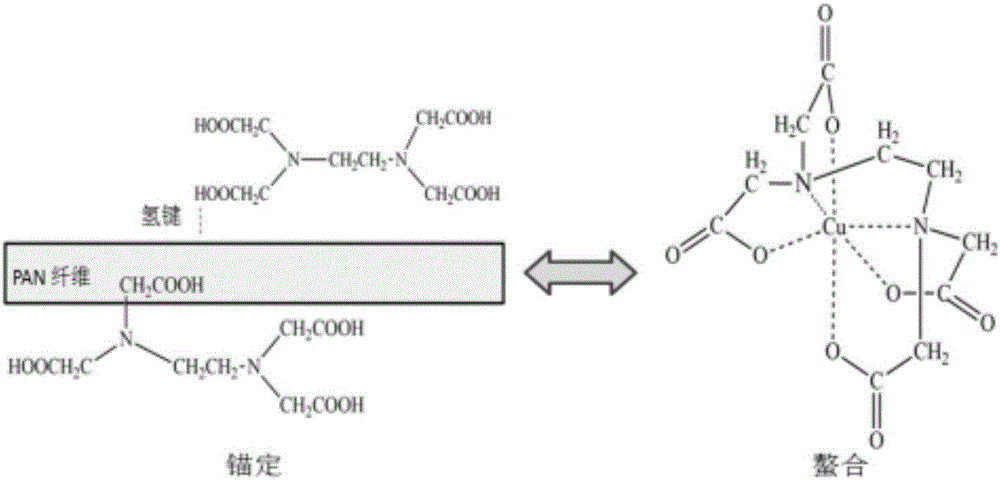

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Adopt ethylenediaminetetraacetic acid (EDTA) chelating agent to prepare the acrylic fiber / copper sulfide composite fiber with antibacterial conductive property, concrete steps are as follows:

[0032] (1) Pretreatment

[0033] a. Get 4g acrylic fiber;

[0034] b. Put the acrylic fiber in a 250mL beaker, add 100mL of 10g / L sodium hydroxide solution, and treat it in a water bath at 80°C for 30min;

[0035] c. Take out the acrylic fibers, wash them thoroughly in distilled water, and dry them at 60°C.

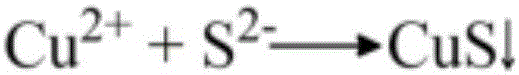

[0036] (2) Preparation of PAN / CuS composite fibers

[0037] d. Take 10g copper sulfate (CuSO 4 ·5H 2 (0) dissolve it in 100mL distilled water in a 250mL beaker, add the above-mentioned pretreated acrylic fibers, and react for 1h under stirring and 80°C water bath conditions;

[0038]e. Take 100mL of 0.2mol / L EDTA aqueous solution and add it to the above copper sulfate solution, react for 1h under the condition of stirring and water bath at 80°C, take it out and dry it a...

Embodiment 2

[0042] Adopt triethanolamine (TEA) chelating agent to prepare the acrylic / copper sulfide composite fiber with antibacterial and conductive properties, the specific steps are as follows:

[0043] (1) Pretreatment

[0044] a. Get 4g acrylic fiber;

[0045] b. Put the acrylic fiber in a 250mL beaker, add 100mL of 10g / L sodium hydroxide solution, and treat it in a water bath at 80°C for 30min;

[0046] c. Take out the acrylic fibers, wash them thoroughly in distilled water, and dry them at 60°C.

[0047] (2) Preparation of PAN / CuS composite fiber

[0048] d. Take 10g copper sulfate (CuSO 4 ·5H 2 (0) dissolve it in 100mL distilled water in a 250mL beaker, add the above-mentioned pretreated acrylic fibers, and react for 1h under stirring and 80°C water bath conditions;

[0049] e. Add 100mL of 0.2mol / L TEA aqueous solution to the above solution, react for 1h under the condition of stirring and water bath at 80°C, take it out and dry at 80°C for 20min, soak three times and dry i...

Embodiment 3

[0053] Adopting (3-aminopropyl) triethoxysilane (APTES) alkane to prepare the acrylic fiber / copper sulfide composite fiber with antibacterial conductive properties, the specific steps are as follows:

[0054] (1) Pretreatment

[0055] a. Get 4g acrylic fiber;

[0056] b. Put the acrylic fiber in a 250mL beaker, add 100mL10g / L sodium hydroxide solution, and treat it in a water bath at 80°C for 30min;

[0057] c. Take out the acrylic fibers, wash them thoroughly in distilled water, and dry them at 60°C.

[0058] (2) Preparation of PAN / CuS composite fiber

[0059] d. Take 10g copper sulfate (CuSO 4 ·5H 2 (0) dissolve it in 100mL distilled water in a 250mL beaker, add the above-mentioned pretreated acrylic fibers, and react for 1h under stirring and 80°C water bath conditions;

[0060] e. Take out the acrylic fiber and dry it at 80°C for 10 minutes.

[0061] f. Immerse the acrylic fiber in 40mL of acetone solution containing 0.5% (3-aminopropyl) triethoxysilane to react at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com