Insulated crack-resistant protective light dry mortar for external thermal insulation of exterior wall and preparation method thereof

A technology for external wall thermal insulation and dry powder mortar is applied in the field of building exterior wall materials, which can solve the problems of easy cracking and durability of plastering mortar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

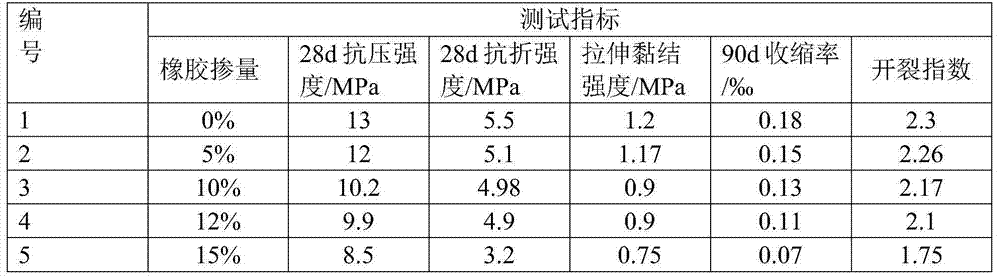

Examples

preparation example Construction

[0025] The preparation method of above-mentioned dry powder mortar comprises the following steps:

[0026] step 1:

[0027] First, weigh the following raw materials according to the mass percentage: 25%-35% Portland cement, 15%-25% vitrified microbeads with a particle size of 0.5mm-5mm, 8%-15% 300-1250 mesh quartz powder, 5%-10% of fly ash floating beads with a particle size of 50μm-200μm, 1%-5% of 40-350 mesh perlite, 5%-15% of 10-150 mesh rubber particles, and 3%-10% of particle size of 0.02μm-100μm metakaolin, 1.0%-1.5% Wacker 5048H flexible water-increasing rubber powder, 0.1%-0.3% polycarboxylate superplasticizer, 0.2%-0.5% polyacrylonitrile fiber, 0.2%-0.4% Hydroxypropyl methylcellulose, the sum of the mass percentages of the above components is 100%;

[0028] Step 2:

[0029] Portland cement weighed in step 1, fly ash floating beads, Wacker 5048H flexible water-increasing rubber powder, quartz powder, perlite, rubber particles, metakaolin, polyacrylonitrile fiber, hy...

Embodiment 1

[0034] step 1:

[0035] First, the following raw materials were weighed according to the mass percentage: 25% Portland cement, 21% vitrified microspheres with a particle size of 3mm, 18% 500 mesh quartz powder, 10% fly ash floating beads with a particle size of 100μm, 5% 200 mesh perlite, 12% 50 mesh rubber particles, 7% metakaolin with a particle size of 50μm, 1.5% German Wacker 5048H flexible water-increasing rubber powder, 0.1% polycarboxylate superplasticizer, 0.2% polyacrylonitrile fiber, 0.2 % hydroxypropyl methylcellulose, the sum of the mass percentages of the above-mentioned components is 100%;

[0036] Step 2:

[0037] Portland cement weighed in step 1, fly ash floating beads, Wacker 5048H flexible water-increasing rubber powder, quartz powder, perlite, rubber particles, metakaolin, polyacrylonitrile fiber, hydroxypropyl methyl fiber Put the plain and polycarboxylate superplasticizers into the gravity-free mixer, set the speed of the stirring spindle to 50 rpm, and...

Embodiment 2

[0040] step 1:

[0041] First, the following raw materials were weighed according to the mass percentage: 35% Portland cement, 25% vitrified microspheres with a particle size of 0.5mm, 14% 300 mesh quartz powder, 5% fly ash floating beads with a particle size of 50μm, 1 % 40 mesh perlite, 15% 100 mesh rubber particles, 3% metakaolin with a particle size of 100μm, 1% German Wacker 5048H flexible water-increasing rubber powder, 0.3% polycarboxylate superplasticizer, 0.5% polypropylene Acrylic fiber, 0.2% hydroxypropyl methylcellulose, the sum of the mass percentages of the above components is 100%;

[0042] Step 2:

[0043] Portland cement weighed in step 1, fly ash floating beads, Wacker 5048H flexible water-increasing rubber powder, quartz powder, perlite, rubber particles, metakaolin, polyacrylonitrile fiber, hydroxypropyl methyl fiber Put the plain and polycarboxylate superplasticizers into the gravity-free mixer, set the speed of the stirring spindle to 50 rpm, and turn o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com